1. Introduction

Since the onset of the Industrial Revolution, fossil fuels have underpinned global energy systems, enabling industrial growth and economic expansion. The International Energy Agency (IEA) estimates that oil and natural gas operations account for about 15% of energy-related emissions—roughly 5.1 billion tons of greenhouse gases each year [

1]. Conventional internal combustion vehicles, reliant on petroleum fuels, remain a major source of urban air pollutants and a significant driver of climate change [

2]. In response, battery-powered new energy vehicles have emerged as a practical route to lower energy use and environmental burdens while advancing sustainable mobility [

3]. As Hu et al. documented, technology trajectories in China’s NEV sector have moved rapidly toward integrated pack architectures and higher levels of functional integration, reshaping constraints at the enclosure level.

Battery pack enclosures are the primary protective structures for traction batteries and are central to the mechanical safety and reliable integration of cells and modules [

4]. Their design directly affects crashworthiness, while mass reduction is indispensable for energy efficiency. Accordingly, high-strength steels, aluminum alloys, and carbon-fiber composites are commonly considered for their strength-to-weight advantages [

5,

6]. A commonly reported relationship is that a 10% decrease in vehicle mass yields about a 5.5% reduction in energy consumption and a comparable improvement in range [

7]. Effective enclosure design therefore calls for coordinated choices of materials, geometry, and manufacturing processes to balance structural safety against weight.

Each material system carries distinct trade-offs. Carbon-fiber composites provide high specific stiffness, but anisotropy complicates load paths, necessitates advanced lay-ups, and increases fabrication cost by roughly 40–60% versus aluminum alloys; its low transverse thermal conductivity can magnify temperature gradients, and its graphite-based spreaders may compromise in-plane strength [

8,

9]. Impact behavior is another concern: Zhou et al. showed with woven-CFRP hat-sections that dynamic bending and axial crushing tend to activate brittle failure modes, limiting the composite’s plastic energy absorption [

10]. Aluminum alloys—particularly AA6061 and AA7075—offer a different balance: specific strengths on the order of 100–150 kN·m/kg, crash performance with energy absorption ≥ 150 kJ/m

3, and thermal conductivity around 120–220 W/m·K, which aids in heat dissipation during fast charging [

11,

12,

13,

14,

15]. Property datasets for 7000-series alloys (e.g., hardness–strength relationships and fatigue characteristics) are well characterized, which facilitates model calibration for simulation-driven design. On the manufacturing side, extrusion and casting enable integral stiffeners and weldable flanges, and joining options such as FSW, SPR, and structural adhesives are compatible with high-volume production; recyclability is favorable, with recovery rates often exceeding 95% [

16,

17].

Two material families dominate enclosure research—aluminum alloys and fiber-metal laminates (FMLs) or all-composite designs. FMLs such as CARALL and GLARE combine the plastic energy absorption of metals with the specific stiffness of composites and can deliver strong fatigue and impact performance; their response, however, is highly sensitive to the metal–composite interface quality and lay-up, and CFRP laminates exhibit strongly anisotropic thermal conductivity with low through-thickness values, which complicates pack-level heat spreading and fire-exposure margins. By contrast, AA6061/AA7075 aluminum remains prevalent in production enclosures owing to its mature extrusion/casting routes and joining options (e.g., friction-stir welding and self-piercing riveting), well-tabulated property datasets for FE calibration, comparatively high thermal conductivity (~130–170 W·m

−1·K

−1) that aids heat dissipation, and established end-of-life recycling pathways (automotive “grave-to-gate” recycling ≈ 91% in the United States). Recent engineering and LCA studies likewise indicate that, while composite/FML enclosures continue to advance, aluminum often remains the primary choice when manufacturability, cost, and recyclability dominate the design trade space [

18].

Beyond material choice, enclosure engineering is shaped by packaging architecture (module-based, CTP/CTC) and a set of cross-domain requirements that must be met simultaneously: crashworthiness under lateral/oblique and side-pole impacts, global and local stiffness, first-model resonance isolation, thermal-runaway mitigation, sealing and maintainability, as well as cost and recyclability [

16,

19]. To protect cells and busbars, the structure must transfer loads from side members and pole-type impacts without triggering brittle fracture or localized buckling, while keeping deformation within allowable limits [

20,

21]. This has motivated cellular and sandwich concepts. Chen et al. designed space-efficient multi-cell protection for cylindrical cells and clarified load-transfer and failure mechanisms in thin-walled layouts, achieving higher specific energy absorption per packaging volume [

4]. Li et al. proposed bio-inspired honeycomb patterns that delay localization and enhance energy absorption with modest mass penalties at pack scale [

5]. For hybrid systems, Wang et al. co-optimized metal–composite enclosures and showed that judicious placement of composite skins and metallic substructures improves crash response without undue weight growth [

7], while Severson et al. outlined a CFRP-skin/aluminum-honeycomb methodology that emphasizes joint design and core selection for stiffness-to-mass gains in demanding applications [

17]. Complementarily, Kulkarni et al. used FEA to map laminate orientation and lay-up effects in CFRP enclosures, highlighting the stiffness–energy-absorption trade-off that must be navigated under impact [

8].

Thermal safety introduces further coupling. Lv et al. experimentally demonstrated that LDPE-enhanced phase-change materials with low fins reduce peak temperature and improve uniformity relative to baseline convective schemes [

15]. Post-event analyses by Sterling et al. documented stiffness loss and progressive damage in composite structures exposed to battery fires, underscoring the need to fold thermal scenarios into structural margins rather than addressing thermal management in isolation [

22]. From a production standpoint, reviews by Graf and Das synthesize alloy families, forming/joining options, and recycling pathways for automotive lightweighting, reinforcing that aluminum systems align well with enclosure targets spanning mass, cost, and end-of-life recovery [

16].

Against this backdrop, high-fidelity finite-element analysis (FEA) is indispensable when mechanical loading, thermal management, and impact response interact. Validation studies suggest that modern models typically track experiments within about 5% [

20]. Several lines of work illustrate feasible routes. Pan et al. pursued lightweight enclosure design using advanced high-strength steels and size optimization, reporting ~10% mass reduction while maintaining structural integrity [

6]. Szabo et al. applied topographical optimization to a battery module case, tuning bead patterns and local stiffeners to raise stiffness with restrained mass increase [

23]. For vehicle-scale packs, Gilaki et al. proposed a model-based design framework that reduces computational effort through hierarchical modeling while preserving essential response fidelity [

24]. In cellular architectures, Dhoke and Dalavi optimized a honeycomb enclosure and achieved a 33.16% mass reduction together with a 40.57% drop in maximum deformation under a 220 kg gravitational load, demonstrating the effectiveness of geometry-driven absorption [

25]. Collectively, these studies point to two practical imperatives: (i) geometry/material co-design is central to enclosure performance; and (ii) tractable computation is necessary as the design space expands to thickness maps, beads, ribs, and joints.

To manage competing objectives under realistic constraints, multi-objective optimization has become standard practice. Deb et al.’s NSGA-II provides a fast, elitist, non-dominated sorting scheme with crowding-distance preservation and remains widely used for enclosure problems [

26]. Alongside Pareto-ranking approaches, decomposition-based methods such as MOEA/D partition the problem into scalar subproblems via weight vectors and exploit neighborhood cooperation; this often yields good spread on the front and offers a convenient handle for constraint treatment in engineering designs with many continuous variables. In parallel, swarm-based algorithms—in particular multi-objective PSO (MOPSO)—are attractive for surrogate-assisted outer loops because of their simple operators and competitive convergence on continuous thickness/geometry spaces; for battery-pack applications, Lin et al. demonstrated that metamodel-driven PSO search can reduce computational cost while keeping stresses within limits and improving modal performance [

27]. Building on the GA family, Naresh et al. integrated FE analysis with global multi-objective optimization for aluminum enclosures and reported 49.41% lower deformation, 35.79% lower stress, and a 19.92% increase in resonant frequency—simultaneous gains across safety and NVH-related metrics [

19]. From the topology side, Huang et al.’s floating-projection topology optimization (FPTO) delivered 15–20% improvements in thermo-mechanical objectives relative to SIMP in multi-objective settings [

28]. For thickness mapping and decision selection, Wang et al. combined an improved NSGA-II, contribution analysis, and TOPSIS to attain 4.31% mass reduction with 5.97% less crash-induced deformation and to provide a clear route from the Pareto set to a single representative design [

21]. Taken together, these results support an integrated workflow in which FE-based responses, decomposition- or swarm-based searching, Pareto ranking, and decision methods are used in concert for battery pack enclosure design [

19,

21,

26,

27,

28].

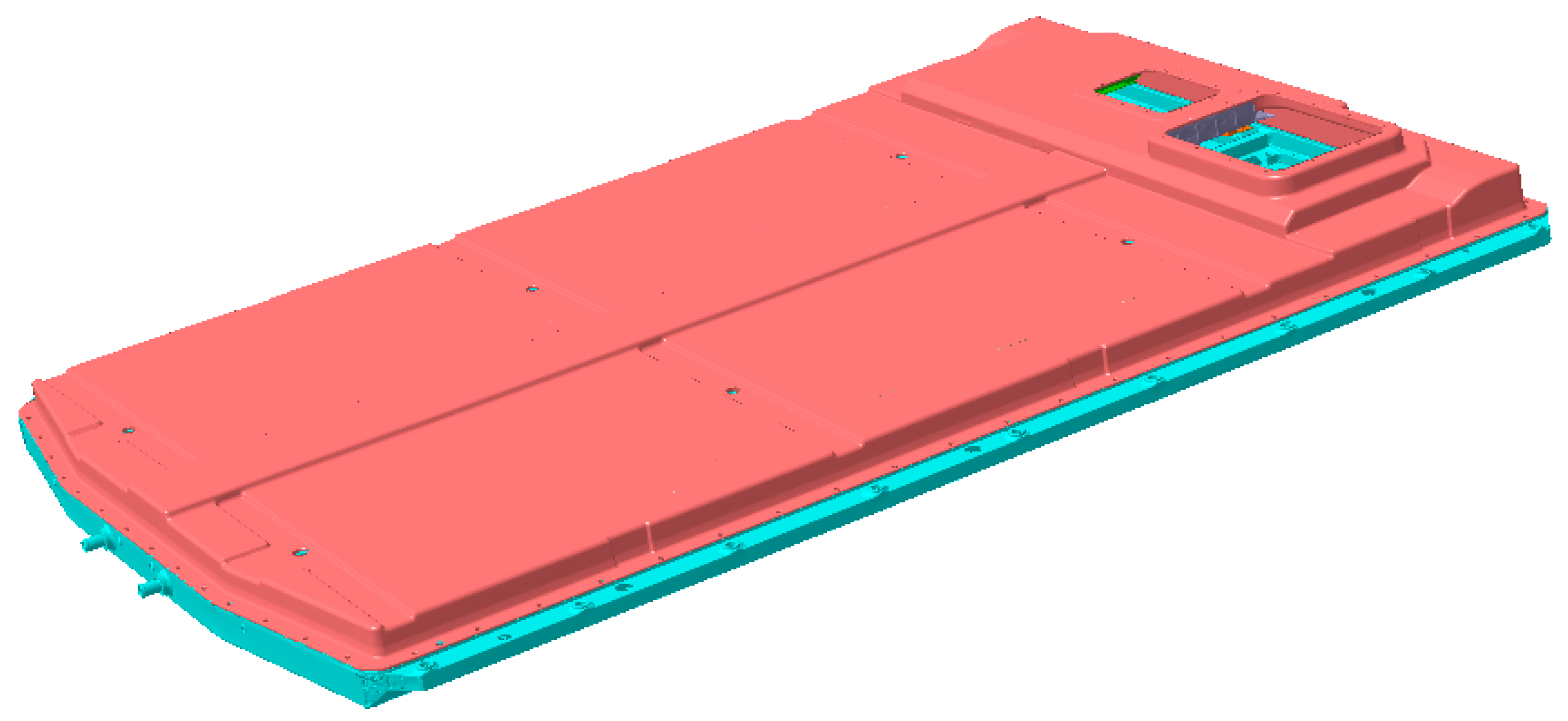

Objectives and contributions: Focusing on a production-representative enclosure, this study prioritizes side-pole-impact deformation as the primary safety metric with mass reduction as a co-objective. The goals are to (1) minimize mass and side-pole-impact deformation under stress and first-model constraints, (2) construct FE-based response surfaces to enable an efficient multi-objective search, and (3) validate manufacturable thickness configurations through FE verification. The contributions are threefold: (i) a constraint-aware workflow that couples RSM with NSGA-II for thickness mapping under side-pole impact; (ii) an engineering-oriented design space that reflects packaging, joining, and thermal considerations; and (iii) FE-verified Pareto solutions that balance lightweighting with deformation control, offering a template for deployable enclosure design.

In summary, despite clear progress in materials and optimization strategies, many studies still lack parameterized models and implementable workflows tailored to production-oriented battery pack enclosures. To address this gap, we develop a methodology that integrates response-surface modeling (RSM), NSGA-II-based multi-objective optimization, and FE simulation for performance validation. Using a representative enclosure from a pure electric vehicle as the case study, the approach seeks a practical balance between mass and crash performance, demonstrating methodological reliability and engineering applicability.

6. Discussion

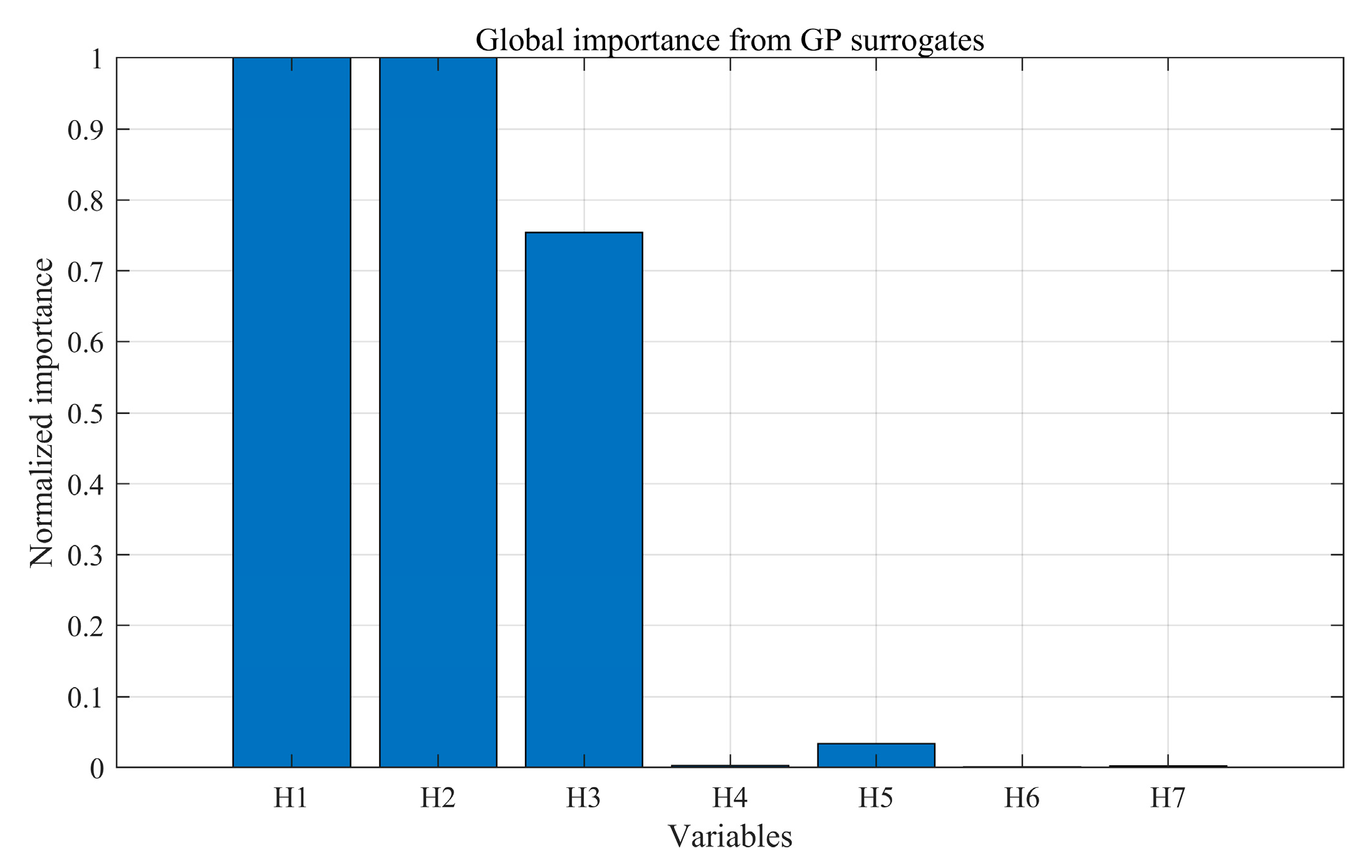

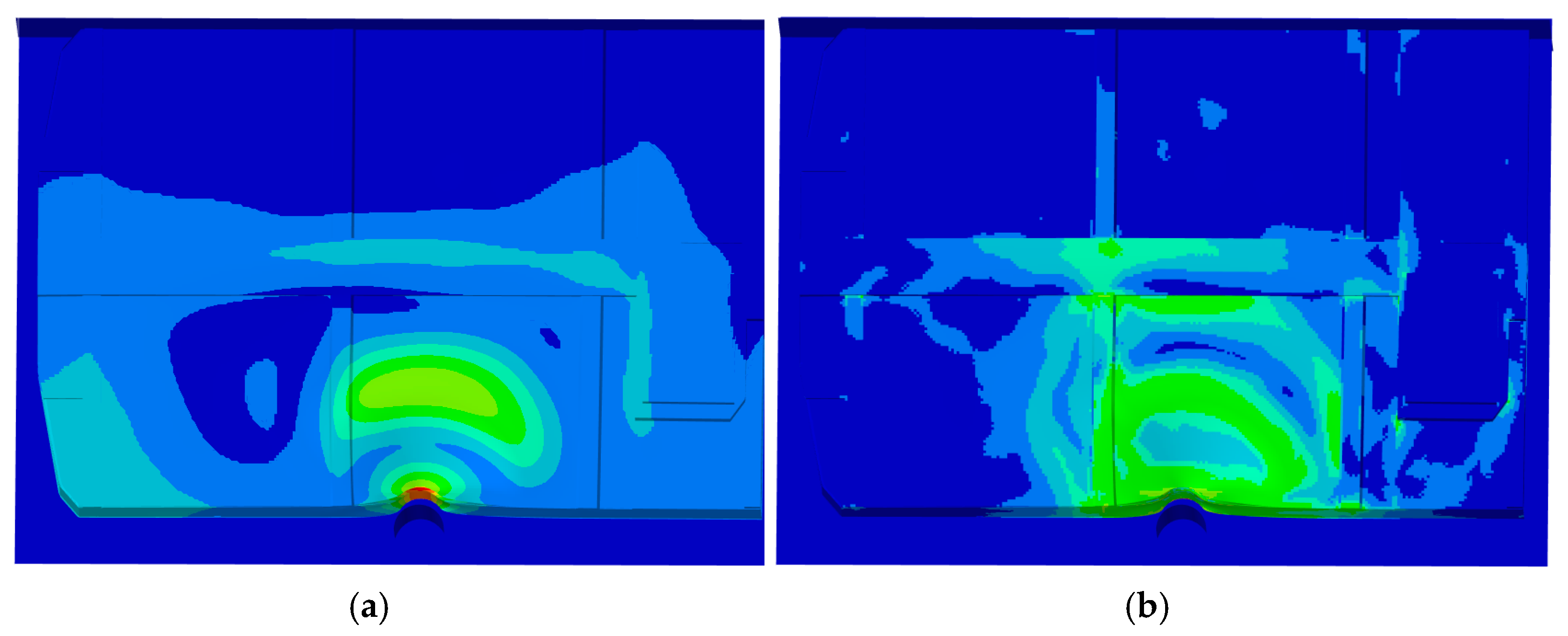

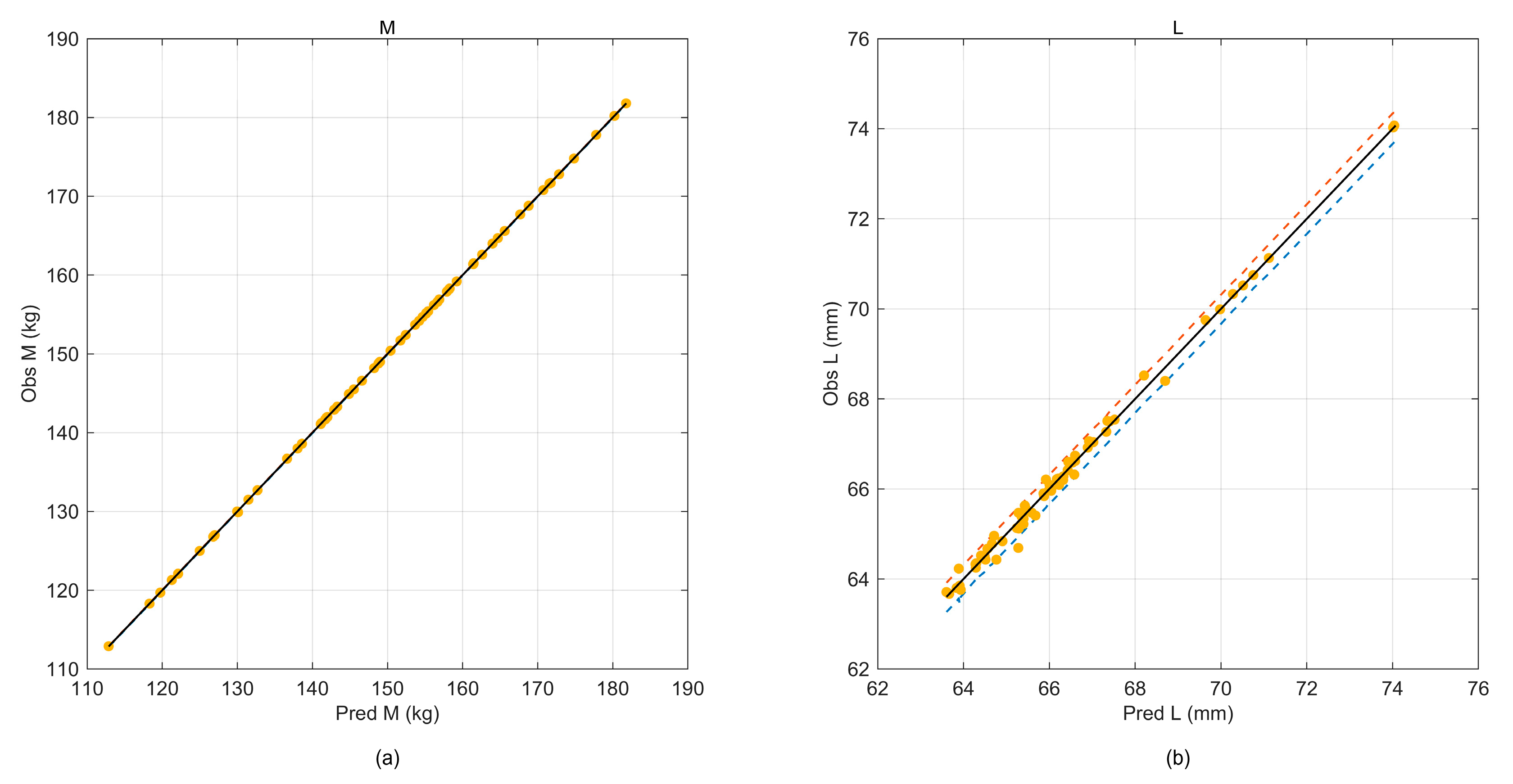

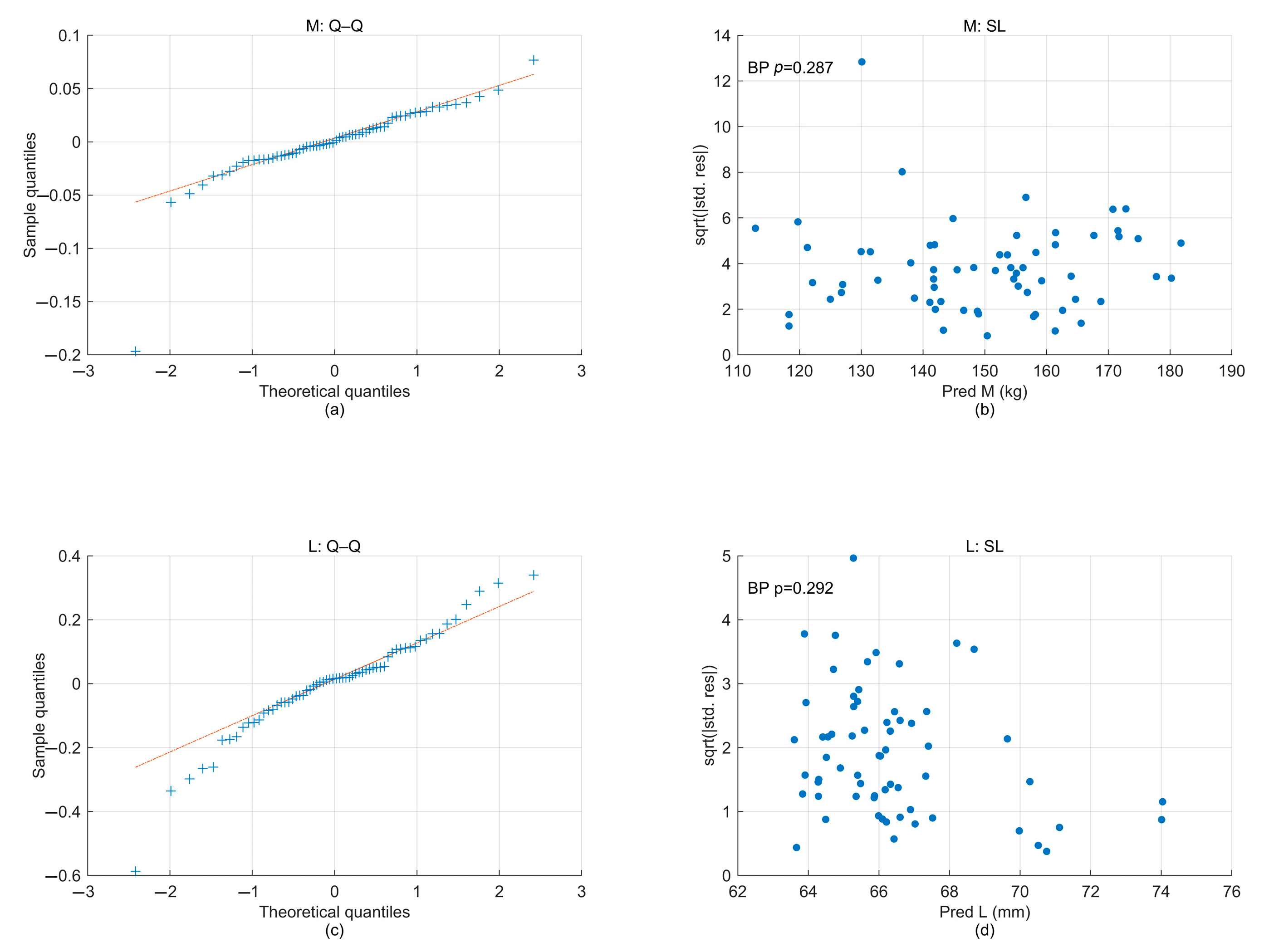

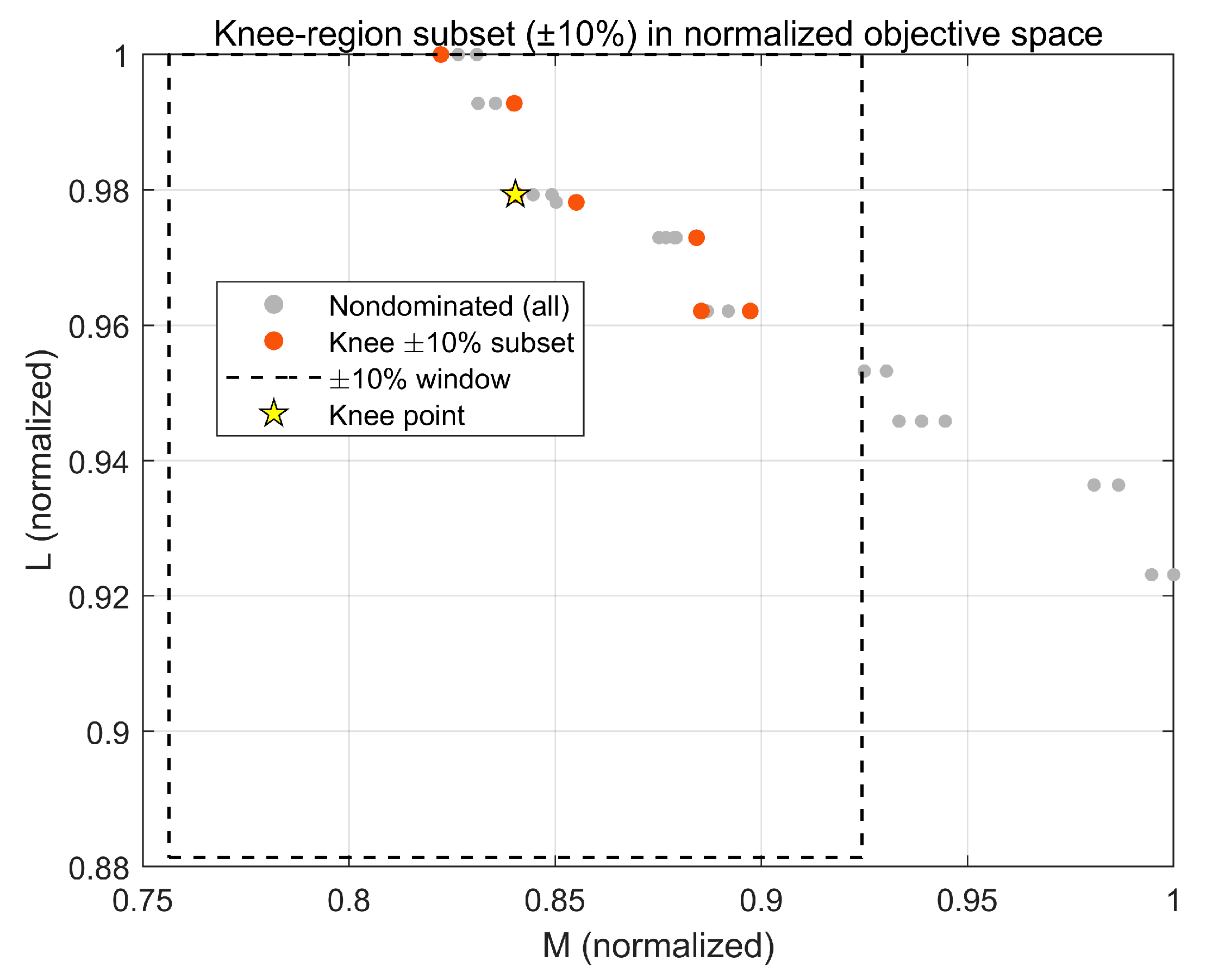

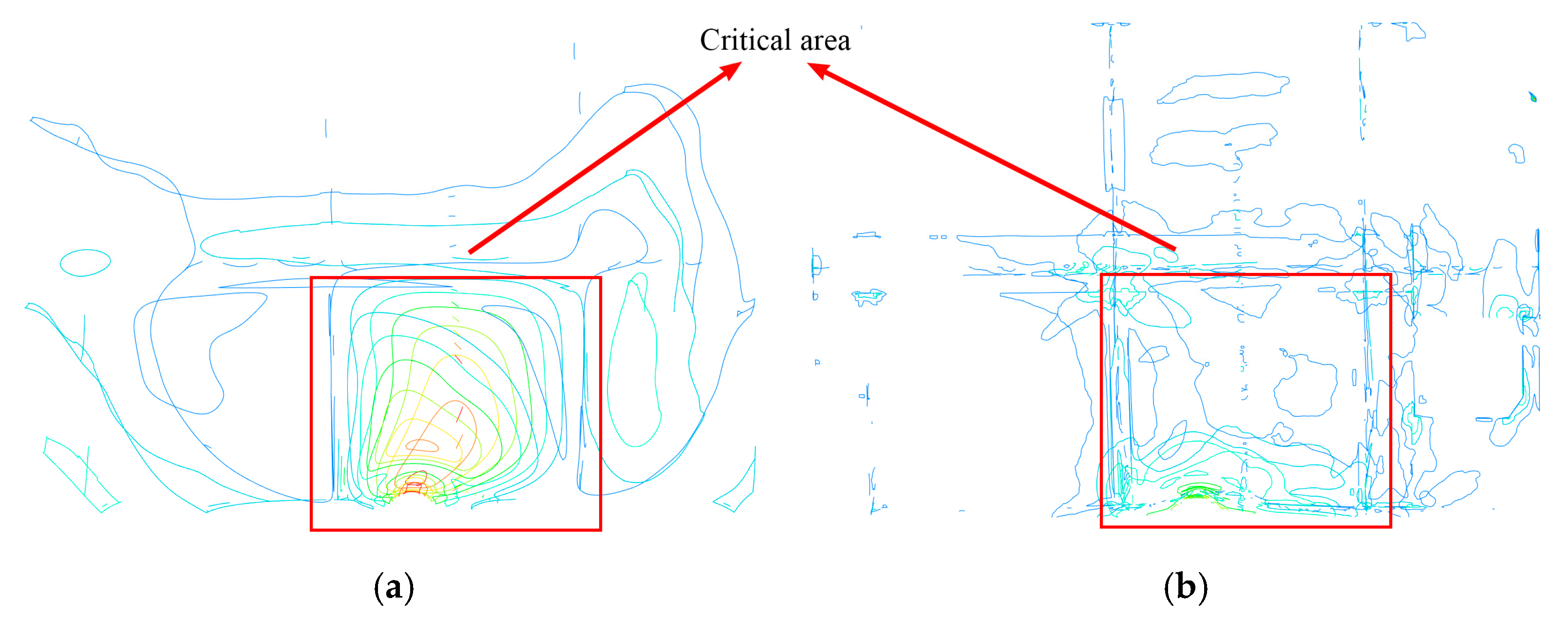

This study developed a surrogate-assisted, constraint-aware workflow for battery pack enclosure (BPE) thickness mapping under side-pole loading, combining a 64-run OLHD dataset, ARD Matérn-5/2 Gaussian-process surrogates, and NSGA-II search with decision making via knee-region windowing and TOPSIS. The representative optimum selected on a mm grid delivers substantial mass reduction with essentially unchanged peak deformation in verification reruns. Specifically, mass drops from 149.40 kg to 115.20 kg (−22.89%) while peak deformation changes by +0.12% (66.17 → 66.25 mm).

Decision robustness was confirmed by post hoc uncertainty penalization, weight-sensitivity checks, and a model-dependency audit against an SE-ARD GP, yielding identical rankings (Kendall’s ) and a moderate knee shift in the normalized plane. Independent FE reruns matched surrogate predictions to within ~0.6% (mass) and ~5% (peak deformation) for the two retained designs.

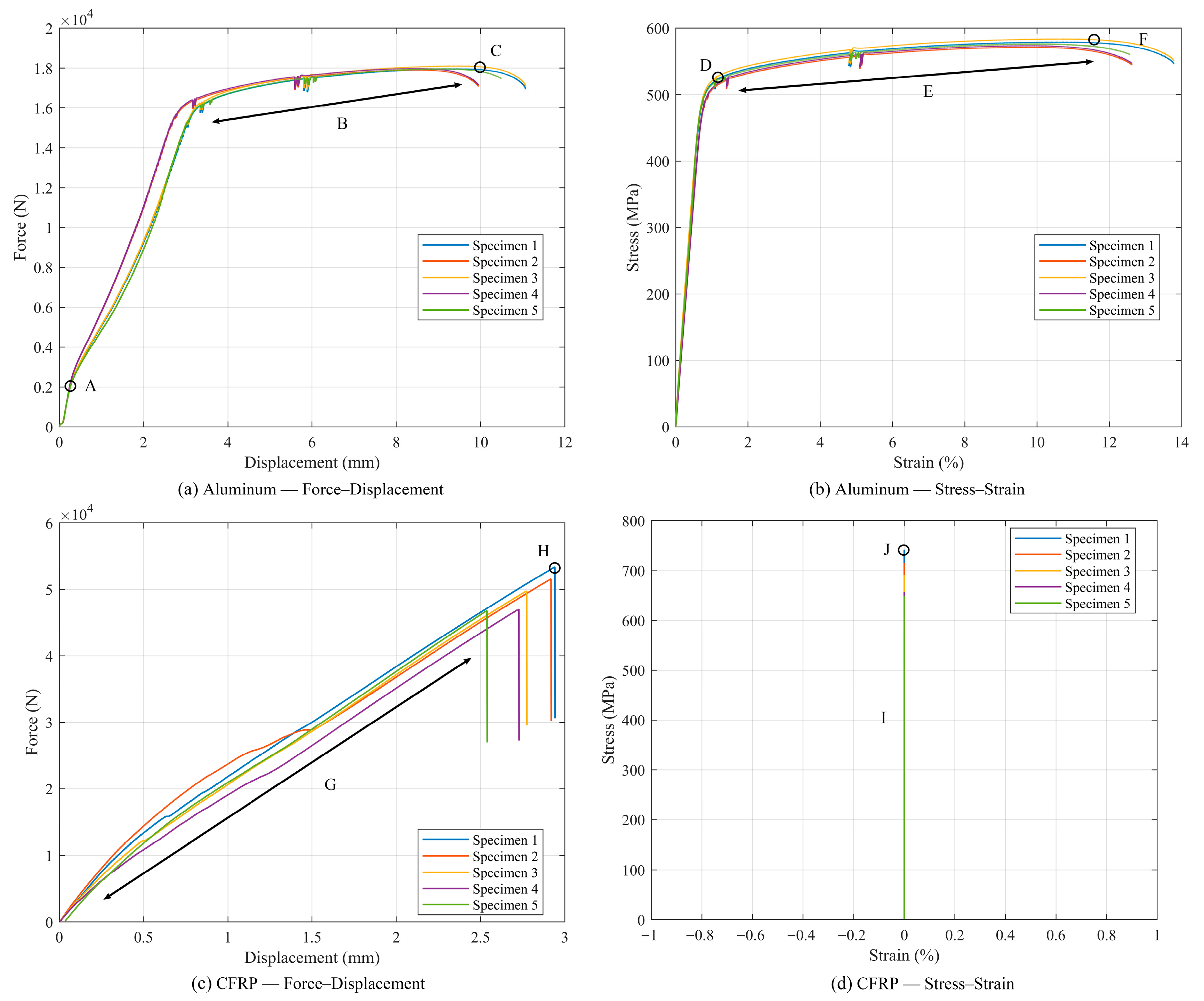

A focused cross-material verification substituting / with an orthotropic CFRP (iso-thickness and constrained iso-mass mappings) showed that, under the present shear-sensitive load path and without lay-up tailoring or joint redesign, CFRP can lower mass but may increase the global peak deformation. The observed trends are consistent with laminate shear moduli and the induced load redistribution.

Key findings

A manufacturable aluminum optimum on mm achieves ~23% mass reduction with comparable peak deformation in FE verification.

The ranking from TOPSIS remains invariant under uncertainty inflation and moderate preference shifts; cross-kernel auditing preserves order ().

CFRP substitution of alone, under iso-thickness or constrained iso-mass, is shear-sensitive; achieving stiffness parity would require laminate/joint design directed at shear-dominated paths.

Engineering/economic note.

The representative thickness-mapped aluminum design selected on a mm grid reduces pack mass by approximately 23% (ΔM ≈ 34 kg), which directly lowers raw-material usage. The overall cost impact additionally depends on gauge availability, forming and joining routes, tooling amortization, and quality-assurance requirements. A full life-cycle cost assessment is beyond the present scope and is planned as follow-on work.

Limitations and outlook.

Limitations: The present study addresses enclosure-level mass–stiffness trade-offs with shell models; detailed joints/fasteners, module clearance, and laminate damage evolution are not explicitly modeled.

The deformation metric L is defined as the peak nodal displacement magnitude during the contact phase of the side-pole load case.

The cross-material check substituted H1/H2 only with linear-elastic orthotropic CFRP (iso-thickness or constrained iso-mass mappings); lay-up tailoring and joint redesign were not included.

At present, no pack-level side-pole test data are available for direct comparison; the only experimental inputs are the coupon tests in

Section 2.2, which were used to calibrate the material models. The staged validation route outlined below is intended to bridge this gap as resources become available.

Conducting a full-vehicle side-pole crash would require pack integration into a body-in-white, full instrumentation, and accredited facility time; a single test typically costs tens to (low) hundreds of thousands of USD, which is beyond the current project budget.

Outlook: Couple enclosure deformation with explicit module-clearance criteria (acceptance per GB 38031-2025 §8.2.4) to convert stiffness surrogates into pass/fail-aware objectives/constraints.

Introduce joint/connector models and contact details to capture load transfer and potential local compliance.

Incorporate laminate damage and pursue lay-up optimization targeted at shear-dominated load paths to close the CFRP stiffness gap.

Execute a staged physical-validation plan as resources permit:

- (i)

Perform coupon/sub-component tests for material calibration (aluminum, CFRP);

- (ii)

A durability-oriented follow-on plan includes fatigue safety factors for joints/ribs, environmental conditioning with repeated-load variants, and model–test correlation;

- (iii)

sled/pendulum tests to emulate the side-pole pulse;

- (iv)

model–test correlation using peak deformation and hotspot metrics.