Due to their high energy density, lithium-ion batteries find extensive applications in electric vehicles (EVs), electric boats, aerospace, and various other industries. Environmental friendliness, low self-discharge rate, and other advantageous properties are exhibited by lithium-ion batteries [

1]. During daily use, the alternating current from the grid is converted to direct current by the inverter to charge the lithium-ion battery [

2]. The continuous cycling of battery charging and discharging leads to structural changes within the battery, affecting the external environment and resulting in capacity degradation and increased internal resistance [

3]. Ultimately, these phenomena result in performance degradation and affect the safety and reliability of battery operation. Therefore, it is necessary to accurately monitor the health status of lithium batteries.

There are two main methods for the health state estimation of lithium-ion batteries: model-based methods and data-driven methods. Model-based methods mainly involve constructing circuit, chemical, or mathematical models that can simulate battery aging status according to the internal or external characteristics of the battery. Model-based methods can be roughly divided into equivalent circuit models, electrochemical models, and empirical models. Equivalent circuit models simulate battery dynamic changes through combinations of electronic components. They have simple equivalent circuit structures and good parameter identification accuracy, and thus have been widely used in the field of battery health state estimation. Reference [

4] uses the recursive least squares method to identify model parameters, estimates battery state through an unscented Kalman filter, and further estimates battery SOH. Reference [

5] proposes a second-order equivalent circuit model that characterizes battery constant-current charging through inductance. The model’s fidelity is improved through parallel inductance, and parameter identification is performed using the non-linear least squares method. The main feature of electrochemical models is their ability to describe the internal chemical reaction characteristics of the battery, which can more accurately describe the battery’s aging mechanism and thus achieve SOH estimation. Reference [

6] simplifies the two-dimensional electrochemical model of lithium-ion batteries, uses genetic algorithms to extract five characteristic parameters to characterize the battery’s aging trend, establishes a degradation model for lithium-ion batteries, and verifies its accuracy. Reference [

7] establishes an electrochemical model for the battery, and experimentally demonstrates that the model can obtain high-precision estimation results. Although electrochemical models can obtain high-precision estimation results, the complex equations they contain make calculations extremely complicated and require high hardware data-processing capabilities. Empirical models generally involve establishing capacity decay models and fitting battery aging trends with empirical formulas. Empirical degradation models can model the entire life cycle of the battery, and the parameters are easy to identify, with small calculation amounts, making them suitable for online applications. Reference [

8] conducts a cycle testing of batteries under different operating conditions and discharge depths, and establishes an empirical model for battery capacity decay through a large amount of empirical data, estimating the SOH of experimental batteries. However, the adaptability of empirical-degradation-model-based methods is poor. Since prior knowledge cannot consider all possible aging trends, when there is deviation in the aging trend, the estimation result will have a significant bias.

Model-based methods mainly simulate the external characteristics of batteries by constructing models, but they have poor adaptability. With the development of computer technology, data-driven SOH methods have gained more and more attention. By utilizing techniques such as machine learning and deep learning, this method estimates the SOH of lithium-ion batteries by establishing the relationship between the health features of batteries and capacity degradation [

9,

10]. This method does not require studying the working mechanism of the battery, but instead utilizes a large amount of data from the cycling process of lithium batteries for training. As a rule, the precision of estimation results obtained typically increases as the number of training samples increases [

11]. This method’s primary research content can be categorized into two parts: health features and the estimation method for mapping the features to capacity.

1.1. Health Features

Although the battery’s voltage, current, and temperature can be monitored and measured in real time through sensors, its health status is not a directly measurable physical quantity. Therefore, in order to estimate the SOH of batteries, it is necessary to establish the mapping relationships between direct or indirect feature parameters related to SOH and these features are called battery health features. In practical applications, in order to achieve the SOH estimation of lithium-ion batteries, the selection of health features should be based on two principles. One approach is to select representative health features that characterize the aging status of the battery. Second, the selected health features should be easily obtained online and better facilitate the online application of battery SOH estimation in practical use. Generally, charging and discharging data of the battery are used to extract health features [

12,

13,

14]. The charging and discharging cycles of the battery will cause certain changes in the voltage, current, and temperature curves during the charging and discharging process. These changes have an inherent connection with battery capacity degradation and can reflect the degree of battery aging. Under experimental conditions, the charge and discharge conditions of the battery are relatively simple, making feature extraction easy. In practical applications, the discharge stage of the battery has complex and variable operating conditions, which makes feature extraction difficult. Therefore, in practical applications, health features are more easily extracted from the charging-stage data of the battery, which is beneficial for realizing the online estimation of battery SOH.

1.2. Developing Methods for Mapping between Features and Capacity Estimation

Data-driven algorithms can effectively mine potential feature information in the battery capacity degradation process and use intelligent algorithms, neural networks, and other offline training historical battery data to test and estimate the SOH of batteries online, thereby achieving an accurate estimation of the SOH of lithium-ion batteries. Data-driven methods include time-series methods [

15,

16,

17,

18], statistical data-driven methods [

19], and machine learning methods [

20,

21,

22,

23,

24,

25]. By learning a large amount of historical data and feature patterns, machine learning algorithms can accurately predict the state of battery health. Compared to traditional physics-based methods, machine learning methods are better able to capture small changes and non-linear relationships within the battery. Additionally, machine learning methods can adaptively adjust based on the actual usage of the battery, improving the accuracy of estimation results. This method can handle various types and brands of batteries, and adapt to various working conditions and environmental changes.

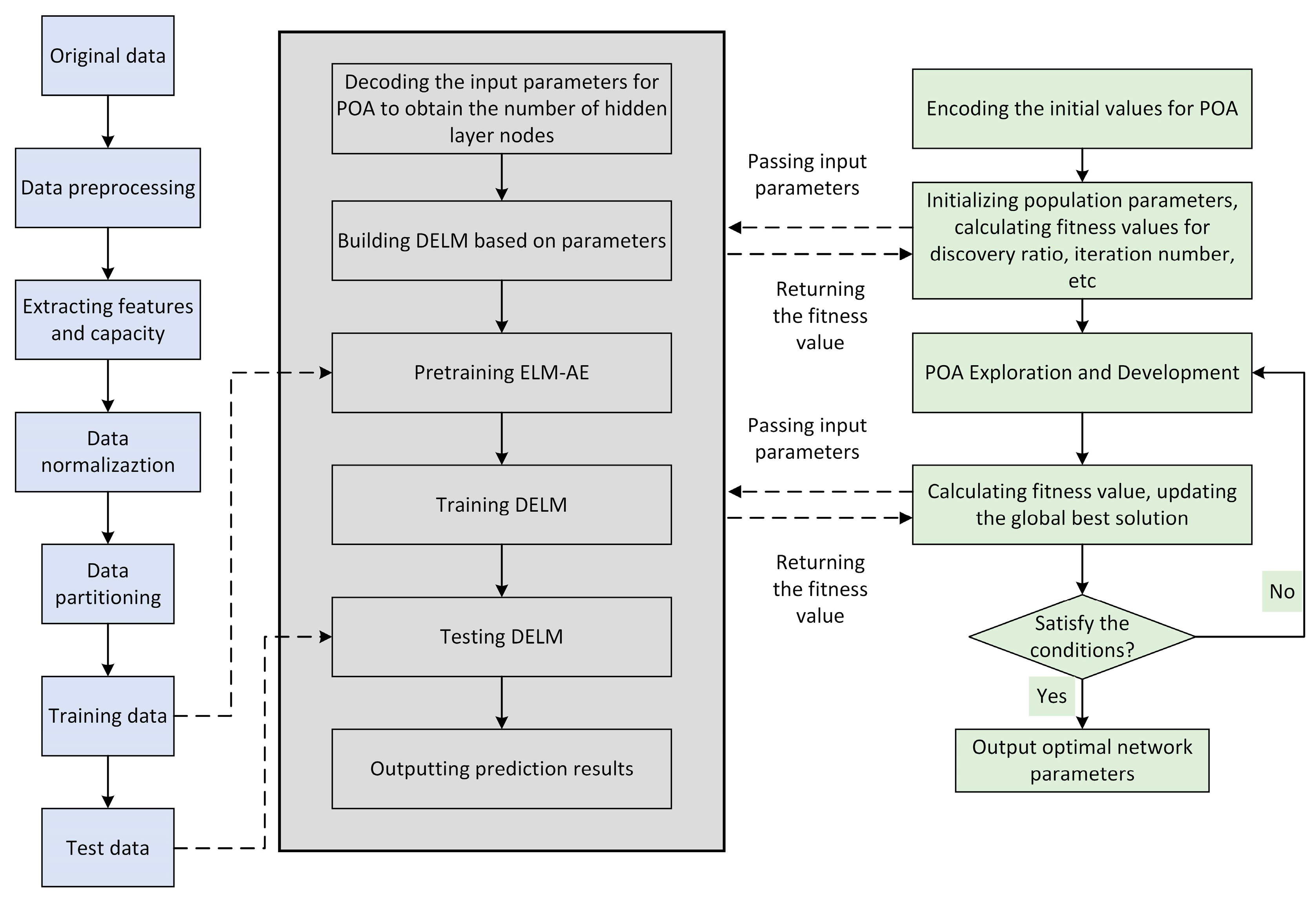

To address the issues of weak usability in health feature extraction, single feature dimensionality, and complex algorithm models in existing data-driven methods, this study proposes an innovative approach. This study first extracts three features from the charging data to indirectly characterize battery capacity degradation: IC peak value, time to reach peak temperature, and constant-current charging time. Considering the limitation of randomly given connection weights and thresholds between the input layer and hidden layer in the traditional DELM algorithm, the POA algorithm is introduced to optimize the model structure. Unlike other swarm intelligence optimization algorithms, POA searches for prey by randomly generating prey, enhancing its global search capability. The random generation of prey solves the problem of excessive reliance on mutation coefficients in other algorithms to escape local optima.

The structure of this paper is as follows:

Section 2 provides an overview of the process of establishing the POA-DELM model.

Section 3 focuses on the analysis and extraction of health features.

Section 4 presents the estimation results and discusses them. Finally,

Section 5 summarizes the main conclusions.