1. Introduction

Environmental challenges such as climate change, resource depletion, and greenhouse gas emissions that threaten our planet have reached a critical stage. This crisis addressal necessitates substantial changes across various sectors, particularly in transportation. One significant development in this area is the hybridization and electrification of vehicle powertrains, which have seen substantial growth in recent years. Battery technology is central to these advancements, especially lithium-ion batteries (LIBs), which have evolved significantly since their inception in the 1990s [

1]. LIBs established themselves as the most promising battery technology for both low- and high-power applications. High specific energy (150–280 Wh·kg

−1) [

2] and high specific power (200–300 W·kg

−1) make them particularly attractive for electrified powertrains. The LIB market was projected to reach USD 47.4 billion by 2023, with an annual growth rate of 15.8% [

3]. This burgeoning market for electric vehicles (EVs) and hybrid electric vehicles (HEVs) has created a substantial demand for high-performing and long-lasting LIBs. Batteries are complex electrochemical systems with nonlinear behavior [

4] and their performance is heavily influenced by internal and external conditions such as ageing and temperature.

To monitor these performances and the state of the battery, an LIB pack is equipped with a battery health management system, which is part of the battery management system (BMS). This acts as the main control system for the battery, ensuring safe usage and providing accurate estimates of key battery states, including state of health (SOH), state of power (SOP), and state of charge (SOC) [

5,

6]. Gupta et al. [

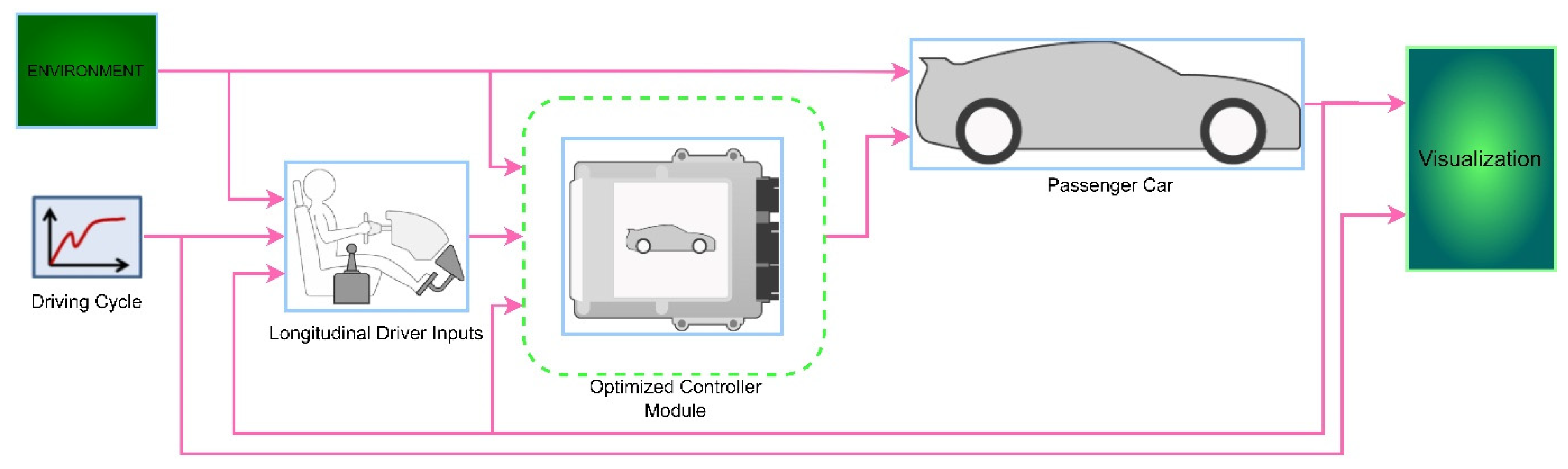

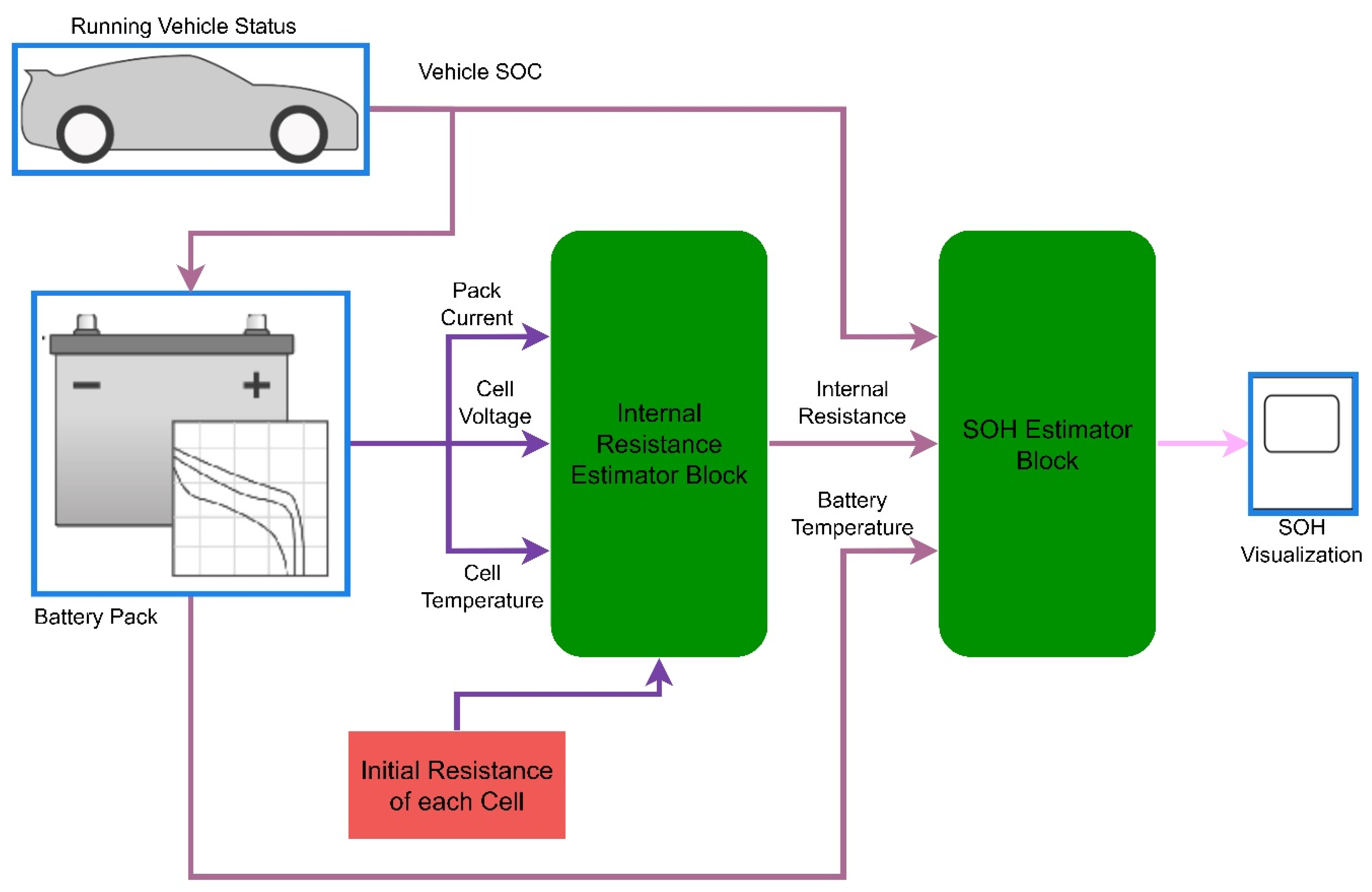

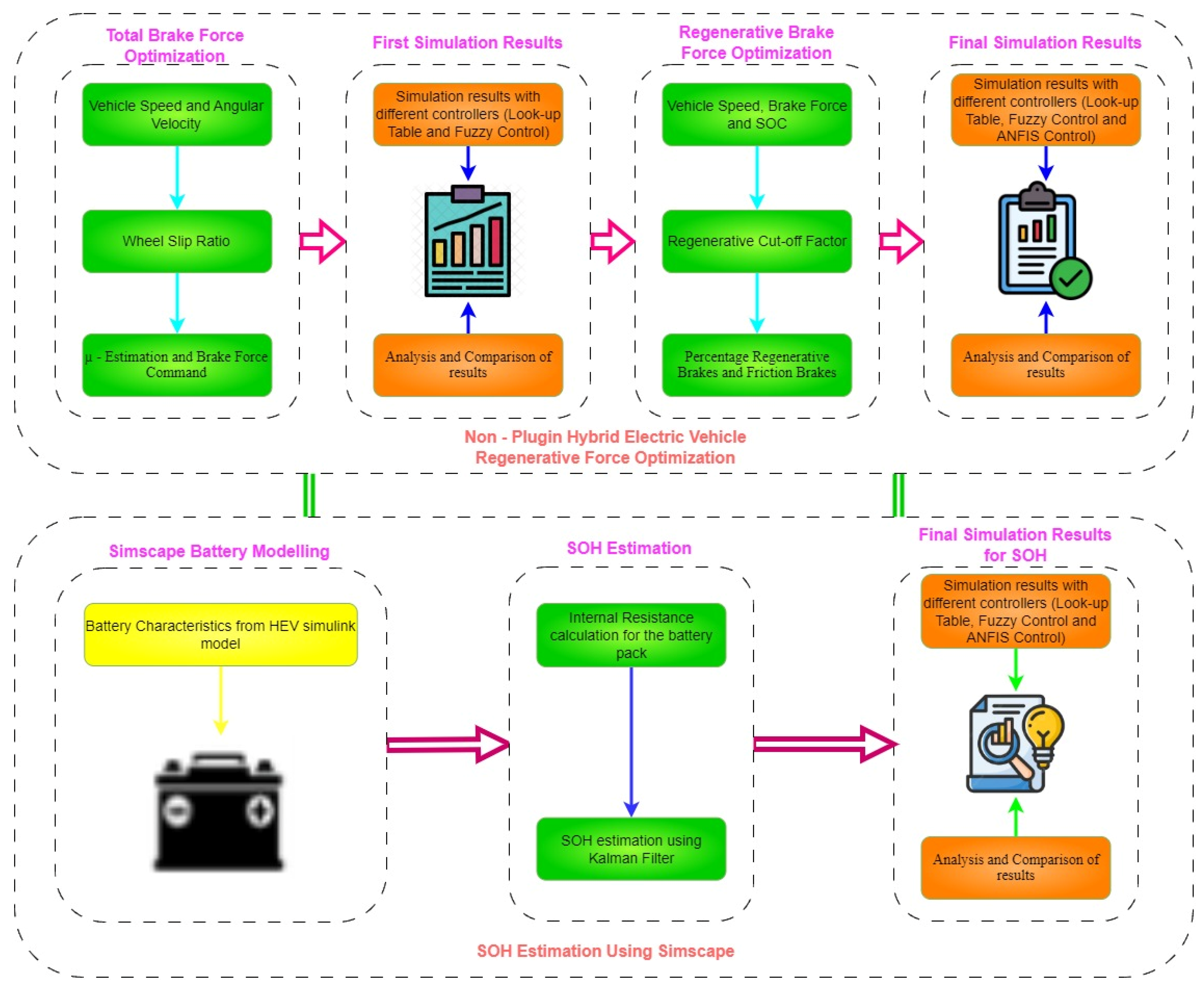

7] proposed a MATLAB/Simulink-based model for regenerative braking control, incorporating lookup table, Fuzzy Logic Control (FLC), and adaptive neuro-fuzzy inference system (ANFIS) strategies for slip-based friction coefficient estimation and braking force optimization. The lookup table approach, although simple, showed limitations in real-time adaptability, resulting in lower efficiency improvements. A Fuzzy Logic Control strategy was developed to enhance µ-estimation, reducing estimation errors to approximately 0.13–0.16% across various driving cycles, thus improving braking accuracy under dynamic conditions. ANFIS-based intelligent control further enhanced the model’s adaptability by learning complex nonlinear relationships between vehicle speed, SOC, and brake pressure, leading to notable improvements in fuel economy (up to 0.437%) and final battery SOC (up to 6.799%) compared to lookup tables. Additionally, a Multi-Objective Optimization (MOO) algorithm was integrated for tuning the regenerative braking cut-off, maximizing energy recovery and braking performance across multiple standard driving cycles. Building upon this foundational work, our research focuses on employing advanced control strategies to study their impact on battery State of Health (SOH) degradation. The accurate estimation of SOH is challenging yet essential due to the battery’s complex and nonlinear behavior. Among these, SOH estimation has garnered increasing attention because it is crucial for real-time automotive applications. Real-time SOH estimation facilitates battery fault diagnosis, helps prevent hazardous incidents, and provides precise insights into battery performance. This information is vital for energy management in HEVs, improving both their efficiency and lifespan. Kim et al. [

8] proposed a MATLAB/Simulink-based model to simulate cell behavior under varying SOC, SOH, temperature and C-rate conditions, providing a reliable tool for real-time monitoring. This approach evidenced a promise in enhancing the accuracy and efficiency of battery state monitoring, thereby contributing to safer and more reliable battery management systems. Another simulation study [

9] involved the design and simulation of a BMS using MATLAB/Simulink and incorporated a neural network controller (NNC), a Fuzzy Logic Controller (FLC), and a statistical model, leveraging a neuro-fuzzy approach for SOC estimation and a multivariate linear regression model for SOH estimation. Experimental results were used to extract battery parameters for model development, achieving over 97% accuracy in SOC and reasonably accurate SOH predictions.

Vasta et al. [

10] explain that model-based methods, utilizing equivalent circuit models (ECMs) and ageing models (AMs), offer theoretical robustness which is often limited by their adaptability to real-world data; data-driven approaches, such as neural networks (NNs) and support vector regression (SVR), excelled in dynamic and complex conditions but require extensive data and significant computational resources. The research work by Murnane et al. [

11] discussed the methods for estimating the SOC and SOH of LIBs used in applications like electric vehicles and grid storage: (i) Coulomb counting: Estimates SOC by integrating current flow over time, calibrated using voltage measurements (ii) Voltage method: Estimates SOC based on the battery’s voltage characteristics, correlating voltage levels with SOC percentages. (iii) Kalman filter: A sophisticated algorithm that combines measurements and predictions to dynamically estimate SOC and predict SOH based on past performance data. Noura et al. [

12] addressed the need for effective battery health management systems in electric and hybrid electric vehicles to tackle transportation challenges while ensuring safety and longevity. This study focused on the battery’s SOH, which is vital for assessing performance, lifespan, and energy management in hybrid systems. Although various methods for estimating SOH exist, many do not meet the demands of real-time automotive applications, which are crucial for battery fault diagnosis and accurate SOC and SOP estimations. The paper reviews the primary SOH estimation methods, highlighting their advantages and limitations concerning real-time compatibility, particularly for hybrid electric vehicles. Additionally, it presents experimental validation of a model-based adaptive filtering method for online and on-board SOH estimation, demonstrating its feasibility and accuracy in real-time scenarios. Breglio et al. [

13] introduced a novel integrated control architecture for automotive battery management systems (BMSs) that focuses on estimating the SOC and SOH of a battery pack with sixteen parallel-connected modules. Architecture addresses the interdependence of algorithms for SOC and SOH estimation, utilizing an equivalent circuit model. Extended Kalman filters (EKFs) compute SOCs, while internal resistances and capacities are estimated using linear filtering and total least squares methods, respectively. Furthermore, model predictive control (MPC) is applied for active balancing. The system’s effectiveness is validated through simulations under various automotive dynamic scenarios.

The pressing environmental challenges of our time, such as climate change, resource depletion, and greenhouse gas emissions, necessitate transformative changes in the transportation sector. Electrification and hybridization of vehicle powertrains represent a pivotal step towards reducing our carbon footprint and mitigating these environmental threats. Thus, the solution is associated with the development of hybrid and electric vehicles. Still, emphasis must be given to propulsion batteries, especially LIBs, which are essential for the optimal performance of these vehicles. Despite the advancements in battery health management systems, existing methods for SOH estimation, such as equivalent circuit models (ECMs) and data-driven techniques like neural networks (NNs) and support vector regression (SVR), have limitations in adaptability, data requirements, and computational demands. Therefore, there is a compelling need for more robust, accurate, and efficient methods to estimate SOH in real-time. This research addresses this need by employing a fuzzy logic estimation method to determine the tire road friction coefficient (TRFC, denoted as μ) accurately based on real-time slip ratio calculations. The slip ratio (s) represents the relative difference between the vehicle’s linear speed and the wheel’s rotational speed, and it plays a critical role in understanding tire grip. An optimal slip value (s*) corresponds to the slip ratio where maximum tire–road friction occurs. In this method, the fuzzy logic system classifies the slip into three zones—low slip (s < s* − λ), critical slip (s* − λ ≤ s < s*), and high slip (s ≥ s*)—and dynamically adjusts the estimated μ depending on the slip zone. If the slip is lower than optimal, μ is increased in larger steps to reflect better road adhesion; if slip is close to the optimal value, μ is fine-tuned with smaller step changes; and if slip exceeds the optimal value, μ is reduced rapidly to prevent overestimation. Fuzzy membership functions such as Z-shaped, trapezoidal, and S-shaped curves are used to define how the adjustment behaves across the slip range. A complete formulation of the fuzzy logic system, the membership functions, and the tuning strategies adopted can be found in the previous research paper from the authors. This research addresses this need by employing a fuzzy logic estimation method to determine the tire road friction coefficient (TRFC) and implementing various control strategies to establish regenerative cut-off points. The development of an SOH estimation model through MATLAB along with a Kalman SOH estimator allows for real-time observation and study of the impact of different control strategies on battery SOH. This innovative approach enhances the accuracy and reliability of SOH estimation and significantly improves battery fault diagnosis, contributing to the overall advancement of battery management systems in the automotive industry. While effective to a degree, these traditional methods often rely on idealized assumptions and are limited in their adaptability to dynamic, real-world operating conditions, making them less suitable for modern, data-intensive applications requiring higher precision and real-time responsiveness.

Despite significant advancements in BMS and regenerative braking strategies, there is a notable lack of research specifically addressing how different control strategies for regenerative cut-off values impact the SOH of batteries. A comprehensive literature survey [

14,

15,

16,

17,

18,

19,

20] reveals a gap in studies analyzing the direct relationship between these strategies and battery degradation over time. Furthermore, limited work has been undertaken to investigate how internal resistance, SOC, and external driving conditions, such as the driving cycle or road conditions, contribute to the degradation of SOH. Internal resistance, a key factor in battery performance, tends to increase over time due to electrochemical ageing, affecting both energy efficiency and thermal management, yet its role in influencing SOH under varied control strategies for regenerative braking remains underexplored. While some studies address the role of SOC in battery health, the combined influence of SOC and varying driving cycles—such as aggressive acceleration, deceleration, and different road terrains—on battery longevity has not been thoroughly quantified. These driving conditions impose variable loads on the battery, directly impacting both SOC and SOH, yet their interaction with regenerative cut-off strategies is understudied. This study also represents the effort to present the industrial applicability of advanced SOH estimation. It also shows the computational challenges of ANFIS implementation in vehicle ECUs. It offers scalable solutions that include lightweight and cloud-assisted models, which makes real-time intelligent battery management possible for commercial HEVs. Thus, there is a pressing need for further research to bridge these knowledge gaps, particularly in exploring how different regenerative control strategies can be optimized to minimize SOH degradation, considering the complex interplay of internal resistance, SOC and real-world driving conditions.

3. Driving Cycle

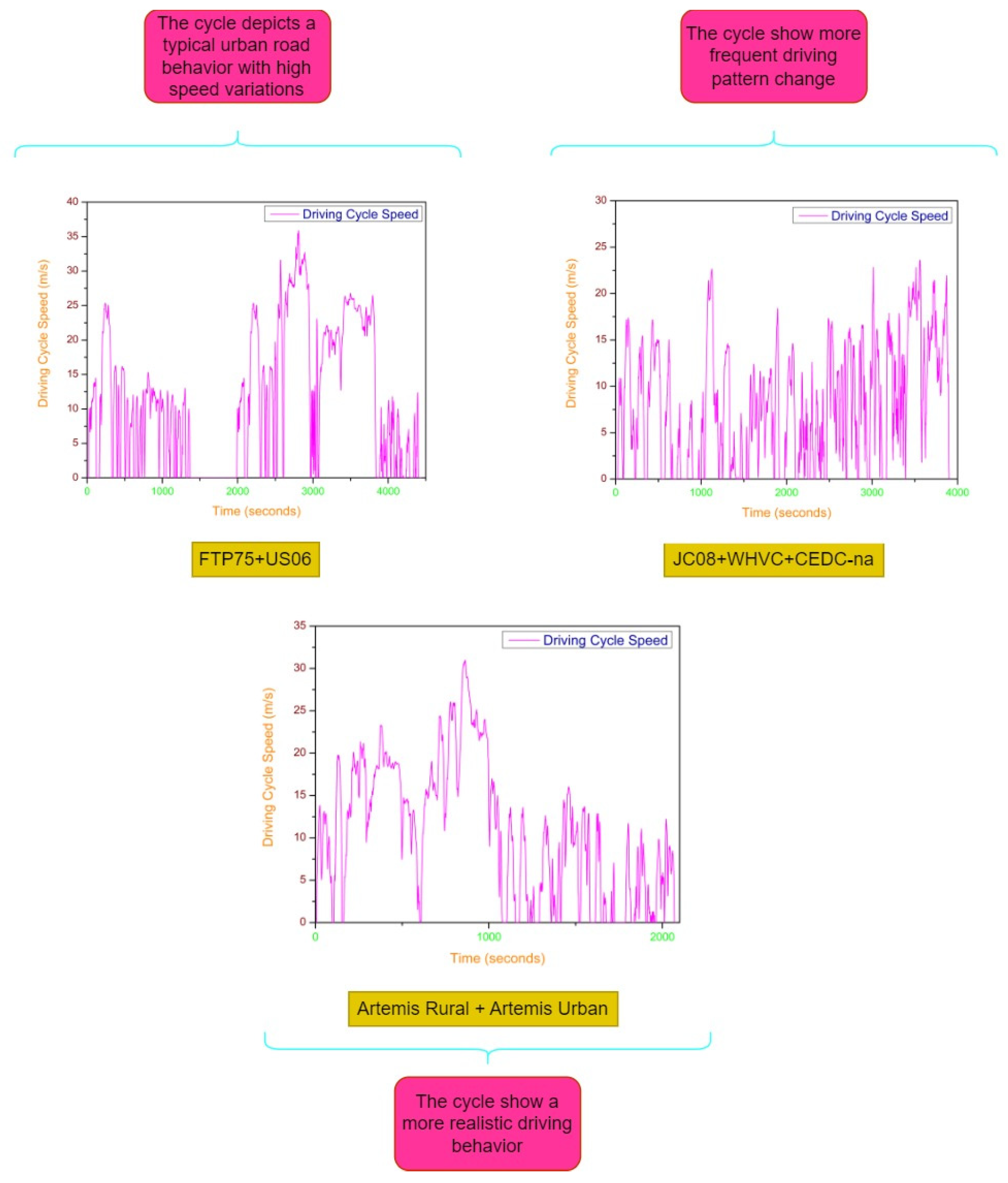

A vehicle’s speed varies dramatically over time; this phenomenon is depicted by a driving cycle, which is a collection of data indications. Driving cycles are standardized tests used to assess how well a car performs, produces less pollution, and is efficient in various driving scenarios. These cycles are crucial for evaluating how cars behave in different conditions because they incorporate fluctuations in speed, acceleration, deceleration, and idling, much like in real-world driving scenarios. In-depth analyses consider all kinds of routes, including rural, urban, and freeway ones, guaranteeing a comprehensive examination of energy usage and vehicle efficiency under various driving circumstances. Multiple cycles have been mixed to construct these driving cycles by national and international standards to capture all aspects of road use in the evaluation process. This method guarantees that the evaluations give a true picture of the performance of the vehicle and reflect normal driving patterns. As a result, three unique driving cycles have been developed, each intended to capture certain driving situations and behaviors.

The federal test procedure (FTP75) and the US06 cycles make up the first driving cycle. FTP75 cycle has a mix of low-speed, stop-and-go traffic that is characteristic of driving in cities. It is frequently used for emissions and fuel efficiency testing in urban contexts. It incorporates several driving phases, such as acceleration, deceleration, and idling, to imitate a regular, everyday commute. Conversely, the US06 cycle reflects harsher urban driving circumstances. Higher acceleration rates and greater top speeds are included to account for situations in which drivers might have to merge into highways or maneuver through clogged city streets. Through the integration of these two cycles, this driving cycle offers a strong framework for assessing how well a vehicle performs in urban environments, emphasizing the car’s emissions profile and fuel efficiency under various driving circumstances.

The second driving cycle is a composite that combines components of the world harmonized vehicle cycle (WHVC) with the Japanese JC08 and CUED-NA cycles. The JC08 cycle is divided into many sections that have consistent idle, accelerating, and deceleration periods. This allows for a thorough evaluation of the vehicle’s performance under normal driving circumstances in Japan. In Australia, the CUED-NA cycle records driving patterns on highways, minor roads, arterial roads, and congested roadways. This information helps to provide a more complex picture of how vehicles behave in various types of situations. The widely accepted WHVC standard adds even more value to this cycle by combining a variety of driving situations from different nations, giving a realistic portrayal of driving circumstances in the actual world.

Following European standards, the third driving cycle combines the rural and urban Artemis cycles. The Artemis cycles are made to mimic a range of typical European driving situations, such as highway driving, countryside cruising, and stop-and-go traffic in cities. This cycle takes into consideration these various situations, making sure that vehicle evaluations match standard driving patterns in Europe and capture the difficulties and features of these settings. By combining these several driving cycles, a thorough evaluation framework is created that makes it possible for manufacturers and academics to measure emissions, fuel economy, and vehicle performance in real-world scenarios. The speed profiles of the three hybrid driving cycles are illustrated in

Figure 4, highlighting the variations in speed, acceleration, and deceleration across different driving scenarios. Through the examination of these profiles, interested parties can obtain important knowledge on how cars function in actual driving situations, which can help in the creation of more eco-friendly and efficient automobiles. Establishing these driving cycles is essential to guaranteeing that automobiles satisfy legal requirements and satisfy customer needs for sustainability, efficiency, and performance.

6. Results and Discussion

The battery’s SOH is a critical factor in determining the performance, lifespan, and efficiency of HEVs. To ensure optimal vehicle functioning, proper monitoring and management of SOH are essential, since batteries deteriorate over time due to usage. With regard to its initial capacity, the battery’s SOH indicates how much energy it can store and release. In addition to lowering driving range, degraded batteries can have a detrimental effect on the effectiveness of energy recovery, power delivery, and regenerative braking systems, all of which are essential to a hybrid electric vehicle’s performance. As a result, close observation of the SOH is necessary to guarantee long-term dependability, prevent unplanned malfunctions, and maximize energy economy. This study evaluates the efficacy of three control systems in maintaining the SOH of the battery during various driving cycles: fuzzy logic, lookup tables, and adaptive neuro-fuzzy inference system (ANFIS). It is essential to track the HEV battery’s SOH for many reasons. Furthermore, the SOH of a battery is closely connected to its efficiency. Batteries lose some of their capacity to hold a charge with age, which can result in a reduction in driving performance and range. Monitoring SOH makes it possible to do routine maintenance and battery replacements on time, maintaining the vehicle’s functionality and efficiency. Moreover, the standard of hover is essential for the efficient operation of regenerative braking systems in hybrid electric vehicles (HEVs), which recover energy lost while braking. Regenerative braking may not function well if SOH is low, which might result in further energy loss and battery deterioration.

Furthermore, SOH affects the battery’s overall longevity. Having a better understanding of how operational circumstances and state of charge (SOC) impact SOH can aid in the development of solutions to increase battery life. Manufacturers may produce more dependable and effective automobiles by utilizing sophisticated control systems that take these aspects into account. By examining the performance of HEV batteries under varied driving scenarios, this study seeks to demonstrate how different control tactics can affect the SOH of HEV batteries. Three control techniques were tested in this study: lookup table, fuzzy logic, and ANFIS. The driving cycles were FTP75 + US06, JC08 + WHVC + CEDC-na, and Artemis Rural + Artemis Urban. These cycles simulate a range of actual driving scenarios that place varying amounts of strain on the battery. The control techniques were compared according to how well they were able to keep the battery’s SOH after 2000 km of driving.

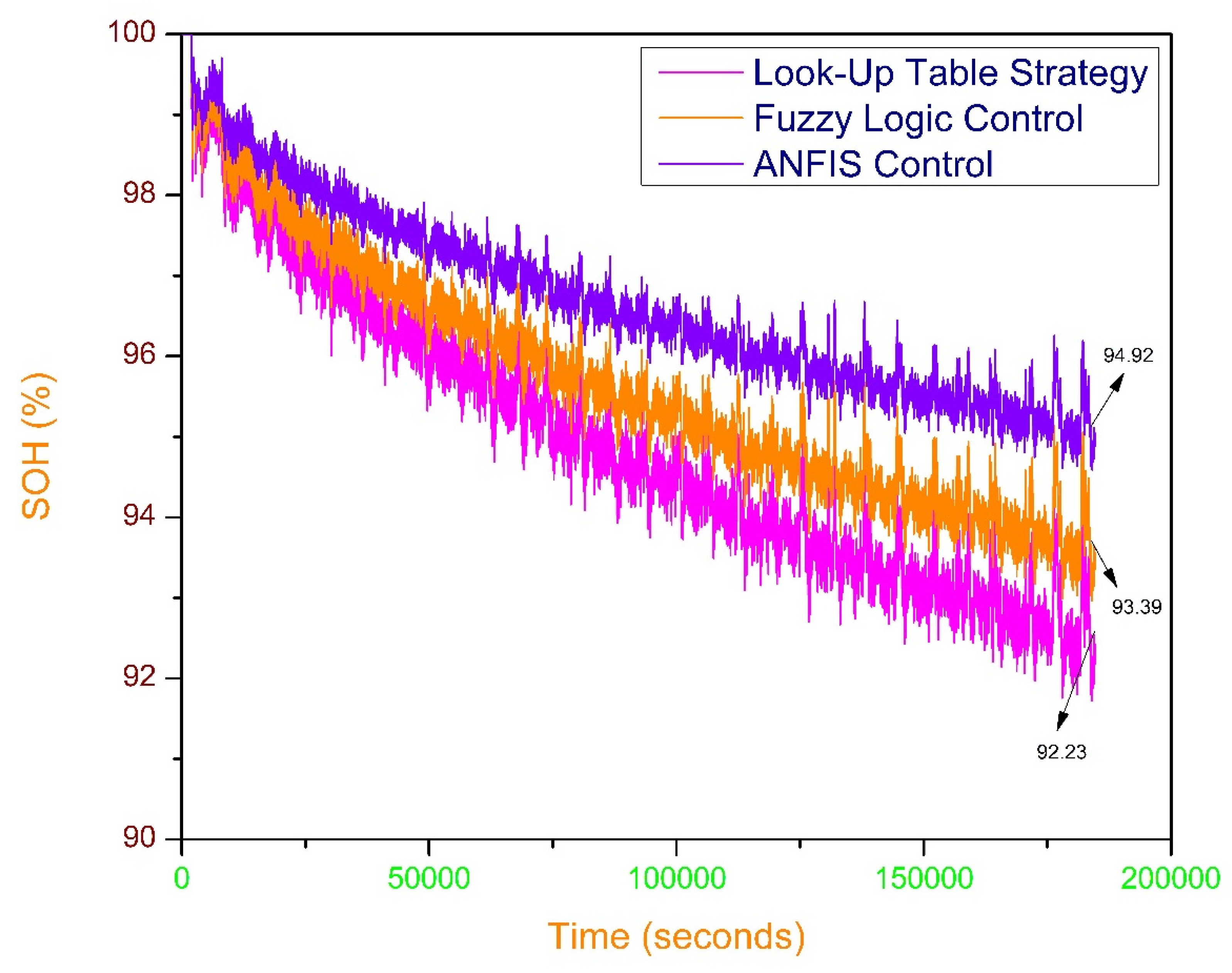

The lookup table control produced a final SOH of 92.23% in the FTP75 + US06 driving cycle, which mimics driving in cities with many stops. At a final SOH of 93.39%, the Fuzzy Logic Control technique outperformed the others. However, ANFIS did better than the other two, obtaining a final SOH of 94.92%, as shown in

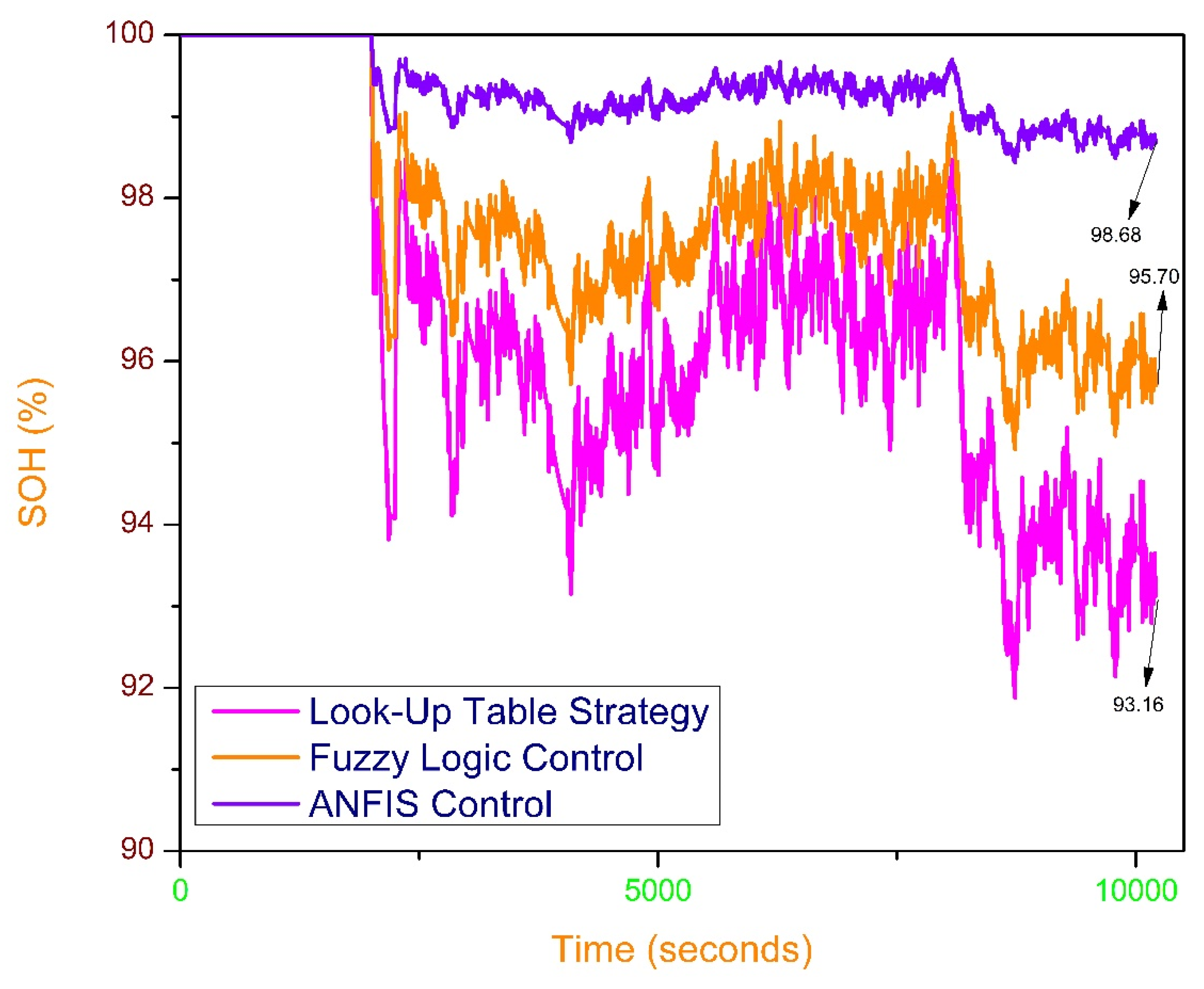

Figure 5. The JC08 + WHVC + CEDC-na driving cycle, which replicates both city and highway driving, showed a steady rise in this direction, as depicted in

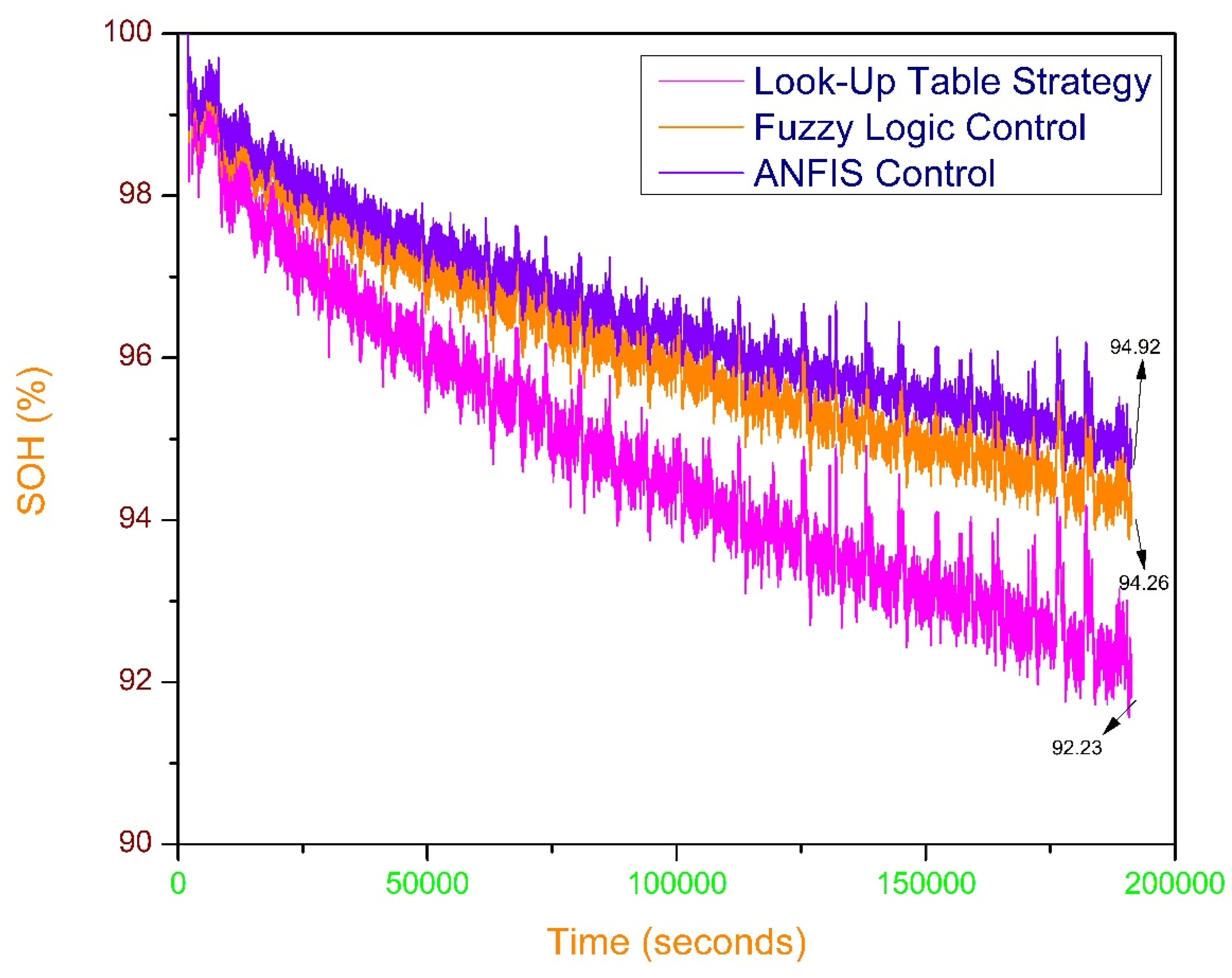

Figure 6. ANFIS once again outperformed with a SOH of 98.68%, while fuzzy logic achieved 95.70% and lookup table control delivered a final SOH of 93.16%. Finally, the final SOH values for the lookup table, fuzzy logic, and ANFIS in the Artemis Rural + Artemis Urban cycle were 92.23%, 94.26%, and 94.92%, respectively, as compared in

Figure 7. The ability of ANFIS to control battery degradation better than both lookup table and fuzzy logic techniques is demonstrated by its consistently better performance throughout all driving cycles. The superior ability of ANFIS to flexibly adapt to situations in real-time is largely responsible for this. ANFIS goes above and beyond, while fuzzy logic provides some flexibility based on input data and the lookup table approach depends on pre-set values that might not take into consideration the unpredictability of driving situations. The battery’s charging and discharging behavior can be continuously optimized by combining the learning capabilities of neural networks with the rule-based decision-making power of fuzzy logic. To prevent overstressing the battery, ANFIS, for instance, may forecast the amount of stress placed on it under intense driving conditions and modify power output or regenerative braking. Comparing this to static or rule-based systems, the smoother battery consumption profile reduces deterioration and better preserves SOH.

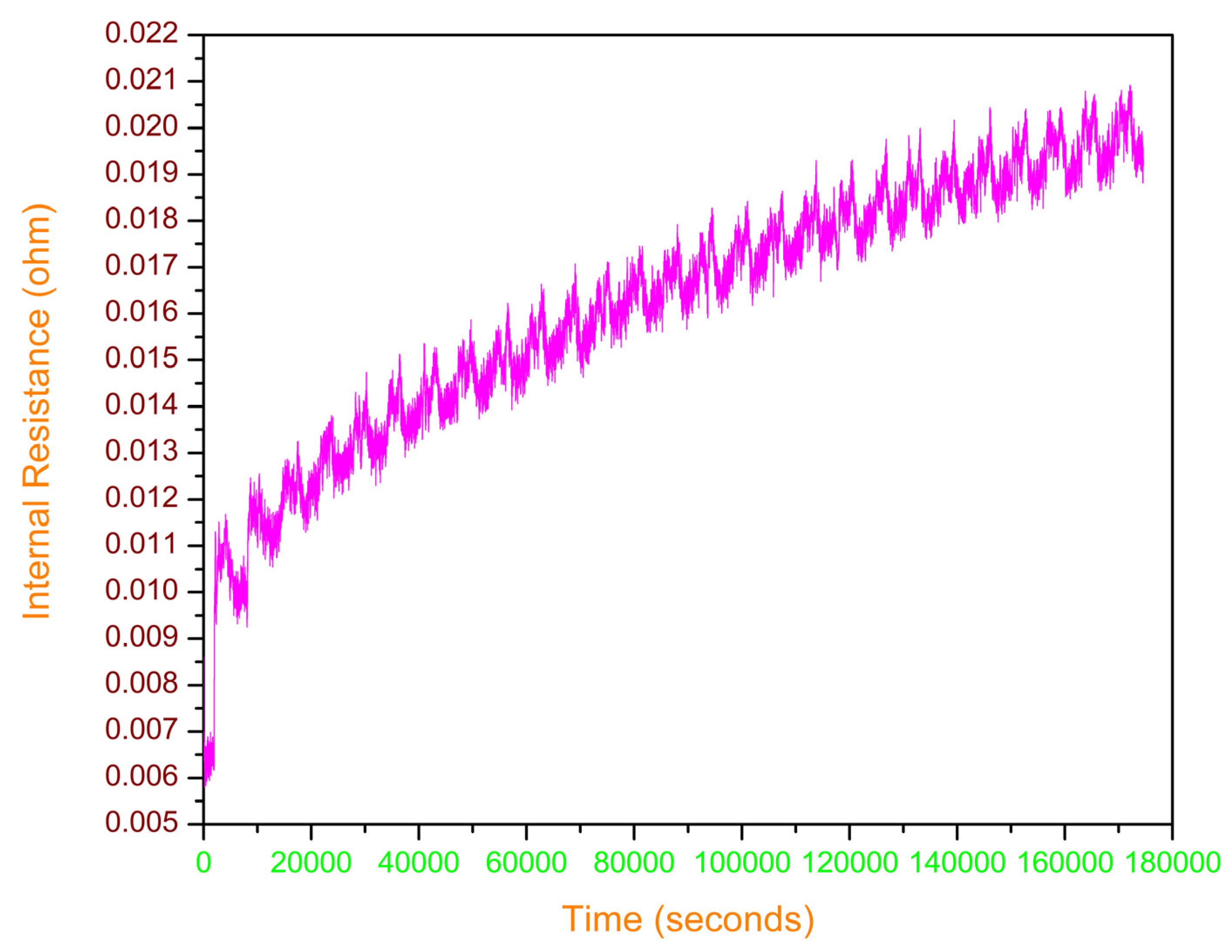

The internal resistance of the battery is another significant component affecting battery SOH. As the battery ages, internal resistance rises, increasing energy losses and decreasing charging and discharging efficiency. Plotting the internal resistance versus time for each of the three driving cycles revealed that the fluctuations in SOH that were observed were closely correlated with the peaks and dips in the resistance curve. The fuzzy logic and lookup table techniques showed larger peaks in internal resistance in the FTP75 + US06 cycle, especially during severe acceleration or significant regenerative braking, which resulted in greater deterioration of the SOH. The influence of these peaks in internal resistance can be seen in the final SOH values, which are 92.23% for the lookup table and 93.39% for fuzzy logic. However, ANFIS was able to control these peaks more effectively, which led to fewer instances of high internal resistance and maintained the battery’s state of health at 94.92%. The combination of city and highway driving in the JC08 + WHVC + CEDC-na cycle also shows a strong correlation between internal resistance and SOH. The lookup table strategy’s lower SOH of 93.16% was correlated with a dramatic increase in internal resistance during high-speed passages. Although resistance spikes were reduced by ANFIS’s capacity to adjust to real-time conditions, fuzzy logic still outperformed it. This led to the greatest SOH of 98.68%, demonstrating a remarkable ability to preserve battery health across a variety of driving scenarios. A recovery trend of battery SOH was witnessed in JC08 + WHVC + CEDC-na driving cycle simulation. The cycle consists of a reasonable and fairly steady driving condition for most of the driving duration which involves a lot of idling, smoother acceleration, and less peak acceleration demand as compared to aggressive urban cycles. Driving a HEV in this manner can help keep it within optimum SOC levels. If the car is continually operated in a low SOC or high SOC environment, degradation is inevitable. Also, the trends in internal resistance were more gradual and displayed fewer peaks compared to similar drivers with tougher driving cycles. If the internal resistance of the battery is lower and more stable, voltage drop and internal heat generation during operation will lessen. This then will lessen the stress on the battery’s electrochemical systems. The combination of stable SOC within a limited range and less fluctuation in internal resistance makes an ideal operating environment, as a result of which model-based estimators may infer temporary stabilization or slight recovering of SOH. The real recovery of used battery materials of aged cells may not happen. But the operating environment becomes less harmful, and it slows down the observed rate of drop in performance. This allows the SOH curve to show a plateau level or mild enhancement during the cycle. Similarly, ANFIS fared better than the other two techniques in the Artemis Rural + Artemis Urban cycle. Fuzzy logic demonstrated an advantage over the lookup table strategy in handling internal resistance throughout the varied demands of driving in rural and urban areas. Nonetheless, ANFIS maintained lower levels of internal resistance because of its greater flexibility and learning capacity, which is correlated with a better-preserved SOH of 94.92%. The change in internal energy of the battery concerning time in each driving cycle is shown in

Figure 8,

Figure 9, and

Figure 10, respectively.

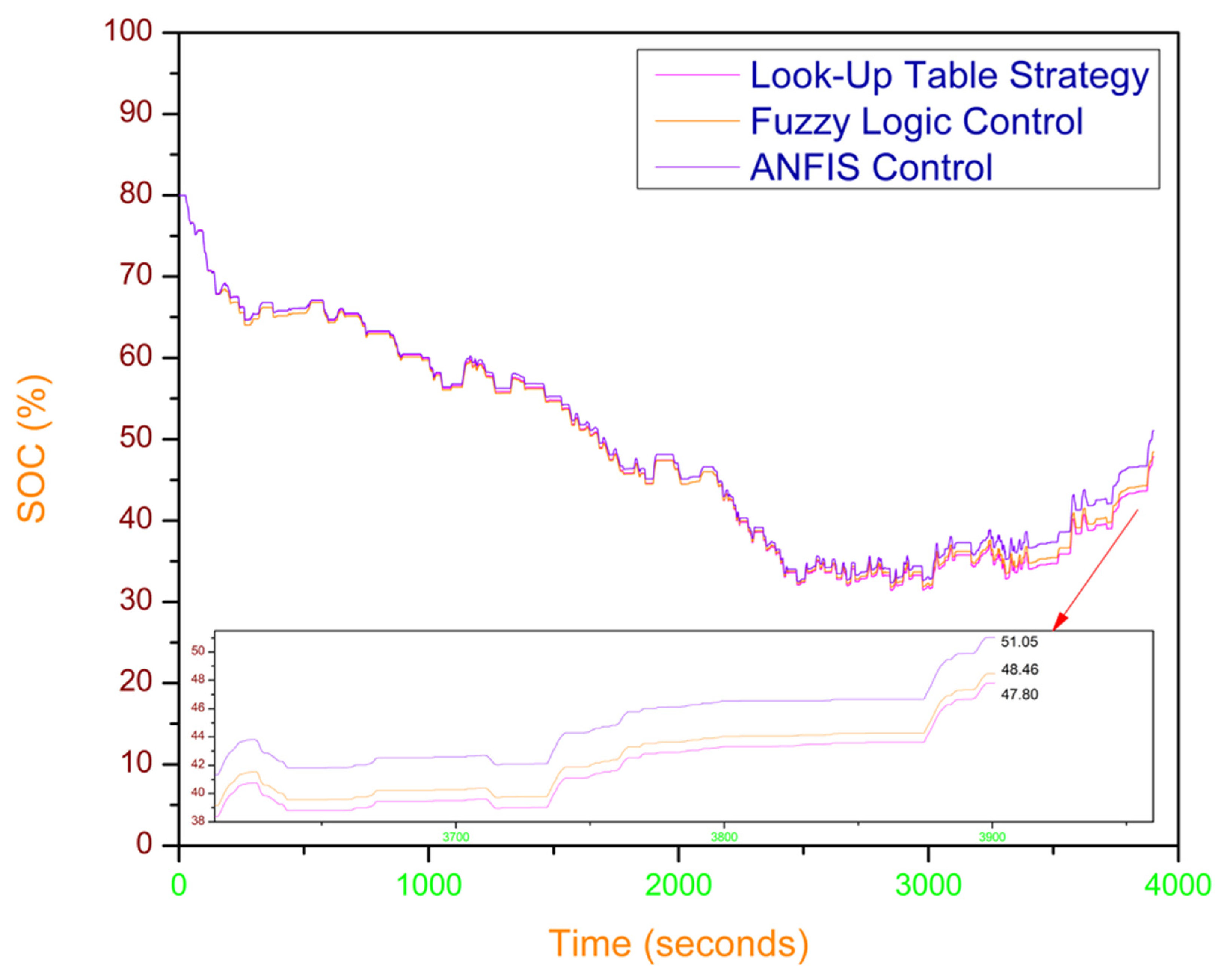

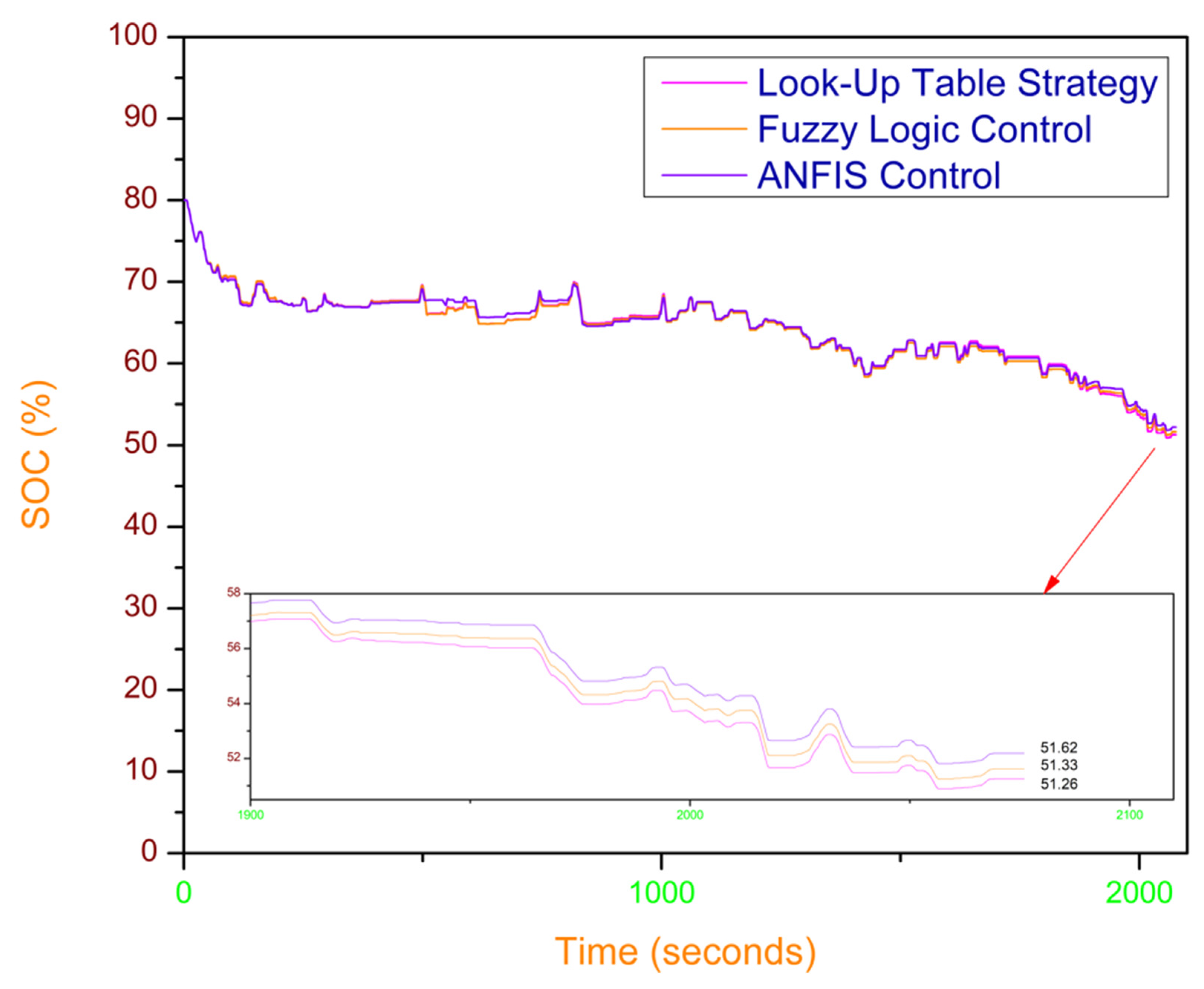

Throughout the three driving cycles, SOC also had a big impact on SOH. Extreme SOC values, whether too high or too low, can hasten battery deterioration. SOC is a measure of the battery’s state of charge. Deeper discharge cycles occur when the SOC falls too low, and this can wear out the electrodes of the battery and result in long-term harm. Comparably, running at a high SOC all the time might cause overcharging, which puts more strain on the battery and shortens its life. SOC regularly dropped during moments of strong acceleration and regenerative braking in the FTP75 + US06 driving cycle, as seen in

Figure 11. In particular, the lookup table and fuzzy logic techniques saw increased SOH deterioration because of the battery being under stress. Because of ANFIS’s improved capacity to control SOC, the SOC profile was smoother, deep drain cycles occurred less frequently, and the battery’s state of health was maintained. The trends in the JC08 + WHVC + CEDC-na cycle were comparable and shown in

Figure 12. In the lookup table method, SOC varied more, which caused SOH decreases to be more dramatic. ANFIS once again maintained SOC more successfully, resulting in fewer deep discharges and overcharging occurrences and maintaining a higher SOH. Fuzzy logic provided modest improvement. SOC swings were frequent in the Artemis countryside + Artemis Urban cycle, as seen in

Figure 13 when driving conditions alternate between countryside cruising and urban stop-and-go traffic. Greater SOH deterioration resulted from the lookup table strategy’s inability to accommodate these variances. Although ANFIS’s adaptive learning capabilities helped it control SOC better and ensure fewer dips and peaks that would otherwise lead to battery deterioration, fuzzy logic still outperformed it in terms of performance.

The outcomes of the three driving cycles show that the best control method for maintaining the SOH of HEV batteries is ANFIS. Because of its dynamic and adaptive learning capabilities, ANFIS consistently provided greater SOH values than the lookup table and fuzzy logic techniques throughout all driving cycles. Through more efficient management of SOC and internal resistance, ANFIS was able to reduce the load on the battery, hence decreasing deterioration and increasing battery life. ANFIS is a better option for advanced battery management in HEVs due to its predictive learning capabilities and capacity to handle nonlinear correlations between input variables. Furthermore, it is crucial to keep an eye on the SOH of HEV batteries. Manufacturers and researchers need to focus on developing efficient battery management systems that guarantee both safety and efficiency, especially considering the growing demand for hybrid and electric cars. The study’s conclusions offer insightful information on how different control schemes may impact the lifespan and performance of batteries. The development of more efficient and sustainable hybrid electric cars will depend on the integration of advanced control systems like ANFIS as the automotive industry continues to change.

The SOH of a HEV’s battery is significantly influenced by the driving conditions it is subjected to, as demonstrated by the three distinct driving cycles: FTP75 + US06, JC08 + WHVC + CEDC-na, and Artemis Rural + Artemis Urban. The FTP75 + US06 cycle, which reflects typical urban road behavior with frequent stops, starts, and high-speed variations, tends to put significant stress on the battery. The frequent acceleration and deceleration cycles, combined with aggressive urban driving, cause more wear on the battery due to higher energy demands and regenerative braking events, leading to faster SOH degradation, and the same can be seen in

Figure 5 which shows higher battery depletion when compared to

Figure 6 or

Figure 7. In contrast, the JC08 + WHVC + CEDC-na cycle represents more frequent changes in driving patterns, with diverse idling, acceleration, and deceleration intervals. This variation in driving behaviors places varying degrees of strain on the battery, leading to more complex wear patterns, but somewhat moderating the overall degradation compared to the more aggressive urban cycle. The third cycle, Artemis Rural + Artemis Urban, mimics more realistic driving behavior by blending rural cruising and urban stop-and-go traffic. This cycle is less aggressive overall but provides a balanced combination of driving conditions. The steady rural portions allow the battery to operate more efficiently with less stress, whereas the urban segments still engage the battery in energy-intensive tasks, making this cycle’s impact on SOH more unpredictable. Overall, the more aggressive urban and varied driving patterns from the first two cycles tend to degrade the battery’s SOH faster than the balanced behavior of the JC08+WHVC+CEDC-na cycle. The findings are all summarized in

Table 1.

ANFIS works better than others in maintaining the SOH of HEV batteries. However, implementing ANFIS comes with a complexity–benefit trade-off. Even though ANFIS supports adaptive learning to enhance SOH retention, it often requires a considerable number of computations, training sets, and onboard processing units, which can increase costs and energy consumption. On the other hand, despite their lower SOH improvement, the fuzzy logic- and lookup table-based methods are simpler and ask for low computational effort, and easier to be applied to vehicle ECUs. So, stakeholders need to think about whether the marginal (4–6%) gain in SOH is worth the challenges and costs. While conducting the simulation, the challenges faced were accurate models of the internal resistance during various driving cycles and real-time response. The adaptive learning component of the computational load causes lag in response that is critical in real life. Also, accurate simulation over long periods requires proper tuning of ANFIS parameters. ANFIS errors in predicting SOC cause SOH to be inaccurate. Optimization strategies are needed to enhance the real-time applicability of ANFIS. SOH management based on adaptive neuro-fuzzy inference systems shows huge potential for vehicle life extension, fleet reliability, and predictive maintenance. Nevertheless, scalability problems still exist for vehicles with limited computing power. Also, the use of lightweight or cloud-supported versions of ANFIS can allow industries to narrow the gap between sophisticated SOH management and its feasible and economically viable implementation.

In summary, efficient control of the SOH of the battery can maximize the performance, efficiency, and life of a HEV battery. Although the ANFIS method has adaptive learning and real-time adjustment based on dynamic conditions, it will be more demanding with regard to its computations and complicate the system. Stakeholders should consider more carefully the trade-offs versus the substantial improvements in battery health and vehicle lifetime. Further optimization to address challenges like internal resistance variation management, real-time responsiveness, and estimator stability is imperative before deploying to the full-scale. Nonetheless, the use of advanced control strategies such as ANFIS will greatly help in the environmental and economic targets of HEVs. As automotive architectures progress, future implementation of intelligent scalable SOH estimation will be a necessity for long-term reliability and sustainability. Future research must aim to make these models more practical, keeping the performance of the variables under control so that hybrid electric vehicles can be a solution.

7. Validation of the Proposed Model

To ensure the proposed simulation models reflect real-world conditions with accuracy and reliability, validation through real-time data is essential. Realistic simulations must incorporate dynamic driving behaviors that mirror actual vehicle operations. Thus, a real-time driving cycle was developed and implemented to validate the presented models. This cycle was constructed by recording the velocity profile of a hybrid vehicle navigating the varied urban landscape of Vellore city, Tamil Nadu. This region offers a mix of stop-and-go traffic, idling, and variable-speed segments—capturing the nuanced interplay of acceleration, deceleration, and idling. The derived driving cycle was then integrated into the MATLAB/Simulink model, serving as a dynamic input that replicates the real-world operational environment. This not only enriches the authenticity of the model but also ensures that the proposed intelligent control strategies are tested under conditions that an actual hybrid electric vehicle (HEV) would experience on the road. Such incorporation enhances the credibility of the simulation results and allows a meaningful assessment of battery behavior, particularly with regard to state of health (SOH) and state of charge (SOC).

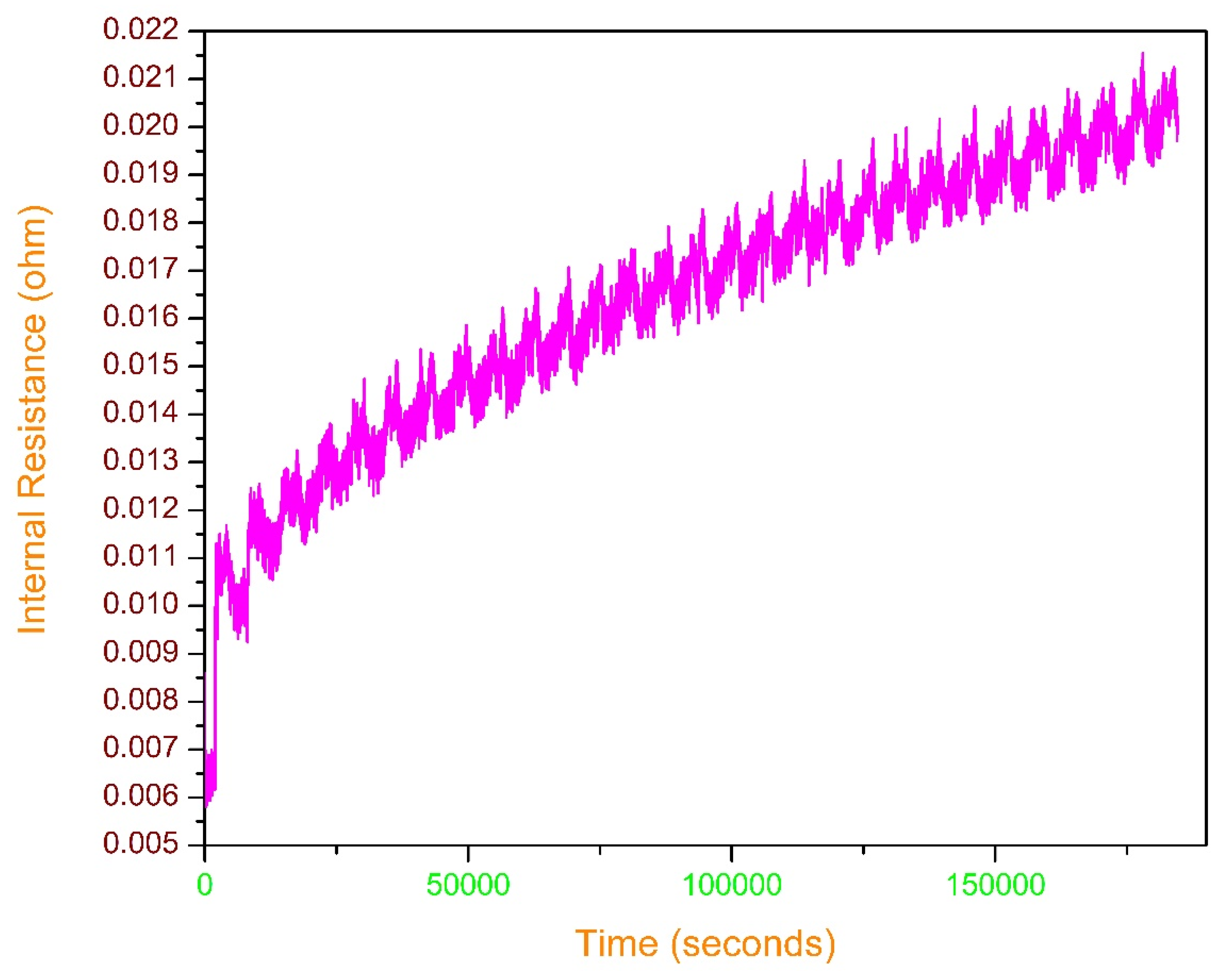

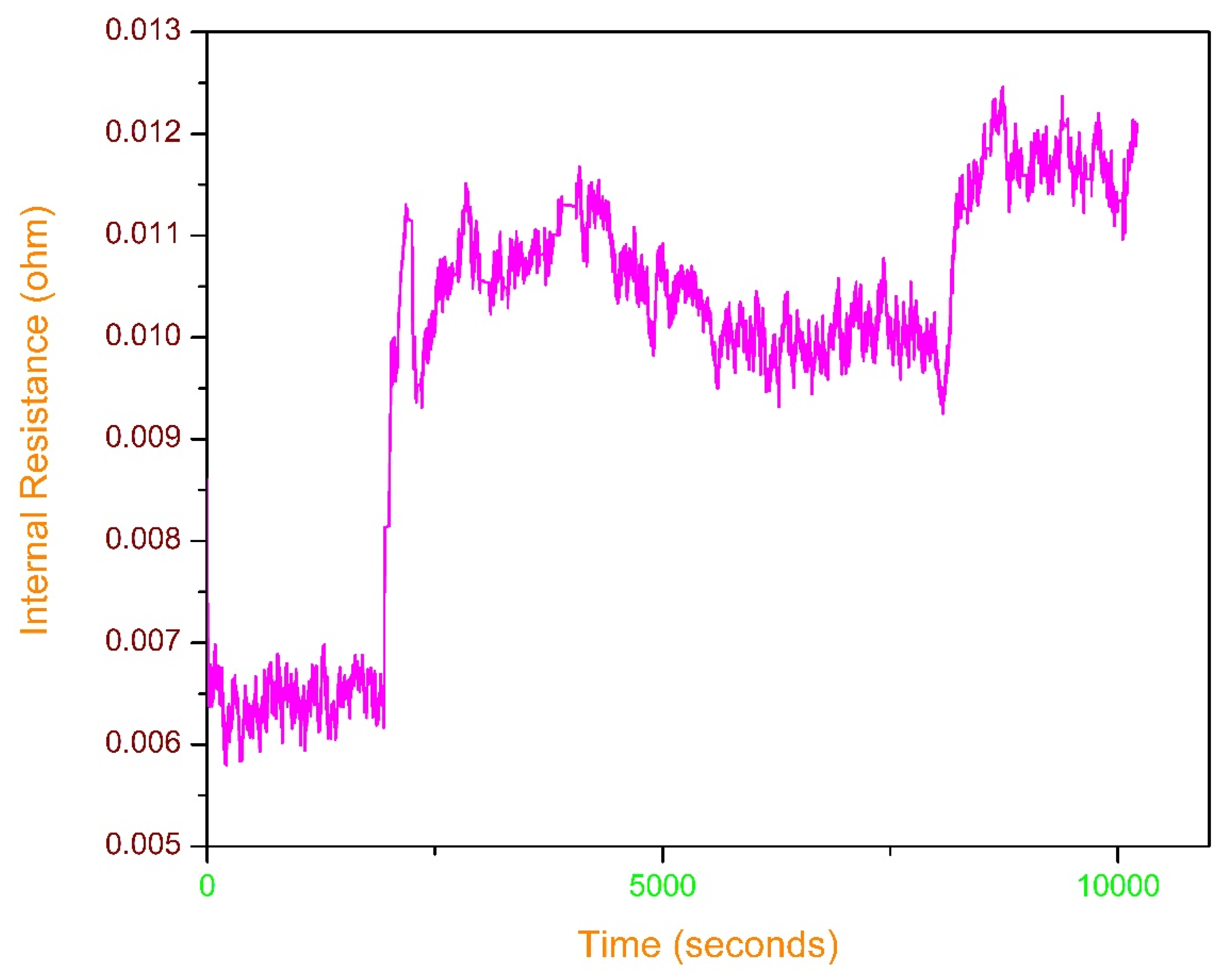

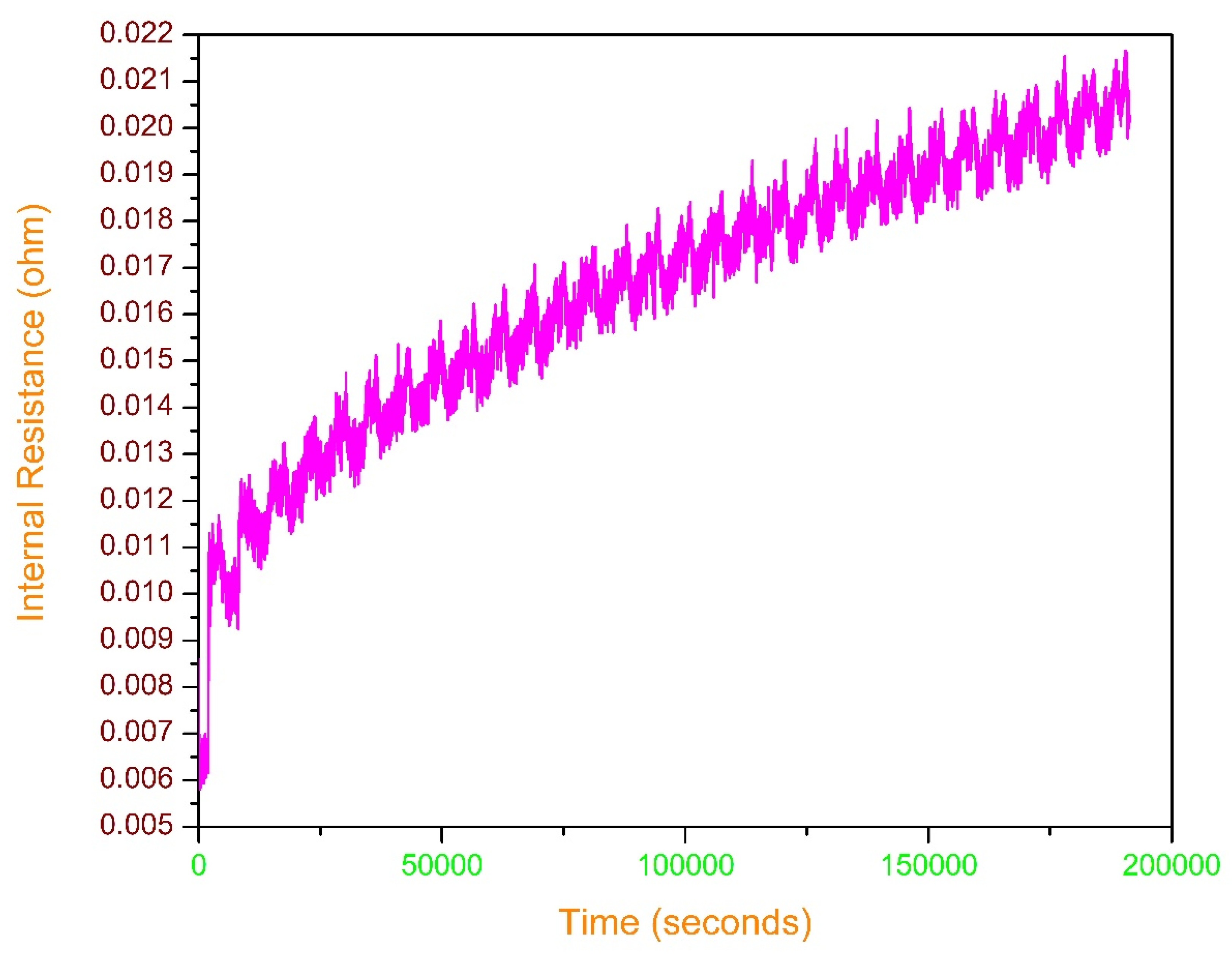

The first part of the validation looks at how internal resistance changes with time. As seen in

Figure 14, internal resistance increases from a value of 0.006 ohms to a value of about 0.020 ohms over the driving period. The battery’s steady-state resistance increase is expected as batteries age, which is in line with the theory. The battery reacts with energetic changes through regenerative braking and load cycles, which keeps on changing in the above cycles. Battery internal resistance is rising and now more voltage drops under load. Also, energy efficiency is lower, which contributes to SOH degradation. As the graph depicts, the simulation adequately captures the tracking of one of the major indicators of battery health, indicating that the model is properly replicating electrochemical aging.

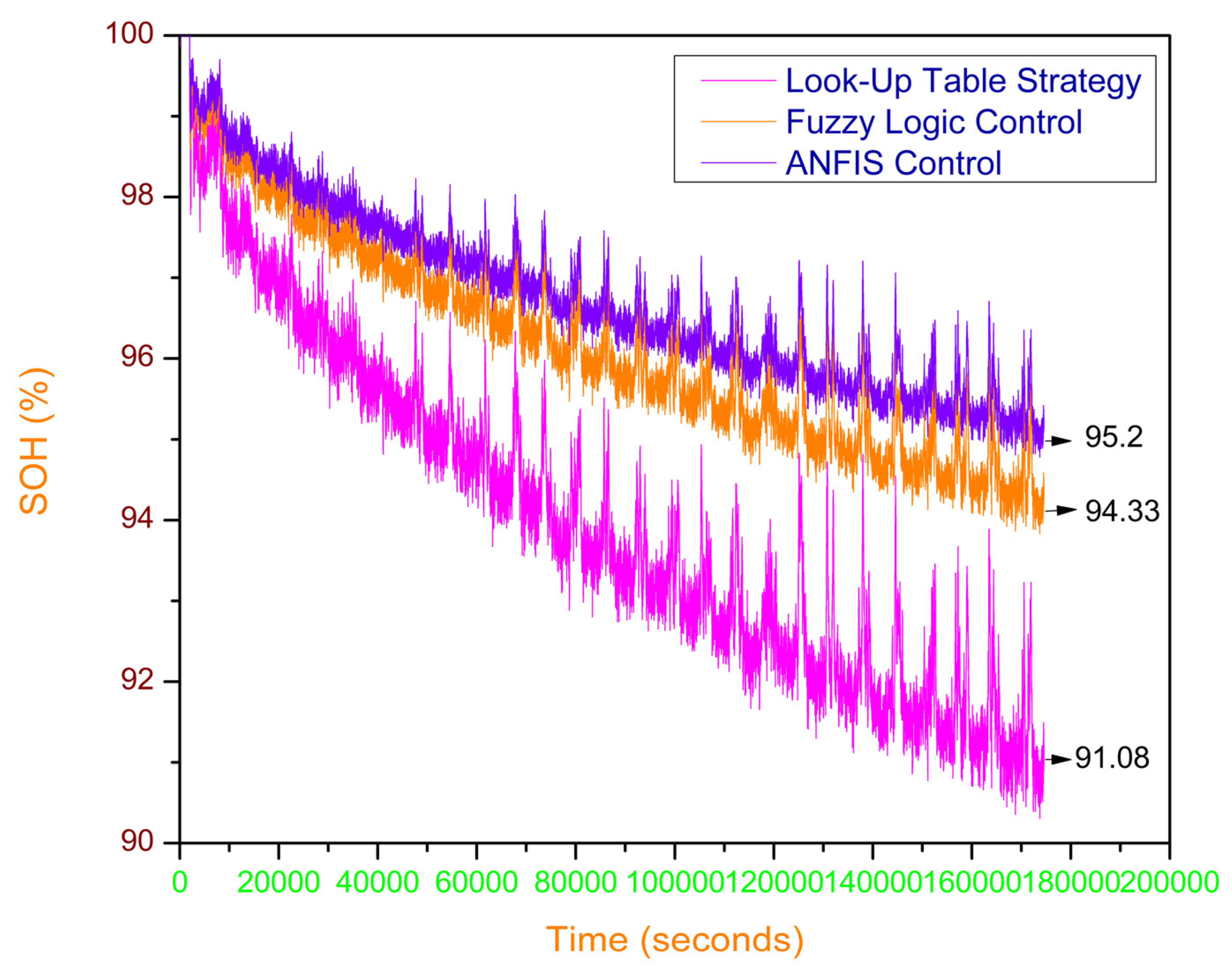

As evidenced by the SOH comparison curves in

Figure 15, the driving distance simulated to be 2000 km shows the performance of three various control strategies including lookup table, Fuzzy Logic Control (FLC), and ANFIS. Therefore, the final SOH values for the strategies are: 91.08% (lookup table), 94.33% (FLC), and 95.2% (ANFIS). Through these values, the influence of smart control strategies on battery degradation is shown. The lookup table method is easy to use but cannot adapt and degrades the SOH greatly. FLC, with its capacity for dynamic adjustment based on its input patterns, exerts a moderate influence. Nonetheless, the ANFIS surpasses both cases, since it learns from earlier data and modifies control strategies based on these data. The reason SOH retention is better under ANFIS is because it can handle the fluctuations in internal resistance and optimize SOC. The ANFIS-based regenerative braking control can enhance the life of the battery under on-road conditions; this is proved.

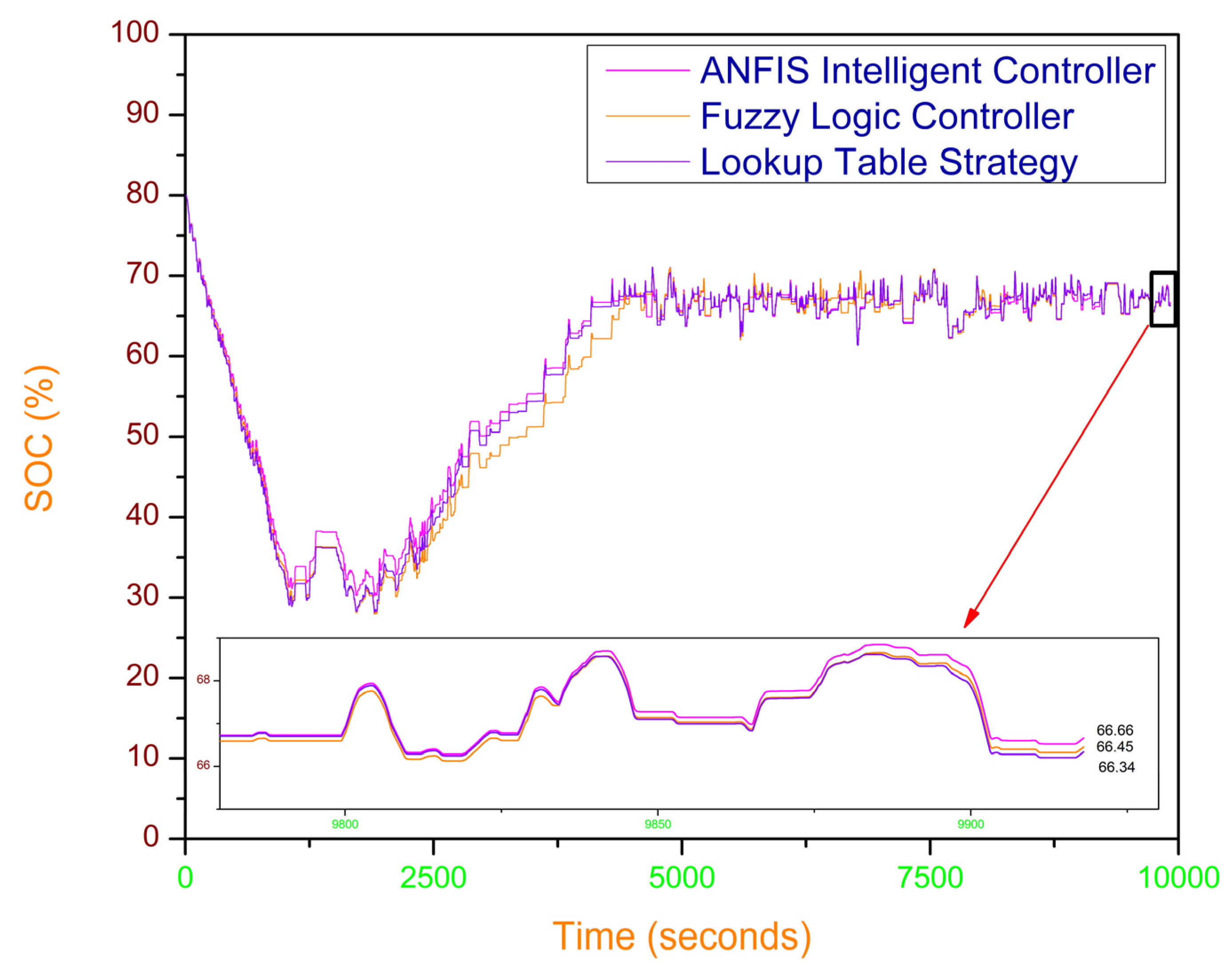

The SOC trends over time are illustrated in

Figure 16, which captures the charge–discharge behavior of the battery during the driving cycle. At the end of the cycle, the final SOC percentages for each strategy were as follows: 66.34% (lookup table), 66.45% (FLC), and 66.66% (ANFIS). Although the difference appears minor, it is crucial, as even a small retention in SOC over extended cycles can translate into substantial gains in driving range and system efficiency. The magnified inset in

Figure 3 further highlights the stability of the ANFIS control during transient events. This reinforces ANFIS’s strength in maintaining consistent charge levels and reducing deep discharge cycles that could accelerate battery wear.

The results observed from all three figures together validate the model’s precision and reliability. As the internal resistance grows, the SOH lowers and SOC alterations arise. Too much internal resistance loses more of the energy in the form of heat, and less is recovered. Variation in the SOC will impact the DoD and DoC, which in turn will affect the SOH. By better managing the SOC and minimizing the resistance spikes, the ANFIS-based strategy not only preserves the SOC but also reduces SOH degradation to create a direct link among the three parameters internal resistance, SOC, and SOH.