Investigation of Effective Factors on Vehicles Integrated Photovoltaic (VIPV) Performance: A Review

Abstract

:1. Introduction

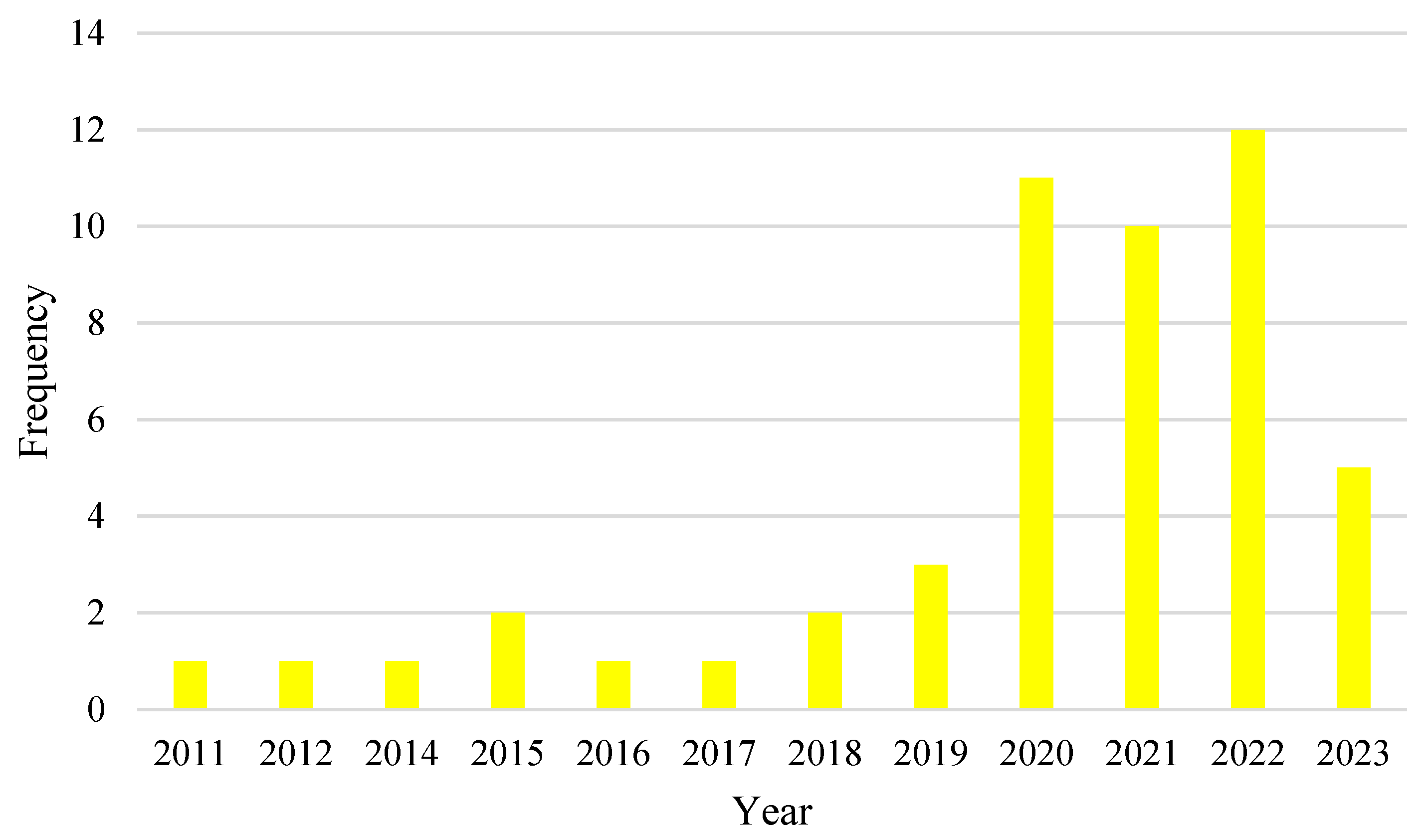

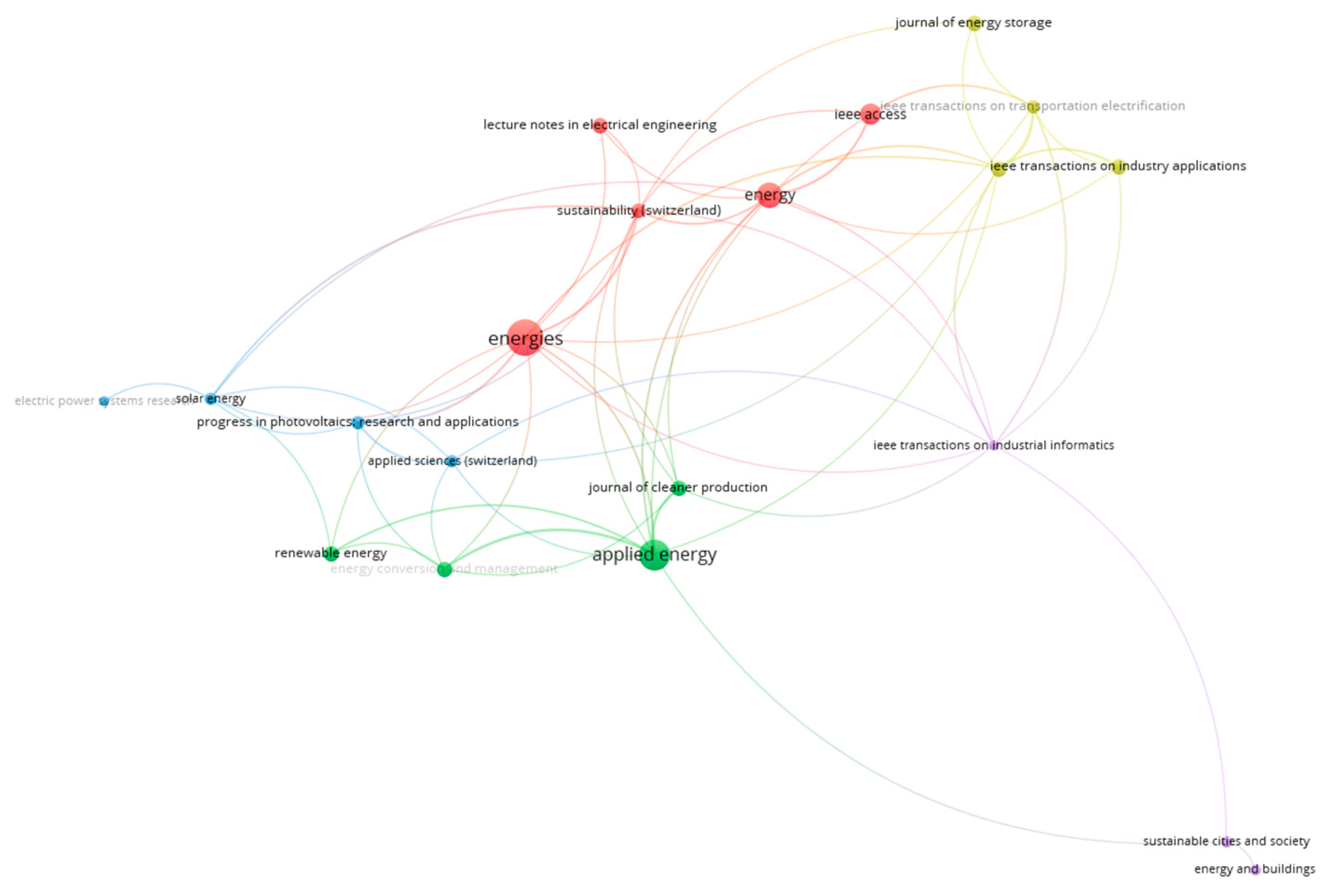

2. A Review of Vehicle-Integrated Photovoltaic

3. Effecting Parameters on Vehicles’ Integrated Photovoltaic Performance

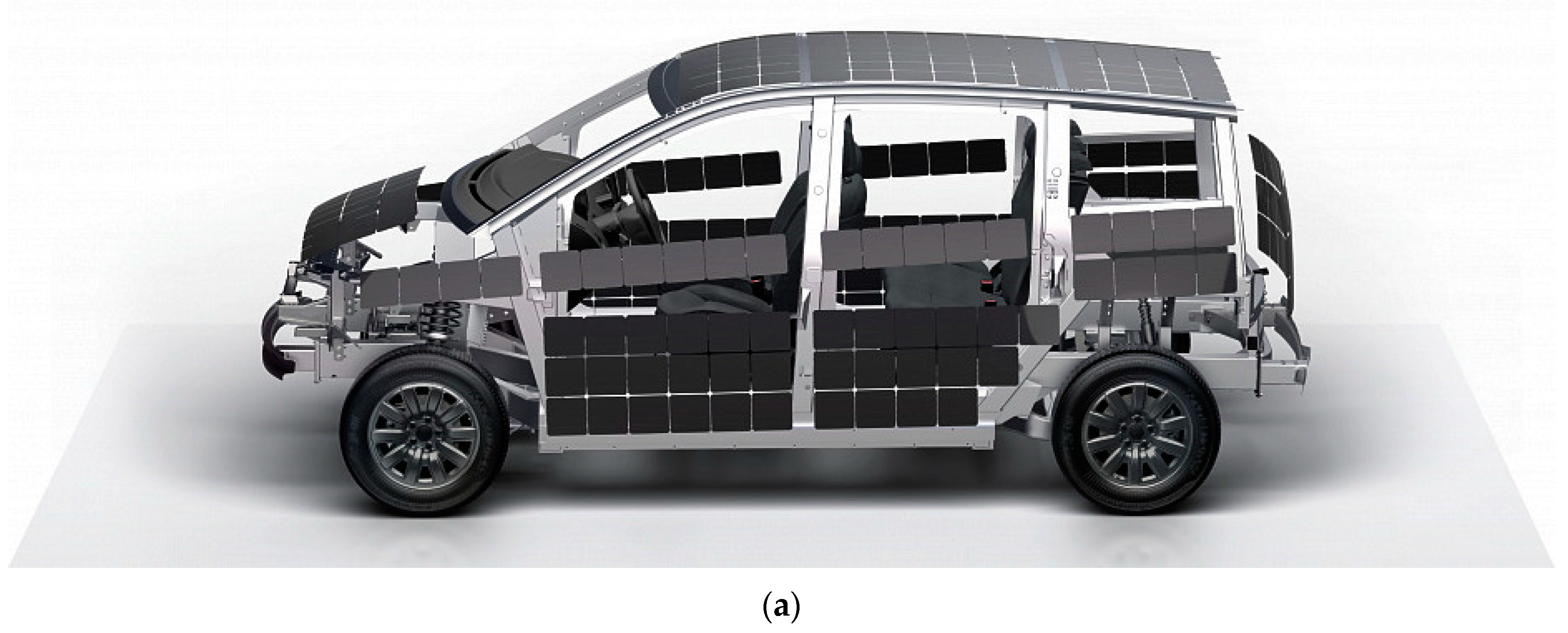

3.1. Installation Position of PV

3.2. PV Cell

3.2.1. Shape and Geometry Design

3.2.2. Type and Material

3.2.3. Interconnections and Electrical Devices

3.2.4. Temperature and Cooling Effect

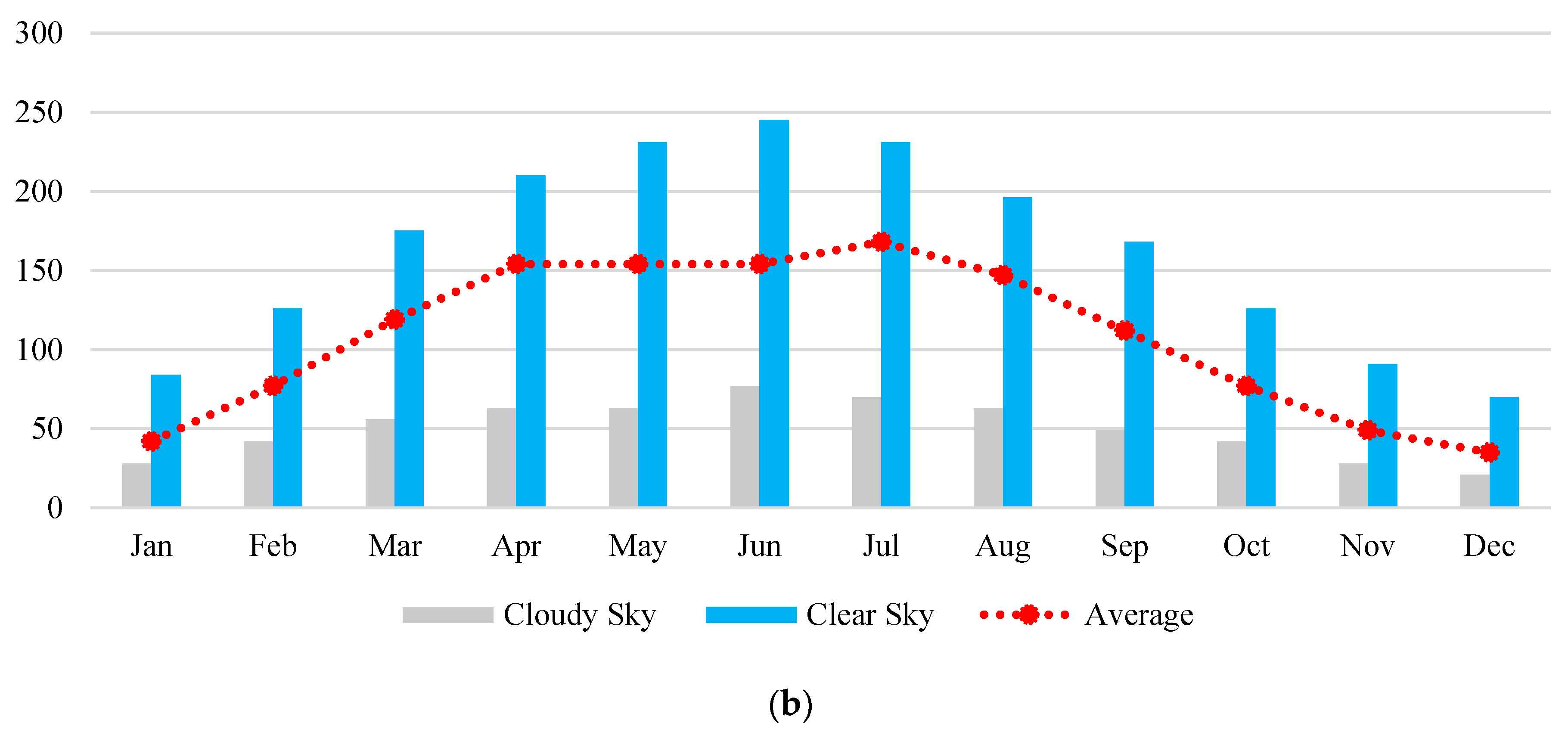

3.3. Environmental Conditions

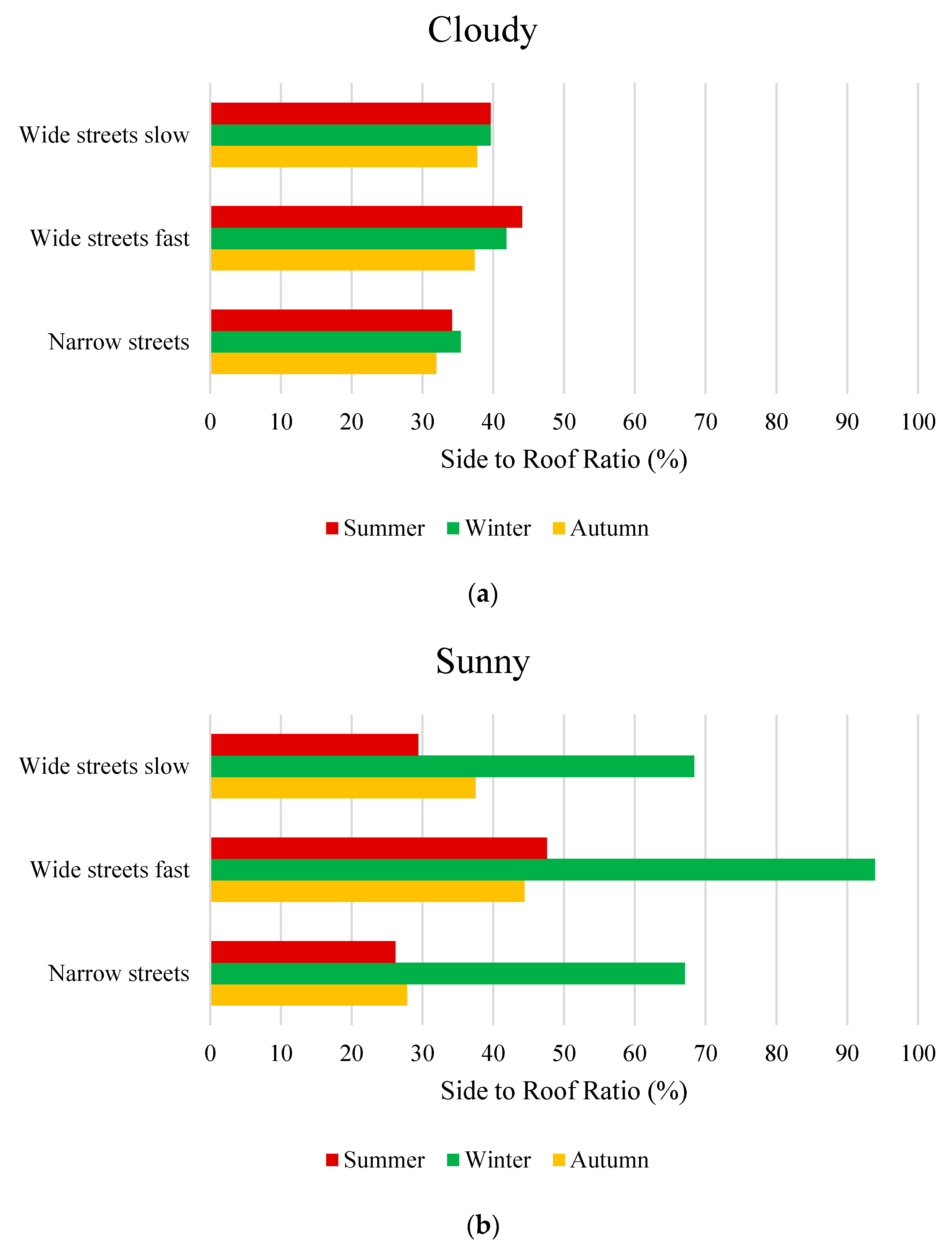

- Narrow streets with high building density with a speed limit of 30 km/h (the height of the building is greater than the distance between the vehicle and the building)

- Wide, slow-moving streets such as alleys and streets with more than one lane in each direction, with a speed limit of 50 km/h (the height of the building is greater than the distance between the vehicle and the building)

- Wide, fast streets with no adjacent buildings (but with several overpasses)

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yamaguchi, M.; Masuda, T.; Nakado, T.; Yamada, K.; Okumura, K.; Satou, A.; Ota, Y.; Araki, K.; Nishioka, K.; Kojima; et al. Analysis for Expansion of Driving Distance and CO2 Emission Reduction of Photovoltaic-Powered Vehicles. IEEE J. Photovolt. 2023, 13, 343–348. [Google Scholar] [CrossRef]

- Global Sales Statistics 2019–2021. 2021. Available online: https://www.oica.net/category/sales-statistics/ (accessed on 20 December 2022).

- CO2 Emissions from Transport Rebounded in 2021, Returning to Their Historical Growth Trend. 2021. Available online: https://www.iea.org/topics/transport (accessed on 22 December 2022).

- Ghosh, A. Possibilities and challenges for the inclusion of the electric vehicle (EV) to reduce the carbon footprint in the transport sector: A review. Energies 2020, 13, 2602. [Google Scholar] [CrossRef]

- Shrivastava, P.; Soon, T.; Mekhilef, S.; Ahmad, F. Economic and Environmental Analysis of a Solar-Powered EV Charging System in India—A Case Study. In Innovations in Electrical and Electronic Engineering: Proceedings of the ICEEE 2021, 17–19 December 2021, NCR New Delhi, India; Springer: Singapore, 2021; pp. 301–315. [Google Scholar]

- Yamaguchi, M.; Nakamura, K.; Ozaki, R.; Kojima, N.; Ohshita, Y.; Masuda, T.; Okumura, K.; Satou, A.; Nakado, T.; Yamada, K.; et al. Analysis for the Potential of High-Efficiency and Low-Cost Vehicle-Integrated Photovoltaics. Solar RRL 2022, 7, 2200556. [Google Scholar] [CrossRef]

- Kronthaler, L.; Maturi, L.; Moser, D.; Alberti, L. Vehicle-integrated Photovoltaic (VIPV) systems: Energy production, Diesel Equivalent, Payback Time; an assessment screening for trucks and busses. In Proceedings of the 2014 IEEE 9th International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 25–27 March 2014; IEEE: New York, NY, USA, 2014. [Google Scholar]

- Manivannan, S.; Kaleeswaran, E. Solar powered electric vehicle. In Proceedings of the 2016 First International Conference on Sustainable Green Buildings and Communities (SGBC), Chennai, India, 18–20 December 2016; IEEE: New York, NY, USA, 2016. [Google Scholar]

- Ekins-Daukes, N.; Kay, M.; Ciesla, A.; Jiang, J.Y.; Yang, Z.; Perez-Wurfel, I.; Hopkins, R.; Mcdonald, J. The Potential for Vehicle Integrated Photovoltaics. In Proceedings of the Asia Pacific Solar Research Conference 2020 (APSRC), Merced, CA, USA, 30 November–2 December 2020; RMIT: Melbourne, Australia, 2020. [Google Scholar]

- Patel, N.; Bittkau, K.; Pieters, B.; Sovetkin, E.; Ding, K.; Reinders, A. Impact of Additional PV Weight on the Energy Consumption of Electric Vehicles with Onboard PV; IEEE: New York, NY, USA, 2023. [Google Scholar]

- Ben Said-Romdhane, M. and S. Skander-Mustapha, A Review on Vehicle-Integrated Photovoltaic Panels. Adv. Technol. Sol. Photovolt. Energy Syst. 2021, 349–370. [Google Scholar]

- Commault, B.; Duigou, T.; Maneval, V.; Gaume, J.; Chabuel, F.; Voroshazi, E. Overview and perspectives for vehicle-integrated photovoltaics. Appl. Sci. 2021, 11, 11598. [Google Scholar] [CrossRef]

- Brito, M.C.; Santos, T.; Moura, F.; Pera, D.; Rocha, J. Urban solar potential for vehicle integrated photovoltaics. Transp. Res. Part D Transp. Environ. 2021, 94, 102810. [Google Scholar] [CrossRef]

- Khan, S.; Sudhakar, K.; Yusof, M.H.B.; Azmi, W.H.; Ali, H.M. Roof integrated photovoltaic for electric vehicle charging towards net zero residential buildings in Australia. Energy Sustain. Dev. 2023, 73, 340–354. [Google Scholar] [CrossRef]

- Markert, J.; Kutter, C.; Newman, B.; Gebhardt, P.; Heinrich, M. Proposal for a Safety Qualification Program for Vehicle-Integrated PV Modules. Sustainability 2021, 13, 13341. [Google Scholar] [CrossRef]

- Filho, A.V.M.; Vasconcelos, A.S.; Junior, W.D.A.; Dantas, N.K.; Arcanjo, A.M.C.; Souza, A.C.; Fernandes, A.L.; Zhang, K.; Wu, K.; Castro, J.F.; et al. Impact Analysis and Energy Quality of Photovoltaic, Electric Vehicle and BESS Lead-Carbon Recharge Station in Brazil. Energies 2023, 16, 2397. [Google Scholar] [CrossRef]

- Ye, B.; Jiang, J.; Miao, L.; Yang, P.; Li, J.; Shen, B. Feasibility study of a solar-powered electric vehicle charging station model. Energies 2015, 8, 13265–13283. [Google Scholar] [CrossRef] [Green Version]

- Goli, P.; Shireen, W. PV powered smart charging station for PHEVs. Renew. Energy 2014, 66, 280–287. [Google Scholar] [CrossRef]

- Minh, P.V.; Le Quang, S.; Pham, M.-H. Technical economic analysis of photovoltaic-powered electric vehicle charging stations under different solar irradiation conditions in Vietnam. Sustainability 2021, 13, 3528. [Google Scholar] [CrossRef]

- Sovetkin, E.; Noll, J.; Patel, N.; Gerber, A.; Pieters, B.E. Vehicle-Integrated Photovoltaics Irradiation Modeling Using Aerial-Based LIDAR Data and Validation with Trip Measurements. Solar RRL 2022, 2200593. [Google Scholar] [CrossRef]

- Enescu, F.M.; Birleanu, F.G.; Raboaca, M.S.; Raceanu, M.; Bizon, N.; Thounthong, P. Electric Vehicle Charging Station Based on Photovoltaic Energy with or without the Support of a Fuel Cell–Electrolyzer Unit. Energies 2023, 16, 762. [Google Scholar] [CrossRef]

- Esfandyari, A.; Norton, B.; Conlon, M.; McCormack, S.J. Performance of a campus photovoltaic electric vehicle charging station in a temperate climate. Solar Energy 2019, 177, 762–771. [Google Scholar] [CrossRef]

- Cheikh-Mohamad, S.; Sechilariu, M.; Locment, F.; Krim, Y. Pv-powered electric vehicle charging stations: Preliminary requirements and feasibility conditions. Appl. Sci. 2021, 11, 1770. [Google Scholar] [CrossRef]

- Karoui, F.; Claudon, F.; Chambion, B.; Catellani, S.; Commault, B. Estimation of integrated photovoltaics potential for solar city bus in different climate conditions in Europe. J. Phys. Conf. Ser. 2023, 2454, 012007. [Google Scholar] [CrossRef]

- Ford C-Max Solar Energi: La Première Vraie Voiture Solaire? 2014. Available online: https://www.lepoint.fr/automobile/innovations/ford-c-max-solar-energi-la-premiere-vraie-voiture-solaire-03-01-2014-1776499_652.php#11 (accessed on 13 March 2023).

- Leutenegger, S.; Jabas, M.; Siegwart, R.Y. Solar airplane conceptual design and performance estimation: What size to choose and what endurance to expect. J. Intell. Robot. Syst. 2011, 61, 545–561. [Google Scholar] [CrossRef]

- Oh, M.; Kim, S.-M.; Park, H.-D. Estimation of photovoltaic potential of solar bus in an urban area: Case study in Gwanak, Seoul, Korea. Renew. Energy 2020, 160, 1335–1348. [Google Scholar] [CrossRef]

- Flixbus Fleet Tests 18% CIGS Panels. 2020. Available online: https://www.pv-magazine.com/2020/02/11/flixbus-fleet-tests-18-cigs-panels/ (accessed on 6 February 2023).

- Spagnolo, G.S.; Papalillo, D.; Martocchia, A.; Makary, G. Solar-electric boat. J. Transp. Technol. 2012, 2, 144–149. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Ku, J.; Kim, S.M.; Park, H.D. A new GIS-based algorithm to estimate photovoltaic potential of solar train: Case study in Gyeongbu line, Korea. Renew. Energy 2022, 190, 713–729. [Google Scholar] [CrossRef]

- Solar Powered Trucks. 2020. Available online: https://tsscgroup.com/products-and-services/truck-bodies-semi-trailers/solar-powered-trucks/ (accessed on 31 January 2023).

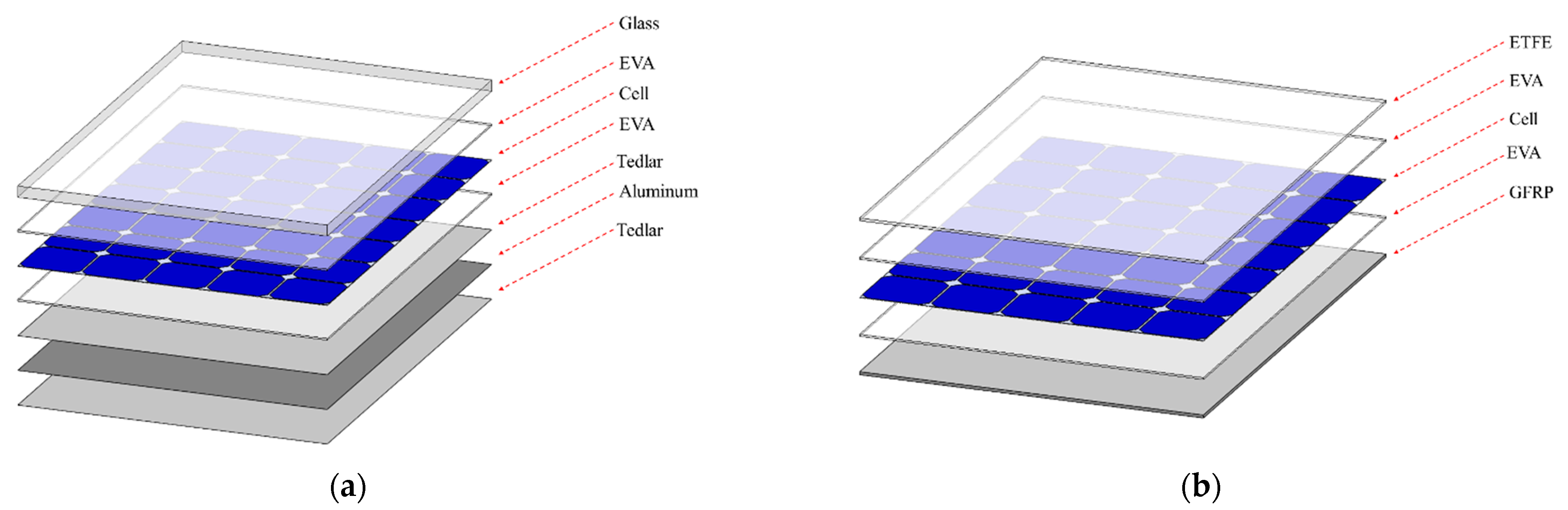

- Kutter, C.; Basler, F.; Alanis, L.E.; Markert, J.; Heinrich, M.; Neuhaus, D.H. Integrated lightweight, glass-free PV module technology for box bodies of commercial trucks. In Proceedings of the 37th European PV Solar Energy Conference and Exhibition, Online, 7–11 September 2020. [Google Scholar]

- Flexible PV Fabric for Heavy Transport. 2021. Available online: https://www.pv-magazine.com/2021/06/02/flexible-pv-fabric-for-heavy-transport/ (accessed on 31 January 2023).

- ‘Solar Power Truck’ Dispatched to Area Affected by Great East Japan Earthquake. 2011. Available online: https://www.japanfs.org/en/news/archives/news_id030963.html (accessed on 6 February 2023).

- Sagaria, S.; Duarte, G.; Neves, D.; Baptista, P. Photovoltaic integrated electric vehicles: Assessment of synergies between solar energy, vehicle types and usage patterns. J. Clean. Prod. 2022, 348, 131402. [Google Scholar] [CrossRef]

- Pavlovic, A.; Sintoni, D.; Fragassa, C.; Minak, G. Multi-objective design optimization of the reinforced composite roof in a solar vehicle. Appl. Sci. 2020, 10, 2665. [Google Scholar] [CrossRef]

- Lee, K.Y.; Park, S. Reducing Charging Burden of Light Electric Vehicles by Integrated Photovoltaic Modules. In Proceedings of the 2022 IEEE Vehicle Power and Propulsion Conference (VPPC), Merced, CA, USA, 1–4 November 2022; IEEE: New York, NY, USA, 2022. [Google Scholar]

- Sion—Infinite mobility. 2018. Available online: https://sonomotors.com/sion.html/ (accessed on 8 January 2023).

- Peibst, R.; Fischer, H.; Brunner, M.; Schießl, A.; Wöhe, S.; Wecker, R.; Haase, F.; Schulte-Huxel, H.; Blankemeyer, S.; Köntges, M.; et al. Demonstration of Feeding Vehicle-Integrated Photovoltaic-Converted Energy into the High-Voltage On-Board Network of Practical Light Commercial Vehicles for Range Extension. Solar RRL 2022, 6, 2100516. [Google Scholar] [CrossRef]

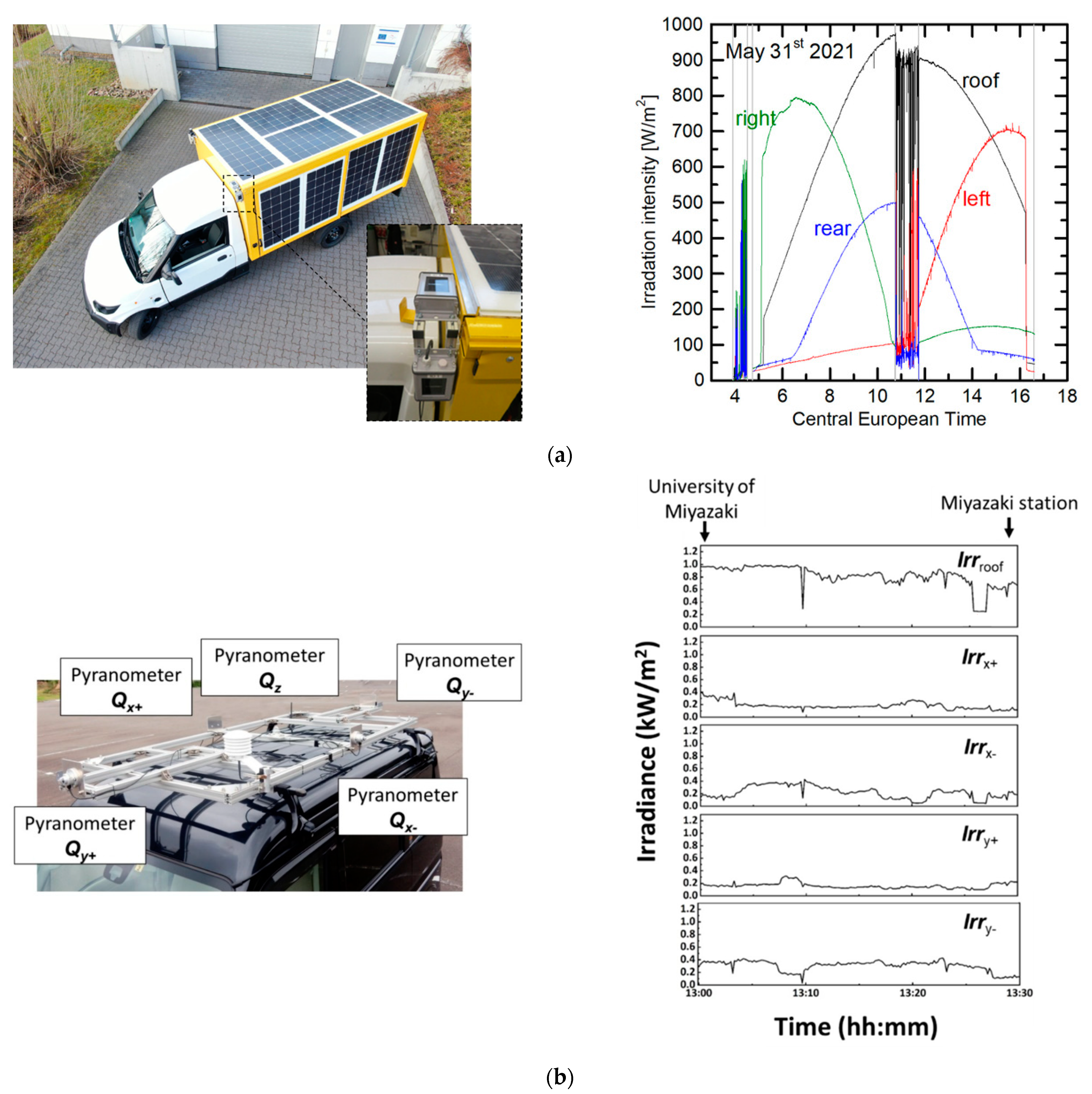

- Araki, K.; Ota, Y.; Yamaguchi, M. Measurement and modeling of 3D solar irradiance for vehicle-integrated photovoltaic. Appl. Sci. 2020, 10, 872. [Google Scholar] [CrossRef] [Green Version]

- Wetzel, G.; Salomon, L.; Krügener, J.; Bredemeier, D.; Peibst, R. High time resolution measurement of solar irradiance onto driving car body for vehicle integrated photovoltaics. Prog. Photovolt. Res. Appl. 2022, 30, 543–551. [Google Scholar] [CrossRef]

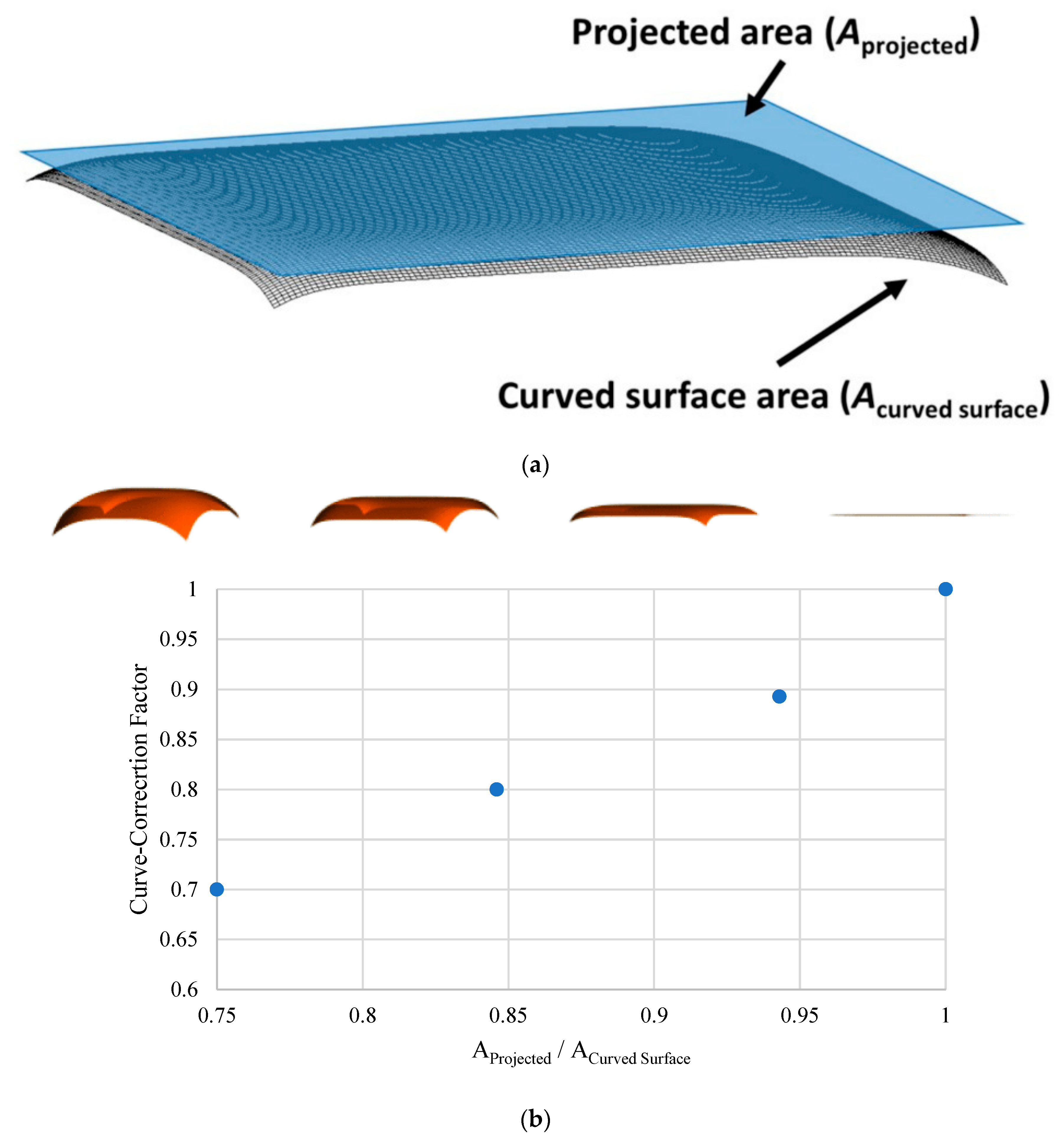

- Ota, Y.; Masuda, T.; Araki, K.; Yamaguchi, M. Curve-correction factor for characterization of the output of a three-dimensional curved photovoltaic module on a car roof. Coatings 2018, 8, 432. [Google Scholar] [CrossRef] [Green Version]

- Ota, Y.; Araki, K.; Nagaoka, A.; Nishioka, K. Facilitating vehicle-integrated photovoltaics by considering the radius of curvature of the roof surface for solar cell coverage. Clean. Eng. Technol. 2022, 7, 100446. [Google Scholar] [CrossRef]

- Araki, K.; Ota, Y.; Lee, K.H.; Yamada, N.; Yamaguchi, M. Curve correction of the energy yield by flexible photovoltaics for VIPV and BIPV applications using a simple correction factor. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; IEEE: New York, NY, USA, 2019. [Google Scholar]

- Tayagaki, T.; Araki, K.; Yamaguchi, M.; Sugaya, T. Impact of nonplanar panels on photovoltaic power generation in the case of vehicles. IEEE J. Photovolt. 2019, 9, 1721–1726. [Google Scholar] [CrossRef]

- Tayagaki, T.; Araki, K.; Yamaguchi, M.; Sugaya, T. Development of high-efficiency and low-cost solar cells for PV-powered vehicles application. Prog. Photovolt. Res. Appl. 2021, 29, 684–693. [Google Scholar]

- Hosseini, S.M.J.; Samadi, H. Solar Energy and Applications; Golestan University: Gorgan, Iran, 2022. [Google Scholar]

- Kim, S.; Holz, M.; Park, S.; Yoon, Y.; Cho, E.; Yi, J. Future options for lightweight photovoltaic modules in electrical passenger cars. Sustainability 2021, 13, 2532. [Google Scholar] [CrossRef]

- Yamada, N. Vehicle-integrated 3D-PV module with III-V and Si solar cells. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 15 June–21 August 2020. [Google Scholar]

- Duigou, T.; Boichon, V.; Brancaz, X.; Chabuel, F.; Francescato, P.; Gaume, J.; Habchi, G.; Lagache, M.; Saffré, P.; Tenchine, L. VIPV: Process development of integrated photovoltaic cells in a double-curved composite structure for automotive application. In Proceedings of the 37th European Photovoltaic Solar Energy Conference and Exhibition, Online, 7–11 September 2020.

- Stein, J.; Reise, C.; Castro, J.B.; Friesen, G.; Maugeri, G.; Urrejola, E.; Ranta, S. Bifacial Photovoltaic Modules and Systems: Experience and Results from International Research and Pilot Applications; Sandia National Lab (SNL-NM): Albuquerque, NM, USA; Fraunhofer: Munich, Germany, 2021. [Google Scholar]

- Yamaguchi, M.; Lee, K.H.; Sato, D.; Araki, K.; Kojima, N.; Takamoto, T.; Masuda, T.; Satou, A. Overview of Si tandem solar cells and approaches to PV-powered vehicle applications. MRS Adv. 2020, 5, 441–450. [Google Scholar] [CrossRef]

- Sato, D.; Lee, K.H.; Araki, K.; Masuda, T.; Yamaguchi, M.; Yamada, N. Design and Evaluation of Low-concentration Static III-V/Si Partial CPV Module for Car-rooftop Application. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; IEEE: New York, NY, USA, 2018. [Google Scholar]

- Sato, D.; Masuda, T.; Tomizawa, R.; Yamada, N. Theoretical concentration limit and maximum annual optical efficiency of static/low-concentration CPV for horizontal integration to vehicle bodies. Opt. Express 2022, 30, 846–863. [Google Scholar] [CrossRef] [PubMed]

- Araki, K.; Ji, L.; Kelly, G.; Ham, A.V.D.; Agudo, E.; Antón, I.; Baudrit, M.; Carr, A.; Herrero, R.; Kurtz, S.; et al. How did the knowledge of CPV contribute to the standardization activity of VIPV? In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2020. [Google Scholar]

- Sato, D.; Lee, K.H.; Araki, K.; Masuda, T.; Yamaguchi, M.; Yamada, N. Design of low-concentration static III-V/Si partial CPV module with 27.3% annual efficiency for car-roof application. Prog. Photovolt. Res. Appl. 2019, 27, 501–510. [Google Scholar] [CrossRef]

- Nukunudompanich, M.; Sriprapai, D.; Sontikaew, S. Aspects of optical and thermal performances in flexible perovskite solar cells made of nanomaterials with potential for development of vehicle-integrated photovoltaics. Mater. Today Proc. 2022, 66, 3163–3167. [Google Scholar] [CrossRef]

- Golubev, T.; Lunt, R.R. Evaluating the Electricity Production of Electric Vehicle-Integrated Photovoltaics via a Coupled Modeling Approach. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Online, 20–25 June 2021; IEEE: New York, NY, USA, 2021. [Google Scholar]

- Macías, J.; Herrero, R.; Núñez, R.; Antón, I. On the effect of cell interconnection in Vehicle Integrated Photovoltaics: Modelling energy under different scenarios. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Online, 20–25 June 2021; IEEE: New York, NY, USA, 2021. [Google Scholar]

- Ashique, R.H.; Salam, Z.; Aziz, M.J.B.A.; Bhatti, A.R. Integrated photovoltaic-grid dc fast charging system for electric vehicle: A review of the architecture and control. Renew. Sustain. Energy Rev. 2017, 69, 1243–1257. [Google Scholar] [CrossRef]

- AbuElrub, A.; Hamed, F.; Saadeh, O. Microgrid integrated electric vehicle charging algorithm with photovoltaic generation. J. Energy Storage 2020, 32, 101858. [Google Scholar] [CrossRef]

- Van Der Kam, M.; van Sark, W. Smart charging of electric vehicles with photovoltaic power and vehicle-to-grid technology in a microgrid; a case study. Appl. Energy 2015, 152, 20–30. [Google Scholar] [CrossRef] [Green Version]

- Carr, A.J.; van den Tillaart, E.; Burgers, A.R.; Köhler, T.; Newman, B.K. Vehicle integrated photovoltaics: Evaluation of the energy yield potential through monitoring and modelling. In Proceedings of the 37th EUPVSEC European PV Solar Energy Conference and Exhibition, Lisbon, Portugal, 7–11 September 2020; WIP GmbH & Co Planungs-KG: Munich, Germany, 2020. [Google Scholar]

- Samadi, H.; Hosseini, M.J.; Ranjbar, A.A.; Pahamli, Y. Thermohydraulic performance of new minichannel heat sink with grooved barriers. Int. Commun. Heat Mass Transf. 2023, 144, 106753. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Masuda, T.; Araki, K.; Ota, Y.; Nishioka, K.; Takamoto, T.; Thiel, C.; Tsakalidis, A.; Jaeger-Waldau, A.; Okumura, K.; et al. Analysis of temperature coefficients and their effect on efficiency of solar cell modules for photovoltaics-powered vehicles. J. Phys. D Appl. Phys. 2021, 54, 504002. [Google Scholar] [CrossRef]

- Tiano, F.A.; Rizzo, G.; Marino, M.; Monetti, A. Evaluation of the potential of solar photovoltaic panels installed on vehicle body including temperature effect on efficiency. ETransportation 2020, 5, 100067. [Google Scholar] [CrossRef]

- Hayakawa, Y.; Sato, D.; Yamada, N. Measurement of the Convective Heat Transfer Coefficient and Temperature of Vehicle-Integrated Photovoltaic Modules. Energies 2022, 15, 4818. [Google Scholar] [CrossRef]

- Park, C.; Park, H.; Jeon, H.; Choi, K.; Suh, J. Evaluation and Validation of Photovoltaic Potential Based on Time and Pathway of Solar-Powered Electric Vehicle. Appl. Sci. 2023, 13, 1025. [Google Scholar] [CrossRef]

- Araki, K.; Ota, Y.; Nishioka, K.; Tobita, H.; Ji, L.; Kelly, G.; Yamaguchi, M. Toward the Standardization of the Car-roof PV–The challenge to the 3-D Sunshine Modeling and Rating of the 3-D Continuously Curved PV Panel. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; IEEE: New York, NY, USA, 2018. [Google Scholar]

- Ng, C.W.; Zhang, J.; Tay, S.E. A tropical case study quantifying solar irradiance collected on a car roof for vehicle integrated photovoltaics towards low-carbon cities. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 15 June–21 August 2020; IEEE: New York, NY, USA, 2020. [Google Scholar]

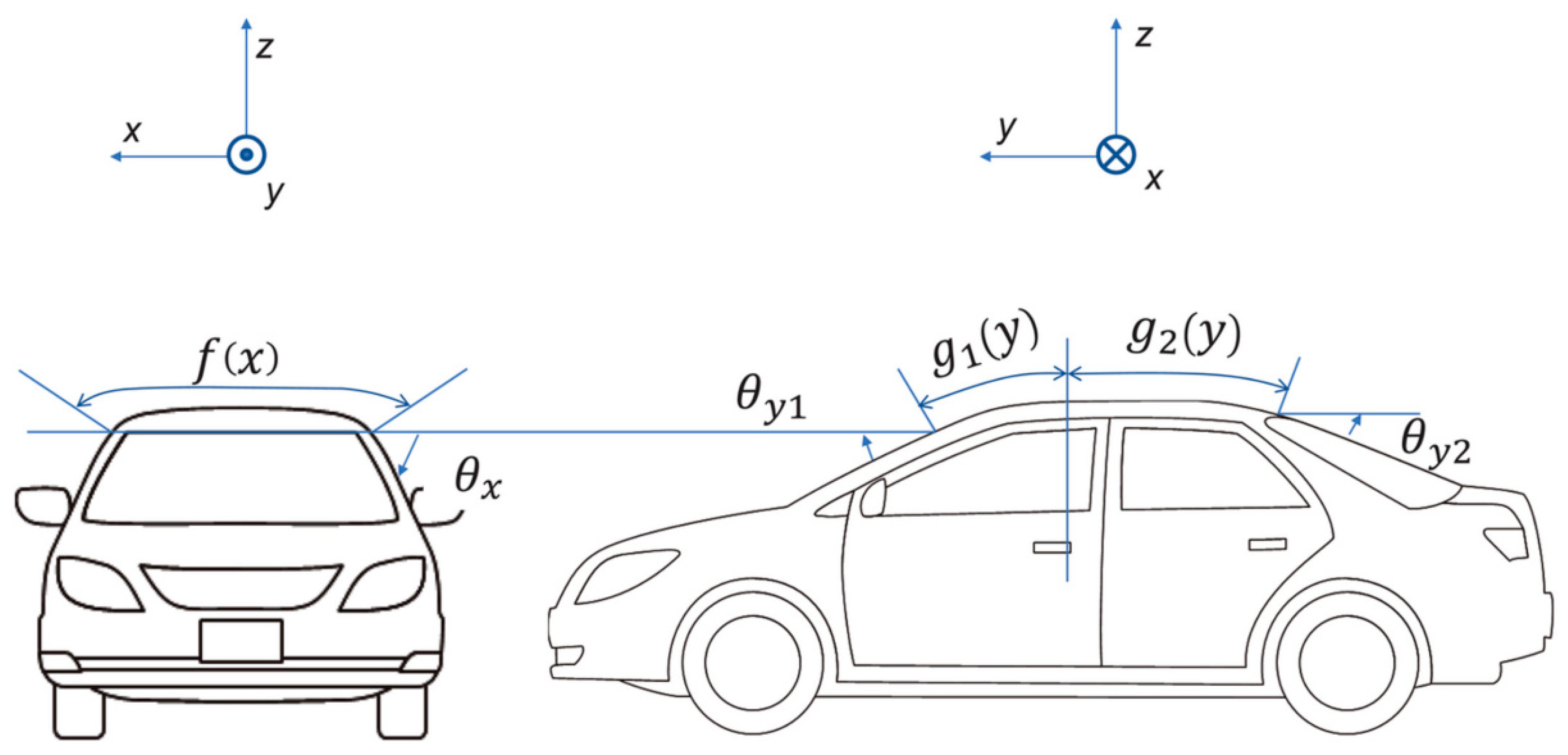

| Parameter | Details |

|---|---|

| Order of the curve of the ridgeline in the width direction | |

| Order of the curve of the front ridge of the side | |

| Order of the curve of the ridgeline behind the side | |

| Tangential angle in the width direction | |

| Forward tangential angle | |

| Backward tangential angle | |

| Relative distance from the top of the vehicle roof to the front end | |

| Relative distance from the top of the vehicle roof to the rear end |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samadi, H.; Ala, G.; Lo Brano, V.; Romano, P.; Viola, F. Investigation of Effective Factors on Vehicles Integrated Photovoltaic (VIPV) Performance: A Review. World Electr. Veh. J. 2023, 14, 154. https://doi.org/10.3390/wevj14060154

Samadi H, Ala G, Lo Brano V, Romano P, Viola F. Investigation of Effective Factors on Vehicles Integrated Photovoltaic (VIPV) Performance: A Review. World Electric Vehicle Journal. 2023; 14(6):154. https://doi.org/10.3390/wevj14060154

Chicago/Turabian StyleSamadi, Hamid, Guido Ala, Valerio Lo Brano, Pietro Romano, and Fabio Viola. 2023. "Investigation of Effective Factors on Vehicles Integrated Photovoltaic (VIPV) Performance: A Review" World Electric Vehicle Journal 14, no. 6: 154. https://doi.org/10.3390/wevj14060154

APA StyleSamadi, H., Ala, G., Lo Brano, V., Romano, P., & Viola, F. (2023). Investigation of Effective Factors on Vehicles Integrated Photovoltaic (VIPV) Performance: A Review. World Electric Vehicle Journal, 14(6), 154. https://doi.org/10.3390/wevj14060154