1. Introduction

Climate change poses significant risks to people and the environment, emphasizing the need for prompt action to mitigate its impact. A key to address this challenge is to reduce greenhouse gas (GHG) emissions across all industries. In 2023, the transport sector alone was responsible for approximately 8 Gt CO

2eq GHG emissions, corresponding to about 15% of the total global GHG emissions [

1]. Of these, approximately 426 Mt CO

2eq were generated by the aviation sector, with an increase of 23% relative to the year 2021 [

1]. Although this currently accounts for only 3% of the current global GHG emissions, projections indicated that emissions could triple by the year 2050 if current fuels remain in use as a result of increased air traffic [

2]. To address these challenges, current research is focusing on the transition of the aviation sector toward more sustainable propulsion technologies. A promising approach is the use of hydrogen fuel cells, which offer high gravimetric energy density and rapid refueling times [

3]. However, their adoption faces significant challenges, such as the space constraints of high-pressure hydrogen storage systems and the limited power density of fuel cells, which affect their suitability for high-velocity, long-range aviation. An alternative is the employment of sustainable aviation fuels (SAFs), such as plant-based biofuels, synthetic fuels, and hydrogenated vegetable oils (HVO) [

4]. These fuels are already employed together with conventional jet fuels in existing commercial aircraft. However, current SAF production is limited to less than 1% of global aviation fuel demand, with challenges including high production costs and feedstock availability [

4]. Finally, electric aviation is gaining traction for short-haul and urban air mobility applications, thanks to advancements in lithium-ion battery (LIB) technology, which provides high power density [

5].

In recent years, this has opened the door to a new generation of electric aircraft, such as drones and light sport aircraft, and spurred the development of new types of vehicles, such as electric vertical take-off and landing aircraft (eVTOL). Similarly to helicopters, eVTOLs are able to depart and land vertically in limited spaces [

6], while causing much less noise and air pollution. These features make them well suited for applications such as air taxis, agriculture or emergency medical vehicles [

6]. Additionally, eVTOLs can travel up to 6 times faster than terrestrial vehicles [

7], offering a valid solution to alleviate traffic congestion in urban and metropolitan areas [

8]. This use case is known as urban air mobility (UAM) [

9]. A practical example of this use case is demonstrated by Joby Aviation, which envisions using eVTOLs to connect New York JFK Airport to central Manhattan in just 7 min, compared to a 49-min car journey (More information available at

https://www.jobyaviation.com/, accessed on 3 February 2025).

Currently, several global original equipment manufacturers (OEMs) are actively developing eVTOLs. Despite their progress, eVTOL design presents several challenges, especially due to the strict requirements on battery performance. High battery capacity is required to enable long-distance flight, while high power output is needed for the take-off and landing phases. These demands, coupled with the limited available space aboard the aircraft, mean that batteries with high gravimetric energy density and power density are needed to make eVTOL flight feasible. Furthermore, batteries must meet specific safety regulations, which are very strict compared to those for electric vehicle (EV) batteries [

8], as outlined by organizations such as the European Aviation Safety Agency (EASA) [

10].

Although high-performance batteries are crucial for eVTOL design, there is only limited research addressing the specific battery requirements for this specific application. For example, [

11] provides an overview of battery chemistries suited for electric aviation. However, it does not address the specific requirements of eVTOLs. The study compares LIBs with nickel–cadmium (Ni–Cd) and lead-acid batteries, both of which are no longer widely used in most mobility application. Additionally, the analysis overlooks the significant performance differences among various LIB chemistries. In [

8], battery requirements for eVTOLs are identified and experimental tests are conducted on two LIB cells. However, this study mainly emphasizes fast charging capabilities, whereas other important performance metrics, such as the gravimetric energy density, are overlooked. Similarly, [

12] describes some key performance metrics for eVTOL batteries. However, the study does not clarify explicit minimum threshold values for the gravimetric energy density and power density to enable eVTOL flight. Additionally, it does not provide simulation or experimental data about the battery performance during flight to support the findings. Likewise, [

13] highlights the limitations of existing electrochemical energy storage systems for eVTOL but fails to specify any requirement for this application. This clear lack of guidelines highlights a gap in the current research and complicates the selection of optimal battery chemistries for this application, making it also challenging to identify suitable emerging technologies to enhance eVTOL performance.

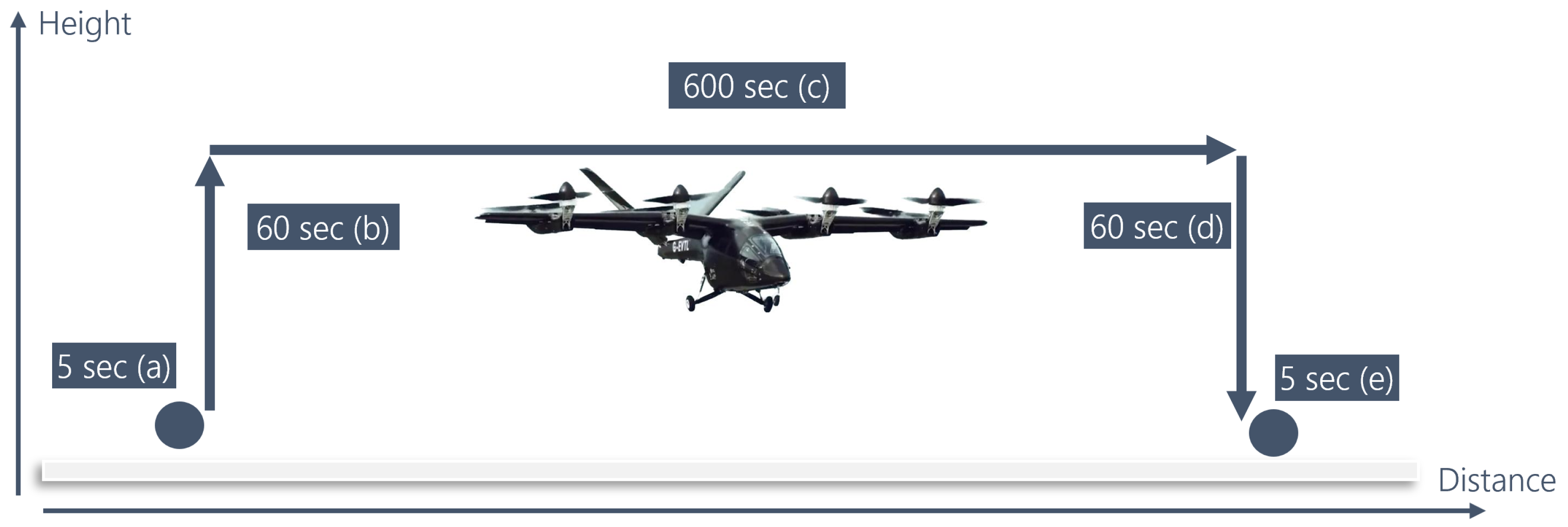

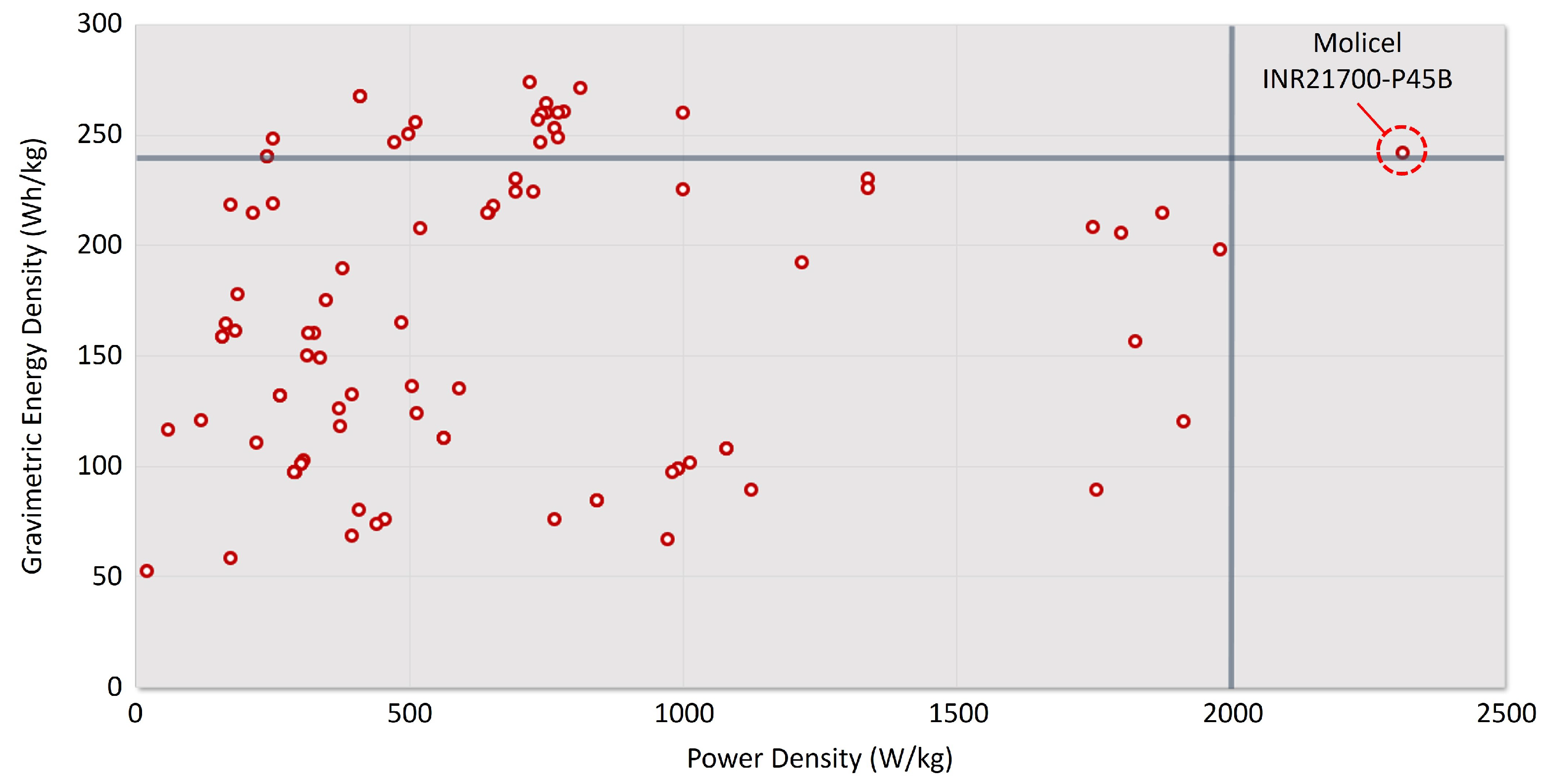

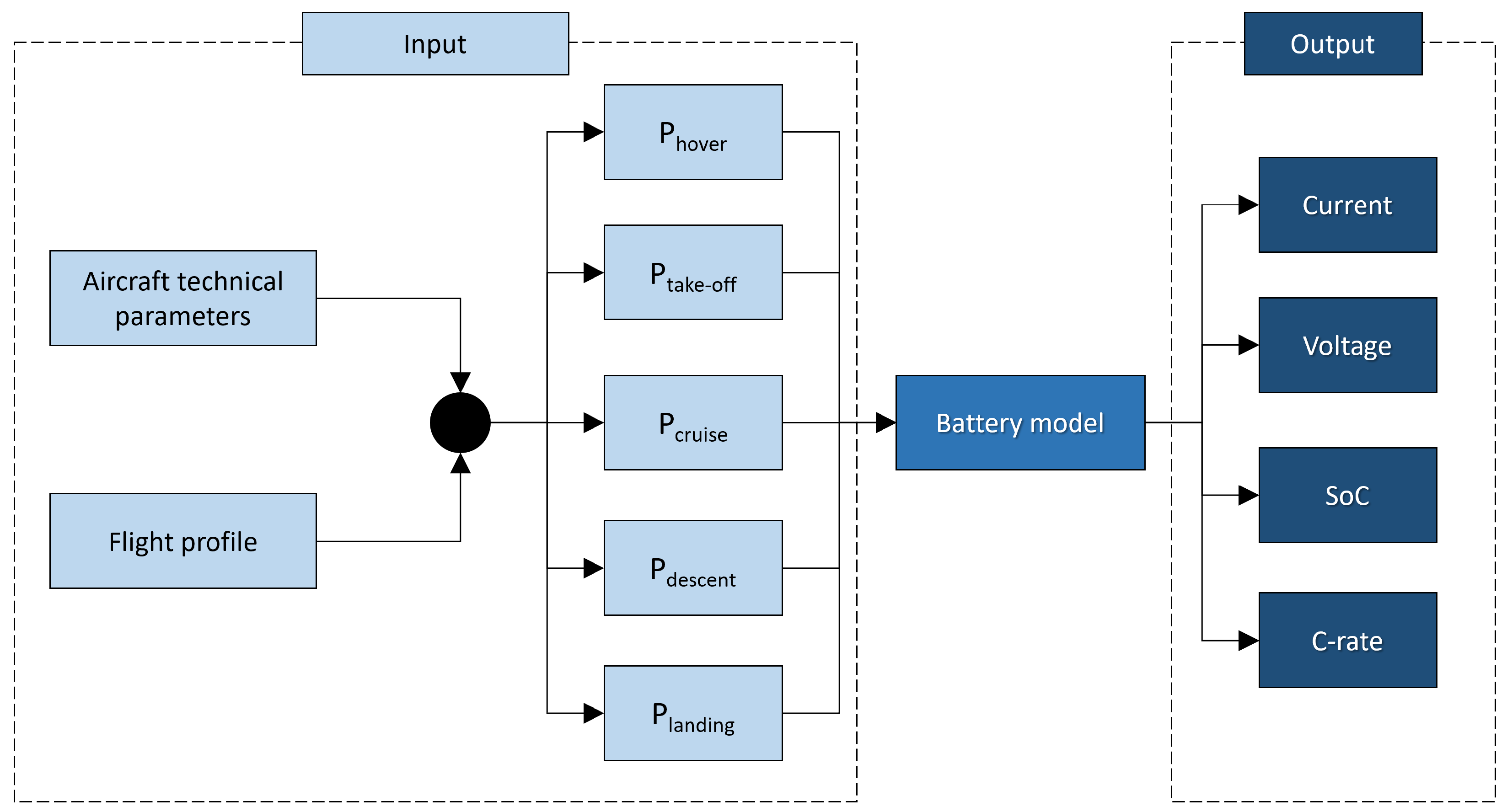

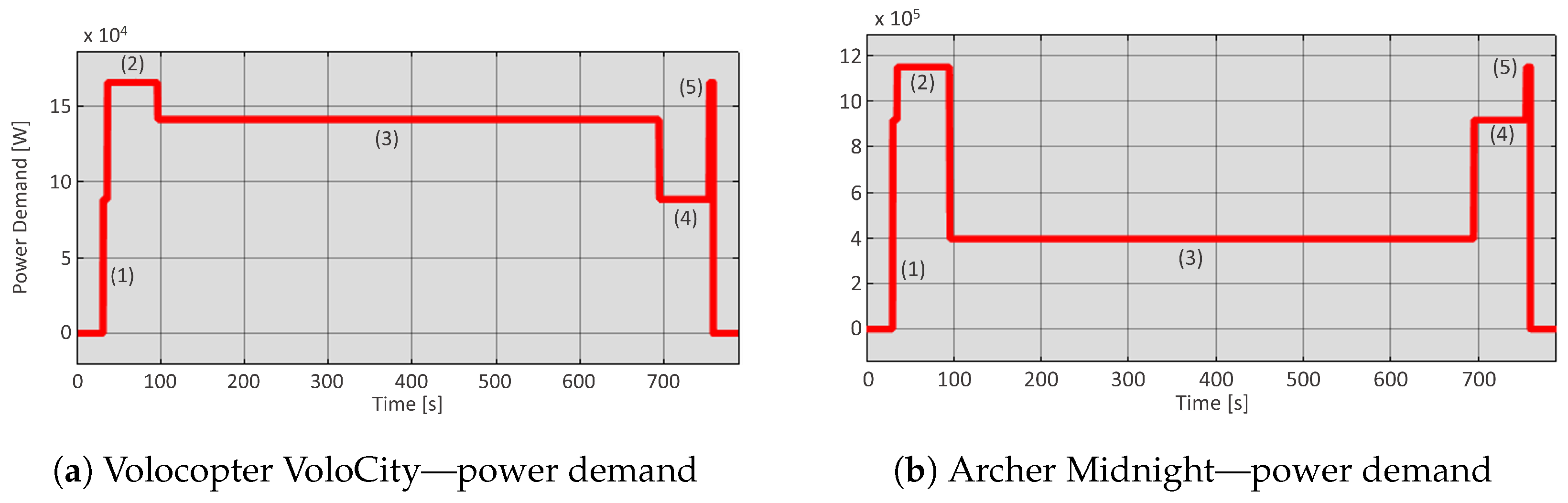

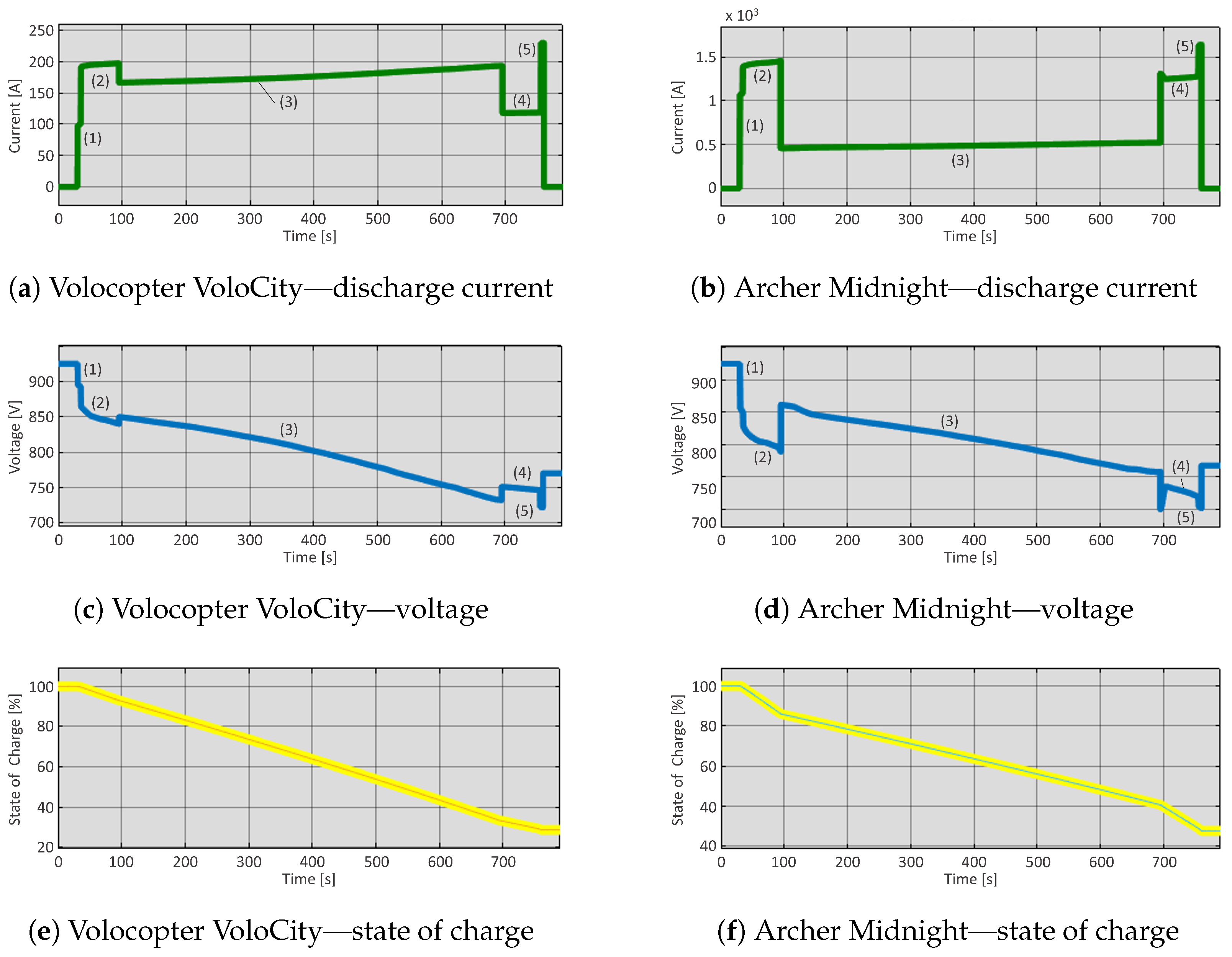

To address the identified research gap, this paper provides a comprehensive analysis to establish the battery requirements for eVTOLs, focusing on technical feasibility. Therefore, the gravimetric energy density and power density are identified as the key requirements to ensure flight with a representative profile while maintaining a battery state of charge (SoC) above a 30% safety threshold. Minimum requirement values for these parameters are identified for two distinct eVTOL models: the VoloCity, a lightweight, wingless vehicle from the OEM Volocopter, and the Midnight, a heavy vectored thrust aircraft from the OEM Archer. Based on these requirements, an extensive evaluation of both current and emerging battery chemistries is conducted to determine the best suited candidates for this application. The findings are verified via simulation using a custom-developed eVTOL simulation model. Based on this, key performance metrics, such as the state of charge (SoC), the discharge current, and the battery voltage are simulated for both battery chemistries to assess their viability.

This paper is structured as follows. In

Section 2.1, the main battery requirements to enable eVTOL flight are determined using mathematical models. In

Section 2.2, the main current and emerging battery chemistries are benchmarked against the requirements and the most suitable candidates are identified. The suitability of the selected battery cells is then verified in

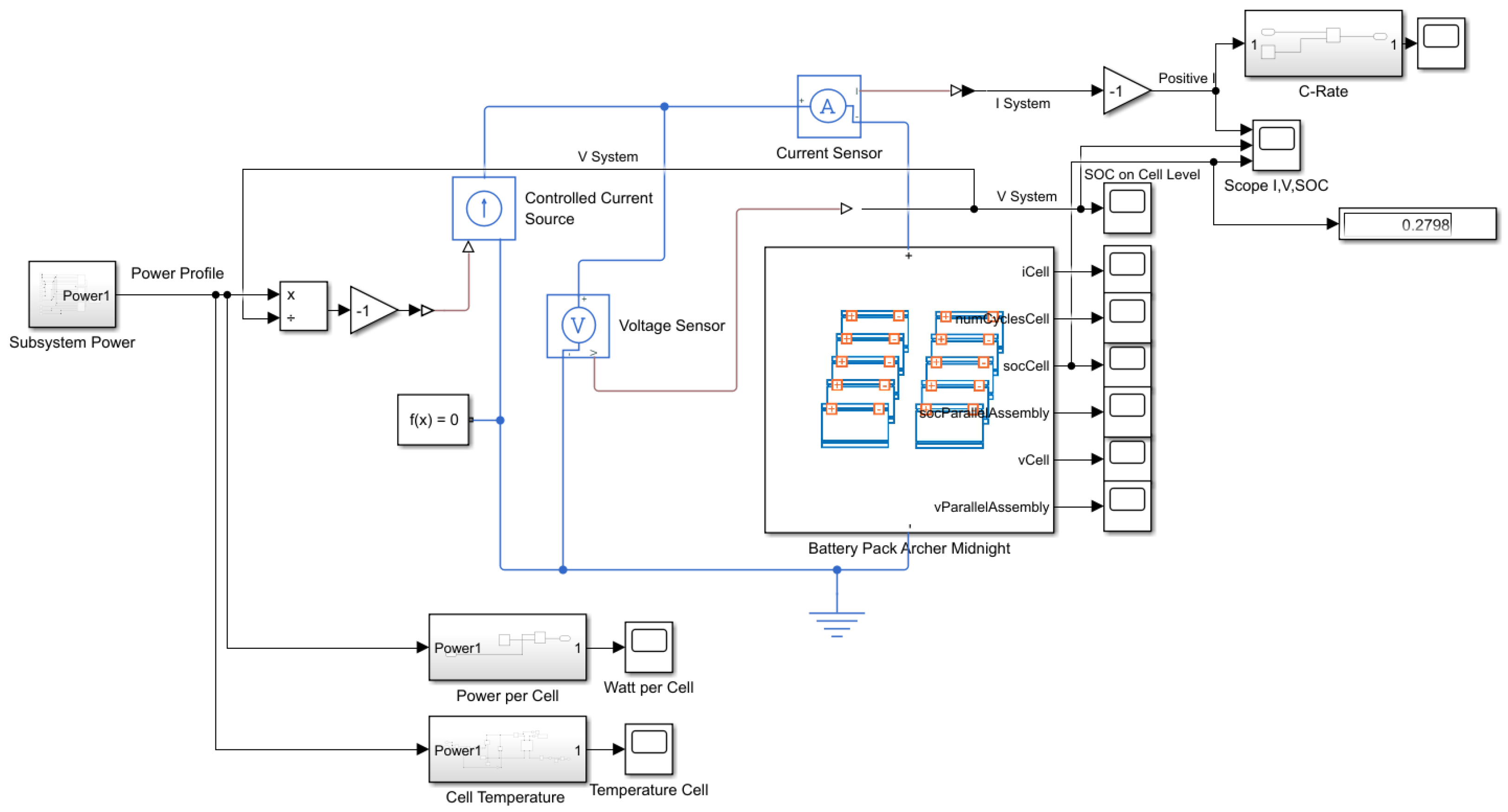

Section 3 via the developed simulation model, which is introduced in

Section 2.3. The conclusions and an outlook on future work are finally provided in

Section 4.

4. Conclusions

The recent development of electric vertical take-off and landing aircraft (eVTOL) shows promising potential to reduce emissions in the aviation sector. Use cases for this technology span from urban air taxis to agriculture and emergency medical vehicles [

6]. However, the successful deployment of eVTOLs strongly depends on overcoming significant challenges in battery technology. This is due to the high energy demands for eVTOL flight, which requires batteries with gravimetric energy and power densities beyond those of most currently available energy storage systems. Additionally, the safety concerns associated with existing high-energy batteries further complicate their suitability for flight operation. Therefore, the development of safe, high-energy and -power batteries is crucial to achieve the required high performance and enable eVTOL flight. However, the absence of clear guidelines specifying battery requirements for eVTOLs poses significant challenges in selecting suitable battery chemistries. This issue is additionally exacerbated by the lack of comprehensive official standards and experimental data from OEMs.

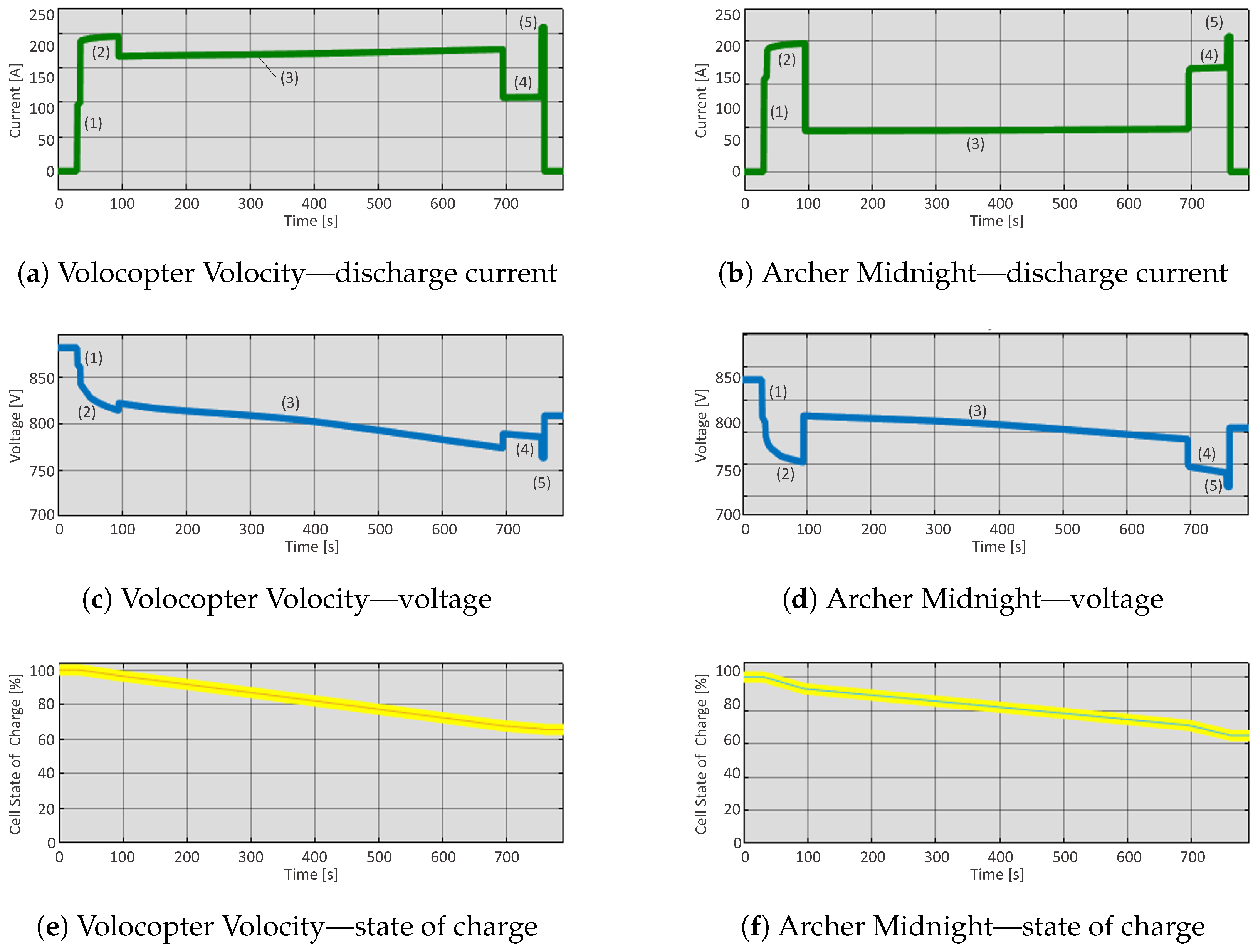

To address this uncertainty, this paper employs analytical models and available data from real eVTOL aircrafts to determine the battery requirements in terms of gravimetric energy density and power density for eVTOL operation. Additionally, currently available battery technologies are benchmarked against these requirements, identifying nickel-based chemistries (such as NMC and NCA) as the most suitable candidates for eVTOL application. To account for the inherent differences among battery cells with the same chemistry, 300 commercial cells are analyzed from a comprehensive database, selecting the Molicel INR21700-P45B cell as the most suitable to enable eVTOL flight. A similar benchmark analysis is also performed for emerging battery chemistries, showing that solid-state batteries (SSBs) with sulfide electrolytes and silicon-based anodes (SiSu) are the most promising for enhancing the performance and safety of eVTOLs.

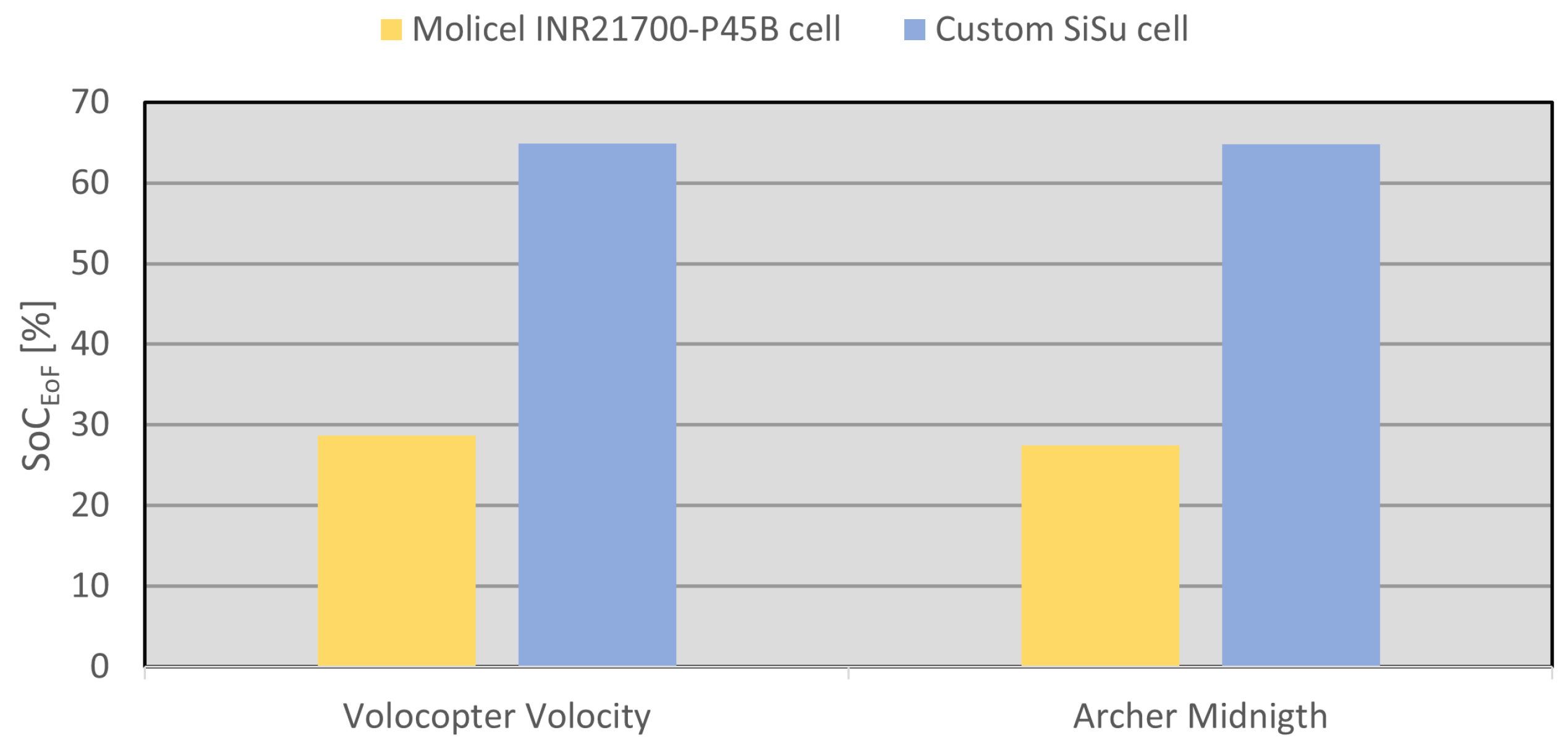

The suitability of these cells is verified via a simulation model designed to estimate parameters such as the battery state of charge (SoC), discharge current, and voltage. Simulations are carried out by using both the Molicel INR21700-P45B cell and a custom SiSu cell for a representative 12-min flight with two commercial eVTOL models, namely the Volocopter VoloCity and the Archer Midnight. The results indicate that the Molicel INR21700-P45B cell is only marginally adequate for high-payload, high-velocity scenarios, as its SoC lies slightly below the safety limit of 30% at the end of flight. The SiSu cell shows a much better performance, with an SoC at the end of flight of 64.9% for the Volocopter VoloCity and 64.8% for the Archer Midnight. This highlights the potential held by solid state batteries to significantly improve the performance of eVTOLs towards commercial applications. The results outlined in this paper can assist manufacturers in making informed decisions on battery selection for eVTOL development, as they highlight the limitations of current state-of-the-art battery technology and emphasize the need for the development and integration of more advanced and powerful battery technologies in future eVTOL designs.

As part of future work, the battery’s thermal properties will be incorporated into the simulation model to better capture their impact on the performance and safety of eVTOLs. Additionally, the benchmark analysis will be extended by considering additional parameters, such as the charging C-rate and cycle life, broadening the scope to identify the most economically suitable battery for eVTOL application. Finally, economic factors, including production and operational costs, as well as manufacturing and technological challenges and environmental impacts, will be incorporated to expand the analysis and offer a more comprehensive assessment of the adoption potential of specific battery technologies for eVTOLs.