Hybridization of ADM-Type Rail Service Cars for Enhanced Efficiency and Environmental Sustainability

Abstract

1. Introduction

2. Materials and Methods

2.1. Hybridization Process of Rail Service Cars

2.1.1. Assessment of the Current ADM Model

- Fuel consumption (high diesel usage).

- Emissions (CO2 and NOx levels exceeding sustainable limits).

- Maintenance (frequent breakdowns and high upkeep costs).

2.1.2. Design and Development of the Hybrid System

- ○

- Electric Traction: High-efficiency torsion electric motors drive the wheel pairs.

- ○

- Battery Storage: Lithium-ion batteries provide supplementary power.

- ○

- Power Management: Intelligent control systems dynamically switch between diesel and electric modes based on operational demands.

- ○

- Regenerative Braking: This converts excess kinetic energy into electrical energy, improving overall system efficiency.

Performance Evaluation Approach

- Energy Consumption: The total energy required for operation under identical load and track conditions was measured for both systems.

- Torque Stability and Wheel Slip Reduction: The torque distribution across the motor–wheel pair was analyzed to quantify improvements in traction and slippage prevention.

- Power Loss Minimization: The losses occurring due to heat dissipation, electrical conversion inefficiencies, and regenerative braking inefficiencies were calculated.

2.2. Technical and Economic Feasibility Analysis

- Fuel consumption is reduced by 42%, minimizing operating expenses.

- There are lower maintenance costs due to fewer moving parts in electric systems.

- Discount rate: 8%.

- Fuel price volatility: ±10% variation per year.

- Battery replacement after 8–10 years.

- Sensitivity analysis revealed that the hybrid model remains profitable even if fuel prices drop by 10% or battery costs increase by 15%.

2.2.1. Infrastructure and Policy Considerations

Alignment with Uzbekistan’s Railway Electrification Plans

- Hybrid retrofits extend the service life of existing diesel units while reducing emissions.

- They support non-electrified regions, maintaining operational flexibility.

- They have potential for integration with Uzbekistan’s renewable energy strategy for further sustainability.

2.2.2. Government Incentives and Policy Support

- Carbon credits for emission reductions.

- Tax exemptions for hybrid conversions.

- Subsidized financing programs for railway modernization.

2.3. Comparative Analysis

3. Results

3.1. Energy Efficiency and Performance Improvements

3.2. Comparative Energy Consumption Trends

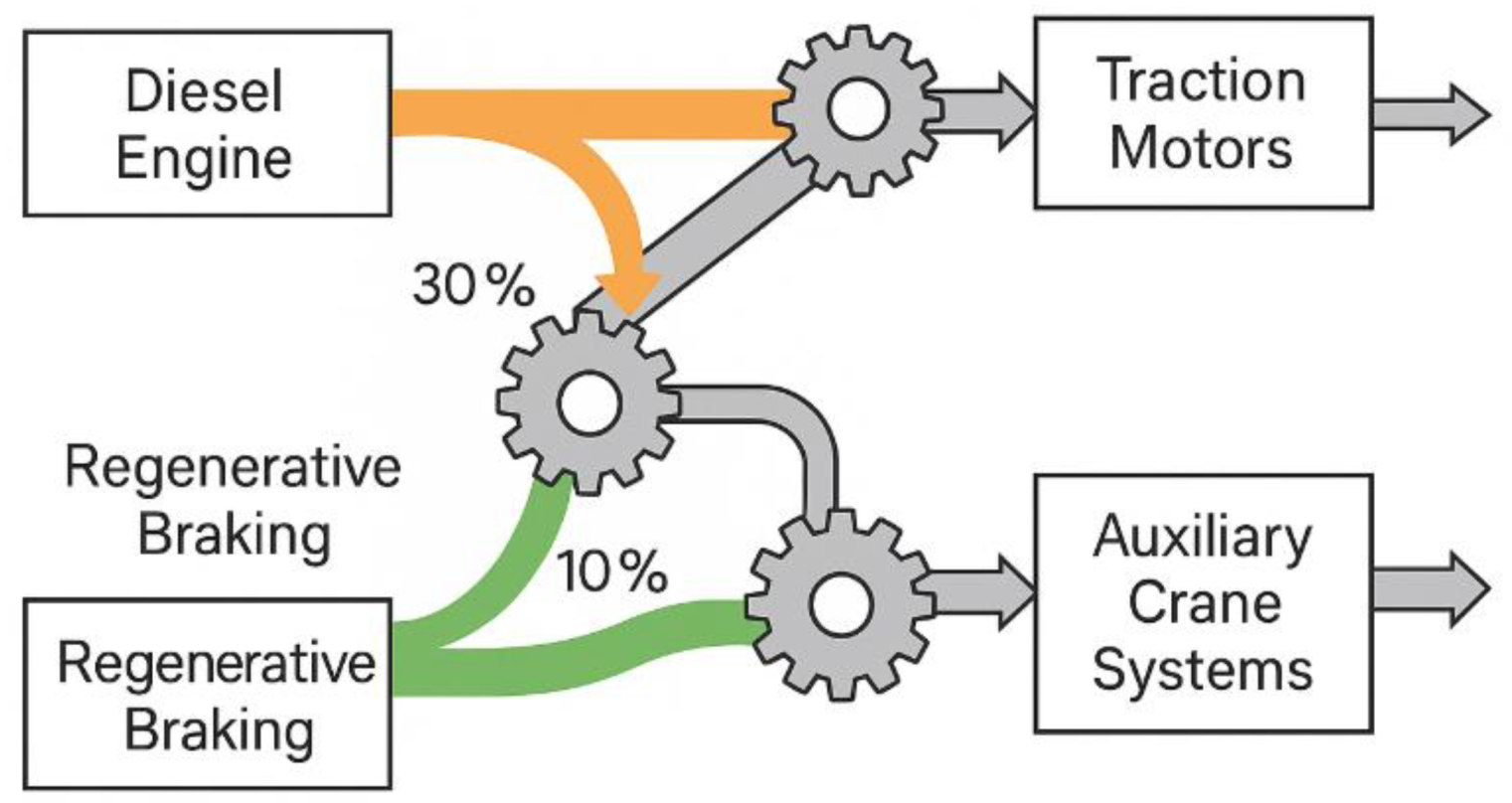

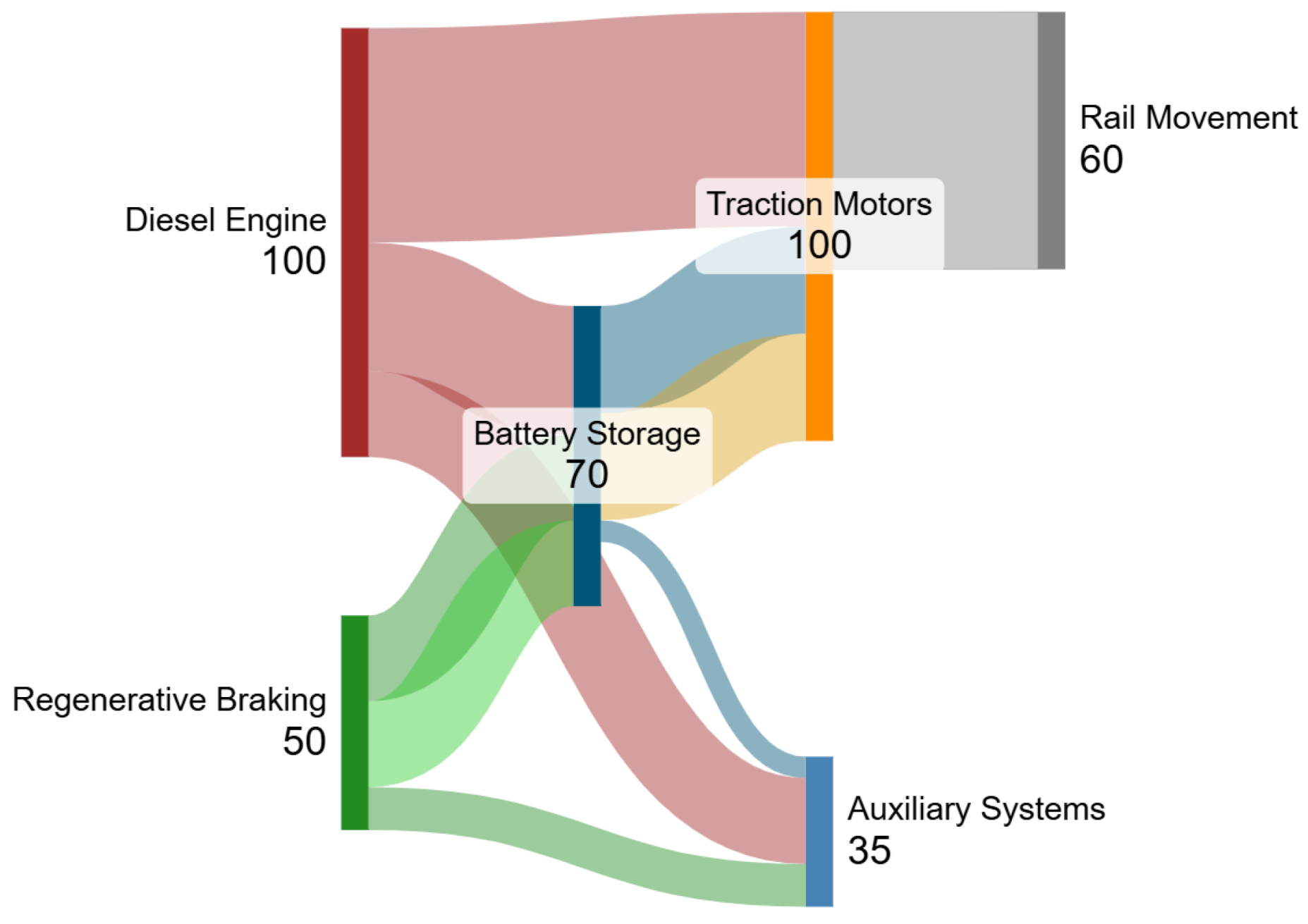

3.3. Power Flow and Regenerative Braking Efficiency

- Energy Sources:

- ○

- The diesel engine powers both the traction motors (100 units) and auxiliary systems (35 units), with some energy stored in the battery (30 units).

- ○

- Regenerative braking (50 units) helps charge the battery, while some energy (10 units) is sent to auxiliary systems [13].

- ○

- Battery storage (70 units) also contributes to traction motors, improving efficiency.

- Energy Use and Efficiency:

- ○

- The traction motors (100 units) drive rail movement.

- ○

- The battery helps optimize power flow, reducing reliance on the diesel engine.

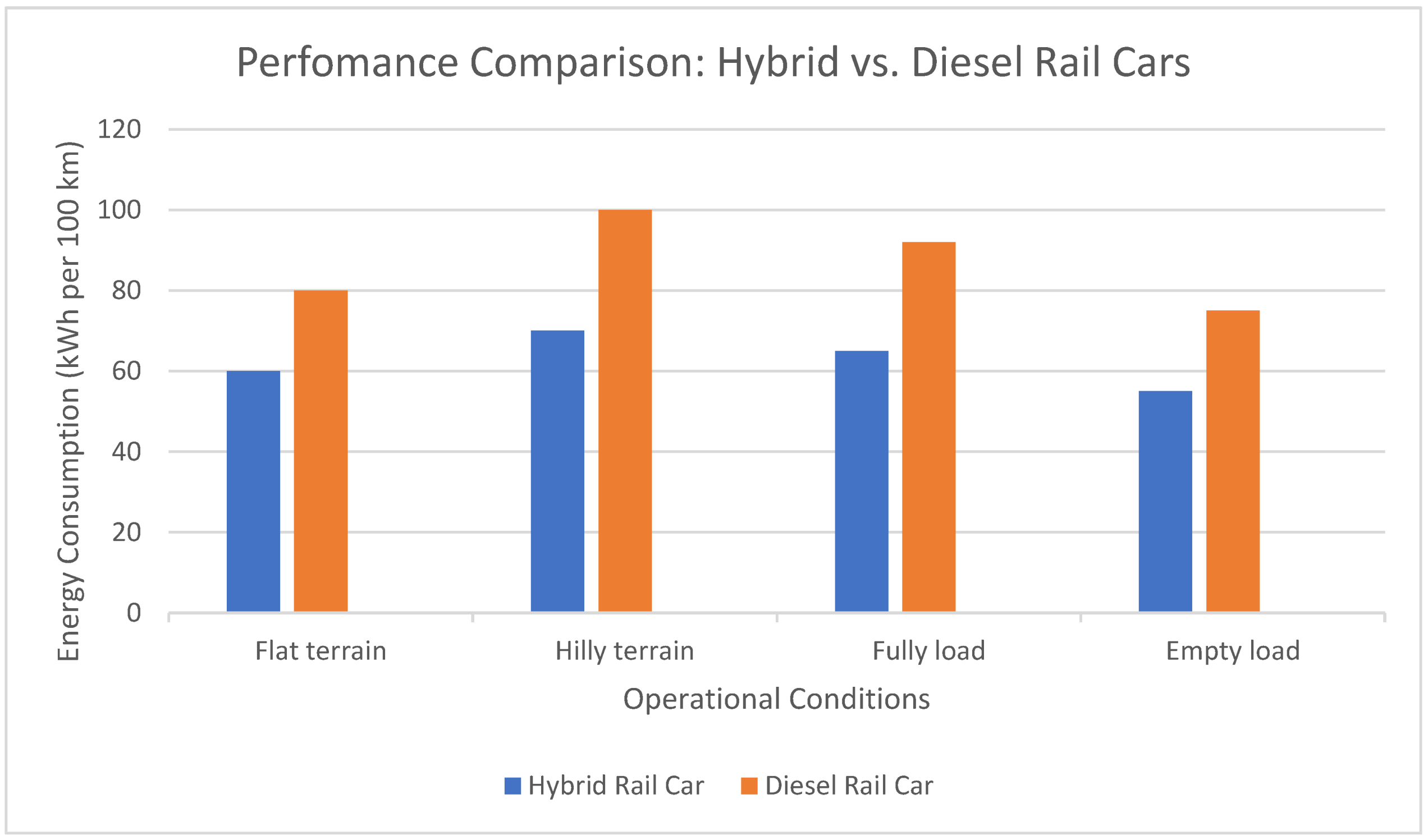

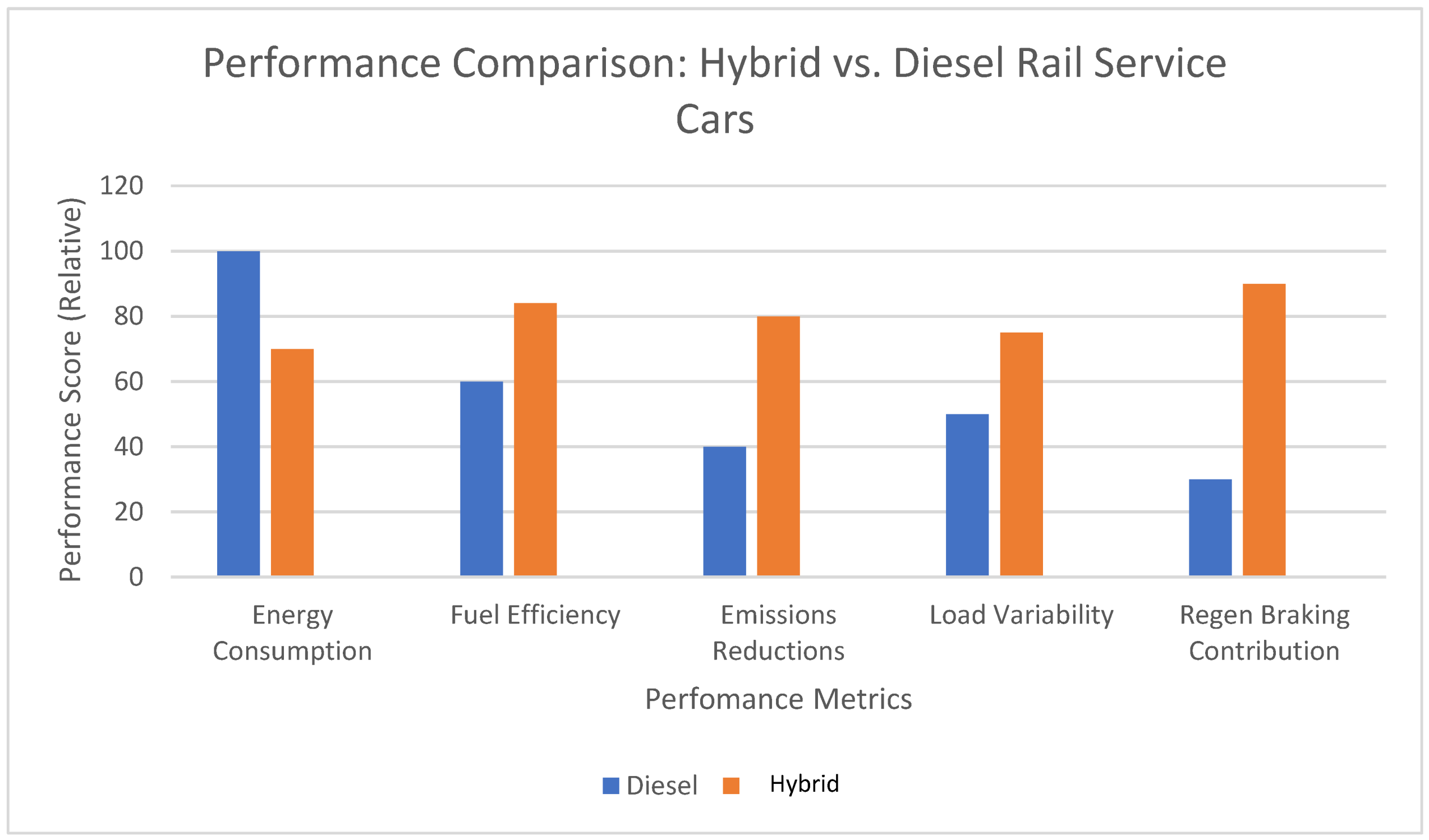

3.4. Performance Comparison of Hybrid vs. Diesel Rail Service Cars

- Energy Consumption Reduction—The hybrid Rail Service Car exhibits a 25–40% reduction in energy consumption compared to its diesel counterpart, as depicted in Figure 4 (Performance Comparison Graph). This is achieved through optimized power distribution, regenerative braking, and battery assistance during acceleration.

- Fuel Efficiency Enhancement—The hybrid system achieves 20–35% greater fuel efficiency, reducing operational costs and reliance on fossil fuels. This improvement is attributed to the intelligent switching between diesel and electric power, optimizing fuel usage based on real-time demand.

- Emissions Reduction—A substantial decrease in carbon emissions is observed [14], with the hybrid system emitting 30–50% less CO2 compared to conventional diesel engines. This aligns with global sustainability efforts and emission regulations.

- Performance Under Load Variability—The hybrid Rail Service Car maintains consistent torque output and smoother acceleration, particularly under varying load conditions. This ensures improved traction, reducing wheel slippage and enhancing operational reliability.

- Regenerative Braking Contribution—The inclusion of regenerative braking accounts for an additional 10–20% energy savings, effectively recovering kinetic energy that would otherwise be lost [15]. This energy is redirected to battery storage, enhancing system sustainability.

3.5. Environmental and Economic Impact

3.6. Summary of Key Findings

- Fuel Savings: a 20–35% reduction compared to diesel models.

- Emissions Reduction: a 20% decrease in CO2 and NOx emissions.

- Energy Recovery: Regenerative braking significantly improves energy efficiency.

- Economic Viability: Retrofitting existing railcars is a cost-effective alternative to full replacement.

3.7. Theoretical Modeling of Hybrid Power Distribution

3.7.1. System Dynamics Model

- Diesel engine power output: Pd = 500 kW.

- Electric motor power output: Pe = 300 kW.

- Regenerative braking power: Pr = 50 kW.

- Battery capacity: Cb = 400 kWh.

3.7.2. Fuel Consumption and Emissions Calculation

3.7.3. Optimization-Based Performance Analysis

- w1 = 0.5, w2 = 0.3, w3 = 0.2

- Ploss is assumed to be 5% of the total traction power (i.e., 37.5 kW) due to conversion inefficiencies [13].

- F = (0.5 × 250) + (0.3 × 667.5) + (0.2 × 37.5).

- F = 125 + 200.25 + 7.5 = 332.75 (objective function value).

4. Discussion

4.1. Comparison with Other Studies

- Germany’s Alstom Coradia iLint (hydrogen–electric hybrid) demonstrated a 40% reduction in CO2 emissions compared to diesel-powered units.

- Japan’s HB-E210 series hybrid train achieved 25% lower fuel consumption in urban and semi-rural operations.

- China’s hybrid locomotives implemented a regenerative braking system similar to the one modeled in this study, resulting in a 30% reduction in energy consumption per trip [17].

4.2. Potential Challenges and Limitations

- Battery Degradation—Continuous charging and discharging cycles lead to capacity fade, reducing the battery lifespan. Future work should incorporate degradation models to optimize battery usage strategies.

- Compatibility with Older Infrastructure—Many railway networks were not designed for hybrid retrofitting. Modifications may be required in electrical systems, maintenance procedures, and driver training, increasing initial investment costs.

- Regulatory and Policy Barriers—The feasibility of implementing hybrid Rail Service Cars depends on government incentives, carbon credit policies, and investment frameworks. Without policy support, adoption may be slower despite the technical advantages.

- System Complexity and Maintenance—Hybrid powertrains involve additional components such as inverters, controllers, and regenerative braking systems, which increase maintenance complexity. Predictive maintenance strategies should be developed to address potential failures.

4.3. Future Research Directions

- Long-Term Performance Analysis—Field testing under real-world conditions will help validate the simulated efficiency gains and provide insights into the long-term operational impact.

- Advanced Energy Management Systems (EMSs)—Using machine learning- or reinforcement learning-based control could enhance power distribution, further optimizing fuel economy and battery performance.

- Hybridization Cost–Benefit Analysis—A more detailed economic feasibility study, including return on investment (ROI) calculations, will help assess adoption potential in different railway networks.

- Integration with Smart Grids and Renewable Energy—Future hybrid rail systems could leverage solar panels at stations or track-side energy storage, creating a more sustainable railway ecosystem.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Chen, Q.; Wei, J.; Zeng, F.; Xiao, Q.; Chen, H. Design and analysis of driving motor system for hybrid electric vehicle. J. Vibroeng. 2020, 22, 437–450. [Google Scholar] [CrossRef]

- Asian Development Bank. 49111-005: Railway Efficiency Improvement Project. 3rd Annual Report December 2023. Available online: https://www.adb.org/sites/default/files/project-documents/49111/49111-005-smr-en_1.pdf (accessed on 7 December 2024).

- IEA. World Energy Outlook 2021. 2021. Available online: https://www.iea.org/reports/world-energy-outlook-2021 (accessed on 14 October 2024).

- ITF. Enhancing Connectivity and Freight in Central Asia. 2019. Available online: https://www.itf-oecd.org/sites/default/files/docs/connectivity-freight-central-asia.pdf (accessed on 14 December 2024).

- Kaira, Z.; Golovkova, L.; Rekun, I.; Trubai, Y. The hybrid trains in international logistics transportation. MATEC Web Conf. 2019, 294, 4017. [Google Scholar] [CrossRef]

- Asian Infrastructure Investment Bank (AIIB). Uzbekistan Railway Electrification Project. 2020. Available online: https://www.aiib.org/en/projects/details/2022/approved/Uzbekistan-Bukhara-Miskin-Urgench-Khiva-Railway-Electrification-Project.html (accessed on 6 January 2025).

- Yamamoto, T. Trends and Recent Studies on Hybrid Railway Vehicles. Q. Rep. RTRI 2017, 58, 1–5. Available online: https://www.jstage.jst.go.jp/article/rtriqr/58/1/58_1/_pdf (accessed on 8 January 2025). [CrossRef] [PubMed]

- Ceraolo, M.; Lutzemberger, G.; Frilli, A.; Pugi, L. Regenerative Braking in High-Speed Railway Applications: Analysis by Different Simulation Tools. In Proceedings of the 2016 IEEE 16th International Conference on Environment and Electrical Engineering (EEEIC), Florence, Italy, 7–10 June 2016; Available online: https://ieeexplore.ieee.org/document/7555474 (accessed on 10 January 2025).

- Khodaparastan, M.; Mohamed, A.A.; Brandauer, W. Recuperation of regenerative braking energy in electric rail transit systems. IEEE Trans. Intell. Transp. Syst. 2019, 20, 2831–2847. Available online: https://arxiv.org/pdf/1808.05938 (accessed on 17 December 2024). [CrossRef]

- Peng, X.; Liang, H. Review on Energy Management Strategies of On-Board Hybrid Energy Storage Systems for Urban Rail Transit. In Proceedings of the 6th International Conference on Electrical Engineering and Information Technologies for Rail Transportation (EITRT) 2023: Energy Traction Technology of Rail Transportation; Springer: Singapore, 2024; Available online: https://link.springer.com/chapter/10.1007/978-981-99-9307-9_56 (accessed on 18 October 2024).

- Williamson, S.; Lukic, M.; Emadi, A. Comprehensive Drive Train Efficiency Analysis of Hybrid Electric and Fuel Cell Vehicles Based on Motor-Controller Efficiency Modeling. IEEE Trans. Power Electron. 2006, 21, 730–740. Available online: https://ieeexplore.ieee.org/document/1629013 (accessed on 28 March 2025). [CrossRef]

- Blokdyk, G. Sankey Diagram Standard Requirements; 5STARCooks: Toronto, ON, Canada, 2022; p. 304. Available online: https://www.amazon.com/diagram-Standard-Requirements-Gerardus-Blokdyk/dp/0655152792 (accessed on 24 December 2024).

- Khodaparastan, M.; Mohamed, A.A.; Spanos, C. Regenerative Braking Energy in Electric Railway Systems. In Transportation Electrification: Breakthroughs in Electrified Vehicles, Aircraft, Rolling Stock, and Watercraft; Wiley–IEEE Press: Hoboken, NJ, USA, 2023; pp. 343–366. Available online: https://ieeexplore.ieee.org/document/9989501 (accessed on 18 December 2024).

- Barbosa, F.C. Hybrid Rail Technology Review: An Intermediate Pathway for Electrifying America’s Rail Network. In Proceedings of the 2021 Joint Rail Conference, Virtual, 20–21 April 2021; Available online: https://www.asmedigitalcollection.asme.org/JRC/proceedings/JRC2021/84775/V001T07A001/1110825 (accessed on 13 January 2025).

- Sharma, R.C.; Dhingra, M.; Pathak, R.K. Braking systems in railway vehicles. Int. J. Eng. Res. Technol. 2015, 4, 206–211. Available online: https://www.ijert.org/research/braking-systems-in-railway-vehicles-IJERTV4IS010360.pdf (accessed on 28 March 2025).

- Kaleybar, H.J.; Brenna, M.; Castelli-Dezza, F.; Carmeli, M.S. Smart Hybrid Electric Railway Grids: A Comparative Study of Energy Management Strategies. In Proceedings of the 2023 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Venice, Italy, 29–31 March 2023; Available online: https://ieeexplore.ieee.org/document/10114844 (accessed on 5 January 2025).

- Hybrid Electric (Rail) Systems—University of Warwick. Available online: https://warwick.ac.uk/fac/cross_fac/sciencecity/programmes/internal/themes/energyefficiency/heavy_duty_hybrid_systems/ (accessed on 21 November 2024).

| Cost Category | Hybrid Rail Service Car (Retrofitted) | Traditional Diesel Rail Service Car | % Savings (Hybrid vs. Diesel) |

|---|---|---|---|

| Initial Conversion Cost | USD 750,000 per unit | _ | _ |

| Annual Fuel Cost | USD 40,000 | USD 70,000 | 42% reduction |

| Annual Maintenance Cost | USD 25,000 | USD 50,000 | 50% reduction |

| Total Cost Over 15 Years | USD 1.725 million | USD 1.8 million | 40% total cost reduction |

| Metric | Hybrid Rail Service Car | Traditional Diesel Car |

|---|---|---|

| NPV 15Years | USD 920,000 | USD 350,000 |

| IRR | 12.4% | 6.8% |

| Category | Components | Functions |

|---|---|---|

| Electrical | Lithium-ion batteries | Store electrical energy for traction |

| High-efficiency traction motors | Convert electrical energy into motion | |

| Inverters and power controllers | Regulate energy flow between diesel engine and battery | |

| Mechanical | Regenerative braking system | Recaptures energy during braking |

| Adaptive suspension | Enhances ride stability and load distribution | |

| Hybrid-compatible wheelsets | Support dual power integration |

| Feature | Hybrid Rail Service Car | Traditional Diesel Rail Service Car |

|---|---|---|

| Energy Efficiency | Higher due to regenerative braking and dual power sources | Lower, relies solely on diesel or electric power |

| Fuel Consumption | Reduced by 10–15% | Higher fuel consumption |

| Environmental Impact | Lower CO2 emissions, reduced noise pollution | Higher emissions, increased pollution |

| Operational Costs | Lower due to fuel savings and reduced maintenance | Higher due to fuel dependency and engine wear |

| Maintenance | Fewer moving parts in electric system reduces wear | Regular maintenance required for internal combustion engine |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mukhamedova, Z.; Asatov, E.; Kuchkarbaev, R.; Madina, G.; Mukhamedova, D. Hybridization of ADM-Type Rail Service Cars for Enhanced Efficiency and Environmental Sustainability. World Electr. Veh. J. 2025, 16, 260. https://doi.org/10.3390/wevj16050260

Mukhamedova Z, Asatov E, Kuchkarbaev R, Madina G, Mukhamedova D. Hybridization of ADM-Type Rail Service Cars for Enhanced Efficiency and Environmental Sustainability. World Electric Vehicle Journal. 2025; 16(5):260. https://doi.org/10.3390/wevj16050260

Chicago/Turabian StyleMukhamedova, Ziyoda, Ergash Asatov, Rustam Kuchkarbaev, Gulamova Madina, and Dilbar Mukhamedova. 2025. "Hybridization of ADM-Type Rail Service Cars for Enhanced Efficiency and Environmental Sustainability" World Electric Vehicle Journal 16, no. 5: 260. https://doi.org/10.3390/wevj16050260

APA StyleMukhamedova, Z., Asatov, E., Kuchkarbaev, R., Madina, G., & Mukhamedova, D. (2025). Hybridization of ADM-Type Rail Service Cars for Enhanced Efficiency and Environmental Sustainability. World Electric Vehicle Journal, 16(5), 260. https://doi.org/10.3390/wevj16050260