3.1.1. Simulation of Random Gust Wind

To calculate the non-stationary wind loads, we first simulated the random gust wind field. In this paper, the gust wind speed is simulated based on the wind speed power spectrum. The commonly used Davenport wind speed power spectrum is constructed based on the wind speed at the standard height, which is not entirely consistent with the actual operating height of the train. Therefore, this paper adopts the Kaimal spectrum provided by the international electrotechnical commission. The expression for the power spectrum is as follows:

where

Su represents the single-sided spectrum of the lateral component,

z denotes the height,

σ and

L represent the standard deviation and the turbulence integral scale, respectively, and

fL represents the reduced frequency. The values for the above parameters are referenced from the literature [

5].

f is the frequency, and

U(

z) represents the mean wind speed at height

z. Since wind speeds are typically measured at the standard height along the railway line, it is necessary to introduce a function for the variation of wind speed with height [

17]:

where

z0 represents the height at which the wind speed decreases to zero, and

zs represents the standard height. Here, the Lanzhou–Xinjiang Railway is taken as an example for study [

18]. The values are set as

z0 = 0.05 m,

zs = 10 m.

There is a certain correlation between wind speeds [

19]. When a train passes through a crosswind area, the leading car, intermediate cars, and tail car are simultaneously disturbed by the turbulent wind field. Therefore, the influence of this correlation needs to be considered. In the gust wind field, this correlation is commonly expressed mathematically using the coherence function of gust wind. Since the length-to-height ratio of the train is relatively large, the wind speed measurement points on the train surface can be regarded as a one-dimensional distribution. Let the number of measurement points be

n, and the spacing between measurement points be ∆. By substituting the commonly used coherence functions of Davenport and Shiotami, for any two measurement points

vj and

vm, the expressions for the two coherence functions are as follows:

Davenport coherence function:

Shiotami coherence function:

where

cv is the exponential decay coefficient, and

L represents the turbulent integral scale.

Combining the two coherence functions, the expression for the random wind speed time history

χu at the

j-th simulation point is as follows [

20].

where ∆

t represents the sampling interval time,

i =

,

M = 2

N,

N is the number of sampling frequency points, and ∆ω is the frequency increment, where ∆

ω =

ω/N.

The Fast Fourier Transform (FFT) technique is introduced to calculate

hjm(

p∆

t), and its expression is as follows.

where

Bjm(

l∆

ω) is as follows:

In the equation, φml is the uniformly distributed random phase angle within [0, 2π].

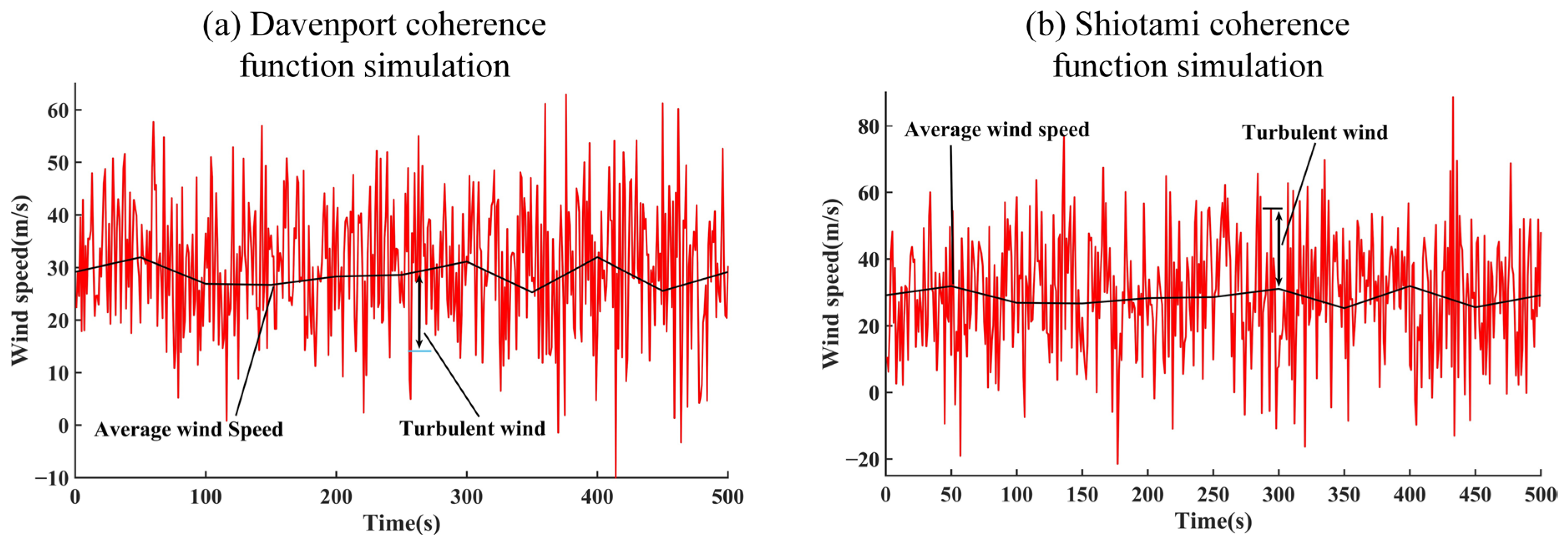

Based on the above formula, the simulated gust wind speed time history is shown in

Figure 2. The mean wind speed data in

Figure 2 are derived from the actual wind speed measurements collected along the Lanzhou–Xinjiang railway line.

Based on the actual wind speed measurement results, it can be found that the maximum instantaneous wind speed in this area does not exceed 60 m/s. Therefore, by comparing the simulated gust wind speed results in

Figure 2, it can be seen that the wind speed time history calculation results based on the Davenport coherence function are more accurate.

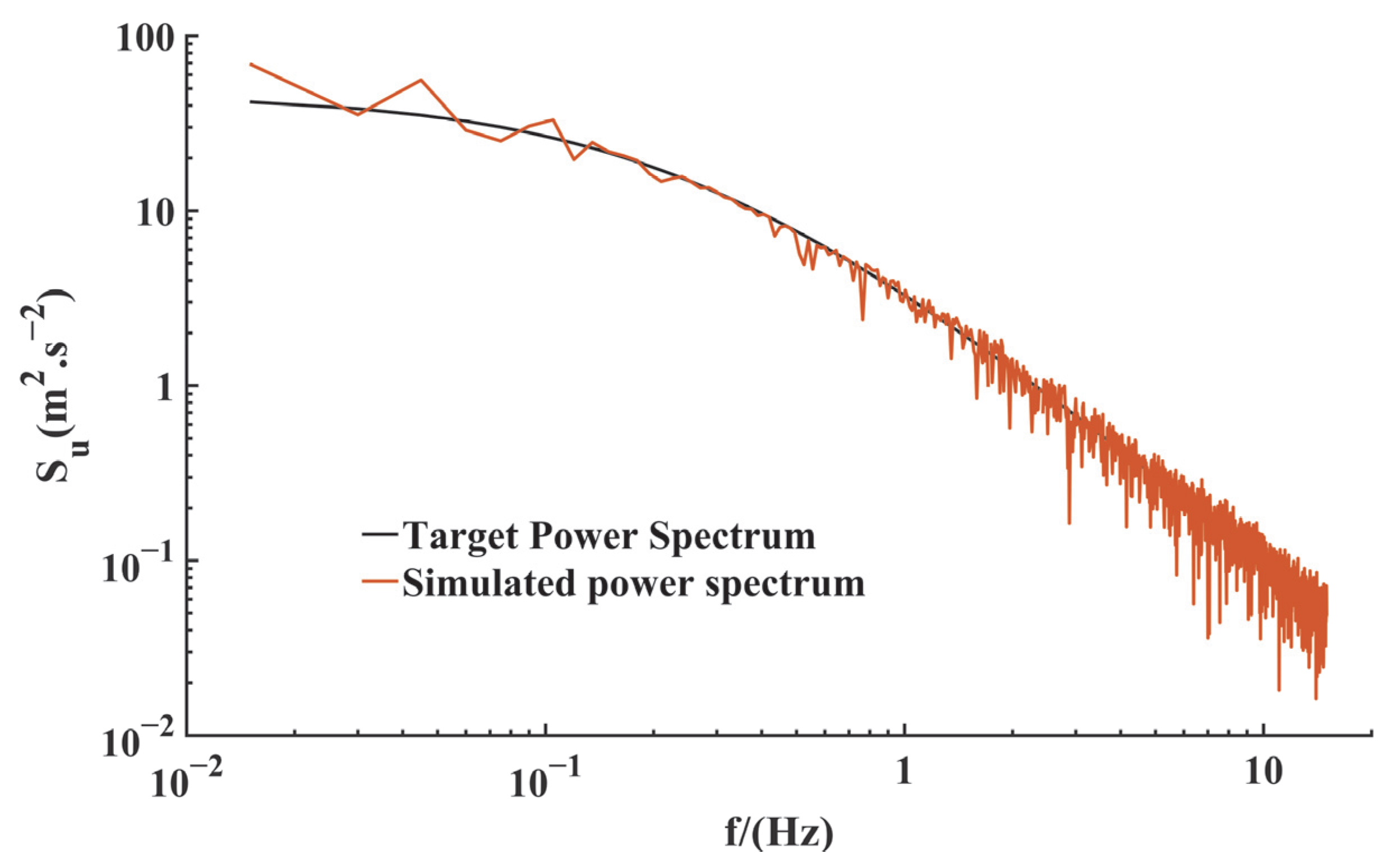

According to the gust wind time history calculation results in

Figure 2, the simulated wind power spectrum is shown in

Figure 3.

Based on the comparison of the wind speed power spectrum fitting degree in

Figure 3, it is found that the wind speed simulation spectrum based on the Davenport coherence function matches the target wind speed power spectrum well, which proves the validity of the simulation results [

21].

3.1.2. Calculation of Non-Stationary Wind Loads

Non-stationary wind loads mainly include the static wind force caused by the mean wind and the buffeting wind force caused by gusty wind. The static wind force on the surface of the train body is as follows [

22].

In the equation, the equivalent static wind force Fst acting on the train surface includes lateral force, vertical force, and rolling moment; u, w, and v represent the lateral, vertical, and longitudinal directions, respectively; ρ is the air density; A is the frontal area of the train body, V represents the train speed, β is the angle between the wind direction and the train’s direction of travel, H is the height of the train’s center of gravity above the subgrade, ψ is the yaw angle of the wind direction, and C(ψ) is the aerodynamic force coefficient.

The buffeting wind force is caused by gusty wind. The equivalent buffeting wind force at the simulated points on the surface of the train is as follows [

22]:

where

E is as follows:

In the equation, similar to the static wind force, the buffeting wind force also includes lateral force, vertical force, and rolling moment; χu and χw represent the lateral and vertical components of the gust wind, respectively. The calculation method for the vertical gust wind is the same as that for the lateral gust wind, but it needs to be combined with the power spectrum of the vertical wind speed.

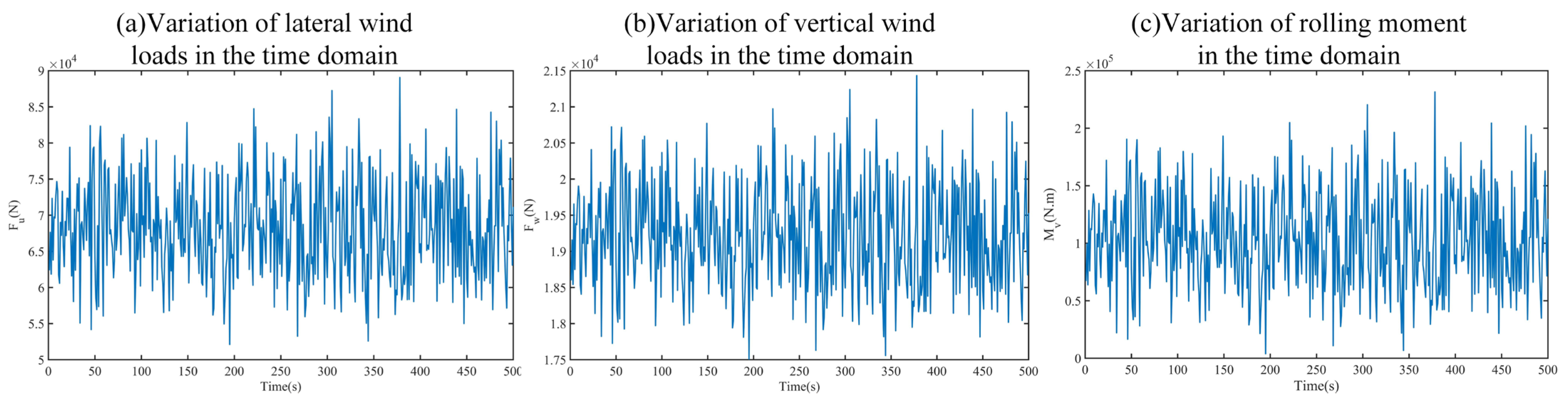

Assuming the train operates at a speed of 160 km/h,

β = 90°, and the wind direction’s principal angle relative to the horizontal plane is referenced from the literature [

5]. The structural dimensions of the train are based on the CRH2 high-speed train. Therefore, the non-stationary wind loads acting on the train are shown in

Figure 4.