1. Introduction

With an estimated increase in oil-powered passenger vehicles (1.5 billion cars on the road projected by 2050 [

1]), considering that oil itself is a finite resource and that the demand for it will increase proportionately, it is therefore commonsense for strategic plans that focus on alternative future transportation methods. Electric vehicles (EVs), or electric traction drives, employ processed electricity rather than crude oil as the powering fuel. In recent times, the EV market has grown significantly [

2,

3,

4,

5]. Certain benefits accruing from the ongoing transition in the transport industry include the reduction of greenhouse gas (GHG) emissions, the promotion of renewable and sustainable energy generation, improved quality of life, opportunities for new investments, and the large-scale creation of jobs, among others.

The transportation sector contributes about 41% of worldwide greenhouse emissions [

6]. No doubt, the electrification of transportation sector is capable of reducing this environmental pollution problem in an effective way through the use of more efficient electrified powertrains. Hence, researchers are more focused on developing alternative, sustainable, and emission-free transportation systems [

7,

8,

9].

The traction motor is an integral part of EV powertrains and plays a significant role in their design architecture. Depending on the application, the selection of a traction motor involves many considerations, such as simple construction, ruggedness, being lightweight, volume, cost, efficiency, torque density, the ease and flexibility of the electric drive control, fault tolerance and harshness capability, a fast and quick torque response especially at starting, a wide constant power speed range (CPSR), low acoustic noise (torque ripple), low rotor inertia, regenerative braking and overload capability, good temperature management, as well as high operational reliability on different driving conditions [

2,

5,

10,

11,

12]. Among these various requirements, an excellent flux weakening defined by a wide CPSR capability curve, as shown in

Figure 1, is often required in EV operational performance.

Traditionally, DC motors [

13,

14], induction motors (IMs) [

15,

16,

17,

18], permanent magnet synchronous motors (PMSMs) [

19,

20,

21,

22], wound rotor synchronous machines (WRSMs) [

23,

24], hybrid synchronous motors (HSM) [

25], and switch reluctance motors (SRMs) [

26,

27], are the most popular traction motors. Each of these traction motor types has its own unique advantages and disadvantages in terms of cost, efficiency, power density, and manufacturability [

2,

28].

Table 1 provides a summary on the industrial uptake of traditional EV motors, while

Table 2 shows their performance characterization [

9,

29,

30,

31] based on a simple five-point rating system, where point one represents the lowest and point five represents the highest grade. Based on the overall score in

Table 2, IMs and PMSMs are seen as the preferred EV motors due to their better performance and operational characteristics. However, based on a thorough characterization provided in [

2], no preference is given on the highlighted motors since each display noteworthy strengths and comparative weaknesses.

Although IMs and PMSMs are widely used in EV powertrains, the search for more competitive traction motors remains an evolving task. To this end, the development of new types of electric traction motors that operate on the flux modulation (FM) principle are emerging [

32,

33,

34,

35,

36,

37,

38]. These machines include the magnetically geared machines [

39,

40,

41,

42], Vernier machines [

43,

44], and stator-mounted PM and wound field machines [

45,

46,

47,

48], to mention a few. Unlike classical electrical machines, FM machines achieve energy conversion by using asynchronous field harmonics. Stator-mounted PM and wound field machines feature rugged and simple rotors and are suitable for high-speed or high-torque applications. Like classical synchronous machines, they can be easily adapted to PM, non-PM, and even hybrid-excited topologies. However, stator-mounted PM and wound field machines are characteristically prone to high-cogging torque and torque ripple due to their double-salient features [

49], which is a matter of concern in EV applications. The candidature of stator-mounted PM and wound field machines for EV drives is due to their excellent flux weakening and CPSR capabilities [

50,

51,

52].

In this paper, an overview will be presented on the trending brushless stator mounted machines (BSMMs) as it relates to their development for traction motor drives. In previous bibliographical niche studies [

4,

5,

10,

25,

30,

31,

32,

37], such an emphasis, as it relates to FM motors in EV applications, has only been at least inferred but never conceptualized. In [

39], the authors focused on the motor designs with reduced rare-earth material, which still limits the scope, while in [

48] the study only focuses on FSPM motors. It is also important to clarify that while the study in [

45] also covers the three variants of BSMMs considered in this study, their study emphasized BSMM topologies with PM excitation, and there was no emphasis placed on EV drivetrains. This current study collects the potential of FM electrical motors in EV drives in terms of their design, analysis, and performance evaluation, with the hope that in the next decade one of these FM motors will make it to the industrial hall of fame summarized in

Table 1. The rest of the paper will be organized as follows:

Section 2 is used to rehearse the variants and main excitation categories of the BSMMs, highlighting machine operating principle and critical EV performance metrics such as torque and flux weakening capabilities. Then,

Section 3 provides a qualitative and quantitative comparison of the highlighted BSMMs in terms of emerging design trends and performance evaluation studies focused on the design of EV traction motors based on PM, wound field, and hybrid-excited FM machines. Lastly, relevant conclusions are drawn in

Section 4.

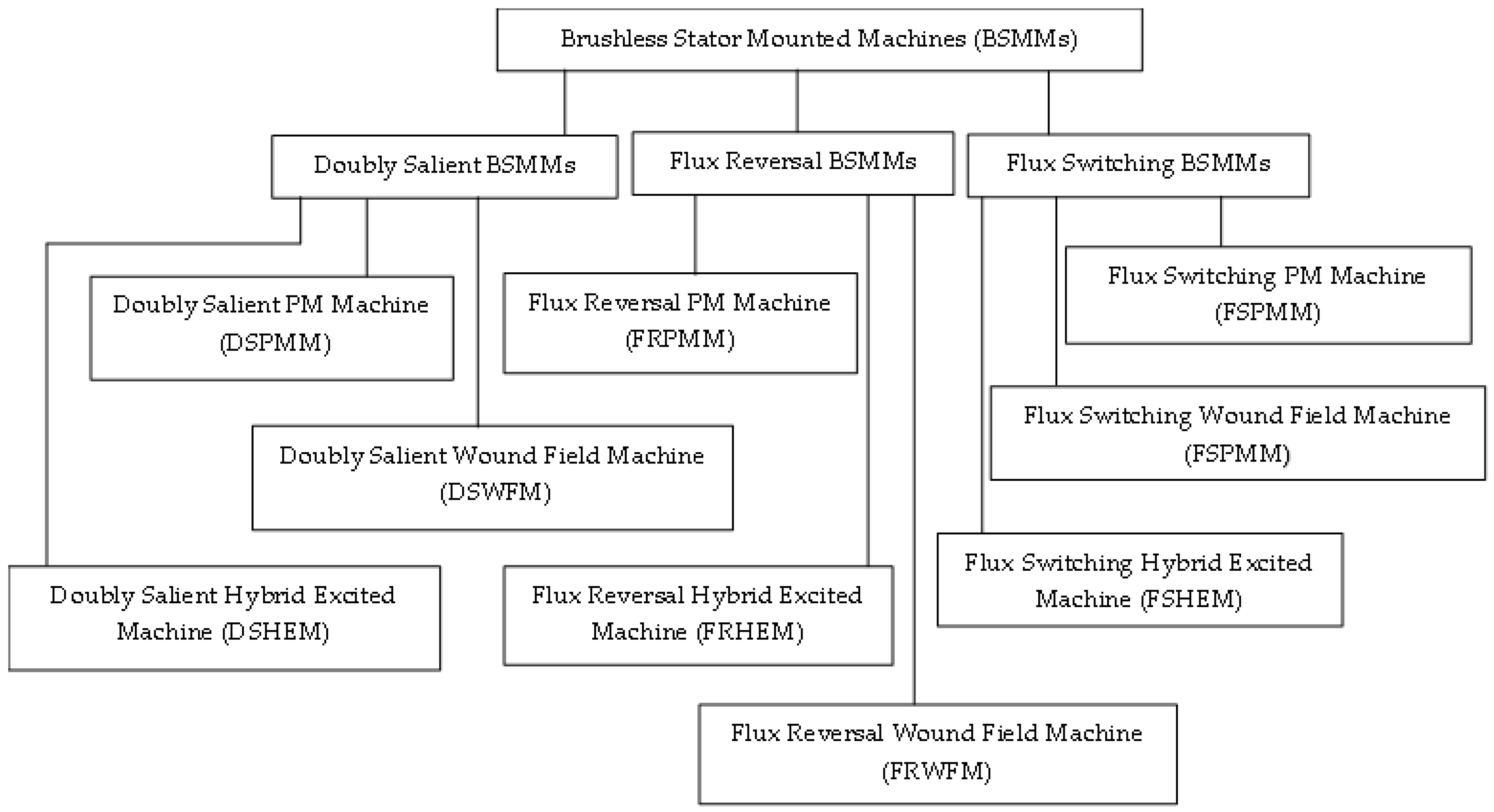

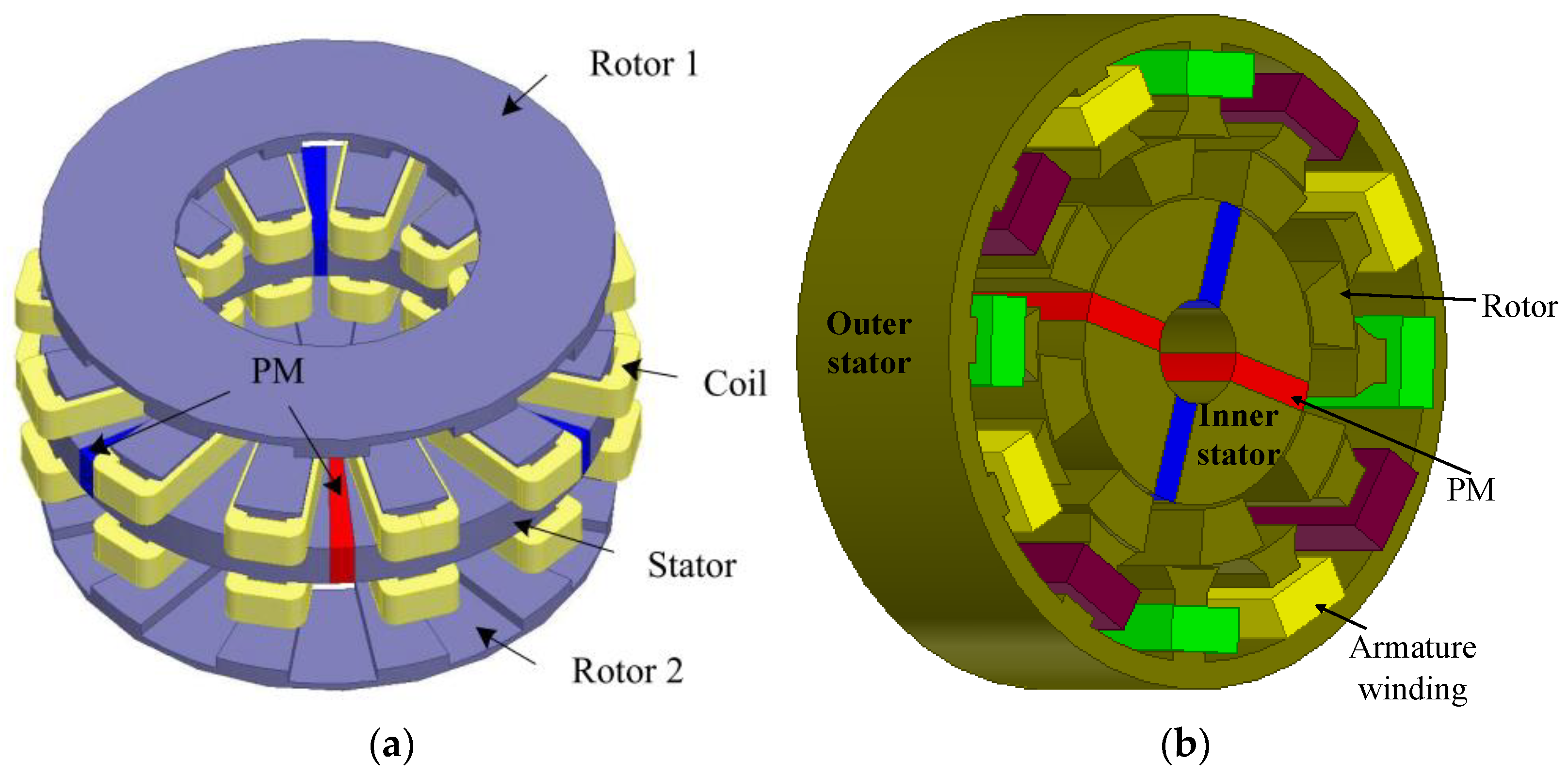

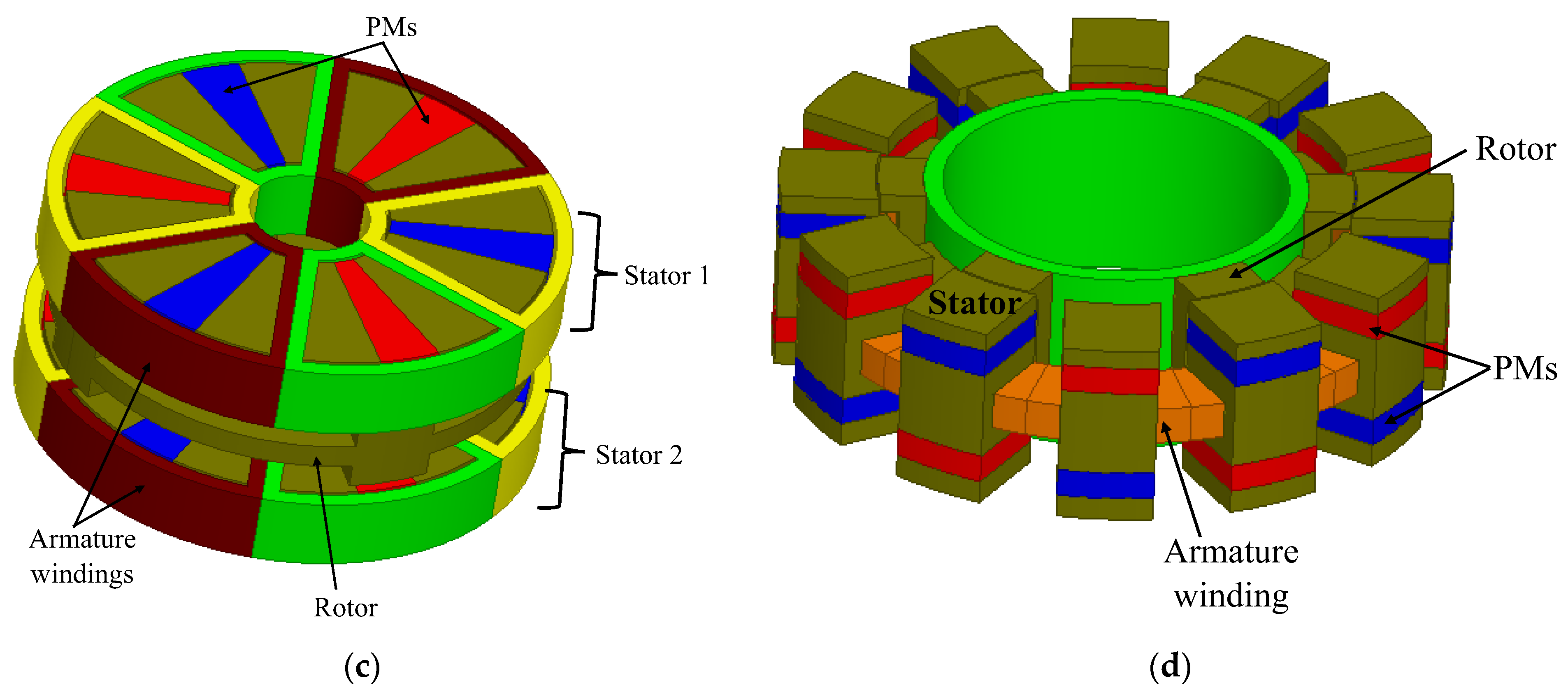

2. Brushless Stator Mounted Machines

These are brushless machines that have their excitation sources located in the stator. Among different types of flux modulation (FM) machines, BSMMs are of great interest in EV application due to their definite advantages in having a robust structure, high power density, and high efficiency. In the case of rotor-PM machines, they usually need to be protected from the centrifugal forces by employing retaining sleeves while a higher risk of irreversible demagnetization results due to poor thermal dissipation of PMs placed in the rotor. Also, in rotor wound field machines, field flux is mostly difficult without the use of slip rings and brushes. In contrast, BSMMs have PMs or DC electromagnets on the stator which help to alleviate the problems suffered by their rotor-mounted counterparts. As a result, BSMMs are suitable for high-speed or high-torque designs. Based on the location of excitation sources in the stator, there are three types of BSMMs: doubly salient BSMMs [

53], in which the excitation sources originate from the stator yoke; flux reversal BSMMs [

54], in which the excitation sources originate from the stator tooth tips; and flux switching BSMMs [

55], in which excitation sources originate from the stator teeth sides. A broad classification of the different BSMMs based on excitation modes is shown in

Figure 2. The following subsections will discuss this classification in terms of operating principles, torque, and field weakening capabilities.

2.1. Doubly Salient BSMMs

Doubly salient BSMMs can be excited using only PM (DSPMM), DC wound field (DSWFM), or a hybrid combination of PM and DC wound field (DSHEM). In this sub-section, the basic principle of operation is first highlighted based on the different excitation topologies, and thereafter a synthesis of the doubly salient BSMMs—in terms of analysis of important EV performance metrics such as torque and flux weakening capability—are undertaken.

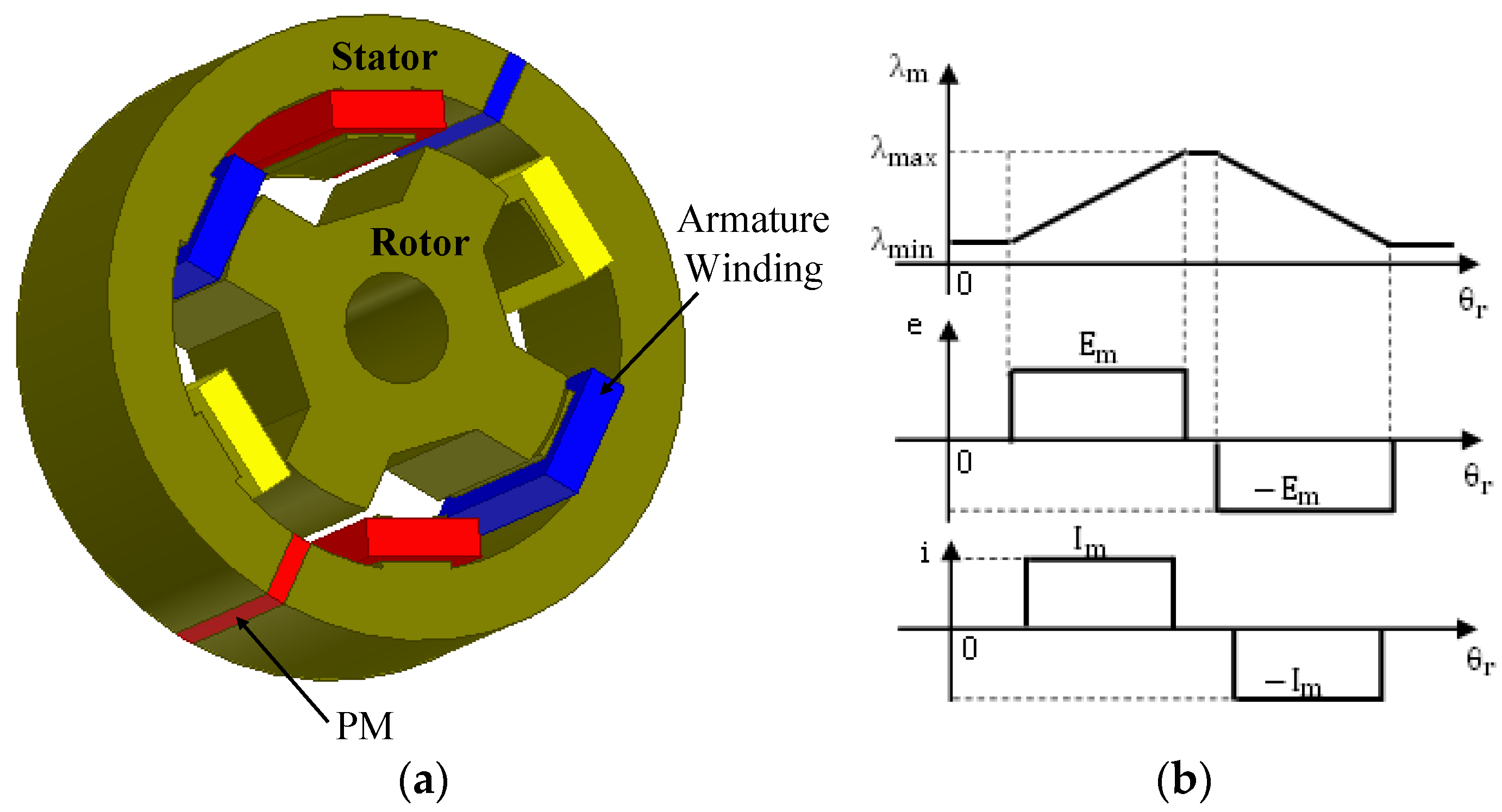

2.1.1. Doubly Salient PM Machine (DSPMM)

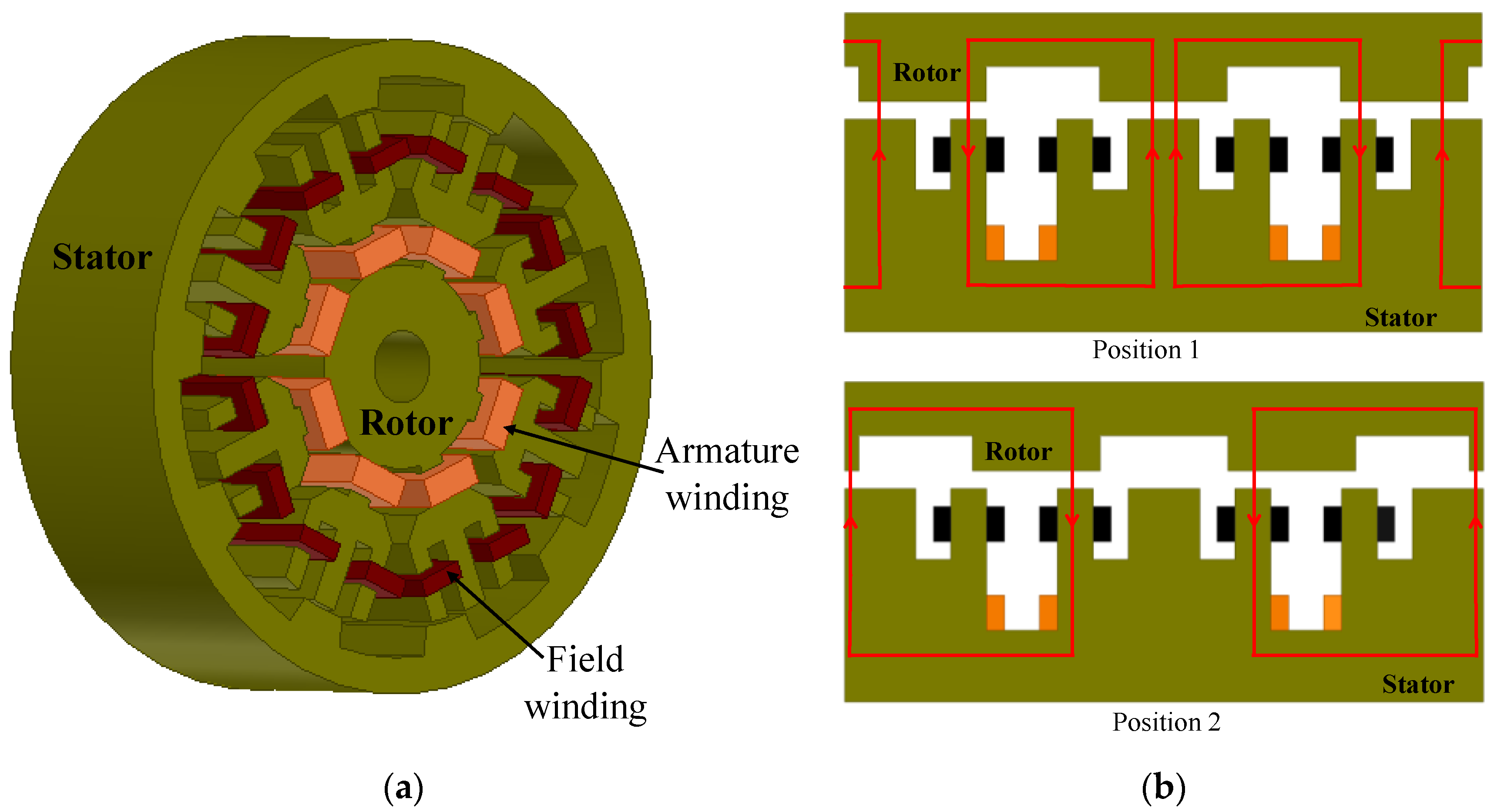

The basic topology of a three-phase 6-stator-pole/4-rotor-tooth (6/4-pole) DSPMM machine is shown in

Figure 3a [

45]. It has six slots in the stator, four salient poles in the rotor, and two pieces of circumferentially magnetized PMs inserted in the stator yoke.

Operating Principles

DSPMM has a small phase winding inductance due to positions of PMs. As the rotor rotate, the flux linkages of these PMs vary. It is this variation of flux that is responsible for back EMF in the stator winding. A non-load plot of flux linkage against rotor position is shown in

Figure 3b [

45,

53]. The shape of the back-EMF is trapezoidal. Thus, brushless DC (BLDC) operation can be adopted. Also, a unidirectional torque is possible by introducing positive and negative current in the winding at the rising and falling of flux linkage, respectively.

Torque Ripple Minimization

Due to presence of salient poles in both the stator and rotor, DSPMMs suffer high-torque ripple [

53,

56]. The torque ripple greatly affects their performance in EV applications by producing motor acoustics and vibrations. Three categories of torque ripples can be described in DSPMM machines [

56]:

First, torque ripple due to double-salient geometry under ideal operating conditions. This torque ripple is expected in any machine with such a topology and is called operating torque ripple.

Second, torque ripple due to operating conditions of the machine such as magnetic saturation, the nature of stator current, and the fringing effect. This torque ripple is dependent on the operating condition and is called practical torque ripple.

Third, torque ripple introduced due to imperfections in the factory production of the machine. Some of the production imperfections that introduce this torque ripple are machine asymmetry and the eccentricity of some rotating parts. This torque ripple is called manufacturing torque ripple.

To minimize torque ripples and improve the performance of DSPMMs, several studies have been carried out, many of which focus on either the design method [

57,

58,

59] or control method [

60,

61,

62]. While the proper sizing of PMs in DSPMM eliminates vibrations and ensures stability [

57], a proper winding configuration minimizes toque ripple [

58]. In [

59], the performance characteristics of DSPMMs with different stator iron core segments were compared. It was shown that

exhibits the best torque capability and smallest torque ripple.

For the control method, a tremendous reduction in torque ripple factor, from 81% to 21%, were seen in [

60] by optimizing the conduction angle of DSPMM using a genetic algorithm. In [

61], a new harmonic current method was proposed to minimize the torque ripple of a DSPMM, while in [

62], a remedial brushless ac (BLAC) operation was proposed and implemented for fault tolerant DSPMM drives. It was shown that BLAC operation can maintain an average torque and reduce torque ripple while retaining self-starting capability under an open-circuit fault.

Field Weakening Capability and Efficiency

DSPMMs have the advantages of high-power density and high efficiency, but a very difficult to control the flux since the main airgap flux comes from PMs. Therefore, the field weakening is very poor, thereby making DSPMMs suffer from a limited CPSR of about two units [

53]. This is a very serious concern in EV application.

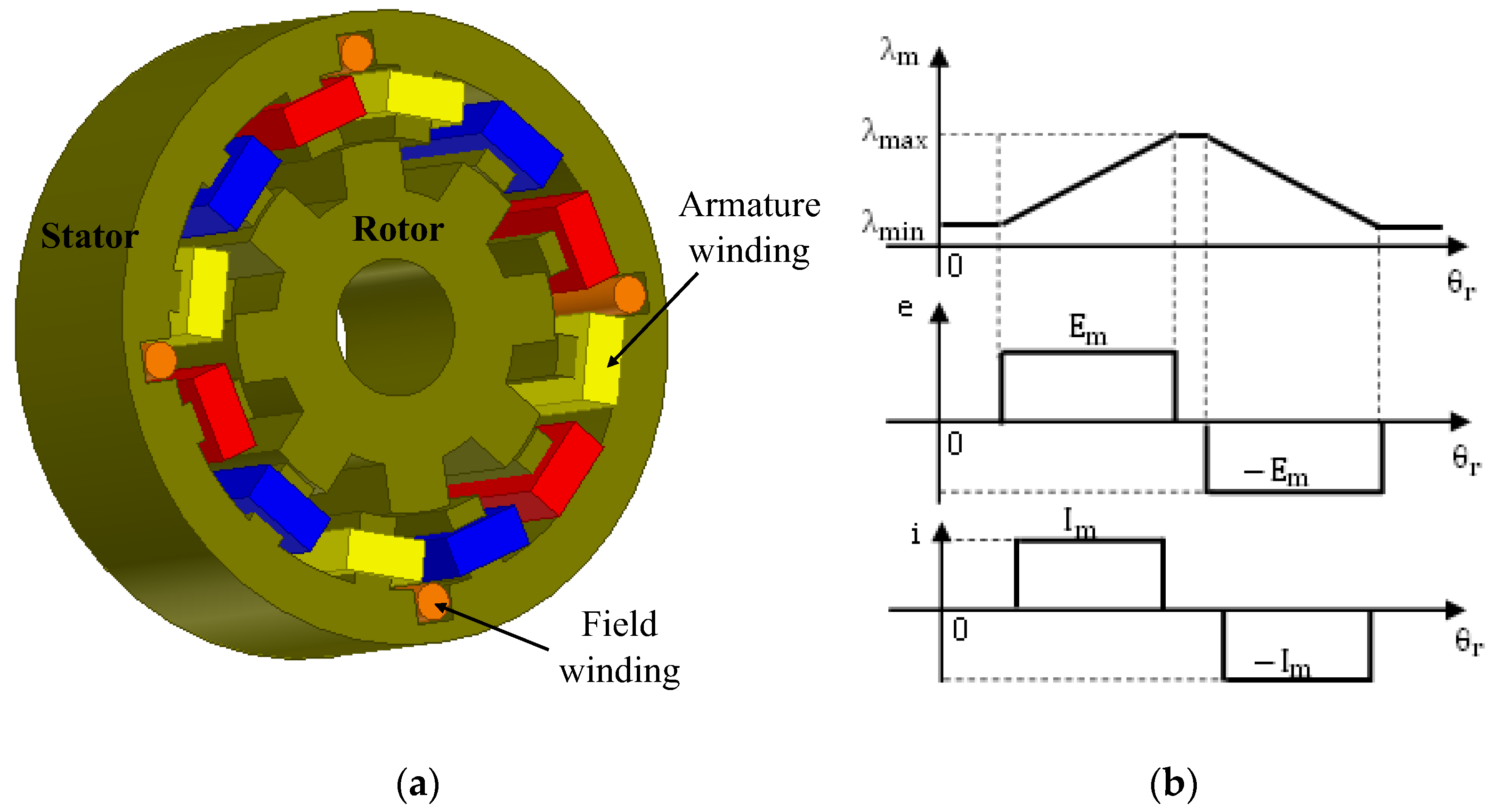

2.1.2. Doubly Salient Wound Field Machine (DSWFM)

To solve the concerns of a limited field airgap flux control and a high cost posed by the DSPMM, a new configuration called the doubly salient wound field motor (DSWFM) was introduced [

63]. In this new configuration, PMs in the DSPMM were replaced with field windings, as shown in

Figure 4a.

Operating Principles

Just like in DSPMMs under no-load conditions, a trapezoidal back-EMF is obtained in the stator winding as the rotor rotates. This necessitates BLDC operation in DSWFM, and like in DSPMMs, unidirectional torque is also possible. A plot of flux variations is shown in

Figure 4b.

Torque Ripple Minimization

Unlike DSPMMs where the torque ripple could be as high as 81% [

56], a DSWFM could yield a torque ripple as low as 6% [

63]. The low torque ripple is because the phase current amplitude is always kept at a constant and in synchronism with the back-EMF.

Field Weakening Capability and Efficiency

With the DSWFM configuration, flux control is possible as demonstrated in [

63]. By adjusting the field current, DSWFMs can provide constant torque when the motor is running at below the rated speed and maintaining a constant power above twice the rated speed. It also yields an efficiency of about 73% near the rated load and below 65% at a light load. Poor efficiency is due to the addition of copper losses from field windings, which limits the application of DSWFM in EV drives.

2.1.3. Doubly Salient Hybrid-Excited Machine (DSHEM)

Since DSPMMs and DSWFMs are limited in EV applications due to their poor field weakening and low efficiency, respectively, both machines were merged to form a new configuration called the doubly salient hybrid-excited machine (DSHEM) [

64], where the excitation sources are from PMs and DC electromagnets, as shown in

Figure 5.

Operating Principles

The PM torque and reluctance torque are two torques produced in DSHEM due to PMs and the double salient geometry of the machine [

64]. PM torque is the most desirable and should be maximized using the appropriate control of the flux linkage variation.

Torque Ripple Minimization

At normal operating speeds, reluctance torque is the main source of torque ripple in DSHEMs, and it should be made as small as possible to have a smoother toque. This is possible by choosing magnitude and wave shape of inductances at the design stage to produce a special self-inductance wave shape that will cancel reluctant torque resulting from variations of self-inductance and ensure less torque ripple. By adjusting the field current, inductances can also be controlled to reduce torque ripple [

64].

Field Weakening Capability

Reference [

64] shows that the hybrid-excitation design of the doubly salient BSMM can achieve a field weakening of 100% and a high-torque density without compromising its performance. The superior torque capability (up to 2 p.u.) of the DSHEM makes it a very good candidate for EV applications.

2.2. Flux Reversal BSMM

The excitation source in the flux reversal BSMM can either be PMs viz., a flux reversal PM machine (FRPMM), DC wound field (FRWFM), or hybrid-excited (FRHEM).

2.2.1. Flux Reversal PM Machine (FRPMM)

FRPMM have the advantages of a robust rotor structure and stator-mounted excitation configuration for easy heat management, making them very promising for both low-speed and high-speed applications [

54]. The basic topology of the FRPMM is shown in

Figure 6a.

Operating Principles

FRPMMs have tooth concentrated winding with PMs placed on their surface, as shown in

Figure 6a. Meanwhile, the phase PM flux-linkage of FRPMMs is bipolar, as shown in

Figure 6b, in contrast to that of DSPMs. Notwithstanding, the suitable operation mode is BLDC.

Torque Ripple Minimization

Despite the advantages of FRPMMs over DSPMMs, their major drawback is their large torque ripple. Cogging torque is the major contributor of this torque ripple and can be minimize by optimizing the motor parameters or by skewing. In [

65], it was shown that both variation in teeth depth and the rotor pole arc influenced the performance of FRPMMs significantly. There was a reduction of 37.31% and 5.36% of torque ripple and average torque, respectively, for the optimal teeth height with three teeth per rotor pole.

In [

66], a rotor tooth pairing method was proposed to reduce cogging torque, while in [

67], a small gap space was introduced between adjacent PMs in the same stator tooth. By this topology, the average torque was improved while cogging and torque ripples were suppressed.

In [

68], the effect of rotor teeth shapes on the performance characteristics of FRPMMs was investigated, which showed that the most effective method for reducing cogging torque in FRPMM—keeping the average torque and back-EMF into consideration—was the proper degree of skew. As an alternative, rotor teeth chamfering can be considered when skewing is not possible.

Field Weakening Capability

As demonstrated in [

69], the electromagnetic torque capability and flux weakening performance of FRPMMs strongly depend on their stator teeth number and rotor pole number combination. For 6/8-pole FRPMM, CSPR was extended to about three times the base speed.

2.2.2. Flux Reversal Wound Field Machine (FRWFM)

The FRWFM topology was developed from FRPMMs by modifying its stator pole to a three-tooth pole structure. In addition, a DC winding is wound on these teeth in such a way as to mimic PMs in the FRPMM, as shown in

Figure 7a [

70].

Operating Principles

When the rotor rotates from position (1) to (2) in

Figure 7b, the polarities of its flux linkages interchange accordingly [

70]. With the bipolar flux linkage characteristics of the topology shown in

Figure 7, FRWFMs enjoy a higher power density compared to their unipolar flux-linkage counterparts.

Torque Ripple Minimization

The lower the torque ripple, the better the torque quality of any motor. To minimize the torque ripple in the FRWFM, the effect of the pole-arc ratio on cogging torque was investigated in [

70]. Results show that a suitable pole-arc ratio minimizes the cogging torque of FRWFMs. For a pole-arc ratio of 1.5, cogging toque was reduced to 6.28% of the rated torque, which is within the acceptable range.

Field Weakening Capability and Efficiency

Just like in DSWFMs, flux control is also emphasized in FRWFM. By adjusting the field current, FRWFMs can provide constant torque when their motors are running at below the rated speed and at a constant power above the rated speed. However, there would be drop in efficiency due to additional copper losses from the field windings, which is a matter of great concern in EV drives.

2.2.3. Flux Reversal Hybrid-Excited Machine (FRHEM)

FRPMMs have a high torque density, and due to their small synchronous inductance, they exhibit a fast transient response. These advantages make FRPMMs a promising candidate for EV application. However, the constant nature of the PMs excited flux density makes wide-speed range operation very difficult without sacrificing the output torque. Therefore, the FRHEM topology tries to address this challenge by combining the merits of FRPMMs and FRWFMs.

Operating Principles

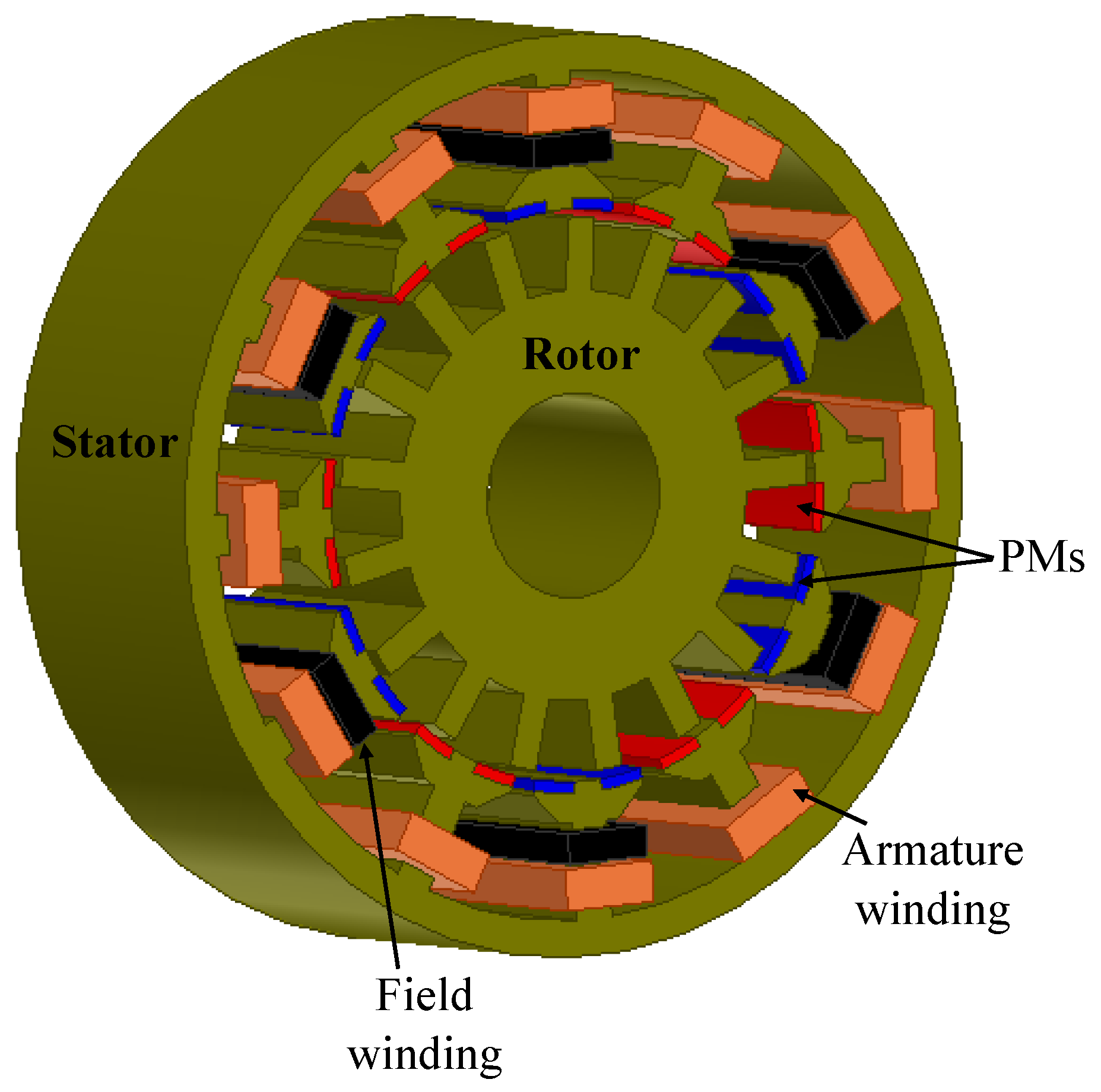

The configuration of the FRHEM is shown in

Figure 8 [

71]. Each stator tooth has PMs with an alternate polarity in its surface, while all the alternate stator teeth are wound with the DC field.

Torque Ripple Minimization

Reference [

72] presented two-dimensional (2-D) finite element-based results for various methods of torque ripple reduction in a flux reversal motor. It was shown that a 60% reduction in the PM height increased the average torque by 73.84% and suppressed torque ripple by 59.84%. Proper skew angles, and an odd number of teeth on the rotor pole, also can also suppress torque ripple.

Field Weakening Capability

A parallel FRHEM is proposed in [

71], as shown in

Figure 8. The flux created by the field coil does not pass through the magnets, thereby offering superior flux weakening capabilities and reducing the risk of PM demagnetization. It is also shown that the torque achieves its maximum value when the ampere turns of the field windings are the same with that of the armature windings. Also, the ferromagnetic pole arc has a significant effect on the flux enhancing and weakening capability of the field windings, and its optimal value for maximum torque is around 0.45 [

71].

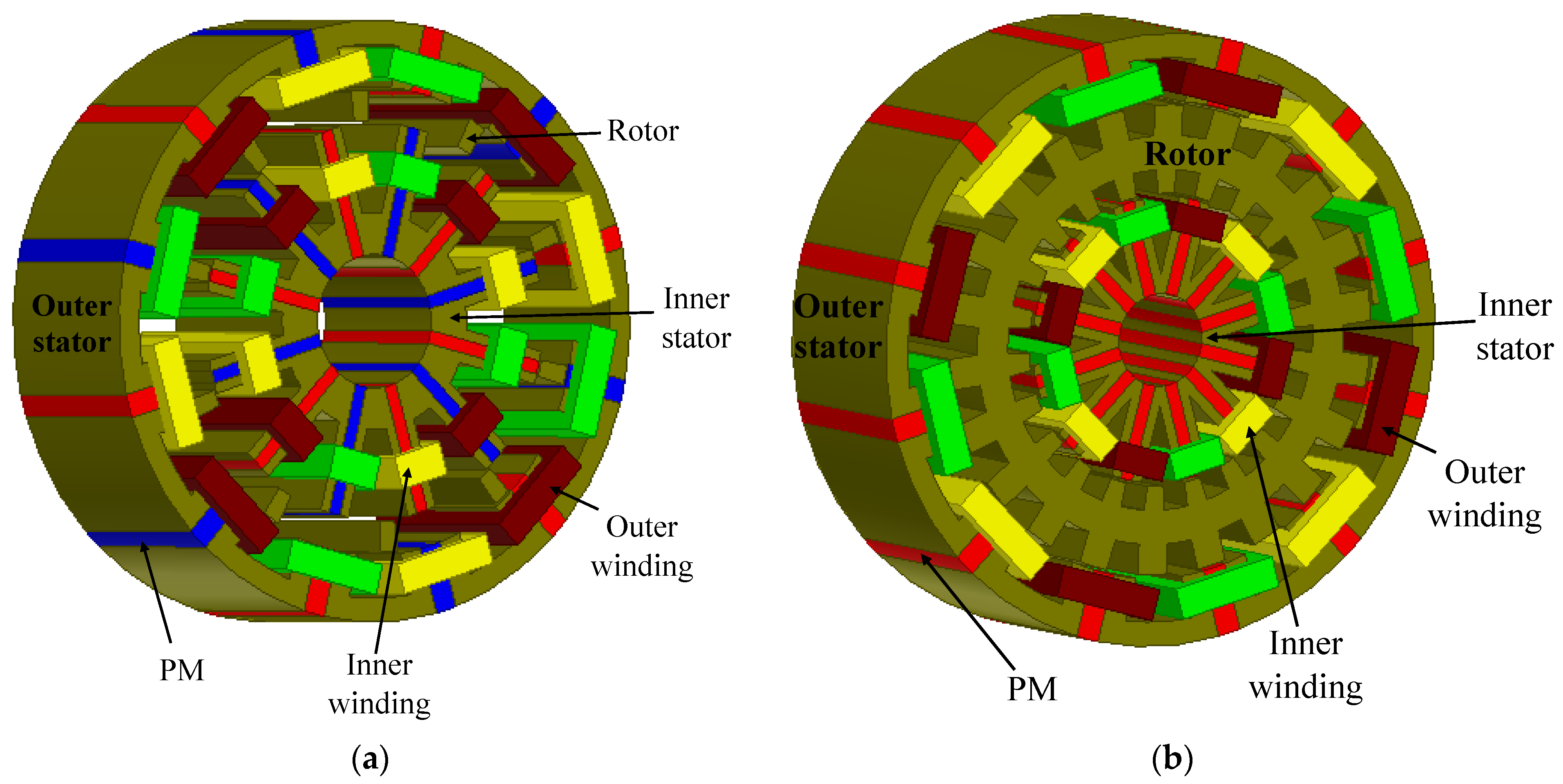

2.3. Flux Switching BSMMs

Based on excitation sources, flux switching BSMMs could be PM-excited (FSPMMs), DC wound field-excited (FSWFMs), or hybrid-excited (FSHEMs).

2.3.1. Flux Switching PM Machine (FSPMM)

FSPMMs have inherent advantages, such as high power and torque densities, suitable heat dissipation, and a passive rotor structure suitable for high-speed traction motors [

55,

73]. However, economic issues are the main limitation of FSPM machines because of their relatively poor PM utilization factor. Furthermore, in view of the salient structure and high degree of saturation, FSPMMs may produce high torque ripple if a proper design is not adopted.

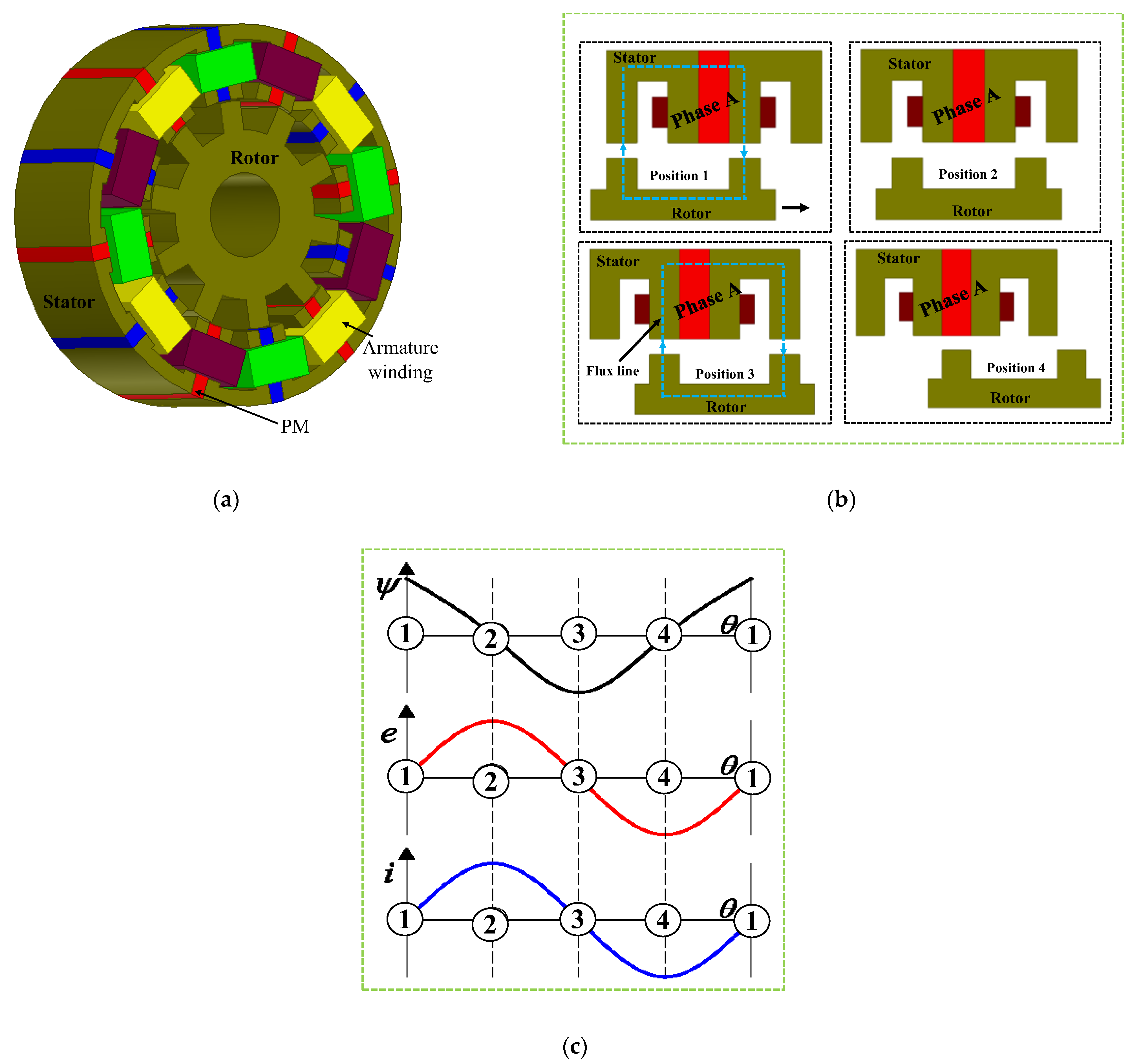

The basic topology of FSPMMs is shown in

Figure 9a [

73]. The rotor of a FSPM is similar to that of switched reluctance motors. While its stator is made of laminated “U-shaped segments”, PMs of alternative polarity are sandwiched between two segments. Each stator pole is wound with fractional slot concentrated winding.

Operating Principles

From

Figure 9b, when the rotor is at position one, the phase A coil experiences maximum flux-linkage due to the alignment of the stator and rotor teeth resulting in the lowest reluctance path. When the rotor moves to position two, the phase A coil experiences zero flux-linkage due to the maximum reluctance of the flux path. At position three, the phase A coil attains a maximum flux-linkage again due to the same reason as in position one, but with the opposite polarity. Then, when the rotor finally moves to position four, rotor teeth align with the PMs, and the phase A coil experiences zero flux linkage due to the maximum reluctance of the flux path. The next movement of the rotor will be to position one, and then the electrical period is completed. The process will repeat again for a continuous rotation of the rotor. When phase current is applied, the idealized waveform of phase A back-EMF is shown

Figure 9c.

Torque Ripple Minimization

Cogging torque dominates the whole torque ripples in FSPMMs because of their doubly salient structure and high air-gap PM flux density. To minimize this cogging torque, researchers have used several approaches, which are either based on design techniques [

74,

75,

76,

77,

78] or control-based techniques [

79,

80]. In [

74], tooth chamfering is proposed where it is shown that the combination of right angles in both stator and rotor teeth can reduce the cogging torque by 80% at a slight expense of electromagnetic torque loss of 1.6%. Cogging torque was mitigated in [

75] by combining two structural variation techniques, namely rotor pole arc concentricity and asymmetric stator tooth-tip installation. In [

76], teeth notching schemes were proposed where it was found that the cogging torque circle diagram of FSPMMs was determined by real flux density distribution rather than the stator or rotor pole number. It was also demonstrated that notching schemes can simultaneously reduce the cogging torque and torque ripple at the minor cost of the average output torque. Reference [

77] proposed rotor shaping in cogging torque reduction, while it is shown in [

78] that short magnets and stator lamination bridge structure are effective in reducing cogging torque in FSPMMs.

For control-based techniques, a specific series of harmonic currents are injected to counteract the corresponding harmonic components of cogging torque [

79]. In [

80], two algorithms based on harmonic current injection and iterative learning controls are proposed to compensate for cogging torque. Although the two schemes can suppress torque ripple, iterative learning control is more general while harmonic current injection is superior in torque pulsation reduction.

Field Weakening Capability and Efficiency

Flux weakening capability is one of the key performance characteristics of the machines used in traction applications. Generally, FSPMMs have a good flux weakening capability, as highlighted in [

51,

81,

82,

83].

As [

81] illustrates, when the split ratio is smaller, the value of the flux weakening factor is higher, which results in a better flux weakening capability. For the 12/10 pole FSPMM, a theoretical infinite operating speed was achieved at the stator outer and inner radii of 45 mm and 21.5 mm, respectively.

In [

82], the flux weakening performance of the conventional and the E-core variant of FSPMMs was investigated and compared. The results showed that when the machines operate as infinite speed drives, the much larger d-axis inductance of the E-core results in lower power at high current. Conversely, while at low currents the maximum output power is the same since it only depends on the maximum phase voltage and currents, but the E-core machine has a better overall power output with speed. It was also shown that both machines can have a similarly constant output power in the high-speed region with the appropriate current–voltage ratio.

A similar comparison was carried out in [

83] for E-core, C-core, and multi-tooth FSPMM variants with the conventional FSPMM. The results showed that the flux weakening capabilities of these variants are much higher than those of the conventional FSPMM. The E-core has the best electromagnetic performance and flux weakening capability followed by the C-core. In [

84], mechanically magnetic field regulated FSPMMs are designed with additional movable mechanical parts, known as flux adjusters, in the machine outer surface.

Generally, iron loss and eddy current losses in conductors increase with the rotor pole number in FSPMMs, while odd rotor pole numbers exhibit lower PM eddy current losses compared to their close even rotor counterpart [

85]. E- and C-core FSPMMs display higher efficiencies compared to conventional types since they only require half the volume of PMs.

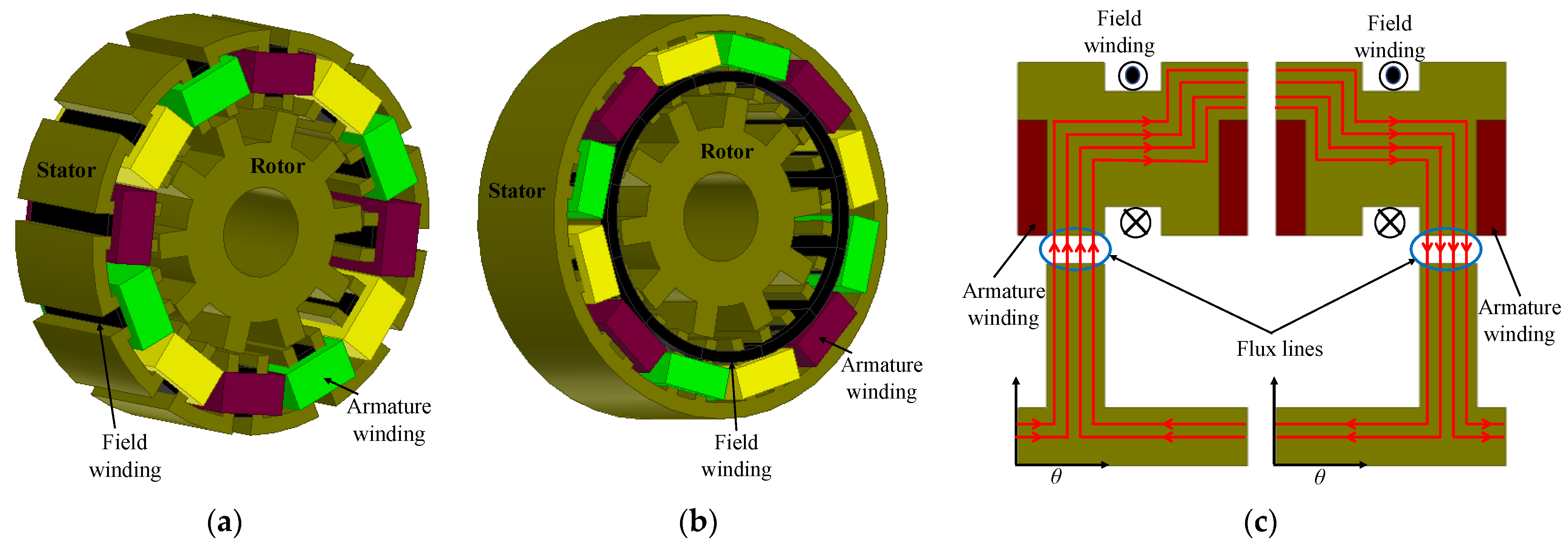

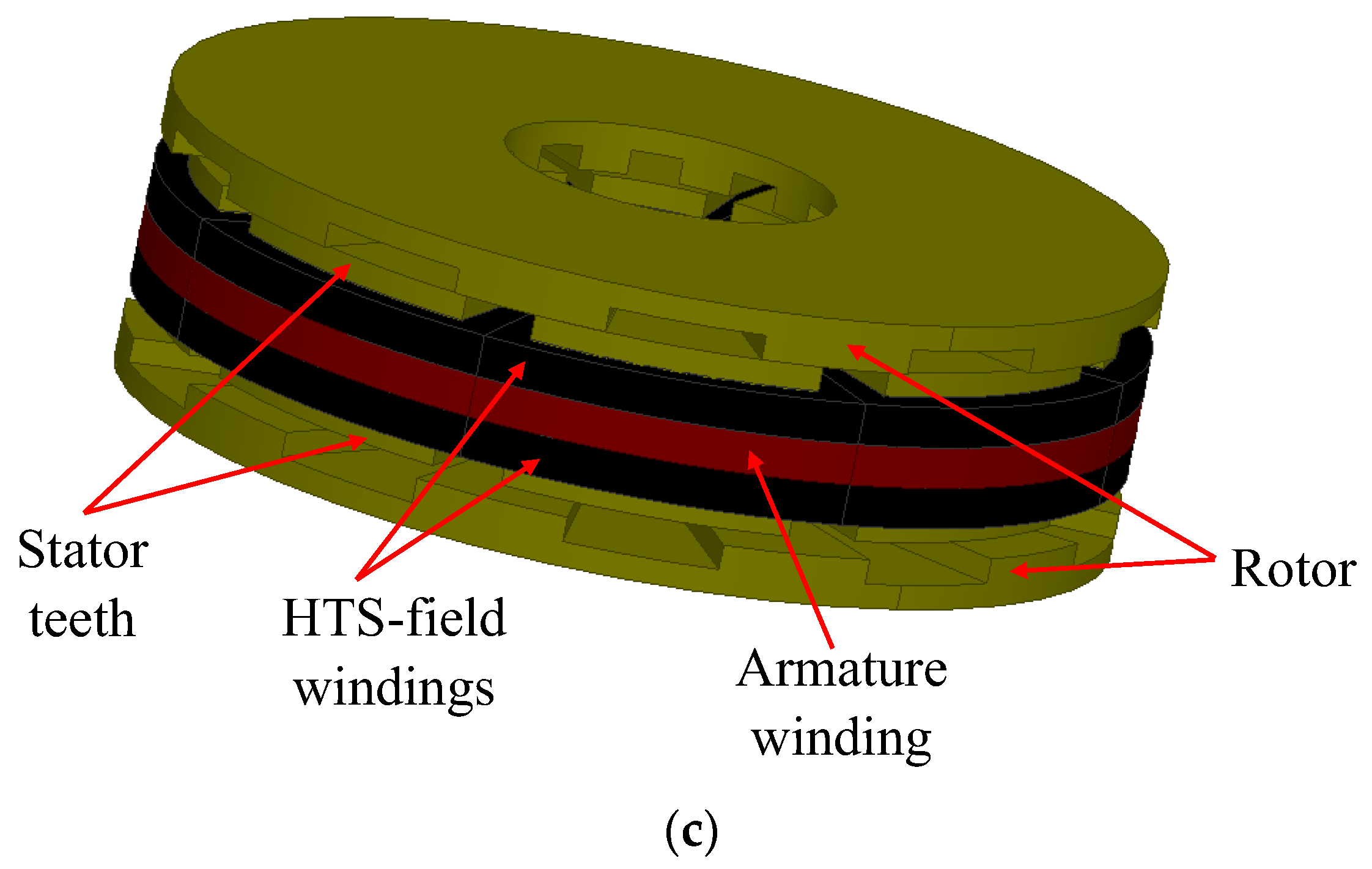

2.3.2. Flux Switching Wound Field Machine (FSWFM)

This is a configuration realized by replacing PM excitation in FSMMs with DC winding excitation, as shown in

Figure 10a. Inheriting characteristics from FSPMMs, FSWFMs exhibit bipolar flux-linkage patterns. As a result, a higher power density can be potentially produced.

Operating Principles

To achieve the bipolar flux-linkage patterns, DC-field windings are arranged toroidally to produce flux, as shown in

Figure 10c [

86]; although, the DC field-windings can also be arranged with dual polarity DC-field concentrated windings, as shown in

Figure 10b. Unlike the FRWFM that modulates flux within the stator tooth, the FSWFM regulates flux within the stator yoke instead. Even though the FSWM can potentially produce a higher torque density, it suffers from more severe saturation problems within its stator iron yoke [

87].

Torque Ripple Minimization

Just like FSPMM, cogging torque dominates the torque ripple in FSWFMs because of their doubly salient structure and high air-gap flux density. In light of this, to minimize cogging torque, some of the techniques used in FSPMMs should be adopted. In [

87], a stepped skewed rotor was suggested for the reduction of cogging torque and torque ripples under various load conditions. In [

50], the openings of the field and armature winding slots of the FSWFM are equated to significantly reduce the torque ripple from 17% to 7% without suffering the average torque.

Field Weakening Capability and Efficiency

FSWFMs have a very suitable performance in terms of flux control, as was demonstrated in [

88]. The flexible characteristic of the average torque, controllable by both the field and armature current, is one of their major advantages when compared to FSPMMs [

88]. In [

86], when rated armature current and voltage per phase are 70.7 A rms and 141.4 V rms, respectively, it was shown theoretically that FSWFMs can achieve an infinite range of speed regulation, although iron losses increase with speed. Thus, low efficiency performance is a cause for worry in EV application. FSWFMs are known to exhibit the highest efficiency among the other two wound field BSMM variants [

87].

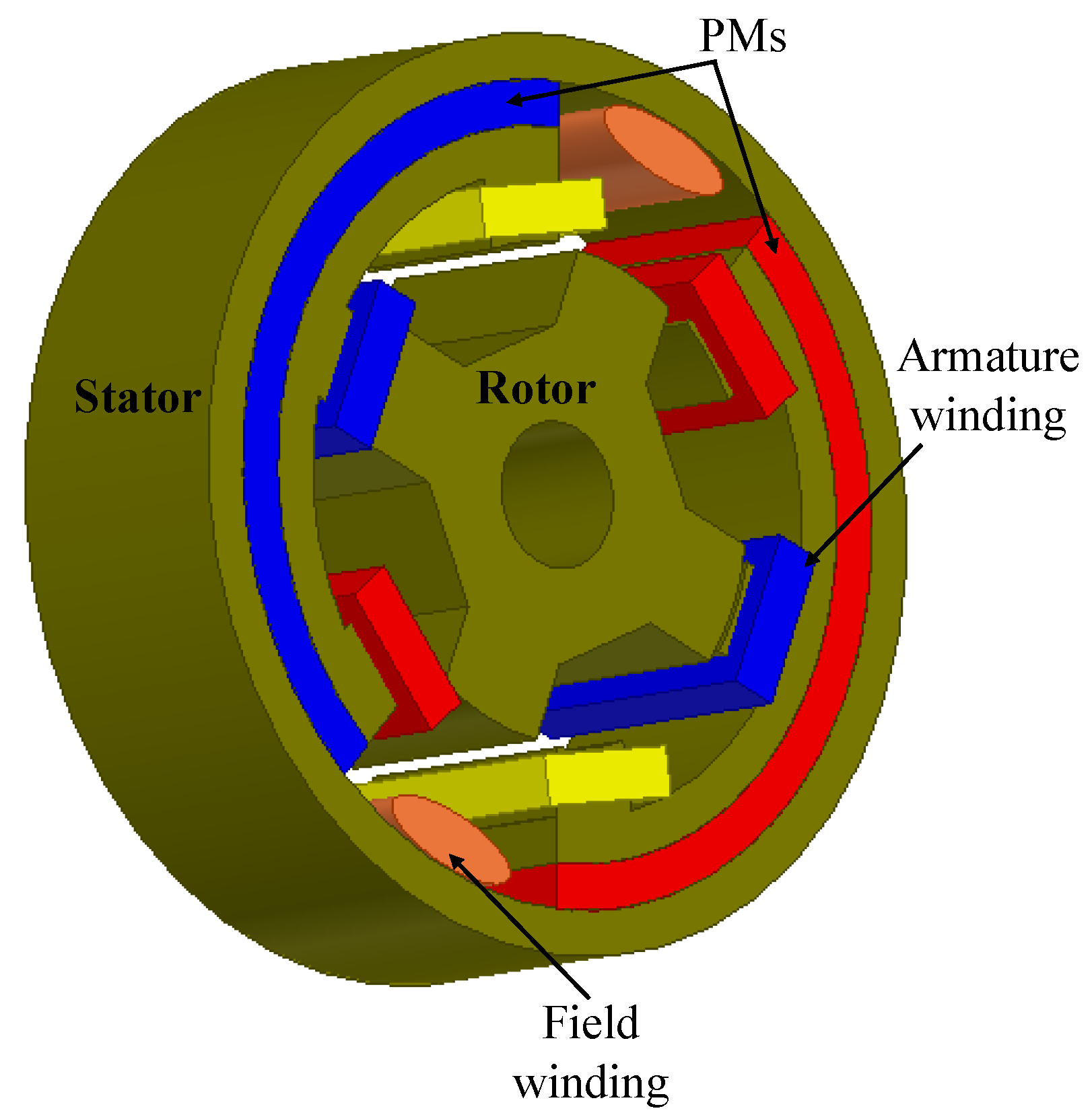

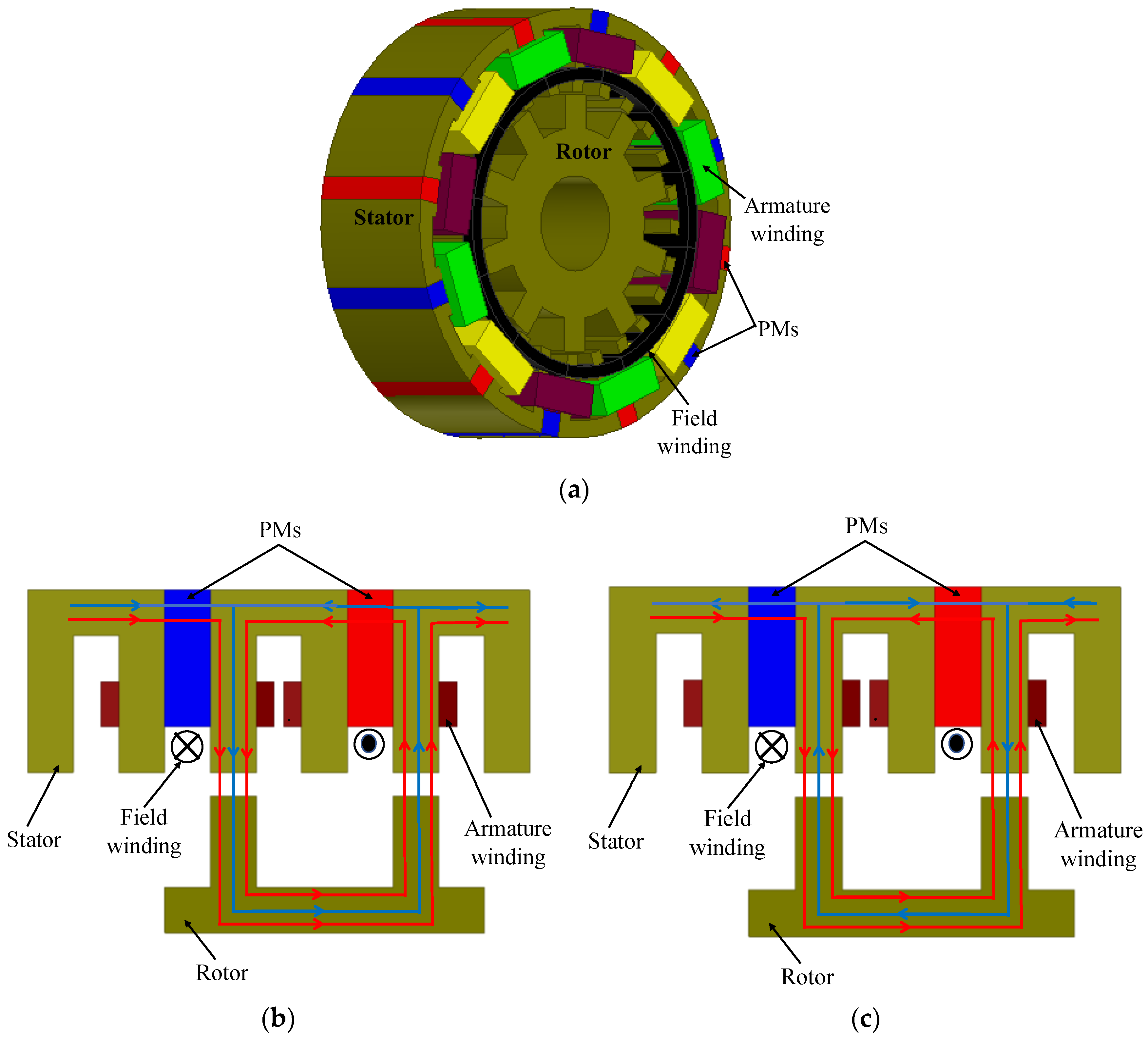

2.3.3. Flux Switching Hybrid-Excited Machine (FSHEM)

The advantages of FSPMMs, and those of FSWFMs, are unified to form a new configuration called ‘flux switching hybrid-excited machines’ (FSHEMs) [

89], as shown in

Figure 11.

Operating Principles

The operating principles of FSHEMs are shown in

Figure 11b,c [

89]. By controlling the magnitude and polarity of the applied currents of FSHEMs, the hybrid excitation function can easily be realized, whereby the airgap flux density of the machine can be strengthened or weakened as indicated in [

89].

Torque Ripple Minimization

Torque ripples cause acoustic noise, fluctuations in speed, vibration, and could also reduce the lifespan of a motor. To reduce the torque ripple, a rotor step skewing method is employed in a 6/13-pole FSHEM, where it was demonstrated that this method can reduce the cogging torque from 0.018 Nm to about 0.004 Nm, while the torque ripple reduces to 1/4th by increasing the skewing step number from 1 to 5 [

90]. However, it should be noted that the rotor skewing step number needs to be as small as possible to simplify the implementation.

Other methods of reducing cogging torque/torque ripple are variable tooth widths, auxiliary slots, and variable roto arcs, among others [

91]. The rotor skewing method remains the best option because it does not only greatly reduce the cogging torque, it also optimizes the back-EMF waveforms.

Field Weakening Capability and Efficiency

Although, FSHEMs are a good candidate for EVs, they have some drawbacks. In [

92], it was shown that due to saturation, field strengthening by means of excitation winding is almost impossible in FSHEMs if rare earth magnets are used, except with ferrite magnets.

In [

93], FSPMMs were compared with FSHEMs, and the results showed that, due to reduced PM volume, the torque and power capabilities of the FSHEM decreased compared to the FSPMM. It was also shown that flux weakening, by means of excitation winding, has less advantages compared to the negative d-axis current method because the additional excitation winding increases the complexity of the motor. Extending the speed-regulation range without a significant reduction in efficiency is one of the key challenges for FSHEMs due to additional copper loss produced by the field excitation.

Reference [

94] proposed a new control strategy for FSHEMs that can operate in both regions of flux enhancement and flux weakening. They utilize a novel feature in which the flux produced by the PMs can be inherently short-circuited through iron flux bridges. In this new strategy, the field excitation current is set to zero to avoid the copper loss of the field winding in the flux weakening region.

4. Conclusions

An overview of three main types of BSMMs—DS-BSMMs, FR-BSMMs and FS-BSMMs—have been presented in this study, with an emphasis on their different excitation modes, operation principles, performance characteristics, and development trends. To evaluate the potential of these emerging electrical machine technologies for EV application, their performance capabilities, such as torque quality, efficiency, and flux weakening capability, are revisited. Also considered was the quantitative evaluation of the BSMMs in terms of their performance characteristics in actual EV motor scenarios, comparing all three motor variants to the well-established commercial Prius-IPM motor, as well as providing insights into some emerging design trends towards the commercialization of these motors. The broad classification of the BSMMs, based on excitation modes, resulted in nine unique BSMMs, of which the main research in terms of EVs are popular with two variants of one machine type—FSPMM and FSHEM. Though random studies are evolving on the rest, others like the DSWFM, DSHEM, and FRWFM are, to the best knowledge of the authors, yet to attract any interest in EV motor drives. While both DS-BSMMs and FR-BSMMs compare less favorably with the Prius-IPM motor, FS-BSMMs exhibit the greatest potentials for EV application due to their high torque density, high efficiency, wide speed operation, and suitable fault-tolerance, among other things. However, further developments in terms of newer design structures and experimental evaluations are still needed to make the FS-BSMM a pioneering candidate for commercial EV applications.