1. Introduction

The SBW system has emerged as the preferred steering solution for next-generation advanced intelligent vehicles due to its distinctive advantages [

1]. Through mechanical decoupling between the steering wheel and wheels, SBW enables the independent design of force transmission and angle response characteristics, significantly enhancing compatibility with intelligent and connected vehicle architectures [

2,

3,

4]. However, at this stage, it is difficult to realize fully autonomous driving technology. The driver still has to participate in the driving process, and the automobile human–machine interface cannot be completely removed [

5]. Due to the special characteristics of its structure, the SBW system is unable to transmit road feel directly through a mechanical connection [

6,

7], and needs to generate road feel through a road feel simulation device in order to ensure that the driver can accurately perceive road information in real time (the main components include steering load, system inertia, and frictional torque, among others), thus ensuring driving safety [

8,

9]. Therefore, the study of road feel simulation is indispensable.

Current research on road feel simulation for SBW systems primarily focuses on road feedback torque planning, with extended studies on the active return control of the steering wheel based on this foundation [

10,

11]. Current research on road feel feedback torque planning primarily focuses on emulating the road feel characteristics of electric power steering (EPS) systems, with two main approaches being adopted: model-based methods (implemented through tire–vehicle dynamics models or observers) and data-driven methods. Among these approaches, tire modeling-based methods suffer from inherent limitations, such as challenging parameter identification and poor environmental adaptability. Consequently, observer-based methods are increasingly emerging as a research focus due to their superior engineering feasibility. Shi et al. developed a terminal sliding mode observer to estimate the rack force in an SBW system, based on which the road feel feedback torque was designed. Simultaneously, they achieved precise control of the road feel motor using active disturbance rejection control. Vehicle experiments demonstrated the effectiveness of the proposed algorithms [

12]. Su et al. designed an ESO to estimate rack force, and developed a personalized road feel feedback torque model by leaving some parameters adjustable [

13]. Zheng et al. used a KFO to estimate the rack force of the steering system and added assist torque to design a road feel torque planning method for SBW systems with the goal of replicating the road feel of the EPS system, and the experimental results showed that the designed road feel torque improved the maneuverability and comfort of the car [

14]. Regarding data-driven methods, Liu et al. developed a data-driven road feel feedback torque model using a CNN-GRU hybrid neural network architecture, and achieved the accurate tracking of desired torque through explicit model predictive control [

15]. Zhao et al. collected road feel torque data from four common driving scenarios, utilized K-Means clustering, analyzed the training dataset, and selected a Gaussian process regression model to train the data in order to obtain road feel information [

16]. Data-driven methods can holistically incorporate various factors affecting road feel to achieve more authentic steering feedback design. However, these approaches present inherent trade-offs between model fidelity and implementation practicality, while requiring substantial real-world vehicle test data for model development and validation. Based on the aforementioned research background, how to improve observer estimation accuracy while providing drivers with real-time and accurate road information has become a key scientific challenge in the field of steering feel simulation [

17,

18]. It should be noted that some observed values from the observer may contain invalid information, making the effective filtering of these interference components another important research issue. To address this challenge, this study proposes a road feel feedback torque design method based on a high-precision disturbance observer. By developing a dedicated filter to optimize the observed values, the proposed approach ensures the precise transmission of road information while further enhancing driving comfort.

Steering wheel active return should also be considered as one of the key aspects in road feel simulation. For steering wheel return control, the steering wheel return performance of the SBW system is related to the maneuvering stability of the car, and poor return performance will increase the driver’s driving burden and reduce driving pleasure [

19]. Xie et al. considered that the automobile self-aligning torque could be significantly reduced on low-adhesion road surfaces, estimated the road-surface adhesion coefficient using the extended Kalman filter, and designed a time-varying sliding mode control algorithm to output different return currents according to different road-surface adhesion coefficients in order to improve the return performance of automobiles on low-adhesion road surfaces [

9]. Zhao et al. proposed an active return control strategy for steering wheels based on sliding mode control (SMC), and a hardware-in-the-loop test showed that the designed control strategy could effectively reduce the return margin angle and improve the maneuvering stability of the car [

11]. In addition, Chen et al. realized the active return control of steering wheels based on the fuzzy logic control algorithm [

20]. Conventional steering wheel active return control strategies often overlook inherent system disturbances and parameter uncertainties. However, nonlinear disturbances can significantly degrade steering return performance, causing positioning inaccuracies that are fundamentally unacceptable for SBW system applications. Therefore, how to enable control algorithms to possess nonlinear disturbance compensation capabilities and thereby enhance their robustness has become a core research focus in this field.

In this study, a novel road feel simulation strategy based on an INSOSMO is proposed. The main contributions of this study are as follows:

- (1)

An INSOSMO is developed for high-precision state estimation: The observer is constructed based on the super-twisting algorithm. The approach incorporates both proportional and integral terms into the super-twisting algorithm, replaces the conventional sign function with an improved Sigmoid function to suppress chattering, and employs the SSA for the global optimization of key parameters. Comparative experiments demonstrate significantly improved observation accuracy over conventional ESO, KFO, and SMO approaches.

- (2)

A two-stage filter is proposed to eliminate extraneous components in road feel feedback torque: The filter combines STKF with a first-order low-pass filter to process the observed values from the INSOSMO. Based on the filtered results, the main road feel torque is designed, which is then superimposed with compensation torque to generate the final road feel feedback torque.

- (3)

Considering steering wheel return control, a steering wheel active return controller accounting for system disturbances is developed: Based on hybrid algorithm theory, the controller employs BSSMC as its core algorithm. To address nonlinear disturbances in the system, an ESO is designed for observation and compensation, thereby enhancing the controller’s robustness.

4. Road Feel Feedback Torque Planning

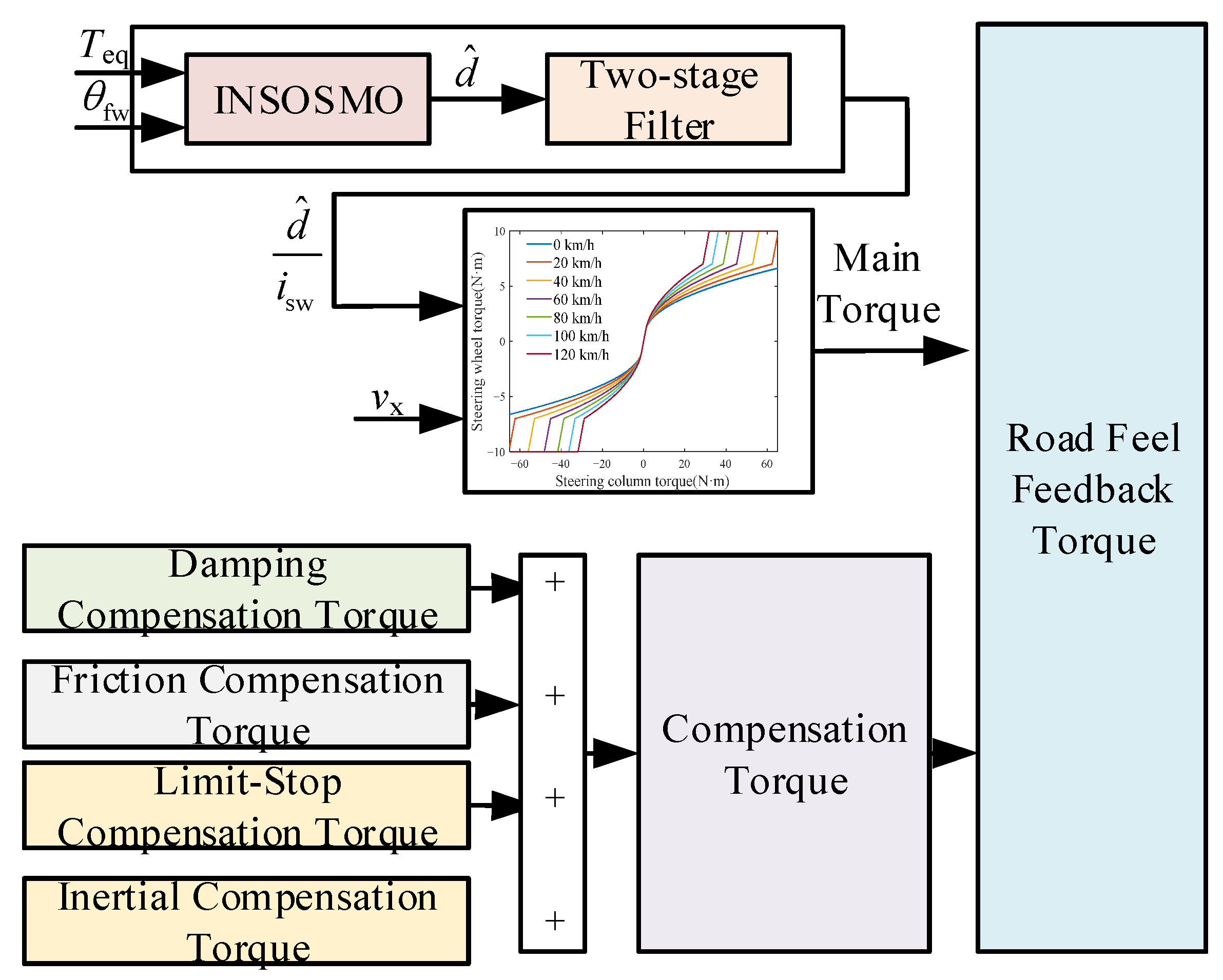

Road feel feedback torque refers to the reactive force perceived by the driver through the steering wheel during vehicle operation, representing a comprehensive manifestation of the vehicle’s overall state, road conditions, and the interactive dynamics of the steering system. The designed road feel feedback torque model consists of two components: the main torque and the compensation torque, as illustrated in

Figure 4. Among them, the main road feel torque is designed based on system disturbance torque

d, observed by the INSOSMO and further processed through a two-stage filter.

4.1. Design of the Two-Stage Filter

The filtering aims to reduce road vibration interference while preserving essential road information for driver perception. A two-order filter combining STKF and a first-order low-pass filter is designed.

- (1)

Design of the strong tracking Kalman filter

The Kalman filter (KF) algorithm is an optimal regression data processing algorithm; in order to make the traditional KF better match the complex system, the KF algorithm is combined with the strong tracking filtering algorithm (STFA), and the STKF is designed to carry out the first level of filtering of . The traditional KF algorithm can be divided into two modules of prediction and update, and its formula is as follows:

Update module:

where

Ak is the system-state matrix at moment

k;

Bk is the system input matrix at moment

k;

Hk is the system output matrix at moment

k;

Pk is the error covariance matrix at moment

k;

Kk is the Kalman filtering gain matrix at moment

k; and

Qk and

Rk are the covariance matrices of the system noise and measurement noise at moment

k.

The STKF algorithm introduces a fading factor during the update of the error covariance matrix [

26], and the error covariance prediction process with the inclusion of the fading factor is expressed as follows:

where

Vk is the new interest covariance matrix;

ρ is the forgetting factor, generally taken as 0.95; and

l is the weakening factor.

l ≥ 1 and takes 5.

- (2)

Design of a first-order low-pass filter

A first-order low-pass filter can effectively isolate high-frequency signals, with the basic formula being

where

p is the filter coefficient;

T is the sampling period, which takes 0.001;

fc is the cutoff frequency;

X(

n) is the current sampling value; and

Y(

n − 1) is the previous filter output value.

In the existing research, Reference [

27] analyzes steering feedback torque from a frequency-domain perspective. The findings indicate that the vehicle motion state-dependent feedback torque components are primarily concentrated below 10 Hz. Therefore, the parameter

p is designed to be 0.0591. Consequently, a first-order low-pass filter is superimposed on the STKF to design the two-stage filter that filters out high-frequency signals and smooths

, thereby enhancing driving feel.

4.2. Design of Road Feel Feedback Torque

4.2.1. Design of Main Road Feel Torque

The system aligning the torque of the tires after the action of the steering system transmission ratio, when transferred to the steering column, is reduced to

Tz/

isw, which can be expressed as the steering column torque

Tcol. The steering column torque

Tcol can be obtained by the following equation:

To provide drivers with an easily adaptable road feel, the source of the road feel is analyzed using a column-type electric power steering system. Based on the curved power assist characteristic curve, the assist torque is designed to guarantee the lightness of the planned road feel torque. The curved power assist characteristic curve introduced for the EPS system is illustrated in

Figure 5.

In addition, an analysis of the steering system reveals that

Tcol is equated to the sum of the assist torque

Tassist and the steering wheel torque

Th. Therefore, based on this mathematical relationship, the steering column torque can be used to inversely obtain the desired steering wheel torque [

6]. MATLAB’s finverse function can be employed to obtain its mathematical inverse function, which expresses the steering wheel torque. The resulting steering wheel torque curve is illustrated in

Figure 6 and is expressed by Equation (53), as follows:

where

Tmain is the main road feel torque.

4.2.2. Design of the Compensation Torque

The main road feel torque can meet basic steering requirements. However, as the SBW system eliminates certain mechanical components, the driver cannot directly perceive information such as inertia, damping, and friction torque, which would normally be generated by these mechanical parts. Therefore, to more realistically simulate the road feel experience during actual driving, it is necessary to design compensation torque to restore these missing mechanical characteristics [

12,

13]. Additionally, since the SBW system lacks corresponding mechanical structures to alert drivers when the steering wheel’s rotation angle reaches its physical limit, it is necessary to design a corresponding limit-stop compensation torque to notify the driver when the steering wheel approaches its virtual limit position.

The final road feel feedback torque

Troadfeel is formulated as

where

where

Tine is the inertial compensation torque;

kine is the inertial compensation torque coefficient;

Tfric is the friction compensation torque;

kfric is the friction compensation torque coefficient;

ρ1 is the gradient coefficient of the friction compensation torque;

Tdam is the damping compensation torque;

kdam is the damping compensation torque coefficient;

v0 is the threshold vehicle speed;

Tlimit is the limit-stop compensation torque;

klimit is the limit-stop compensation torque coefficient; and

θlimit is the steering wheel maximum rotation angle.

5. Steering Wheel Active Return Control Strategy

5.1. Driving Intent Judgment

To avoid confusion with traditional steering systems, the action of the steering wheel returning to its original position after the driver releases the steering wheel is called “return”, while the operation in which the steering wheel is not released by the driver is called “steering”. Driver driving intention judgment can be expressed as

where

is the steering wheel dead zone angle.

5.2. Design of the Steering Wheel Active Return Controller

To enhance the steering wheel’s active return performance and prevent insufficient low-speed return or high-speed return overshoot, we designed an active return controller. The difference between the actual steering wheel angle and the desired angle is selected as the input, while the return torque from the road feel motor serves as the control output. Considering that the BSSMC algorithm is well suited for uncertain nonlinear systems that can be state-linearized or possess strict feedback parameter structures [

28], this algorithm is adopted to design the steering wheel active return strategy. Equation (6) shows a dynamic analysis of the steering wheel subsystem during the return process, where its formula is as follows:

where

Treturn is the steering wheel return torque;

Jeq1 is the equivalent moment of inertia between the feedback motor and the steering wheel;

Beq1 is the equivalent damping coefficient between the feedback motor and the steering wheel;

d2 is the system disturbance; and

, in the subsequent simulations, is set as a sine function with an amplitude of 0.5 N·m and a period of 5 s.

Let

and

u =

GmTreturn. From Equation (57), the state-space equation is derived as follows:

where

Define the angular error

e1 as

The steps for the design of the backstepping sliding mode control algorithm are as follows:

Step 1: Define the Lyapunov function:

Take , where c1 > 0 and e2 is the virtual control quantity, i.e., .

If e2 = 0, then is satisfied, and the next design step is required.

Step 2: Define the sliding mode surface as

in conjunction with the sliding mode variable structure control and define the Lyapunov function:

To satisfy

, the controller is designed:

where

k is a constant.

In addition, an extended state observer is designed to observe the system disturbance

d2.

where

l1,

l2, and

l3 are the observer gain coefficients, respectively.

Therefore, Equation (67) can be rewritten as

At this point, the design of the steering wheel return controller based on the backstepping sliding mode algorithm has been completed.

The stability of the algorithm is proved below:

Substituting Equation (69) into Equation (66), the sliding mode gain

hk3 must satisfy

hk3 >

ϵ +

D2, where

ϵ is the upper bound of the ESO estimation error:

Let

Q be equal to

because

Then,

Q is guaranteed to be a positive definite matrix satisfying

By appropriately selecting the values of h, c1, and λ1, matrix Q can be made positive and definite, thereby ensuring that . According to LaSalle’s invariance principle, the controller is guaranteed to achieve asymptotic convergence.

6. Simulation Verification

Based on the above, MATLAB/Simulink software is utilized to build the relevant simulation model, and joint simulation with CarSim is carried out for verification. The computer employed in this simulation is manufactured by Lenovo Group (Beijing, China), with the following detailed hardware configuration: the Intel Core i5-12400F processor (12th Gen, 2.50 GHz), the NVIDIA RTX 3050 graphics card, the 16 GB DDR4 RAM (3200 MHz), and the 512 GB PCIe 4.0 SSD. The operating system is 64-bit Windows 11, and the simulation software included CarSim 2019.0 and MATLAB R2021a.

6.1. Verification of Observer Performance

The parameters of the model are selected as follows:

Jeq = 21.88 kg·m

2;

Beq = 76.21 N·m·s/rad;

K = 194.25;

isw = 18.5;

α = 0.3;

p/

q = 1.5;

k = 20;

ε = 10;

G = −40.88;

λ = 50;

c = 0.9;

n1 = 50;

n2 = 50;

k1 = 28.9336;

k2 = 20;

β1 = 206.5169;

β2 = 139.81;

β3 = −7,504,840;

k4 = 70;

ε4 = 0.5;

c2 = 50;

c3 = 50; and system friction torque set to

. Additionally, the backstepping control (BSC) algorithm is introduced as the steering angle tracking comparative algorithm. Furthermore, to demonstrate the superiority of the proposed INSOSMO, the SMO, ESO, and KFO [

14] are added for comparison. The SSA fitness iteration curve is shown in

Figure 7.

First, the verification of the observer performance is conducted through both sinusoidal tests and the double-lane-change (DLC) test. For the sinusoidal test, the steering wheel angle input is set as a sine wave with an amplitude of 50 deg and a frequency varying from 0.2 Hz to 0.5 Hz within 20 s at a vehicle speed of 80 km/h. For the DLC test, the steering wheel angle input is set according to the standard DLC trajectory, with a vehicle speed of 60 km/h. In order to clarify the observation error of each observer, the MAE is introduced to represent the error under different tests. The MAE can be expressed as

where

n is the number of samples,

pv is the predicted value, and

av is the actual value.

The specific results are shown in

Table 1.

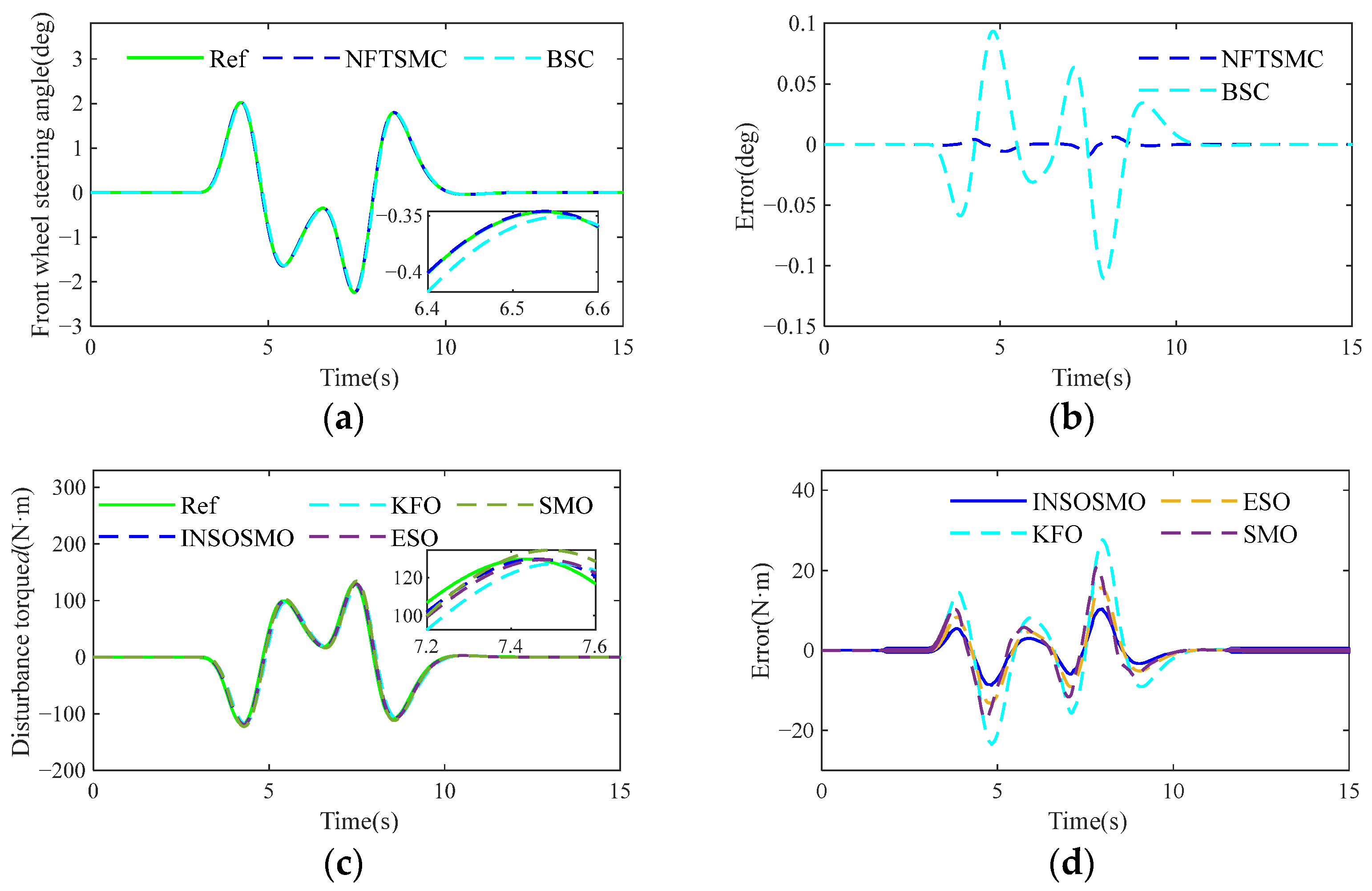

The sinusoidal test is conducted to simulate obstacle avoidance maneuvers in daily driving scenarios, where vehicles navigate through multiple obstacles via repeated left–right steering. The analysis of

Figure 8a,b reveals that NFTSMC exhibits superior tracking accuracy compared to BSC. As the steering frequency increases, the tracking error of both control algorithms progressively rises, indicating that high-frequency steering induces larger errors. The maximum tracking error, attributed to system disturbance torque

d, occurs at the peak steering angle. Specifically, NFTSMC achieves a peak error of 0.0503 deg, while BSC yields 0.1511 deg, representing a 66.7% reduction in tracking error. It is evident that NFTSMC demonstrates superior tracking accuracy and can more precisely respond to driver input commands. Consequently, the system disturbance torque

d observed based on this method better aligns with the driver’s expectations, and the resulting road feel torque more accurately reflects road information under the driver’s intended operating conditions. The further analysis of

Figure 8c,d demonstrates that the INSOSMO outperforms KFO, ESO, and SMO in observation accuracy, enabling precise feedforward compensation for the control algorithm. Additionally, as shown in

Table 1, the observation performance of the INSOSMO is enhanced by 62.5%, 34.7%, and 60.1%, respectively.

The DLC test is conducted to simulate vehicle lane-switching behavior. The analysis of

Figure 9a,b demonstrates that NFTSMC maintains significantly higher tracking accuracy than BSC. During the lane-change maneuver, tracking errors progressively increase for both algorithms, with peak errors occurring at approximately 7.6 s—0.0088 deg for NFTSMC versus 0.1105 deg for BSC—coinciding with the transition back to straight-line driving.

Figure 9c,d reveal that the system disturbance torque

d observation error also peaks at this critical phase, confirming its substantial impact on control precision. Furthermore,

Table 1 shows that the observation performance of INSOSMO is enhanced by 61.8%, 33.8%, and 43.1%, respectively.

Consequently, the results demonstrate that NFTSMC maintains superior tracking accuracy; the system disturbance torque d directly degrades control precision; and the INSOSMO achieves precise disturbance estimation, laying the foundation for road feel feedback torque design.

6.2. Verification of Road Feel Feedback Torque

The performance evaluation of road feel feedback torque can be quantified based on the dynamic mapping relationship between lateral acceleration, steering wheel torque, and steering wheel angle. In high-speed driving conditions, where steering precision and stability are prioritized, the high-speed on-center handling test is typically employed to assess road feedback torque. Conversely, in low-speed driving conditions, where steering ease is the primary objective, the low-speed lemniscate test is commonly used for evaluation. Furthermore, to comprehensively validate the dynamic performance of the designed road feel feedback torque, the steering wheel torque filtering test and the steering angle limit test are incorporated alongside the high-speed on-center handling test and low-speed lemniscate test for more thorough verification. The parameters of the road feel torque are selected as follows: kine = 0.15 kg·m2; kfric = 0.65 N·m·s/deg; ρ1 = 60; kdam = 0.03 kg·m/deg; v0 = 30 km/h; klimit = 0.65 N·m/deg; and θlimit = 370 deg.

The lemniscate test: The lemniscate test evaluates steering wheel torque–angle characteristics across speeds, while validating compliance with low-speed steering effort requirements. In CarSim, the vehicle speed is set at 15 km/h to conduct a simulation test along a lemniscate path for one complete revolution, and the obtained simulation results are presented in

Figure 10.

As analyzed in

Figure 10, the work required by the driver to rotate the steering wheel during a low-speed lemniscate test is significantly less than that of the EPS system, while the average friction torque of the SBW system’s steering wheel is also smaller than that of the EPS system. Additionally, due to the presence of friction torque, when the steering wheel begins to rotate, the torque suddenly increases to 0.81 N·m. When the steering wheel angle is between 0 deg and 80 deg, the steering wheel torque gradient is relatively large. When the steering wheel rotation angle exceeds 80 deg, the steering wheel torque gradient starts to decrease. When the steering wheel angle reaches 321 deg, the steering wheel torque reaches its maximum value of 3.25 N·m. It can be seen that the designed road feel feedback torque can meet the lightness requirements under low-speed driving conditions.

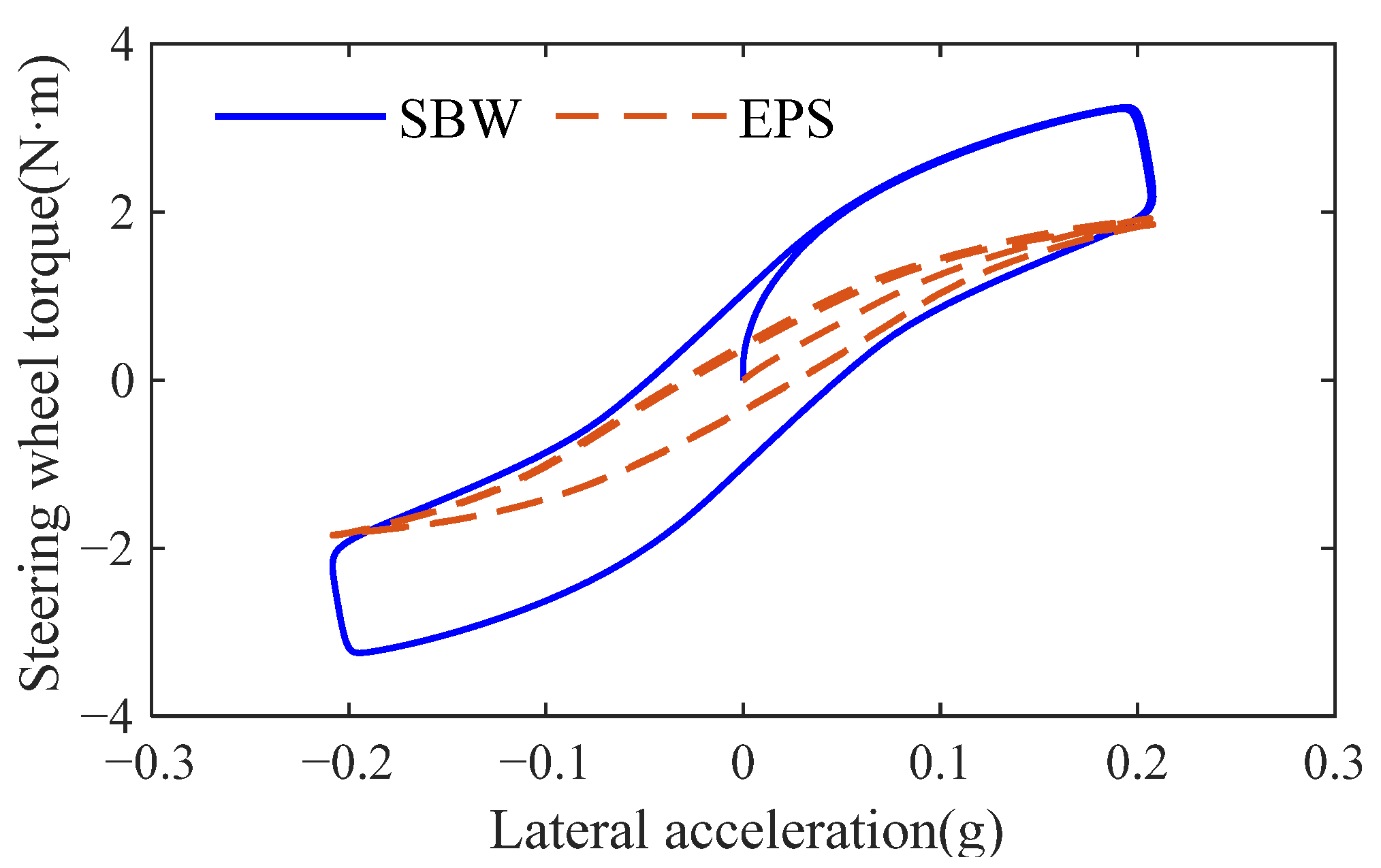

On-center handling test: The on-center handling test is used to evaluate the change in the steering wheel torque gradient of a vehicle at high speed. According to the ISO standard [

29], set the vehicle speed to 100 km/h. Apply a sinusoidal steering wheel input with an amplitude of 12 deg and a period of 0.2 Hz, generating a maximum lateral acceleration of approximately 0.2 g . The resulting simulation data are presented in

Figure 11.

Based on the analysis of

Figure 11, the steering wheel torque of the SBW system at 0 g lateral acceleration is significantly greater than that of the EPS system, indicating that it possesses stronger system dry friction characteristics that can effectively prevent unintended vehicle lateral motion caused by driver misoperation. The torque gradient of the SBW system at 0 g is significantly greater than that of the EPS system, demonstrating clearer road feel during straight-line driving conditions, which helps drivers better perceive the steering wheel’s center position through road feel variations. At 0.1 g lateral acceleration, the SBW system’s steering wheel torque gradient is significantly greater than the EPS system’s, with the SBW system’s maximum torque being 3.17 N·m compared to the EPS system’s 1.82 N·m. This indicates that during high-speed steering maneuvers, the designed road feel feedback torque is clearer and more stable, meeting the design requirements for road feel feedback torque.

Steering wheel torque filtering test: To validate the effectiveness of the designed two-order filter, a sinusoidal steering wheel input with an amplitude of 40 deg and a frequency of 0.1 Hz is applied at a constant vehicle speed of 60 km/h. The observed system disturbance torque is then processed through the filter. The simulation results are presented in

Figure 12.

The analysis of

Figure 12 demonstrates that the two-stage filter effectively smooths the steering wheel torque while reducing force discontinuities, yet preserves essential road roughness information. This achieves the objective of improving driver steering feel.

Steering angle limit test: To verify the effectiveness of the designed limit-stop compensation torque, the steering wheel limit rotation angle is set to 360 deg, with the vehicle speed set to 10 km/h, steering wheel angle input set to a sinusoidal signal with an amplitude of 370 deg and a frequency of 1/60 Hz, and simulation time set to 60 s. The results are shown in

Figure 13.

As can be analyzed from

Figure 13, when the steering wheel angle exceeds 360 deg, the system triggers the limit-stop compensation torque mechanism, causing the steering wheel torque to rapidly increase to 5.78 N·m. At this point, if the driver continues to turn the steering wheel, they will experience significant resistance, which effectively alerts the driver that the steering wheel has reached its limit position.

6.3. Verification of the Steering Wheel Active Return Strategy

In order to verify the effectiveness of the designed steering wheel active return controller, the vehicle speed is set to 30 km/h and to 80 km/h, the driver inputs a constant torque to the steering wheel, and then the driver releases the steering wheel after 4 s to obtain the change curve of the steering wheel angle over time under the steering wheel active return controller designed. The simulation results are shown in

Figure 14. The parameters of the ESO-BSSMO are selected as follows:

Jeq1 = 4.30026 kg·m

2;

Beq1 = 2.3169 N·m·s/rad;

l1 = 599.9462;

l2 = 119,970;

l3 = −312,000;

k3 = 2;

c1 = 70;

λ1 = 15; and

h = 25.

Based on the analysis of

Figure 14a,b, the designed driving intention judgment program can accurately determine the driver’s intention, where “0” represents the steering process and “1” represents the active return process. At the time of 4 s, when the driver releases the steering wheel, the steering wheel begins to return to the center. Without the inclusion of active return control, the steering wheel exhibits insufficient return during low-speed return and overshoot during high-speed return. The residual return angle at low speed is approximately 2.5 deg. Moreover, the rate of speed adjustment is too slow; the return overshoot at high speed is approximately 5.5 deg. However, with the addition of active return control, the steering wheel can effectively avoid these issues and improve the return performance of the SBW system. Furthermore, under low-speed return conditions, the steering wheel achieves recentering at 4.4 s, while at high-speed conditions, recentering is completed by 4.3 s.

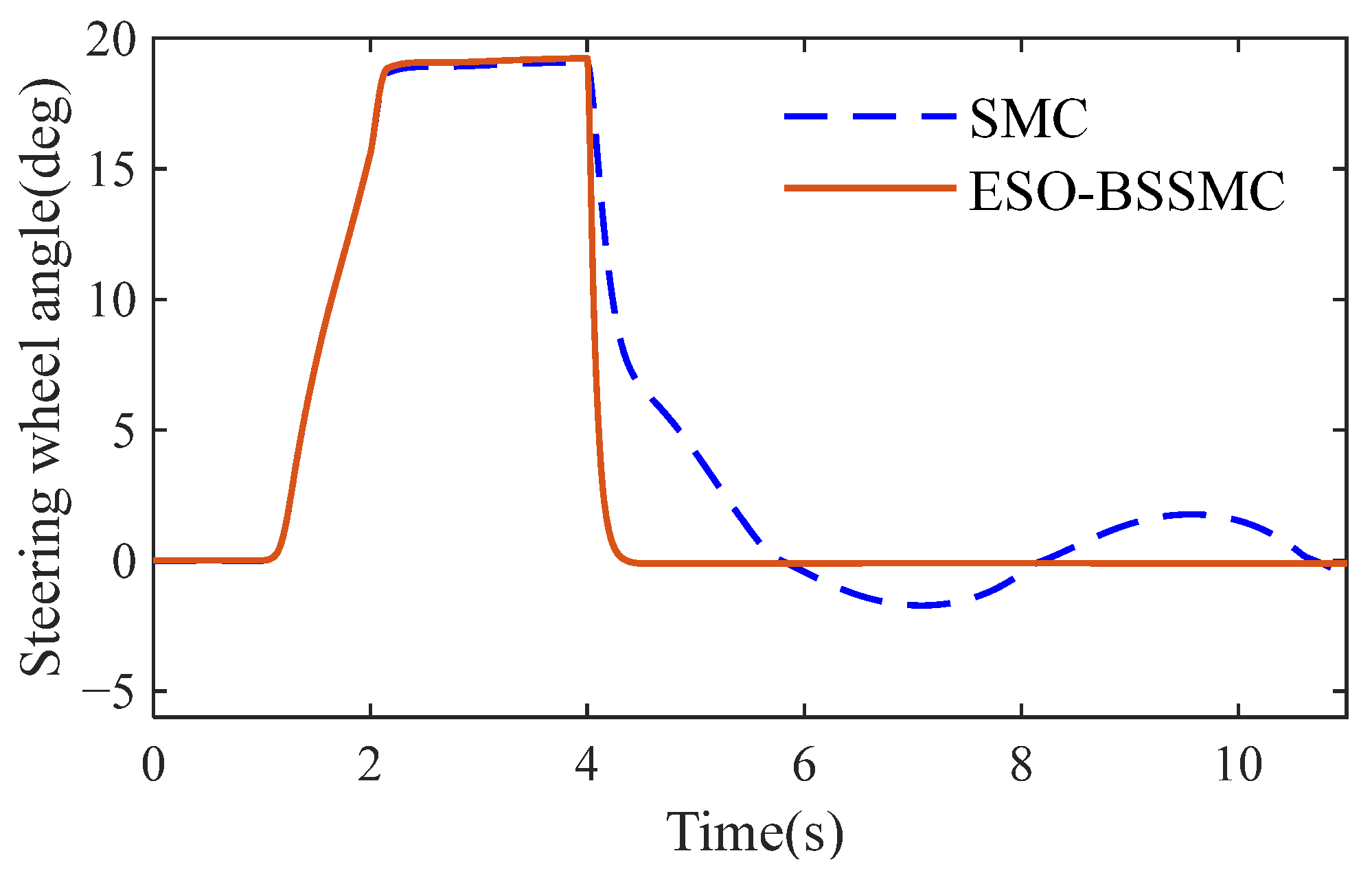

Additionally, a continuous disturbance torque is incorporated during the return process, and comparative analysis is conducted with a return controller (SMC) from the existing literature [

11]. The simulation results are shown in

Figure 15.

Based on the analysis of

Figure 15, it can be seen that under the influence of the disturbance torque, it is difficult for SMC to achieve an accurate return-to-center of the steering wheel. In contrast, the controller designed in this study can realize accurate return-to-center of the steering wheel and possesses better robustness.