Criterion Circle-Optimized Hybrid Finite Element–Statistical Energy Analysis Modeling with Point Connection Updating for Acoustic Package Design in Electric Vehicles

Abstract

1. Introduction

2. The Hybrid FE-SEA Method Theory

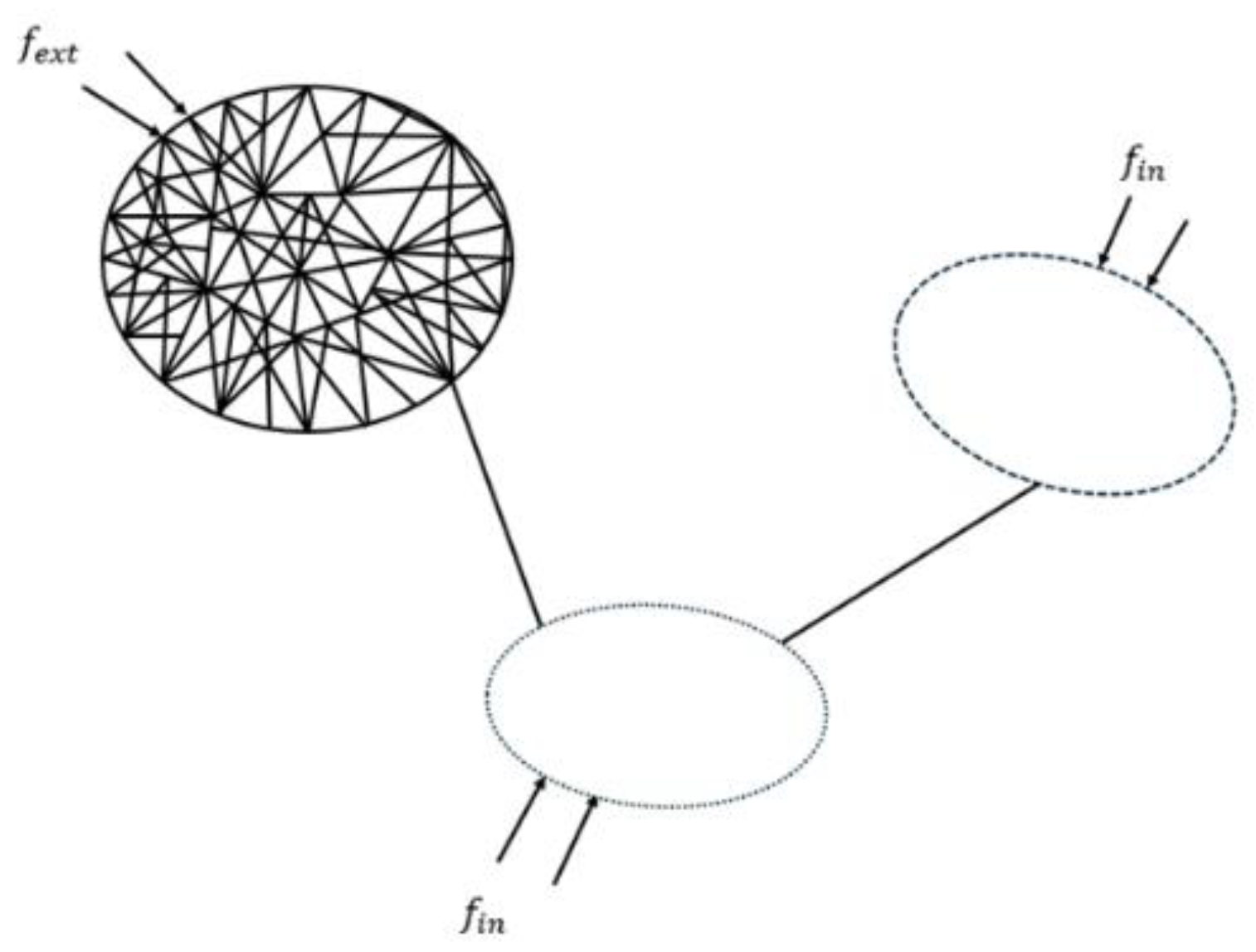

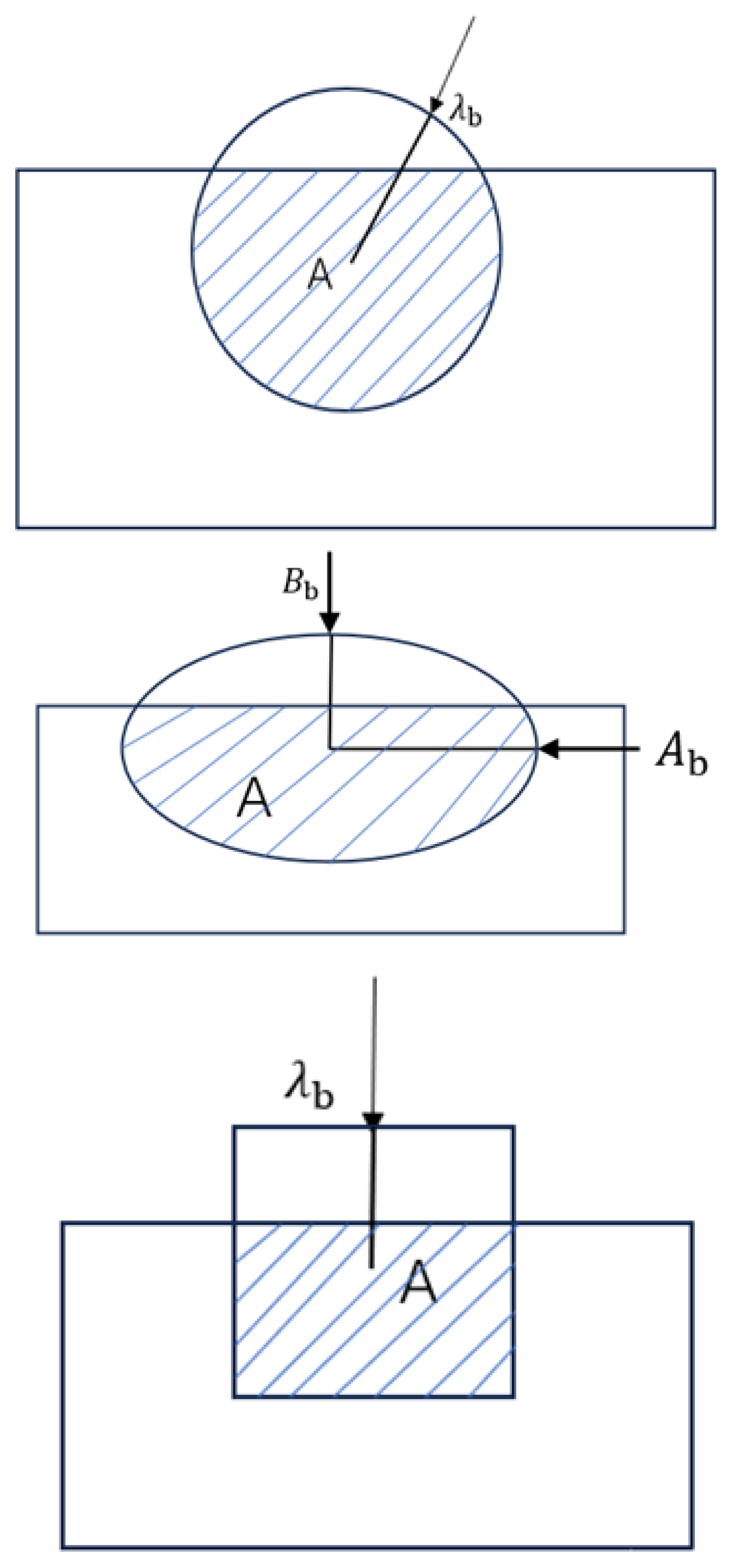

2.1. Basic Theory of the Hybrid FE-SEA Method

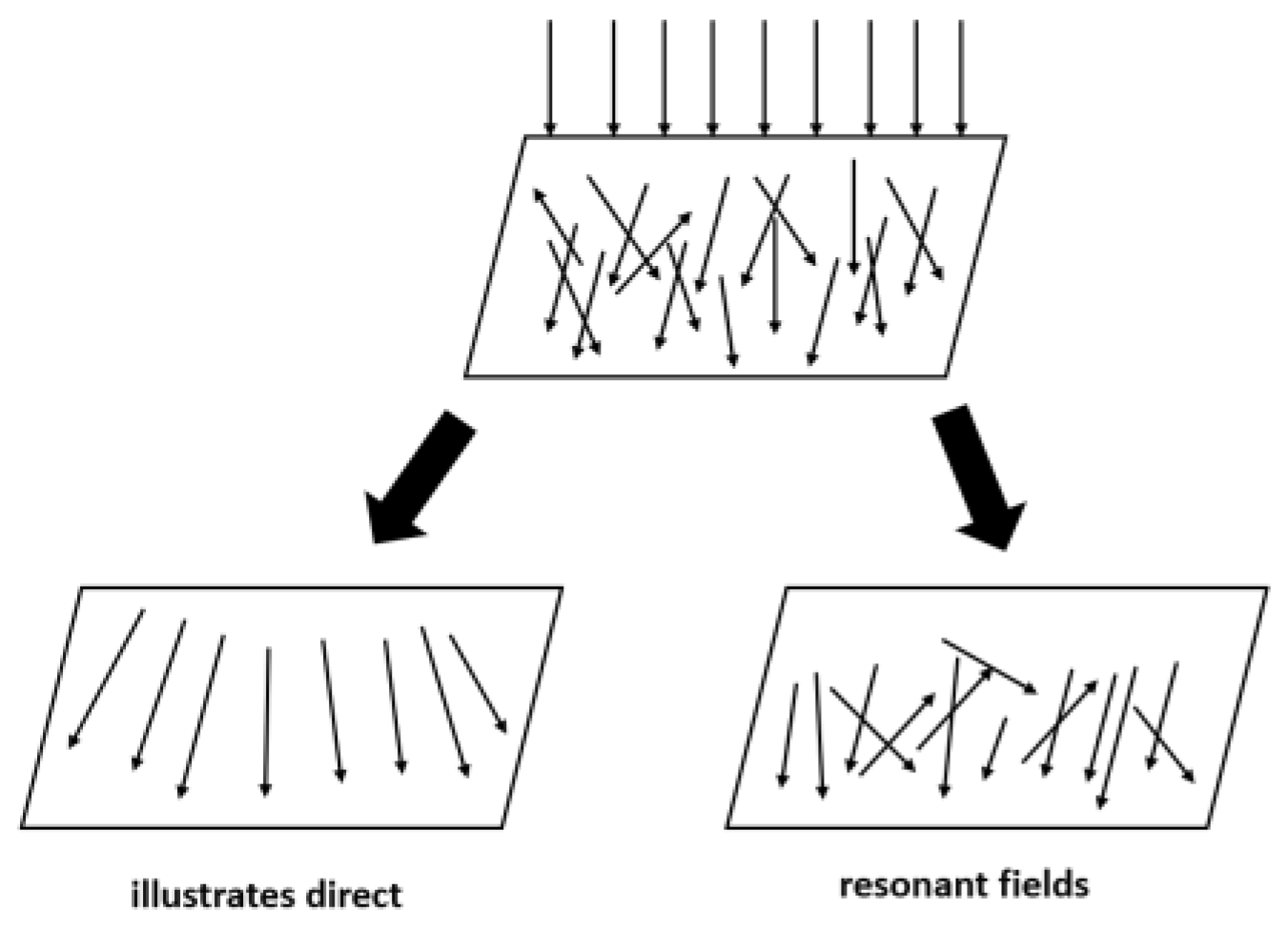

2.2. Mutual Exchange Principle Based on Wave Theory

2.3. Coupled System Equations

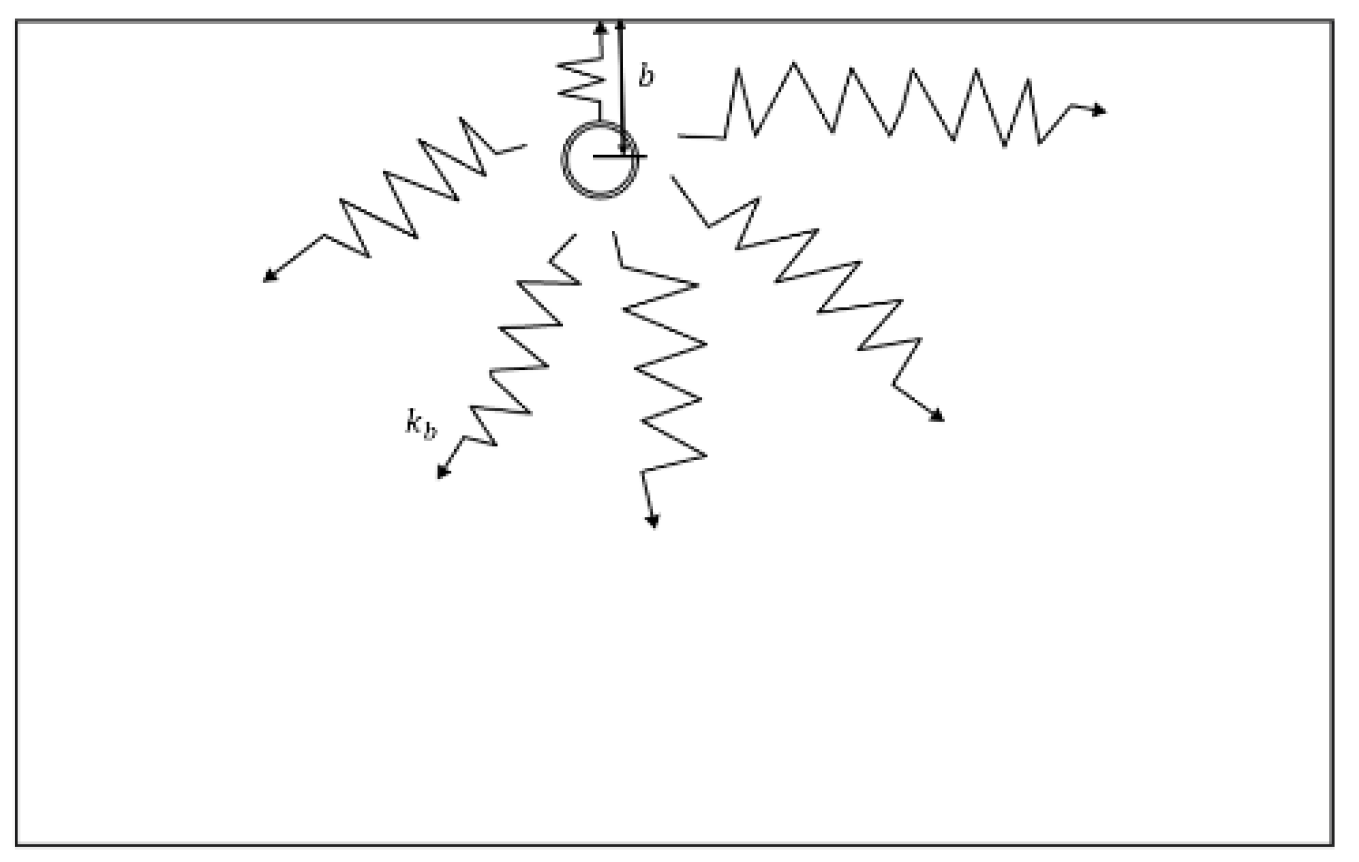

3. The Hybrid FE-SEA Point Connection Model

3.1. Finite Element Model for No-Boundary Plate Structure Hybrid Point Connection

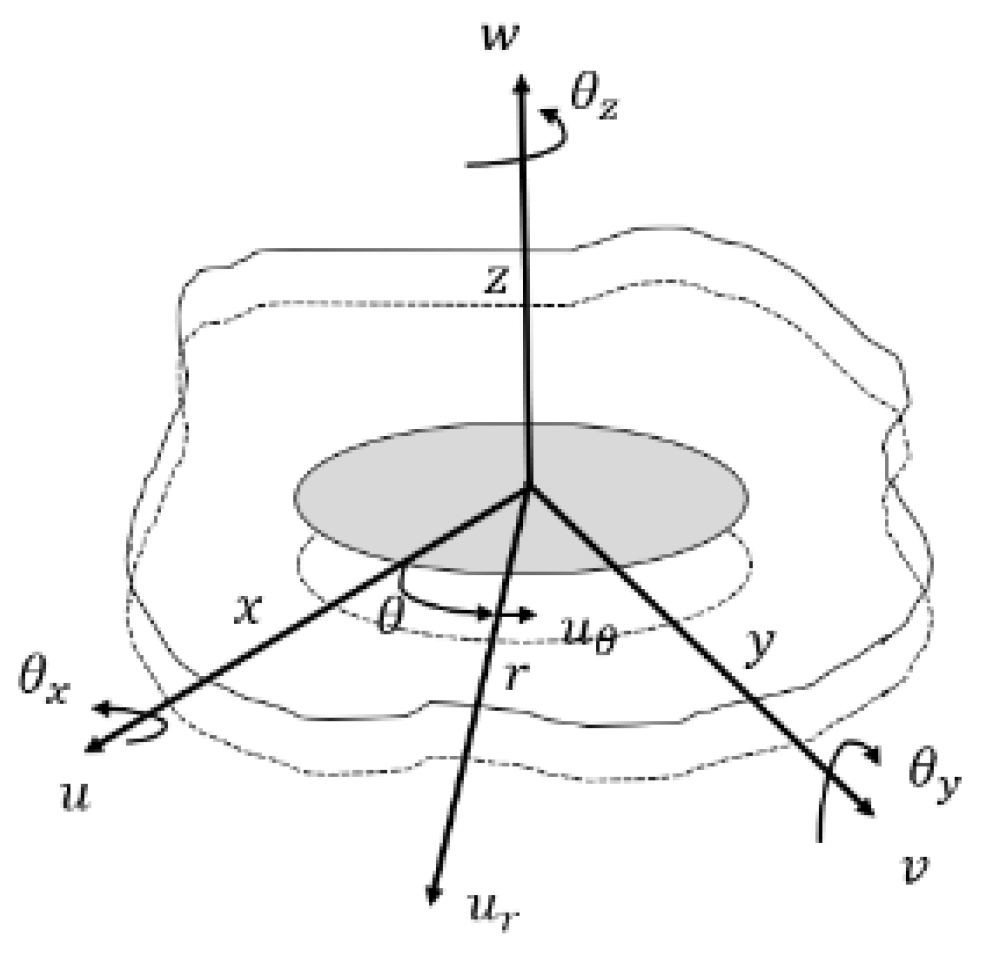

3.1.1. Equations of Motion for No-Boundary Plate Structure

3.1.2. The Relationship Between Displacement and Wave Number

3.1.3. Relationship Between Forces and Waves at Connections

3.1.4. Direct Field Dynamic Stiffness Matrix of Mixed Point Connection

4. Point Connection Correction Factor

4.1. Conventional Point Connection Correction Methods

4.2. Wave-Based Correction Factor Model

4.3. Circular Optimization Determination

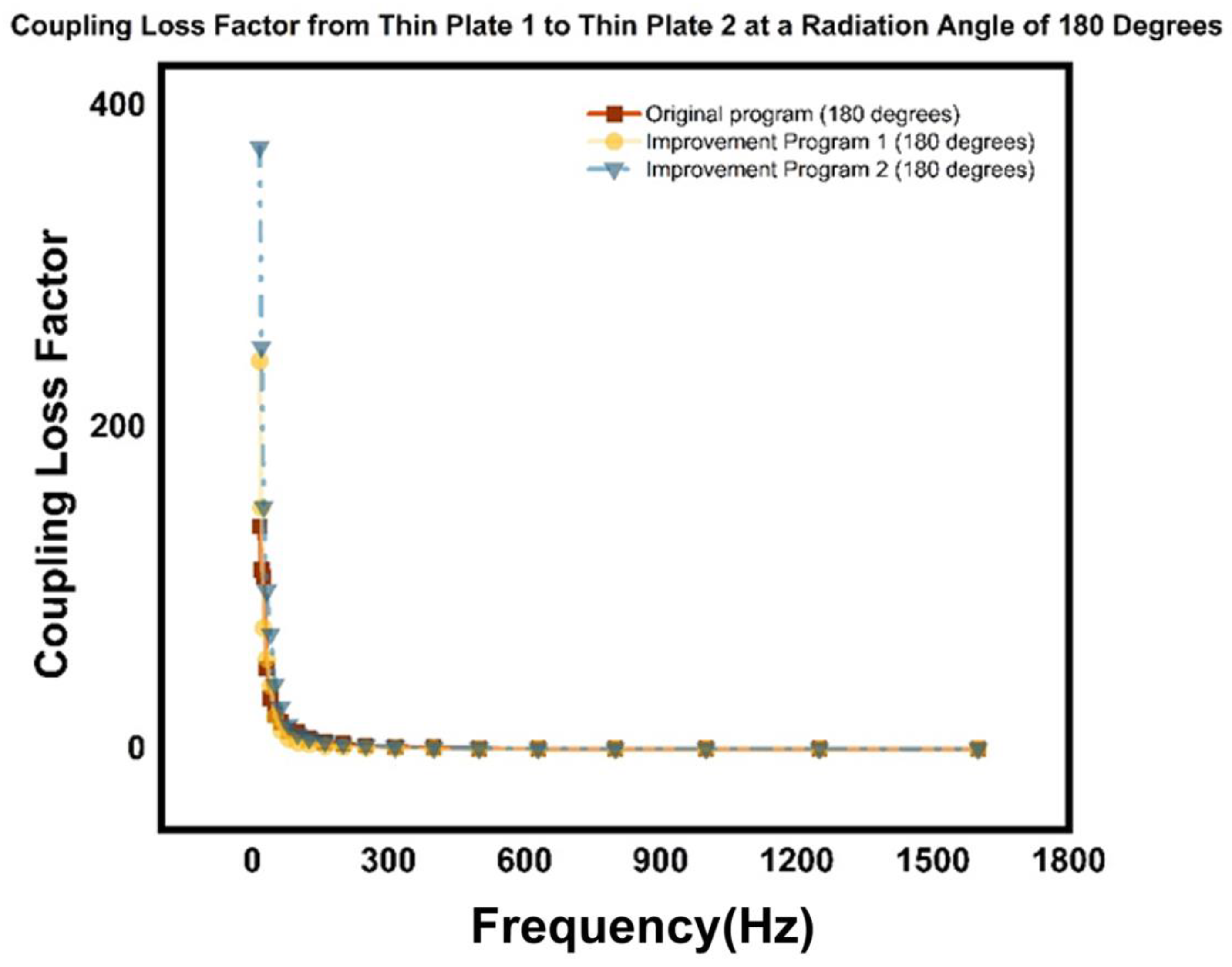

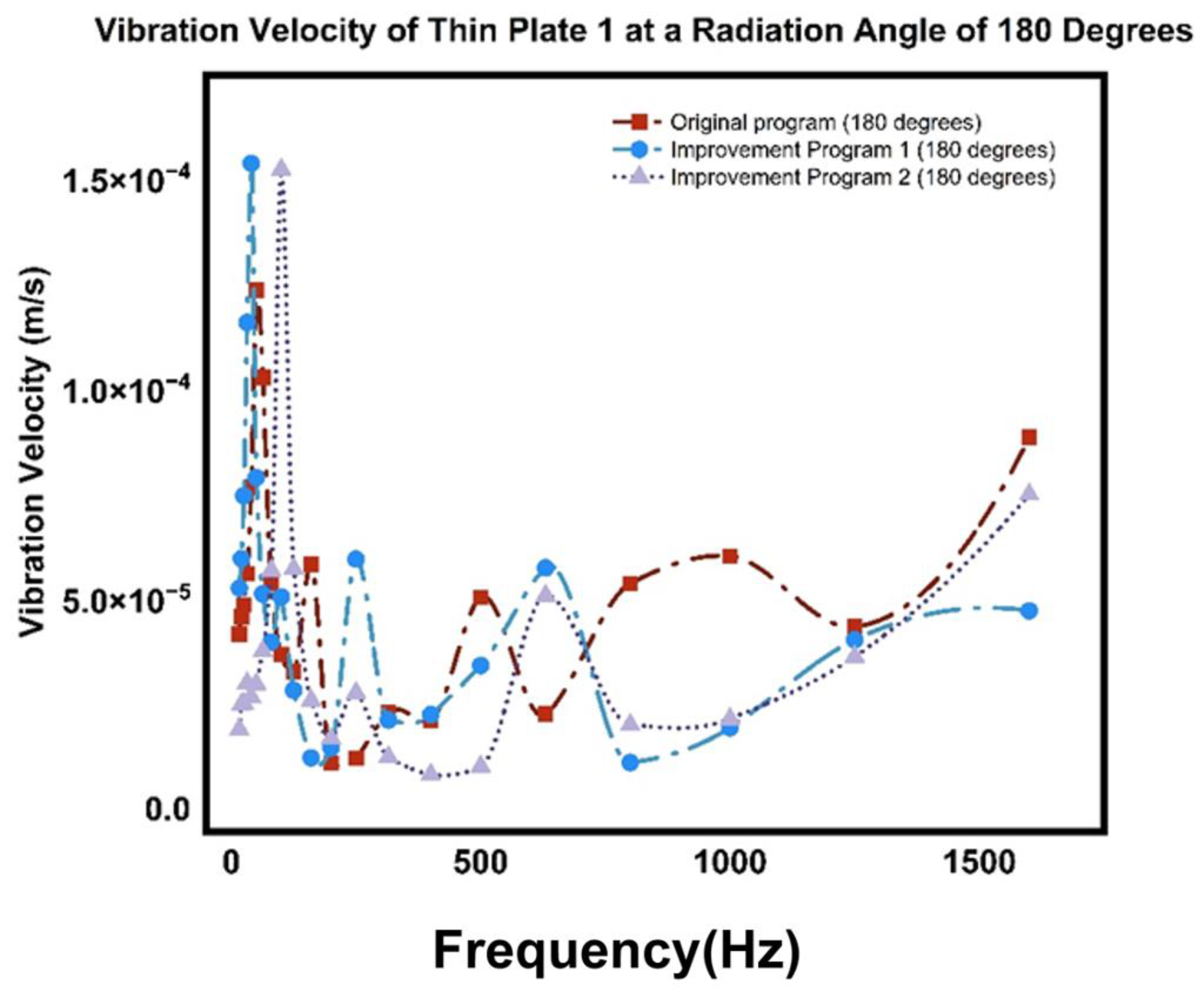

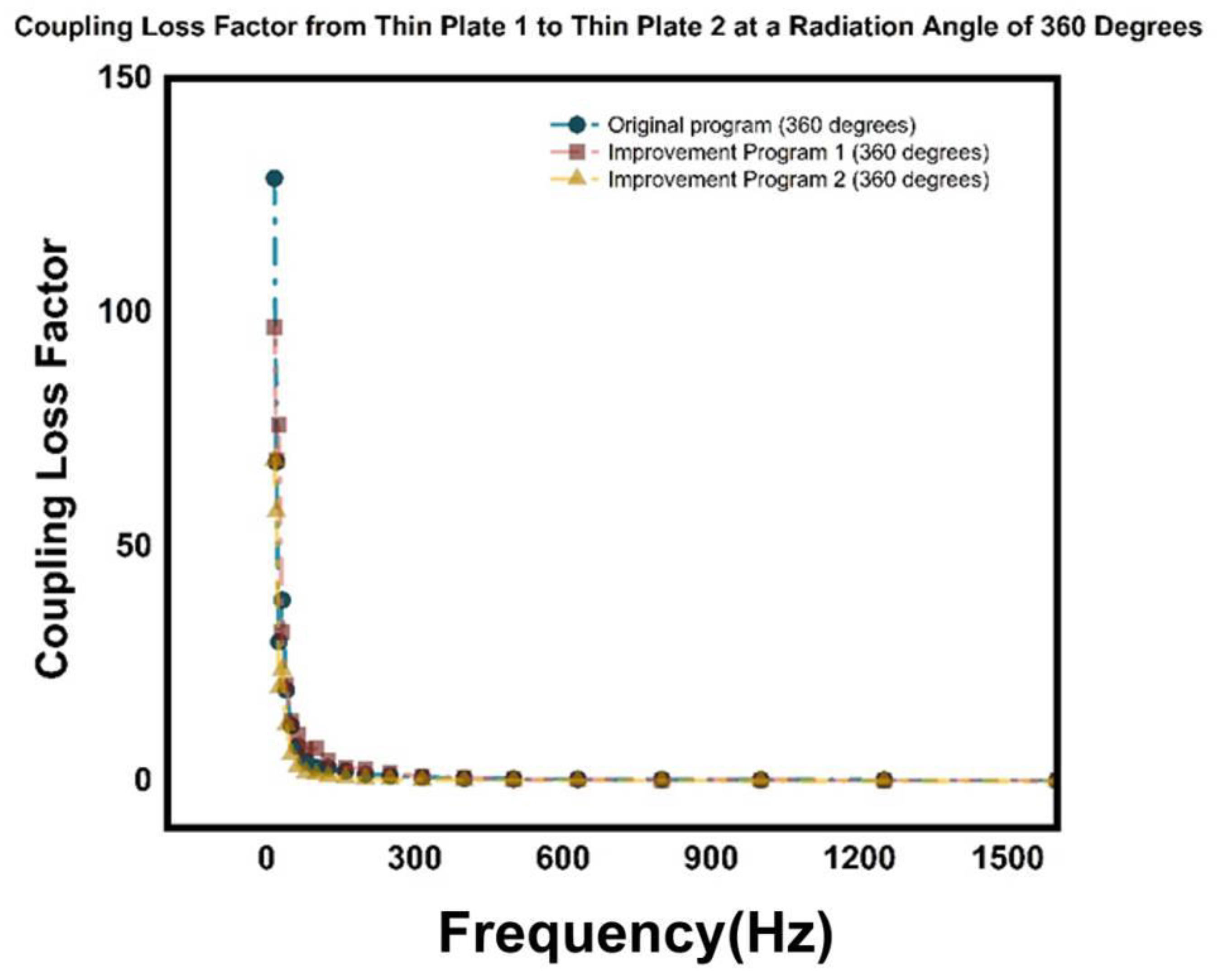

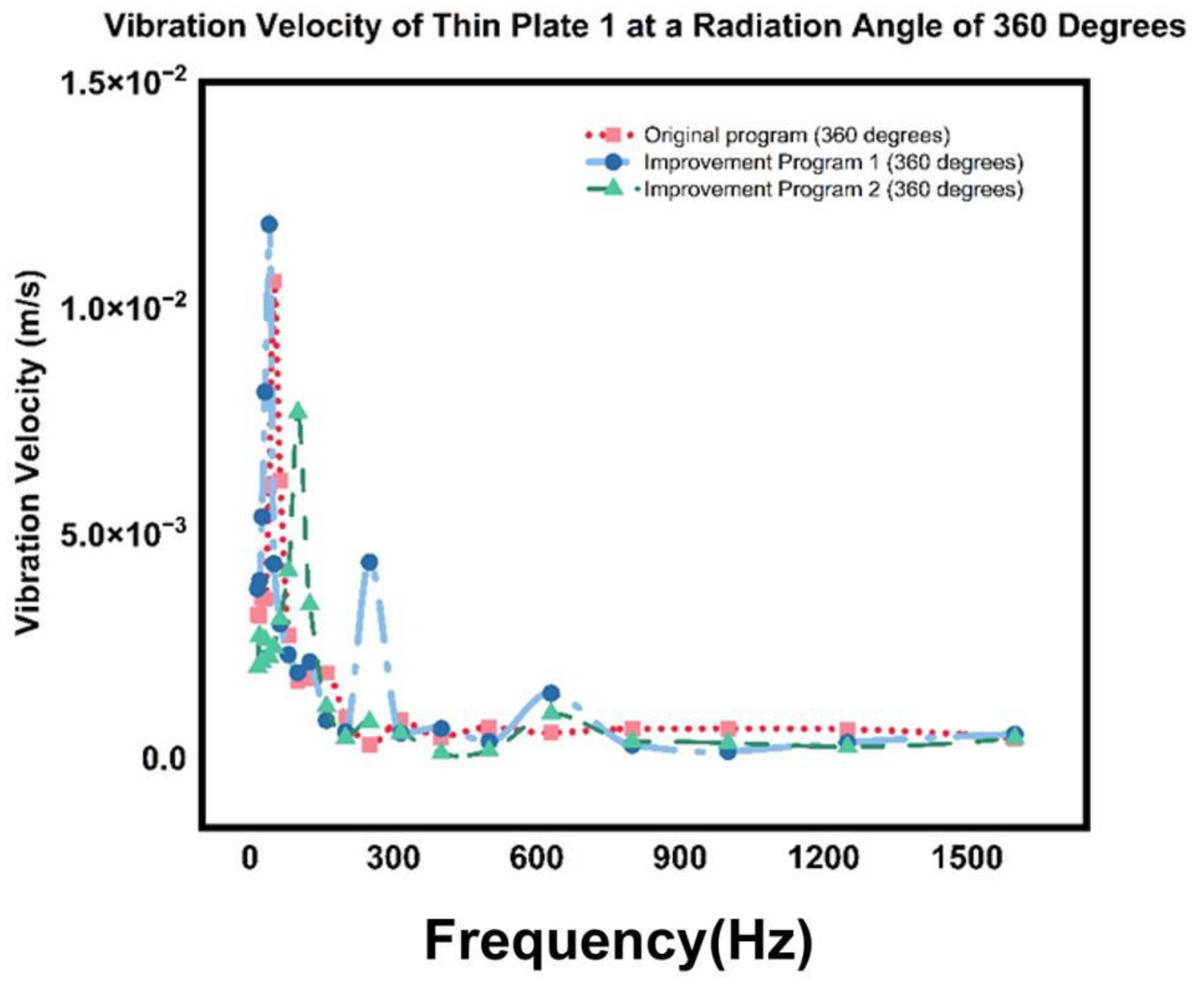

5. Mixed Point Connection Correction

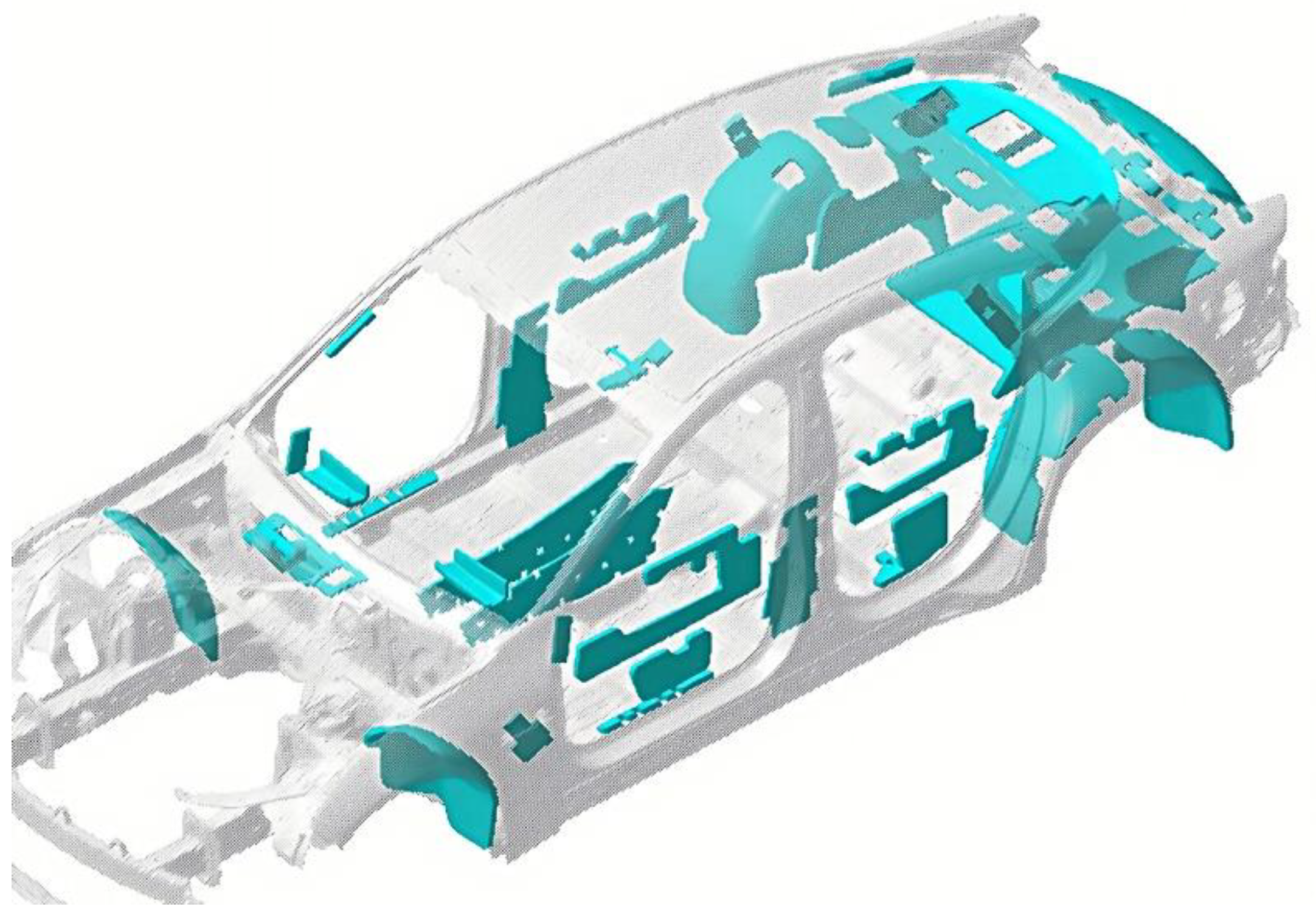

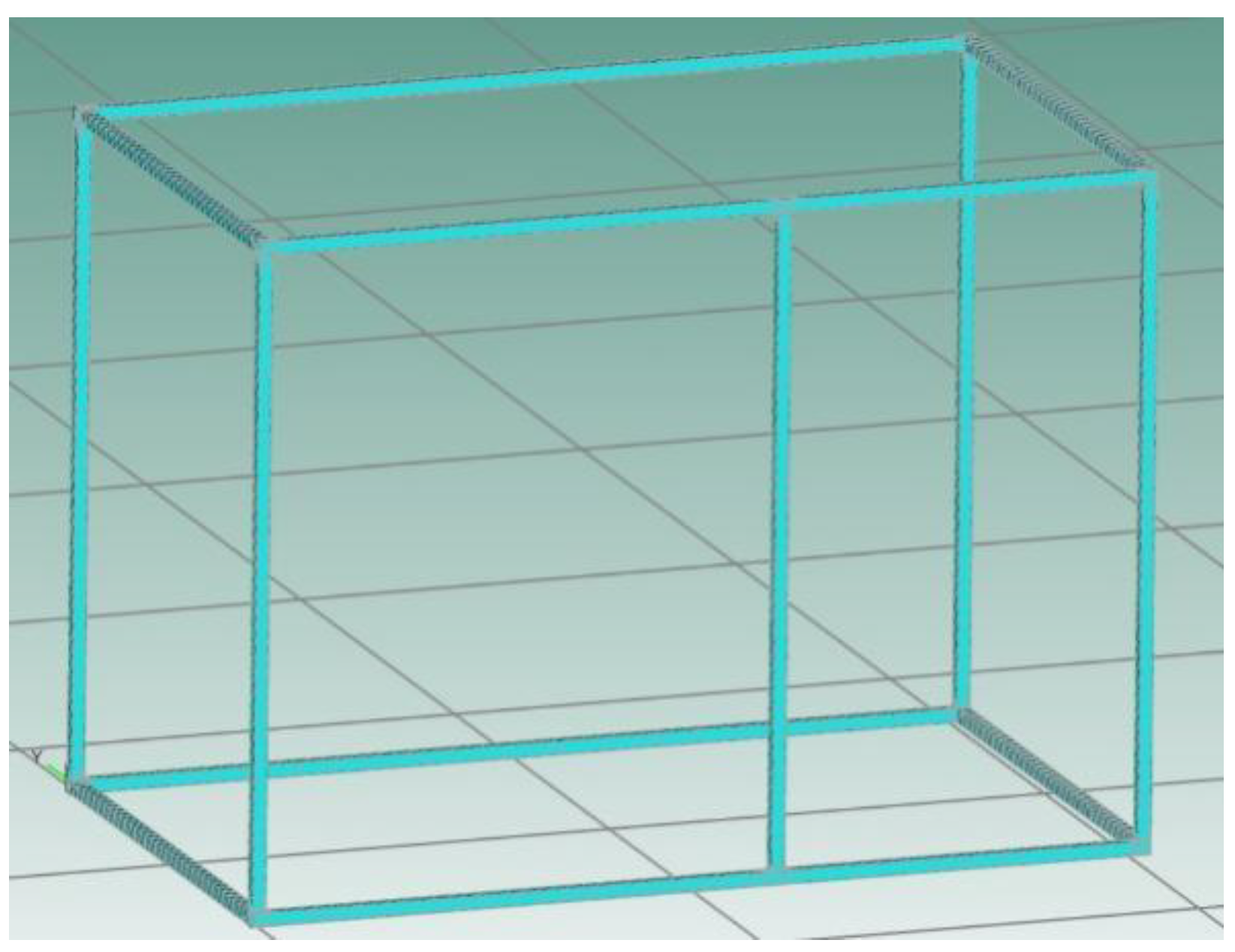

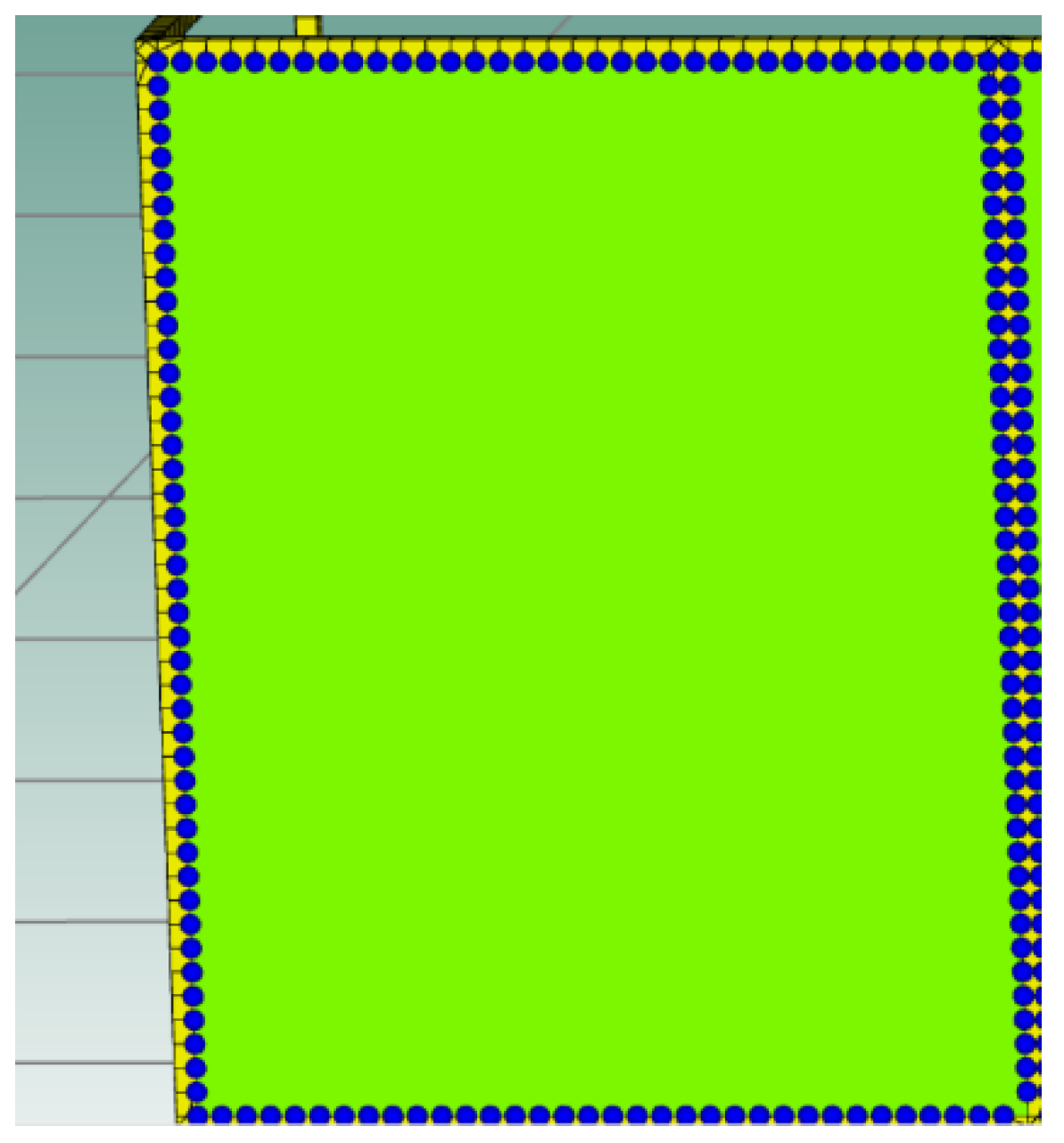

5.1. Construction of the Mixed Point Model

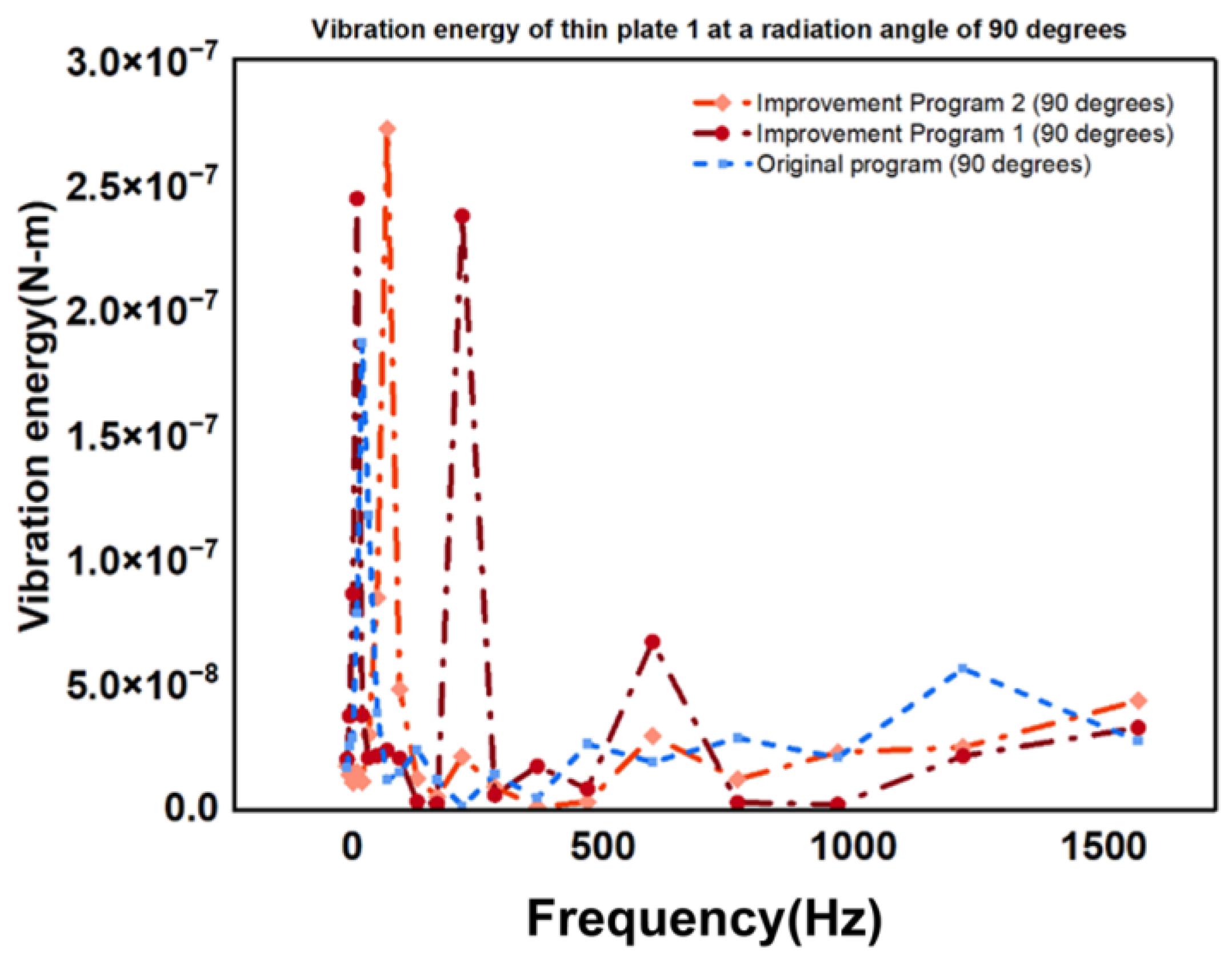

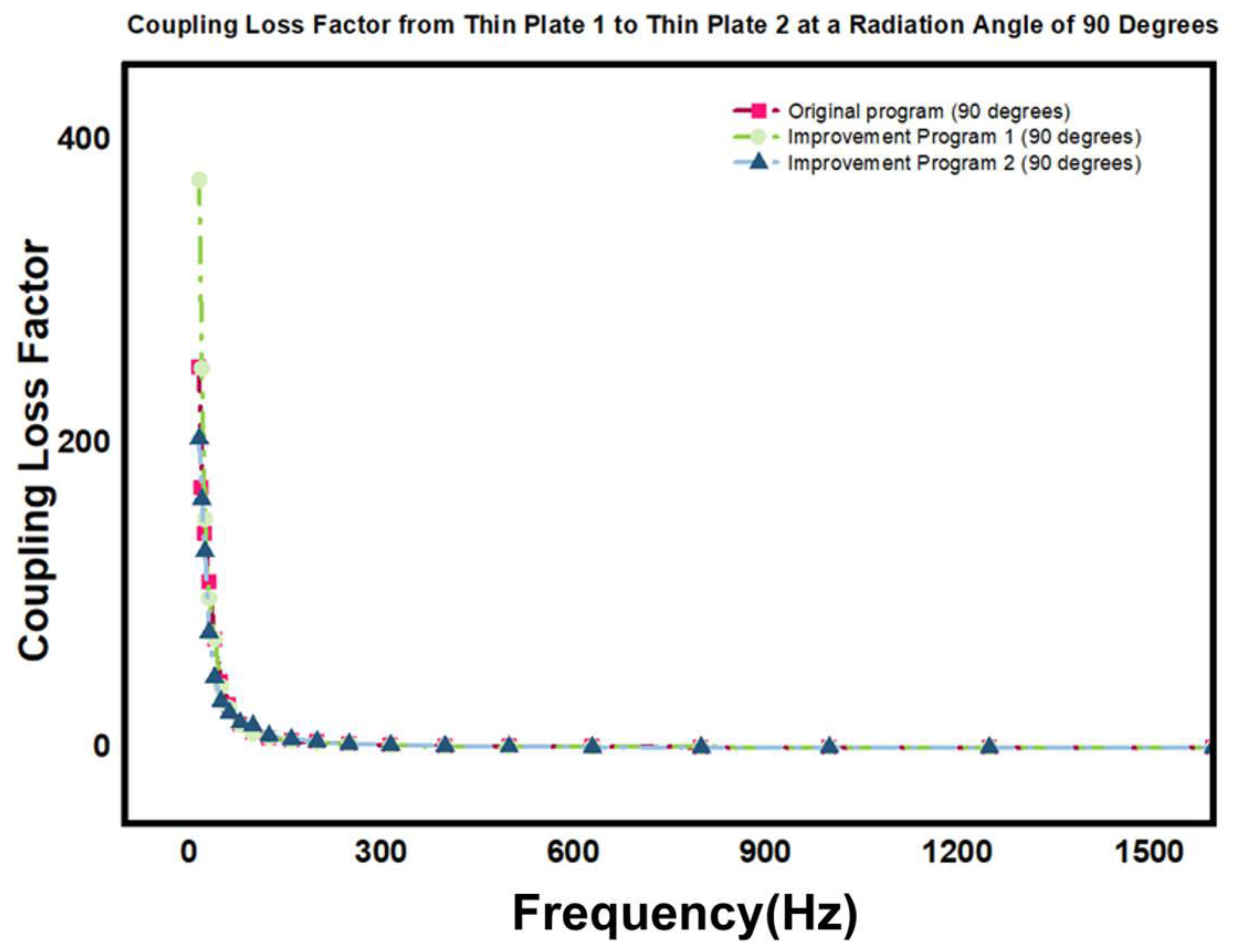

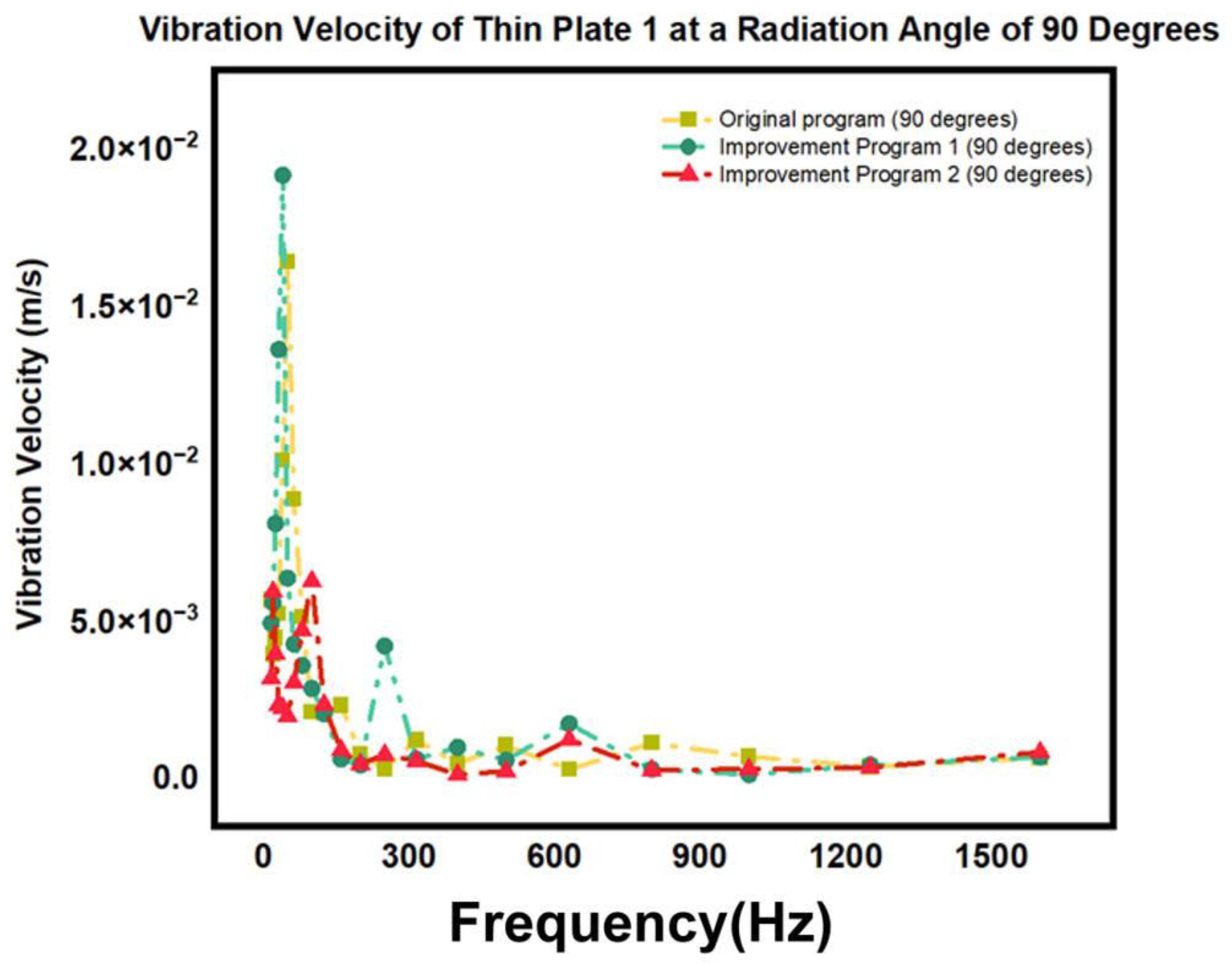

5.2. Simulation Analysis of the Model Under a 90-Degree Radiation Angle

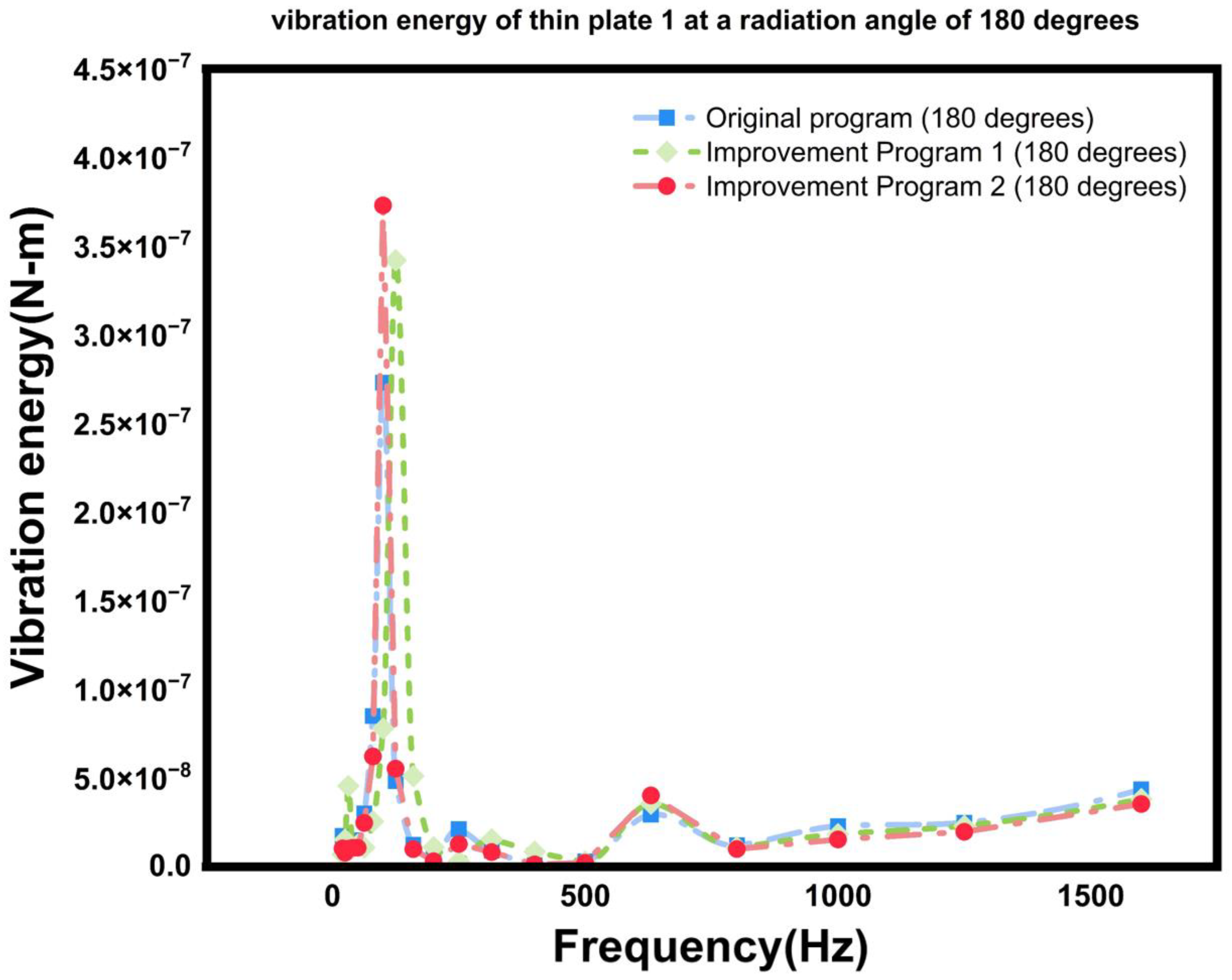

5.3. Simulation Analysis of the Model at a Radiation Angle of 360 Degrees

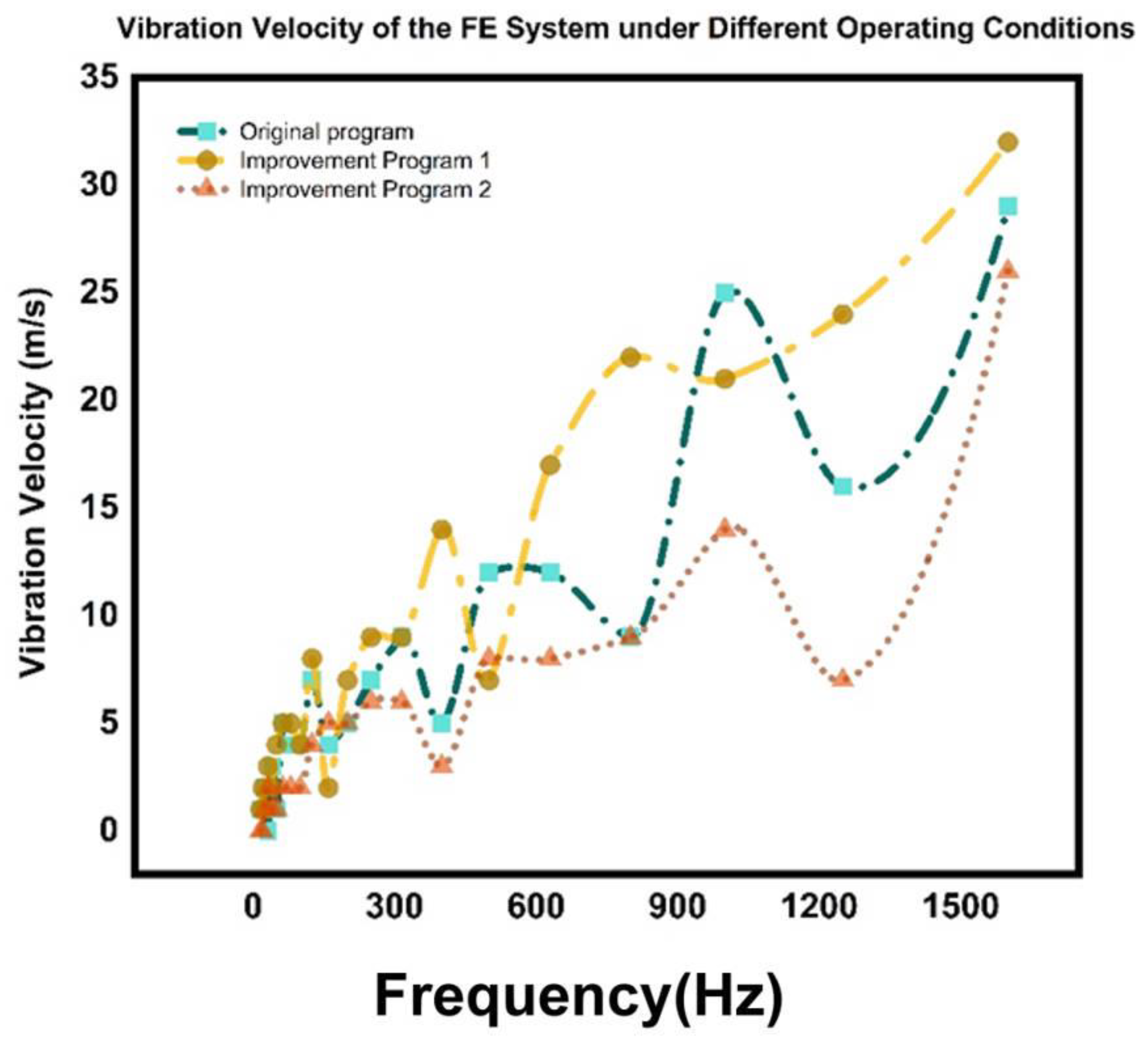

5.4. Analysis of Different Working Conditions Under the FE Subsystem

6. Conclusions and Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, W.; Ma, X.; Han, Z.; Zou, Y. Research on the Correction Factor of Hybrid FE-SEA Point Connections. J. Comput. Mech. 2015, 32, 225–231. [Google Scholar] [CrossRef]

- Su, J.; Zheng, L.; Nie, J. Research on Modeling Joining and Joining Modification Method of Hybrid FE-SEA Model. Sci. Rep. 2023, 13, 15853. [Google Scholar] [CrossRef] [PubMed]

- Luo, W.; Cao, H.; Zhang, Z.; Jiang, X.; Tang, K. Analysis of Train Intersection Noise on Bridges Based on the Hybrid FE-SEA Method. J. East China Jiaotong Univ. 2021, 38, 1–7. [Google Scholar]

- Chen, S.; Wang, D.; Song, X.; Chen, J.; Zan, J. Prediction of Internal Noise in Acoustic Cavities Based on the Hybrid FE-SEA Method. Vib. Shock. 2010, 29, 236–238. [Google Scholar]

- He, Y.; Jin, X.; Qin, X. FE-SEA Hybrid Modeling and Analysis Method for In-Car Mid-Frequency Noise. Automot. Technol. 2012, 10, 11–14. [Google Scholar]

- Charpentier, A.; Sreedhar, P.; Gardner, B.; Fukui, K. Use of a Hybrid FE-SEA Model of a Trimmed Vehicle to Improve the Design for Interior Noise; SAE: Warrendale, PA, USA, 2009. [Google Scholar]

- Wang, Y.; Zhang, J.; Yu, W.; Li, Q.; Liu, Y. Analysis of Automotive Wind Noise Propagation Characteristics Based on Statistical Energy Method. J. Tongji Univ. (Nat. Sci. Ed.) 2018, 46, 1696–1704. [Google Scholar]

- Binxing, W.; Xiaomin, L.; Sifa, Z.; Ren, Y.; Liu, Y. Prediction of In-Car Sound Pressure Levels in Heavy Trucks. Automot. Eng. 2016, 38, 234–241. [Google Scholar] [CrossRef]

- Che, Y.; Liu, H.; Guo, S.; Wang, Q. Prediction of In-Car Noise in Pure Electric Vehicles Based on SEA Model. J. Wuhan Univ. Tech. Inf. Manag. Eng. 2013, 35, 627–630. [Google Scholar]

- Deyuan, Y.; Qizheng, W. Principles and Applications of Statistical Energy Analysis; Beijing Institute of Technology Press: Beijing, China, 1995. [Google Scholar]

- Zhang, Y.; Wang, K.; Sheng, X.; Ou, J.; Meng, T. Analysis of Mid-Frequency Noise in a Special Vehicle Using Hybrid FE-SEA Method. Mech. Sci. Technol. 2018, 37, 1698–1704. [Google Scholar] [CrossRef]

- Langley, R.S.; Bremner, P. Hybrid FE-SEA Modeling for Mid-Frequency Vibroacoustic Analysis. J. Sound Vib. 2021, 512, 116256. [Google Scholar]

- Ma, X.; Zhu, W.; Han, Z. Wave-Based Correction for Hybrid FE-SEA Point Connections. Mech. Syst. Signal Process. 2022, 172, 108932. [Google Scholar]

- Zhang, Y.; Wang, K.; Sheng, C. NVH Optimization in Electric Vehicles Using Hybrid FE-SEA. Appl. Acoust. 2023, 205, 109023. [Google Scholar]

- Shorter, P.J.; Langley, R.S. Vibro-Acoustic Analysis of Complex Systems. J. Sound Vib. 2005, 288, 669–699. [Google Scholar] [CrossRef]

- Shorter, P.J.; Langley, R.S. A Hybrid FE-SEA Method for the Analysis of Complex Vibroacoustic Systems. J. Acoust. Soc. Am. 2005, 105, 1657–1671. [Google Scholar]

- Mace, B.R.; Shorter, P.J. Energy Flow Models from Finite Element Analysis. J. Sound Vib. 2000, 233, 369–389. [Google Scholar] [CrossRef]

| Name | Poisson’s Ratio | Elastic Modulus (GPa) | Damping Loss Factor | Structural Thickness (mm) | |

|---|---|---|---|---|---|

| Steel Beam | 7800 | 0.30 | 200 | 0.01 | 2 |

| Aluminum Plate | 2700 | 0.33 | 70 | 0.01 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wu, T.; Su, J. Criterion Circle-Optimized Hybrid Finite Element–Statistical Energy Analysis Modeling with Point Connection Updating for Acoustic Package Design in Electric Vehicles. World Electr. Veh. J. 2025, 16, 563. https://doi.org/10.3390/wevj16100563

Li J, Wu T, Su J. Criterion Circle-Optimized Hybrid Finite Element–Statistical Energy Analysis Modeling with Point Connection Updating for Acoustic Package Design in Electric Vehicles. World Electric Vehicle Journal. 2025; 16(10):563. https://doi.org/10.3390/wevj16100563

Chicago/Turabian StyleLi, Jiahui, Ti Wu, and Jintao Su. 2025. "Criterion Circle-Optimized Hybrid Finite Element–Statistical Energy Analysis Modeling with Point Connection Updating for Acoustic Package Design in Electric Vehicles" World Electric Vehicle Journal 16, no. 10: 563. https://doi.org/10.3390/wevj16100563

APA StyleLi, J., Wu, T., & Su, J. (2025). Criterion Circle-Optimized Hybrid Finite Element–Statistical Energy Analysis Modeling with Point Connection Updating for Acoustic Package Design in Electric Vehicles. World Electric Vehicle Journal, 16(10), 563. https://doi.org/10.3390/wevj16100563