Research on Active Avoidance Control of Intelligent Vehicles Based on Layered Control Method

Abstract

1. Introduction

1.1. State of Path Planning Research

1.2. State of Path Tracking Research

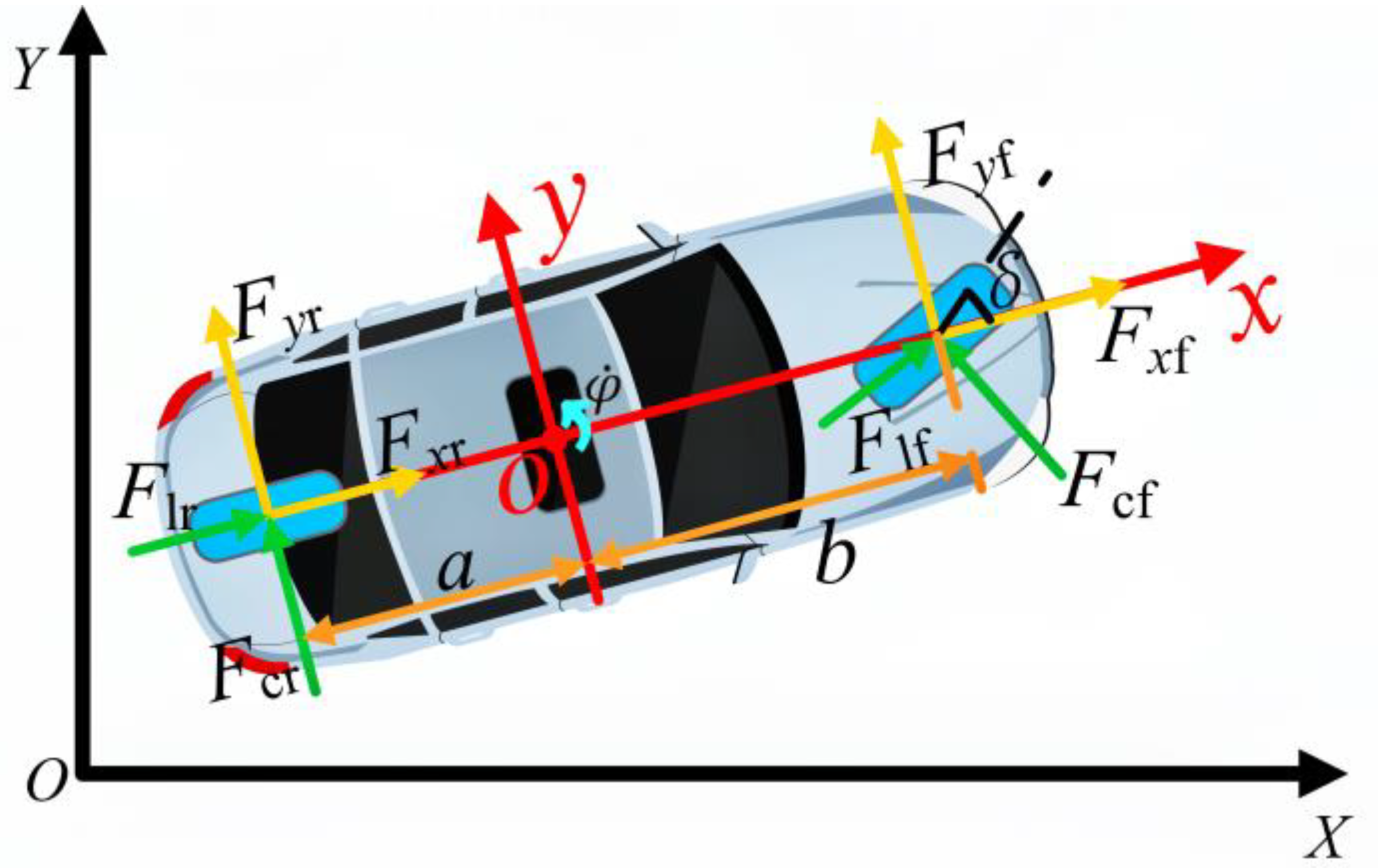

2. Vehicle and Tire Model

2.1. Three-Degree-of-Freedom Vehicle Dynamics Model

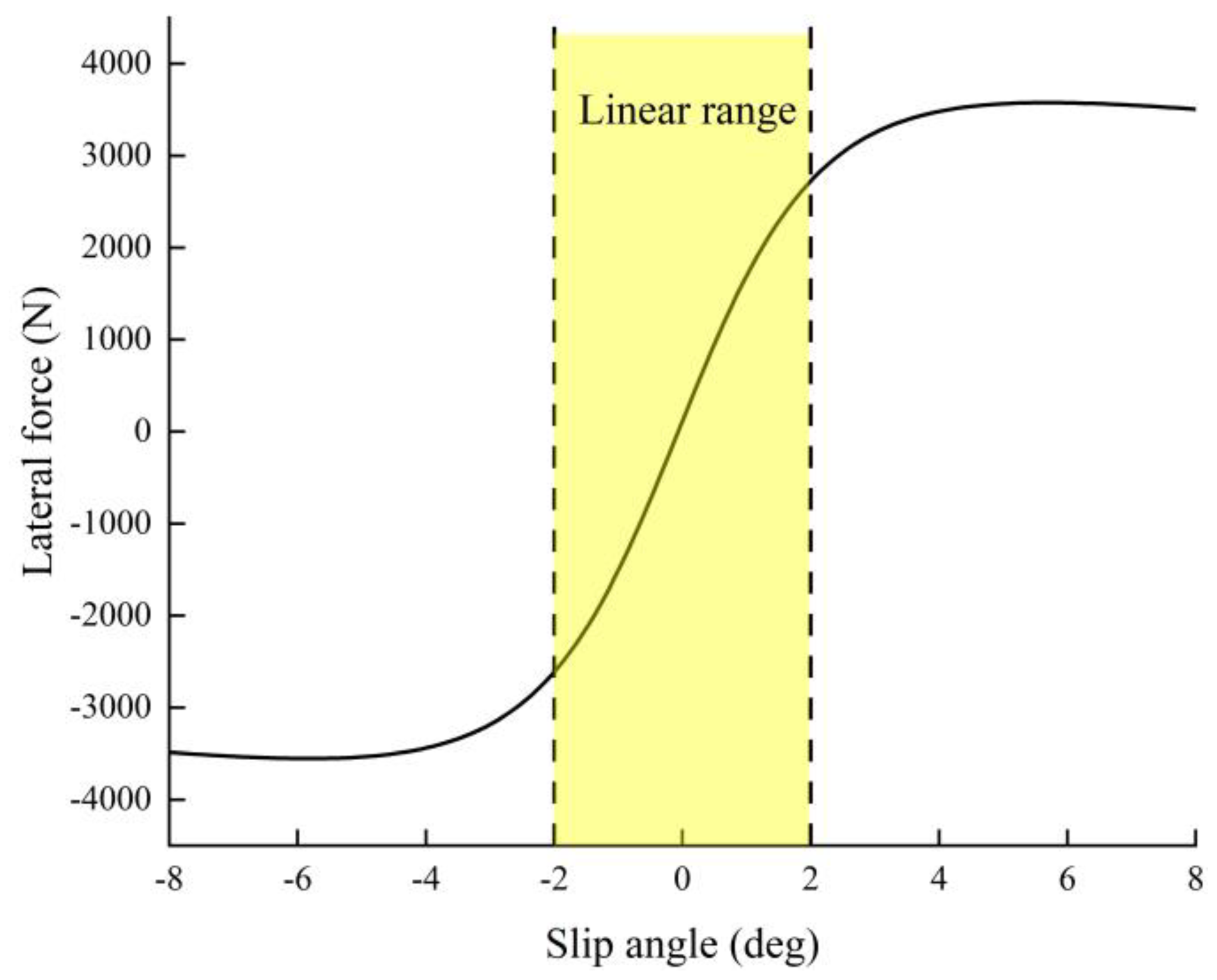

2.2. Magic Formula Tire Model

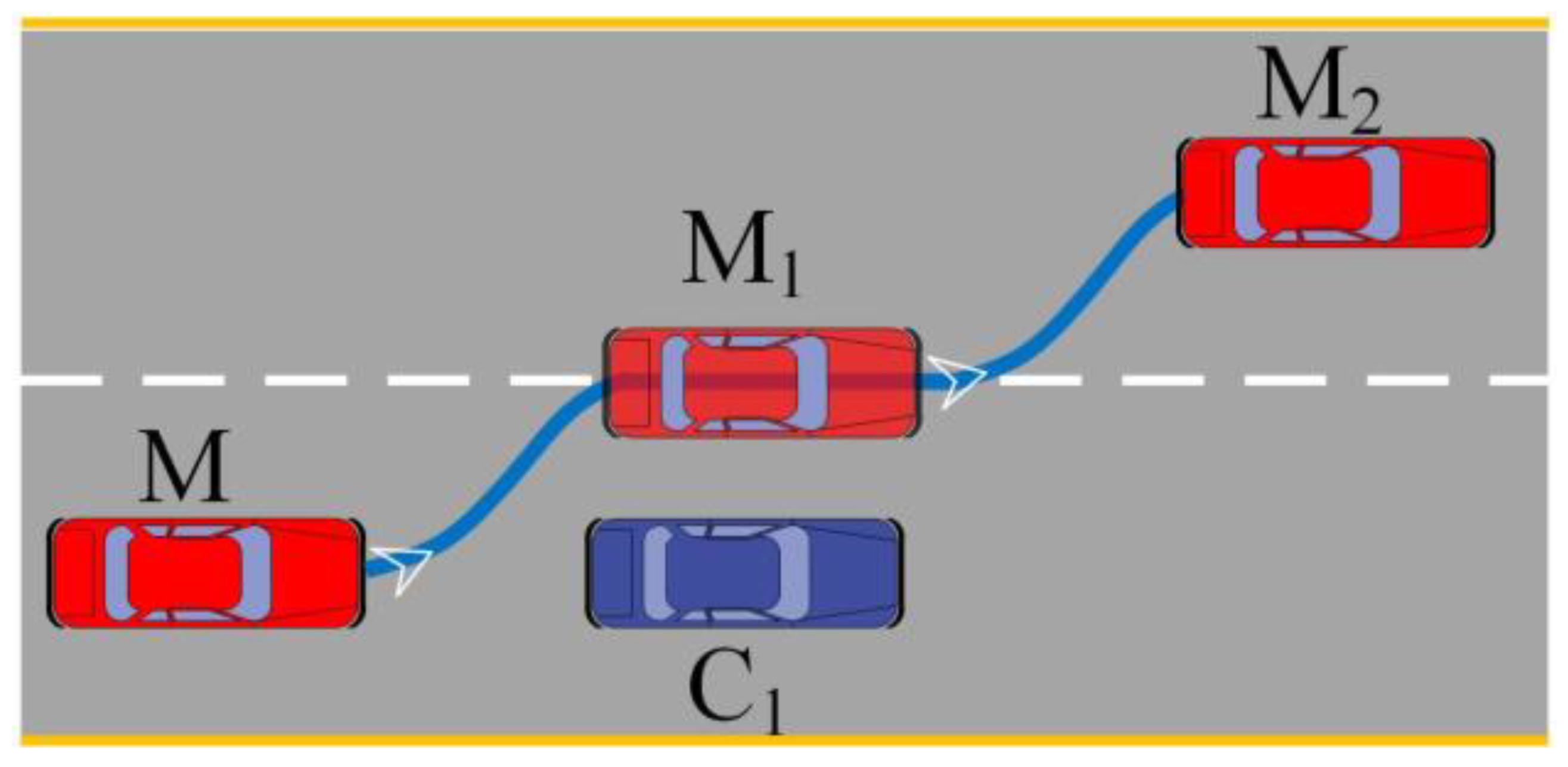

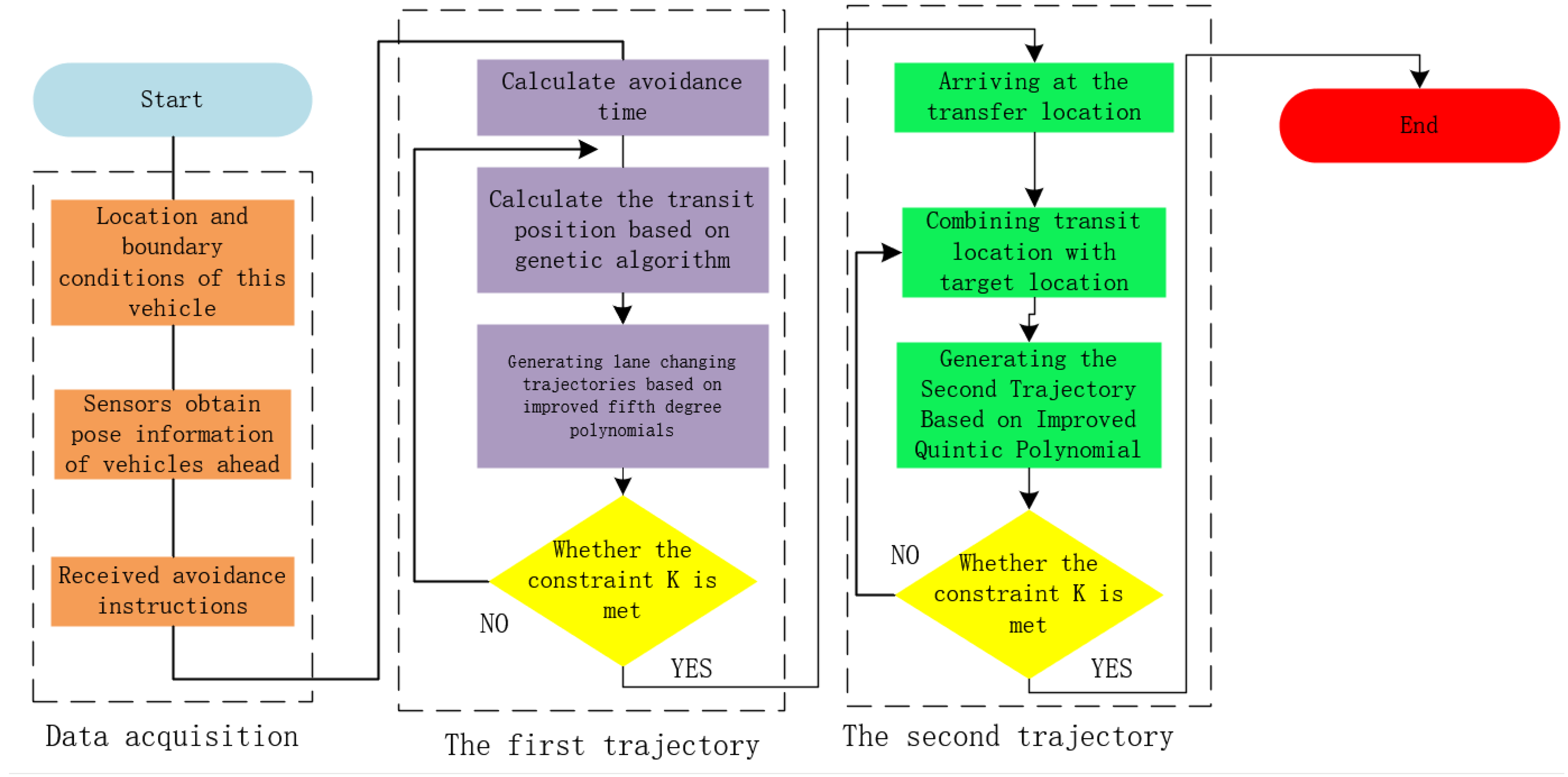

3. Double Quintic Polynomial Path Planning Incorporating Genetic Algorithms

3.1. Estimated Time of Avoidance

3.1.1. Traffic Vehicle Stationary

3.1.2. Traffic Vehicles from Stationary to Motion

3.1.3. Uniform Motion of Traffic Vehicles

3.1.4. Transit Vehicle Variable Speed Motion

3.2. Double Quintuple Polynomial Avoidance Path Planning

3.2.1. Vehicle Status Setting

3.2.2. Constraint Establishment

- (1)

- Setting the longitudinal and lateral acceleration constraints for two-lane change trajectories

- (2)

- Adding acceleration constraints

- (3)

- Maximum longitudinal displacement constraint

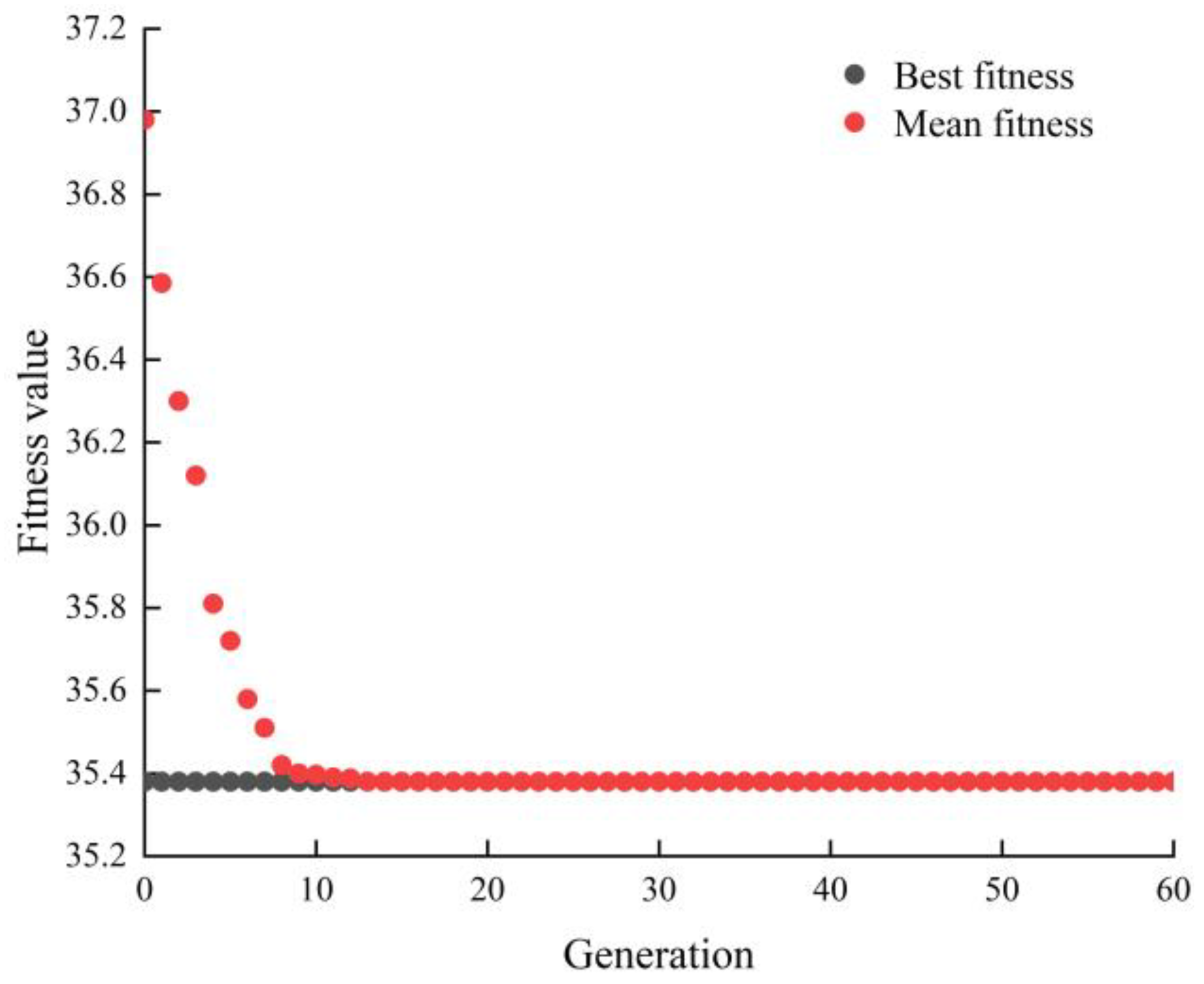

3.3. Genetic Algorithm Objective Function Solution

3.4. Evaluation Function Design

4. Path Tracking

4.1. MPC Principles

4.2. Objective Function Design

4.3. Constraint Establishment

- (1)

- Center-of-mass lateral deflection constraints.

- (2)

- Pavement adhesion coefficient constraints.

- (3)

- Tire side deflection constraints.

4.4. Simulation of Path Tracking and Result Analysis

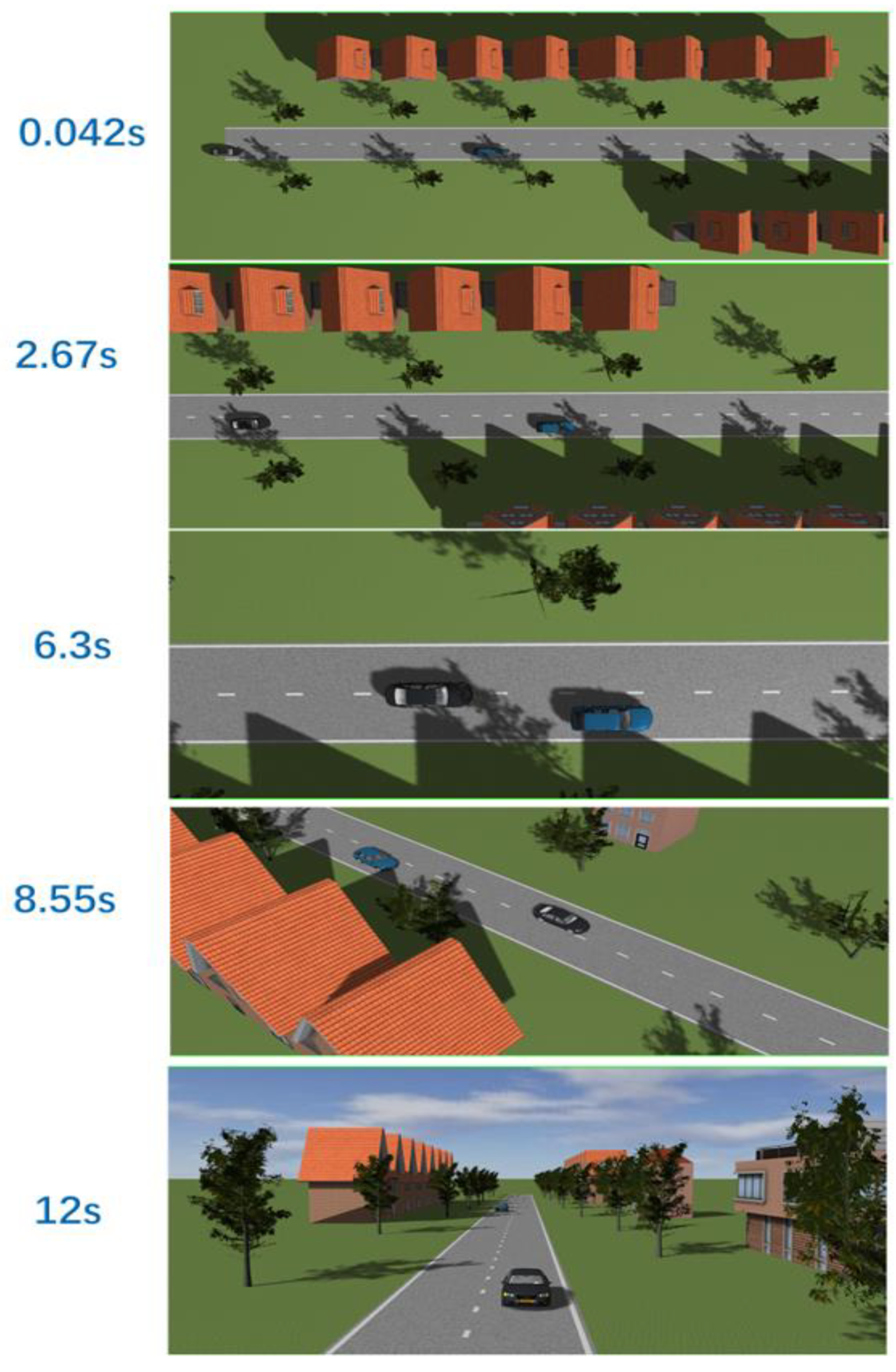

5. Simulation Verification

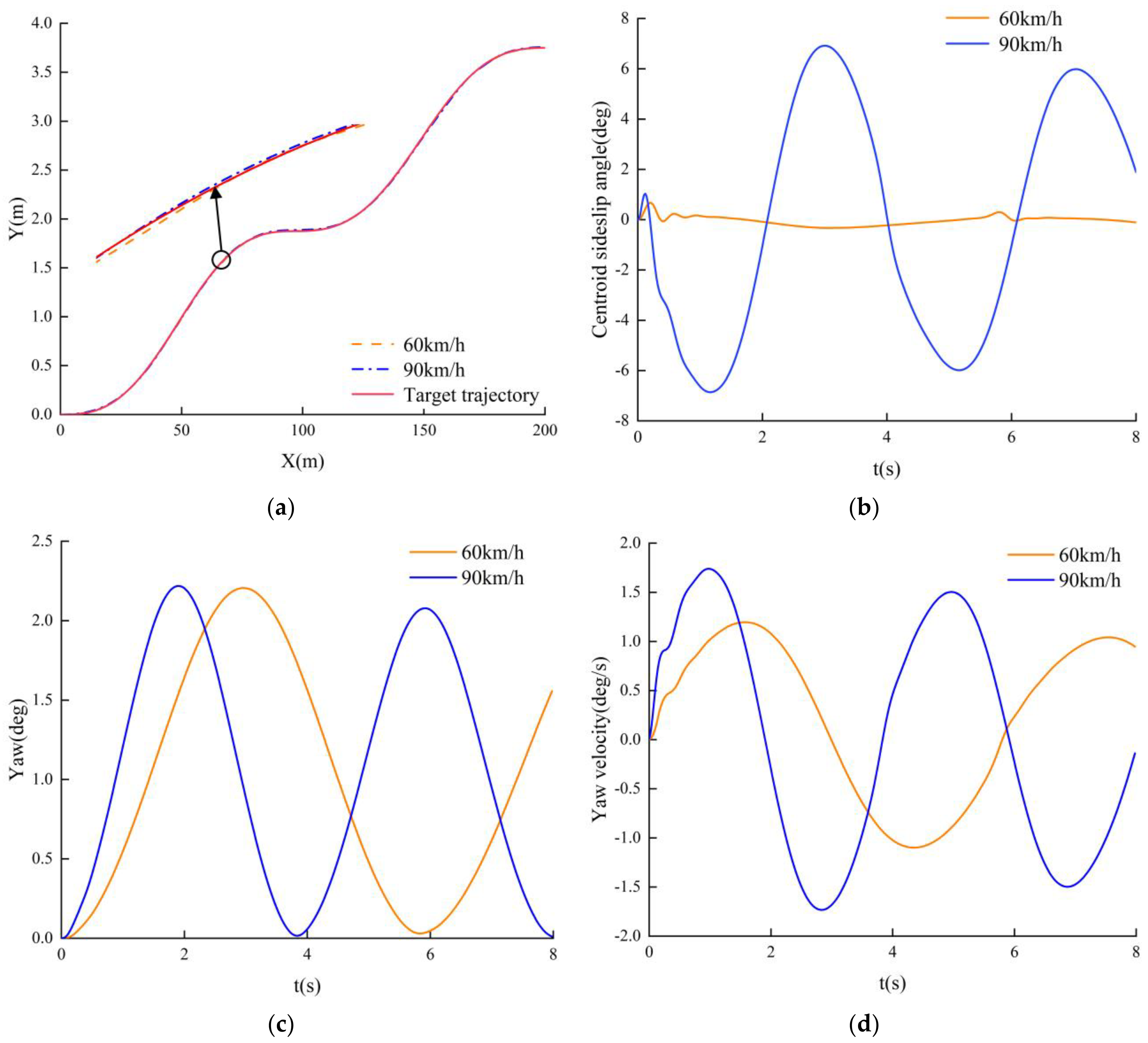

5.1. Effect of Vehicle Speed on the Controller

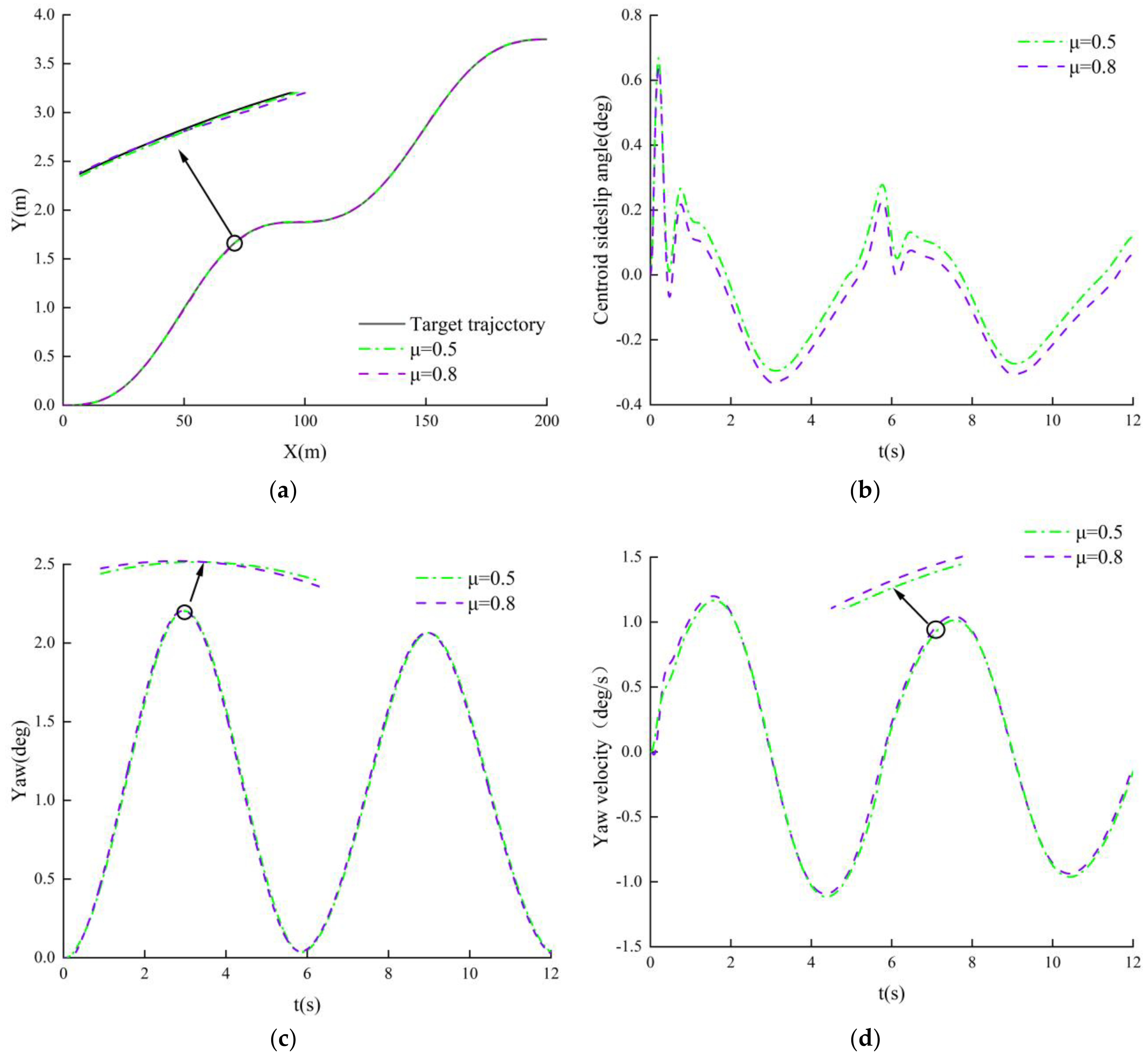

5.2. Influence of the Road Surface Adhesion Coefficient on the Controller

6. Conclusions

- (1)

- The scheme is feasible to control the active avoidance of intelligent vehicles using hierarchical control.

- (2)

- The double quintic polynomial avoidance algorithm designed by integrating a genetic algorithm converts the avoidance path planning problem into a nonlinear planning problem and solves the optimal avoidance path by genetic algorithm under the satisfaction of boundary conditions as well as constraints. Simulation results show that the designed avoidance algorithm has high real-time and robustness.

- (3)

- An MPC path tracking controller is designed based on intelligent vehicles and a predefined path. The objective function and controller constraints are formulated according to the dynamic requirements of intelligent vehicles, while the preview step size and sampling period in MPC are adjusted in real time. Simulation results demonstrate that the trajectory tracking controller improves tracking accuracy while ensuring vehicle stability [41]. Moreover, it exhibits good adaptability and stability under varying vehicle speeds and road adhesion conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- An, L.; Chen, T.; Cheng, A.; Fang, W. A simulation on the path planning of intelligent vehicles based on artificial potential field algorithm. Automot. Eng. 2017, 39, 1451–1456. [Google Scholar]

- Hu, Y.; Qu, T.; Liu, J.; Shi, Z.Q.; Zhu, B.; Cao, D.P.; Chen, H. Human-machine cooperative control of intelligent vehicle: Recent developments and future perspectives. Acta Autom. Sin. 2019, 45, 1261–1280. [Google Scholar]

- Zha, Y.; Yu, M.; Ma, F.; Zheng, X. Research on path tracking for intelligent driving vehicle based on steering-by-wire. Automob. Technol. 2021, 7–13. [Google Scholar] [CrossRef]

- Wei, T.; Chen, L. Path planning for mobile robot based on improved genetic algorithm. J. Beijing Univ. Aeronaut. Astronaut. 2020, 46, 703–711. [Google Scholar]

- Zheng, H.; Feng, G.; Pu, W.; Xu, M. Global Path Planning in a Closed Environment Based on the DijkstraAlgorithm. Automot. Pract. Technol. 2023, 48, 7–11. [Google Scholar] [CrossRef]

- Ren, B.; Wang, X.; Deng, W.; Nan, J.; Zong, R.; Ding, J. Path optimization algorithm for automatic parking based on hybrid A* and reeds-shepp curve with variable radius. China J. Highw. Transp. 2022, 35, 317–327. [Google Scholar]

- Ren, X. Research on Path Planning of Self-Driving Vehicle Based on Improved RRT Algorithm. Master’s Thesis, Chang’an University, Xi’an, China, 2021. [Google Scholar]

- Yu, Z.; Li, Y.; Xiong, L. A Review of Motion Planning Algorithms for Autonomous Vehicles. J. Tongji Univ. (Nat. Sci. Ed.) 2017, 45, 1150–1159. [Google Scholar]

- Zhou, W.; Guo, X.; Pei, X.; Zhang, Z.; Yu, J. Study on path planning and tracking control for intelligent vehicle based on RRT and MPC. Automot. Eng. 2020, 42, 1151–1158. [Google Scholar]

- Du, M.; Mei, T.; Chen, J.; Zhao, P.; Liang, H.; Huang, R.; Tao, X. RRT-based motion planning algorithm for intelligent vehicle in complex environments. Robot 2015, 37, 443–450. [Google Scholar]

- Arab, A.; Yu, K.; Yi, J.; Song, D. Motion planning for aggressive autonomous vehicle maneuvers. In Proceedings of the 2016 IEEE International Conference on Automation Science and Engineering (CASE), Fort Worth, TX, USA, 21–25 August 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 221–226. [Google Scholar]

- Li, X.; An, H. Research on Path Planning for Unmanned Delivery Vehicles Based on Genetic Algorithm. Logist. Technol. 2024, 47, 4–7. [Google Scholar] [CrossRef]

- Li, Z.; Jia, Y.; Jiang, X. Research on Mobile Robot Path Planning Based on Improved Genetic Algorithm. Mod. Inf. Technol. 2024, 8, 180–183+188. [Google Scholar] [CrossRef]

- Wang, X.; Shi, H.; Zhang, C. Path planning for intelligent parking system based on improved ant colony optimization. IEEE Access 2020, 8, 65267–65273. [Google Scholar] [CrossRef]

- Han, G.; Fu, W.; Wang, W. The study of intelligent vehicle navigation path based on behavior coordination of particle swarm. Comput. Intell. Neurosci. 2016, 2016, 6540807–6540817. [Google Scholar] [CrossRef]

- Li, H.; Luo, Y.; Wu, J. Collision-free path planning for intelligent vehicles based on Bézier curve. IEEE Access 2019, 7, 123334–123340. [Google Scholar] [CrossRef]

- Ghariblu, H.; Moghaddam, H.B. Trajectory planning of autonomous vehicle in freeway driving. Transp. Telecommun. J. 2021, 22, 278–286. [Google Scholar] [CrossRef]

- Chen, L.; Qin, D.; Xu, X.; Cai, Y.; Xie, J. A path and velocity planning method for lane changing collision avoidance of intelligent vehicle based on cubic 3-D Bezier curve. Adv. Eng. Softw. 2019, 132, 65–73. [Google Scholar] [CrossRef]

- Niu, G.; Li, W.; Wei, H. Intelligent vehicle lane changing trajectory planning based on double quintic polynomials. Automot. Eng. 2021, 43, 978–986+1004. [Google Scholar]

- Sun, Y. Quantitative Evaluation of Intelligence Levels for Unmanned Ground Vehicles. Master’s Thesis, Beijing Institute of Technology, Beijing, China, 2014. [Google Scholar]

- Yao, Q.; Tian, Y.; Wang, Q.; Wang, S. Control Strategies on Path Tracking for Autonomous Vehicle: State of the Art and Future Challenges. IEEE Access 2020, 8, 161211–161222. [Google Scholar] [CrossRef]

- Carlucho, I.; De Paula, M.; Acosta, G.G. An adaptive deep reinforcement learning approach for MIMO PID control of mobile robots. ISA Trans. 2020, 102, 280–294. [Google Scholar] [CrossRef]

- Nie, X.; Xiong, Y.; Pan, Y. Multi-condition co-simulations of vehicle stability control via fuzzy pid algorithm. J. Dyn. Control 2021, 19, 46–52. [Google Scholar]

- Wang, X.; Ling, M.; Rao, Q.; Liu, C.; Zhai, S. Research on fusion algorithm of unmanned vehicle path tracking based on improved stanley algorithm. Automob. Technol. 2022, 7, 25–31. [Google Scholar]

- Amer, N.H.; Hudha, K.; Zamzuri, H.; Aparow, V.R.; Abidin, A.F.Z.; Kadir, Z.A.; Murrad, M. Adaptive modified Stanley controller with fuzzy supervisory system for trajectory tracking of an autonomous armoured vehicle. Robot. Auton. Syst. 2018, 105, 94–111. [Google Scholar] [CrossRef]

- Sun, Y.; Dai, Q.; Liu, J.; Zhao, X.; Guo, H. Intelligent vehicle path tracking based on feedback linearization and LOR under extreme conditions. In Proceedings of the 2022 41st Chinese Control Conference (CCC), Hefei, China, 25–27 July 2022; pp. 5383–5389. [Google Scholar]

- Zhang, J.; Yang, M.; Chen, Y.D.; Li, H.; Chen, N.; Zhang, Y. Research on Sliding Mode Control for Path Following in Variable Speed of Unmanned Vehicles. Optim. Eng. 2025, 1–28. [Google Scholar] [CrossRef]

- Xie, X.; Wang, Y.; Jin, L.; Guo, B.; Wei, Q.; He, Y. MPC Trajectory Tracking Control Based on Changing Control Time-Step Length. J. Jilin Univ. (Eng. Ed.) 2022, 1–10. [Google Scholar] [CrossRef]

- Guirguis, J.M.; Hammad, S.; Maged, S.A. Path tracking control based on an adaptive MPC to changing vehicle dynamics. Int. J. Mech. Eng. Robot. Res. 2022, 11, 535–541. [Google Scholar] [CrossRef]

- Wang, Y.; Cai, Y.; Chen, L.; Wang, H.; Li, J.; Chu, X. Design of a Path Tracking Controller for Intelligent Vehicles Based on Model Predictive Control. Automot. Technol. 2017, 10, 44–48. [Google Scholar] [CrossRef]

- Li, S.; Zhang, M. Research on Lane Change Path Planning for Intelligent Vehicles Based on Dual Quintic Polynomials. J. Nanjing Univ. Inf. Sci. Technol. 2024, 16, 155–163. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, Y.; Jiang, S.; Han, Y. Trajectory Planning and Tracking Control for Autonomous Overtaking on Highways. J. Automot. Saf. Energy 2022, 13, 463–472. [Google Scholar]

- Liang, C.; Li, Y.; Li, Z.; Shen, Z. Dynamic Performance Research of the Magic Formula Tire Model. Automot. Pract. Technol. 2020, 45, 116–119. [Google Scholar] [CrossRef]

- Gong, J.; Jiang, Y.; Xu, W. Model Predictive Control for Self-Driving Vehicles; Beijing Institute of Technology Press: Beijing, China, 2014. [Google Scholar]

- Nam, H.; Choi, W.; Ahn, C. Model predictive control for evasive steering of an autonomous vehicle. Int. J. Automot. Technol. 2019, 20, 1033–1042. [Google Scholar] [CrossRef]

- Li, G. Vehicle Obstacle Avoidance Path Planning and Tracking Based on Model Predictive Control. Automot. Pract. Technol. 2024, 49, 49–54. [Google Scholar] [CrossRef]

- Gu, X.; Li, J. Path Tracking Control Method for Autonomous Vehicles. Automot. Eng. 2019, 264, 11–14. [Google Scholar]

- Lu, Y. Study on PreScan/CarSim/Simulink Combined Simulation Method. J. Jiamusi Univ. (Nat. Sci. Ed.) 2020, 38, 118–121. [Google Scholar]

- Zhu, B.; Zhang, P.; Liu, B.; Zhao, J.; Sun, Y. Safety Evaluation Method for Autonomous Vehicles Based on Natural Driving Data. China J. Highw. Transp. 2022, 35, 283–291. [Google Scholar]

- Zhang, L.; Liu, M.; Liu, Z.; Xie, L. Joint Simulation Study of Vehicle Adaptive Cruise Control System. Mech. Des. Manuf. 2022, 69–72+77. [Google Scholar] [CrossRef]

- Du, R.; Hu, H.; Gao, K.; Huang, H. Research on Trajectory Tracking Control for Autonomous Vehicles Based on Variable Prediction Horizon MPC. J. Mech. Eng. 2022, 58, 275–288. [Google Scholar]

| Vehicle Speed (m/s) | Vehicle Acceleration (m/s2) | Distance Between This Vehicle and Traffic (m) | Traffic Vehicle Speed (m/s) | Traffic Vehicle Acceleration (m/s2) | First Avoidance Time (s) | Staging Post (m) |

|---|---|---|---|---|---|---|

| 17 | 0 | 40 | 0 | 0 | 2.1177 | 35.38 |

| 17 | −2 | 40 | 0 | 0 | 2.52 | 36.17 |

| 17 | 0 | 40 | 12 | 0 | 7.2 | 109.94 |

| 17 | 0 | 40 | 18 | −2 | 6.01785 | 95.83 |

| 23 | 0 | 40 | 18 | −2 | 3.87 | 85.46 |

| Parameter | Value | Unit |

|---|---|---|

| Vehicle mass | 1723 | kg |

| Vehicle length | 4 | m |

| Vehicle width | 1.9 | m |

| Center of mass height | 0.54 | m |

| Front Tire Cornering Stiffness | 66,900 | N·rad−1 |

| Rear Tire Cornering Stiffness | 62,700 | N·rad−1 |

| Distance from front wheel to center of mass | 1.232 | m |

| Distance from the rear wheel to the center of mass | 1.468 | m |

| Moment of inertia around the z-axis | 4175 | Kg·m2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Li, Q.; Ma, Q. Research on Active Avoidance Control of Intelligent Vehicles Based on Layered Control Method. World Electr. Veh. J. 2025, 16, 211. https://doi.org/10.3390/wevj16040211

Wang J, Li Q, Ma Q. Research on Active Avoidance Control of Intelligent Vehicles Based on Layered Control Method. World Electric Vehicle Journal. 2025; 16(4):211. https://doi.org/10.3390/wevj16040211

Chicago/Turabian StyleWang, Jian, Qian Li, and Qiyuan Ma. 2025. "Research on Active Avoidance Control of Intelligent Vehicles Based on Layered Control Method" World Electric Vehicle Journal 16, no. 4: 211. https://doi.org/10.3390/wevj16040211

APA StyleWang, J., Li, Q., & Ma, Q. (2025). Research on Active Avoidance Control of Intelligent Vehicles Based on Layered Control Method. World Electric Vehicle Journal, 16(4), 211. https://doi.org/10.3390/wevj16040211