1. Introduction

Sustainable supply chain practises in the manufacture of electric vehicles are critical to developing a greener and more ecologically responsible automotive sector. These practises represent a comprehensive strategy for reducing the environmental impact of electric vehicles over their entire life cycle, from raw material extraction as well as component production to vehicle assembly and end-of-life recycling. In this scenario, important elements of sustainable supply chains include responsible material procurement, energy-efficient manufacturing methods, decreased emissions during transportation, and novel recycling strategies for battery disposal. Businesses that prioritise sustainability in electric vehicle manufacturing supply chains not only contribute to a cleaner planet but also meet rising consumer demand for environmentally conscious modes of transportation, strengthening the auto sector’s dedication to a more sustainable as well as energy-efficient future. As businesses become more aware of their need to address environmental issues and advance sustainability, a strategic approach known as “green supply chain management” (GSCM) has grown in importance. Fundamentally, GSCM revolves around incorporating environmentally friendly practises and concepts into each stage of the supply chain, from purchasing and production to distributing and disposing of waste. This comprehensive viewpoint recognises the enormous environmental and social repercussions of supply chain operations, making them crucial areas of intervention for lowering carbon footprints, preserving resources, and minimising adverse societal effects. The use of environmentally friendly suppliers, decreased energy use, waste reduction and recycling, ethical sourcing, and the adoption of cleaner transportation strategies are only a few examples of the practises covered by GSCM programmes [

1,

2,

3].

By putting GSCM concepts into practice, businesses want to lessen their environmental impact as well as improve operational effectiveness, cut costs, and satisfy the rising demands of environmentally concerned customers and governing bodies. In a nutshell, GSCM is a vital business strategy that helps organisations balance financial success with commitment to the environment, ultimately fostering a healthier and more resilient future. The idea of sustainability has become crucial for businesses in a wide range of industries in an era marked by increased environmental awareness and worries about the depletion of finite resources. GSCM has developed as a crucial technique for coordinating supply chain activities with ecological as well as social sustainability goals as global stakeholders demand greater accountability from enterprises. GSCM entails integrating environmentally friendly practises throughout the full supply chain lifetime, such as lowering carbon emissions, cutting waste, and ethically procuring resources [

4,

5,

6,

7,

8]. GSCM practises emphasise the incorporation of sustainability and environmental responsibility into supply chain activities, and they represent a paradigm shift in contemporary company operations. These practises cover a wide range of tactics and programs designed to lessen the supply chain’s environmental impact while boosting social and economic performance. Organisations that use GSCM practises aim to reduce their environmental impact, improve resource efficiency, ensure moral and ethical business practises, and eventually satisfy legislative obligations as well as the rising needs of environmentally conscious consumers. The use of GSCM practises has become crucial to establishing long-term competitiveness as well as resilience in the constantly changing world of supply chain management in an era of increased environmental consciousness and global sustainability problems. The several GSCM practises are depicted in

Figure 1.

The importance of GSCM cannot be understated because the supply chain is a crucial intersection where businesses may have a significant impact on operational effectiveness, environmental impacts, and overall corporate responsibility. However, organisations face significant difficulties in implementing GSCM practises successfully and measuring their success afterward. This is caused in part by how intricate and varied sustainability is. Decision-makers find it challenging to evaluate GSCM practises holistically since they frequently cover a wide range of criteria, such as energy efficiency, waste management, and carbon footprint reduction [

9,

10,

11]. Furthermore, stakeholders can communicate their preferences as well as observations in subjective or linguistic terms instead of precise numerical values, making evaluations of sustainability prone to ambiguity, imprecision, and subjective judgment. Therefore, the complexities and uncertainties present in GSCM analyses may not be adequately captured by conventional decision-making tools and procedures.

The technique of ordering preference by similarity to the ideal solution (Fuzzy TOPSIS) stands out as a widely utilised approach in the realm of multi-criteria decision-making. This method, initially introduced by Hwang and Yoon in 1981, incorporates both ideal and negative ideal alternatives, making it a robust and easily computable framework. Furthermore, TOPSIS offers a high degree of interpretability and has found applications in various practical domains. Consequently, researchers have taken a keen interest in TOPSIS, particularly in the post-millennium era, recognising it as a focal point of investigation and exploration [

12,

13,

14]. To evaluate and rate GSCM practises, this research study introduces a novel method based on the incorporation of Fuzzy TOPSIS. A fuzzy technique-based strategy is used because of its capacity to deal with the inherent uncertainty as well as ambiguity that frequently exists in real-world decision-making scenarios, such as those found in the evaluation of sustainable practises in electric vehicle supply chains. Unlike conventional approaches that rely on sharp, binary values, fuzzy logic enables more nuanced depictions of imprecise and confusing information. This results in greater performance since it more truly depicts the intricacies of multi-criteria decision-making. Fuzzy approaches analyse an element’s degree of membership or non-membership in a set, providing a flexible and adaptive framework for evaluating and ranking possibilities. This flexibility allows decision-makers to balance and prioritise criteria in a way that more accurately reflects the real-world situation, resulting in more reliable and informed judgments about the sustainability of the electric vehicle supply chain. The main objective is to provide a formal and statistical framework that allows organisations to methodically evaluate and rank their GSCM projects while accepting the inherently complex and uncertain nature of sustainability evaluations. This study uses Fuzzy TOPSIS to give decision-makers a flexible tool that can take linguistic factors, shaky data, and subjective judgments into account when evaluating sustainability. This method not only improves the objectivity and thoroughness of GSCM assessments; however, it also gives organisations the power to decide how best to allocate resources and efforts in order to improve the environmental performance of their supply chains.

2. Related Works

Organisations all around the world have worked to discover and apply sustainable supply chain management practises that have a positive influence on the environment, society, and the economy. A wealth of research has been conducted to examine different GSCM practises and how they affect sustainability results in the drive for more sustainable supply chains. As a basis for the assessment approach used in this study, we examine major studies and findings connected to GSCM practises in this section by delving deeply into the body of current literature. We seek to contextualise our approach and add to the continuing discussion on sustainable supply chain management by looking at the development of GSCM practises and the learnings from earlier investigations.

Researchers and practitioners together have made major advancements and contributions to the research landscape around GSCM practises. The relevance of analysing aspects such as green design, green purchasing, green transformation, green logistics, and reverse logistics was highlighted by Uygun and Dede [

15] when they presented a model integrating fuzzy Multiple-Criteria Decision Making (MCDM) techniques for assessing GSCM performance. To enable comprehensive assessment, Wang & Chan [

16] also suggested a fuzzy hierarchical TOPSIS approach, highlighting the significance of organisational strategy alignment with green practises. By providing a thorough framework and an evaluation methodology, Kusi-Sarpong et al. [

17] tackled the void in the literature addressing green supply chain practises in the mining industry. The importance of recognising and removing barriers was highlighted by Shahin et al. [

18], who used fuzzy TOPSIS and DEMATEL to prioritise challenges in GSCM within the pharmaceutical business.

In the setting of the COVID-19 pandemic, Khokhar et al. [

19] developed a fuzzy multi-criteria method for assessing sustainability, offering an adaptable decision-making tool for SSCM planning. Dos Santos et al.’s [

20] hybrid Entropy-TOPSIS-F framework for choosing green suppliers showed how fuzzy techniques may be used to deal with uncertainty. In an actual case study, Hashemi et al. [

21] employed Fuzzy TOPSIS to rank the most crucial GSCM practises, placing an emphasis on procedures such as green purchasing and recycling. An innovative hybrid fuzzy MCDM model for evaluating green suppliers that combines DEMATEL, ANP, and TOPSIS was presented by Büyüközkan & ifçi [

22]. A fuzzy AHP-TOPSIS methodology was put forth by Boutkhoum et al. [

23] for locating and assessing appropriate GSCM practises in industrial organisations. Dhull and Narwal [

24] used fuzzy TOPSIS to prioritise GSCM drivers in Indian manufacturing industries while taking into account views from the public, business, and government. Indeed, the study of GSCM practises has gotten a lot of interest from authors and academics all over the world [

25,

26,

27,

28,

29,

30]. GSCM practises have been examined and evaluated in numerous studies employing a range of approaches and frameworks. The variety and evolution of GSCM research are highlighted by these studies collectively, which have contributed insightful techniques and useful insights to the field. This study makes a contribution in this regard by introducing a thorough framework for GSCM practice evaluation and using the Fuzzy TOPSIS to rank these practises, thus dealing with the particular requirements of organisations aiming for sustainable supply chains.

This study aims to carve out a distinct niche among the many research projects looking at GSCM practises by providing a thorough and flexible evaluation framework using the Fuzzy TOPSIS. Although many studies have examined GSCM practises separately or in certain situations, the innovative aspect of this research is its holistic approach, which makes it possible to combine the assessment of various practises against a number of sustainability criteria. This strategy tackles the urgent need for a flexible decision support tool that enables organisations to make decisions that are catered to their unique aims and contextual nuances. It does so by combining the adaptability of the Fuzzy TOPSIS methodology with this strategy. This research promotes the collaborative endeavour towards a more accountable, resilient, and sustainable worldwide market by providing a framework that reflects the interconnection and relative relevance of GSCM practises.

3. Materials and Methods

We describe the framework and methods used to evaluate and rank GSCM practises employing the Fuzzy TOPSIS in this section. A broad range of criteria covering environmental impact, cost effectiveness, social responsibility, regulatory compliance, supplier engagement, innovation and technology adoption, resilience, and risk mitigation were identified in order to start this study. Given the inherent uncertainty and linguistic character of some inputs, data for each criterion was gathered using a combination of quantitative measurements, historical records, and expert judgements.

The Fuzzy TOPSIS approach was then used to assess and rank a variety of GSCM solutions. The imprecision of some data points and stakeholder preferences were captured using linguistic variables as well as fuzzy numbers. A thorough analysis that included quantitative methods and stakeholder feedback to reflect the relative relevance of each criterion resulted in the weighting of the criteria. Following the creation of the fuzzy decision matrix, every alternative’s ideal as well as anti-ideal solutions were determined.

By calculating the Fuzzy TOPSIS rating for each alternative depending on how close it is to the ideal answer, the ranking of GSCM practises was achieved. Statistical analyses were carried out to evaluate how resilient the rankings were to changes in the weights of the criteria as well as the inputs of the data. Using specialised software tools throughout the assessment process ensured consistency and precision in the use of the Fuzzy TOPSIS technique. This methodical strategy offers a thorough assessment of GSCM practises while taking preferences and unknowns into consideration. It also acts as a useful decision-support tool for businesses looking to advance their supply chain sustainability activities.

3.1. Identification of Different Criteria

The identification of various and pertinent criteria is the first and most important step in rating and assessing GSCM practises utilising the Fuzzy TOPSIS. These standards operate as the fundamental building blocks for evaluating the performance and sustainability of GSCM practises throughout the supply chain. The selection procedure included a thorough analysis of the body of knowledge on GSCM and sustainability, discussions with subject matter experts, and an examination of regulations and standards related to the industry. This multimodal approach led to the establishment of a set of distinct and precise criteria. Each criterion contributes to an overall evaluation of GSCM practises that takes into account environmental, economic, and social factors in a different way. This meticulous criteria selection stage establishes the foundation for a strong and thorough evaluation framework, allowing organisations to carefully analyse and rank their supply chain sustainability initiatives.

3.1.1. Environmental Impact

One of the main components of our methodology for GSCM practise assessment is the environmental effect criterion. Both the direct and indirect impacts of the supply chain’s operations on the environment are measured and classified. We assess other aspects of environmental sustainability under this criterion, such as decreases in carbon emissions, energy use, water use, trash creation, and pollutant emissions. The objective is to evaluate how GSCM procedures help to reduce the supply chain’s ecological footprint. We acquire important insights into how closely GSCM activities adhere to environmental stewardship objectives by closely examining elements such as greenhouse gas emissions, energy efficiency, resource conservation, and eco-friendly sourcing. As awareness of the environment and attempts to combat climate change increase, this criterion is crucial in directing organisations towards methods that encourage sustainable practises while minimising their environmental impact.

3.1.2. Cost Efficiency

The cost efficiency criterion is a key component of our approach to evaluating GSCM practises. It investigates the financial effects of supply chain sustainability initiatives. We assess the degree to which GSCM practises result in cost reductions and financial sustainability within the context of this criterion. This entails a thorough examination of operational efficiency enhancements, cost-related waste reductions, resource, and energy optimization, as well as the possibility for increased profitability via sustainable practises. This criterion’s main goal is to show that GSCM practises are not only economically beneficial but also environmentally friendly, as businesses increasingly realise that sustainability may have a significant positive impact on their bottom line. Organisations may make educated decisions that support their environmental and economic sustainability goals by measuring the cost savings as well as the effectiveness benefits associated with GSCM. This helps to create a supply chain that is more resilient and sustainable.

3.1.3. Social Responsibility

Our approach for assessing GSCM practises includes a crucial factor called the social responsibility criterion. It emphasises the importance of sociological and ethical factors that are integrated into supply chain management. We evaluate the degree to which GSCM practises uphold ethical sourcing, fair labour standards, and community involvement under this criterion. This entails assessing workplace rights, diversity and inclusion programmes, and ethical sourcing techniques. We also look at how GSCM affects regional communities and society at large. The objective is to make sure that GSCM practises not only lessen environmental impact but also improve the wellbeing of all engaged stakeholders. A key component of sustainable supply chain management is social responsibility, which reflects the growing significance of moral and humanitarian principles in corporate practises. By including this criterion, businesses can tie their GSCM initiatives to more general social goals, highlighting their dedication to moral business conduct and societal benefit.

3.1.4. Regulatory Compliance

Regulatory compliance is a key element in our approach to rating GSCM practises. It assesses how effectively GSCM practises comply with and are in compliance with regional, national, and international environmental and sustainability laws, rules, and standards. The criterion includes a thorough analysis of a broad range of regulatory requirements, from product labelling and ethical sourcing legislation to emissions norms and waste disposal restrictions. The objective is to make sure that GSCM practises adhere to both obligatory compliance requirements and voluntary sustainability efforts. Organisations exhibit their dedication to moral and legal business practises by closely examining regulatory compliance, thereby reducing legal risks and potential liabilities. This criterion highlights the crucial role that GSCM plays in achieving and maintaining legal adherence while promoting sustainability goals and encouraging an ethical and lawful supply chain.

3.1.5. Supplier Engagement

One of the most important criteria in our approach for assessing GSCM practises is supplier participation. It emphasises how crucial it is to develop cooperative partnerships with suppliers in order to advance sustainability throughout the supply chain. We evaluate how much GSCM practises support supplier involvement in green projects and sustainable practises based on this criterion. This involves assessing how well suppliers adhere to sustainability standards, practise ethical sourcing, and are dedicated to minimising environmental impacts. For businesses looking to expand the impact of their sustainability initiatives across their own activities, supplier engagement is a potent tool. Organisations may influence positive change throughout the supply chain, improve transparency, and forge a shared commitment to eco-friendly practises by integrating suppliers into their sustainability ecosystem. This criterion emphasises the significance of supplier involvement as a critical factor in the sustainability of the supply chain and a catalyst for GSCM success.

3.1.6. Innovation and Technology Adoption

The innovation and technology adoption criterion are crucial to our approach to evaluating GSCM practises. It evaluates the application of cutting-edge technologies and creative methods designed to improve sustainability throughout the supply chain. This criterion assesses how much GSCM practises use environmentally friendly innovations such as energy-efficient equipment, cutting-edge waste reduction methods, real-time monitoring systems, and sustainable transportation options. Adoption of new technologies and innovation helps to save money and improve operations while also promoting environmental sustainability. By placing emphasis on this criterion, businesses can show that they are dedicated to being on the cutting edge of sustainable practises, utilising technological breakthroughs to lessen their carbon footprint as well as boost supply chain sustainability as a whole. It emphasises the need for innovation as a fundamental facilitator for GSCM practises, ensuring that companies remain adaptable and competitive in a climate where environmental responsibility is always changing.

3.1.7. Resilience and Risk Mitigation

The criterion of resilience and risk reduction is of utmost significance in this framework for rating GSCM practises. It focuses on analysing the tactics and procedures used in the supply chain to increase resilience to shocks and reduce supply- and supply-related hazards. Measures including supply chain diversity, emergency planning, climate resilience, and catastrophe readiness are included in this criterion. The objective is to evaluate how GSCM practises reduce supply chain vulnerability to risks such as natural disasters, resource scarcity, and regulatory changes, thereby contributing to the supply chain’s long-term stability and sustainability. Organisations can guarantee the continuity of their activities while preserving their commitment to environmental stewardship by placing a strong emphasis on resilience and risk mitigation. This criterion emphasises the reciprocal relationship between company resilience and sustainability, highlighting the significance of GSCM practises in creating resilient and flexible supply chains for the future.

3.2. Identification of Different Alternatives

The procedure of selecting many alternatives is a crucial phase in this study’s investigation into the evaluation and ranking of GSCM practises using the Fuzzy TOPSIS. We have carefully analysed a broad range of GSCM practises, each of which represents a different strategy for promoting sustainability throughout the supply chain. These options cover a wide range of tactics, including programmes for supplier involvement, ethical procurement, green packaging, and energy-efficient manufacturing. These solutions were found after a thorough analysis of best practises relevant to the industry, discussions with subject-matter experts, and the study of actual case studies. We intend to give organisations a complete toolkit for assessing and prioritising their sustainability projects by identifying and describing these distinctive GSCM alternatives. This wide range of options highlights the complexity of GSCM and guarantees that our assessment framework can take into account the variety of practises that can improve environmental and social responsibility along the supply chain.

3.2.1. Water Management (SCP1)

Within the framework we offer for evaluating GSCM practises, water management is a key alternative that emphasises the need for effective and sustainable water use in the supply chain. This alternative concentrates on the evaluation of tactics and procedures designed to cut down on water use, minimise water waste, and lessen the effects of water use on the environment. It includes practises including wastewater treatment, rainwater harvesting, ethical water sourcing, and water recycling. We want to determine how well businesses manage water resources throughout their supply chain operations by analysing this alternative. By lowering the risks of water scarcity, reducing pollution, and protecting this priceless resource, water management is in line with environmental sustainability goals. Additionally, it helps with cost-cutting, regulatory compliance, and building a resilient supply chain that can survive problems with water. The worldwide necessity for tackling water scarcity as well as environmental degradation through sustainable supply chain practises is reflected in this option, which emphasizes the crucial importance of responsible water management in achieving comprehensive GSCM.

3.2.2. Supply Chain Transparency (SCP2)

Within our framework for evaluating GSCM practises, supply chain transparency is a critical alternative that emphasises the value of visibility and responsibility throughout the supply chain. This option addresses the degree to which businesses maintain supply chain activities’ openness, enabling stakeholders to track product origins, confirm business ethics, and keep an eye on environmental effects. It includes tactics such as the deployment of blockchain technology, supplier audits, and data-sharing projects. By assessing this alternative, we hope to determine how successfully businesses encourage openness and transparency in their supply chains, which not only improves sustainability but also fosters trust with stakeholders and consumers. Transparency in the supply chain is a potent instrument for accountability, risk reduction, and the advancement of moral and sustainable behaviour. It places a strong emphasis on the importance of visibility and information exchange as tools for promoting responsible supply chain management as well as a more ethical and sustainable global market. This option highlights the necessity for organisations to prioritise transparency as a key element of GSCM practises by reflecting the rising need for transparency from consumers as well as regulatory bodies.

3.2.3. Waste Reduction and Recycling (SCP3)

The option of waste reduction and recycling is viewed as a pillar of sustainable supply chain operations in the assessment methodology for GSCM practises. It represents the dedication to reducing waste generation along the supply chain and maximising resource recovery and reuse. This approach includes techniques such as waste stream analysis, recycling programme execution, and the implementation of circular economy ideas. We want to evaluate how well organisations manage their waste streams while contributing to a more sustainable future by analysing trash reduction and recycling practises. By lessening the environmental costs of trash disposal, this alternative not only supports environmental objectives but also encourages cost savings, improves resource efficiency, and lessens the supply chain’s ecological impact. It emphasises the critical role that ethical waste management plays in accomplishing comprehensive GSCM as well as shows how businesses can minimise their negative environmental effects while maximising resource efficiency.

3.2.4. Product Life Cycle Assessment (SCP4)

Under this framework for assessing GSCM practises, Product Life Cycle Assessment (PLCA) is a crucial option that concentrates on the thorough investigation of a product’s whole life cycle, from raw material extraction to disposal or recycling. In this option, the environmental effects, energy use, and resource utilisation at each stage of a product’s life are quantified while taking manufacture, transportation, and usage into account. We want to determine how businesses analyse and reduce the ecological impact of their products by studying PLCA. The PLCA is a tool that may be used to find chances for sustainability advancements, improve product design, and make wise judgments about materials and procedures. It emphasises the significance of a comprehensive strategy for sustainability, ensuring that businesses comprehend and take into consideration the complete range of environmental repercussions connected to their products. This option represents the increased focus on environmentally friendly items that customers and regulators are placing on products and their supply networks. The PLCA is essential in directing businesses towards more ethical and sustainable product creation and management.

3.2.5. Stakeholder Engagement (SCP5)

Stakeholder engagement, which emphasises the active participation of many stakeholders, such as employees, consumers, local communities, and non-governmental organisations, in sustainability projects, is a crucial alternative within our framework for assessing GSCM practises. In order to develop sustainable supply chain practises, this alternative evaluates how much an organisation fosters open and cooperative connections with its stakeholders. It includes actions such as getting input, having conversations, and developing sustainability solutions together. By rating this alternative, we hope to determine how well organisations include stakeholder viewpoints and involve them in the selection of a supply chain sustainability strategy. Engaging stakeholders not only reflects transparency and moral principles but also makes use of many viewpoints to find cutting-edge and successful sustainability measures. It emphasizes how crucial it is to take into account how supply chain practises will affect society as a whole and shows how businesses may gain from working together to promote sustainability, develop goodwill, increase brand loyalty, and effect positive change in the communities they serve. This option highlights the need for organisations to actively interact with stakeholders to produce significant and long-lasting sustainability outcomes and represents the rising understanding that sustainability is a collective endeavour.

3.2.6. Supplier Collaboration (SCP6)

Within this framework for evaluating GSCM practises, supplier cooperation is a key alternative that emphasises the value of developing collaborative partnerships with suppliers to advance sustainability objectives. This option emphasises how much an organisation works with its suppliers to promote sustainable practises, ethical sourcing, and eco-friendly activities. It includes tactics such as shared sustainability targets, knowledge sharing, and collaborative sustainability programmes. We evaluate this alternative to see how well businesses work with their supply chain partners to broaden the impact of sustainability initiatives. Collaboration with suppliers not only corresponds with ethical and environmental sustainability goals but also maximises the aggregate influence of supply chain stakeholders for all-encompassing sustainability advancements. It emphasises the idea that sustainability is a shared duty among all supply chain players and highlights the transformative possibilities of strong supplier relationships in developing a responsible and sustainable supply chain ecosystem. This alternative represents the rising understanding of how interrelated supply chain operations are, as well as the necessity of cooperation to produce sustainable results.

3.2.7. Transportation Optimization (SCP7)

Within this framework for analysing GSCM practises, transportation optimization is a significant alternative that highlights the importance of effective and environmentally friendly transportation techniques in the supply chain. This option aims to deliver goods in a timely and economical manner while reducing the environmental impact of transportation activities. It includes tactics such as load consolidation, modal shift to cleaner modes of transportation (such as electric automobiles, rail, or sea transport), and route optimization. By rating this alternative, we hope to gauge how well businesses have integrated environmentally friendly transportation methods into their supply chain management procedures. The improvement of the supply chain’s general effectiveness as well as cost savings and emissions reductions are all benefits of transportation optimization. It emphasises the crucial role that ethical transportation management plays in achieving comprehensive GSCM as well as illustrates how businesses can reduce their carbon footprints while still satisfying the needs of a sustainable and effective supply chain. This option emphasises the growing significance of sustainable logistics in minimising environmental effects while ensuring the efficient movement of goods via international supply networks.

3.2.8. Energy-Efficient Manufacturing (SCP8)

Considering this methodology for assessing GSCM practises, energy-efficient manufacturing stands out as a strong alternative. Optimizing energy use throughout the production process is a major focus of this option. It entails implementing cutting-edge technologies, energy-saving machinery, and environmentally friendly manufacturing practises with the intention of minimising energy waste and carbon emissions. Manufacturing that uses less energy not only supports environmental sustainability objectives but also considerably lowers costs and improves operational effectiveness. By assessing this alternative, we hope to determine how effectively businesses have incorporated energy-efficient practises into their manufacturing procedures, thereby reducing their resource and carbon footprint. This option highlights how adopting sustainable manufacturing techniques can improve supply chain sustainability and competitiveness while simultaneously lowering environmental impacts.

3.2.9. Green Packaging (SCP9)

Under this framework for assessing GSCM practises, green packaging is a crucial option that emphasises the relevance of sustainable packaging solutions in minimising environmental effects. In order to reduce the environmental impact of packing and transportation, this alternative focuses on using recyclable and eco-friendly packaging materials. Green packaging not only tackles the environmental issues brought on by excessive waste; however, it also helps to save costs and improves brand perception. We evaluated this alternative to see how well businesses have incorporated eco-friendly packaging practises into their supply chain activities. It emphasises the value of sustainable packaging in lowering resource consumption, minimising waste, and lowering carbon emissions from transportation, all while supplying the rising demand for ecologically friendly products from customers throughout the world. This option demonstrates how, in the quest for comprehensive sustainability and ethical business practises, GSCM practises extend to every aspect of the supply chain, including the packaging stage.

3.2.10. Ethical Sourcing (SCP10)

In our methodology for assessing GSCM practises, ethical sourcing is a significant alternative, indicating the vital importance of ethical and sustainable sourcing techniques in supply chain operations. This option symbolises a dedication to the ethical treatment of supply chain participants, fair labour practises, and the responsible sourcing of raw materials. Beyond simply following the law, ethical sourcing emphasises wider ethical issues in supply chain management. We evaluate this option to determine how successfully organisations uphold moral principles, curtail unethical behaviour, and foster social responsibility. The moral and humanitarian aspects of sustainability are aligned with ethical sourcing, which also enhances corporate reputation, reduces risk, and benefits local communities. It emphasises the significance of social responsibility as a key element of GSCM and serves as an example of how businesses may advance environmental sustainability throughout the supply chain while also making positive contributions to society. This option highlights the necessity for organisations to prioritise ethical sourcing practises in today’s worldwide marketplace and represents the rising ethical consciousness of stakeholders and consumers.

3.3. Fuzzy TOPSIS Approach

Supply chain management as well as sustainability evaluation are two areas where the Fuzzy TOPSIS is a complex multi-criteria decision-making (MCDM) technique that has seen tremendous growth. By introducing fuzzy logic, which enables the depiction of inconsistencies and ambiguity in decision-making processes, fuzzy TOPSIS expands on the conventional TOPSIS method. This makes it especially appropriate for complicated and confusing scenarios where decision-makers must assess and rank alternatives using a variety of sometimes ill-defined criteria. Fuzzy TOPSIS is a powerful method used in this study for evaluating and ranking GSCM practises. Fuzzy TOPSISs capacity to deal with the inherent ambiguity and subjectivity sometimes involved with sustainability assessments is the basis for its relevance in this situation. It might be difficult to exactly quantify the various factors used in GSCM, such as environmental impact, cost effectiveness, social responsibility, and regulatory compliance. Given that it enables the modelling of linguistic variables and expert judgments, fuzzy TOPSIS thrives in circumstances where criteria are inherently ambiguous [

31,

32,

33,

34,

35].

Additionally, Fuzzy TOPSIS offers the simultaneous, systematic examination of many different possibilities while facilitating the integration of many criteria. This research provides a structured method to evaluate and rank various GSCM practises, assisting organisations in selecting the ones that best meet their unique sustainability objectives and constraints. By utilising Fuzzy TOPSIS, this research advances sustainable supply chains by offering a solid technique that recognises the difficulties and uncertainties involved in assessing GSCM procedures.

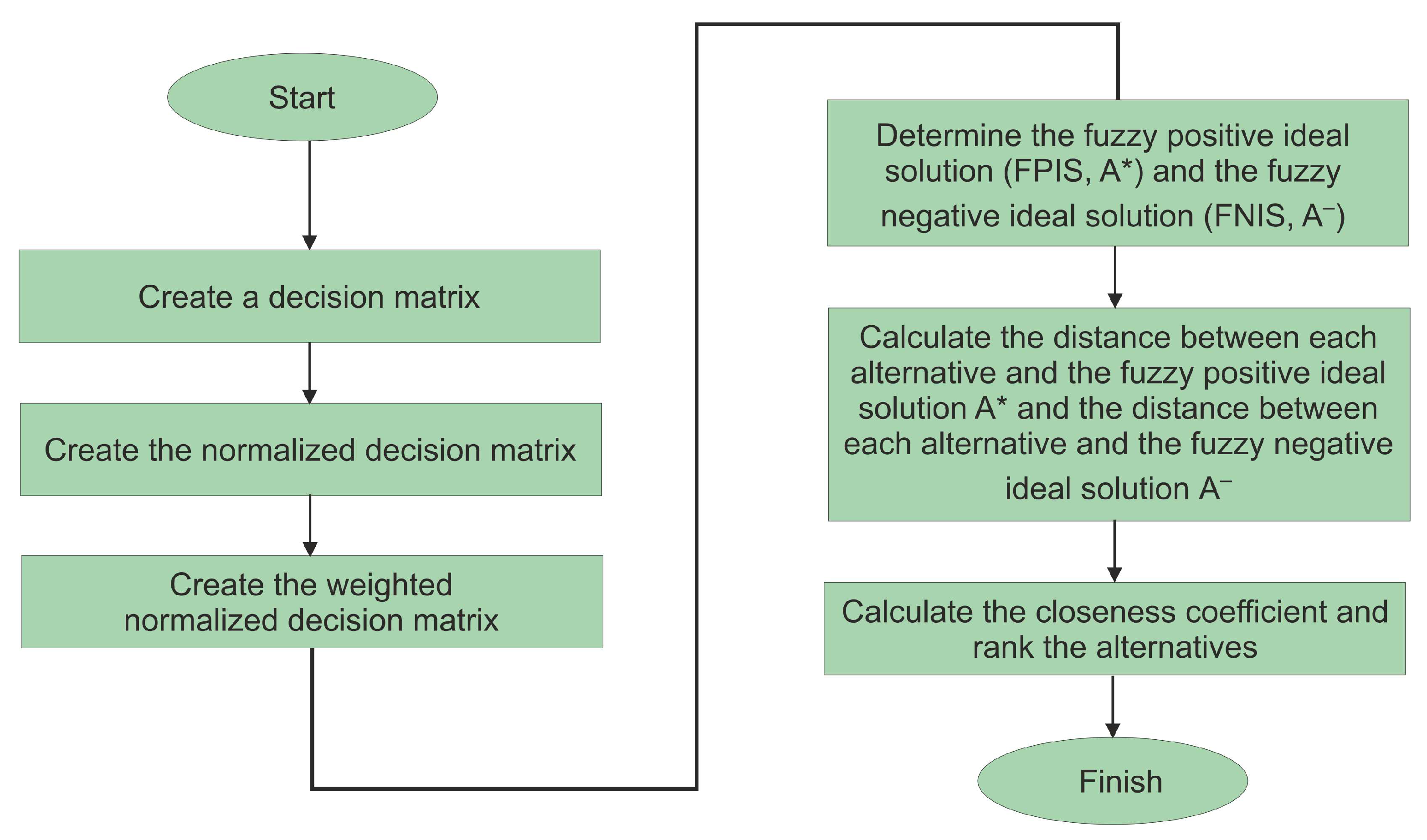

Figure 2 shows the functional diagram of the Fuzzy TOPSIS approach.

4. Results

Fuzzy TOPSIS was used to evaluate GSCM practises, and the results shed light on how well certain supply chain efforts performed in terms of sustainability. We discovered that GSCM practises showed various degrees of success in delivering sustainability goals across the evaluated categories. Notably, practises emphasising waste reduction and energy-efficient manufacturing frequently placed high, demonstrating their significant benefits for both economic effectiveness and environmental sustainability. In recognition of their major contributions to social responsibility as well as ethical supply chain management, ethical sourcing techniques also received noteworthy rankings. Transportation optimization has established itself as a key practise in the quest for sustainability by demonstrating a balance between decreasing environmental impact and increasing operational efficiency. The interconnectedness of environmental, social, and ethical factors within supply chains is further reinforced by the practises of stakeholder engagement and supply chain transparency. These findings illustrate the diverse character of GSCM and the potential for organisations to decide on their sustainability activities in an educated manner, supported by a thorough evaluation framework and the adaptability of the Fuzzy TOPSIS approach.

Step 1: Create a decision matrix

The Fuzzy TOPSIS approach is used in this study to compare ten alternatives to a set of seven criteria. Information on the many sorts of criteria and the weights that have been assigned to each is provided in the

Table 1 below.

The following

Table 2 shows the fuzzy scale used in the model.

The alternatives are assessed based on numerous criteria, and the decision matrix’s findings are presented as follows: It should be noted that the matrix below in

Table 3 represents the arithmetic mean of all experts if more than one expert participates in the evaluation.

Step 2: Create the normalised decision matrix

Based on the positive and negative ideal solutions, a normalised decision matrix can be calculated by the following relation:

The normalised decision matrix is shown in the

Table 4 below.

Step 3: Create the weighted normalised decision matrix

Considering the different weights of each criterion, the weighted normalised decision matrix can be calculated by multiplying the weight of each criterion in the normalised fuzzy decision matrix according to the following formula:

where

represents weight of criterion

.

The following

Table 5 shows the weighted normalised decision matrix.

Step 4: Determine the fuzzy positive ideal solution (FPIS, A*) and the fuzzy negative ideal solution (FNIS, A−)

The FPIS and FNIS of the alternatives can be defined as follows:

where

is the max value of

i for all the alternatives and

is the min value of

i for all the alternatives.

B and

C represent the positive and negative ideal solutions, respectively.

The positive and negative ideal solutions are shown in the

Table 6 below.

Step 5: Calculate the distance between each alternative and the fuzzy positive ideal solution and the distance between each alternative and the fuzzy negative ideal solution

The distance between each alternative and FPIS and the distance between each alternative and FNIS are respectively calculated as follows:

d is the distance between two fuzzy numbers. When given two triangular fuzzy numbers (

) and (

), e distance between the two can be calculated as follows:

Note that and are crisp numbers.

The

Table 7 below shows distance from positive and negative ideal solutions.

Step 6: Calculate the closeness coefficient and rank the alternatives

The closeness coefficient of each alternative can be calculated as follows:

The best alternative is closest to the FPIS and farthest to the FNIS. The closeness coefficient of each alternative and its ranking order are shown in the

Table 8 below.

The following

Figure 3 shows the closeness coefficient of each alternative.

The outcomes of the ranking analysis for the GSCM practises show how varied and interrelated the supply chain’s sustainability is. The top-ranked option was ethical sourcing (SCP10), demonstrating its critical role in fostering social responsibility as well as environmental stewardship. The second-highest ranking practise was closely followed by energy-efficient manufacturing (SCP8), highlighting its major contribution to cutting greenhouse gas emissions and improving cost effectiveness. The third-placed SCP3, Waste Reduction and Recycling, highlighted the critical role that circular economy principles have in reducing resource waste and environmental damage. Green packaging (SCP9) and transportation optimization (SCP7) were also prominently shown, underscoring the critical role that packaging and logistics procedures play in lowering the carbon footprint of the supply chain. Product life cycle assessment (SCP4), which was notably ranked lower, may be a less immediate priority for organisations given its extensive data requirements and long-term focus. These findings highlight how carefully organisations must prioritise GSCM practises in order to match them with their unique objectives and contextual factors. These results highlight the intrinsic complexity of GSCM, where a variety of practises play crucial roles in addressing sustainability’s many facets. The Ci values give organisations a platform on which to build GSCM strategies that are tailored to their unique goals and environment. The performance of GSCM practises depends on their alignment with organisational goals and the changing nature of supply chain operations, which must be understood despite the rankings’ useful insights.

The findings of this study provide a thorough evaluation of GSCM practises and insightful information about their respective influence on sustainability goals. These results provide a solid platform for organisations looking to improve the sustainability of their supply chains. It is essential to understand that GSCM is not a one-size-fits-all strategy; rather, it calls for a customised approach that is in line with the unique objectives and external circumstances of each organisation. The rankings provided here serve as a starting point; however, the adaptation and integration of GSCM activities within an organisation’s larger sustainability agenda determines their eventual success. Organisations may set out on a road towards a more ecologically responsible, socially conscious, and financially effective supply chain using the rankings as a starting point, helping to ensure a more sustainable future for everybody.

5. Discussion

The rating of GSCM solutions demonstrated here highlights the complexity and multifaceted nature of supply chain sustainability activities. Even though these rankings offer insightful information, it is important to understand that an organisation’s particular goals, priorities, and circumstances will determine which GSCM practises are the most suitable. This debate will focus on the relevance of these results and highlight this study’s wider ramifications. The importance of this study rests in its capacity to offer organisations an organised and methodical method of assessing and ranking GSCM practises. It provides a useful starting point for decision-makers in various industries and circumstances by providing a generalised ranking. The importance of ethical supply chain practises that are in line with social responsibility and environmental stewardship is highlighted by the rise of ethical sourcing as the highest priority. The potential for considerable reductions in environmental impact and cost savings through sustainable production methods is highlighted by energy-efficient manufacturing as well as waste reduction practises.

The top rankings’ inclusion of green packaging and transportation optimization highlights the interconnection of several GSCM components and the importance of packaging and logistics in lowering the supply chain’s carbon footprint. Collaboration among suppliers is valued for the cascading effects it has on the sustainability of the supply chain, highlighting the importance of coordinated efforts from all stakeholders. The importance of supply chain transparency and stakeholder involvement in promoting sustainable practises and mitigating risk are both highlighted by their high rankings.

The addition of water management emphasizes the significance of prudent water stewardship, which aligns with environmental sustainability as well as risk reduction. Finally, despite being acknowledged as important, product life cycle evaluation is given a lower priority due to the complexity and data needs connected with this practise. The importance of this study resides in its capacity to assist organisations in selecting which GSCM practises to prioritise in light of their particular goals and contextual considerations. It emphasizes the need for a comprehensive and flexible strategy by acknowledging the complex interplay between the supply chain’s social, environmental, and economic elements of sustainability. By accomplishing this, this research advances sustainable supply chain practises, ultimately encouraging a company climate that is more environmentally conscious, socially responsible, and financially efficient.

While this research provides helpful perspectives into the evaluation of sustainable practises in electric vehicle supply chains utilising a fuzzy technique-based approach, its limitations must be acknowledged. To begin, while real-world case studies are useful, they may not provide a thorough representation of all possible events, possibly restricting the generalizability of findings. Furthermore, the specific fuzzy technique employed, and its parameters may necessitate additional validation as well as sensitivity analysis to ensure robustness across several contexts. Moreover, while we discuss the interconnection of many practises, a more thorough assessment of the potential trade-offs and synergies between different practises would deepen the analysis. We also recognise the need for additional detailed information and in-depth study to improve the clarity and applicability of our approach. Although our study included case studies from several industries to demonstrate the practical application of our suggested framework, we recognise that a more thorough analysis is required to effectively compare these instances with existing research and support our primary arguments. We intend to go deeper into each case study in future research endeavours, giving a meticulous analysis that scrutinises how our approach matches with and contributes to the current body of literature. We hope to accomplish this by providing a clearer and more appealing narrative that substantiates the efficacy of our technique in the setting of electric vehicle supply chain sustainability. This additional depth of analysis will not only enhance the practical implications of our work but also provide readers with a more comprehensive understanding of the real-world impact and relevance of our proposed approach.

6. Conclusions

This research has made major contributions to both theoretical and practical elements of electric vehicle (EV) supply chain sustainability. We offered a complete methodology for using Fuzzy TOPSIS to evaluate and prioritise sustainable practises in the EV manufacturing industry, shedding light on the complex nature of sustainability throughout environmental, social, and economic dimensions. Our findings highlight the critical importance of waste reduction, energy-efficient manufacturing, ethical sourcing, environmentally friendly packaging, supplier collaboration, supply chain transparency, stakeholder engagement, and product life cycle assessment in promoting holistic sustainability in the EV industry. We emphasise the importance of tailoring GSCM practises to each organisation’s specific goals and conditions. Furthermore, our analysis highlights some interesting paths for future GSCM research. Investigating the incorporation of new innovations such as artificial intelligence, blockchain, and the Internet of Things (IoT) in GSCM practises provides an opportunity to improve efficiency, transparency, and environmental impact reduction. Empirical case studies from various businesses and geographical regions might help us better understand GSCM implementation and effects. Furthermore, investigating the robustness of GSCM in the face of global shocks and shifts in consumer preferences is an important issue for future research. We can foster sustainable supply chains by continuously improving our understanding of GSCM practises and their effects.