A Brief Overview of Modeling Estimation of State of Health for an Electric Vehicle’s Li-Ion Batteries

Abstract

1. Introduction

2. Benchmark of Li-Ion Batteries SOH

- Capacity fade;

- Internal resistance;

- Voltage and voltage profile;

- Cycle life;

- Temperature behavior;

- Self-discharge rate;

- State of charge (SOC) accuracy.

3. Public Datasets for Li-Ion Batteries SOH

- NASA battery dataset (battery aging data);

- The CALCE battery dataset;

- SELI dataset (Swedish Electric Vehicle Fleet);

- UCI Machine Learning Repository: battery SOH dataset;

- Battery Management System (BMS) battery dataset;

- The G2 battery dataset;

- ECOBATT dataset;

- The LIB battery dataset.

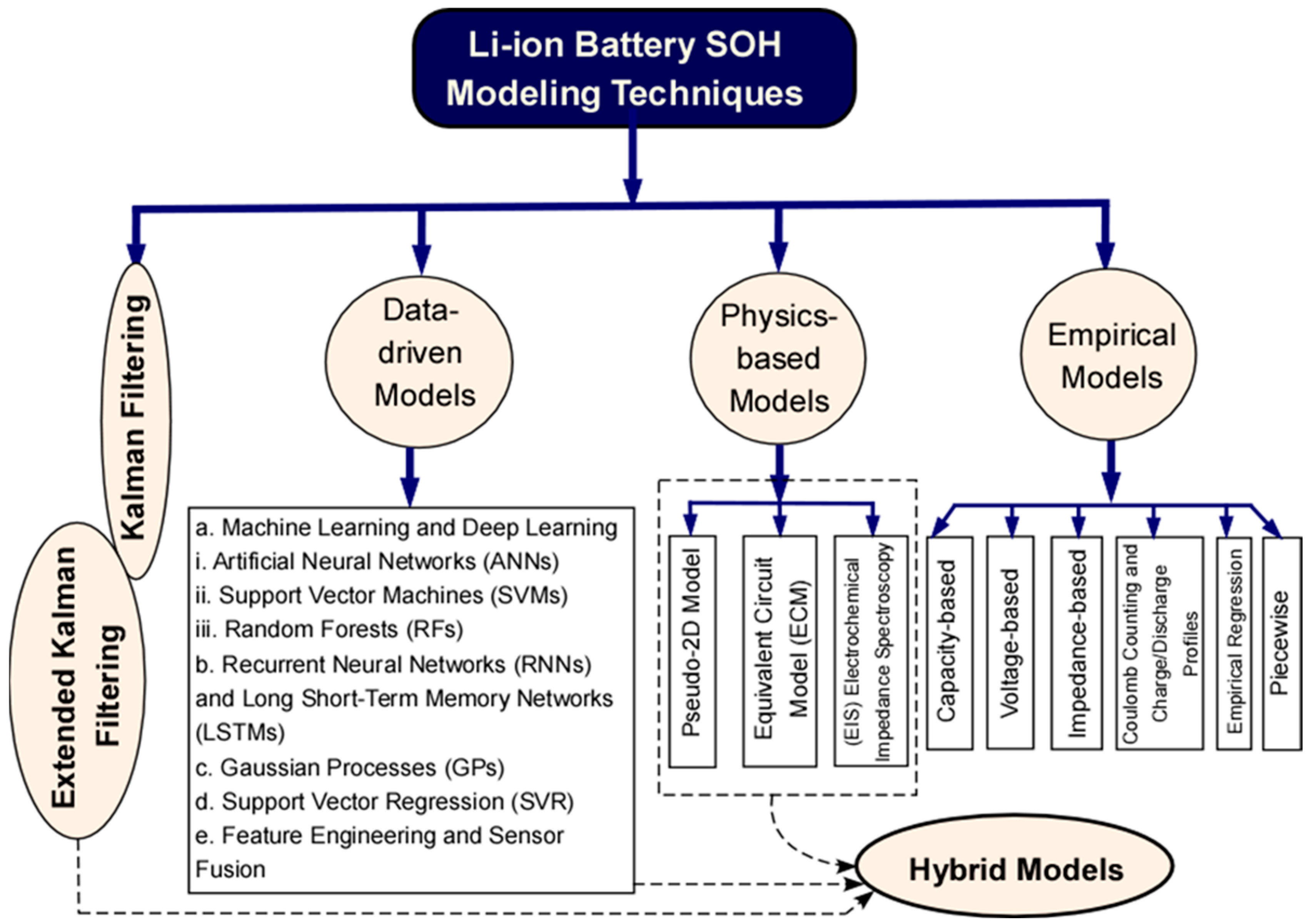

4. Li-Ion Batteries SOH Modeling Techniques

- Empirical models;

- Physics-based models;

- Data-driven models;

- Kalman filtering and extended Kalman filtering;

- Hybrid models.

4.1. Empirical Models

- Capacity-based models;

- Voltage-based models;

- Impedance-based models;

- Coulomb counting and charge/discharge profiles;

- Empirical regression models;

- Piecewise models.

4.2. Physics-Based Models

- Pseudo-2D Model—a detailed representation of electrochemical interactions and ion transport.

- Equivalent Circuit Model (ECM)—A simplified electrical analog of battery behavior.

- Electrochemical Impedance Spectroscopy (EIS)—A frequency-based diagnostic tool for identifying degradation mechanisms.

4.3. Data-Driven Models

- Machine learning and Deep Learning;

- Recurrent neural networks (RNNs) and Long Short-Term Memory Networks (LSTMs)

- Gaussian processes (GPs)

- Support Vector Regression (SVR)

- Feature Engineering and Sensor Fusion

4.4. Kalman Filtering and Extended Kalman Filtering

4.5. Hybrid Models

5. Strength and Weakness of Li-Ion SOH Modeling Estimation Techniques

| Model Type | Strengths | Limitations and Weaknesses | Practical Applicability |

|---|---|---|---|

| Pseudo-2D Model |

|

Limited to lab-scale validation

| Simulates electrochemical processes (e.g., lithium-ion diffusion) for detailed degradation analysis [81]. Example: Used to study capacity fade in NMC batteries under high C-rates [81]. |

| Physics-based Models |

|

| Captures degradation mechanisms (e.g., SEI growth, lithium plating) for long-term SOH prediction [82]. Example: Applied to predict capacity loss in LFP batteries at varying temperatures [82]. |

| Data-driven Models |

|

| Uses machine learning (e.g., ANN, SVM, Random Forest) for SOH estimation from operational data [83]. Example: Random Forest used to predict SOH in EV batteries with 95% accuracy [83]. |

| Kalman Filter (KF) and Extended Kalman Filter (EKF) Models | KF:

| KF:

| KF: Estimates SOH in real-time using voltage and current measurements [84]. Example: KF used for online SOH estimation in BMS applications, achieving < 3% error [85]. EKF: Handles nonlinear battery dynamics for improved SOH estimation [86]. Example: EKF applied to estimate SOH in Li-ion batteries under dynamic load conditions [86]. |

| Hybrid Models |

|

| Combines physics-based and data-driven approaches for robust SOH estimation [87]. Example: Hybrid model used to predict RUL in grid storage batteries with 90% accuracy [87]. |

6. Future-Estimation Techniques for the SOH of Li-Ion Batteries

6.1. Future Research Directions

6.2. Current Limitations

6.3. Potential Solutions

6.4. Resolving Limitations

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ANN | Artificial neural network |

| BMS | Battery management system |

| ECM | Equivalent Circuit Model |

| EIS | Electrochemical Impedance Spectroscopy |

| EKF | Extended Kalman filter |

| EV | Electric vehicle |

| GP | Gaussian process |

| KF | Kalman filter |

| Li-ion | Lithium-ion |

| LFP | Lithium iron phosphate |

| LSTM | Long Short-Term Memory |

| RF | Random Forest |

| RNN | Recurrent neural network |

| RUL | Remaining useful life |

| SEI | Solid Electrolyte Interphase |

| SOH | State of health |

| SVM | Support vector machine |

| SVR | Support vector regression |

Appendix A

| Number of Accesses | Data Availability |

|---|---|

| 1 | https://www.nasa.gov (accessed on 15 December 2024). |

| 2 | https://calce.umd.edu/battery-data (accessed on 15 December 2024). |

| 3 | https://www.svenskaelektriska.se/ (accessed on 15 December 2024). |

| 4 | https://archive.ics.uci.edu/ml/datasets (accessed on 15 December 2024). |

| 5 | https://www.kaggle.com/ (accessed on 15 December 2024). |

| 6 | Not publicly available but can be accessed upon request from GE or associated research projects. |

| 7 | https://www.ecobatt.eu/ (accessed on 15 December 2024). |

| 8 | Available via academic research groups on platforms like ResearchGate. |

References

- De Santis, M.; Agnelli, S.; Silvestri, L.; Di Ilio, G.; Giannini, O. Characterization of the powertrain components for a hybrid quadricycle. In Proceedings of the International Conference of Numerical Analysis and Applied Mathematics 2015, ICNAAM 2015, Rhodes, Greece, 22–28 September 2015; AIP Conference Proceedings. AIP Publishing: Melville, NY, USA, 2016; Volume 1738, p. 270007. [Google Scholar] [CrossRef]

- Zhang, J.; Li, K. State-of-Health Estimation for Lithium-Ion Batteries in Hybrid Electric Vehicles—A Review. Energies 2024, 17, 5753. [Google Scholar] [CrossRef]

- Leng, F.; Tan, C.; Pecht, M. Effect of Temperature on the Aging rate of Li Ion Battery Operating above Room Temperature. Sci. Rep. 2015, 5, 12967. [Google Scholar] [CrossRef] [PubMed]

- He, T.; Gong, Z. State of health estimation for lithium-ion batteries using a hybrid neural network model with Multi-scale Convolutional Attention Mechanism. J. Power Sources 2024, 609, 234680. [Google Scholar] [CrossRef]

- You, H.; Zhu, J.; Wang, X.; Jiang, B.; Sun, H.; Liu, X.; Wei, X.; Han, G.; Ding, S.; Yu, H.; et al. Nonlinear health evaluation for lithium-ion battery within full-lifespan. J. Energy Chem. 2022, 72, 333–341. [Google Scholar] [CrossRef]

- Tarascon, J.M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Goodenough, J.B.; Park, K.S. The Li-ion rechargeable battery: A perspective. J. Am. Chem. Soc. 2013, 135, 1167–1176. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Z. A review of state of health estimation methods for lithium-ion batteries. J. Power Sources 2020, 479, 228722. [Google Scholar]

- Li, W.; Zhang, C. State of health estimation of lithium-ion batteries based on machine learning: A review. Energies 2019, 12, 3584. [Google Scholar]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Mierlo, J.V.; Bossche, P. Critical review of state of health estimation methods ofLi-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Andwari, A.M.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of battery electric vehicle technology andreadiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, C.; Jiang, J.; Zhang, W.; Zhang, L.; Wang, Y. Review on state-of-health of lithium-ion batteries: Characterizations, estimations and applications. J. Clean. Prod. 2021, 314, 128015. [Google Scholar] [CrossRef]

- Xiong, R.; Li, L.; Tian, J. Towards a smarter battery management system: A critical review on battery state of health monitoring methods. J. Power Sources 2018, 405, 18–29. [Google Scholar] [CrossRef]

- Ungurean, L.; Carstoiu, G.; Micea, M.V.; Groza, V. Battery state of health estimation: A structured review of models, methods and commercial devices. Int. J. Energy Res. 2017, 41, 151–181. [Google Scholar] [CrossRef]

- Lipu, M.H.; Hannan, M.; Hussain, A.; Hoque, M.; Ker, P.J.; Saad, M.; Ayob, A. A review of state of health and remaining useful life estimation methods for lithium-ion battery in electric vehicles: Challenges and recommendations. J. Clean. Prod. 2018, 205, 115–133. [Google Scholar] [CrossRef]

- Li, Y.; Liu, K.; Foley, A.M.; Zülke, A.; Berecibar, M.; Nanini-Maury, E.; Van Mierlo, J.; Hoster, H.E. Data-driven health estimation and lifetime prediction of lithium-ion batteries: A review. Renew. Sustain. Energy Rev. 2019, 113, 109254. [Google Scholar] [CrossRef]

- Wei, Z.; Zhao, J.; Ji, D.; Tseng, K.J. A multi-timescale estimator for battery state of charge and capacity dual estimation based on an online identified model. Appl. Energy 2017, 204, 1264–1274. [Google Scholar] [CrossRef]

- Hu, X.S.; Jiang, J.C.; Cao, D.P.; Egardt, B. Battery health prognosis for electric vehicles using sample entropy and sparse bayesian predictive modeling. IEEE Trans. Ind. Electron. 2016, 63, 2645. [Google Scholar] [CrossRef]

- Khaleghi, S.; Karimi, D.; Beheshti, S.H.; Hosen, S.; Behi, H.; Berecibar, M.; Van Mierlo, J. Online health diagnosis of lithium-ion batteries based on nonlinear autoregressive neural network. Appl. Energy 2021, 282, 116159. [Google Scholar] [CrossRef]

- Richardson, R.R.; Birkl, C.R.; Osborne, M.A.; Howey, D.A. Gaussian process regression for in situ capacity estimation of lithium-ion batteries. EEE Trans. Ind. Inform. 2018, 15, 127–138. [Google Scholar] [CrossRef]

- Dai, H.; Wei, X.; Sun, Z. A new SOH prediction concept for the power lithium-ion battery used on HEVs. In Proceedings of the Vehicle Power and Propulsion Conference, VPPC’09, Dearborn, MI, USA, 7–10 September 2009; IEEE: New York, NY, USA, 2009; pp. 1649–1653. [Google Scholar]

- Liu, H.; Ouyang, M. State of Health Estimation for Lithium-Ion Batteries in Electric Vehicles. J. Power Sources 2014, 249, 1076–1084. [Google Scholar]

- Basia, A.; Simeu-Abazi, Z.; Gascard, E.; Zwolinski, P. Review on State of Health estimation methodologies for lithium-ion batteries in the context of circular economy. CIRP J. Manuf. Sci. Technol. 2021, 32, 517–528. [Google Scholar] [CrossRef]

- Halim, A.A.E.B.A.E.; Bayoumi, E.H.E.; El-Khattam, W.; Ibrahim, A.M. Implications of Lithium-Ion Cell Temperature Estimation Methods for Intelligent Battery Management and Fast Charging Systems. Bull. Pol. Acad. Sci. Tech. Sci. 2024, 72, e149171. [Google Scholar] [CrossRef]

- Halim, A.A.E.B.A.E.; Bayoumi, E.H.E.; El-Khattam, W.; Ibrahim, A.M. An Improved Equalization Technique for Fast Charging of Electric Vehicles. Ain Shams Eng. J. 2024, 15, 102727. [Google Scholar] [CrossRef]

- Halim, A.A.E.B.A.E.; Bayoumi, E.H.E.; El-Khattam, W.; Ibrahim, A.M. Development of Robust and Accurate Thermo-electrochemical Models for Lithium-ion Batteries. e-Prime-Adv. Electr. Eng. Electron. Energy 2023, 6, 100342. [Google Scholar] [CrossRef]

- Abd El, A.A.E.B.; Bayoumi, E.H.E.; El-Khattam, W.; Ibrahim, A.M. Effect of Fast Charging on Lithium-Ion Batteries: A Review. SAE Int. J. Mater. Manuf. (Int. J. Electrified Veh.) 2023, 12, 361–388. [Google Scholar] [CrossRef]

- Halim, A.A.E.B.A.E.; Bayoumi, E.H.E.; El-Khattam, W.; Ibrahim, A.M. Electric Vehicles: A Review of their Components and Technologies. Int. J. Power Electron. Drive Syst. 2022, 13, 2041–2061. [Google Scholar] [CrossRef]

- Sharma, A.; Weng, X. Battery degradation modeling using experimental data from NASA battery aging dataset. J. Energy Storage 2020, 32, 101807. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, C.; Zhao, Y. Advances in lithium-ion battery health state prediction. J. Energy Storage 2019, 24, 100790. [Google Scholar]

- Wang, X.; Dai, K.; Hu, M.; Ni, N. Lithium-ion battery health state and remaining useful life prediction based on hybrid model MFE-GRU-TCA. J. Energy Storage 2024, 95, 112442. [Google Scholar] [CrossRef]

- Smith, K.; Lee, J.; Johnson, M. A comprehensive review of battery datasets for state of health estimation. IEEE Trans. Transp. Electrif. 2022, 8, 1234–1245. [Google Scholar]

- Rashid, M.; Faraji-Niri, M.; Sansom, J.; Sheikh, M.; Widanage, D.; Marco, J. Dataset for rapid state of health estimation of lithium batteries using EIS and machine learning: Training and validation. Data Brief 2023, 48, 109157. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Zhang, Y.; Chen, H. High-resolution battery datasets for degradation modeling. IEEE Access 2022, 10, 56789–56801. [Google Scholar]

- Zhao, Y.; Li, Y. A review of state-of-health estimation methods for lithium-ion batteries. Energy Rep. 2021, 7, 722–730. [Google Scholar] [CrossRef]

- Sukkam, N.; Katongtung, T.; Suttakul, P.; Mona, Y.; Achariyaviriya, W.; Tippayawong, K.Y.; Tippayawong, N. Machine Learning Prediction of a Battery’s Thermal-Related Health Factor in a Battery Electric Vehicle Using Real-World Driving Data. Information 2024, 15, 553. [Google Scholar] [CrossRef]

- Yang, F.; Tan, J. State-of-health estimation of lithium-ion batteries: A review on models, algorithms, and challenges. IEEE Access 2020, 8, 101740–101755. [Google Scholar]

- Wang, F.; Zhai, Z.; Liu, B.; Zheng, S.; Zhao, Z.; Chen, X. Open access dataset, code library and benchmarking deep learning approaches for state-of-health estimation of lithium-ion batteries. J. Energy Storage 2024, 77, 109884. [Google Scholar] [CrossRef]

- Lee, C.; Kim, Y. Prognostic models for battery life prediction using G2 battery dataset. J. Power Sources 2020, 466, 228323. [Google Scholar] [CrossRef]

- Krishna, G.; Singh, R.; Gehlot, A.; Shaik, V.A.; Twala, B.; Priyadarshi, N. IoT-based real-time analysis of battery management system with long range communication and FLoRa. Results Eng. 2024, 23, 102770. [Google Scholar] [CrossRef]

- Huang, J.; Li, X. Data-driven models for battery health estimation using ECOBATT data. IEEE Trans. Ind. Electron. 2020, 67, 10123–10130. [Google Scholar]

- Moy, K.; Khan, M.A.; Fasolato, S.; Pozzato, G.; Allam, A.; Onori, S. Second-life lithium-ion battery aging dataset based on grid storage cycling. Data Brief 2024, 57, 111046. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Liu, C. Modeling and prediction of lithium-ion battery state-of-health using the LIB dataset. J. Electrochem. Energy Convers. Storage 2021, 18, 1–12. [Google Scholar] [CrossRef]

- Tran, M.; Messo, T.; Luhtala, R.; Sihvo, J.; Roinila, T. Used Lithium-Ion Batteries in Second-Life Applications: Feasibility Study. In Proceedings of the 2022 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 9–13 October 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Chen, M.; Wang, J.; Jiang, H. A data-driven capacity degradation model for lithium-ion batteries based on empirical data. J. Power Sources 2016, 330, 257–265. [Google Scholar]

- Sun, S.; Zhang, H.; Ge, J.; Che, L. State-of-health estimation for lithium-ion battery using model-based feature optimization and deep extreme learning machine. J. Energy Storage 2023, 72, 108732. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.-C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Ng, K.S.; Moo, C.-S.; Chen, Y.-P.; Hsieh, Y.-C. Enhanced coulomb counting method for estimating state-of-charge and state-of-health of lithium-ion batteries. Appl. Energy 2009, 86, 1506–1511. [Google Scholar] [CrossRef]

- Ghanbari, M.; Gholamian, M. A nonlinear regression model for state of health estimation of lithium-ion batteries. Energy 2020, 194, 116846. [Google Scholar]

- Li, J.; Xu, X.; Wang, Y.; Chen, R.; Liu, C. Bi-Level Optimizing Model for Microgrids with Fast Lithium Battery Energy Storage Considering Degradation Effect. IEEE Access 2023, 11, 34643–34658. [Google Scholar] [CrossRef]

- Newman, J.; Thomas-Alyea, K.E. Electrochemical Systems; Wiley: Hoboken, NJ, USA, 2004. [Google Scholar]

- Wang, Z.; Ouyang, M. Capacity degradation of lithium-ion batteries: A physics-based model. J. Power Sources 2015, 274, 1096–1102. [Google Scholar]

- Ouyang, T.; Ye, J.; Xu, P.; Wang, C.; Xu, E. Estimation of state-of-charge and state-of-health for lithium-ion battery based on improved firefly optimized particle filter. J. Energy Storage 2023, 68, 107733. [Google Scholar] [CrossRef]

- Meddings, N.; Heinrich, M.; Overney, F.; Lee, J.-S.; Ruiz, V.; Napolitano, E.; Seitz, S.; Hinds, G.; Raccichini, R.; Gaberšček, M.; et al. Application of electrochemical impedance spectroscopy to commercial Li-ion cells: A review. J. Power Sources 2020, 480, 228742. [Google Scholar] [CrossRef]

- Zhang, J.; Li, L.; Zou, Z. State-of-health prediction of lithium-ion batteries using deep learning and a hybrid model. IEEE Trans. Ind. Electron. 2019, 66, 5124–5132. [Google Scholar]

- Zhang, H.; Yang, L. State of health prediction of lithium-ion batteries based on a support vector machine model. J. Power Sources 2020, 475, 228538. [Google Scholar]

- Chen, X.; Liu, J. Data-driven state of health prediction for lithium-ion batteries based on random forest regression. Appl. Energy 2020, 267, 115013. [Google Scholar]

- Wu, M.; Zheng, Y.; Li, Y. State of health prediction of lithium-ion batteries using deep learning and LSTM. IEEE Access 2019, 7, 40268–40275. [Google Scholar]

- Xie, X.; Yu, D.; Liu, Z. Data-driven battery health estimation based on Gaussian process regression. IEEE Trans. Veh. Technol. 2019, 68, 5262–5272. [Google Scholar]

- Liu, X.; Zhang, L. Support vector regression based state of health prediction for lithium-ion batteries. Energy 2018, 163, 316–324. [Google Scholar]

- Zhao, J.; Liu, Y.; Wei, Y. A data-driven approach for state-of-health estimation of lithium-ion batteries based on feature fusion. Energy 2018, 156, 160–167. [Google Scholar]

- Chen, R.G.; Xie, M.L.; Li, M.D. State of Health Estimation of Lithium-Ion Batteries Using Kalman Filter. Energy Procedia 2019, 158, 1409–1414. [Google Scholar]

- Lu, D.J.; Yang, H.X.; Liu, Y.; Zhou, Z.X. State of Health Estimation for Lithium-Ion Batteries Using Extended Kalman Filter. IEEE Trans. Ind. Electron. 2016, 63, 3135–3145. [Google Scholar]

- Singh, S.; Ebongue, Y.E.; Rezaei, S.; Birke, K.P. Hybrid Modeling of Lithium-Ion Battery: Physics-Informed Neural Network for Battery State Estimation. Batteries 2023, 9, 301. [Google Scholar] [CrossRef]

- Wang, C.; Li, R.; Cao, Y.; Li, M. A hybrid model for state of charge estimation of lithium-ion batteries utilizing improved adaptive extended Kalman filter and long short-term memory neural network. J. Power Sources 2024, 620, 235272. [Google Scholar] [CrossRef]

- Zhao, H.; Chen, Z.; Shu, X.; Shen, J.; Lei, Z.; Zhang, Y. State of health estimation for lithium-ion batteries based on hybrid attention and deep learning. Reliab. Eng. Syst. Saf. 2023, 232, 109066. [Google Scholar] [CrossRef]

- Wu, J.; Meng, J.; Lin, M.; Wang, W.; Wu, J.; Stroe, D.-I. Lithium-ion battery state of health estimation using a hybrid model with electrochemical impedance spectroscopy. Reliab. Eng. Syst. Saf. 2024, 252, 110450. [Google Scholar] [CrossRef]

- Maleki, S.; Ray, B.; Hagh, M.T. Hybrid framework for predicting and forecasting State of Health of Lithium-ion batteries in Electric Vehicles. Sustain. Energy Grids Netw. 2022, 30, 100603. [Google Scholar] [CrossRef]

- Tao, J.; Wang, S.; Cao, W.; Fernandez, C.; Blaabjerg, F. A Comprehensive Review of Multiple Physical and Data-Driven Model Fusion Methods for Accurate Lithium-Ion Battery Inner State Factor Estimation. Batteries 2024, 10, 442. [Google Scholar] [CrossRef]

- Guo, W.; Sun, Z.; Vilsen, S.B.; Meng, J.; Stroe, D.I. Review of “grey box” lifetime modeling for lithium-ion battery: Combining physics and data-driven methods. J. Energy Storage 2022, 56 (Pt A), 105992. [Google Scholar] [CrossRef]

- Ke, X.; Hong, H.; Zheng, P.; Zhang, S.; Zhu, L.; Li, Z.; Cai, J.; Fan, P.; Yang, J.; Wang, J.; et al. State-of-health estimation for lithium-ion batteries using relaxation voltage under dynamic conditions. J. Energy Storage 2024, 100 (Pt A), 113506. [Google Scholar] [CrossRef]

- Sorouri, H.; Oshnoei, A.; Che, Y.; Teodorescu, R. A comprehensive review of hybrid battery state of charge estimation: Exploring physics-aware AI-based approaches. J. Energy Storage 2024, 100 (Pt B), 113604. [Google Scholar] [CrossRef]

- Pandey, S.V.; Parikh, N.; Prochowicz, D.; Akin, S.; Satapathi, S.; Tavakoli, M.M.; Kalam, A.; Yadav, P. Predicting the state parameters of lithium ion batteries: The race between filter-based and data driven approaches. Sustain. Energy Fuels 2023, 7, 598–628. [Google Scholar] [CrossRef]

- Dini, P.; Colicelli, A.; Saponara, S. Review on Modeling and SOC/SOH Estimation of Batteries for Automotive Applications. Batteries 2024, 10, 34. [Google Scholar] [CrossRef]

- Xiao, D.; Sharif-Khodaei, Z.; Aliabadi, M. Aliabadi Hybrid physics-based and data-driven impact localisation for composite laminates. Int. J. Mech. Sci. 2024, 274, 109222. [Google Scholar] [CrossRef]

- El-Dalahmeh, M.; Al-Greer, M.; Bashir, I. Physics-based model informed smooth particle filter for remaining useful life prediction of lithium-ion battery. Measurement 2023, 214, 112838. [Google Scholar] [CrossRef]

- Kim, E.; Kim, M.; Kim, J.; Kim, J.; Park, J.H.; Kim, K.T.; Park, J.-H.; Kim, T.; Min, K. Data-driven methods for predicting the state of health, state of charge, and remaining useful life of li-ion batteries: A comprehensive review. Int. J. Precis. Eng. Manuf. 2023, 24, 1281–1304. [Google Scholar] [CrossRef]

- Liang, Y.; Emadi, A.; Gross, O.; Vidal, C.; Canova, M.; Panchal, S.; Kollmeyer, P.; Naguib, M.; Khanum, F. A Comparative Study Between Physics, Electrical and Data Driven Lithium-Ion Battery Voltage Modeling Approaches; SAE Technical Paper Series; SAE International: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Zhang, Y.; Gu, P.; Duan, B.; Zhang, C. A hybrid data-driven method optimized by physical rules for online state collaborative estimation of lithium-ion batteries. Energy 2024, 301, 131710. [Google Scholar] [CrossRef]

- MLipu, M.H.; Rahman, M.A.; Mansor, M.; Ansari, S.; Meraj, S.T.; Hannan, M. Hybrid and combined states estimation approaches for lithium-ion battery management system: Advancement, challenges and future directions. J. Energy Storage 2024, 92. [Google Scholar] [CrossRef]

- Eleftheriadis, P.; Gangi, M.; Leva, S.; Rey, A.V.; Groppo, E.; Grande, L. Comparative study of machine learning techniques for the state of health estimation of Li-Ion batteries. Electr. Power Syst. Res. 2024, 235, 110889. [Google Scholar] [CrossRef]

- Jokar, A.; Rajabloo, B.; Désilets, M.; Lacroix, M. Review of simplified Pseudo-two-Dimensional models of lithium-ion batteries. J. Power Sources 2016, 327, 44–55. [Google Scholar] [CrossRef]

- Couto Luis, D.; Odile, C.; Jan, S.; Raf, P.; Grietus, M. Physics-Based Lifetime Modeling and Parameter Identification of Lithium-Ion Batteries Under Various Degradation Conditions. Available online: https://ssrn.com/abstract=5093185 (accessed on 7 January 2025).

- Sun, Z.; He, W.; Wang, J.; He, X. State of Health Estimation for Lithium-Ion Batteries with Deep Learning Approach and Direct Current Internal Resistance. Energies 2024, 17, 2487. [Google Scholar] [CrossRef]

- Yang, F.; Mao, Q.; Zhang, J.; Hou, S.; Bao, G.; Cheng, K.-W.E.; Dai, J.; Lam, K.-H. Real-time state-of-charge estimation for rechargeable batteries based on in-situ ultrasound-based battery health monitoring and extended Kalman filtering model. Appl. Energy 2025, 381, 125161. [Google Scholar] [CrossRef]

- Hend Fahmy, M.; Hasanien, H.M.; Alsaleh, I.; Ji, H.; Alassaf, A. State of health estimation of lithium-ion battery using dual adaptive unscented Kalman filter and Coulomb counting approach. J. Energy Storage 2024, 88, 111557. [Google Scholar] [CrossRef]

- Sarıkurt, T.; Ceylan, M.; Balıkçı, A. A hybrid battery model and state of health estimation method for lithium-ion batteries. In Proceedings of the 2014 IEEE International Energy Conference (ENERGYCON), Cavtat, Croatia, 13–16 May 2014; pp. 1349–1356. [Google Scholar]

- Lee, J.-H.; Lee, I.-S. Estimation of Online State of Charge and State of Health Based on Neural Network Model Banks Using Lithium Batteries. Sensors 2022, 22, 5536. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, L.; Liu, X. Hybrid models for state of health prediction in lithium-ion batteries. IEEE Trans. Ind. Informat. 2022, 18, 1790–1799. [Google Scholar]

- Wang, Z.; Zhang, W.; Li, B. Aging mechanisms and modeling of Li-ion batteries. J. Power Sources 2020, 459, 228020. [Google Scholar]

- Chen, M.; Chen, J.; Huang, Y. Hybrid machine learning-based models for lithium-ion battery state of health estimation. Energy Rep. 2021, 7, 189–199. [Google Scholar]

- Cao, S.; Xu, S.; Zhang, L. Real-time monitoring and battery management system with state of health estimation. IEEE Trans. Transp. Electrif. 2021, 7, 113–121. [Google Scholar]

- Ng, M.-F.; Sun, Y.; Seh, Z.W. Machine learning-inspired battery material innovation. Energy Adv. 2023, 2, 449–464. [Google Scholar] [CrossRef]

- Valizadeh, A.; Amirhosseini, M.H. Machine Learning in Lithium-Ion Battery: Applications, Challenges, and Future Trends. SN Comput. Sci. 2024, 5, 717. [Google Scholar] [CrossRef]

- Zhao, J.; Qu, X.; Han, X.; Wu, Y.; Burke, A. Cross-Material Battery Capacity Estimation Using Hybrid-Model Fusion Transfer Learning. J. Power Sources 2024, 575, 235674. [Google Scholar] [CrossRef]

- Wong, K.L.; Chou, K.S.; Tse, R.; Tang, S.-K.; Pau, G. A Novel Fusion Approach Consisting of GAN and State-of-Charge Estimator for Synthetic Battery Operation Data Generation. Electronics 2023, 12, 657. [Google Scholar] [CrossRef]

- Schindler, J.; Brand, M.; Sauer, D.U. Comprehensive Battery Aging Dataset: Capacity and Impedance Fade for 228 Commercial NMC/C+SiO Lithium-Ion Cells. Sci. Data 2024, 11, 38. [Google Scholar] [CrossRef]

| Benchmark | Definition | Measurement | Significance | Pros | Cons |

|---|---|---|---|---|---|

| Capacity Fade | The battery’s capacity reflects its ability to store and deliver energy. Over time, chemical degradation reduces capacity, signaling health deterioration [22]. | SOH is calculated by comparing the current capacity relative to the initial rated capacity [23]. | A significant capacity drop shortens battery life and reduces performance, making this a primary indicator of SOH [22,23]. | Directly reflects the usable energy storage capability of the battery [22]. Easy to measure and widely used in SOH estimation [23]. | Requires full charge/discharge cycles, which may not be practical in real-time monitoring. Sensitive to operating conditions (e.g., temperature, C-rate) [22]. |

| Internal resistance | Refers to the opposition to current flow within the battery, which increases with aging and degradation [23,24,25,26]. | Measured via Electrochemical Impedance Spectroscopy (EIS) or by observing the voltage drop under load [22]. | Elevated internal resistance generates heat, reduces efficiency, and accelerates capacity fade, often correlating with decreased SOH [23,24,25,26]. | Indicates power delivery capability and aging mechanisms (e.g., SEI growth). Can be measured without fully discharging the battery [23,24,25,26]. | Measurement requires specialized equipment (e.g., impedance analyzers). Affected by temperature and SOC, complicating interpretation [23,24,25,26]. |

| Voltage and Voltage Profile | Voltage is the potential difference between the battery’s terminals, with characteristic charge/discharge curves that shift as the battery degrades [27,28]. | Monitored under different charge/discharge conditions; deviations from typical voltage curves highlight potential issues [22,28]. | Changes in nominal voltage or unusual fluctuations can indicate poor battery health or imbalanced cells [23,27]. | Provides real-time insights into battery behavior during charge/discharge. Easy to measure using standard BMS sensors [27,28]. | Voltage alone may not fully capture degradation mechanisms. Voltage profiles can vary significantly with load and temperature [23,28]. |

| Cycle life | The number of full charge/discharge cycles before capacity drops below a specific threshold (typically 80% of initial capacity) [23,26]. | Counted and compared against the manufacturer’s expected cycle life under standard conditions [26,27,28]. | Batteries exceeding expected cycles may exhibit reduced SOH due to material degradation [23,28]. | Directly correlates with battery lifespan and degradation over time. Useful for predicting end-of-life (EOL) conditions [27,28]. | Requires long-term testing, making it impractical for real-time SOH estimation. Cycle life can vary significantly depending on usage patterns [27,28]. |

| Temperature behavior | Temperature significantly impacts performance and SOH, with elevated temperatures accelerating component degradation [24]. | Monitored during operation; anomalies like excessive heat buildup indicate potential issues [24,28]. | Abnormal temperature behavior can signal degradation, affecting battery health and safety [24]. | Highlights thermal stability and safety concerns (e.g., thermal runaway). Helps identify abnormal heating, which can indicate degradation [24]. | Requires precise temperature sensors and thermal management systems. Temperature effects are complex and may not directly correlate with SOH [28]. |

| Self-Discharge Rate | The rate at which a battery loses charge when idle, increasing with age and degradation [27,28]. | Measured over time; an elevated rate suggests internal issues [27]. | High self-discharge rates can indicate internal shorts or rising resistance, both indicative of poor SOH [27,28]. | Indicates internal leakage and potential aging mechanisms (e.g., SEI growth). Useful for identifying defective or degraded cells [27]. | Difficult to measure accurately in real-world applications. Requires long periods of inactivity, which is impractical for active systems [28]. |

| State of Charge (SOC) Accuracy | SOC represents the current charge level of the battery. Accurate SOC estimation is critical for effective battery management [22,27]. | Evaluated by comparing the predicted SOC against actual charge levels [22,28]. | Aging reduces SOC estimation accuracy, impacting performance and the reliability of battery management systems [23,27]. | Reflects the battery’s ability to accurately estimate remaining energy. Critical for real-time battery management and user feedback [23]. | SOC estimation errors can mask true SOH degradation. - SOC accuracy depends on voltage and current measurements, which can be noisy [27]. |

| Dataset | Description | Usefulness | Applicability | Gaps | Limitations | Case Study | Access |

|---|---|---|---|---|---|---|---|

| NASA Battery | Provided by NASA’s Prognostics Center of Excellence (PCoE), this dataset includes charge/discharge data, voltage, current, and temperature profiles for lithium-ion batteries under various operating conditions [29]. | Commonly used for SOH modeling and degradation prediction tasks [29]. | Detailed cycle-by-cycle data for SOH and RUL prediction [30]. | Limited to 18,650 cells; lacks data from extreme conditions. | Controlled lab conditions; small sample size. | Used in [30] to develop an LSTM model for RUL prediction, achieving 95% accuracy in cycle life estimation. | NASA PCoE Dataset |

| CALCE Battery | Developed by the University of Maryland’s CALCE, this dataset contains aging cycles, charge/discharge characteristics, and voltage variations for lithium-ion batteries [31]. | Widely utilized for performance degradation analysis and developing thermal and voltage-based SOH models [31]. | High-resolution data for capacity fade and impedance modeling [32]. | Limited to LCO chemistry; lacks metadata on manufacturing. | Focuses on calendar aging; noisy impedance measurements. | Applied in [32] to study capacity fade using Gaussian Process Regression, with RMSE < 2% for SOH estimation. | CALCE Battery Data |

| SELI | The Swedish Electric Vehicle Fleet dataset provides SOC, temperature, voltage, and current data collected over months of EV operation, reflecting real-world conditions [33]. | Useful for SOH estimation and condition monitoring in real-world EV scenarios [33]. | Real-world EV battery data for practical SOH analysis [34]. | Limited raw data availability; incomplete metadata. | Narrow operating conditions; potential inconsistencies in data collection. | Used in [34] to train a Random Forest model for SOH prediction in EVs, achieving 90% accuracy. | SELI Dataset |

| UCI Machine Learning Repository | Contains battery modeling datasets, including lithium-ion battery charge/discharge cycles, with variables such as current, voltage, and temperature [35]. | Suitable for developing classification or regression models for battery SOH estimation [35]. | Structured format for benchmarking ML models [36]. | Limited cycle data; lacks impedance measurements. | Controlled conditions; small sample size and limited chemistries. | Employed in [36] to benchmark SVM and ANN models for SOH estimation, with SVM achieving 92% accuracy. | UCI Repository |

| BMS Battery | Focused on charge/discharge profiles, this dataset includes detailed current, voltage, and temperature data for lithium-ion batteries [37]. | Helpful for predicting battery health and identifying failure conditions [37]. | Real-time BMS data for online SOH estimation [38]. | Limited to specific battery packs; lacks metadata on usage history. | Noisy data due to real-world conditions; limited extreme scenario coverage. | Utilized in [38] to develop an online SOH estimation algorithm using Kalman filtering, with < 3% error. | Kaggle BMS Dataset |

| G2 Battery | Provided by General Electric, this dataset includes cell voltage, temperature, current, and resistance measurements for lithium-ion batteries used in grid applications [39]. | Valuable for long-term battery degradation modeling and SOH prediction [39]. | Grid storage data for stationary energy SOH analysis [40]. | Limited to lithium iron phosphate (LFP) chemistry; lacks detailed cycle data. | Focuses on long-term aging; potential biases in data collection. | Applied in [40] to model capacity degradation using a physics-based approach, achieving 94% accuracy. | Not publicly available; access can be requested through GE or associated research projects. |

| ECOBATT | Real-world EV battery data, including voltage, current, and temperature, collected during routine operations [41]. | Effective for investigating SOH and remaining useful life (RUL) in EV applications [41]. | Recycled battery data for second-life SOH studies [42]. | Small sample size; lacks detailed usage history metadata. | Inconsistent data due to recycling variations; limited operating condition coverage. | Used in [42] to evaluate second-life battery performance, showing 80% capacity retention after 500 cycles. | ECOBATT Dataset |

| LIB Battery | Focuses on lithium-ion battery performance, covering charge/discharge cycles, aging effects, and current/voltage/temperature profiles [43]. | Highly useful for predicting battery degradation and supporting BMS research [43]. | Multi-chemistry data for comparative SOH analysis [44]. | Limited to lab conditions; lacks impedance data. | Small sample size; focuses on specific degradation mechanisms. | Employed in [44] to compare NMC and LFP degradation rates, identifying NMC as more susceptible to capacity fade. | Available via academic research platforms such as ResearchGate. |

| Model Type | Definition | Example |

|---|---|---|

| Capacity-Based | Focuses on correlating capacity degradation over cycles with operational factors such as charge/discharge cycles, temperature, and current rates. | Cycling performance: Monitors discharge capacity over time and models deterioration using experimental data. For instance, ref. [45] developed a model to forecast capacity degradation across various operating conditions using cycle data. |

| Voltage-Based | Examines the voltage profile to correlate with the battery’s residual health, capturing aging effects such as increased resistance or electrolyte loss. | Voltage profile monitoring: Utilizes voltage profiles during charge/discharge cycles to predict SOH. For example, ref. [46] used voltage measurements to estimate SOH and analyzed the impact of temperature variations on battery performance. |

| Impedance-Based | Leverages Electrochemical Impedance Spectroscopy (EIS) to assess SOH, as impedance rises with battery degradation. | Impedance monitoring: Collects impedance spectra at various frequencies to link impedance changes with degradation processes. In [47], the relationship between aging and impedance increases was analyzed to develop empirical SOH estimation models. |

| Coulomb Counting and Charge/Discharge Profiles | Measures total charge input/output to detect discrepancies indicating degradation. | Regression-based models: Construct equations linking parameters (e.g., capacity, voltage, resistance) with SOH [48]. For example, ref. [49] applied regression techniques to predict SOH from long-term cycling experiment data. |

| Piecewise | Segments the battery lifecycle into distinct phases with varying degradation rates for each phase. | Phase-based modeling: Captures degradation behavior in distinct lifecycle stages. For instance, ref. [50] employed a piecewise approach to model battery degradation, incorporating factors such as temperature and state of charge (SOC). |

| Model Type | Definition | Example |

|---|---|---|

| Pseudo-2D Model | A widely utilized physics-based approach for evaluating battery performance, the pseudo-2D model employs differential equations to represent lithium-ion transport, potential distribution, and electrochemical reactions at the electrode/electrolyte interface. | Effectively simulates battery behavior over extended cycles and provides insights into degradation mechanisms under varying operational conditions (e.g., temperature, current rate) [51,52]. |

| Equivalent Circuit Model (ECM) | ECM simplifies battery behavior into an electrical network of resistors, capacitors, and voltage sources. It captures battery degradation through simulated increases in impedance and decreases in capacity, with resistors representing internal resistance and capacitors mimicking charge storage dynamics. | Widely applied in real-time battery health monitoring due to its computational efficiency and suitability for integration into BMS [53]. |

| Electrochemical Impedance Spectroscopy (EIS) | A diagnostic technique for measuring battery impedance across a range of frequencies. Often integrated with physics-based models, EIS links changes in impedance to internal degradation mechanisms. | Highly effective in identifying solid electrolyte interphase (SEI) layer formation and evaluating its influence on battery aging and performance [54]. |

| Model Type | Applications |

|---|---|

| Machine Learning and Deep Learning | Artificial neural networks (ANNs): Widely utilized for SOH estimation due to their ability to capture complex, nonlinear relationships between battery parameters. ANN models, including feedforward neural networks, are trained on historical data to predict battery health degradation based on variables such as voltage, current, and temperature [55]. Support Vector Machines (SVMs): Applied in SOH forecasting by analyzing key features such as impedance, voltage, and temperature. SVMs are particularly effective with small datasets and are known for their superior classification accuracy [56]. Random Forests (RFs): A robust ensemble learning method, random forests have been successfully employed for SOH prediction by aggregating data from various sensors and conditions. The model constructs multiple decision trees to provide a reliable and precise evaluation of battery health [57]. |

| Recurrent Neural Networks (RNNs) and Long Short-Term Memory Networks (LSTMs) | These models are highly suited for sequence prediction tasks, making them ideal for battery SOH estimation where time-series data (historical performance) plays a significant role. LSTM networks are particularly adept at capturing long-term dependencies in the data, which is crucial for understanding battery degradation over time [58]. |

| Gaussian Processes (GPs) | Gaussian processes offer a probabilistic approach to quantify uncertainty in SOH predictions. They are especially useful in scenarios involving sparse or noisy data, as they provide confidence intervals alongside predictions [59]. |

| Support Vector Regression (SVR) | SVR is used to predict continuous values, making it suitable for SOH assessment based on historical battery performance data. It has shown promising results in accurately estimating the remaining useful life (RUL) of Li-ion batteries [60]. |

| Feature Engineering and Sensor Fusion | The performance of data-driven models can be significantly improved by the careful selection and engineering of features derived from operational data. Additionally, sensor fusion, which integrates data from multiple sensors (e.g., temperature, voltage, current), provides a more comprehensive view of the battery’s SOH [61]. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bayoumi, E.H.E.; De Santis, M.; Awad, H. A Brief Overview of Modeling Estimation of State of Health for an Electric Vehicle’s Li-Ion Batteries. World Electr. Veh. J. 2025, 16, 73. https://doi.org/10.3390/wevj16020073

Bayoumi EHE, De Santis M, Awad H. A Brief Overview of Modeling Estimation of State of Health for an Electric Vehicle’s Li-Ion Batteries. World Electric Vehicle Journal. 2025; 16(2):73. https://doi.org/10.3390/wevj16020073

Chicago/Turabian StyleBayoumi, Ehab H. E., Michele De Santis, and Hilmy Awad. 2025. "A Brief Overview of Modeling Estimation of State of Health for an Electric Vehicle’s Li-Ion Batteries" World Electric Vehicle Journal 16, no. 2: 73. https://doi.org/10.3390/wevj16020073

APA StyleBayoumi, E. H. E., De Santis, M., & Awad, H. (2025). A Brief Overview of Modeling Estimation of State of Health for an Electric Vehicle’s Li-Ion Batteries. World Electric Vehicle Journal, 16(2), 73. https://doi.org/10.3390/wevj16020073