Traction Synchronous Motors with Rotor Field Winding: A Literature Review

Abstract

1. Introduction

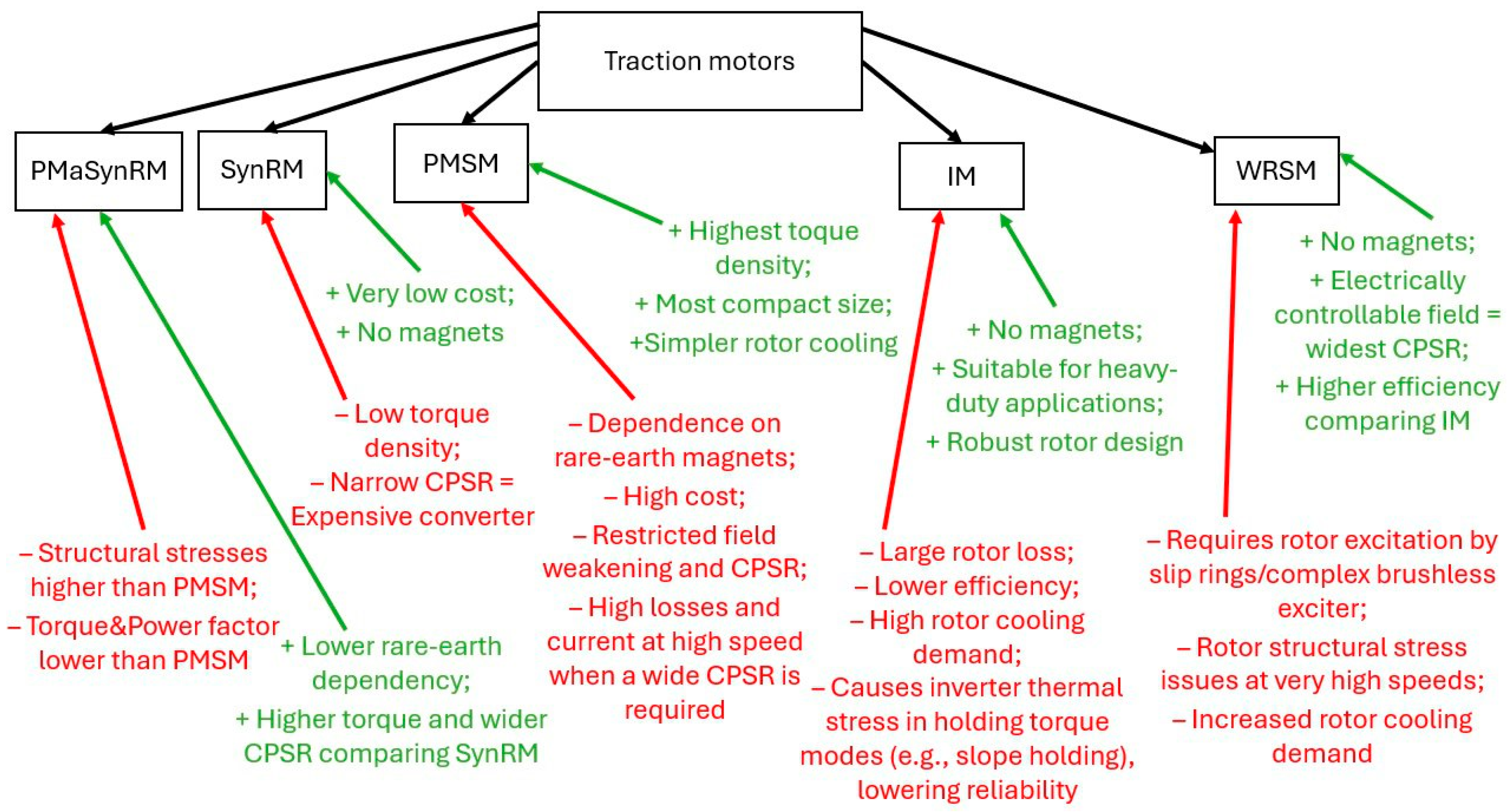

2. Commercial Traction Wound-Rotor Synchronous Motors for Ground Vehicles (1980s–Present Time)

2.1. Railroad Traction

2.2. Road Vehicles

3. Comparative Analysis of EV Traction Motors in the Scientific Literature

3.1. General WRSM Evaluation Compared to Other Motor Types

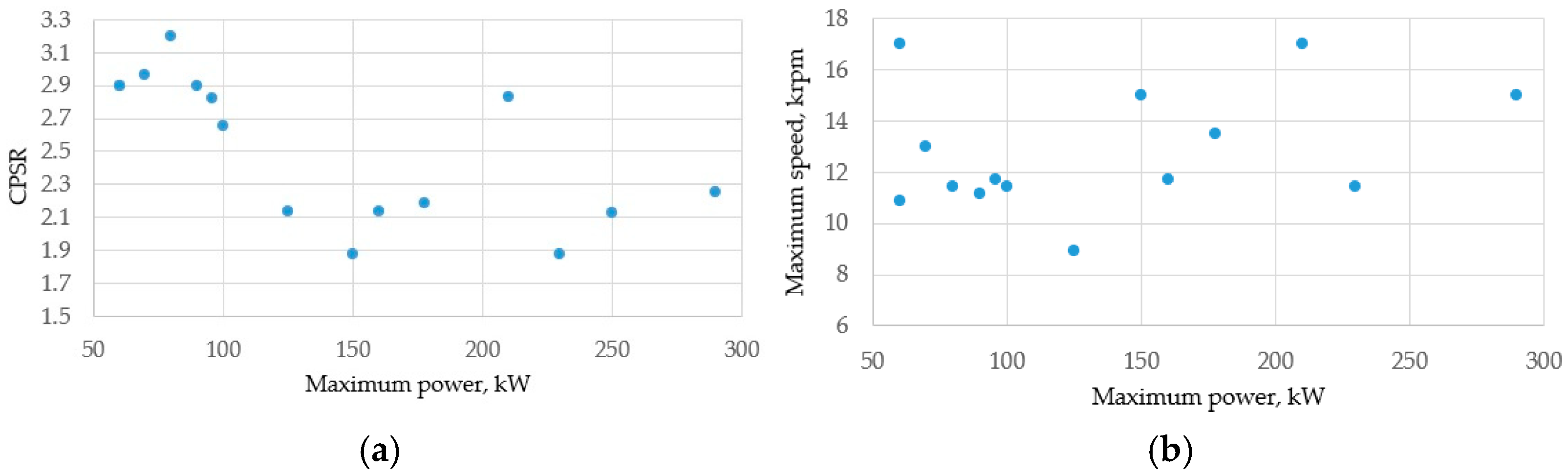

3.2. Light Electric Vehicles

3.3. Electric Trucks

3.4. Summary

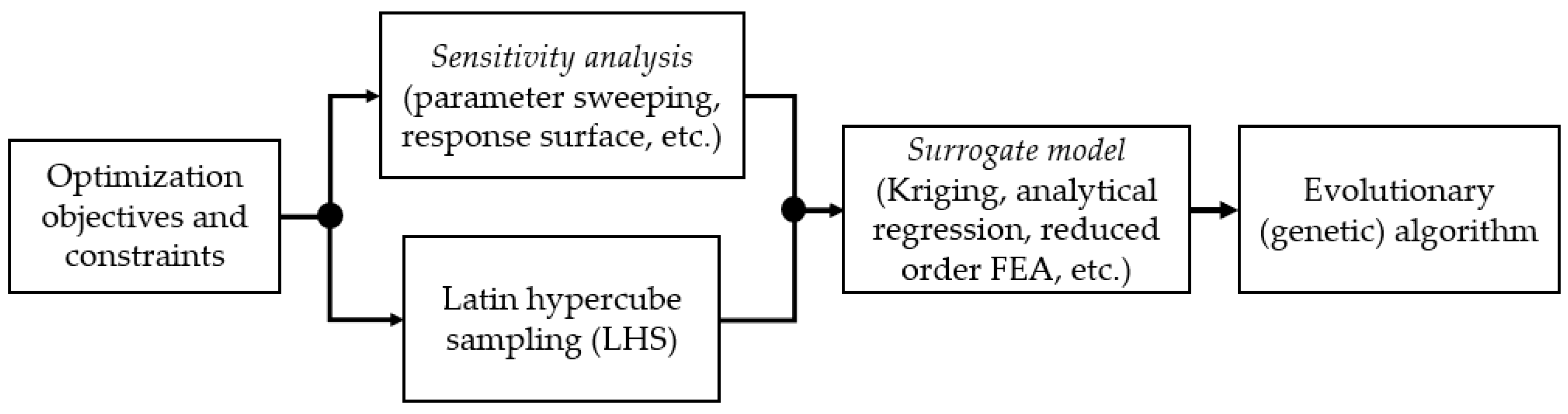

4. Design Optimization of Wound-Rotor Synchronous Motors

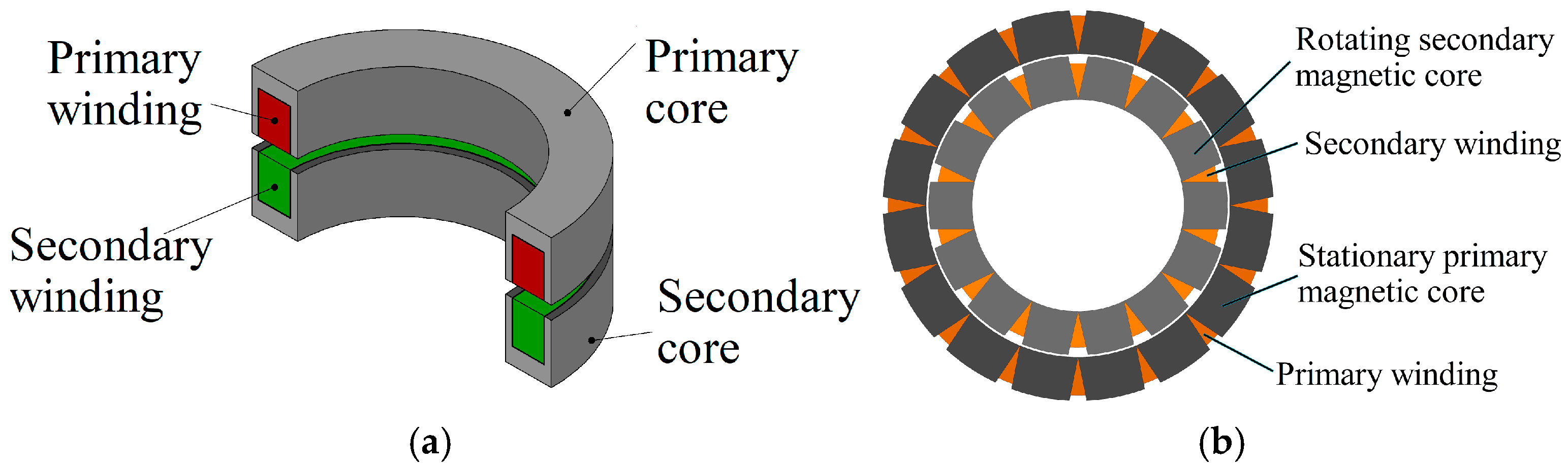

5. Brushless WRSM

5.1. Brushes and Slip Rings Excitation

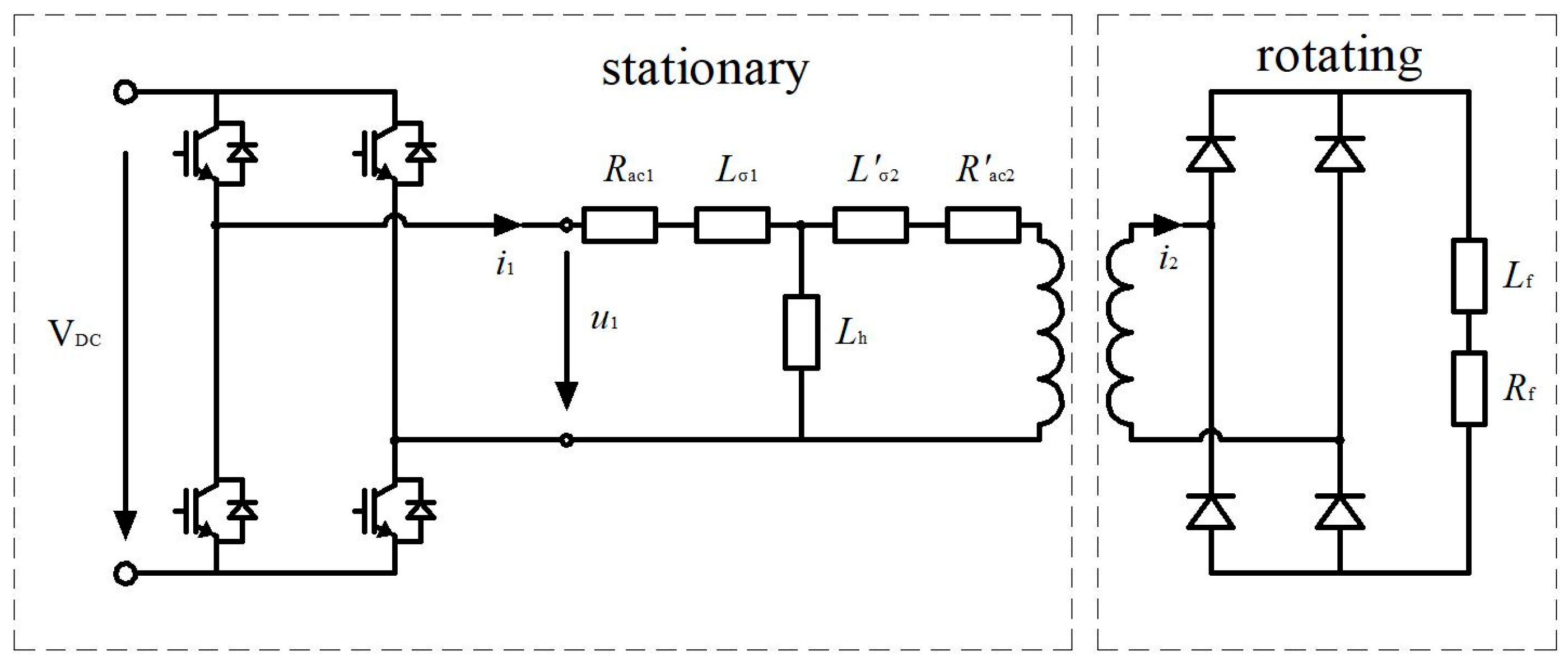

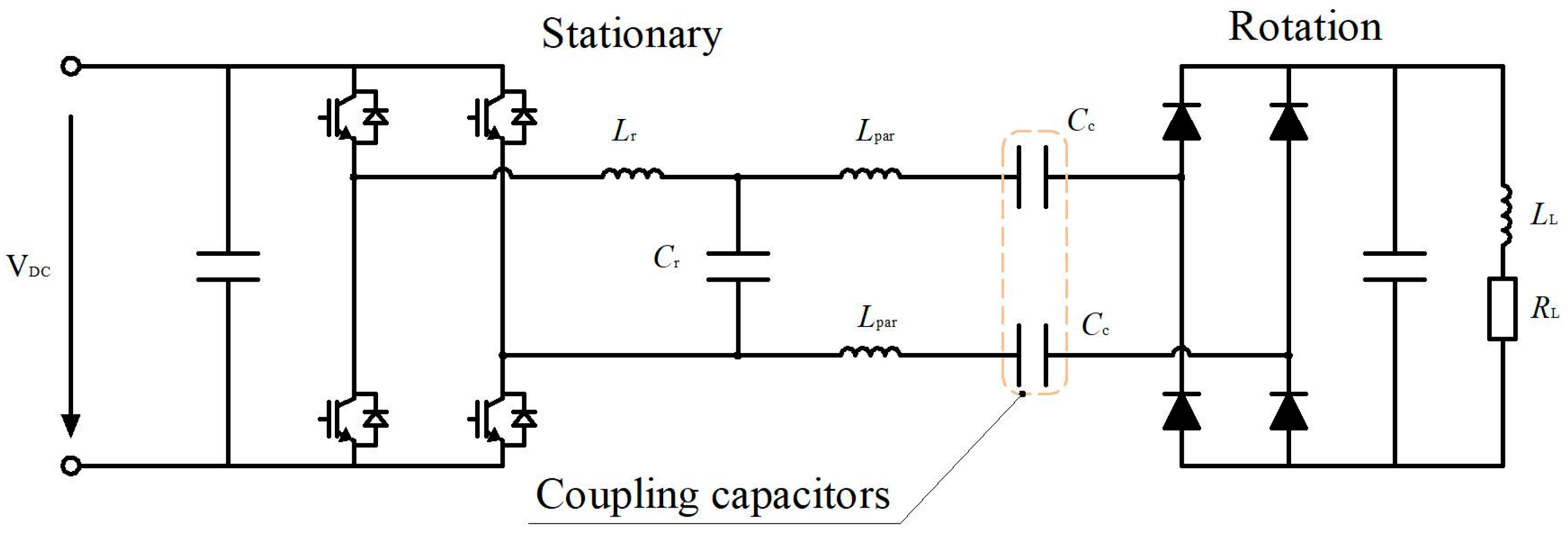

5.2. WRSMs Equipped with a Separate Brushless Exciter

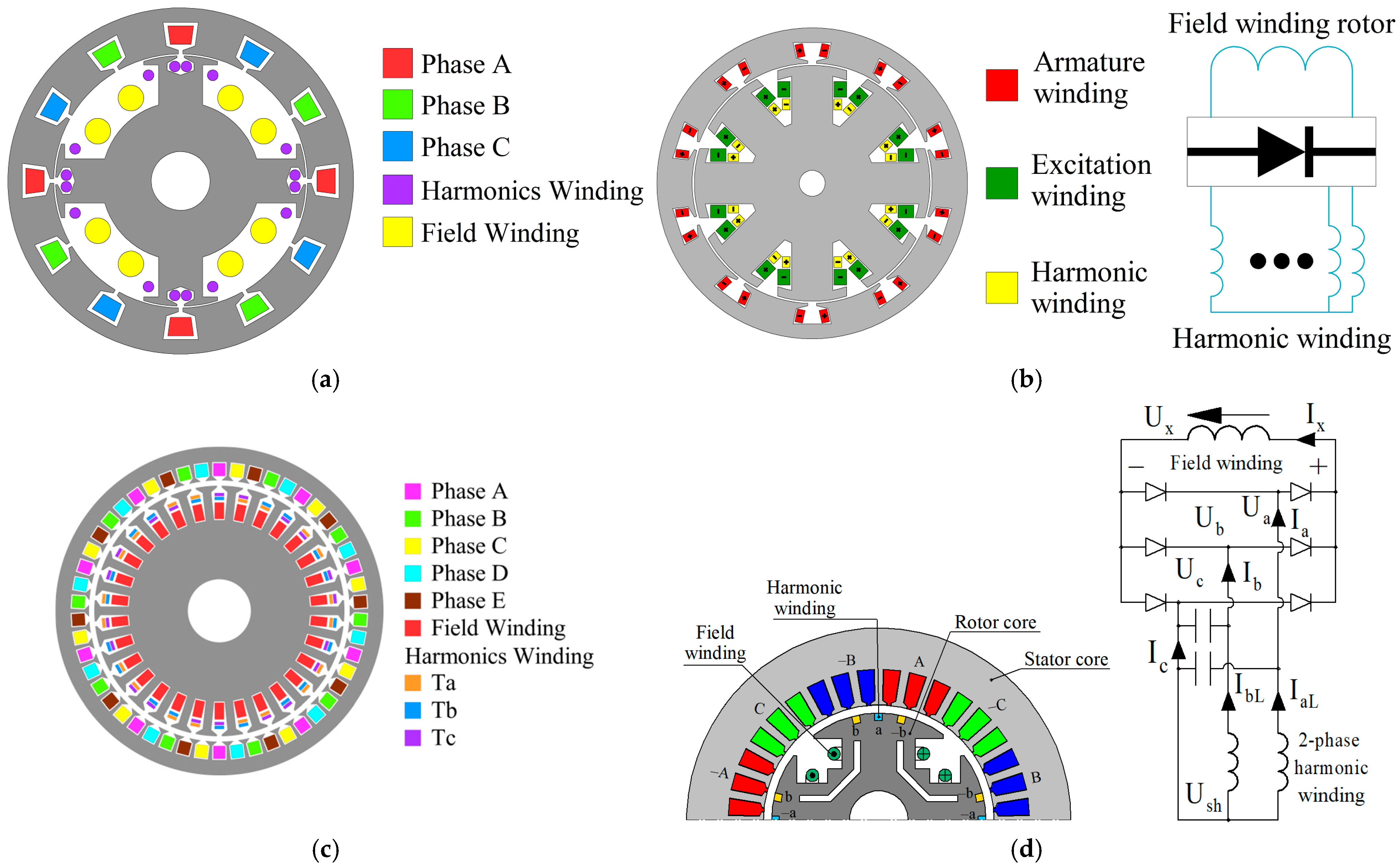

5.3. Synchronous Machines with Harmonic Excitation

6. Discussion

6.1. Discussion of Design Optimization Methods

6.2. Discussion of Brushless Excitation Techniques

6.3. Discussion of Comparison of WRSMs and Other Motor Types

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CPSR | Constant-power speed range |

| EESM | Electrically excited synchronous machine (Externally excited synchronous machine) |

| EMF | Electromotive force |

| EV | Electric vehicle |

| FEA | Finite element analysis |

| FEM | Finite element method |

| GA | Genetic algorithm |

| HESM | Harmonic-excited synchronous machine |

| HeWRSM | Hybrid-excited wound rotor field synchronous machine |

| IM | Induction machine |

| IPMSM | Interior permanent magnet synchronous machine |

| LHS | Latin hypercube sampling |

| PMSM | Permanent-magnet synchronous machine |

| PMaSynRM | Permanent-magnet-assisted synchronous reluctance motor/machine |

| PWM | Pulse-width modulation |

| SESM | Separately excited synchronous machine |

| SHM | Synchronous homopolar machine |

| SMC | Soft magnetic composites |

| SynRM | Synchronous reluctance motor/machine |

| WFSM | Wound-rotor field synchronous machine |

| WRSM | Wound-field rotor synchronous machine |

| WLTP | Worldwide light vehicle test procedure |

References

- International Energy Agency. Global EV Outlook 2025: Executive Summary; International Energy Agency: Paris, France; Available online: https://www.iea.org/reports/global-ev-outlook-2025/executive-summary (accessed on 17 August 2025).

- The French Train a Grande Vitesse: Focusing on the TGV-Atlantique Walter C. Streeter, The University of California Transportation Center. 1992. Available online: https://www.uctc.net/research/facultypapers_1990_start.html (accessed on 23 July 2025).

- Renfe S-100. Renfe Group. Available online: https://www.renfe.com/es/en/renfe-group/renfe-group/fleet-of-trains/s-100 (accessed on 15 August 2025).

- SNCF TGV-A, 8.5.10. Available online: https://documents.epfl.ch/users/a/al/allenbac/www/documents/Fich0510.pdf (accessed on 23 July 2025).

- Petit, G. Evolution of the electrical equipment of TGV trainsets. In Proceedings of the International Conference on Main Line Railway Electrification 1989, York, UK, 25–28 September 1989; pp. 403–407. [Google Scholar]

- Steimel, A. Electric Traction—Motive Power and Energy Supply: Basics and Practical Experience; Oldenbourg Industrieverlag: Munich, Germany, 2008. [Google Scholar]

- ALSTOM High Speed Trains More than 30 Years of Experience, September 2013. Available online: https://www.sitkrp.org.pl/storage/media/Zarz%C4%85d%20G%C5%82%C3%B3wny/articles/239/file/646f8b1f8678c.pdf (accessed on 5 August 2025).

- The High Speed Rail System in Korea: Project Story, Alstom Transport. 2004. Available online: https://web.archive.org/web/20040912012842/http://www.webmag.transport.alstom.com/eMag/externe/international/korea/ktx/mar2004/1/_files/file_225_39190.pdf (accessed on 5 August 2025).

- Sybic Techniques. Présentation de la Sybic: La Sybic ou BB 26000 Peut Être Utilisée. Available online: https://web.archive.org/web/20040217173213/http://www.sybics.com/sybic_techniques.htm#fichetech (accessed on 23 July 2025).

- Renault Zoe E-tech 100% Electric. 2022. Available online: https://autocatalogarchive.com/wp-content/uploads/2022/10/Renault-ZOE-2022-UK.pdf (accessed on 5 August 2025).

- Cui, D.; Ekergård, B. Traction Motors in Electric Vehicles: A Snapshot of Technologies and Performance. 2024. Available online: https://www.hv.se/globalassets/dokument/iv/e-drive-2---report.pdf (accessed on 5 August 2025).

- Grunditz, E.A.; Thiringer, T. Performance Analysis of Current BEVs Based on a Comprehensive Review of Specifications. IEEE Trans. Transp. Electrific. 2016, 2, 270–289. [Google Scholar] [CrossRef]

- Specifications of the BMW iX3, Valid from 07/2020. 2020. Available online: https://www.press.bmwgroup.com/global/article/detail/T0314265EN/specificationsof-the-bmw-ix3-valid-from-07/2020?language=en (accessed on 5 August 2025).

- The BMW i7 M70 xDrive. 2023. Available online: https://www.press.bmwgroup.com/global/article/detail/T0412894EN/thebmw-i7-m70-xdrive?language=en (accessed on 5 August 2025).

- Charge Faster, Drive Further: BMW Group Reveals Revolutionary Electric Drive Concept with 800V Technology for the Neue Klasse. 2025. Available online: https://www.press.bmwgroup.com/global/article/detail/T0448099EN/charge-faster-drive-further:-bmw-group-reveals-revolutionary-electric-drive-concept-with-800v-technology-for-the-neue-klasse (accessed on 8 June 2025).

- Beck, F. Rotor and Method for Producing a Rotor. U.S. Patent 2024/0186872A1, 6 June 2024. Available online: https://patents.google.com/patent/US20240186872A1/en?oq=US20240186872A1 (accessed on 8 June 2025).

- Eibl, M. Rotor and Electric Machine. U.S. Patent 12323017B2, 3 June 2025. Available online: https://patents.google.com/patent/US12323017B2/en (accessed on 23 October 2025).

- Loos, D.; Tremaudant, Y. Rotor shaft of an Electric Motor. U.S. Patent 12231021B2, 18 February 2025. Available online: https://patents.google.com/patent/US12231021B2/en (accessed on 23 October 2025).

- Loos, D. Support Device for a Rotor of a Separately Excited Internal-Rotor Synchronous Machine Consisting of a Support Ring and a Star Disk. U.S. Patent 11349367B2, 31 May 2022. Available online: https://patents.google.com/patent/US11349367B2/zh (accessed on 23 October 2025).

- 2024 Nissan Ariya Press Kit. Available online: https://usa.nissannews.com/en-US/releases/2024-nissan-ariya-press-kit?selectedTabId=release-8b852be848fc49da275d0ef8df13d0d7 (accessed on 5 August 2025).

- 2024 Nissan Ariya e-4ORCE Specifications. Available online: https://usa.nissannews.com/en-US/releases/2024-nissan-ariya-press-kit?selectedTabId=release-8b852be848fc49da275d0ef8df160bd9 (accessed on 5 August 2025).

- Rolls-Royce Spectre: The Rolls-Royce that Changes Everything. 2023. Available online: https://www.press.rolls-roycemotorcars.com/rolls-royce-motor-cars-pressclub/article/detail/T0422818EN/rolls-royce-spectre:-the-rolls-royce-that-changes-everything?language=en (accessed on 5 August 2025).

- Minimalist All-Rounder: The New MINI Countryman. 2023. Available online: https://www.press.bmwgroup.com/global/article/detail/T0433118EN/minimalist-all-rounder:-the-new-mini-countryman?language=en (accessed on 5 August 2025).

- Smart Electric Drive Technical Data, Engines and Motor. 2017. Available online: https://web.archive.org/web/20170920232925/https://www.smart.com/en/en/index/smart-forfour-electric-drive-453/technical-data.html#engine0 (accessed on 5 August 2025).

- Mikati, K.; Motte, E.; Bernardin, F. Wound Rotor Synchronous Electric Machine. U.S. Patent 11075561B2, 27 July 2021. Available online: https://patents.google.com/patent/US11075561B2/en (accessed on 23 October 2025).

- Tavakoli, S.; Dell Agnese, A.; Frabolot, F. Cage for Wound Rotor of a Synchronous Electric Machine. U.S. Patent 11283322B2, 22 March 2022. Available online: https://patents.google.com/patent/US11283322B2/en (accessed on 23 October 2025).

- Tavakoli, S.; Pressoir, J. Wound-Type Rotor for a Synchronous Electric Machine. EP Patent 3776814B1, 16 August 2023. Available online: https://patents.google.com/patent/EP3776814B1/en (accessed on 23 October 2025).

- Motte, E.; Bernardin, F.; Birolleau, D. Rotor of Electric Machine. FR Patent 3068538B1, 10 January 2020. Available online: https://patents.google.com/patent/FR3068538B1/en (accessed on 23 October 2025).

- Motte, E.; Vivas-Marquez, D. Winding Guide for Electric Machine Rotor. FR Patent 3127087B1, 22 September 2023. Available online: https://patents.google.com/patent/FR3127087B1/en (accessed on 23 October 2025).

- Dunesme, X.; Gabillard, S.; Henocq, B.; Motte, E.; Thierry, M. Coil Head Guide, Wound Rotor of Electric Machine and Electric Machine Comprising such a Wound Rotor. FR Patent 3145844B1, 30 May 2025. Available online: https://patents.google.com/patent/FR3145844B1/en (accessed on 23 October 2025).

- Dunesme, X.; Gabillard, S.; Motte, E. Guiding Device for Winding an Electric Machine Rotor. FR Patent 3146037B1, 23 May 2025. Available online: https://patents.google.com/patent/FR3146037B1/en (accessed on 23 October 2025).

- Tavakoli, S.; Dell Agnese, A. Wire Guiding Device for a Rotor of a Synchronous Electric Machine of the Wound Rotor Type. EP Patent 3827505B1, 24 August 2022. Available online: https://patents.google.com/patent/EP3827505B1/en (accessed on 23 October 2025).

- ZF Products for Passenger Cars, I2SM. Available online: https://www.zf.com/products/en/cars/products_77186.html (accessed on 5 August 2025).

- ZF Products for Passenger Cars. EM:SELECT. Available online: https://www.zf.com/products/en/cars/products_66245.html (accessed on 5 August 2025).

- Dieckhoff, T.; Birkenmaier, G.; Schreibmüller, N.; Schwab, M.; Pfeiffer, D.; Schuh, H.; Kraft, P.; Budach, R.; Zajonc, M.; Raimann, M.; et al. Rotor Arrangement for a Separately Excited Synchronous Machine. DE Patent 102022207340B3, 25 January 2024. Available online: https://patents.google.com/patent/DE102022207340B3/en (accessed on 23 October 2025).

- Schönekäs, J.; Kraft, P. Rotor Arrangement for a Separately Excited Synchronous Machine and Separately Excited Synchronous Machine. DE Patent 102024202598B4, 16 October 2025. Available online: https://patents.google.com/patent/DE102024202598B4/en (accessed on 23 October 2025).

- Büttner, A.; Bartha, A.; Dieckhoff, T.; Budach, R.; Kraft, P. Rotor Shaft with Integrated Exciter, Rotor Earthing and Rotor Position Sensor. DE Patent 102024203702B3, 18 September 2025. Available online: https://patents.google.com/patent/DE102024203702B3/en (accessed on 23 October 2025).

- Valeo and MAHLE Expand Their Product Range of Magnet Free Electric Motors to Upper Segment Applications. 2024. Available online: https://newsroom.mahle.com/press/en/press-releases/valeo-and-mahle-expand-their-product-range-of-magnet-free-electric-motors-to-upper-segment-applications-106048# (accessed on 11 June 2025).

- Gritzki, M. Energy-Saving Rotor Flux Control for an Electrically Excited Synchronous Motor as Well as Drive System, Vehicle and Operating Method Therefor. D. E. Patent 102023118736A1, 14 July 2023. Available online: https://patents.google.com/patent/DE102023118736A1/en?oq=DE102023118736A1 (accessed on 5 August 2025).

- Siepker, C.; Wieczorek, C.; Bach, R.; Wolf, N.; Schlereth, A. Rotor for an Electric Machine Having a Radial Cooling Duct in the Laminated Core. U.S. Patent 12374945B2, 29 July 2025. Available online: https://patents.google.com/patent/US12374945B2/en (accessed on 23 October 2025).

- Wolf, N.; Schlereth, A.; Noack, R.; Siepker, C.; Wieczorek, C. Rotor for an Electrical Machine Having a Tubular Cooling Channel. U.S. Patent Application US20250047154A1, 6 February 2025. Available online: https://patents.google.com/patent/US20250047154A1/en (accessed on 23 October 2025).

- Wolf, N.; Schlereth, A. Interlocked Lamination Package for Winding of EESM Rotor by Process. U.S. Patent 2025/0055358A1, 13 February 2025. Available online: https://patents.google.com/patent/US20250055358A1/en?oq=US20250055358A1 (accessed on 5 August 2025).

- Automobile-Catalog the Catalog of Cars. Car Specs Database. Available online: www.automobile-catalog.com (accessed on 4 October 2025).

- Specifications of the BMW iX1 xDrive30, Valid from 11/2022. Available online: https://www.press.bmwgroup.com/global/article/detail/T0404224EN/specifications-of-the-bmw-ix1-xdrive30-valid-from-11/2022?language=en (accessed on 5 August 2025).

- Specifications of the BMW iX2 eDrive20, Valid from 03/2024. 2024. Available online: https://www.press.bmwgroup.com/global/article/detail/T0439779EN/specifications-of-the-bmw-ix2-edrive20-valid-from-03/2024?language=en (accessed on 5 August 2025).

- The BMW i7 M70 xDrive. 2023. Available online: https://www.press.bmwgroup.com/united-kingdom/article/detail/T0413542EN_GB/the-bmw-i7-m70-xdrive?language=en_GB (accessed on 5 August 2025).

- The New BMW iX M60. 2022. Available online: https://www.press.bmwgroup.com/global/article/detail/T0348394EN/the-new-bmw-ix-m60?language=en (accessed on 5 August 2025).

- The New BMW 7 Series. 2022. Available online: https://www.press.bmwgroup.com/global/article/detail/T0380173EN/the-new-bmw-7-series?language=en (accessed on 5 August 2025).

- The New BMW iX xDrive40 and New BMW iX xDrive50. 2021. Available online: https://www.press.bmwgroup.com/global/article/detail/T0327077EN/thenew-bmw-ix-xdrive40-and-new-bmw-ix-xdrive50?language=en (accessed on 5 August 2025).

- The First-Ever BMW i4. 2021. Available online: https://www.press.bmwgroup.com/global/article/detail/T0333329EN/the-first-ever-bmw-i4?language=en (accessed on 5 August 2025).

- The New BMW 5 Series Sedan. 2023. Available online: https://www.press.bmwgroup.com/global/article/detail/T0416261EN/the-new-bmw-5-series-sedan?language=en (accessed on 5 August 2025).

- The New BMW 5 Series Touring. 2024. Available online: https://www.press.bmwgroup.com/global/article/detail/T0439374EN/the-new-bmw-5-series-touring?language=en (accessed on 5 August 2025).

- Widmer, J.D.; Martin, R.; Kimiabeigi, M. Electric vehicle traction motors without rare earth magnets. Sustain. Mater. Technol. 2015, 3, 7–13. [Google Scholar] [CrossRef]

- Estenlund, S.; Alakula, M.; Reinap, A. PM-less machine topologies for EV traction: A literature review. In Proceedings of the 2016 International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Toulouse, France,, 2–4 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Gobbi, M.; Sattar, A.; Palazzetti, R.; Mastinu, G. Traction motors for electric vehicles: Maximization of mechanical efficiency—A review. Appl. Energy 2024, 357, 122496. [Google Scholar] [CrossRef]

- Petrelli, G.; Nuzzo, S.; Zou, T.; Barater, D.; Franceschini, G.; Gerada, C. Review and future developments of wound field synchronous motors in automotive. In Proceedings of the 2023 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Venice, Italy, 22–24 March 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Nategh, S.; Boglietti, A.; Jahirul, I.M. A comprehensive study on different motor topologies used in passenger car EV segment. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Gneiting, C.; Waldhof, M.; Parspour, N. A systematic design methodology based on data clustering for automotive drive cycle oriented optimization of electrically excited synchronous machines. In Proceedings of the 2022 IEEE 7th Southern Power Electronics Conference (SPEC), Nadi, Fiji, 12–15 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Tokat, E.; Nguyen, D.-K. Drive cycle comparison of a PMSM and an EESM for a traction application utilizing modular stator manufacturing. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Lee, O.M.; Abbasian, M. Reducing rare-earth magnet reliance in modern traction electric machines. Energies 2025, 18, 2274. [Google Scholar] [CrossRef]

- Popescu, M.; Goss, J.; Staton, D.A.; Hawkins, D.; Chong, Y.C.; Boglietti, A. Electrical vehicles—Practical solutions for power traction motor systems. IEEE Trans. Ind. Appl. 2018, 54, 2751–2762. [Google Scholar] [CrossRef]

- Filippini, F.; Pastura, M.; Bianchi, N. PM and PM-less motors for electric vehicles: A comparative analysis. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Credo, A.; Fabri, G.; Centi, F.; Collazzo, F.P.; Villani, M. Comparison of rare-earth free synchronous motors for traction applications. In Proceedings of the 2025 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Valletta, Malta, 28–29 April 2025; IEEE: Piscataway, NJ, USA, 2025; pp. 1–6. [Google Scholar] [CrossRef]

- Chen, H.; Tang, J.; Liu, Y.; Jiang, B.; Boscaglia, L. Electromagnetic performance investigation of a brushless electrically excited synchronous machine for long-distance heavy-duty electric vehicles. IEEE Trans. Transp. Electrif. 2025, 11, 225–235. [Google Scholar] [CrossRef]

- Mademlis, G.; Liu, Y.; Tang, J.; Boscaglia, L.; Sharma, N. Performance evaluation of electrically excited synchronous machine compared to PMSM for high-power traction drives. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1793–1799. [Google Scholar] [CrossRef]

- Dmitrievskii, V.; Prakht, V.; Valeev, E.; Paramonov, A.; Kazakbaev, V.; Anuchin, A. Comparative study of induction and wound rotor synchronous motors for the traction drive of a mining dump truck operating in wide constant power speed range. IEEE Access 2023, 11, 68395–68409. [Google Scholar] [CrossRef]

- Prakht, V.; Dmitrievskii, V.; Kazakbaev, V.; Anuchin, A. Comparative study of electrically excited conventional and homopolar synchronous motors for the traction drive of a mining dump truck operating in a wide speed range in field-weakening region. Mathematics 2022, 10, 3364. [Google Scholar] [CrossRef]

- Song, Z.; Liang, Y. Overview of High Overload Motors. IEEE Trans. Ind. Appl. 2024, 60, 8611–8626. [Google Scholar] [CrossRef]

- Guo, F.; Salameh, M.; Krishnamurthy, M.; Brown, I.P. Multimaterial magneto-structural topology optimization of wound field synchronous machine rotors. IEEE Trans. Ind. Appl. 2020, 56, 3656–3667. [Google Scholar] [CrossRef]

- Asef, P.; Vagg, C. A physics-informed Bayesian optimization method for rapid development of electrical machines. Sci. Rep. 2024, 14, 4526. [Google Scholar] [CrossRef]

- Ban, B.; Kersten, A.; Skoog, S.; Sjöberg, L.; Stipetić, S.; Batra, T. Comparative analysis of electric motor designs: Traditional steel laminations vs. soft magnetic composite materials. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Singh, S.; Krüger, R.; Doppelbauer, M. Comparison of optimized hairpin and pull-in winding high-speed electrically excited synchronous machines for traction applications. In Proceedings of the 2023 13th International Electric Drives Production Conference (EDPC), Regensburg, Germany, 28–29 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Mirahki, H.; Atallah, K.; Rodrigues, L.; Cawkwell, T. Concept design and optimization methodology of a wound field synchronous motor for commercial vehicle applications. In Proceedings of the 2023 IEEE Energy Conversion Congress and Exposition (ECCE), Nashville, TN, USA, 29 October–2 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 4330–4337. [Google Scholar] [CrossRef]

- Di Gioia, A.; Brown, I.P.; Nie, Y.; Knippel, R.; Ludois, D.C.; Dai, J.; Hagen, S.; Alteheld, C. Design and demonstration of a wound field synchronous machine for electric vehicle traction with brushless capacitive field excitation. IEEE Trans. Ind. Appl. 2018, 54, 1390–1403. [Google Scholar] [CrossRef]

- Muthusamy, M.; Xue, S.; Bobba, D.; Shoeb, A.; Acharya, V.M.; Imamura, R. Design and optimization of wound field synchronous machines for traction applications. In Proceedings of the 2024 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 19–21 June 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Tang, N.; Sossong, D.; Krause, N.; Hou, X.; Liben, M.J.; Ludois, D.C.; Brown, I.P. Implementation of a metamodel-based optimization for the design of a high power density wound field traction motor. IEEE Trans. Ind. Appl. 2023, 59, 6726–6735. [Google Scholar] [CrossRef]

- Brown, I.P.; Ludois, D.C. Wound Field and Hybrid Synchronous Machines for EV Traction with Brushless Capacitive Rotor Field Excitation; Final Report; U.S. Department of Energy: Oak Ridge, TN, USA, 2022. Available online: https://www.osti.gov/biblio/1837809 (accessed on 23 July 2025).

- Müller, S.; Maier, D.; Parspour, N. Inductive electrically excited synchronous machine for electrical vehicles—Design, optimization and measurement. Energies 2023, 16, 1657. [Google Scholar] [CrossRef]

- Sano, H.; Narita, K.; Semba, K.; Suzuki, Y.; Yamada, T. Multidisciplinary optimization of an electrically excited synchronous motor. In Proceedings of the 2023 IEEE Energy Conversion Congress and Exposition (ECCE), Nashville, TN, USA, 29 October–2 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 4360–4364. [Google Scholar] [CrossRef]

- Ran, Z.; Zhu, Z.Q.; Chen, Z.; Younkins, M.; Farah, P. Novel system-level driving-cycle-oriented design co-optimization of electrical machines for electrical vehicles. IEEE Access 2024, 12, 131734–131749. [Google Scholar] [CrossRef]

- Petrelli, G.; Nuzzo, S.; Barater, D.; Zou, T.; Franceschini, G.; Gerada, C. Preliminary sensitivity analysis and optimisation of a wound field synchronous motor for traction applications. In Proceedings of the 2023 AEIT International Conference on Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Modena, Italy, 11–13 July 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Frias, A.; Pellerey, P.; Lebouc, A.K.; Chillet, C.; Lanfranchi, V.; Friedrich, G.; Albert, L.; Humbert, L. Rotor and stator shape optimization of a synchronous machine to reduce iron losses and acoustic noise. In Proceedings of the 2012 IEEE Vehicle Power and Propulsion Conference (VPPC), Seoul, Republic of Korea, 9–12 October 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 98–103. [Google Scholar] [CrossRef]

- Seo, H.-S.; Park, C.-B.; Kim, S.-H.; Lei, G.; Guo, Y.; Lee, H.-W. Utilizing micro-genetic algorithm for optimal design of permanent-magnet-assisted WFSM for traction machines. Appl. Sci. 2024, 14, 5150. [Google Scholar] [CrossRef]

- Hussain, A.; Baig, Z.; Toor, W.T.; Ali, U.; Idrees, M.; Al Shloul, T.; Ghadi, Y.Y.; Alkahtani, H.K. Wound rotor synchronous motor as promising solution for traction applications. Electronics 2022, 11, 4116. [Google Scholar] [CrossRef]

- Hussain, A.; Atiq, S.; Kwon, B. Optimal design and experimental verification of wound rotor synchronous machine using subharmonic excitation for brushless operation. Energies 2018, 11, 554. [Google Scholar] [CrossRef]

- Yu, K.-T.; Ban, H.-R.; Kim, S.-W.; Park, J.-B.; Choi, J.-Y.; Shin, K.-H. Electromagnetic analysis and multi-objective design optimization of a WFSM with hybrid GOES-NOES core. World Electr. Veh. J. 2025, 16, 399. [Google Scholar] [CrossRef]

- Lu, H.; Deutsch, J.; Doppelbauer, M. Mechanical design of a high-speed permanent magnet assisted electrically excited synchronous machine as traction motor. In Proceedings of the 2022 International Power Electronics Conference (IPEC-Himeji 2022-ECCE Asia), Himeji, Japan, 15–19 May 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1528–1535. [Google Scholar] [CrossRef]

- de Santiago, J. Electrical motor drivelines in commercial all-electric vehicles: A review. IEEE Trans. Veh. Technol. 2012, 61, 475–484. [Google Scholar] [CrossRef]

- Nøland, J.K.; Nuzzo, S.; Tessarolo, A.; Alves, E.F. Excitation system technologies for wound-field synchronous machines: Survey of solutions and evolving trends. IEEE Access 2019, 7, 109699–109718. [Google Scholar] [CrossRef]

- Stancu, C.; Ward, T.; Rahman, K.; Dawsey, R.; Savagian, P. Separately excited synchronous motor with rotary transformer for hybrid vehicle application. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 5844–5851. [Google Scholar] [CrossRef]

- Raminosoa, T.; Wiles, R. Contactless rotor excitation for traction motors. In Proceedings of the 2018 IEEE Energy Conversion Congress and Exposition (ECCE), Portland, OR, USA, 23–27 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 6448–6453. [Google Scholar] [CrossRef]

- Weber, J.-N.; Rehfeldt, A.; Vip, S.-A.; Ponick, B. Rotary transformer with electrical steel core for brushless excitation of synchronous machines. In Proceedings of the 2016 XXII International Conference on Electrical Machines (ICEM), Lausanne, Switzerland, 4–7 September 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 884–889. [Google Scholar] [CrossRef]

- Maier, D.; Heinrich, J.; Zimmer, M.; Maier, M.; Parspour, N. Contribution to the system design of contactless energy transfer systems. IEEE Trans. Ind. Appl. 2019, 55, 316–326. [Google Scholar] [CrossRef]

- Illiano, E. Design of a Highly Efficient Brushless Current Excited Synchronous Motor for Automotive Purposes. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2014. Available online: https://www.research-collection.ethz.ch/bitstream/handle/20.500.11850/155089/eth-47717-02.pdf (accessed on 2 November 2025).

- Illiano, E. Synchronous Machine with Switching Element in the Excitation Circuit. U.S. Patent 8963476B2, 24 February 2015. Available online: https://patents.google.com/patent/US8963476B2/en (accessed on 2 November 2025).

- Krupp, H. Method and Device for Demagnetizing at Least One Field Winding, in Particular a Rotor of an Electric Motor. DE Patent 102016207392B4, 28 January 2021. Available online: https://patents.google.com/patent/DE102016207392B4/en (accessed on 2 November 2025).

- Tran, V.-K.; Park, B.-G.; Han, P.-W.; Paul, S.; Lee, J.-G.; Chun, Y.-D. Design of high efficiency wound field synchronous motor for short-distance electric mobility in given driving cycle. In Proceedings of the 2024 International Conference on Electrical Machines (ICEM), Torino, Italy, 1–4 September 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–7. [Google Scholar] [CrossRef]

- Tang, J.; Liu, Y.; Sharma, N. Modeling and experimental verification of high-frequency inductive brushless exciter for electrically excited synchronous machines. IEEE Trans. Ind. Appl. 2019, 55, 4613–4623. [Google Scholar] [CrossRef]

- Tang, J.; Liu, Y. Design and experimental verification of a 48 V 20 kW electrically excited synchronous machine for mild hybrid vehicles. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Tang, J.; Liu, Y.; Lundberg, S. Estimation algorithm for current and temperature of field winding in electrically excited synchronous machines with high-frequency brushless exciters. IEEE Trans. Power Electron. 2021, 36, 3512–3523. [Google Scholar] [CrossRef]

- Lin, C.; Pathmanathan, M.; Rodriguez, P.; Bertoldi, F.; Kabir, M.A.; Janhunen, T.; Paloheimo, P. Self-excited synchronous machine using airgap harmonics. IEEE Trans. Ind. Electron. 2021, 68, 6584–6594. [Google Scholar] [CrossRef]

- Ayub, M.; Hussain, A.; Jawad, G.; Kwon, B. Brushless operation of a wound-field synchronous machine using a novel winding scheme. IEEE Trans. Magn. 2019, 55, 8201104. [Google Scholar] [CrossRef]

- Wang, X.; Xiong, Z.; Jiang, H.; Li, Y.; Lin, X.; Xie, W. Field oriented control strategy for five-phase self-excited synchronous motor based on injecting high-frequency current. In Proceedings of the IECON 2023—49th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 16–19 October 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Ayub, M.; Bukhari, S.S.; Jawad, G.; Arif, A.; Kwon, B.I. Utilization of reluctance torque for improvement of the starting and average torques of a brushless wound field synchronous machine. Electr. Eng. 2021, 103, 2327–2333. [Google Scholar] [CrossRef]

- Chung, J.; Hofmann, H. Brushless self-excited synchronous field-winding machine with five- and higher-phase design using independently controlled spatial harmonics. IEEE Trans. Energy Convers. 2023, 39, 533–543. [Google Scholar] [CrossRef]

- Dmitrievskii, V.; Kazakbaev, V.; Prakht, V.; Paramonov, A.; Goman, V. Performance analysis of traction synchronous machine with rotor field winding and two-phase harmonic field exciter with PWM supply. IEEE Access 2025, 13, 109087–109098. [Google Scholar] [CrossRef]

- Yao, F.; An, Q.; Sun, L.; Lipo, T.A. Performance investigation of a brushless synchronous machine with additional harmonic field windings. IEEE Trans. Ind. Electron. 2016, 63, 6756–6766. [Google Scholar] [CrossRef]

- Jawad, G.; Ali, Q.; Lipo, T.A.; Kwon, B. Novel brushless wound rotor synchronous machine with zero-sequence third-harmonic field excitation. IEEE Trans. Magn. 2016, 52, 8106104. [Google Scholar] [CrossRef]

- Yao, F.; An, Q.; Gao, X.; Sun, L.; Lipo, T.A. Principle of operation and performance of a synchronous machine employing a new harmonic excitation scheme. IEEE Trans. Ind. Appl. 2015, 51, 3890–3898. [Google Scholar] [CrossRef]

- Bukhari, S.S.H.; Memon, A.A.; Madanzadeh, S.; Sirewal, G.J.; Gandoy, D.-J.; Ro, J.S. Novel single inverter-controlled brushless wound field synchronous machine topology. Mathematics 2021, 9, 1739. [Google Scholar] [CrossRef]

- Abdel-Wahed, A.T.; Abdel-Khalik, A.S.; Hamdy, R.A.; Hamad, M.S.; Ahmed, S. Self-excited wound rotor synchronous motors for electric vehicles: Techniques and multiphase winding design strategies. Alex. Eng. J. 2025, 123, 271–310. [Google Scholar] [CrossRef]

- Yao, F.; Sun, L.; Sun, D.; Lipo, T.A. Design and excitation control of a dual three-phase zero-sequence current starting scheme for integrated starter/generator. IEEE Trans. Ind. Appl. 2021, 57, 3776–3786. [Google Scholar] [CrossRef]

- Ayub, M.; Bukhari, S.; Jawad, G.; Kwon, B. Brushless wound rotor synchronous machine with third-harmonic field excitation. Electr. Eng. 2019, 102, 259–265. [Google Scholar] [CrossRef]

- Ayub, M.; Bukhari, S.; Jawad, G.; Kwon, B. Brushless wound field synchronous machine with third-harmonic field excitation using a single inverter. Electr. Eng. 2019, 101, 165–173. [Google Scholar] [CrossRef]

- Bukhari, S.; Sirewal, G.; Chachar, F.; Ro, J.-S. Dual-inverter-controlled brushless operation of wound rotor synchronous machines based on an open-winding pattern. Energies 2020, 13, 2205. [Google Scholar] [CrossRef]

- Munir, H.M.; Ali, Q.; Rodriguez, J.; Abdelrahem, M. Brushless synchronous machine with dual-frequency inverter for high torque and low ripple operation. IEEE Access 2025, 13, 88268–88277. [Google Scholar] [CrossRef]

- Bukhari, S.S.H.; Mangi, F.H.; Sami, I.; Ali, Q.; Ro, J.-S. High-harmonic injection-based brushless wound field synchronous machine topology. Mathematics 2021, 9, 1721. [Google Scholar] [CrossRef]

- Humza, M.; Yazdan, T.; Ali, Q.; Cho, H.-W. Brushless operation of wound-rotor synchronous machine based on sub-harmonic excitation technique using multi-pole stator windings. Mathematics 2023, 11, 1117. [Google Scholar] [CrossRef]

- Jong-seok, N.; Sabir, S.; Bukhari, H. Single-Inverter-Controlled Brushless Technique for Wound Rotor Synchronous Machines. KR Patent 20230075074A, 2021. Available online: https://patents.google.com/patent/KR20230075074A (accessed on 2 November 2025).

| Model Name | Maximum Power, kW | Maximum Torque, N∙m | Maximum Speed, RPM | Ref. |

|---|---|---|---|---|

| Railway | ||||

| TGV Atlantique | 1300 | NA | 3982 | [2,4,5] |

| KTX-I | 1130 | NA | 4000 | [8] |

| Sybic BB 26000/26500 | 2800 | NA | 1930 | [9] |

| Automotive | ||||

| Renault ZOE R135 | 100 | 245 | 11,300 | [10,12,43] |

| Renault Twingo Z.E. | 60 | 160 | 11,450 | [11,43] |

| Renault ZOE R110 | 80 | 225 | 10,900 | [11,43] |

| Renault Kango Z.E. | 90 | 245 | 11,450 | [11,43] |

| Renault Megane EV40 | 96 | 250 | 11,155 | [11,43] |

| Renault Megane EV60, Scenic EV87 | 160 | 300 | 11,688 | [11,43] |

| Renault Scenic EV60 | 125 | 280 | 8900 | [11,43] |

| Renault Fluence Z.E. | 70 | 226 | 11,000 | [11,43] |

| Nissan Ariya FWD Empower+ | 178 | 300 | 13,520 | [20,43] |

| Nissan Ariya Platinum+ e-4ORCE | 290 | 599 | 13,520 | [21,43] |

| Rolls-Royce Spectre | Forward: 190 Rear: 360 | Forward: 365 Rear: 710 | NA | [22] |

| MINI Countryman E | 150 | 250 | 15,000 | [23,43] |

| MINI Countryman SE ALL4 | 230 | 494 | 15,000 | [23,43] |

| Smart EQ Forfour, Fortwo, Cabrio | 60 | 160 | 11,450 | [24,43] |

| BMW iX3 | 210 | 400 | 17,000 | [12,43] |

| BMW X1 iX1 xDrive30 | Forward: 140 Rear: 140 | Forward: 247 Rear: 247 | NA | [44] |

| BMW iX2 iX2 eDrive20 | 150 | 250 | NA | [45] |

| BMW i7 M70 xDrive, iX M60 | Forward: 190 Rear: 360 | Forward: 365 Rear: 650 | NA | [46,47] |

| BMW i7 xDrive60 | Forward: 190 Rear: 230 | Forward: 365 Rear: 380 | NA | [48] |

| BMW iX xDrive40, xDrive50 | Forward: 190 Rear: 200 | Forward: 290 Rear: 340 | NA | [49] |

| BMW i4, i5 eDrive40: Sedan, Touring | 250 | 430 | 17,000 | [43,50,51,52] |

| Application | Motor Ratings | Ref. |

|---|---|---|

| Light electric vehicles | ||

| D–E-class EV | Maximum power 225 kW | [57] |

| A-class battery EV | Rated power 30 kW, maximum power 60 kW, maximum torque 122 N∙m, CPSR 3.39:1 | [58] |

| Mid-size light EV | Maximum power 160 kW, maximum torque 320 N∙m, CPSR 2.8:1 | [59] |

| WLTP class 3 EV | Maximum power 162 kW, maximum torque 400 N∙m, CPSR 3.16:1 | [60] |

| Light battery EV | Maximum power 270 kW, maximum torque 430 N∙m, CPSR 2.73:1 | [61] |

| Light EV | Rated power 90 kW, rated torque 200 N∙m, CPSR 5:1 | [62] |

| C-class EV | Rated power of 150 kW, rated torque 240 N∙m, CPSR 2.33:1 | [63] |

| Electric trucks | ||

| 90-ton hybrid electric off-highway truck | Rated power 370 kW, maximum torque 8833 N∙m, CPSR 10:1 | [66,67,68] |

| 40-ton long-distance heavy electric truck | Maximum power 215 kW, rated power 42 kW, maximum torque 581 N∙m, CPSR 2.67:1 | [64] |

| 40-ton long-distance heavy electric truck | Maximum power 250 kW, rated power 50 kW, maximum torque 800 N∙m, CPSR 1.6:1 | [65] |

| Application | Optimization Algorithm | Motor Ratings | Ref. |

|---|---|---|---|

| Off-highway electric hybrid truck | Nelder–Mead | Rated power 370 kW, maximum torque 8833 N∙m, CPSR 10:1 | [67] |

| Hybrid electric vehicle | Solid Isotropic with Material Penalization | Rated power 92.5 kW, rated torque 221 N∙m | [69] |

| Electric vehicle | Physics-informed Bayesian | Rated power 80 kW, rated torque 250 kW | [70] |

| Hybrid electric vehicle | Differential Evolution | Rated power 160 kW, maximum torque 280 N∙m, CPSR 2.17:1 | [71] |

| Electric vehicle | Global Response Search | CPSR 2.33:1 | [72] |

| Battery electric vehicle | Genetic Algorithm | Rated power 75.5 kW, maximum torque 350 N∙m, CPSR 3.22:1 | [73] |

| Electric vehicle | Differential Evolution | Rated power 55 kW, peak torque 190.55 N∙m, CPSR 3:1 | [74] |

| Passenger electric vehicle | Genetic Algorithm | Rated torque 200 N∙m | [75] |

| Passenger electric vehicle | Evolutionary Algorithm | Rated power 55 kW, maximum power 190 kW | [76] |

| Passenger electric vehicle | Genetic Algorithm | Rated power 75.4 kW, rated torque 150 N∙m, CPSR 2.58:1 | [78] |

| Electric vehicle | Genetic Algorithm | Rated power 80 kW, rated torque 250 N∙m, CPSR 2.58:1 | [79] |

| Electric vehicle | Genetic Algorithm | Maximum power 326 kW, CPSR 3:1 | [80] |

| Electric vehicle | Genetic Algorithm | Maximum torque 150 N∙m | [81] |

| Electric vehicle | Evolutionary Algorithm | Maximum torque 50 N∙m | [82] |

| Electric vehicle | Genetic Algorithm | Rated power 5 kW, rated torque 31.83 N∙m | [83] |

| Passenger electric vehicle | Genetic Algorithm | Rated power 60 kW, rated torque 207 N∙m, CPSR 4.88:1 | [84] |

| Electric vehicle | Genetic Algorithm | Rated power 746 W, rated torque 7.91 N∙m, CPSR 4.17:1 | [85] |

| Electric vehicle | Genetic Algorithm | Rated power 64 kW, rated torque 340 N∙m | [86] |

| Brushless Excitation Method | Ref. |

|---|---|

| Separate brushless exciter | |

| Rotary transformer | [90,91,92,93,94,95,96,97] |

| Capacitive coupler | [74,76,77] |

| Built-in brushless excitation | |

| Injected zero-sequence harmonic MMF excitation | [104,106,108,109,112,113,114,115,117] |

| Winding spatial harmonic MMF excitation | [103,105,106,107,108,109,110,111,112,113,114,115,116,117,118] |

| Application | Brushless Excitation Method | Motor Ratings | Experimental Prototype | Ref. |

|---|---|---|---|---|

| Separate brushless exciter | ||||

| Hybrid electric vehicle | Rotary transformer | Peak torque 310 N∙m, peak power 70 kW, CPSR 3.25:1 | Yes | [90] |

| Hybrid electric vehicle | Rotary transformer | Peak torque 280 N∙m, peak power 160 kW, CPSR 2.4:1 | Yes | [94] |

| Mild hybrid electric vehicle | Rotary transformer | Peak torque 40 N∙m, rated power 20 kW, CPSR 2:1 | Yes | [98,99] |

| Electric mini cargo truck | Rotary transformer | Rated torque 118 N∙m, rated power 22 kW, CPSR 1.55:1 | No | [97] |

| Built in brushless excitation | ||||

| Electric vehicle | Injected zero-sequence harmonic MMF excitation | 1 kW | No | [104,114] |

| Starter-generator | Injected zero-sequence harmonic MMF excitation | 1.5 kW | Yes | [112] |

| Electric vehicle | Injected zero-sequence harmonic MMF excitation | 3 kW | No | [117] |

| Electric vehicle | Winding spatial harmonic MMF excitation | Peak torque 86 N∙m, peak power 32 kW, CPSR 3.27:1 | No | [105] |

| Electric vehicle | Injected zero-sequence harmonic MMF excitation | 2 kW | No | [106] |

| Feature | Ref. |

|---|---|

| Coupled electromagnetic and mechanical constraints | [69,71,74,75,79,82] |

| Coupled electromagnetic and thermal constraints | [69,73,74,75,79] |

| Optimization for multiple operating points (driving cycle) | [67,71,72,73,75,77,80,82] |

| Experimental validation presented | [74,75,78,85,87] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prakht, V.; Dmitrievskii, V.; Kazakbaev, V.; Valeev, E.; Goman, V. Traction Synchronous Motors with Rotor Field Winding: A Literature Review. World Electr. Veh. J. 2025, 16, 633. https://doi.org/10.3390/wevj16110633

Prakht V, Dmitrievskii V, Kazakbaev V, Valeev E, Goman V. Traction Synchronous Motors with Rotor Field Winding: A Literature Review. World Electric Vehicle Journal. 2025; 16(11):633. https://doi.org/10.3390/wevj16110633

Chicago/Turabian StylePrakht, Vladimir, Vladimir Dmitrievskii, Vadim Kazakbaev, Eduard Valeev, and Victor Goman. 2025. "Traction Synchronous Motors with Rotor Field Winding: A Literature Review" World Electric Vehicle Journal 16, no. 11: 633. https://doi.org/10.3390/wevj16110633

APA StylePrakht, V., Dmitrievskii, V., Kazakbaev, V., Valeev, E., & Goman, V. (2025). Traction Synchronous Motors with Rotor Field Winding: A Literature Review. World Electric Vehicle Journal, 16(11), 633. https://doi.org/10.3390/wevj16110633