Trigger-Based PDCA Framework for Sustainable Grid Integration of Second-Life EV Batteries

Abstract

1. Introduction

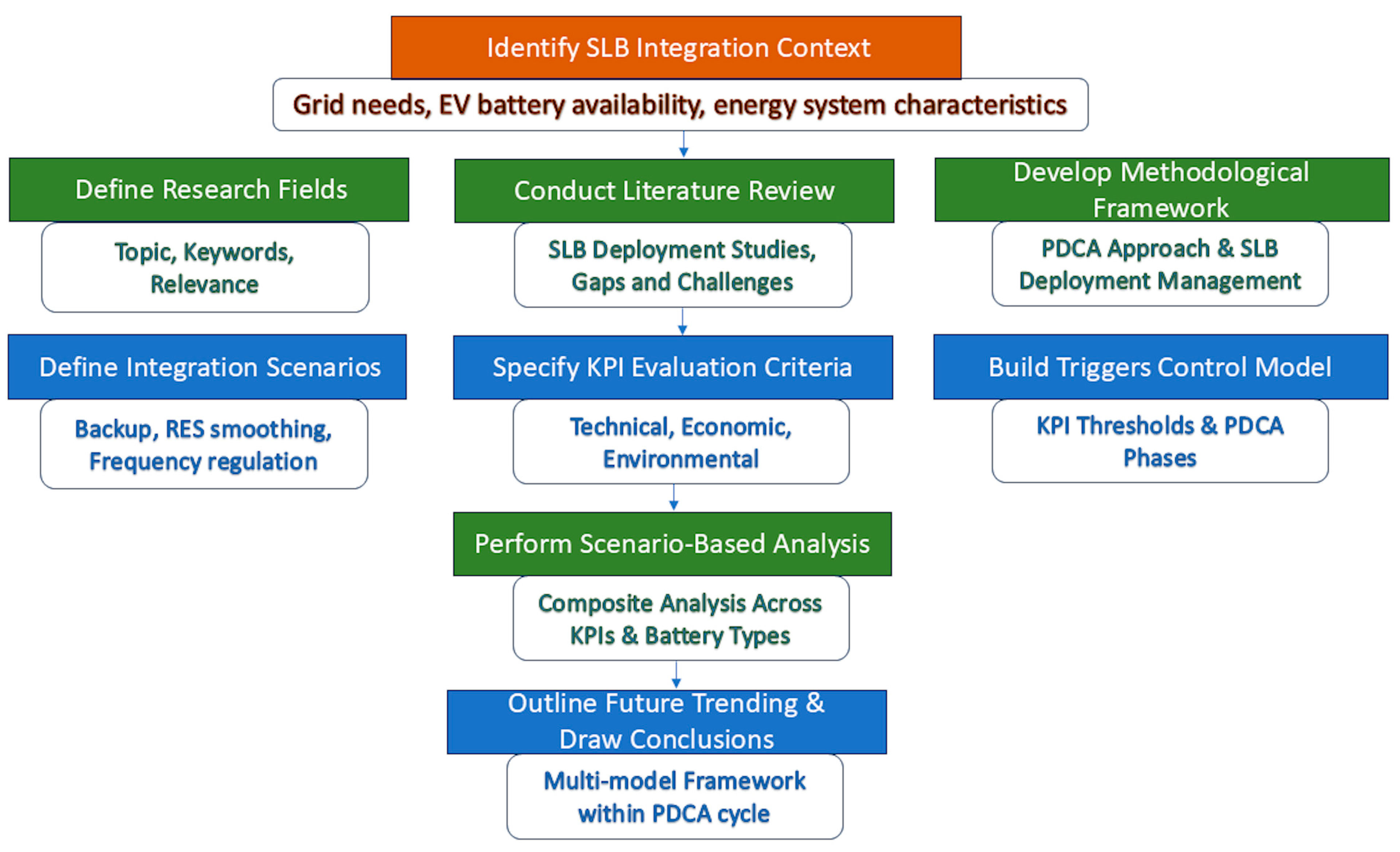

- to develop a PDCA-based operational management framework for SLB deployment;

- to integrate technical, economic, and environmental KPIs into a trigger-based control loop;

- to test the applicability of the framework through scenario-based simulation;

- to identify key limitations and implementation challenges.

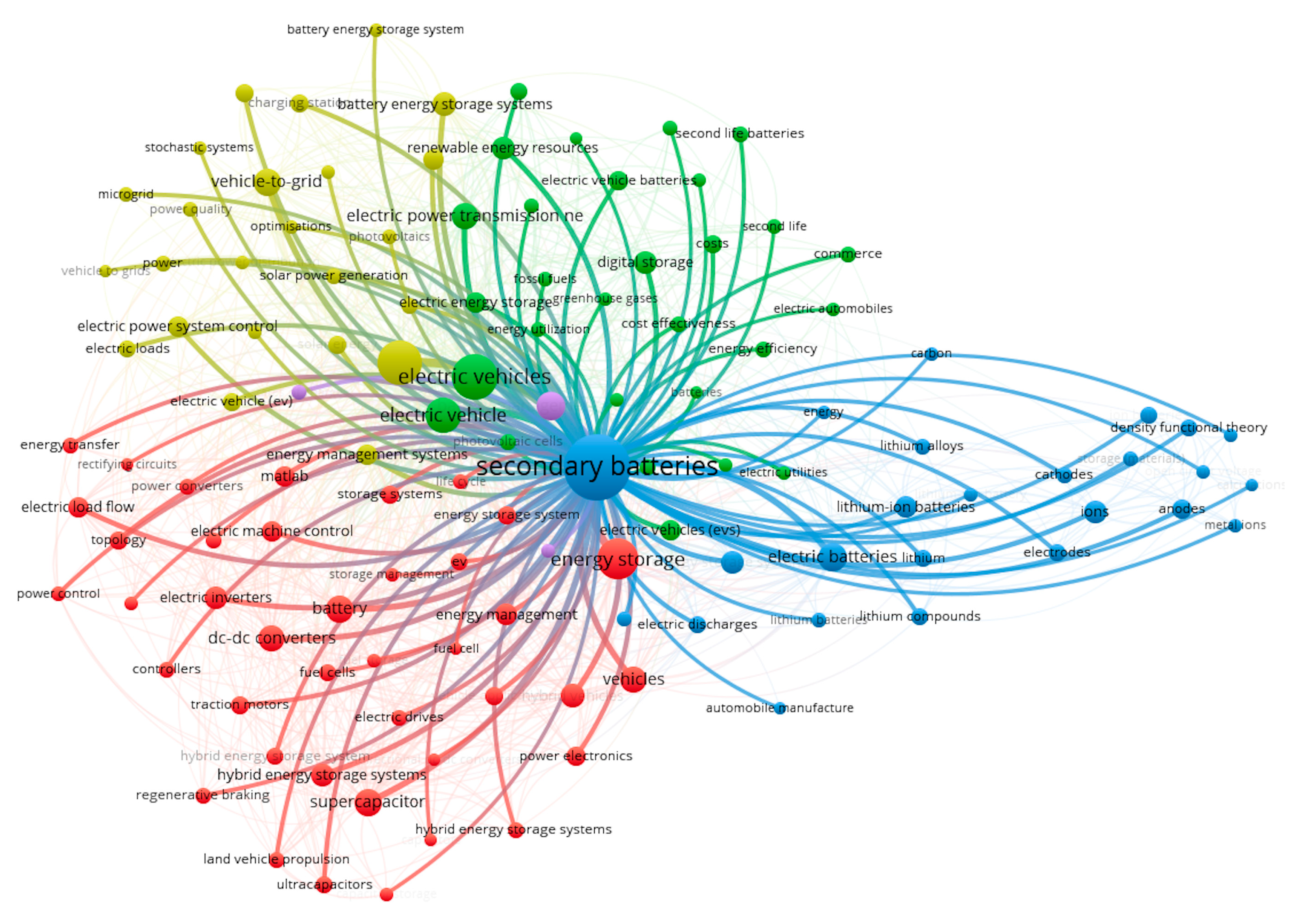

2. Literature Review

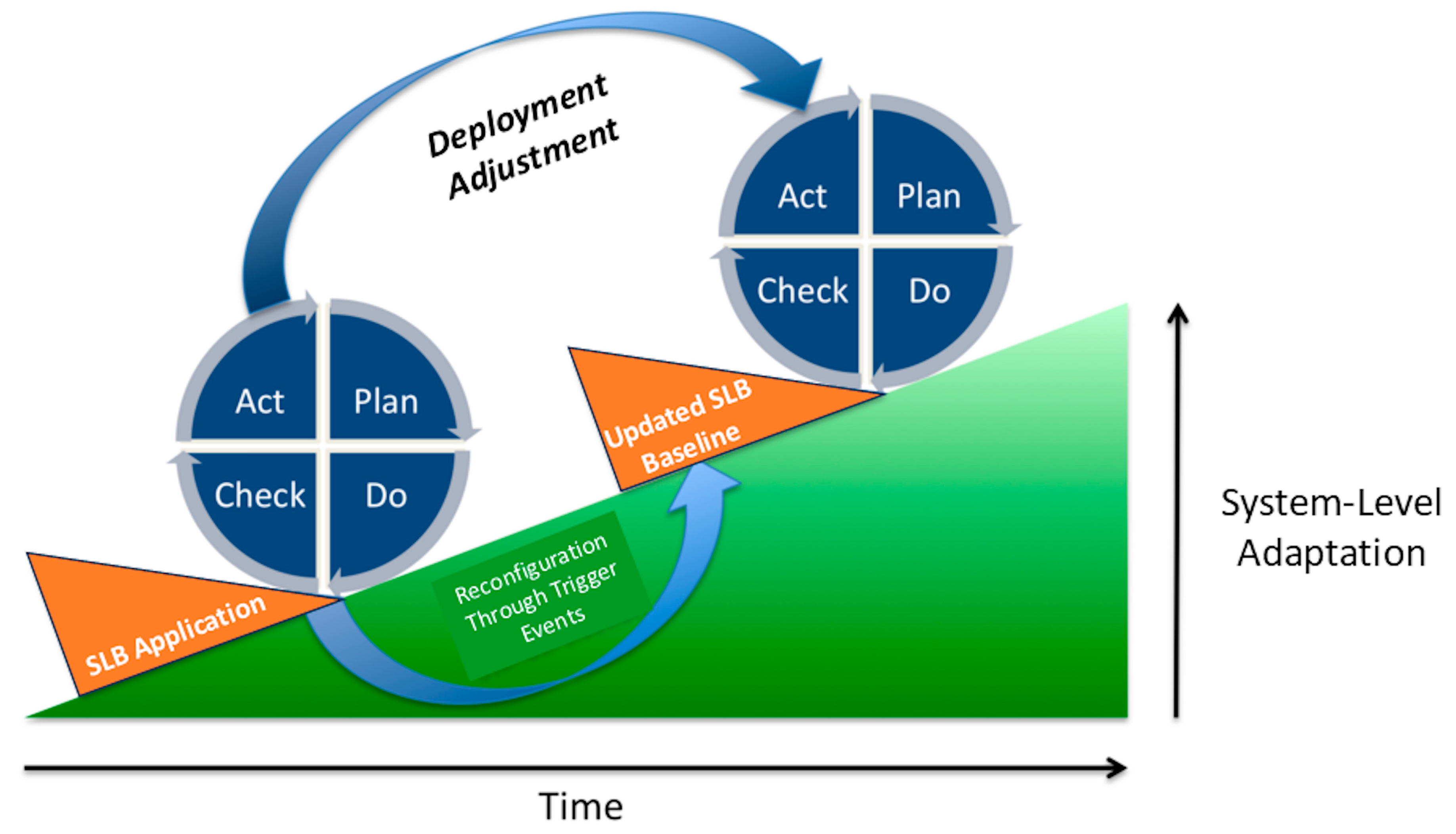

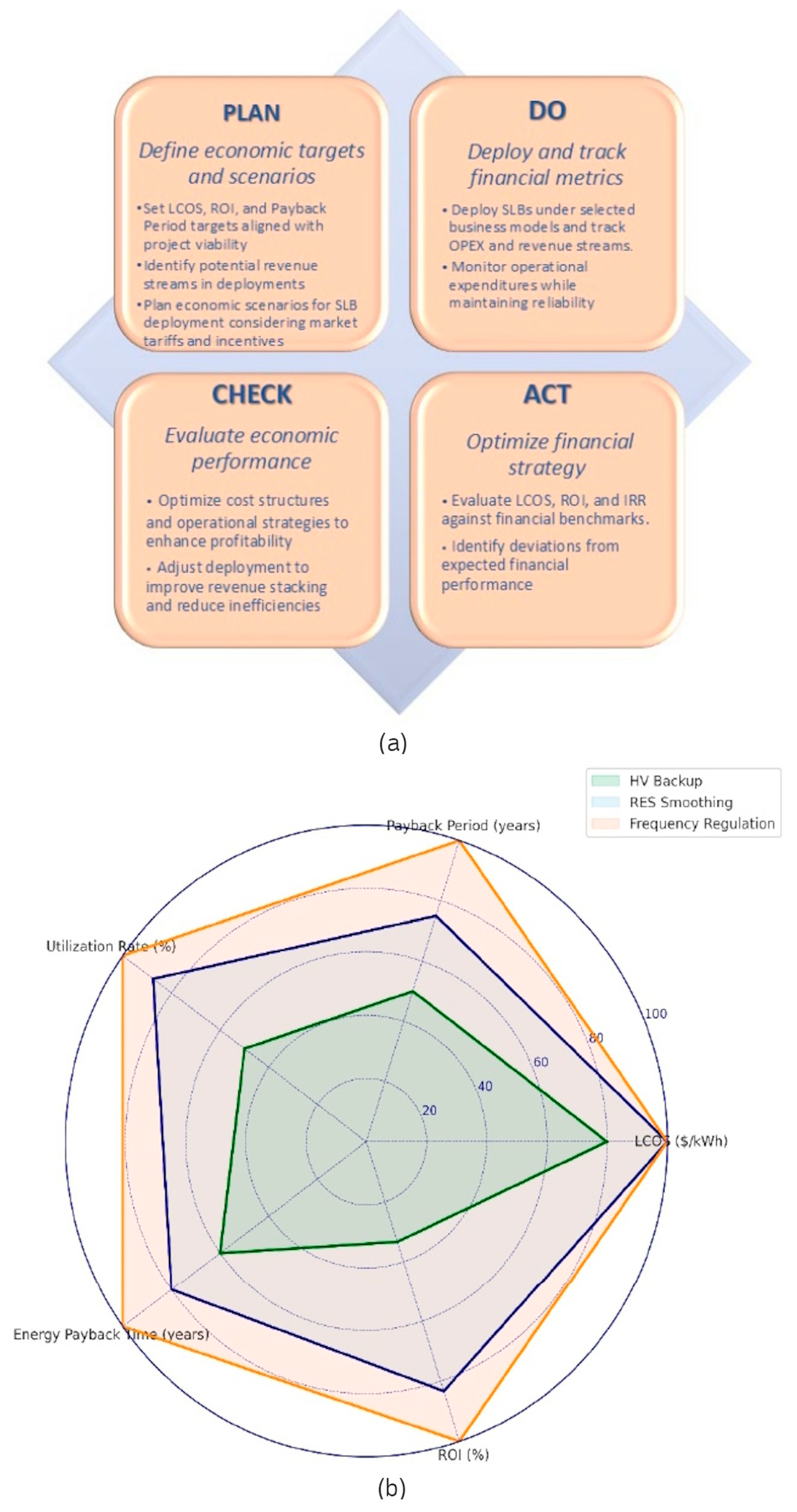

3. PDCA Cycle as a Planning Tool

3.1. PDCA Logic for SLB Deployment

3.2. Operationalization of the PDCA Cycle for SLB Integration

3.3. PDCA as a Lifecycle Management Strategy for SLB Deployment

4. Key Performance Indicators for SLB Management Within the PDCA Framework

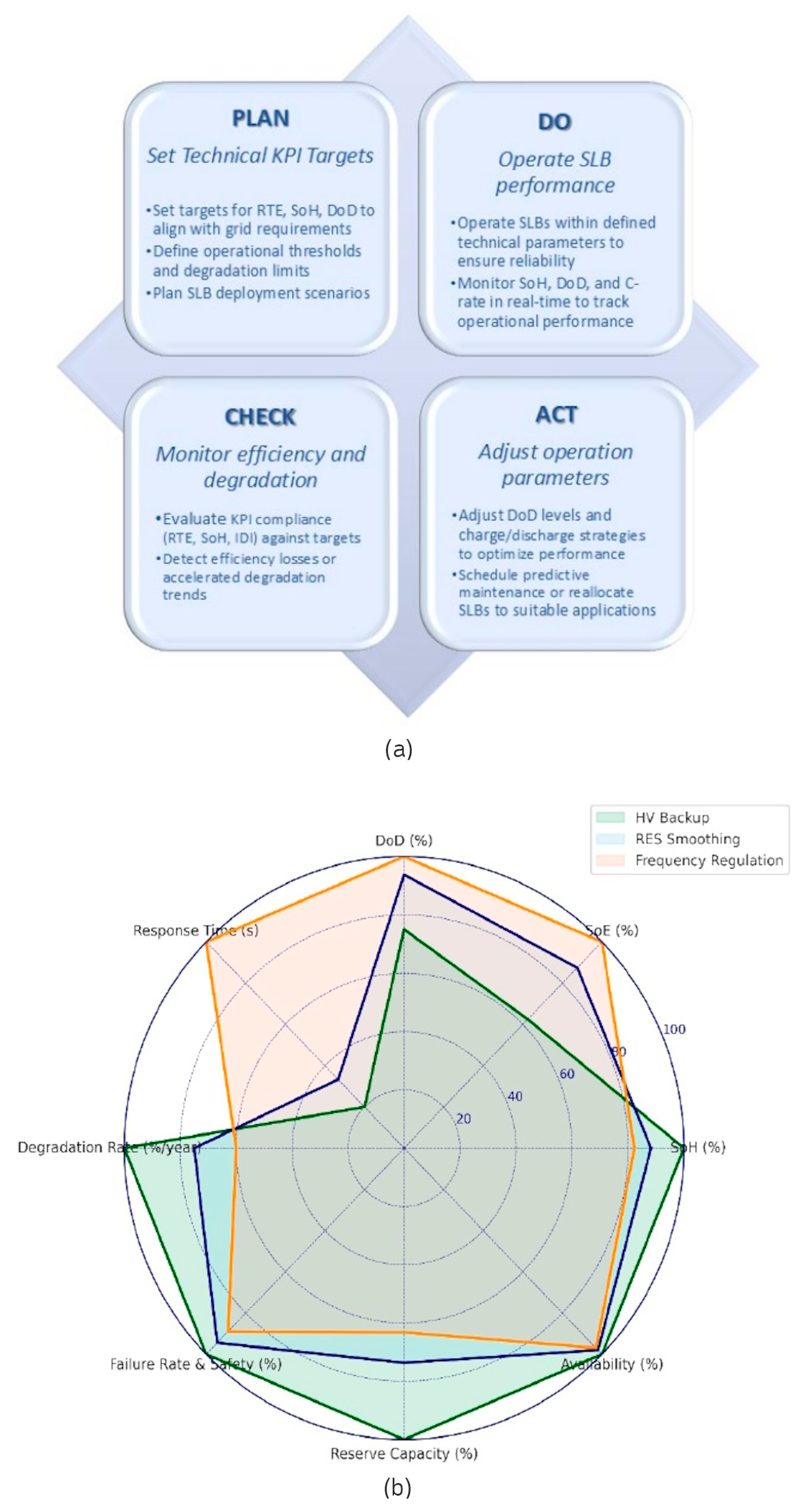

4.1. Scenario Definitions and Assumptions

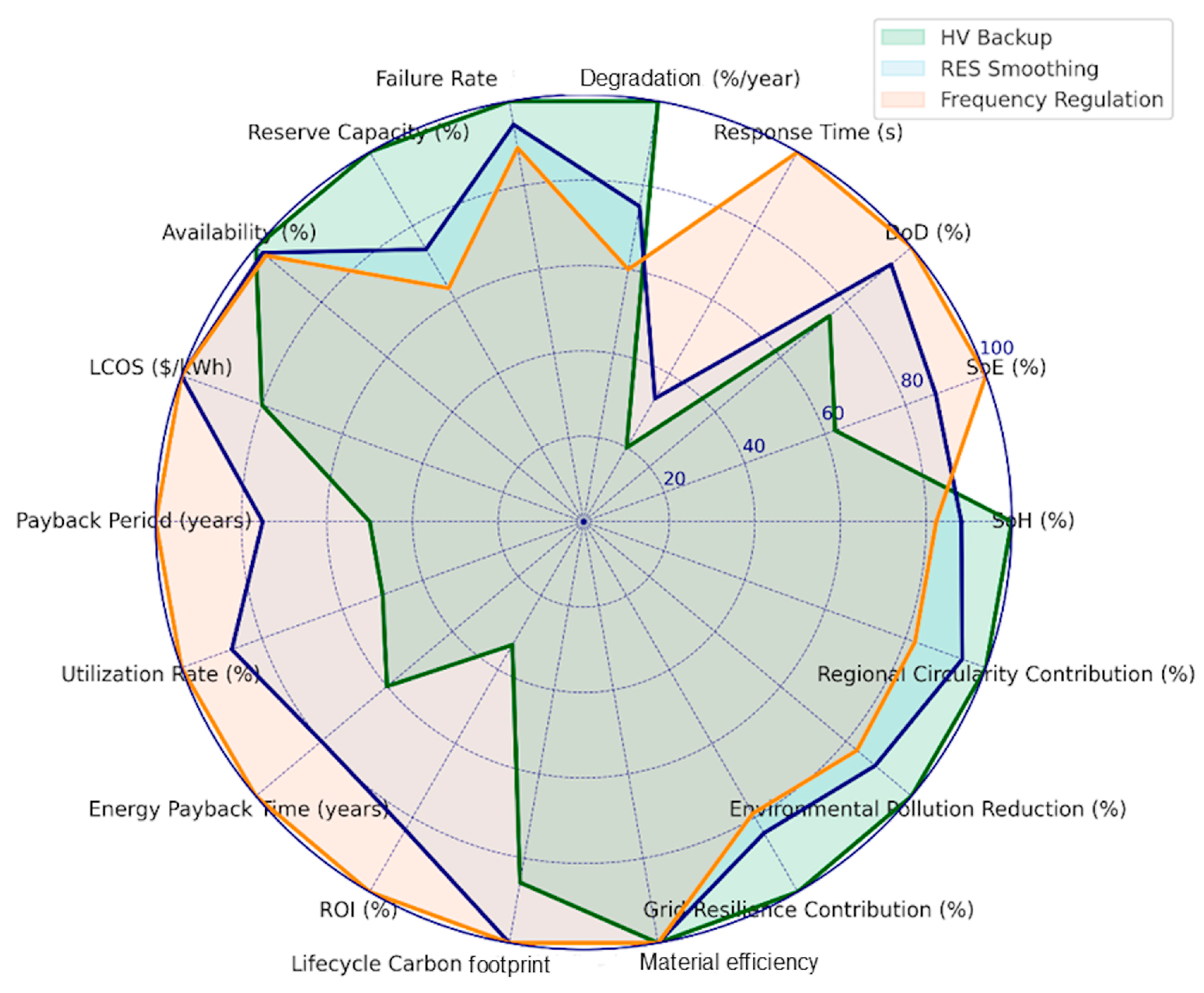

- (a)

- Scenario 1: HV Backup. SLBs are deployed as reserve power sources at medium-voltage substations, providing support during outages and unplanned events. Performance is characterised by infrequent deep discharges with long idle periods. The primary KPIs include State of Health (SOH) and Round-Trip Efficiency (RTE). Planning targets are SOH > 70% and RTE > 85%. Real-time monitoring ensures that, when SOH falls below 65% (trigger threshold), the SLB is reallocated to a less demanding application to extend residual value and defer disposal.

- (b)

- Scenario 2: RES Smoothing. In this case, SLBs are integrated to mitigate fluctuations in photovoltaic (PV) and wind power output, absorbing surplus generation and smoothing short-term variability. Operational patterns involve moderate cycling with medium depth-of-discharge (DoD). Key KPIs include DoD range (target 60–70%) and the Integral Degradation Index (IDI). When the IDI exceeds 0.85 (trigger threshold), the battery is reassigned to low-cycling roles such as frequency regulation or strategic reserve to preserve functionality and mitigate further degradation.

- (c)

- Scenario 3: Frequency Regulation. Here, SLBs provide rapid-response ancillary services, balancing short-term frequency deviations through intensive cycling. This scenario places greater stress on battery lifespan, requiring close tracking of cost-effectiveness. Economic KPIs, such as Levelized Cost of Storage (LCOS) and Return on Investment (ROI), guide performance evaluation. A dynamic LCOS threshold (180–200 USD/MWh) serves as a trigger for re-evaluation. If exceeded, the SLB is shifted to services with lower cycling intensity or retired if no viable use remains.

4.2. Technical KPIs for SLB Integration

4.3. Economic KPIs for SLB Deployment

4.4. Environmental KPIs for Evaluation of SLB Sustainability

4.5. Composite Scenario-Based KPIs Visualization

4.6. Trigger-Based Control Logic

4.7. KPI-Triggered Operational Model

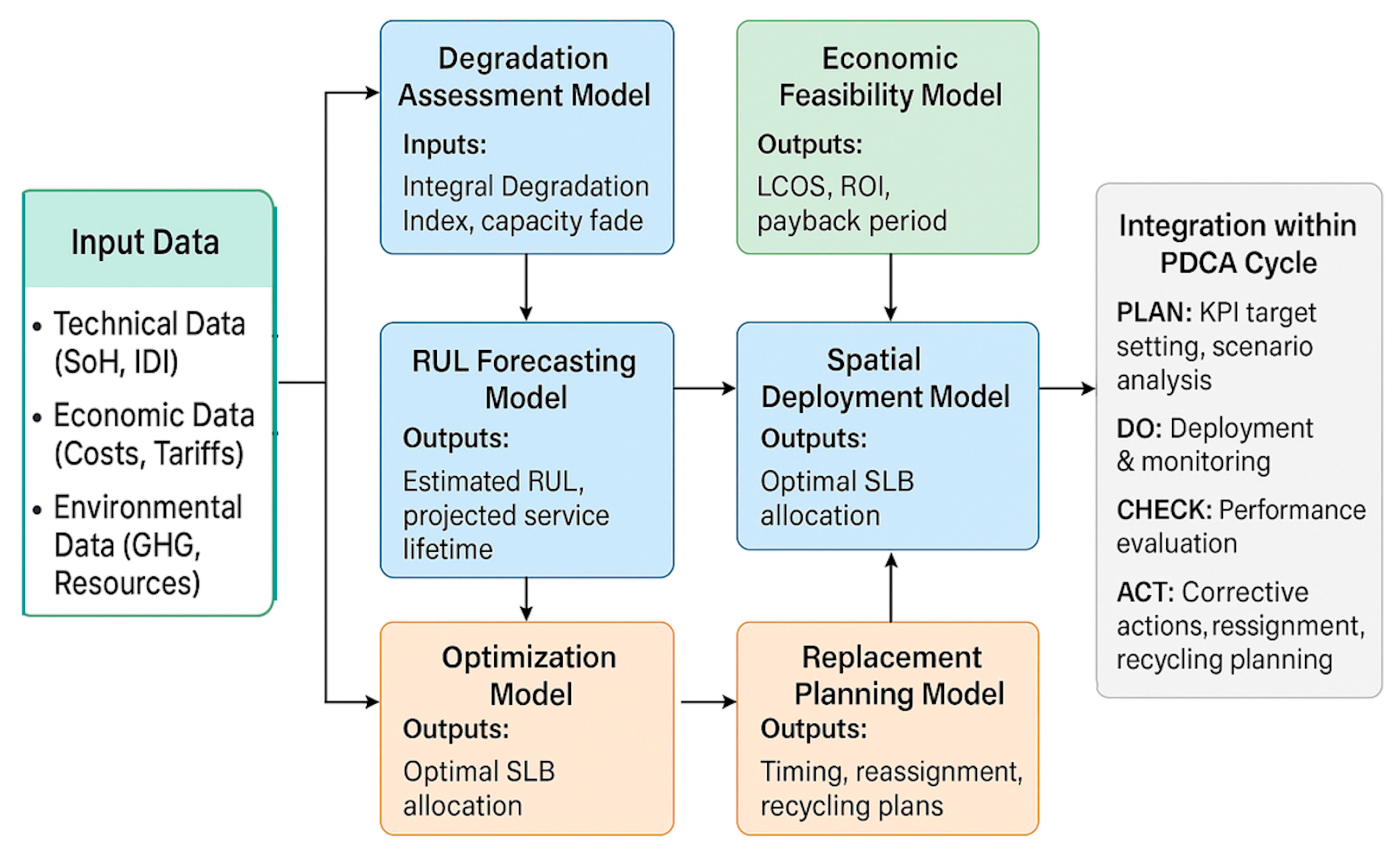

- Plan: Define KPI targets and thresholds based on scenario evaluation.

- Do: Deploy batteries and begin monitoring.

- Check: Evaluate deviations using real-time KPI inputs.

- Act: Apply A(t) based on logic rule to modify or continue the operational strategy.

4.8. Future Research: Multi-Model Framework for SLB Deployment

5. Discussion

5.1. Benchmarking with SOTA Methods

5.2. Environmental KPIs and Sustainability Implications

5.3. Limitations

5.4. Future Work

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| BESS | Battery Energy Storage System |

| BMS | Battery Management System |

| DOD | Depth of Discharge |

| EMS | Energy Management System |

| EV | Electric Vehicle |

| GHG | Greenhouse Gas |

| HV | High Voltage |

| IDI | Integral Degradation Index |

| IRR | Internal Rate of Return |

| KPI | Key Performance Indicator |

| LCOS | Levelized Cost of Storage |

| LIB | Lithium-Ion Battery |

| NPV | Net Present Value |

| O&M | Operation and Maintenance |

| PBP | Payback Period |

| PDCA | Plan-Do-Check-Act |

| RES | Renewable Energy Sources |

| ROI | Return on Investment |

| RTE | Round-Trip Efficiency |

| RUL | Remaining Useful Life |

| SLB | Second-Life Battery |

| SOH | State of Health |

References

- Reaching Climate Objectives: The Role of Carbon Dioxide Removals. Energy Transition Comission, October 2021. Available online: https://www.energy-transitions.org/wp-content/uploads/2021/05/ETC-NegEmiss-White-paper-v4-Final.pdf (accessed on 7 April 2025).

- Asif, M. (Ed.) The 4Ds of Energy Transition: Decarbonization, Decentralization, Decreasing Use and Digitalization, 1st ed.; Wiley: Hoboken, NJ, USA, 2022. [Google Scholar] [CrossRef]

- EEA. Trends and Projections in Europe 2023; European Environment Agency: Copenhagen, Denmark, 2023; 83p, Available online: https://www.eea.europa.eu/publications/trends-and-projections-in-europe-2023 (accessed on 15 April 2025).

- EEA. EEA Greenhouse Gas—Data Viewer. Available online: https://www.eea.europa.eu/data-and-maps/data/data-viewers/greenhouse-gases-viewer (accessed on 24 April 2025).

- United Nations Department of Economic and Social Affairs. Frontier Technology Issues: Lithium-Ion Batteries—A Pillar for a Fossil-Fuel-Free Economy. Available online: https://www.un.org/development/desa/dpad/publication/frontier-technology-issues-lithium-ion-batteries-a-pillar-for-a-fossil-fuel-free-economy/ (accessed on 14 April 2025).

- Yang, H.; Hu, X.; Zhang, G.; Dou, B.; Cui, G.; Yang, Q.; Yan, X. Life cycle assessment of secondary use and physical recycling of lithium-ion batteries retired from electric vehicles in China. Waste Manag. 2024, 178, 168–175. [Google Scholar] [CrossRef]

- Saudi Gazette. Global Battery Demand to Surge by 2030, Supply Headaches on the Horizon. Saudi Gazette, 16 August 2021. Available online: https://saudigazette.com.sa/article/617999/BUSINESS/Powering-up-Global-battery-demand-to-surge-by-2030-supply-headaches-on-the-horizon (accessed on 14 April 2025).

- A New Circular Economy Action Plan for a Cleaner and More Competitive Europe. 2020. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. An Official Website of the European Union. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=COM%3A2020%3A98%3AFIN (accessed on 15 April 2025).

- Global Electric Vehicle Outlook 2025: EV Batteries. Available online: https://iea.blob.core.windows.net/assets/7ea38b60-3033-42a6-9589-71134f4229f4/GlobalEVOutlook2025.pdf (accessed on 19 April 2025).

- EV Battery Current and Forecast Market Analysis. Available online: https://www.fortunebusinessinsights.com/industry-reports/electric-vehicle-battery-market-101700 (accessed on 1 May 2025).

- Statista. Second Life Battery Capacity—Globally 2030. 2019. Available online: https://www.statista.com/statistics/876624/global-second-life-battery-capacity/ (accessed on 7 April 2025).

- Ministry of Infrastructure of Ukraine. National Transport Strategy of Ukraine up to 2030. Available online: http://publications.chamber.ua/2017/Infrastructure/UDD/National_Transport_Strategy_2030.pdf (accessed on 10 January 2025). In Ukrainian.

- Kostenko, G.P. Situation analysis of electric transport development prospects and its integration into Ukrainian power system. Power Eng. Econ. Tech. Ecol. 2023, 1, 71. [Google Scholar] [CrossRef]

- Kostenko, G. Overview of European trends in electric vehicle implementation and the influence on the power system. Syst. Res. Energy 2022, 1, 62–71. [Google Scholar] [CrossRef]

- Ivanenko, N. The impact of the implementation of electric transportation on the Ukraine’s integrated power system functioning. Syst. Res. Energy 2023, 1, 4–11. [Google Scholar] [CrossRef]

- Kostenko, G.P.; Zgurovets, O.V.; Tovstenko, M.M. SWOT-analysis of electric transport and V2G implementation for power system sustainable development in Ukraine. IOP Conf. Ser. Earth Environ. Sci. 2023, 1254, 012030. [Google Scholar] [CrossRef]

- Kostenko, G.; Zaporozhets, A.; Babak, V.; Uruskyi, O.; Titko, V.; Denisov, V. Second-Life EV Batteries Application in Energy Storage Systems for Sustainable and Resilient Power Sector. In Systems, Decision and Control in Energy VII; Babak, V., Zaporozhets, A., Eds.; Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2025; Volume 595. [Google Scholar] [CrossRef]

- Kostenko, G.; Zaporozhets, A. World experience of legislative regulation for lithium-ion electric vehicle batteries considering their second-life application in power sector. Syst. Res. Energy 2024, 2, 97–114. [Google Scholar] [CrossRef]

- Kostenko, G.; Zaporozhets, A. Transition from electric vehicles to energy storage: Review on targeted lithium-ion battery diagnostics. Energies 2024, 17, 5132. [Google Scholar] [CrossRef]

- Yao, L.; Yang, B.; Cui, H.; Zhuang, J.; Ye, J.; Xue, J. Challenges and progresses of energy storage technology and its application in power systems. J. Mod. Power Syst. Clean Energy 2016, 4, 519–528. [Google Scholar] [CrossRef]

- Amir, M.; Deshmukh, R.G.; Khalid, H.M.; Said, Z.; Raza, A.; Muyeen, S.; Nizami, A.S.; Elavarasan, R.M.; Saidur, R.; Sopian, K. Energy storage technologies: An integrated survey of developments, global economical/environmental effects, optimal scheduling model, and sustainable adaption policies. J. Energy Storage 2023, 72, 108694. [Google Scholar] [CrossRef]

- Zaporozhets, A.; Kostenko, G.; Zgurovets, O.; Deriy, V. Analysis of Global Trends in the Development of Energy Storage Systems and Prospects for Their Implementation in Ukraine. In Power Systems Research and Operation; Kyrylenko, O., Denysiuk, S., Strzelecki, R., Blinov, I., Zaitsev, I., Zaporozhets, A., Eds.; Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2024; Volume 512. [Google Scholar] [CrossRef]

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A Review on Battery Market Trends, Second-Life Reuse, and Recycling. Sustain. Chem. 2021, 2, 167–205. [Google Scholar] [CrossRef]

- Miao, Y.; Hynan, P.; von Jouanne, A.; Yokochi, A. Current Li-ion battery technologies in electric vehicles and opportunities for advancements. Energies 2019, 12, 1074. [Google Scholar] [CrossRef]

- Pagliaro, M.; Meneguzzo, F. Lithium battery reusing and recycling: A circular economy insight. Heliyon 2019, 5, e01866. [Google Scholar] [CrossRef] [PubMed]

- Kurland, S.D. Energy use for GWh-scale lithium-ion battery production. Environ. Res. Commun. 2020, 2, 012001. [Google Scholar] [CrossRef]

- Tao, Y.; Rahn, C.D.; Archer, L.A.; You, F. Second life and recycling: Energy and environmental sustainability perspectives for high-performance lithium-ion batteries. Sci. Adv. 2021, 7, eabi7633. [Google Scholar] [CrossRef]

- Dong, Q.; Liang, S.; Li, J.; Kim, H.C.; Shen, W.; Wallington, T.J. Cost, energy, and carbon footprint benefits of second-life electric vehicle battery use. iScience 2023, 26, 107195. [Google Scholar] [CrossRef]

- Illa Font, C.H.; Siqueira, H.V.; Machado Neto, J.E.; Santos, J.L.F.D.; Stevan, S.L., Jr.; Converti, A.; Corrêa, F.C. Second Life of Lithium-Ion Batteries of Electric Vehicles: A Short Review and Perspectives. Energies 2023, 16, 953. [Google Scholar] [CrossRef]

- Reinhardt, R.; Christodoulou, I.; Gassó-Domingo, S.; Amante García, B. Towards sustainable business models for electric vehicle battery second use: A critical review. J. Environ. Manag. 2019, 245, 432–446. [Google Scholar] [CrossRef]

- Haram, M.H.S.M.; Sarker, M.T.; Ramasamy, G.; Ngu, E.E. Second life EV batteries: Technical evaluation, design framework, and case analysis. IEEE Access 2023, 11, 138799–138812. [Google Scholar] [CrossRef]

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.I.; Swierczynski, M.; Goikoetxea, A. Battery second life: Hype, hope or reality? A critical review of the state of the art. Renew. Sustain. Energy Rev. 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Prenner, S.; Part, F.; Jandric, A.; Bordes, A.; Leonhardt, R.; Jung-Waclik, S.; Huber-Humer, M. Enabling circular business models: Preconditions and key performance indicators for the market launch of repurposed second-life lithium-ion batteries from electric vehicles. Int. J. Energy Res. 2024, 8331870. [Google Scholar] [CrossRef]

- Kostenko, G. Accounting calendar and cyclic ageing factors in diagnostic and prognostic models of second-life EV batteries application in energy storage systems. Syst. Res. Energy 2024, 3, 21–34. [Google Scholar] [CrossRef]

- Neubauer, J.; Smith, K.; Wood, E.; Pesaran, A. Identifying and Overcoming Critical Barriers to Widespread Second Use of PEV Batteries. National Renewable Energy Laboratory, 2015. Available online: https://www.nrel.gov/docs/fy15osti/63332.pdf (accessed on 10 March 2025).

- Sandberg, E. Second Life Applications for Degraded EV Batteries: Evaluating Benefits Based on Remaining Useful Life and Battery Configurations. Master’s Thesis, Linköping University, Linköping, Sweden, 2023. Available online: https://urn.kb.se/resolve?urn=urn:nbn:se:liu:diva-196013 (accessed on 10 May 2025).

- Fichtner, M. Recent research and progress in batteries for electric vehicles. Batter. Supercaps 2022, 5, e202100224. [Google Scholar] [CrossRef]

- Hasselwander, S.; Meyer, M.; Österle, I. Techno-economic analysis of different battery cell chemistries for the passenger vehicle market. Batteries 2023, 9, 379. [Google Scholar] [CrossRef]

- Zaporozhets, A.; Babak, V.; Kostenko, G.; Zgurovets, O.; Denisov, V.; Nechaieva, T. Power System Resilience: An Overview of Current Metrics and Assessment Criteria. In Systems, Decision and Control in Energy VI; Studies in Systems, Decision and Control; Babak, V., Zaporozhets, A., Eds.; Springer: Cham, Switzerland, 2024; Volume 561. [Google Scholar] [CrossRef]

- Ma, J.; Li, Y.; Grundish, N.S.; Goodenough, J.B.; Chen, Y.; Guo, L.; Peng, Z.; Qi, X.; Yang, F.; Qie, L.; et al. The 2021 battery technology roadmap. J. Phys. D Appl. Phys. 2021, 54, 183001. [Google Scholar] [CrossRef]

- Tsiropoulos, I.; Tarvydas, D.; Lebedeva, N. Li-Ion Batteries for Mobility and Stationary Storage Applications—Scenarios for Costs and Market Growth; EUR 29440 EN; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar] [CrossRef]

- Chirumalla, K.; Kulkov, I.; Parida, V.; Dahlquist, E.; Johansson, G.; Stefan, I. Enabling battery circularity: Unlocking circular business model archetypes and collaboration forms in the electric vehicle battery ecosystem. Technol. Forecast. Soc. Chang. 2024, 199, 123044. [Google Scholar] [CrossRef]

- Vu, F.; Rahic, M.; Chirumalla, K. Exploring Second Life Applications for Electric Vehicle Batteries. In SPS2020: Advances in Transdisciplinary Engineering; Säfsten, K., Elgh, F., Eds.; IOS Press: Amsterdam, The Netherlands, 2020; Volume 13, pp. 273–284. [Google Scholar] [CrossRef]

- BNEF. Battery Pack Prices Fall to an Average of $132/kWh, but Rising Commodity Prices Start to Bite. November 2021. Available online: https://about.bnef.com/blog/battery-pack-prices-fall-to-an-average-of-132-kwh-but-rising-commodity-prices-start-to-bite/ (accessed on 16 June 2025).

- Tadayon, L.; Frey, G. Multi-Level Simulation Framework for Degradation-Aware Operation of a Large-Scale Battery Energy Storage Systems. Energies 2025, 18, 2708. [Google Scholar] [CrossRef]

- Zhong, S.; Yuan, B.; Guang, Z.; Chen, D.; Li, Q.; Dong, L.; Ji, Y.; Dong, Y.; Han, J.; He, W. Recent progress in thin separators for upgraded lithium-ion batteries. Energy Storage Mater. 2021, 41, 805–841. [Google Scholar] [CrossRef]

- Jiao, N.; Evans, S. Business models for sustainability: The case of second-life electric vehicle batteries. Procedia CIRP 2016, 40, 250–255. [Google Scholar] [CrossRef]

- Martinez-Laserna, E.; Sarasketa-Zabala, E.; Sarria, I.V.; Stroe, D.I.; Swierczynski, M.; Warnecke, A.; Timmermans, J.M.; Goutam, S.; Omar, N.; Rodriguez, P. Technical viability of battery second life: A study from the ageing perspective. IEEE Trans. Ind. Appl. 2018, 54, 2703–2713. [Google Scholar] [CrossRef]

- Kotak, Y.; Marchante Fernandez, C.; Canals Casals, L.; Kotak, B.S.; Koch, D.; Geisbauer, C.; Trilla, L.; Gomez-Nunez, A.; Schweiger, H.-G. End of electric vehicle batteries: Reuse vs. recycle. Energies 2021, 14, 2217. [Google Scholar] [CrossRef]

- Bobba, S.; Mathieux, F.; Ardente, F.; Blengini, G.A.; Cusenza, M.A.; Podias, A.; Pfrang, A. Life cycle assessment of repurposed electric vehicle batteries: An adapted method based on modelling energy flows. J. Energy Storage 2018, 19, 213–225. [Google Scholar] [CrossRef]

- Nissan Motor Corporation. Electric Vehicle Lithium-Ion Battery. Available online: https://www.nissan-global.com/EN/INNOVATION/TECHNOLOGY/ARCHIVE/LI_ION_EV/ (accessed on 30 March 2025).

- InsideEVs ET. Battery Capacity Loss Warranty Chart for 30 kWh Nissan LEAF. Available online: https://insideevs.com/news/326563/battery-capacity-loss-warranty-chart-for-2016-30-kwh-nissan-leaf/ (accessed on 30 April 2025).

- Koroma, M.S.; Costa, D.; Philippot, M.; Cardellini, G.; Hosen, M.S.; Coosemans, T.; Messagie, M. Life cycle assessment of battery electric vehicles: Implications of future electricity mix and different battery end-of-life management. Sci. Total Environ. 2022, 831, 154859. [Google Scholar] [CrossRef] [PubMed]

- Shafiekhani, M.; Oadrdan, M. Addressing electricity transmission network congestions using battery energy storage systems—A case study of Great Britain. Appl. Energy 2025, 384, 125418. [Google Scholar] [CrossRef]

- Horesh, N.; Quinn, C.; Wang, H.; Zane, R.; Ferry, M.; Tong, S.; Quinn, J.C. Driving to the future of energy storage: Techno-economic analysis of a novel method to recondition second life electric vehicle batteries. Appl. Energy 2021, 295, 117007. [Google Scholar] [CrossRef]

- Fang, Y.; Fan, R.; Liu, Z. A study on the energy storage scenarios design and the business model analysis for a zero-carbon big data industrial park from the perspective of source-grid-load-storage collaboration. Energy Rep. 2023, 9 (Suppl. 7), 2054–2068. [Google Scholar] [CrossRef]

- DIgSILENT Power Generation. Power System Solutions DIgSILENT. Available online: https://www.digsilent.de/en/power-generation.html (accessed on 1 August 2025).

- TIMES Ukraine. Available online: https://www.timesukraine.tokni.com/about (accessed on 1 August 2025).

- Enertile® Website. The Enertile Optimisation Model. Available online: https://enertile.eu/enertile-en/methodology/optimisation.php (accessed on 5 August 2025).

- Canals Casals, L.; Amante García, B.; Canal, C.C. Second life batteries lifespan: Rest of useful life and environmental analysis. J. Environ. Manag. 2019, 232, 354–363. [Google Scholar] [CrossRef]

- Neigum, K.; Wang, Z. Technology, economic, and environmental analysis of second-life batteries as stationary energy storage: A review. J. Energy Storage 2024, 103, 114393. [Google Scholar] [CrossRef]

- Hu, X.; Feng, F.; Liu, K.; Zhang, L. State estimation for advanced battery management: Key challenges and future trends. Renew. Sustain. Energy Rev. 2019, 114, 109334. [Google Scholar] [CrossRef]

- Moen, R. Foundation and History of the PDSA Cycle. Available online: https://deming.org/wp-content/uploads/2020/06/PDSA_History_Ron_Moen.pdf (accessed on 30 April 2025).

- Moen, R.; Norman, C. Evolution of the PDCA Cycle. Available online: https://www.studocu.vn/vn/document/truong-dai-hoc-kinh-te-va-quan-tri-kinh-doanh-dai-hoc-thai-nguyen/quan-tri-kinh-doanh/pdca-evolution-of-the-pdca-cycle/58037091 (accessed on 30 April 2025).

- Deming’s 14 Points for Management. Available online: https://deming.org/explore/fourteen-points/ (accessed on 30 April 2025).

- ASQ. The Deming Cycle (PDCA) Explained: A Comprehensive Guide to Continuous Improvement. Brightly Software. 2025. Available online: https://www.brightlysoftware.com/learning-center/deming-cycle-pdca-explained-comprehensive-guide-continuous-improvement (accessed on 30 April 2025).

- Arveson, P. The Deming Cycle. Available online: https://balancedscorecard.org/bsc-basics/articles-videos/the-deming-cycle (accessed on 30 April 2025).

- Investopedia. What Does PDCA Stand for in Business? Plan–Do–Check–Act Cycle. Investopedia 2010. Available online: https://www.investopedia.com/terms/p/pdca-cycle.asp (accessed on 30 April 2025).

- Dziadkowiec, J.M.; Balon, U.; Niewczas-Dobrowolska, M. Key Performance Indicators (KPIs) in the Quality Management System. Int. J. Qual. Res. 2024, 18, 473–486. [Google Scholar]

- Isniah, S.; Purba, H.H.; Debora, F. Plan do check action (PDCA) method: Literature review and research issues. J. Syst. Manag. Ind. 2020, 4, 72–81. [Google Scholar] [CrossRef]

- Patel, P.M.; Deshpande, V.A. Application of Plan-Do-Check-Act Cycle for Quality and Productivity Improvement A Review. Int. J. Res. Appl. Sci. Eng. Technol. (IJRASET) 2017, 5, 197–201. Available online: https://www.ijraset.com/fileserve.php?FID=6095 (accessed on 30 April 2025).

- Peças, P.; Encarnação, J.; Gambôa, M.; Sampayo, M.; Jorge, D. PDCA 4.0: A New Conceptual Approach for Continuous Improvement in the Industry 4.0 Paradigm. Appl. Sci. 2021, 11, 7671. [Google Scholar] [CrossRef]

- Taylor, M.J.; McNicholas, C.; Nicolay, C.; Darzi, A.; Bell, D.; Reed, J.E. Systematic review of the application of the plan-do-study-act method to improve quality in healthcare. BMJ Qual Saf. 2014, 23, 290–298. [Google Scholar] [CrossRef]

- Candiello, A.; Cortesi, A. KPI-Supported PDCA Model for Innovation Policy Management in Local Government. In Electronic Government; EGOV 2011; Lecture Notes in Computer Science; Janssen, M., Scholl, H.J., Wimmer, M.A., Tan, Y., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; Volume 6846. [Google Scholar] [CrossRef]

- Hasan, Z.; Hossain, M.S. Improvement of Effectiveness by Applying PDCA Cycle or Kaizen: An Experimental Study on Engineering Students. J. Sci. Res. 2018, 10, 159–173. [Google Scholar] [CrossRef]

- Taufik, D.A. PDCA Cycle Method implementation in industries: A systematic literature review. Ind. Eng. Manag. 2020, 1, 157–166. [Google Scholar] [CrossRef]

- Kushariyadi, K. Performance Management Based on Key Performance Indicators (KPI) to improve Organizational Effectiveness. Maneggio 2025, 2, 90–102. [Google Scholar] [CrossRef]

- Asih, I.; Purba, H.P.; Sitorus, T.M. Key Performance Indicators: A Systematic Literature Review. J. Strategy Perform. Manag. 2020, 8, 142–155. [Google Scholar]

- Zhang, K.; Shardt, Y.A.W.; Chen, Z.; Yang, X.; Ding, S.X.; Peng, K. A KPI-based process monitoring and fault detection framework for large-scale processes. ISA Trans. 2017, 68, 276–286. [Google Scholar] [CrossRef]

- Denysov, V.; Kulyk, M.; Babak, V.; Zaporozhets, A.; Kostenko, G. Modeling nuclear-centric scenarios for Ukraine’s low-carbon energy transition using diffusion and regression techniques. Energies 2024, 17, 5229. [Google Scholar] [CrossRef]

- Kostenko, G.P.; Zaporozhets, A.O.; Zaporozhets, N.V.; Verpeta, V.O. Aspects of integrating renewable distributed generation into the energy supply system of Ukraine. Probl. Econ. 2024, 2, 83–93. [Google Scholar] [CrossRef]

- Denysov, V.; Babak, V.; Zaporozhets, A.; Nechaieva, T.; Kostenko, G. Energy System Optimization Potential with Consideration of Technological Limitations. In Nexus of Sustainability; Zagorodny, A., Bogdanov, V., Zaporozhets, A., Eds.; Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2024; Volume 559. [Google Scholar] [CrossRef]

- Denysov, V.; Babak, V.; Zaporozhets, A.; Nechaieva, T.; Kostenko, G. Quasi-dynamic energy complexes optimal use on the forecasting horizon. In Systems, Decision and Control in Energy VI; Babak, V., Zaporozhets, A., Eds.; Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2024; Volume 561. [Google Scholar] [CrossRef]

- Maistrenko, N. Taking into account environmental constraints on emissions in economic models long-term forecasting of energy consumption (review of publications). Syst. Res. Energy 2023, 3, 85–94. [Google Scholar] [CrossRef]

- Babak, V.; Kulyk, M. Development of the New Electro-Thermal Energy System Structure for Providing of Ukraine’s Energy Market Profitability. In Systems, Decision and Control in Energy, V; Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2023; Volume 481. [Google Scholar] [CrossRef]

- Hotra, O.; Kulyk, M.; Babak, V.; Kovtun, S.; Zgurovets, O.; Mroczka, J.; Kisała, P. Organisation of the structure and functioning of self-sufficient distributed power generation. Energies 2024, 17, 27. [Google Scholar] [CrossRef]

- Zgurovets, O.; Kulyk, M.M. Possibilities to form a modern reserve of supporting frequency in integrated power systems based on storage batteries for automatic adjustment of frequency and power. Syst. Res. Energy 2022, 1–2, 20–29. [Google Scholar] [CrossRef]

- Babak, V.P.; Kulyk, M.M. Possibilities and perspectives of the consumers-regulators application in systems of frequency and power automatic regulation. Tech. Electrodyn. 2023, 4, 72–80. [Google Scholar] [CrossRef]

- Elhuni, R.M.; Ahmad, M.M. Key Performance Indicators for Sustainable Production Evaluation in Oil and Gas Sector. Procedia Manuf. 2017, 11, 718–724. [Google Scholar] [CrossRef]

- Feiz, R.; Johansson, M.; Lindkvist, E.; Moestedt, J.; Påledal, S.N.; Svensson, N. Key performance indicators for biogas production—Methodological insights on the life-cycle analysis of biogas production from source-separated food waste. Energy 2020, 200, 117462. [Google Scholar] [CrossRef]

- Brint, A.; Genovese, A.; Piccolo, C.; Taboada-Perez, G.J. Reducing data requirements when selecting key performance indicators for supply chain management: The case of a multinational automotive component manufacturer. Int. J. Prod. Econ. 2020, 233, 107967. [Google Scholar] [CrossRef]

- Cherni, J.; Martinho, R.; Ghannouchi, S.A. Towards Improving Business Processes based on preconfigured KPI target values, Process Mining and Redesign Patterns. Procedia Comput. Sci. 2019, 164, 279–284. [Google Scholar] [CrossRef]

- Schmidt, O.; Melchior, S.; Hawkes, A.; Staffell, I. Projecting the Future Levelized Cost of Electricity Storage Technologies. Joule 2019, 3, 81–100. [Google Scholar] [CrossRef]

- Assad, F.; Alkan, B.; Chinnathai, M.K.; Ahmad, M.H.; Rushforth, E.J.; Harrison, R. A framework to predict energy related key performance indicators of manufacturing systems at early design phase. Procedia CIRP 2019, 81, 145–150. [Google Scholar] [CrossRef]

- Wang, D.; Coignard, J.; Zeng, T.; Zhang, C.; Saxena, S. Quantifying electric vehicle battery degradation from driving vs. vehicle-to-grid services. J. Power Sources 2016, 332, 193–203. [Google Scholar] [CrossRef]

- Dubarry, M.; Baure, G.; Devie, A. Durability and reliability of EV batteries under electric utility grid operations: Path dependence of battery degradation. J. Electrochem. Soc. 2018, 165, A773. [Google Scholar] [CrossRef]

- Eddahech, A.; Briat, O.; Woirgard, E.; Vinassa, J.M. Remaining useful life prediction of lithium batteries in calendar ageing for automotive applications. Microelectron. Reliab. 2012, 52, 2438–2442. [Google Scholar] [CrossRef]

- Gharebaghi, M.; Rezaei, O.; Li, C.; Wang, Z.; Tang, Y. A Survey on Using Second-Life Batteries in Stationary Energy Storage Applications. Energies 2025, 18, 42. [Google Scholar] [CrossRef]

- Neubauer, J.; Wood, E.; Pesaran, A. A second life for electric vehicle batteries: Answering questions on battery degradation and value. SAE Int. J. Mater. Manf. 2015, 8, 530–537. [Google Scholar] [CrossRef]

- Haram, M.H.S.M.; Lee, J.W.; Ramasamy, G.; Ngu, E.E.; Thiagarajah, S.P.; Lee, Y.H. Feasibility of utilising second life EV batteries: Applications, lifespan, economics, environmental impact assessment, and challenges. Alex. Eng. J. 2021, 60, 4517–4536. [Google Scholar] [CrossRef]

- Assunção, A.; Moura, P.S.; de Almeida, A.T. Technical and economic assessment of the secondary use of repurposed electric vehicle batteries in the residential sector to support solar energy. Appl. Energy 2016, 181, 120–131. [Google Scholar] [CrossRef]

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Sunny, M.S.; Sami, N.M. A comprehensive review on second-life batteries: Current state, manufacturing considerations, applications, impacts, barriers & potential solutions, business strategies, and policies. IEEE Access 2019, 7, 73215–73252. [Google Scholar] [CrossRef]

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Tong, S.; Fung, T.; Klein, M.P.; Weisbach, D.A.; Park, J.W. Demonstration of reusing electric vehicle battery for solar energy storage and demand side management. J. Energy Storage 2017, 11, 200–210. [Google Scholar] [CrossRef]

- Li, J.; Wang, Y.; Tan, X. Research on the classification method for the secondary uses of retired lithium-ion traction batteries. Energy Procedia 2017, 105, 2843–2849. [Google Scholar] [CrossRef]

- Wang, L.; Pan, C.; Liu, L.; Cheng, Y.; Zhao, X. On-board state of health estimation of LiFePO4 battery pack through differential voltage analysis. Appl. Energy 2016, 168, 465–472. [Google Scholar] [CrossRef]

- Baghadadi, I.; Briat, O.; Hyan, P.; Vinassa, J.M. State of health assessment for lithium batteries based on voltage-time relaxation measure. Electrochim. Acta 2016, 194, 461–472. [Google Scholar] [CrossRef]

- Waag, W.; Kabitz, S.; Sauer, D. Experimental investigation of the lithium-ion battery impedance characteristic at various conditions and aging states and its influence on the application. Appl. Energy 2013, 102, 885–897. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z.; Yan, J. Prognostic health condition for lithium battery using the partial incremental capacity and Gaussian process regression. J. Power Sources 2019, 421, 56–67. [Google Scholar] [CrossRef]

- Kostenko, G.; Zaporozhets, A. Enhancing the power system resilience through the application of micro power systems (microgrid) with renewable distributed generation. Syst. Res. Energy 2023, 3, 25–38. [Google Scholar] [CrossRef]

- Kostenko, G. Cluster-based deployment of second-life EV batteries for reliable and sustainable backup power solution in power systems. Syst. Res. Energy 2025, 1, 40–60. [Google Scholar] [CrossRef]

- Denysov, V.; Kostenko, G.; Babak, V.; Shulzhenko, S.; Zaporozhets, A. Accounting the Forecasting Stochasticity at the Power System Modes Optimization. In Systems, Decision and Control in Energy V; Studies in Systems, Decision and Control; Zaporozhets, A., Ed.; Springer: Cham, Switzerland, 2023; Volume 481. [Google Scholar] [CrossRef]

- Han, X.; Liang, Y.; Ai, Y.; Li, J. Economic evaluation of a PV combined energy storage charging station based on cost estimation of second-use batteries. Energy 2018, 165, 326–339. [Google Scholar] [CrossRef]

- Bai, B.; Xiong, S.; Song, B.; Xiaoming, M. Economic analysis of distributed solar photovoltaics with reused electric vehicle batteries as energy storage systems in China. Renew. Sustain. Energy Rev. 2019, 109, 213–229. [Google Scholar] [CrossRef]

- Madlener, R.; Kirmas, A. Economic viability of second use electric vehicle batteries for energy storage in residential applications. Energy Procedia 2017, 105, 3806–3815. [Google Scholar] [CrossRef]

- Sun, S.I.; Chipperfield, A.J.; Kiaee, M.; Wills, R.G.A. Effects of market dynamics on the time-evolving price of second-life electric vehicle batteries. J. Energy Storage 2018, 19, 41–51. [Google Scholar] [CrossRef]

- Song, Z.; Feng, S.; Zhang, L.; Hu, Z.; Hu, X.; Yao, R. Economy analysis of second-life battery in wind power systems considering battery degradation in dynamic processes: Real case scenarios. Appl. Energy 2019, 251, 113411. [Google Scholar] [CrossRef]

- Katwala, A. The Spiralling Environmental Cost of our Lithium Battery Addiction. WIRED U.K., December 2018. Available online: https://www.wired.co.uk/article/lithium-batteries-environment-impact (accessed on 15 April 2025).

- Kuki, Á.; Lakatos, C.; Nagy, L.; Nagy, T.; Kéki, S. Energy use and environmental impact of three lithium-ion battery factories with a total annual capacity of 100 GWh. Environments 2025, 12, 24. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J.; Arsenault, R.; Bae, C.; Ahn, S.; Lee, J. Cradle-to-gate emissions from a commercial electric vehicle Li-ion battery: A comparative analysis. Environ. Sci. Technol. 2016, 50, 7715–7722. [Google Scholar] [CrossRef]

- Lyu, W.; Hu, Y.; Liu, J.; Chen, K.; Liu, P.; Deng, J.; Zhang, S. Impact of battery electric vehicle usage on air quality in three Chinese first-tier cities. Sci. Rep. 2024, 14, 21. [Google Scholar] [CrossRef] [PubMed]

- Rossi, F.; Tosti, L.; Basosi, R.; Cusenza, M.A.; Parisi, M.L.; Sinicropi, A. Environmental optimization model for the European batteries industry based on prospective life cycle assessment and material flow analysis. Renew. Sustain. Energy Rev. 2023, 183, 113485. [Google Scholar] [CrossRef]

- Cox, B.; Mutel, C.L.; Bauer, C.; Mendoza Beltran, A.; van Vuuren, D.P. Uncertain environmental footprint of current and future battery electric vehicles. Environ. Sci. Technol. 2018, 52, 4989–4995. [Google Scholar] [CrossRef]

- Dunn, J.B.; Gaines, L.; Kelly, J.C.; James, C.; Gallagher, K.G. The significance of Li-ion batteries in electric vehicle life-cycle energy and emissions and recycling’s role in its reduction. Energy Environ. Sci. 2015, 8, 158–168. [Google Scholar] [CrossRef]

- Picatoste, A.; Justel, D.; Mendoza, J.M.F. Analysing Repurposing Solutions for Electric Vehicle Batteries: Circularity Indicators, LCA and Methodological Guidelines. 2023. Available online: https://www.researchgate.net/profile/Aitor-Picatoste/publication/373993858_Analysing_repurposing_solutions_for_electric_vehicle_batteries_circularity_indicators_LCA_and_methodological_guidelines/links/650828759fdf0c69dfd9193d/Analysing-repurposing-solutions-for-electric-vehicle-batteries-circularity-indicators-LCA-and-methodological-guidelines.pdf (accessed on 10 May 2025).

- Bekaert, E. Second Life Batteries for a Sustainable Energy Transition. CIC energiGUNE, 5 October 2021. Available online: https://cicenergigune.com/en/blog/second-life-batteries-sustainable-energy-transition (accessed on 10 May 2025).

- European Parliament. Batteries: Deal on New EU Rules for Design, Production and Waste Treatment. 12 September 2022. Press Release. Available online: https://www.europarl.europa.eu/news/en/press-room/20221205IPR60614/batteries-deal-on-new-eu-rules-for-design-production-and-waste-treatment (accessed on 10 August 2025).

- Battery Passport Content Guidance. Executive Summary. Available online: https://thebatterypass.eu/assets/images/content-guidance/pdf/2023_Battery_Passport_Content_Guidance_Executive_Summary.pdf (accessed on 10 August 2025).

- Zaporozhets, A.; Kostenko, G.; Zgurovets, O. Preconditions and main features of electric vehicles application for frequency regulation in the power system. In Proceedings of the 3rd International Workshop on Information Technologies: Theoretical and Applied Problems (ITTAP 2023), Kryvyi Rih, Ukraine, 22–24 November 2023; CEUR Workshop Proceedings. Volume 3628, pp. 43–54. Available online: https://ceur-ws.org/Vol-3628/paper4.pdf (accessed on 10 May 2025).

- Shpak, N.; Muzychenko-Kozlovska, O.; Gvozd, M.; Sorochak, O. Assessment of the Investment and Innovation Environmental Attractiveness of the Country: On the Example of Ukraine. In Systems, Decision and Control in Energy VII; Babak, V., Zaporozhets, A., Eds.; Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2025; Volume 595. [Google Scholar] [CrossRef]

- Babak, V.; Nikitin, Y.; Teslenko, O. Holistic approach to the systemic transformation of the electric power industry, district heating and municipal infrastructure. Syst. Res. Energy 2024, 4, 6–25. [Google Scholar] [CrossRef]

- Kostenko, G.; Zgurovets, O. Current state and prospects for development of renewable distributed generation in Ukraine. Syst. Res. Energy 2023, 2, 4–17. [Google Scholar] [CrossRef]

- Zaichenko, S.; Trachuk, A. Methodology for Modeling Selected Structural Components of Renewable Energy Sources in Ukraine and Assessment of Their Resources and Energy Conversion Technologies. In Systems, Decision and Control in Energy VII; Babak, V., Zaporozhets, A., Eds.; Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2025; Volume 595. [Google Scholar] [CrossRef]

- Zaporozhets, A.; Babak, V.; Kulyk, M.; Denysov, V. Novel Methodology for Determining Necessary and Sufficient Power in Integrated Power Systems Based on the Forecasted Volumes of Electricity Production. Electricity 2025, 6, 41. [Google Scholar] [CrossRef]

| Method/Authors (Year) | Scope/Strengths | Limitations (Relevance to SLB) | Ref. |

|---|---|---|---|

| Haram et al., IEEE Access (2023) | Techno-economic assessment of SLB lifetime and costs | Focus on cost, lacks PDCA cycle or KPI-trigger control | [31] |

| Martinez-Laserna et al., IEEE TIA (2018) | Degradation modelling, RUL assessment | Technical focus only, no economic or governance dimension | [32] |

| Prenner et al., Int. J. Energy Res. (2024) | KPIs for circular business models of SLB | KPI definition only, no integration with PDCA or dispatch logic | [33] |

| Tadayon & Frey, Energies (2025) | Multi-level degradation-aware operation of BESS | Strong LIB focus, not tailored to SLB variability | [45] |

| DIgSILENT PowerFactory | Large-scale grid simulation, RES + storage integration | No SLB-specific degradation modelling, no KPI-trigger logic | [57] |

| TIMES model | Long-term techno-economic optimisation for energy systems | Macro-level only, lacks operational control and lifecycle adaptation | [58] |

| ENERTILE | RES integration and storage for European grids | No SLB focus, no adaptive PDCA management | [59] |

| Canals, Casals, & Amante, J. Environ. Manag. (2019) | RUL + environmental impact of SLB | Valuable LCA insights, no integrated PDCA management | [60] |

| Neigum & Wang, J. Energy Storage (2024) | Review of SLB technology, economy, and environment | Descriptive, no operational management framework | [61] |

| Hu et al., Renew. Sust. Energy Rev. (2019) | State estimation for advanced BMS | Diagnostics only, no KPI–circular economy integration | [62] |

| Proposed KPI–PDCA framework | Integrates technical, economic, and environmental KPIs; PDCA cycle; trigger-based logic; 6-model multimodel architecture; scenario evaluation (HV Backup, RES Smoothing, FR) | Proof-of-concept; requires further empirical validation | - |

| PDCA Phase | Core Management Actions | Monitoring Priorities | Decision Triggers |

|---|---|---|---|

| PLAN | Define KPI targets, scenario selection, lifecycle and economic modeling | Feasibility, resource efficiency, emission impacts | Regulatory requirements, resource constraints |

| DO | Deploy and operate SLBs, implement control strategies, real-time data collection | SOH, SOE, utilization rate, operational anomalies | Performance deviation, technical constraints |

| CHECK | Evaluate KPI compliance, degradation assessment, environmental monitoring | KPI tracking vs. targets, degradation rates | Threshold crossings (SOH drop, LCOS increase) |

| ACT | Adjust operational parameters, reallocate SLBs, initiate refurbishment or recycling plans | Improvement needs, strategy effectiveness | Economic underperformance, safety margins reached |

| KPI | Description | Measurement Method | Reference Values | Data Source | PDCA Phase |

|---|---|---|---|---|---|

| Round-Trip Efficiency (RTE) | Ratio of energy discharged to energy charged, indicating the conversion efficiency of SLB system | % calculated from charge/discharge energy over time | >85% for optimal operation | BMS, EMS logs | Check, Act |

| Depth of Discharge (DOD) | Proportion of battery capacity used during a cycle, affecting degradation rate | % of nominal capacity | 60–80% for balanced degradation and usability | BMS | Do, Check |

| State of Health (SOH) | Remaining capacity and performance relative to initial state | % of initial capacity; impedance analysis | >70% for active grid applications | BMS diagnostics | Check |

| Integral Degradation Index (IDI) | Composite metric combining calendar, cyclic, and stochastic ageing | Dimensionless index (0–1 scale) | <0.85 for continued use in active roles | Calculated from operational data | Check, Act |

| C-rate | Charge/discharge current relative to capacity, impacts ageing | 0.2–0.5 C for typical SLB use | ≤0.5 C in grid support | BMS | Do, Check |

| Internal Resistance (IR) | Resistance within the battery, indicating degradation level | measured under load | Threshold increases with degradation; monitor trend | BMS | Check |

| Remaining Useful Life (RUL) | Projected operational lifespan under current usage | Cycles or years forecast | 3–7 years in grid | Prognostic algorithms | Plan, Check |

| Reliability indicator R(t) | Ratio of uninterrupted operation time to total operating time during SLB use | calculated | ≥0.95 for critical applications | SLB system logs, monitoring systems | Check, Act |

| KPI | Description | Measurement Method | Reference Values | Data Source | PDCA Phase |

|---|---|---|---|---|---|

| Levelized Cost of Storage (LCOS) | Average cost per kWh stored/discharged over SLB lifetime | USD/MWh calculated from total costs and energy throughput | <150–200 USD/MWh for economic viability | Financial analysis, EMS data | Plan, Check |

| Payback Period (PBP) | Time to recover initial investment from operational savings | Years calculated from cash flow | 4–6 years typical | Financial tracking | Plan, Check |

| Return on Investment (ROI) | Profitability measure over project lifetime | % calculated from net profit/investment | >10–15% desirable | Financial reports | Check |

| Revenue Stacking Potential | Ability to generate multiple revenue streams (e.g., FR, arbitrage) | Qualitative + USD tracking | Scenario-dependent | EMS, market data | Plan, Do |

| Operational Expenditure (OPEX) | Ongoing costs for maintenance and operation | USD/year | Minimized within system reliability constraints | O&M logs, financial | Do, Check |

| Amortization Period | Period over which investment cost is spread | Years | Typically 5–10 years | Financial planning | Plan |

| Internal Rate of Return (IRR) | Discount rate making NPV zero | % | >8–12% acceptable | Financial calculation | Check |

| KPI | Description | Measurement Method | Reference Values | Data Source | PDCA Phase |

|---|---|---|---|---|---|

| Lifecycle GHG Emissions Reduction | Reduction in CO2-eq emissions vs. new batteries or fossil alternatives | kg CO2-eq saved per kWh | >30% reduction target | LCA studies, EMS data | Plan, Check |

| Material Efficiency | Ratio of energy delivered to embodied material energy | Dimensionless ratio | >1.5 | LCA, material input data | Check, Act |

| Energy Payback Time (EPBT) | Time needed to repay energy used for SLB repurposing | Years | <0.2 years | Repurposing data, use profile | Do, Check |

| Circularity Score (CS) | Combined indicator of reuse and recyclability | Normalized score (0–1) | >0.8 | Material flow analysis | Act, Check |

| Environmental Pollution Reduction | Reduction in harmful emissions and waste during SLB usage | % reduction compared to baseline | >50% | Emissions inventory, LCA | Do, Check |

| Stage of SLB Integration | Dominant KPI Role | Example Metrics | Typical Trade-Offs | Strategic Purpose |

|---|---|---|---|---|

| Initial Screening | Filtering Indicator | SOH, RUL Estimate | Risk of underutilization vs. safety | Select technically viable units |

| Scenario Matching | Suitability Scoring | DoD, LCOS, Payback | High revenue vs. fast degradation | Match batteries to optimal use cases |

| Pilot Operation | Performance Benchmark | RTE, Thermal Profile | Efficiency vs. complexity of monitoring | Identify systemic weaknesses |

| Mid-Term Assessment | Threshold Evaluation | IDI, SOH Drift | Conservative operation vs. underuse | Adjust cycle depth or duty profile |

| Portfolio Optimization | Decision Trigger | Degradation Rate, LCOS | Short-term gains vs. asset longevity | Reallocate or retire based on ROI decline |

| KPI | Threshold Value | Sources | Trigger Condition | Action (Do/Act) | Data | PDCA Phase |

|---|---|---|---|---|---|---|

| RTE | >85% | [9,23,99] | Drop below 80% | Adjust DOD, review charge rates | EMS, BMS | Check, Act |

| DOD | 60–80% | [95,96] | Deviates >10% from plan | Limit cycles, adjust dispatch | BMS | Do, Check |

| SOH | >70% | [48,98] | Drop to 65–70% | Reassign to a low-stress application | BMS diagnostics | Check, Act |

| IDI | <0.85 | [34] | Exceeds 0.85 | Trigger reassessment, reallocation | Calculated | Check, Act |

| LCOS | <200 USD/MWh | [28,45,93,100] | Exceeds threshold | Evaluate cost drivers, optimise ops | Financial analysis | Plan, Check |

| PBP | 4–6 years | [100,113] | Extends beyond 7 years | Recalculate financial plan | Financial tracking | Plan |

| ROI | >10–15% | [9,44] | Falls below 8% | Adjust business model | Financial reports | Check |

| GHG Reduction | >30% | [33,127,128] | Drops below 25% | Investigate inefficiencies | LCA data | Check |

| Resource Savings | 20–40% | [98,127,128] | Drops significantly | Review reuse logistics | LCA analysis | Check |

| Model Name | Input Parameters | Outputs | Methods Used | PDCA Phase |

|---|---|---|---|---|

| Degradation Assessment Model | Calendar age, cycle count, temperature, load history | Integral Degradation Index, capacity fade rates | Empirical modelling, regression, and machine learning | PLAN, DO |

| Remaining Useful Life Forecasting Model | SOH(t), IDI, operational history | Estimated RUL, projected service lifetime | Time series forecasting, exponential smoothing, threshold-based rules | PLAN, CHECK |

| Economic Feasibility Model | Costs, service life, efficiency, tariffs/profits | LCOS, NPV, IRR, payback period | Financial modelling, scenario analysis, LCOS calculation | PLAN |

| Optimisation Model for SLB Allocation | Costs, reliability, location, and environmental impacts | Optimal SLB deployment across scenarios | Multi-criteria optimisation, mathematical programming | PLAN, DO |

| Spatial Deployment Model | Load profiles, infrastructure, RES share, regional risks | Feasibility maps, object ranking for deployment | GIS analysis, spatial multi-criteria assessment | PLAN |

| Replacement Planning Model | SOH, IDI, degradation thresholds | Replacement timing, reuse or disposal recommendations | Threshold rules, dynamic replacement planning | CHECK, ACT |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kostenko, G.; Zaporozhets, A. Trigger-Based PDCA Framework for Sustainable Grid Integration of Second-Life EV Batteries. World Electr. Veh. J. 2025, 16, 584. https://doi.org/10.3390/wevj16100584

Kostenko G, Zaporozhets A. Trigger-Based PDCA Framework for Sustainable Grid Integration of Second-Life EV Batteries. World Electric Vehicle Journal. 2025; 16(10):584. https://doi.org/10.3390/wevj16100584

Chicago/Turabian StyleKostenko, Ganna, and Artur Zaporozhets. 2025. "Trigger-Based PDCA Framework for Sustainable Grid Integration of Second-Life EV Batteries" World Electric Vehicle Journal 16, no. 10: 584. https://doi.org/10.3390/wevj16100584

APA StyleKostenko, G., & Zaporozhets, A. (2025). Trigger-Based PDCA Framework for Sustainable Grid Integration of Second-Life EV Batteries. World Electric Vehicle Journal, 16(10), 584. https://doi.org/10.3390/wevj16100584