Path Planning and Guidance Laws of a Formula Student Driverless Car

Abstract

:1. Introduction

- Develop an algorithm for path planning under the assumptions that there is an a priori knowledge of the track layout and an algorithm for online obstacle avoidance considering static obstacles;

- Design different control strategies to effectively steer the vehicle, as well as a low-level controller, in order to obtain more accurate results, ensure vehicle stability, and avoid wheel lock or spin;

- Test, evaluate, and compare the different algorithms, using a developed, realistic model of the vehicle.

- Use the centerline to place the attractive force, to cut the corners while keeping within track;

- Implement decoupled planning (not just decoupled control);

- Deal with obstacle avoidance using transverse forces, to ensure that they are overcome without unduly decelerating the movement and, thus, wasting energy;

- Values for the observation, warning, and danger radius should vary continuously with velocity (using a spline).

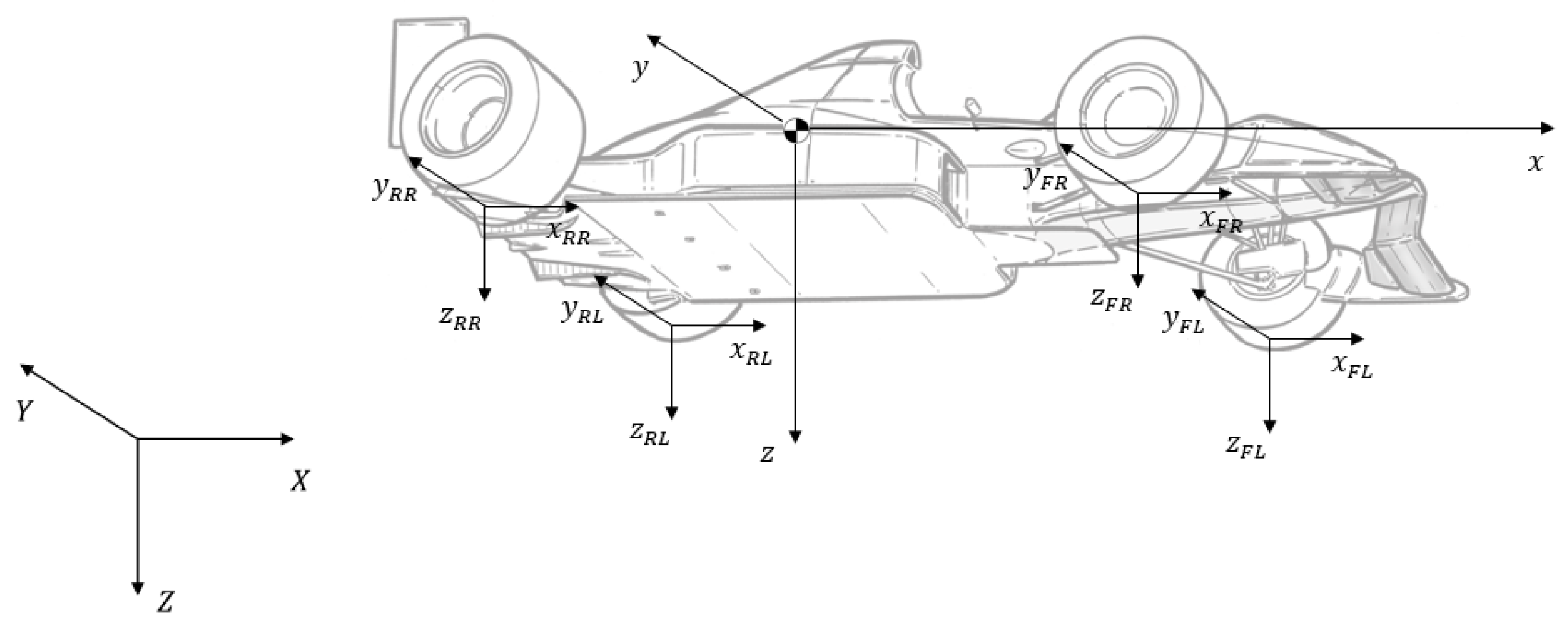

2. Vehicle Modelling

2.1. Realistic Model

- The linear and angular velocities of the centre of gravity (CG) expressed in the local frame (6 variables);

- The CG position expressed in the global frame (3 variables);

- The Euler angles associated with the rotations from global to local frame (3 variables);

- The angular speeds of each of the four wheels (4 variables).

- The four wheel torques ;

- The steering angle .

- The suspension deformations ;

- The slip ratios ;

- The slip angles ;

- The forces and moments resulting from the tire–ground interaction.

2.2. Simplified Models

3. Planning Algorithms

3.1. Path Planning

- →

- Backward pass

- A user-defined limit ;

- →

- Forward pass

- →

- Powertrain constraint

3.2. Obstacle Avoidance

- Track limits and obstacles are differentiated, meaning that they are defined by different repulsive fields;

- The obstacles’ repulsive force is forced to have the direction of the vehicle’s closest edge, instead of being perpendicular to the contour lines from the different danger levels;

- The ability to check if a given obstacle was already overtaken is included (when the CG is ahead of all the edges of the rectangle representing that same obstacle);

- The ability to change the repulsive and attractive gains if a collision is predicted (by projecting the current trajectory a fixed distance ahead) is incorporated.

- Since a negative velocity is not allowed in FS competitions, the profile is changed to take this constraint into account;

- If no possible passage is detected, the reference speed is set to zero;

- Due to possible chattering caused by a linear piecewise profile, a cubic spline interpolation is performed between the different radii, allowing a smooth transition between regions;

- To avoid an “overshoot” in the observation zone, the velocity associated with this outer radius is slightly decreased from the maximum velocity;

- and are parameterised as a function of the velocity, with a linear relation, and not established as fixed values. is fixed, encompassing the vehicle with an extra safety distance.

4. Decoupled Control Approach

4.1. Available Sensors and Required Estimations

4.2. Longitudinal Control

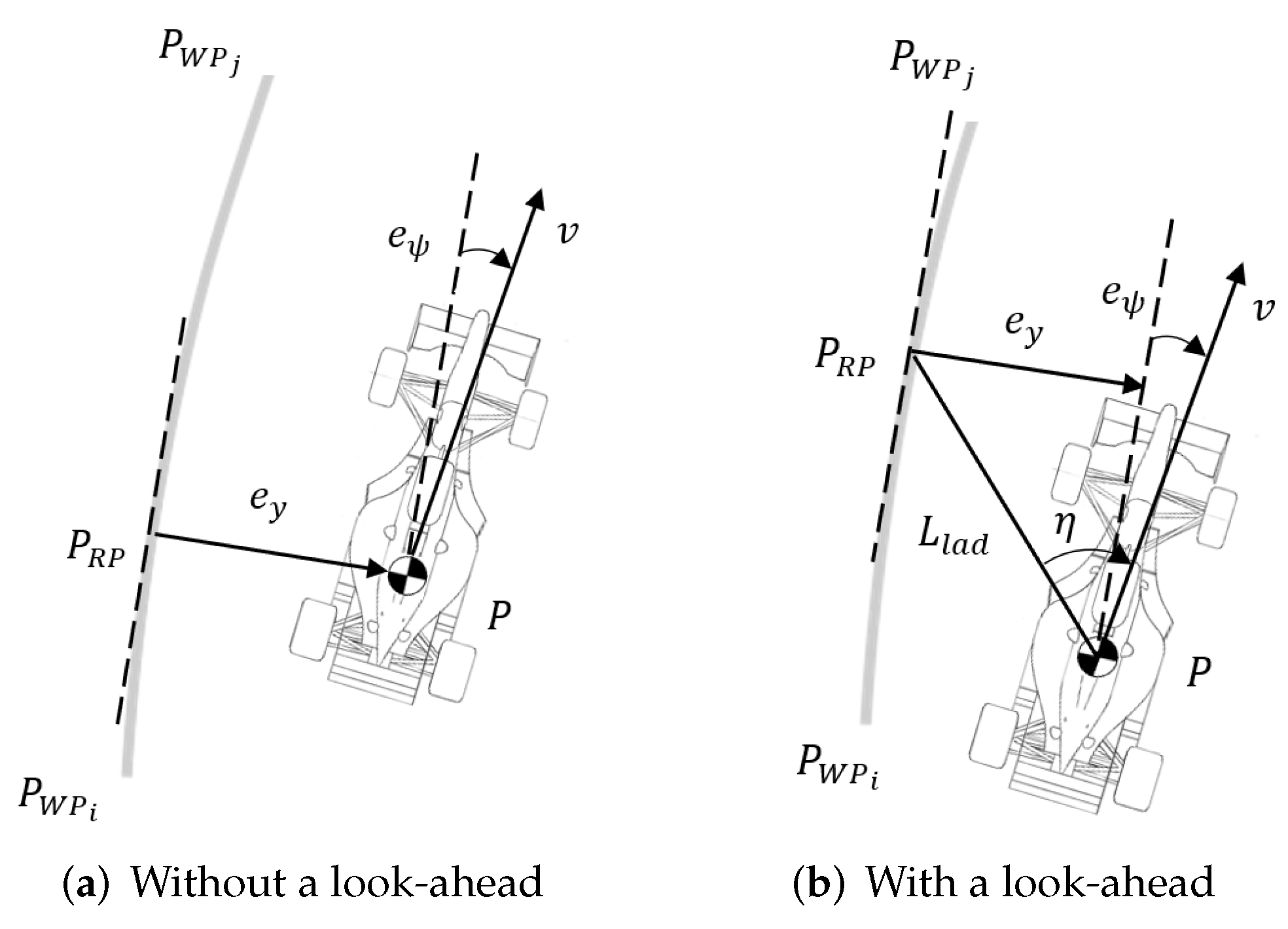

4.3. Lateral Control

- →

- Pure pursuit (PP)

- →

- Linear quadratic Gaussian (LQG)

- →

- Kinematics lateral speed (KLS)

- →

- Modified sliding mode (MSM)

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SAE | Society of Automotive Engineers |

| GPS | Global Positioning System |

| FS | Formula Student |

| FST | Formula Student team from Instituto Superior Técnico—Universidade de Lisboa |

| LiDAR | Light detection and ranging |

| MPC | Model predictive control |

| DOF | Degree of freedom |

| 4WD | Four-wheel driven |

| CG | Centre of gravity |

| RWD | Rear-wheel driven |

| PP | Pure pursuit |

| LQG | Linear quadratic Gaussian |

| LQR | Linear quadratic regulator |

| ARE | Algebraic Riccati equation |

| KLS | Kinematics lateral speed |

| MSM | Modified sliding mode |

| FSG | Formula Student Germany |

| FSI | Formula Student Italy |

| RMS | Root-mean-square |

| DNF | Did not finish |

References

- Pendleton, S.; Andersen, H.; Du, X.; Shen, X.; Meghjani, M.; Eng, Y.; Rus, D.; Ang, M.H. Perception, Planning, Control, and Coordination for Autonomous Vehicles. Machines 2017, 5, 6. [Google Scholar] [CrossRef]

- Phan, D.; Bab-Hadiashar, A.; Lai, C.Y.; Crawford, B.; Hoseinnezhad, R.; Jazar, R.N.; Khayyam, H. Intelligent energy management system for conventional autonomous vehicles. Energy 2020, 116476. [Google Scholar] [CrossRef]

- Liu, T.; Hu, X. A Bi-Level Control for Energy Efficiency Improvement of a Hybrid Tracked Vehicle. IEEE Trans. Ind. Inform. 2018, 1616–1625. [Google Scholar] [CrossRef] [Green Version]

- Hall, J.; Bassett, M.; Tate, L.; Hochgreb, S. Energy Efficiency of Autonomous Car Powertrain; SAE Technical Paper; SAE: Warrendale, PA, USA, 2018; p. 2018–1–1092. [Google Scholar] [CrossRef]

- Van Brummelen, J.; O’Brien, M.; Gruyer, D.; Najjaran, H. Autonomous vehicle perception: The technology of today and tomorrow. Transp. Res. Part C 2018, 89, 384–406. [Google Scholar] [CrossRef]

- Gonzalez Bautista, D.; Pérez, J.; Milanes, V.; Nashashibi, F. A Review of Motion Planning Techniques for Automated Vehicles. IEEE Trans. Intell. Transp. Syst. 2015, 17, 1135–1145. [Google Scholar] [CrossRef]

- Schwarting, W.; Alonso-Mora, J.; Rus, D. Planning and Decision-Making for Autonomous Vehicles. Annu. Rev. Control Robot. Auton. Syst. 2018, 1. [Google Scholar] [CrossRef]

- Alcalá, E.; Puig, V.; Quevedo, J. LPV-MP planning for autonomous racing vehicles considering obstacles. Robot. Auton. Syst. 2020, 124, 103392. [Google Scholar] [CrossRef]

- Duhé, J.F.; Victor, S.; Melchior, P. Contributions on artificial potential field method for effective obstacle avoidance. Fract. Calc. Appl. Anal. 2021, 24, 421–446. [Google Scholar] [CrossRef]

- Laurenza, M.; Pepe, G.; Antonelli, D.; Carcaterra, A. Car collision avoidance with velocity obstacle approach: Evaluation of the reliability and performace of the collision avoidance maneuver. In Proceedings of the 2019 IEEE 5th International forum on Research and Technology for Society and Industry (RTSI), Florence, Italy, 9–12 September 2019; pp. 465–470. [Google Scholar] [CrossRef] [Green Version]

- Gerdts, M.; Karrenberg, S.; Müller-Beßler, B.; Stock, G. Generating locally optimal trajectories for an automatically driven car. Optim. Eng. 2009, 10, 439–463. [Google Scholar] [CrossRef]

- Liniger, A. Path Planning and Control for Autonomous Racing. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2018. [Google Scholar]

- Bonab, S.A.; Emadi, A. Optimization-based Path Planning for an Autonomous Vehicle in a Racing Track. In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; pp. 3823–3828. [Google Scholar] [CrossRef]

- Paden, B.; Čap, M.; Yong, S.Z.; Yershov, D.; Frazzoli, E. A Survey of Motion Planning and Control Techniques for Self-Driving Urban Vehicles. IEEE Trans. Intell. Veh. 2016, 1, 33–55. [Google Scholar] [CrossRef] [Green Version]

- Valls, M.I.; Hendrikx, H.F.; Reijgwart, V.J.; Meier, F.V.; Sa, I.; Dubé, R.; Gawel, A.; Bürki, M.; Siegwart, R. Design of an Autonomous Racecar: Perception, State Estimation and System Integration. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 3823–3828. [Google Scholar] [CrossRef] [Green Version]

- Thrun, S.; Montemerlo, M.; Dahlkamp, H.; Stavens, D.; Aron, A.; Diebel, J.; Fong, P.; Gale, J.; Halpenny, M.; Hoffmann, G.; et al. Stanley: The Robot that Won the DARPA Grand Challenge. J. Field Robot. 2006, 23, 661–692. [Google Scholar] [CrossRef]

- Andresen, L.; Brandemuehl, A.; Honger, A.; Kuan, B.; Vodisch, N.; Blum, H.; Reijgwart, V.; Bernreiter, L.; Schaupp, L.; Chung, J.; et al. Accurate Mapping and Planning for Autonomous Racing. In Proceedings of the 2020 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Las Vegas, NV, USA, 25–29 October 2020; pp. 4743–4749. [Google Scholar] [CrossRef]

- Kabzan, J.; Valls, M.I.; Reijgwart, V.; Hendrikx, H.F.C.; Ehmke, C.; Prajapat, M.; Bühler, A.; Gosala, N.; Gupta, M.; Sivanesan, R.; et al. AMZ Driverless: The Full Autonomous Racing System. arXiv 2020, arXiv:1905.05150. [Google Scholar] [CrossRef]

- De Angelis Cordeiro, R.; Azinheira, J.; Paiva, E.; Bueno, S. Dynamic modelling and bio-inspired LQR approach for off-road robotic vehicle path tracking. In Proceedings of the 16th International Conference on Advanced Robotics (ICAR), Montevideo, Uruguay, 25–29 November 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Kong, J.; Pfeiffer, M.; Schildbach, G.; Borrelli, F. Kinematic and dynamic vehicle models for autonomous driving control design. In Proceedings of the 2015 IEEE Intelligent Vehicles Symposium (IV), Seoul, Korea, 28 June–1 July 2015; pp. 1094–1099. [Google Scholar] [CrossRef]

- Rajamani, R. Vehicle Dynamics and Control, 2nd ed.; Springer: New York, NY, USA, 2012; ISBN 978-1461414322. [Google Scholar]

- Randal, W.; Beard, T.W.M. Small Unmanned Aircraft: Theory and Practice; Princeton University Press: Princeton, NJ, USA, 2012; pp. 30–31. ISBN 9780691149219. [Google Scholar]

- Barroso, A. Traction Control of a Formula Student prototype. Master’s Thesis, Instituto Superior Tecnico, Lisbon, Portugal, 2021. [Google Scholar]

- Pacejka, H.B.; Bakker, E. The Magic Formula Tyre Model. Veh. Syst. Dyn. 1992, 21, 1–18. [Google Scholar] [CrossRef]

- Gillespie, T.D. Fundamentals of Vehicle Dynamics, 1st ed.; Society of Automotive Engineers Inc.: Warrendale, PA, USA, 1992; pp. 196–206. ISBN 9781560911999. [Google Scholar]

- Rucco, A.; Notarstefano, G.; Hauser, J. Computing minimum lap-time trajectories for a single-track car with load transfer. In Proceedings of the 2012 IEEE 51st IEEE Conference on Decision and Control (CDC), Grand Wailea Maui, HI, USA, 10–13 December 2012; pp. 6321–6326. [Google Scholar] [CrossRef]

- Perantoni, G.; Limebeer, D.J. Optimal control for a Formula One car with variable parameters. Veh. Syst. Dyn. 2014, 52, 653–678. [Google Scholar] [CrossRef] [Green Version]

- Lot, R.; Biral, F. A Curvilinear Abscissa Approach for the Lap Time Optimization of Racing Vehicles. IFAC Proc. Vol. 2014, 47, 7559–7565. [Google Scholar] [CrossRef]

- Subosits, J.; Gerdes, J.C. Autonomous vehicle control for emergency maneuvers: The effect of topography. In Proceedings of the 2015 American Control Conference (ACC), Chicago, IL, USA, 1–3 July 2015; pp. 1405–1410. [Google Scholar] [CrossRef]

- Kapania, N.R.; Subosits, J.; Christian Gerdes, J. A Sequential Two-Step Algorithm for Fast Generation of Vehicle Racing Trajectories. J. Dyn. Syst. Meas. Control 2016, 138. [Google Scholar] [CrossRef] [Green Version]

- Valério, D.; Costa, J. An Introduction to Fractional Control; The Institution of Engineering and Technology: Stevenage, UK, 2013; ISBN 978-1-84919-546-1. [Google Scholar]

- Pacejka, H.B. Tire and Vehicle Dynamics, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar] [CrossRef]

- Casqueiro, A.; Ruivo, D.; Moutinho, A.; Martins, J. Improving Teleoperation with Vibration Force Feedback and Anti-collision Methods. In Proceedings of the Robot 2015: Second Iberian Robotics Conference, Lisbon, Portugal, 19–21 November 2015; Reis, L.P., Moreira, A.P., Lima, P.U., Montano, L., Muñoz-Martinez, V., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 269–281. [Google Scholar] [CrossRef]

- Dominguez, S.; Ali, A.; Garcia, G.; Martinet, P. Comparison of lateral controllers for autonomous vehicle: Experimental results. In Proceedings of the 2016 IEEE 19th International Conference on Intelligent Transportation Systems (ITSC), Rio de Janeiro, Brazil, 1–4 November 2016; pp. 1418–1423. [Google Scholar] [CrossRef] [Green Version]

- Ogata, K. Modern Control Engineering, 5th ed.; Prentice Hall: Hoboken, NJ, USA, 2009. [Google Scholar]

- Droździel, P.; Tarkowski, S.; Rybicka, I.; Wrona, R. Drivers’ reaction time research in the conditions in the real traffic. Open Eng. 2020, 10, 35–47. [Google Scholar] [CrossRef] [Green Version]

- Dolgov, D.; Thrun, S.; Montemerlo, M.; Diebel, J. Practical search techniques in path planning for autonomous driving. In Proceedings of the First International Symposium on Search Techniques in Artificial Intelligence and Robotics—STAIR-08, Chicago, IL, USA, 13–14 July 2008; pp. 32–37. [Google Scholar]

- Stentz, A. Optimal and efficient path planning for partially-known environments. In Proceedings of the 1994 IEEE International Conference on Robotics and Automation (ICRA), San Diego, CA, USA, 8–13 May 1994; pp. 3310–3317. [Google Scholar]

| Notation | Description | Value | Units |

|---|---|---|---|

| m | Mass | 256 | kg |

| Moment of inertia around x | 39.00 | kg | |

| Moment of inertia around y | 141.61 | kg | |

| Moment of inertia around z | 160.62 | kg | |

| R | Wheels radius | 0.228 | m |

| Distance of front axis to the CG | 0.816 | m | |

| Distance of rear axis to the CG | 0.724 | m | |

| L | Wheelbase | 1.54 | m |

| Track width | 1.20 | m | |

| CG height | 0.265 | m | |

| Projected frontal area | 1.05 | ||

| Wheels’ rotational inertia | 0.24 | kg | |

| Half-length of contact patch | 0.06 | m | |

| For the realistic model only | |||

| CG translation coefficient | 0.8 | kg/m | |

| CG downforce coefficient | 1.96 | kg/m | |

| CG rotation coefficient | 0.001 | kg | |

| Wheels’ rotation coefficient | 0.003 | kg | |

| c | Damping coefficient for each suspension quarter | 2000 | N·s/m |

| Spring constant for front suspension quarter | 52490 | N/m | |

| Spring constant for rear suspension quarter | 45000 | N/m | |

| Front suspension quarter motion ratio | 1.11 | – | |

| Rear suspension quarter motion ratio | 1.14 | – | |

| Notation | Value for FSG | Value for FSI | Units |

|---|---|---|---|

| 1 | 1 | N/m | |

| 2 | 1 | N | |

| 10 | 2.5 | - | |

| 4 | 6 | - | |

| 6.16 | 6.54 | m | |

| 0.75 | 0.75 | m | |

| 1.50 | 1.04 | m | |

| 0.70 | 0.70 | - | |

| 26.5 | 26.5 | m/s |

| FSG | FSI | |||||

|---|---|---|---|---|---|---|

| Reference Path | t(s) | Improvement | t(s) | Improvement | ||

| Centerline | 30.86 s | – | – | 24.43 s | – | – |

| Potential Field | 27.00 s | 3.86 s | 12.50% | 21.59 s | 2.84 s | 11.63% |

| FSG Track | FSI Track | ||||||

|---|---|---|---|---|---|---|---|

| Controller | RMS() (m) | Time (s) | Penalty | RMS() (m) | Time (s) | Penalty | |

| PP | 1 | 0.05 | 27.62 | – | 0.07 | 22.15 | – |

| 2 | 0.07 | 27.59 | – | 0.12 | 22.19 | – | |

| LQG | 1 | 27.69 | 0.04 | – | 0.05 | 22.26 | – |

| 2 | – | – | DNF | – | – | DNF | |

| KLS | – | 0.05 | 27.67 | – | 0.05 | 22.13 | – |

| MSM | – | 0.10 | 27.62 | – | 0.11 | 22.13 | – |

| Distance (m) | ||||

| Velocity (m/s) | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, S.D.R.; Azinheira, J.R.; Botto, M.A.; Valério, D. Path Planning and Guidance Laws of a Formula Student Driverless Car. World Electr. Veh. J. 2022, 13, 100. https://doi.org/10.3390/wevj13060100

Santos SDR, Azinheira JR, Botto MA, Valério D. Path Planning and Guidance Laws of a Formula Student Driverless Car. World Electric Vehicle Journal. 2022; 13(6):100. https://doi.org/10.3390/wevj13060100

Chicago/Turabian StyleSantos, Solange D. R., José Raul Azinheira, Miguel Ayala Botto, and Duarte Valério. 2022. "Path Planning and Guidance Laws of a Formula Student Driverless Car" World Electric Vehicle Journal 13, no. 6: 100. https://doi.org/10.3390/wevj13060100

APA StyleSantos, S. D. R., Azinheira, J. R., Botto, M. A., & Valério, D. (2022). Path Planning and Guidance Laws of a Formula Student Driverless Car. World Electric Vehicle Journal, 13(6), 100. https://doi.org/10.3390/wevj13060100