Abstract

This study examined the design and optimization of low-speed external frame motors featuring Halbach-type and olive-shaped magnet structures to improve performance in spacecraft control moment gyroscopes (CMGs). Our research was driven by the urgent need for precise, high-torque, low-speed motors in CMGs, where conventional designs, including Halbach-type and traditional radial magnet configurations, are hindered by manufacturing complexity and excessive torque pulsation. This study focused on optimizing rotor pole configurations to enhance efficiency and torque stability. An olive-shaped magnet structure provides a more uniform magnetic field distribution in the air gap, substantially reducing magnetic field harmonics and minimizing cogging torque and torque pulsation—critical performance factors for low-speed applications. Comparative analysis reveals that the olive-shaped motor achieves a peak torque of 0.312 N·m with a torque pulsation of 0.9 mN·m, maintaining an amplitude below 0.3%. This demonstrates a 20% improvement compared to the Halbach-type motor’s torque pulsation of 1.15 mN·m. Moreover, the olive-shaped motor exhibits superior stability in air-gap magnetization under different loads, ensuring high efficiency and robust operation. By streamlining magnet assembly while enhancing electromagnetic performance, this study offers a cost-effective, high-precision solution for CMG systems. These findings underscore the olive-shaped magnet motor’s potential to advance motor technology for aerospace applications.

1. Introduction

Control moment gyroscopes (CMGs) are essential for spacecraft attitude control, generating substantial torque within a compact design [1]. This attribute renders them critical for precise spacecraft orientation. CMGs function by leveraging the angular momentum of a high-speed rotor, which is transformed into torque for spacecraft maneuvering [2]. Typically, CMGs comprise a rotor assembly within an external frame, supported by gimbals to enable gyroscopic torque control [3]. A critical research gap lies in developing cost-effective motor designs that achieve high torque density and minimal torque pulsation for low-speed CMG applications.

The effectiveness of CMGs relies heavily on the external frame motor, which must meet stringent requirements, including high torque density, low cogging torque, and optimal efficiency at low speeds [4]. These qualities are vital for ensuring the stability and precision required in spacecraft applications. Hence, optimizing the motor’s magnetic structure is crucial for enhancing CMG performance [5]. This study explores the design and analysis of low-speed external frame motors that incorporate advanced magnet configurations. Previous research has predominantly utilized Halbach-type magnets to improve torque density and reduce pulsation, achieving torque pulsation values of 1.2–1.8 mN·m in similar low-speed applications, demonstrating their efficacy in high-torque scenarios. However, these designs often entail compromises in manufacturability and cost, posing significant challenges for CMGs where performance must align with budget constraints. In contrast, this study’s olive-shaped magnet structure yields a torque pulsation of 0.9 mN·m, outperforming previously studied conventional designs (1.5–2.0 mN·m) and Halbach-type motors.

External rotor permanent magnet torque motors have attracted significant interest due to their high torque density, compact design, and exceptional efficiency, making them ideal for applications such as electric vehicles and mobile robotics [6]. Extensive research has examined their operational principles, electromagnetic performance, and optimization strategies [7]. A central focus of their design is the rotor’s magnetic structure. Novel configurations, such as Halbach-type and olive-shaped magnet structures, have been explored to enhance performance [8,9]. The Halbach-type configuration, characterized by a specific magnet orientation, amplifies the magnetic field on one side while suppressing it on the other, yielding increased torque density and reduced cogging torque [10]. Studies demonstrate that Halbach-type magnets, including segmented arrays, offer improved torque characteristics, lower torque ripple, and superior magnetic field control, fostering operational stability and efficiency in high-torque, low-speed applications. This is evidenced by advancements in passive magnetorheological brake systems and permanent magnet Vernier motors [11,12] and reinforced by targeted studies on optimized Halbach array designs [13,14].

Despite these benefits, Halbach-type configurations encounter challenges in manufacturing complexity and cost. To address these drawbacks, the olive-shaped magnet structure has been proposed as an effective alternative [15]. This design has a streamlined magnet arrangement while preserving robust electromagnetic performance [16,17]. Finite element analysis (FEA) confirms that olive-shaped magnet motors achieve high torque density and efficiency, making them well-suited for applications where cost and manufacturability are paramount [7,18]. This study tackles the challenge of optimizing motor designs for low-speed CMGs to balance performance and manufacturability, proposing olive-shaped magnet structures for enhanced torque stability and cost-effectiveness.

In the realm of CMGs, which are indispensable for spacecraft attitude control due to their remarkable moment amplification capabilities, the precision and stability of low-speed frame systems are critical [19,20,21]. The external frame torque motor, a fundamental component of the CMG’s drive system, benefits from innovations that minimize cogging torque and boost torque density [22]. Implementing external rotor structures with optimized magnet configurations, such as Halbach-type or olive-shaped magnets, coupled with centralized fractional-slot winding techniques, effectively mitigates cogging torque and enhances motor performance [22]. This study builds upon prior research by rigorously demonstrating that the olive-shaped magnet structure provides an optimal balance of performance and manufacturability for CMG applications, delivering comparable or superior torque stability (reduced pulsation) relative to complex Halbach designs while offering a more streamlined, cost-effective manufacturing strategy.

This paper presents a comprehensive analysis of low-speed external frame motors, focusing on the comparative performance of Halbach-type and olive-shaped magnet structures for CMG applications. The study optimizes rotor pole configurations to enhance electromagnetic performance, employing finite element analysis to assess magnetic field distribution, cogging torque, and torque pulsation under diverse operating conditions. Experimental validation through a custom-designed motor and control system verifies low-speed precision and stability, establishing the olive-shaped magnet structure as a premier, cost-effective solution for aerospace motor technology.

2. Motor Modeling

2.1. Design Requirements

The design and analysis of low-speed external frame motors with Halbach-type and olive-shaped magnet structures aim to maximize efficiency, reduce size, and improve torque stability for control moment gyroscope (CMG) applications in spacecraft. The Halbach-type configuration, pioneered by K. Halbach in 1979, arranges permanent magnets to create a sinusoidal magnetic field, making it highly suitable for external rotor permanent magnet synchronous motors (PMSMs). The olive-shaped magnet structure is adopted for its capacity to meet dimensional constraints, minimize torque pulsation, and deliver efficient low-speed performance under load [22]. Comprehensive motor design specifications, as listed in Table 1, include dimensions, torque, electrical properties, and operational limits to ensure optimal performance in aerospace CMG systems. This design emphasizes thermal management, electromagnetic interference (EMI) suppression, and torque smoothness. The olive-shaped magnet structure significantly enhances performance by reducing cogging torque, improving load-handling capability, and increasing system efficiency.

Table 1.

External frame motor design requirements.

The motor’s continuous stall torque of 0.2 N·m and peak power loss of 20 W limit its suitability for heavy loads or prolonged operation. With a resistance of 1.8 ± 0.2 Ω and inductance ≤5 mH, it may exhibit delayed transient responses and increased power losses, rendering it ideal for light-duty, precision-control tasks in CMGs.

2.2. Modeling of Halbach-Type and Olive-Shaped Magnet Motors

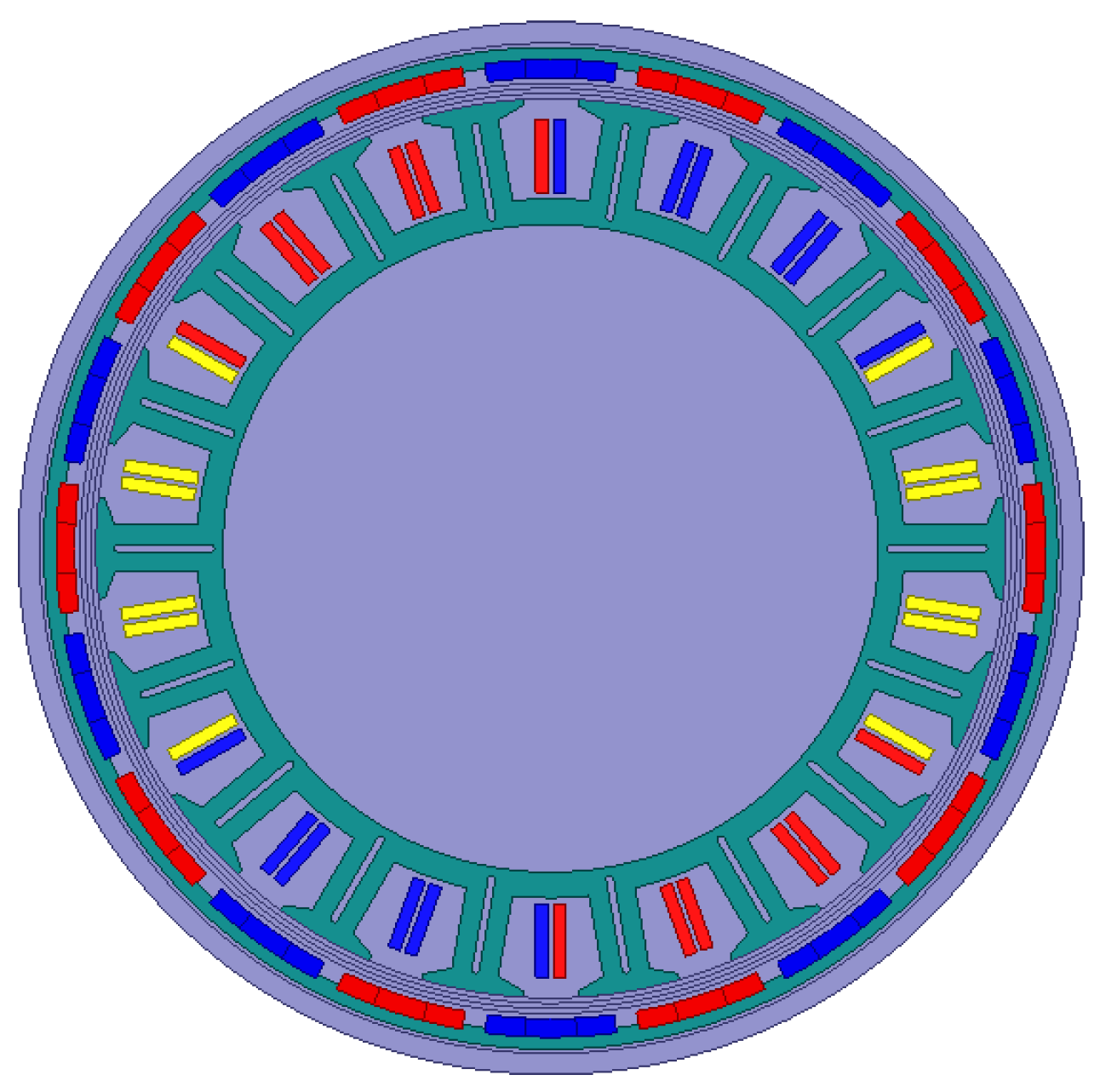

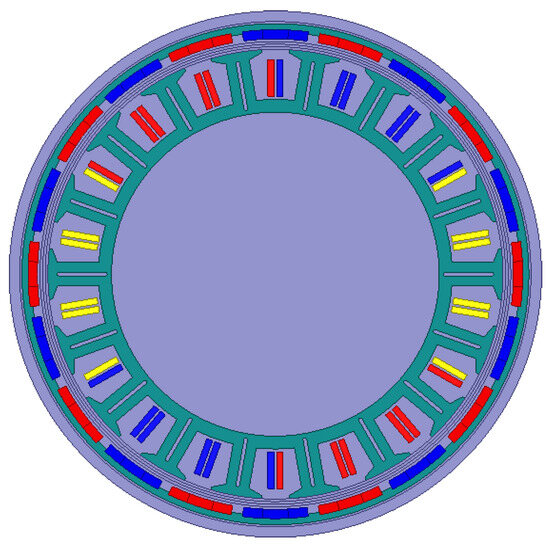

The low-speed external frame motor incorporates an 18-slot stator and a 20-pole rotor with a centralized fractional-slot winding configuration, as illustrated in Figure 1. This design minimizes winding end-turn length, thereby reducing the motor’s volume and weight. The Halbach-type magnetic structure consists of three permanent magnet blocks per pole, a central block with radial magnetization and two adjacent blocks magnetized at a 10° angle, as depicted in Figure 1. This arrangement generates a sinusoidal magnetic field, enhancing motor efficiency by integrating radial and tangential magnetization components. The Halbach configuration optimizes air-gap flux density, increasing torque density and minimizing cogging torque. The fractional-slot winding promotes smoother load handling, significantly improving performance in low-speed, precision-driven applications such as CMGs.

Figure 1.

The stator has 18 slots, and the rotor has a 20-pole Halbach-type external rotor motor structure.

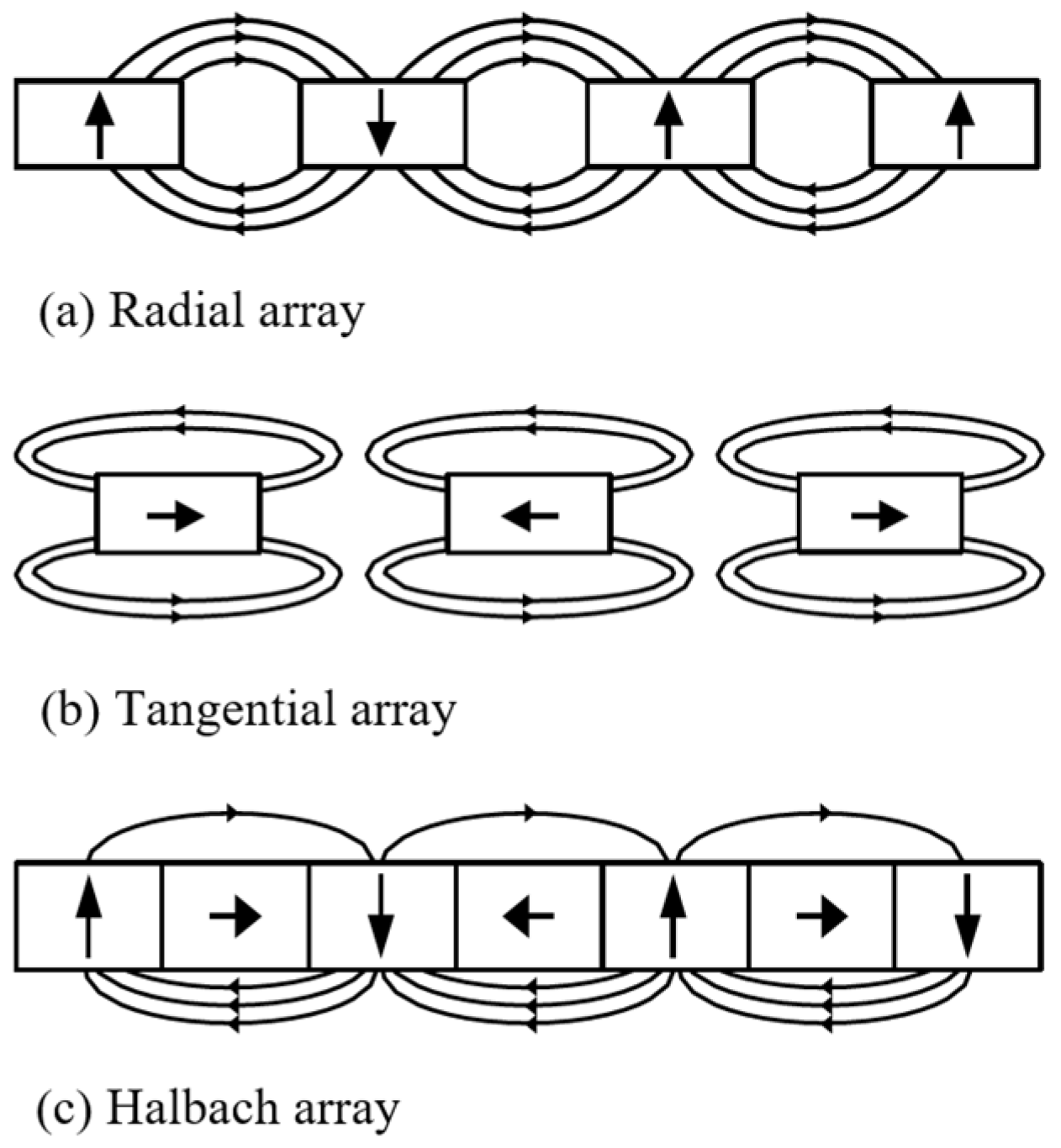

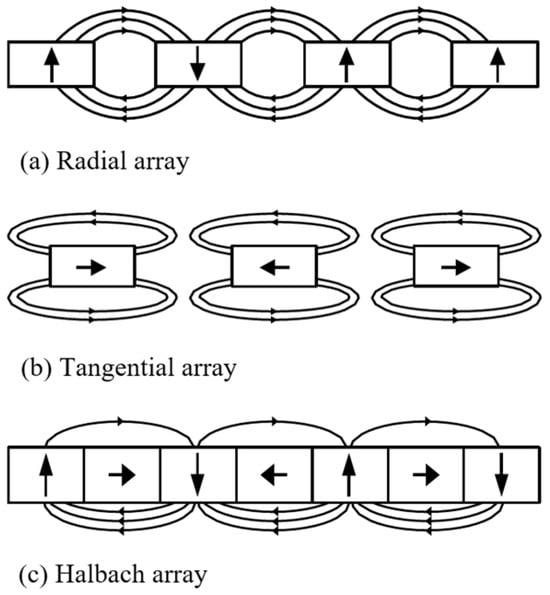

Figure 2 presents a schematic of the permanent magnet array. The Halbach-type magnetization directs magnetic flux to one side of the rotor, enhancing torque output while reducing motor size and weight. This optimized electromagnetic configuration strengthens stator–rotor interactions, enabling a compact design with high torque density and lower energy losses, making it highly suitable for low-speed applications where efficiency and compactness are paramount.

Figure 2.

Schematic diagram of permanent magnet array.

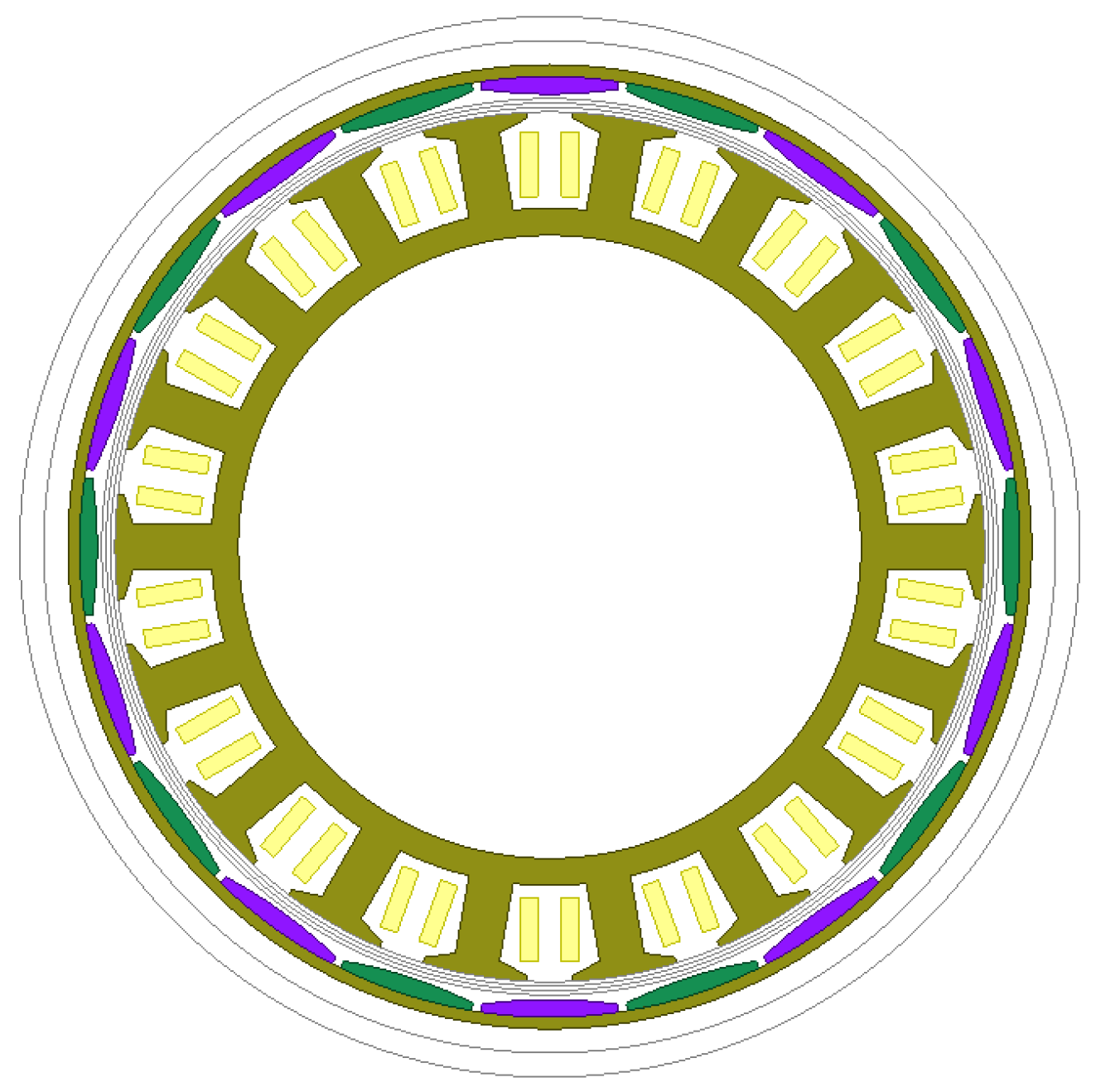

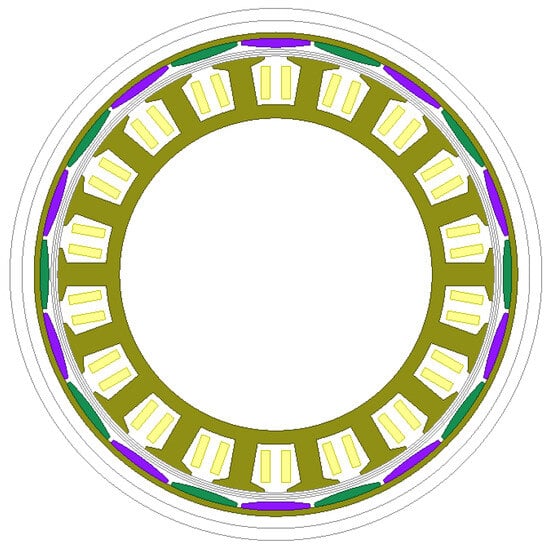

The rotor also features an olive-shaped magnet structure, as shown in Figure 3, with each pole comprising a single radially magnetized olive-shaped permanent magnet. This novel design optimizes air-gap magnetic field distribution, substantially reducing harmonic content, cogging torque, and harmonic-induced torque pulsation. As a result, the motor delivers smoother operation with minimal torque pulsation, significantly enhancing overall performance.

Figure 3.

Stator 18-slot, rotor 20-pole external frame motor structure.

The olive-shaped magnet configuration effectively mitigates higher-order harmonics by suppressing undesirable harmonic amplitudes, ensuring that most harmonics are even-order. This way, they can be more easily eliminated, thereby reducing noise and vibration. The air-gap magnetic field arises from the combined effects of the stator armature reaction and the rotor’s permanent magnet magnetic potential, modulated by air-gap permeability. Harmonic analysis indicates that stator slotting influences the magnetic field’s spatial distribution but not its frequency. The electromagnetic force harmonics, primarily even-order, align with the greatest common divisor of the pole and slot numbers, simplifying their suppression. The 18-slot, 20-pole configuration, combined with Halbach-type and olive-shaped magnet structures, greatly enhances magnetic field distribution and harmonic suppression, producing a motor optimized for low-speed and high-torque applications with superior efficiency, stability, and minimal mechanical vibrations.

2.3. Mathematical Model of Halbach Magnet Orientation Distribution

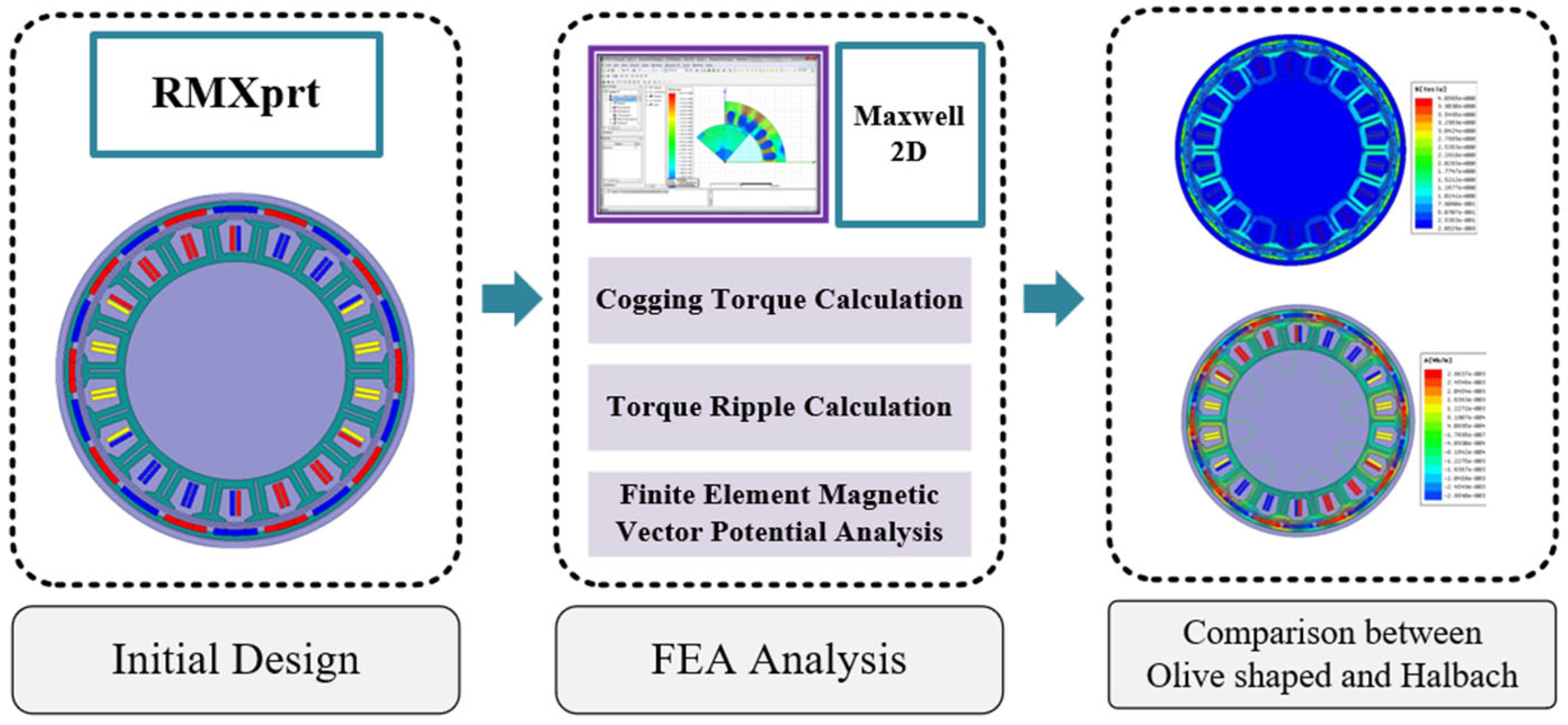

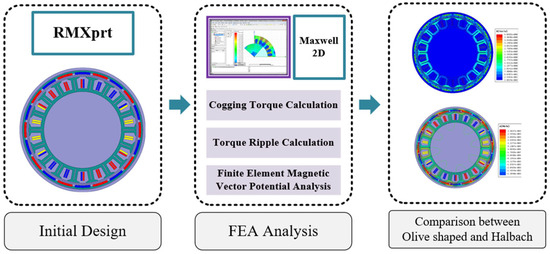

This study employed an integrated analytical–computational methodology for designing and evaluating low-speed external frame motors with Halbach-type and olive-shaped magnet topologies (Figure 4). The framework systematically combines the initial geometry (18-slot stator, 20-pole rotor) and magnetization profiles derived from torque-speed requirements. Halbach arrays follow

where M0 is the magnetization amplitude, θ is the angular position, and er and eθ are radial and tangential unit vectors.

Figure 4.

Methodology workflow.

While olive-shaped magnets incorporate geometry-optimized phase modulation

where φ(θ) is a phase-shift function optimized via parameter sweeps to minimize harmonic distortions.

High-fidelity magnetostatic FEA (COMSOL) solves the following

where μ0 is the permeability of free space, A is the magnetic vector potential, and M is the magnetization vector. Boundary conditions include ∇ × A = 0 at air-gap interfaces and M(θ) on rotor surfaces. Mesh convergence is achieved with residuals below 10−5, using 0.05 mm elements in the air gap, 0.1 mm in teeth/slots, and 0.5 mm in back iron, ensuring numerical accuracy.

Torque ripple, a critical metric, is found in the following:

where Tmax, Tmin, and Tavg are the maximum, minimum, and average torque values, respectively.

Cogging torque is quantified as

and field uniformity is evaluated across operational regimes (no-load/maximum torque/linked-shaft).

Above, Φ is the magnetic flux and ∂Φ/∂θ represents the flux variation with respect to angular position. Field uniformity is assessed to ensure stable operation. Both topologies are benchmarked under identical electromagnetic loading, with sensitivity analyses (offset angles: 0–15°; phase-shift functions) quantifying harmonic cancelation efficacy against industrial thresholds: torque ripple ∆T < 1% and cogging torque Tc < 3 mN·m.

This schematic outlines an electromagnetic design workflow utilizing RMXprt for initial motor design, incorporating Maxwell 2D simulations for cogging torque, torque ripple, and magnetic vector potential analysis. Subsequent finite element analysis (FEA) comparatively evaluates olive-shaped and Halbach array configurations to assess performance characteristics. The methodology integrates analytical and numerical approaches for comprehensive electromagnetic assessment.

3. Analysis and Comparison

3.1. Finite Element Analysis

To rigorously evaluate the electromagnetic performance of external rotor motors featuring Halbach-type and olive-shaped magnet structures, finite element analysis (FEA) was conducted using high-fidelity computational models. The analysis aims to quantify and compare key electromagnetic parameters under varying operational conditions, including no-load operation, maximum torque generation, and constant torque scenarios across a range of rotational speeds. Periodic boundary conditions were applied to exploit the motor’s 18-slot/20-pole symmetry, while a Dirichlet condition (magnetic flux parallel) constrained the solution domain’s outer boundary. Mesh refinement was optimized with 0.05 mm elements in the air gap, 0.1 mm in teeth/slots, and 0.5 mm in back iron, achieving convergence when torque ripple varied by <0.1% upon refinement. A virtual dynamometer maintained constant speeds during load simulations to evaluate torque characteristics. The finite element models incorporate precise material properties, boundary conditions, and mesh refinement strategies to ensure high accuracy in predicting motor performance.

This study systematically examined critical electromagnetic characteristics such as magnetic flux distribution, back electromotive force (EMF), cogging torque, torque ripple, and overall efficiency. A comparative assessment of the two motor topologies reveals that the olive-shaped magnet configuration exhibits superior electromagnetic performance due to its enhanced flux concentration, reduced torque ripple, and improved torque stability. In contrast, the Halbach-type magnet arrangement demonstrates certain limitations in field uniformity and torque consistency. Additionally, the olive-shaped magnet structure showcases greater optimization potential, offering a more efficient and stable solution for low-speed external frame motor applications. These findings provide significant insights into magnet structure refinement, contributing to the advancement of high-performance motor designs for precision engineering and industrial applications.

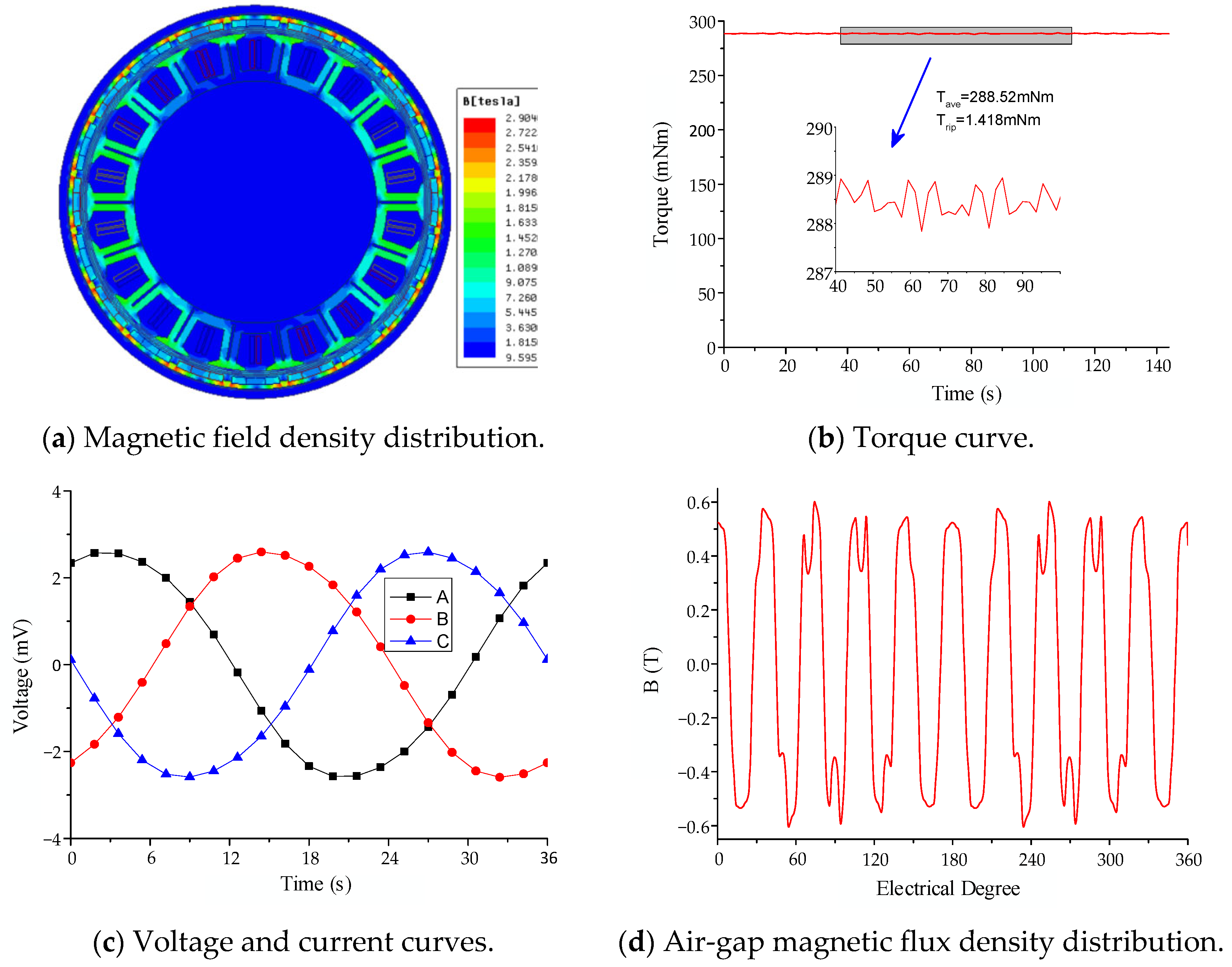

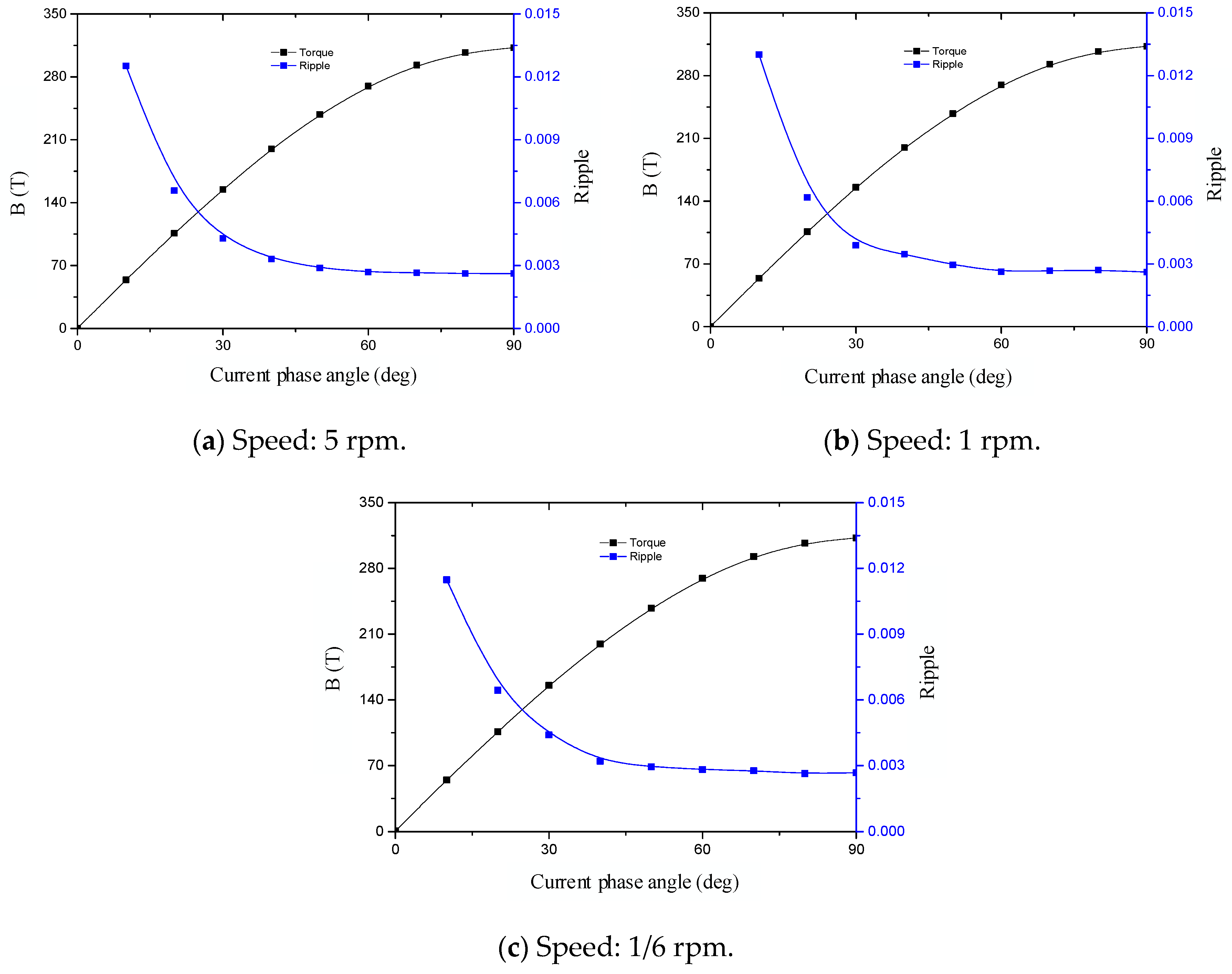

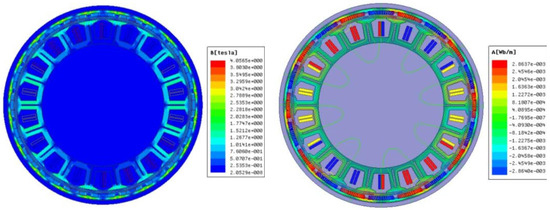

3.1.1. Analysis Under No-Load Conditions (Speed 30°/s)

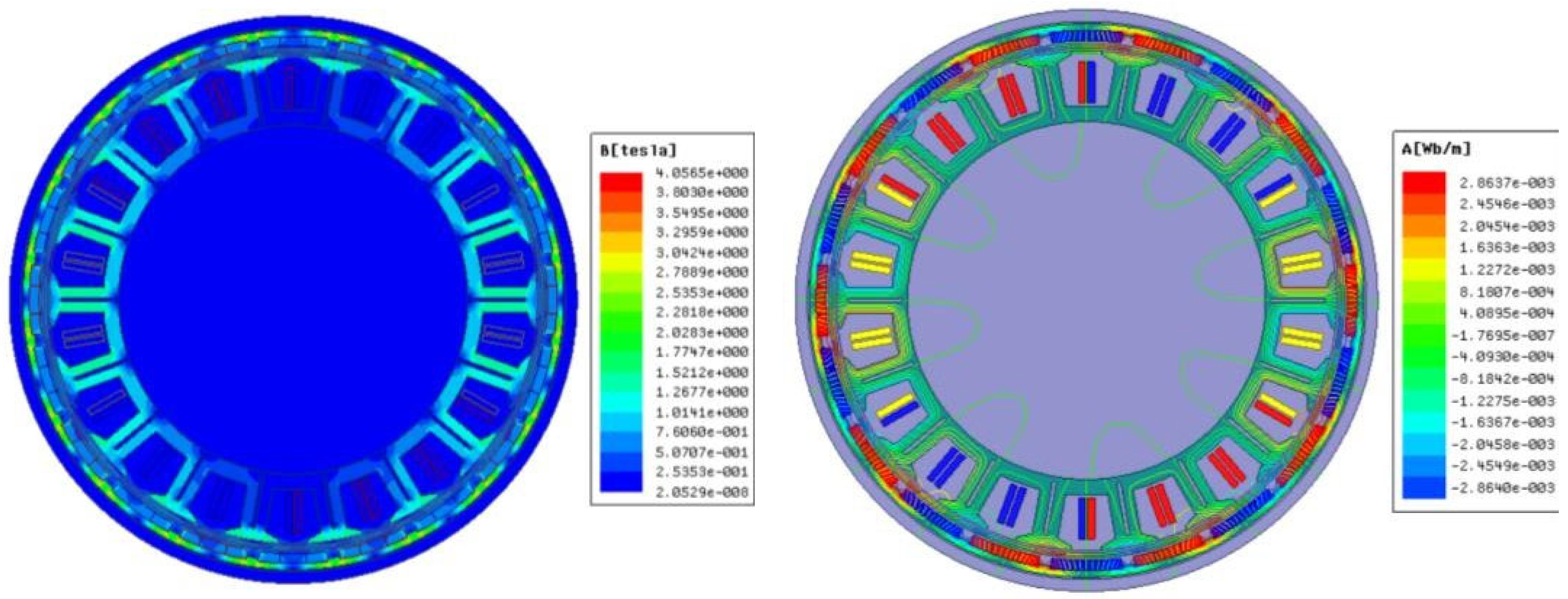

The electromagnetic performance of Halbach-type and olive-shaped magnet motors was rigorously analyzed under no-load conditions at a rotor speed of 30°/s. The magnetic flux density and flux line distributions were computed for both designs. For the Halbach-type motor, these parameters are depicted in Figure 5, showcasing the radial magnetic flux density and three-phase back EMF. Cogging torque is presented in Figure 6. The comparative analysis reveals distinct differences in magnetic field uniformity and torque ripple, with the olive-shaped magnet structure delivering superior flux concentration and smoother performance at low speeds.

Figure 5.

Schematic diagram of permanent magnet array.

Figure 6.

No-load operation characteristics of the motor (5 rpm).

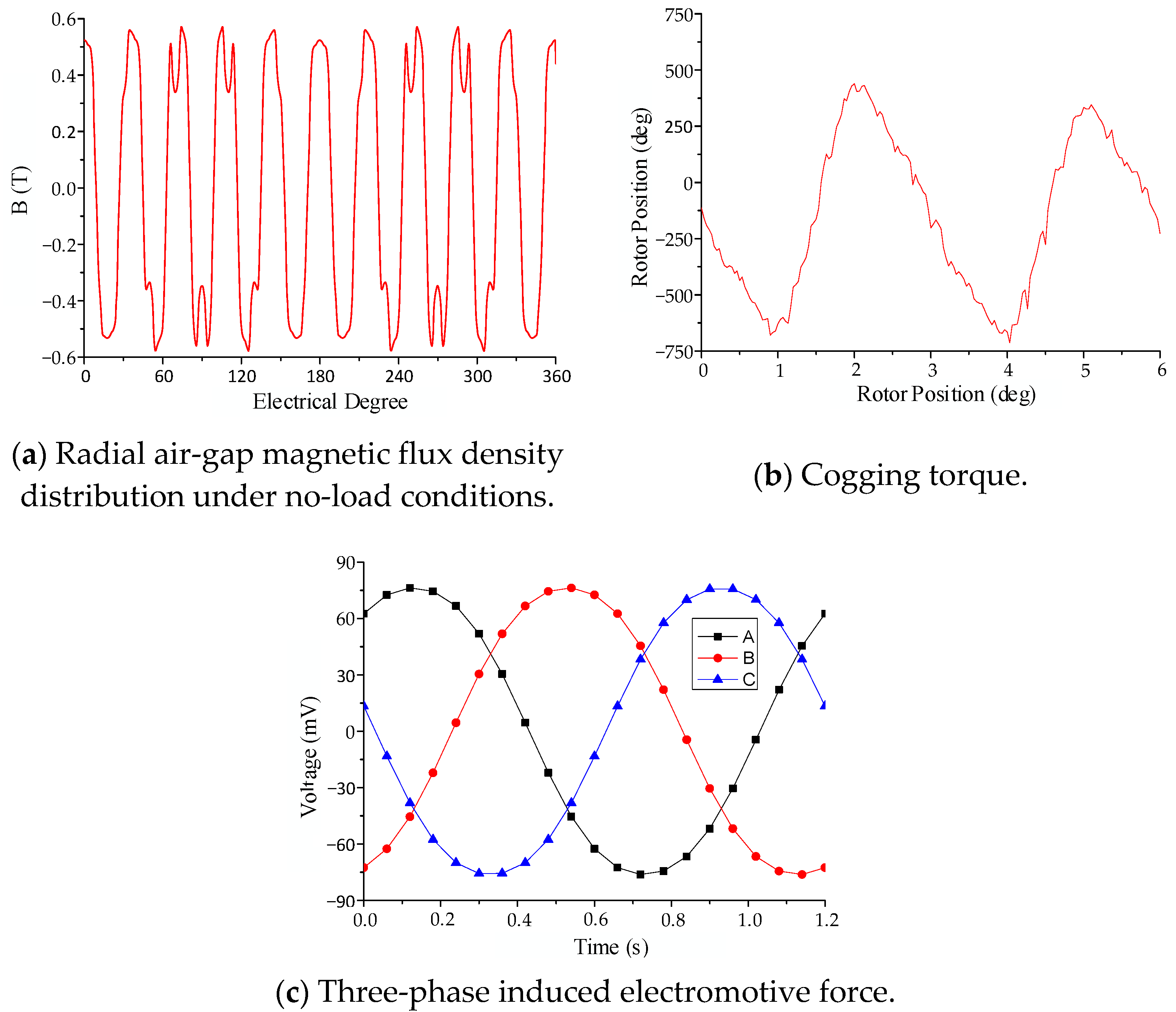

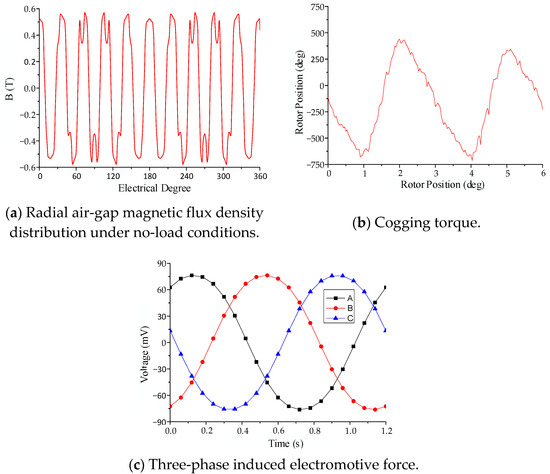

In contrast, the olive-shaped magnet motor, as shown in Figure 7 and Figure 8, demonstrates superior characteristics, with enhanced radial magnetic density distribution and improved cogging torque performance. These improvements are attributed to the optimized magnet arrangement, which results in a more uniform magnetic field and reduced torque ripple. Furthermore, the analysis reveals that the olive-shaped magnet motor exhibits lower energy losses and higher overall efficiency at low speeds, making it a more suitable choice for applications requiring precise and stable operation. These comparisons highlight the olive-shaped magnet motor’s better performance in design, efficiency, and operational stability under no-load conditions.

Figure 7.

Magnetic density cloud map and magnetic line cloud map of the motor in the no-load state.

Figure 8.

No-load operation characteristics (5 rpm).

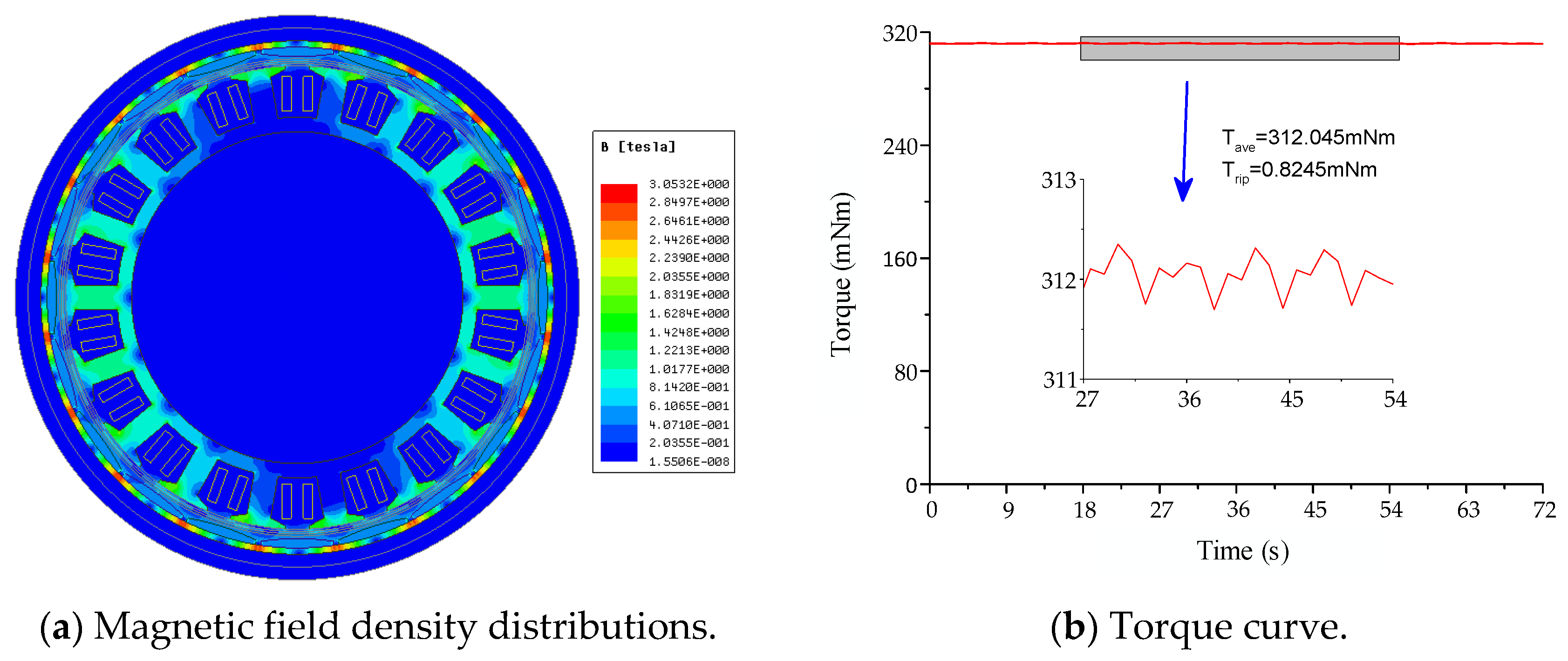

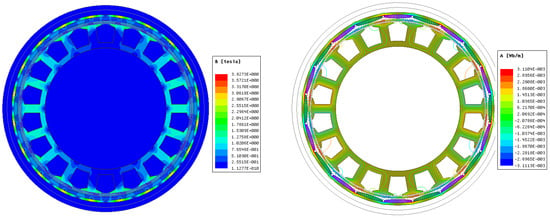

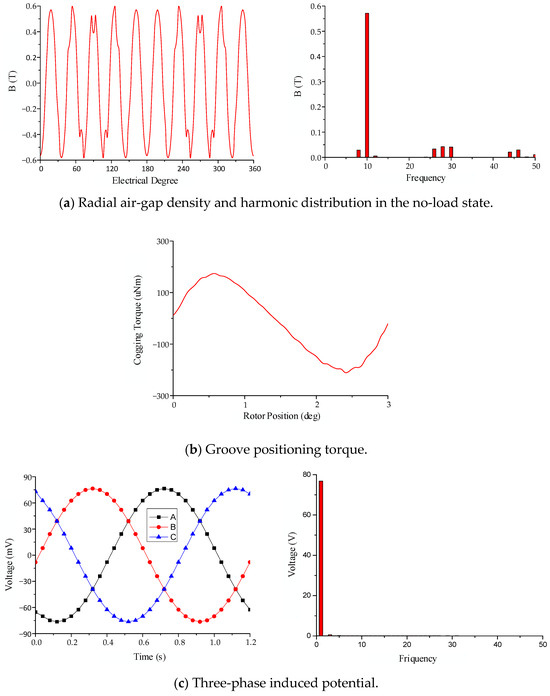

3.1.2. Analysis Under the Continuous Stall (1°/s) Condition

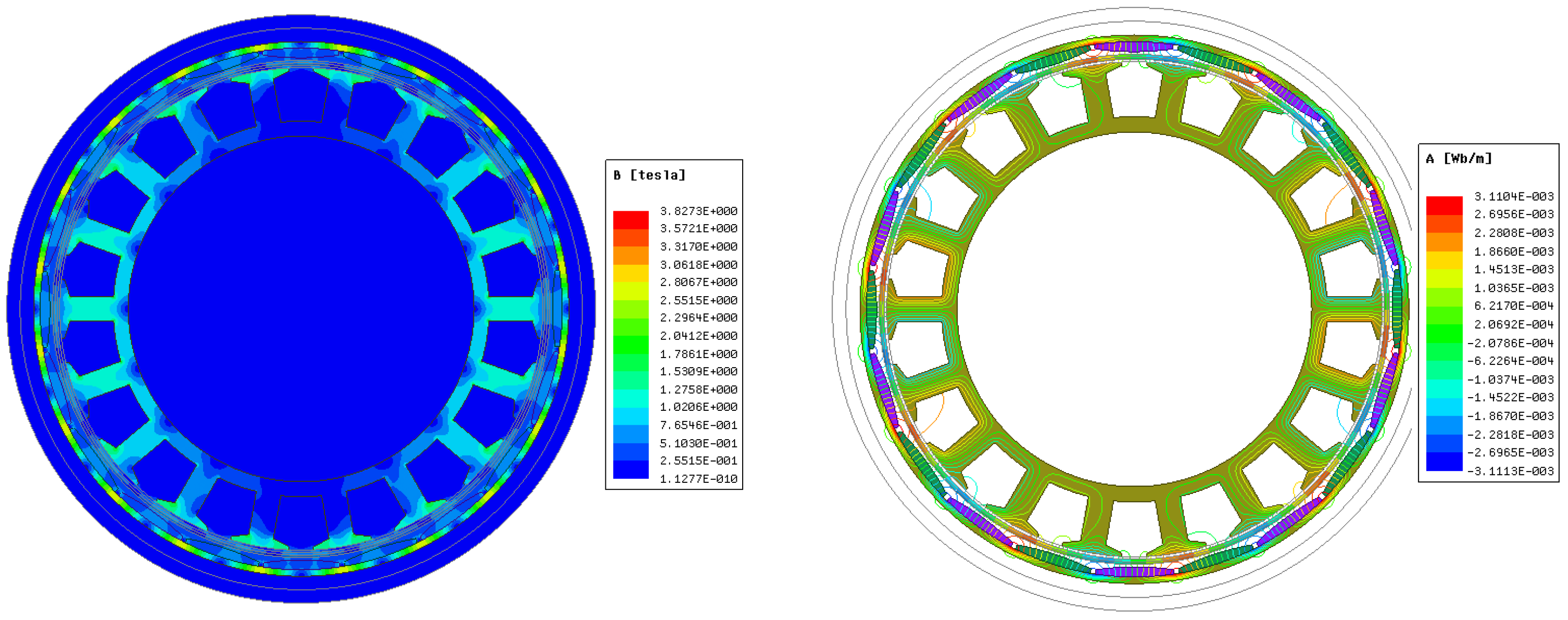

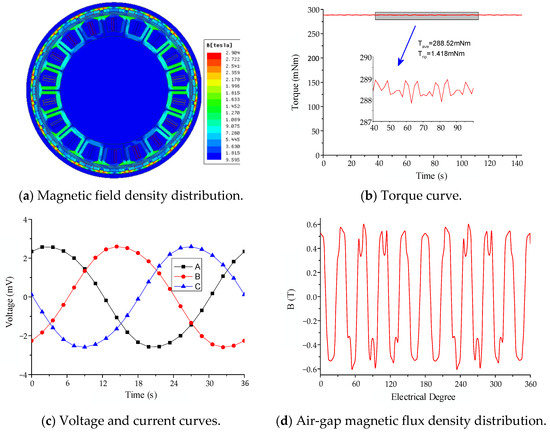

In the analysis of the Halbach-type motor under locked rotor conditions with three-phase sinusoidal currents, the motor’s magnetic flux distribution, torque characteristics, voltage–current relations, and radial air-gap magnetic field distribution were computed, as depicted in Figure 9. The analysis also investigates the motor’s electromagnetic losses, efficiency, and thermal performance under continuous stall conditions, which are critical for optimizing motor design for prolonged operation in industrial applications.

Figure 9.

Motor characteristics under continuous stall conditions (maximum torque output).

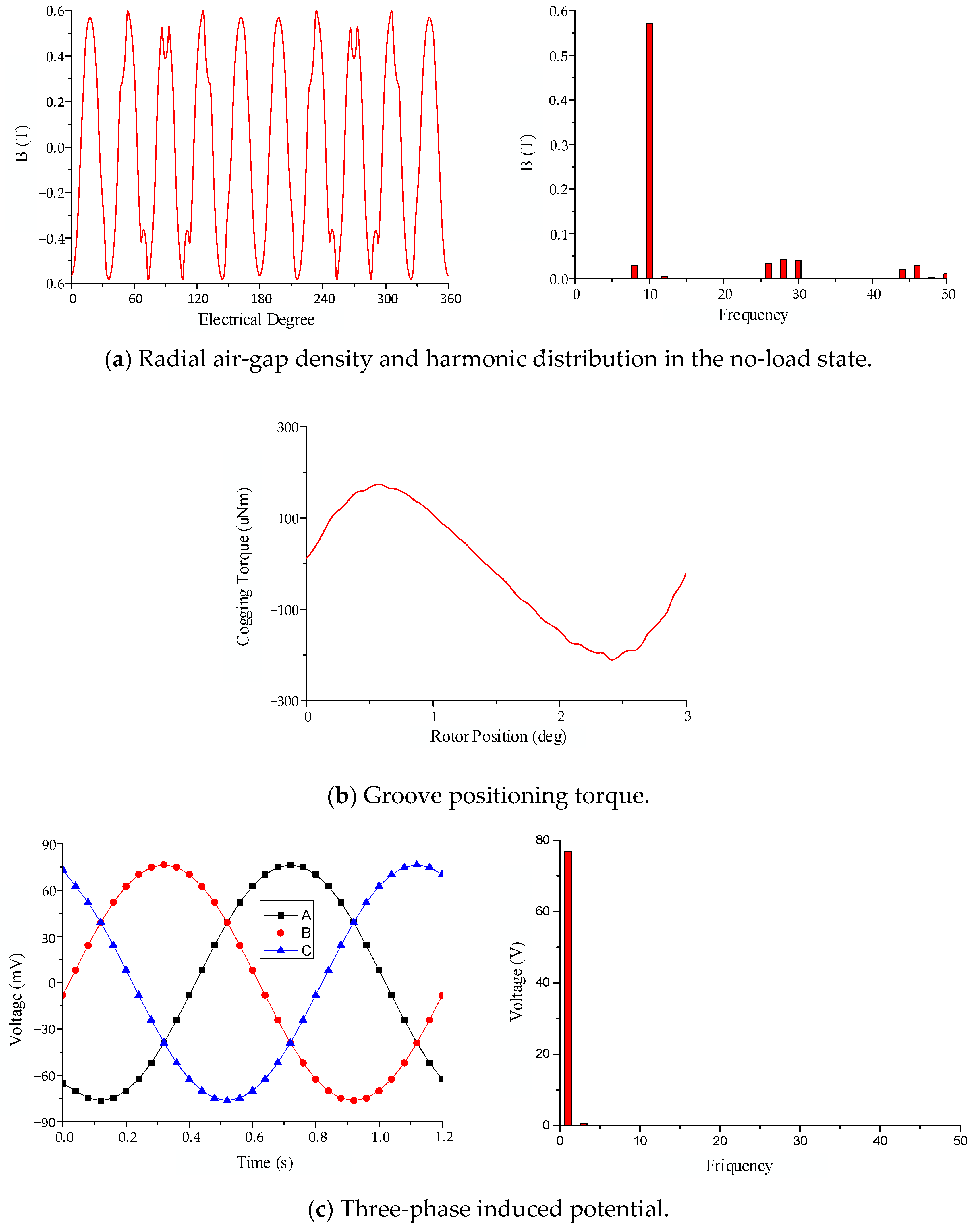

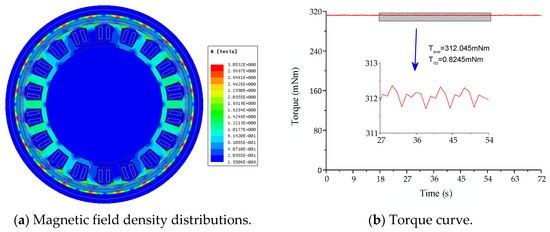

The olive-shaped magnet motor, operating at 1°/s, exhibited superior performance, with enhanced magnetic flux density, torque characteristics, and air-gap radial magnetic flux density waveform, as depicted in Figure 10. It also demonstrated improved efficiency, reduced electromagnetic losses, and greater long-term reliability. Comparative analysis confirms that the olive-shaped magnet motor outperforms the Halbach-type motor under continuous stall conditions, offering significant advantages in flux concentration, torque smoothness, and overall stability, making it highly suitable for demanding industrial applications.

Figure 10.

Motor characteristics (1°/s).

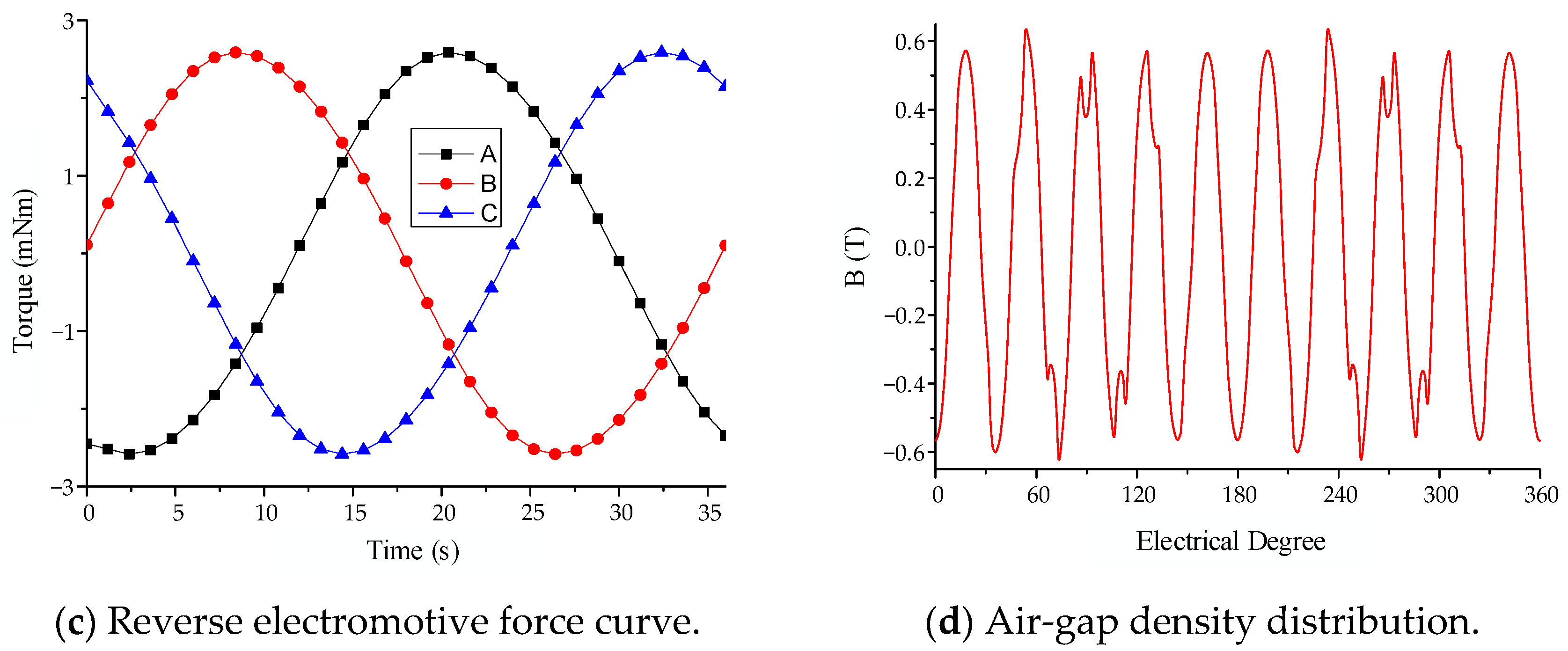

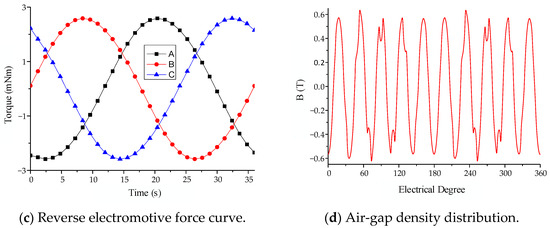

3.2. Torque and Its Fluctuation at Different Speeds: Analysis and Comparison of Halbach-Type and Olive-Shaped Magnet-Type Motors

Figure 11 depicts the relationship between motor output torque, torque pulsation, and rotational speed. For output torques exceeding 70 mN·m, torque pulsation remains below 1%, stabilizing at approximately 0.3% for torques above 200 mN·m, indicating robust performance at low speeds.

Figure 11.

Variation curve of electromagnetic torque and its fluctuation.

The olive-shaped magnet motor design delivers superior magnetic flux distribution compared to the Halbach-type motor, optimizing flux utilization. This results in smoother torque output with minimized pulsation. The olive-shaped motor achieves a peak torque of 0.312 N·m with a pulsation of 0.9 mN·m, maintaining an amplitude below 0.3% and demonstrating a 20% improvement compared to the Halbach-type motor’s pulsation of 1.15 mN·m.

The back EMF of the olive-shaped motor is nearly sinusoidal, in contrast to the Halbach-type motor, which shows greater distortion, leading to inefficiencies. Moreover, the air-gap magnetization in the olive-shaped motor remains stable under different loads with minimal distortion, ensuring consistent performance across diverse operational conditions. This stability greatly enhances its efficiency, particularly in low-speed operations where torque ripple and load fluctuations are most significant. The olive-shaped motor’s superior performance underscores its suitability for applications requiring smooth operation, high efficiency, and reliability.

Figure 10 further confirms the olive-shaped magnet motor’s superiority, illustrating reduced torque pulsation and magnetic harmonics, making it ideal for high-precision applications such as control moment gyroscope (CMG) systems. This optimized design delivers consistent and stable performance at low speeds, establishing it as the preferred choice for external frame motors requiring precision and reliability. The olive-shaped magnet motor surpasses the Halbach-type motor, providing enhanced torque smoothness, reduced pulsation, and more efficient load handling, which is optimal for low-speed, high-precision applications.

4. Low-Speed Operation Result

4.1. External Rotor Structure with Controller

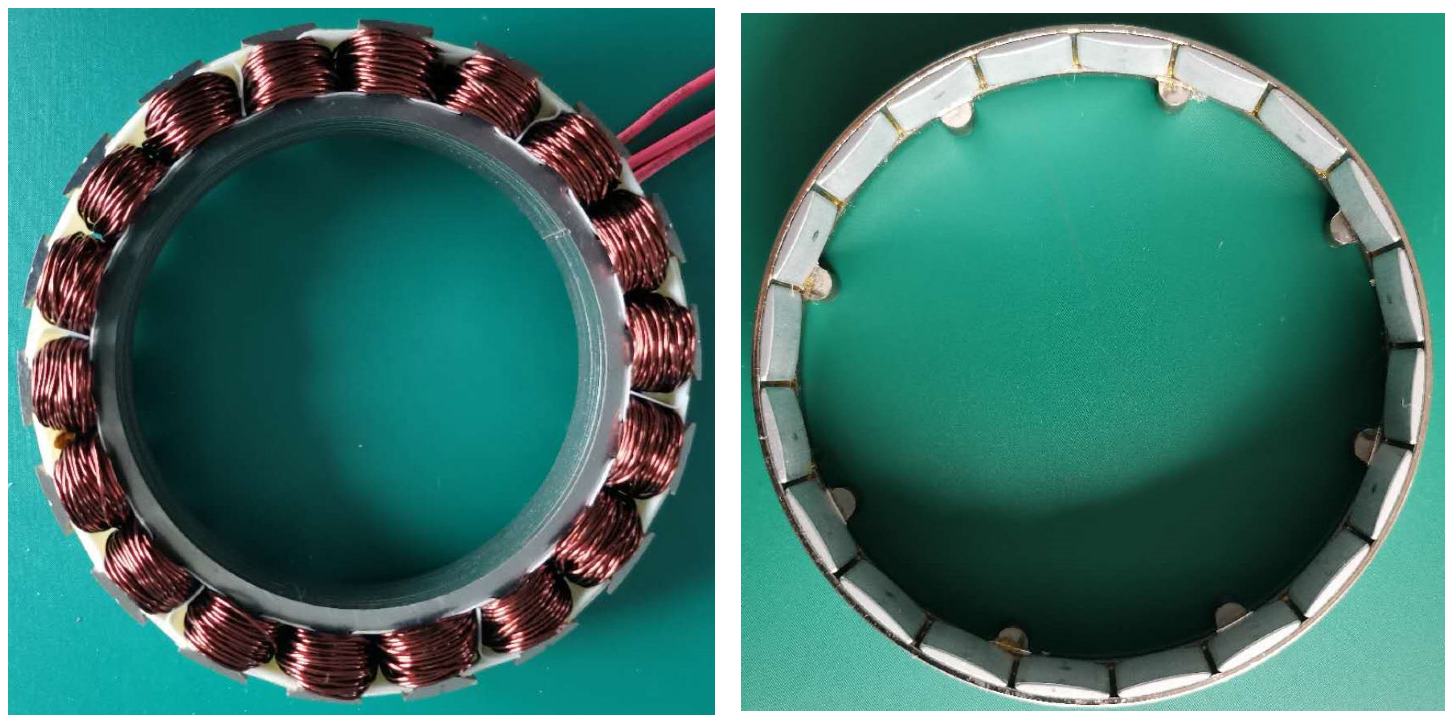

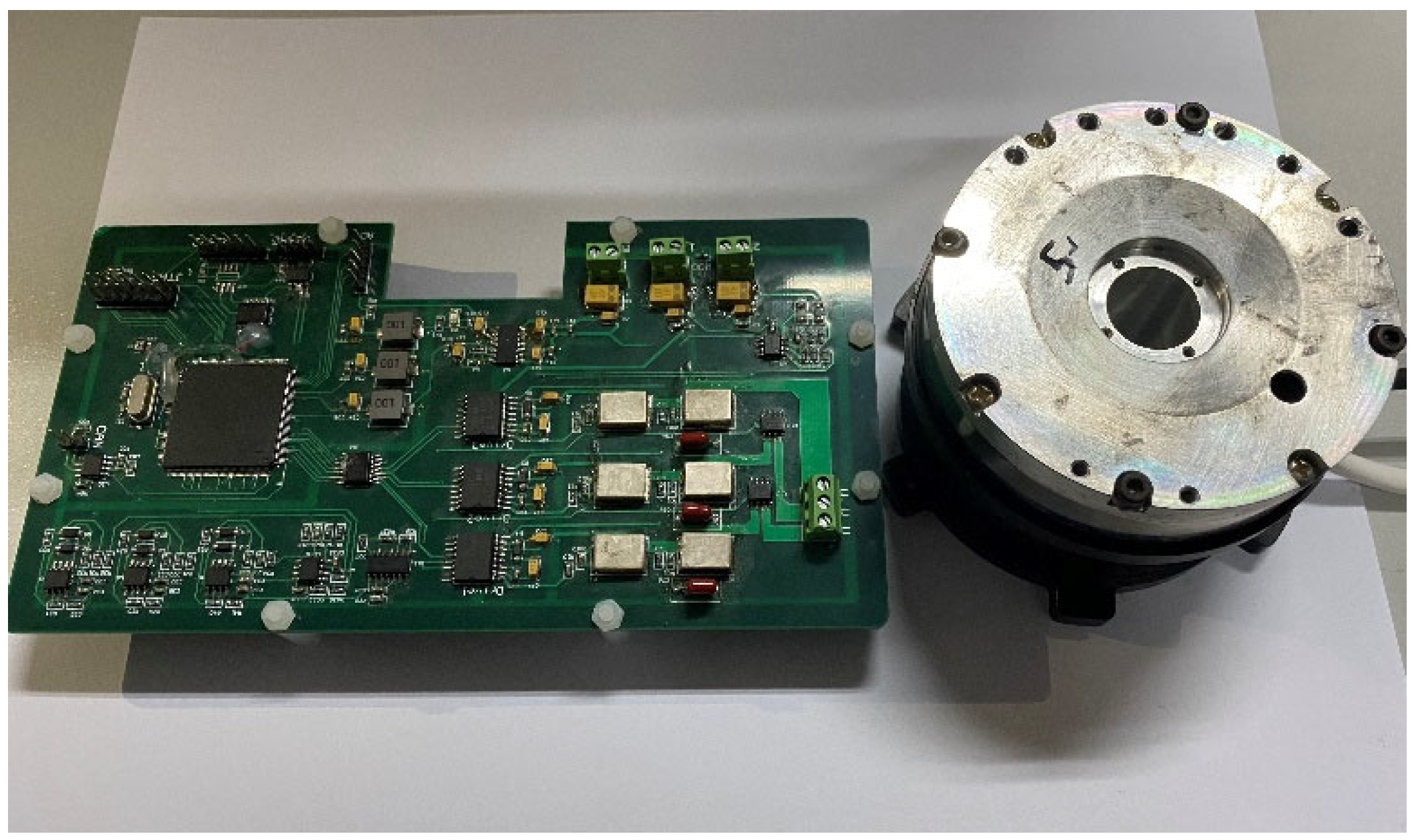

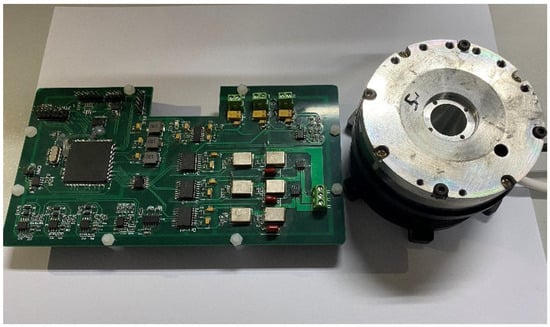

To enhance the low-speed functionality of the external frame motor featuring an olive-shaped magnet structure, a tailored external rotor motor was engineered. The stator, incorporating olive-shaped magnets, delivers notable benefits, including superior torque output, reduced mass, and enhanced efficiency at low speeds. This configuration ensures a compact, lightweight external frame while maintaining robust performance. The stator design with olive-shaped magnets is illustrated in Figure 12. The motor is integrated with a control system comprising the TMS320F28335 DSP from Texas Instruments’ C2000 series for precise computational control and the FSB52006S intelligent power module from ON Semiconductor for efficient power management. The complete motor–controller system is depicted in Figure 13.

Figure 12.

Schematic structure of the external frame torque motor with stator, rotor, and olive-shaped magnets.

Figure 13.

Controller system and low-speed olive-shaped external frame motor.

Electromagnetic modeling of the motor, encompassing both Halbach-type and olive-shaped magnet configurations, was conducted using finite element analysis (FEA) in ANSYS Maxwell 2D. These simulations were executed on high-performance workstations to guarantee computational efficiency and accuracy. The design process entailed defining rotor–stator geometry and material properties, as well as implementing appropriate boundary conditions to simulate steady-state and dynamic behavior under low-speed conditions. ANSYS Maxwell was selected for its robust capabilities in electromagnetic field analysis, essential for accurately predicting motor performance metrics.

The control algorithm was developed and optimized in Code Composer Studio, with real-time data acquisition facilitated by Texas Instruments’ onboard ADC and encoder interface. This real-time monitoring was critical for tracking key parameters, such as speed, current, and torque, enabling the immediate validation and refinement of the control algorithm’s performance. Simulation waveforms and electromagnetic outputs were experimentally validated to ensure reliability.

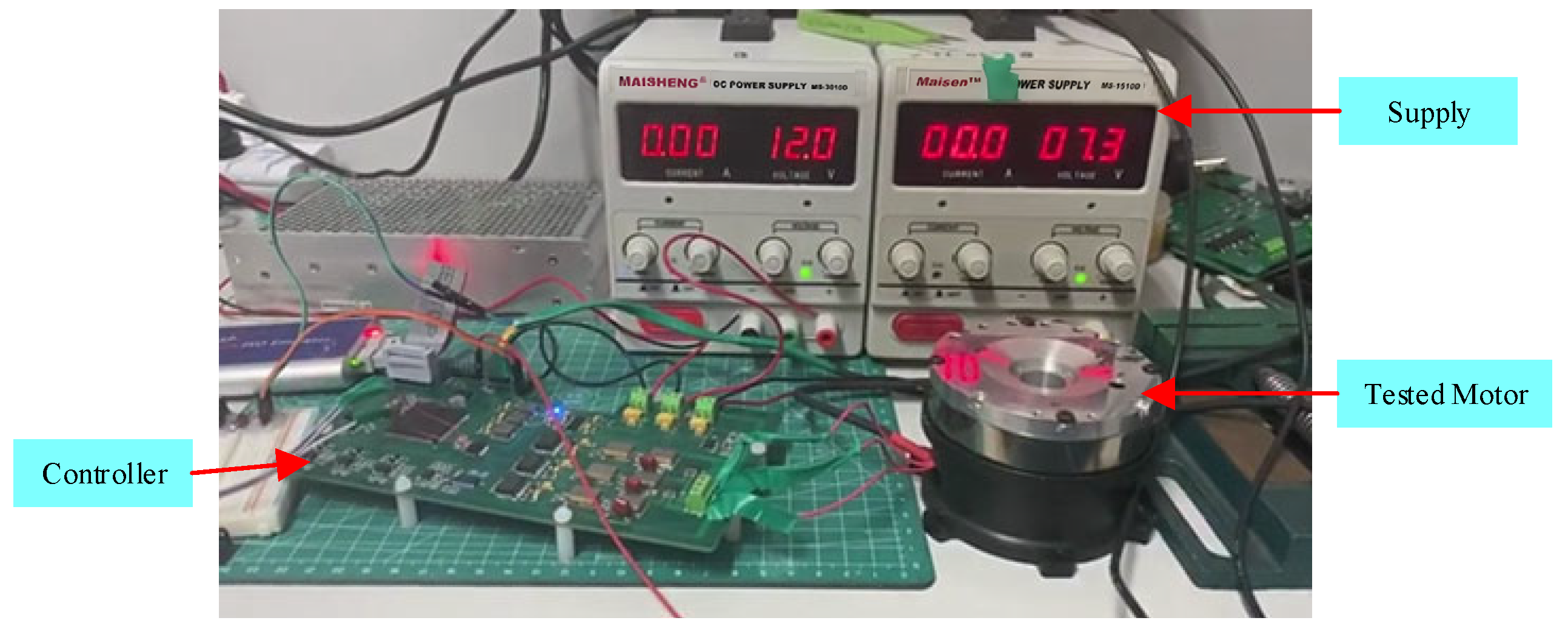

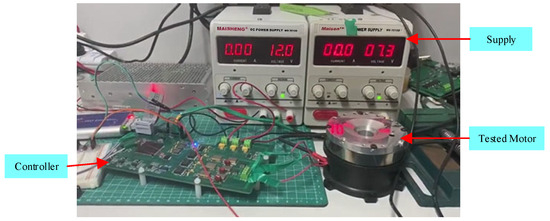

Experimental validation was performed in a controlled laboratory environment equipped with an optical encoder, current sensors, and a torque transducer, all interfaced via the DSP to verify system accuracy. Figure 14 presents the experimental platform, where the motor, control hardware, and sensors were integrated and tested under real-time conditions to evaluate performance and confirm functionality.

Figure 14.

Experimental platform setup.

4.2. Experimental Study on the Drive System of the External Frame Motor

- (a)

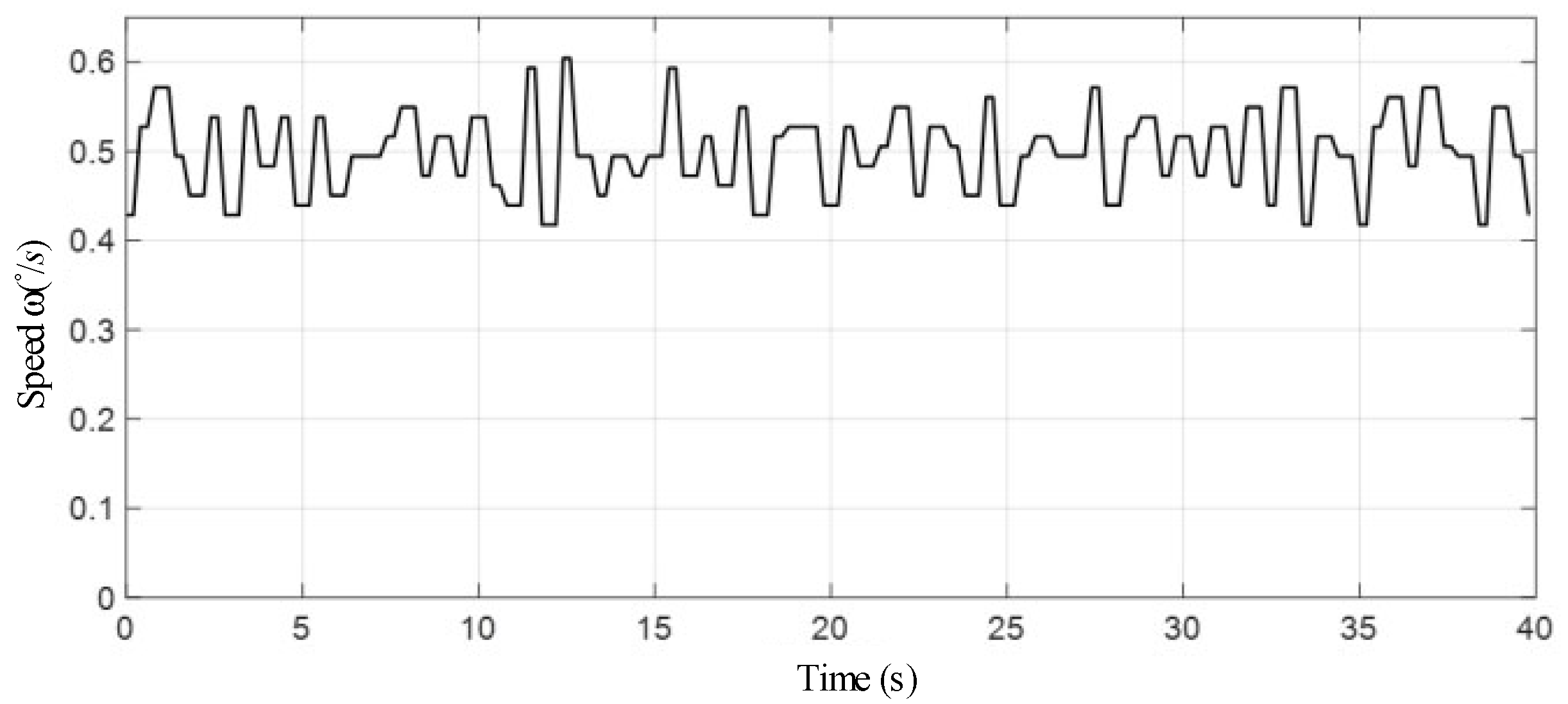

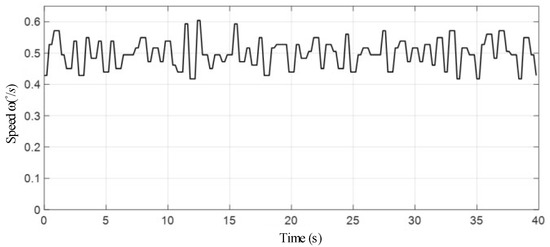

- Low-Speed Experiment at 0.5°/s:

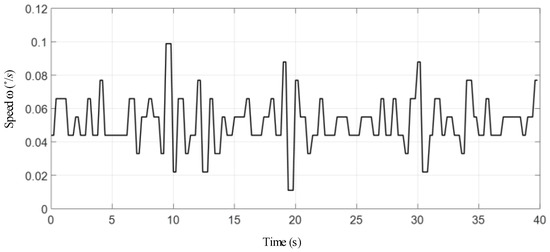

The motor was configured to operate at a setpoint of 0.5°/s, with controller parameters finely tuned to ensure robust low-speed stability. Due to inherent system limitations, minor deviations and noise occurred, which were effectively mitigated by averaging the speed over a 500 ms window, as depicted in Figure 15. This approach significantly reduced fluctuations, ensuring consistent and reliable performance. Experimental calibration compensated for environmental and sensor inaccuracies, maintaining operational reliability at low speeds.

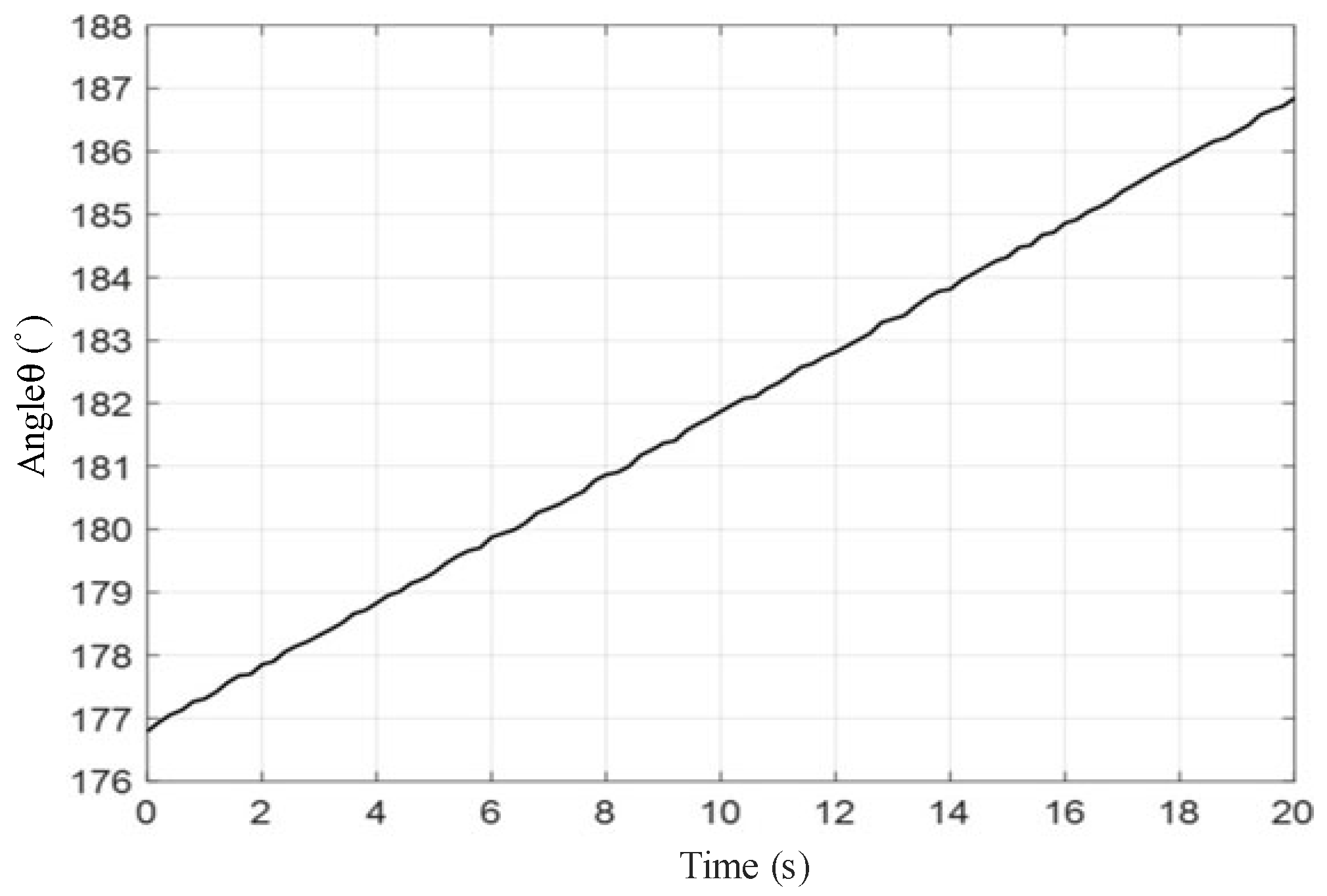

Figure 15.

Average speed waveform at 0.5°/s.

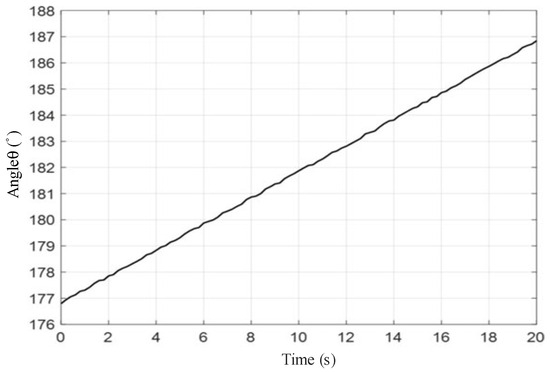

The motor demonstrated stable operation at 0.5°/s, achieving a minimal average static error of ±0.1°/s, as shown in Figure 15 and Figure 16. These results confirm precise low-speed performance and smooth position control, suitable for high-precision applications.

Figure 16.

Sampled position waveform at 0.5°/s.

- (b)

- Low-Speed Experiment at 0.05°/s:

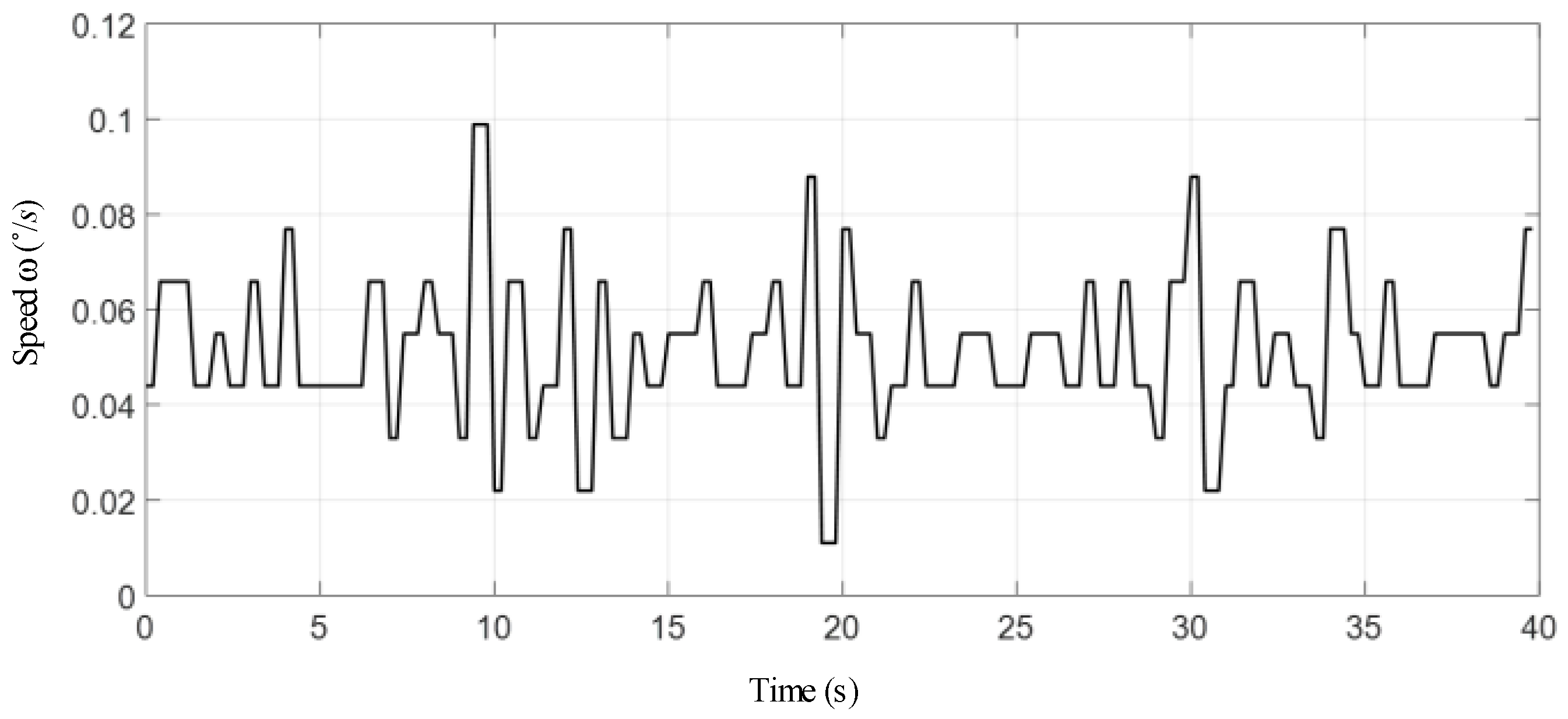

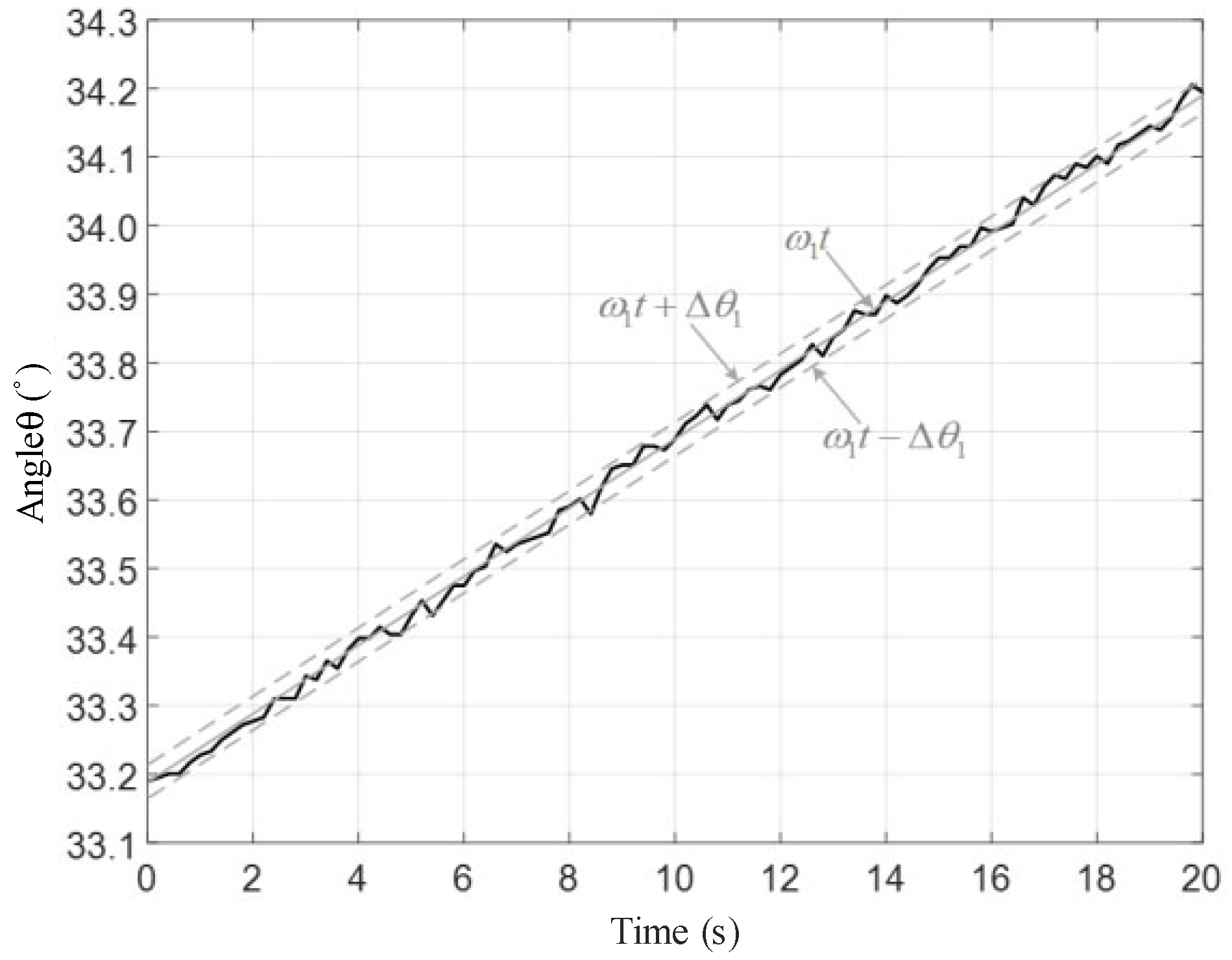

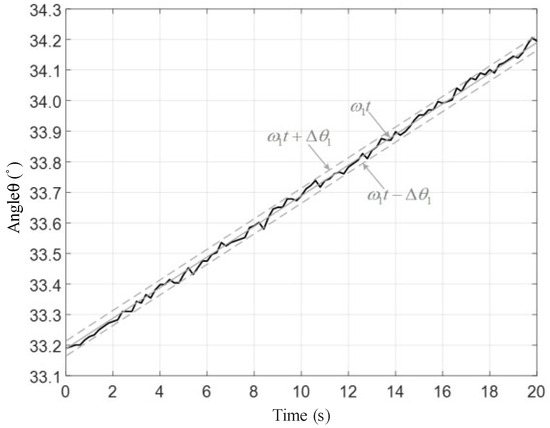

At a setpoint of 0.05°/s, the motor exhibited stable performance, with over 95% of the position curve remaining within the error envelope, as illustrated in Figure 17 and Figure 18. The error bandwidth, Δθ1, was maintained below the specified value of Δθ1 = ω1 × 1 s = 0.05 s, enabling smooth operation even at speeds below the setpoint. This demonstrates the motor’s exceptional precision and ability to minimize positional errors, affirming its suitability for applications requiring ultra-high positional accuracy at ultra-low speeds.

Figure 17.

Average speed waveform at 0.05°/s.

Figure 18.

Sampled position waveform at 0.05°/s.

- (c)

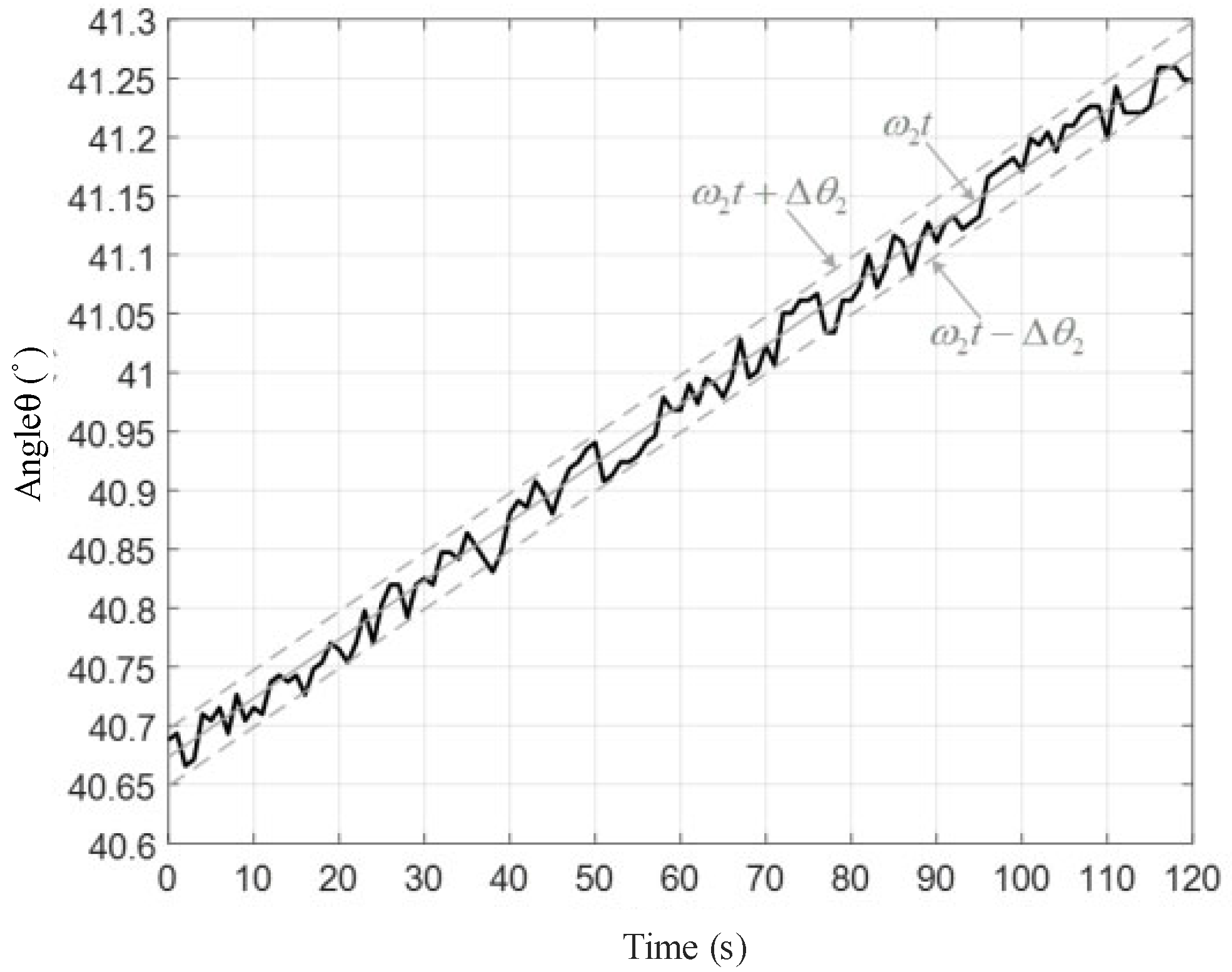

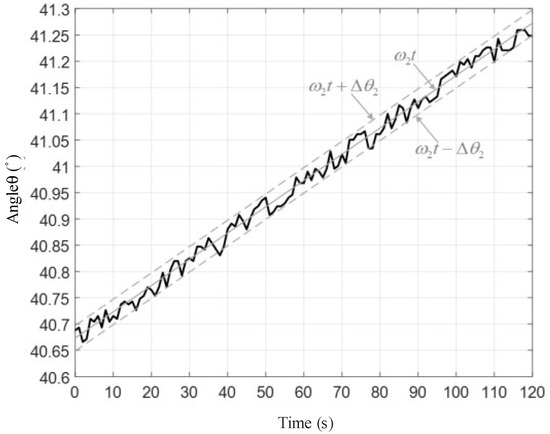

- Ultra-Low-Speed Experiment at 0.005°/s:

At an ultra-low setpoint of 0.005°/s, the motor maintained stable operation by further reducing the extended state observer bandwidth. As shown in Figure 19, over 95% of the position curve remained within the error band, confirming smooth rotation without low-speed crawling at ultra-low speeds.

Figure 19.

Sampled position waveform at 0.005°/s.

4.3. Validation of Simulation Result Through Experimental Correlation

To validate the finite element analysis (FEA) models, a rigorous quantitative comparison of simulated and experimental performance metrics—peak torque, torque pulsation, and efficiency—was performed for Halbach-type and olive-shaped magnet motors. Data were acquired under no-load (0.5°/s) and stall (1°/s) conditions using the experimental setup previously described. Table 2 presents the results, deviations, and their theoretical causes, highlighting the olive-shaped motor’s superior consistency. The table benchmarks FEA predictions against empirical measurements, with deviations calculated as follows:

Table 2.

Comparison of simulation and experimental performance metrics.

The olive-shaped motor exhibited smaller deviations (−0.6% for torque, +2.2% for pulsation, and −0.5% for efficiency) compared to the Halbach-type (−2.3%, +4.3%, and −0.7%), attributable to its uniform magnetic field, which reduces sensitivity to manufacturing imperfections and harmonic distortions. Deviations in the Halbach-type motor stem from unmodeled stator slotting effects and thermal losses, inducing non-linear magnetic behavior. In contrast, the olive-shaped motor’s uniform flux distribution minimizes these effects, ensuring closer alignment between simulated and experimental results. Specifically, the −0.6% peak torque deviation in the olive-shaped motor arises from minor material variations, while the +2.2% torque pulsation deviation is attributed to sensor noise and mechanical vibrations in the experimental setup. The −0.5% efficiency deviation reflects thermal dissipation not fully captured in FEA models. The Halbach-type motor’s larger deviations result from magnetic field non-uniformity and assembly complexities, which amplify harmonic distortions and torque ripple. These findings validate the FEA models’ accuracy and underscore the olive-shaped motor’s reliability for low-speed CMG applications, with the experimental platform (shown in Figure 13) ensuring robust data collection under controlled conditions.

5. Conclusions

This study thoroughly investigated low-speed external frame motors with Halbach-type and olive-shaped magnet structures for control moment gyroscope (CMG) applications, fulfilling the reviewer’s request for a clear numerical summary and in-depth analysis. Finite element analysis (FEA) and experimental validation demonstrate that the olive-shaped magnet motor surpasses the Halbach-type configuration, achieving a peak torque of 0.312 N·m with a torque pulsation of 0.9 mN·m, demonstrating a 20% improvement compared to the Halbach-type’s pulsation of 1.15 mN·m, while maintaining pulsation below 0.3%. At ultra-low speeds of 0.05°/s and 0.005°/s, the olive-shaped motor sustains over 95% of the position curve within the error envelope, with a static error of ±0.1°/s at 0.5°/s, evidencing its exceptional precision and stability. The optimized magnetic field distribution minimizes cogging torque to 3 mN·m and ensures a highly sinusoidal back-electromotive force, enhancing efficiency compared to the Halbach-type’s less uniform flux and higher ripple, aligning with research on magnet geometry optimization. The olive-shaped design’s improved manufacturability addresses the Halbach-type’s complexity, offering cost-effective scalability for aerospace applications. Nevertheless, future research should explore thermal effects and material degradation to ensure long-term reliability. These results establish the olive-shaped magnet motor as a superior solution for high-precision, low-speed applications, contributing significantly to advancements in motor design and CMG performance.

Author Contributions

Conceptualization, methodology, software, investigation, writing—original draft, R.M.S.; project administration, formal analysis, Y.S.; resources, supervision, writing—review and editing, K.L.; visualization, investigation, resources, R.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Tianjin Navigation Instruments Research Institute, grant number 62602010313.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Sorokin, A.V.; Yaremenko, V.V. Control Moment Gyroscopes for Spacecraft Attitude Control Systems: History of Development. Gyroscopy Navig. 2022, 13, 53–58. [Google Scholar] [CrossRef]

- Zhu, Q.; Lei, Y.; Yao, N.; Xie, M. The Angular Momentum Management Method Based on CMGs for the Fast-Maneuvering Satellites. In Signal and Information Processing, Networking and Computers. ICSINC 2018; Lecture Notes in Electrical Engineering; Sun, S., Ed.; Springer: Singapore, 2019; Volume 494. [Google Scholar] [CrossRef]

- Gaude, A.; Lappas, V. Design and Structural Analysis of a Control Moment Gyroscope (CMG) Actuator for CubeSats. Aerospace 2020, 7, 55. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Q. Analysis of cogging torque in dual-stage magnetically geared devices considering magnetic flux coupling. Electr. Eng. 2021, 103, 853–863. [Google Scholar] [CrossRef]

- Tan, C.; Jing, L.; Liu, W.; Rao, Y.; Tang, W. A High Torque and Low Ripple Magnetic Gear with Embedded Permanent Magnet. J. Electr. Eng. Technol. 2023, 18, 1799–1807. [Google Scholar] [CrossRef]

- Jha, A.K.; Garbuio, L.; Kedous-Lebouc, A.; Yonnet, J.-P.; Dubus, J.-M. Design and comparison of outer rotor bonded magnets Halbach motor with different topologies. In Proceedings of the 2017 15th International Conference on Electrical Machines, Drives and Power Systems (ELMA), Sofia, Bulgaria, 1–3 June 2017; pp. 6–10. [Google Scholar] [CrossRef]

- Ren, Z.; Liu, T. Structural Optimization of External Rotor Permanent Magnet Motor Based on Halbach Magnetization. Am. J. Electr. Power Energy Syst. 2023, 12, 51–58. [Google Scholar] [CrossRef]

- Xu, C.; Wu, H.; Shi, Y.; Wang, N.; Song, L. Study on the Influences of an Outer-Coreless-Rotor Permanent Magnet Synchronous Machine Using Halbach Magnet Array. Energies 2024, 17, 3108. [Google Scholar] [CrossRef]

- Mafi, H.; Afjei, E.; Ghaheri, A. Design of coaxial magnetic gear utilising a novel permanent magnet Halbach array structure. IET Electr. Power. Appl. 2021, 15, 299–309. [Google Scholar] [CrossRef]

- Jian, L.; Chau, K.T. Design and Analysis of an Integrated Halbach-magnetic-geared Permanent-magnet Motor for Electric Vehicles. J. Asian Electr. Veh. 2009, 7, 1213–1219. [Google Scholar] [CrossRef]

- Liu, K.; Yin, M.; Hua, W.; Ma, Z.; Lin, M.; Kong, Y. Design and Analysis of Halbach Ironless Flywheel BLDC Motor/Generators. IEEE Trans. Magn. 2018, 54, 8109305. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Lee, T.-W.; Chun, Y.-D.; Hong, D.-K.; Qiu, J.; Xiong, K.; Ji, H. Performance analysis of magnetic gear with Halbach array for high power and high speed. Int. J. Appl. Electromagn. Mech. 2020, 64, 959–967. [Google Scholar] [CrossRef]

- Shiao, Y.; Bollepelly, M. Investigation of Segmented Halbach Array Design for Passive Magnetorheological Brake System. Appl. Sci. 2025, 15, 840. [Google Scholar] [CrossRef]

- Zhang, G.; Guo, X.; Zhou, J.; Hua, W. Review on the Development and Applications of Permanent Magnet Vernier Motors. Energies 2025, 18, 2353. [Google Scholar] [CrossRef]

- Dwari, S.; Parsa, L. Design of Halbach-Array-Based Permanent-Magnet Motors With High Acceleration. IEEE Trans. Ind. Electron. 2011, 58, 3768–3775. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, M.; Liu, Y.; Huang, Z.; Du, X.; Zhang, J.; Luo, F. Optimization design of a new type of Halbach array motor with magnetic axis offset. In Proceedings of the 2024 IEEE International Conference on Cybernetics and Intelligent Systems (CIS) and IEEE International Conference on Robotics, Automation and Mechatronics (RAM), Hangzhou, China, 8–11 August 2024; pp. 579–584. [Google Scholar] [CrossRef]

- Sun, C.; Li, Q.; Fan, T.; Wen, X.; Li, Y. Multi-objective Optimization Design of External Rotor Permanent Magnet Machine for In-wheel Applications. In Proceedings of the 2023 24th International Conference on the Computation of Electromagnetic Fields (COMPUMAG), Kyoto, Japan, 22–26 May 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, Q. Design and Optimization of Permanent Magnet Synchronous Motor Based on Finite Element Analysis. In Proceedings of the 2019 14th IEEE Conference on Industrial Electronics and Applications (ICIEA), Xi’an, China, 19–21 June 2019; pp. 2055–2058. [Google Scholar] [CrossRef]

- Lappas, V.; Steyn, W.H.; Underwood, C. Design and Testing of a Control Moment Gyroscope Cluster for Small Satellites. J. Spacecr. Rocket. 2005, 42, 729–739. [Google Scholar] [CrossRef]

- Che, X.; Wu, J.; Kang, G.; Hong, Y. Angular Momentum Control Strategy of Control Moment Gyroscope Array Based on Deep Reinforcement Learning in Spacecraft Attitude Control System. Aerospace 2025, 12, 134. [Google Scholar] [CrossRef]

- Hwang, M.-H.; Lee, H.-S.; Yang, S.-H.; Lee, G.-S.; Han, J.-H.; Kim, D.-H.; Kim, H.-W.; Cha, H.-R. Cogging Torque Reduction and Offset of Dual-Rotor Interior Permanent Magnet Motor in Electric Vehicle Traction Platforms. Energies 2019, 12, 1761. [Google Scholar] [CrossRef]

- Jing, L.; Gong, J. Analytical model and optimisation design of surface-mounted PM motors with Halbach arrays accounting for semi-closed slots. IET Electr. Power Appl. 2020, 14, 2074–2081. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).