1. Introduction

For developing countries, the price of electric vehicles is still relatively high. This is because the population of electric cars is still very small, and there are no locally produced electric vehicles. In some third countries, where electric cars still have to be imported, the prices on the road are not affordable for the lower-middle class.

One solution that can be offered is to convert conventional vehicles into electric vehicles. This method is believed to be one of the solutions for obtaining cheap electric cars. However, government regulations are, of course, needed for this.

Conversion capability can increase the bargaining power of supplying electric motor systems to established vehicle manufacturers. In addition, it can also provide an opportunity to convert used ICE vehicles into electric vehicles. Therefore, the results of this study are expected to be considered by the government to realize such regulations.

Another strategic goal is to gain independence in the manufacturing of electric cars. As we know, Indonesia is a country with a long history in vehicle manufacturing. However, for more than two decades, no local brand has emerged. The reason is that Indonesia is “locked” into only being a motor vehicle manufacturer, otherwise known as the sole agent of a brand holder. Moreover, government support for the development and growth of local vehicle manufacturers has not been fully proven. This is because the government still sees opportunity as a trader in the short term, with the lobbying of established vehicle companies and their strong influence on the government.

If this research is successful and valuable, hopefully it can be applied by other countries that are also not yet independent in their designing and manufacturing of vehicles.

This research can be considered in designing electric vehicles both for public and private cars. There have been previous studies on power systems in electric vehicles for public transportation [

1,

2]. Regarding indirect energy use factors—namely, energy charging sources that incidentally still rely on coal or diesel power plants—reducing air pollution, especially carbon dioxide, is always a challenge [

3]. In the era of electric vehicles, we hear less and less about improving vehicle performance by modifying the combustion chamber. Instead, this is achieved by adding a fuel supply, using a turbocharger, remapping the ICU, or other ways to increase compression [

4]. Other researchers have improved performance by optimizing the transmission parameters [

5].

However, electric vehicles house electric motors, batteries, converters, and motor controllers. Thus, other researchers have optimized the battery management system (BMS) into a hybrid system [

6].

There have been many outstanding reviews of converter designs. With various types of converter architectures, careful consideration is needed to determine the type, adapted to the vehicle’s character, especially in the battery and inverter parts. The stability of the converter when the battery voltage is close to the lower limit of its operating voltage is very important. An EV needs a reliable and efficient converter [

7]. The results of the review can be implemented into products if equipped with initial planning for power and road conditions (drive cycle) [

8].

In this study, an ICE vehicle was modified by replacing its engine with an electric motor. The hope was that the performance would be higher than, or at least the same as, the previous engine in terms of power and torque.

In less than a decade, regulations for the use of electric vehicles will be enacted. Indeed, the era of electric cars will not necessarily eliminate ICE vehicles. Still, if the rules state that ICE vehicles cannot be used anymore, many ICE vehicles will become carcasses. The decision to convert ICE vehicles into electric cars is one solution. Low-cost green cars (LCGCs) are small vehicles in high demand in Indonesia. The country’s large population and the possible high cost of electric cars provide the background for research on converting these vehicles into electric cars. One thing that must be considered when converting an ICE vehicle into an electric vehicle is the suitability of the power needs of the electric motor, battery, and route to be traversed. Despite the number of conversion kits on the market, this does not guarantee their suitability for our vehicles and needs. To determine their suitability, some analysis is required. Therefore, the authors tested an ICE that had been converted into an electric car. The motor and battery power were predetermined, and the test results were also used as material for verification of the electric vehicle analysis software being built.

Research on the energy needs of electric vehicles related to driving behavior is carried out in many countries, because driving habits affect a car’s energy needs as a whole. The energy requirements for electric motors are influenced by the conditions and contours of roads and traffic. The geographical location of a country influences the need for air conditioner energy, and it can be concluded that this energy requirement affects the power system design and charging costs. These parameters must be taken into account for economies of scale [

9,

10].

The short-term perspective is to be able to take advantage of ex-ICE vehicles. However, one of the long-term goals is to provide suggestions to electric vehicle regulators in Indonesia. In the future, according to this research, for urban routes in Indonesia that are congested, it will be sufficient to design electric vehicles with small power and torque. Thus, it is necessary to analyze the character of an electric motor on a proper route.

This paper is expected to facilitate the initial planning of the required electric vehicle power associated with environmental and road conditions. Furthermore, with power requirement analysis, there are essential derivatives for designing electric motors, braking systems, inverters/converters, batteries, etc.

The authors did not find any EV design software that could be used for free, although some can be downloaded and used online. Big EV companies definitely have such software; however, for commercial, copyright, and confidentiality reasons, it cannot be accessed openly.

The use of software such as MATLAB is beneficial for researchers in the EV field. However, this software requires a good understanding of programming and coding. Not all people who want to get into the EV field understand this. Thus, the purpose of making the software in this paper was to help make it easier for scientists, engineers, or practitioners to determine the power capacity, motor, and battery of electric vehicles. It is planned that this software will be installed on the University of Indonesia Research Center for Advance Vehicle’s (RCAVe) website so that anyone can use it.

2. Materials and Methods

The vehicle used was an ICE vehicle with a power of 65 HP/6000 RPM and a torque of 86 Nm/3600 RPM [

11]. The gear ratio of the car is shown in

Table 1 [

12].

The existing transmission of the vehicle was still used with the consideration that when the car is going uphill or for its first time being run, there is an option to use gears that have ample torque. In this study, the gear positions used were first, second, third, and reverse. The combination of the transmission with the motor specifications produced the maximum theoretical speed of each gear according to

Table 2. The transmission was coupled to an electric motor with a power of 7.5 kW and a rated speed of 3440 r/min. The specifications of an electric motor as a drivetrain are shown in

Table 3 [

13].

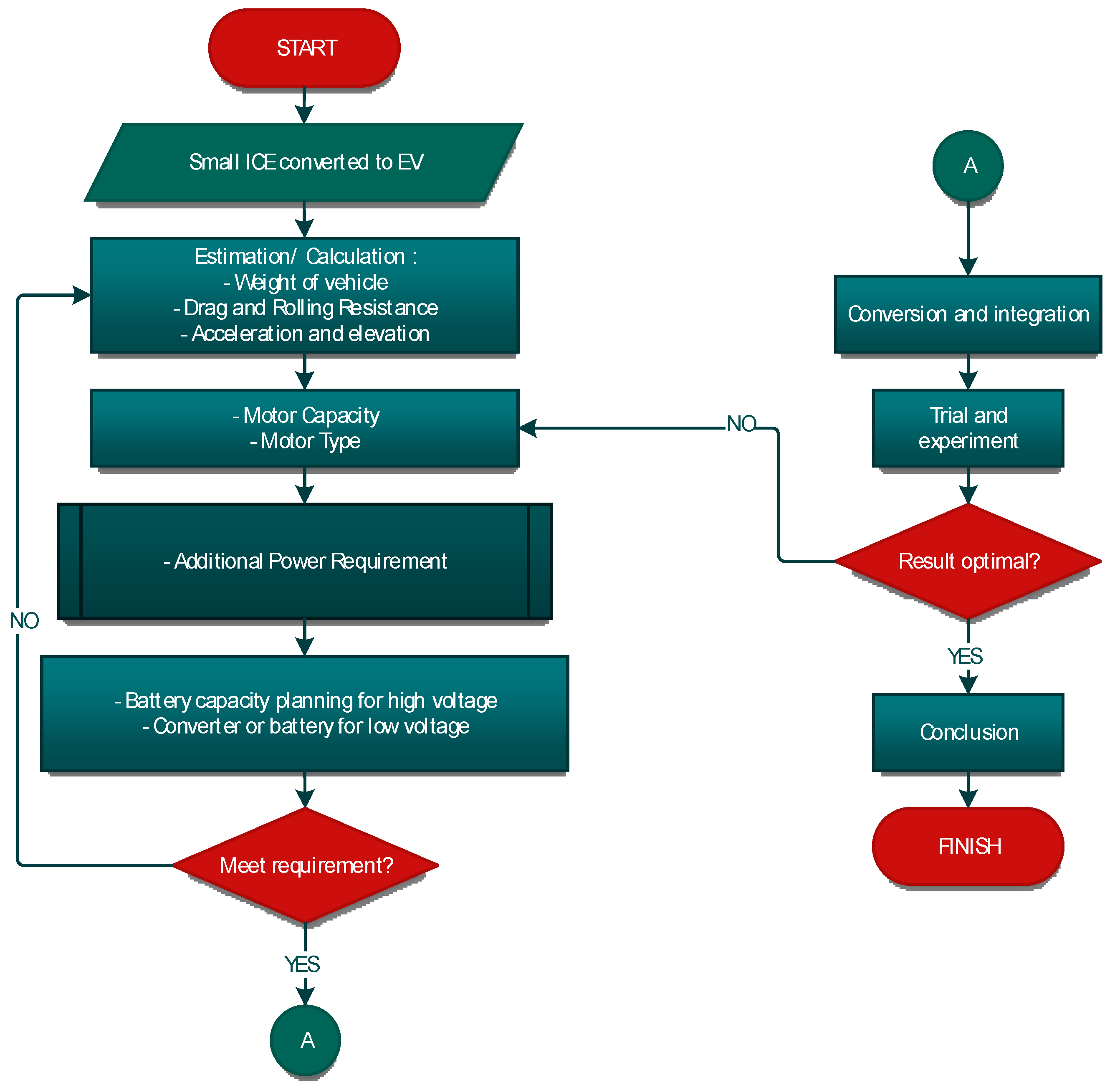

The decision to use a 7.5 kW motor resulted from calculations and analysis (

Figure 1). The experiment represents urban road routes in metropolitan cities around Jakarta, and so is not directly related to the power and torque of the converted ICE engine. Therefore, the experiment only used third gear where the maximum speed that can be achieved was less than 60 km/h. This speed is higher than the speed regulation for vehicles in the city, but can still qualify for cars driving on the highway in towns.

Meanwhile, the selection of induction motors was based on Indonesia not having adequate natural resources for magnetic materials. Only rare earth is available [

14]. Thus, it is hoped that this research can provide suggestions and further inspiration for the design and development of induction or other motors without permanent magnets.

An inverter motor was used to control the motor rotation, with a rated speed of up to 3000 rpm. This inverter has a rated output of 72 VAC 3-phase with an input of 72 VDC from the battery. The inverter specifications that were used are outlined in

Table 4.

Table 1 shows the ratio of each transmission gear only. The output from the gearbox was then coupled to the front axles with a specific ratio by shifting the gear, resulting in a system ratio. With the maximum revolutions per minute of the electric motor, combined with the system ratio, it is possible to determine the top speed for each gear position, as shown in

Table 2.

From

Table 2, we can see that by holding the gear shifter in the third position, the ratio is almost 1:6. Thus, with a motor rotation of 3440 rpm, the vehicle’s maximum speed is 58 km/h.

The speed range of the motor was between 0 and 5875 rpm (

Table 3). In comparison, the inverter was limited to 3000 rpm. Thus, the rotation of the motor could not exceed its capabilities. If the inverter torque were 22.3 Nm (

Table 4) and the system ratio 1:6, the final torque obtained would be more than 110 Nm, which is higher than Ayla’s ICE with 86 Nm of torque.

Twenty-four packs of lithium-ion batteries were used with a capability per pack of 3.2 VDC 200 AH. The batteries were connected in series so that a voltage of 76.8 VDC was obtained.

The main motor power requirement calculation is influenced by a vehicle’s weight, acceleration, aerodynamic resistance, rolling resistance, and incline angle. In addition, speed is also an influential factor. Therefore, the power requirement was formulated as follows:

With Formula (1), it can be found that the heavier the vehicle, the greater the power required. Vehicle weight consumes the most significant proportion of electrical power. This is why research related to vehicle weight is also being carried out, especially in relation to the design of the body and chassis. A lighter chassis and body and a greater strength will be of tremendous benefit [

15]. Furthermore, this will affect the determination of the battery capacity. The best electric vehicle is that with a single charge, which can travel as far as required without sacrificing the number and comfort of passengers. The goal of all of this is the achievement of suitable costs for the manufacturing and operation of electric vehicles [

16]. If not efficient, the design is considered a failure or unworthy of being marketed.

Other researchers have conducted tests on hybrid vehicles. As a result, there is a correction to the standard formula by adding coefficients [

17,

18]. Another study showed a similar research approach but did not modify the formula. Instead, it only provided a calculation of the deviation between theoretical calculations and actual measurements. This latest research also developed software to help drivers know the status of battery power usage [

19].

If the motor power capacity, maximum motor revolutions per minute, and maximum vehicle speed are set first, we can find the vehicle’s full acceleration. Then, the acceleration is calculated using Formula (2), although it is necessary to determine some parameters before using this formula, as listed in

Table 5.

As previously explained, the vehicle used for the power analysis was a Daihatsu Ayla with manual transmission. The car was converted and the ICE was replaced with an electric motor. The motor was connected to the existing manual transmission. This converter is needed to match the motor shaft with the clutch compartment in the transmission. This converter is one of the novelties of this research, which was tested for durability. The vehicle was run with the transmission set in the third gear position.

Other electrical loads such as power steering and the air conditioner were not activated, as it was deemed that the analysis should focus on the main power requirements. In the Ayla, the type of power steering used was fully electric or EPS. This type of power steering is quite efficient to apply because it only works if there is a steering movement trigger. An idle load from the hydraulic pump in the electro-hydraulic power steering type burdens the vehicle while driving. This is why this EPS was also developed for use in larger vehicles such as trucks or buses [

20].

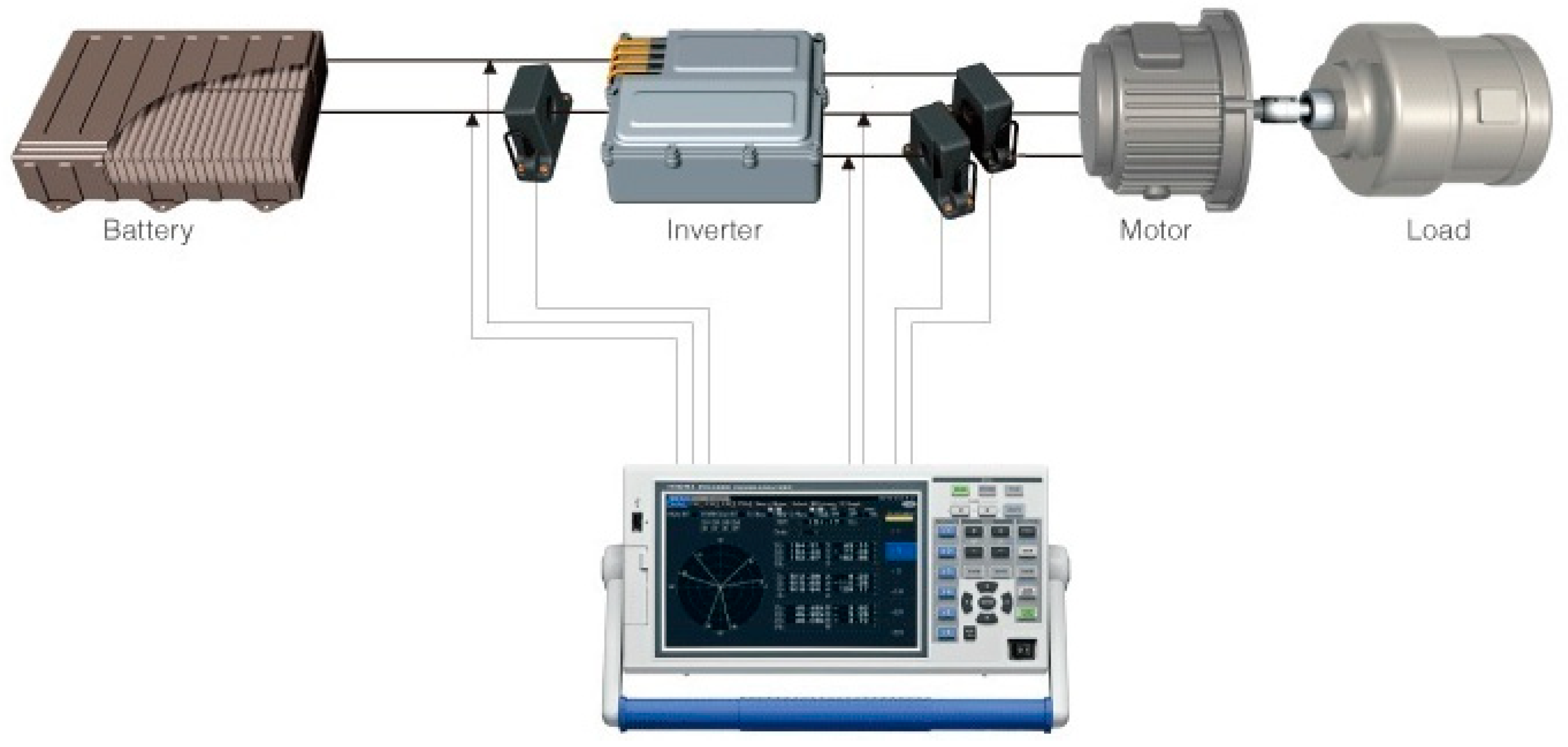

The voltage sensor was installed in parallel at the battery output and on the inverter output before entering the motor. Clamp-type current sensors were installed so that the cables passed through the clamp hole. As the battery was installed, one current sensor and two current sensors were installed at the output of the inverter before entering the motor. These sensors were plugged into their respective ports on the power analyzer, as shown in

Figure 2.

A GPS data recorder was installed on the vehicle so that the parameters of distance, speed, and elevation could be measured. These data were necessary for proof of the power analyzer measurement data. The time in power analyzer with GPS was synchronized so that incoming data could be synchronized later. The GPS tracking software used was GeoTrack.

The vehicle was tested with a passenger load of three people. A 4.4 km route was used that had the characteristics of an urban road with a few climbs and descents. The car was faced with obstacles that are common on the streets in densely populated cities in third countries. The speed was set at a limit of 50 km/h.

The haversine formula was used to determine the distance between GPS coordinates, as shown below:

The resulting value was the curved distance following the circumference of the Earth. The haversine formula is for estimating the actual diameter at each location of the Earth, which can differ. Therefore, the haversine distance can be modified by taking into account elevation or altitude to obtain a distance that is close to the actual distance. The authors believe that such modification is valid because the distance between the later GPS points was short. The actual distance approach was formulated as follows:

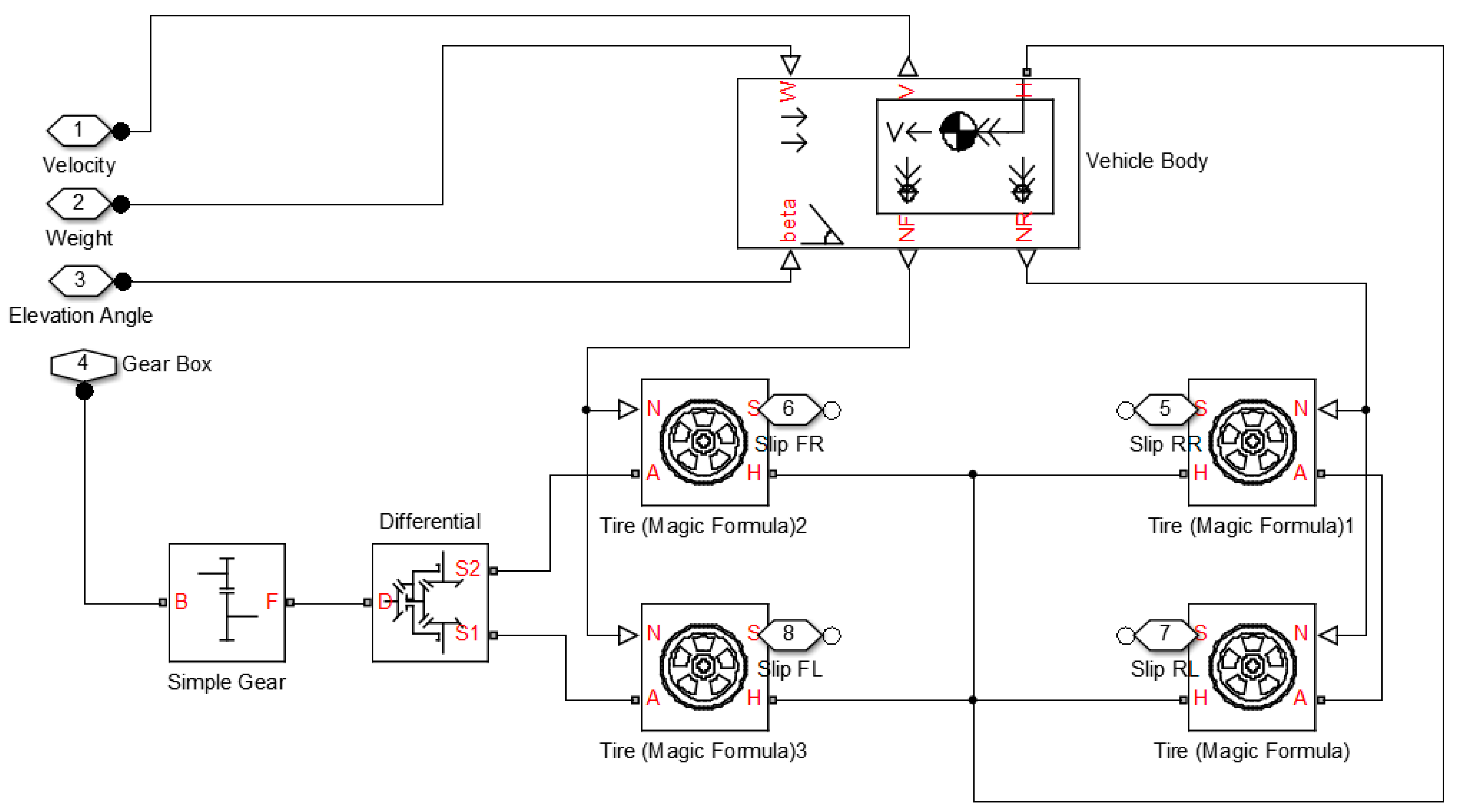

The Ayla’s vehicle body, for this test, when described with MATLAB was as shown in

Figure 2.

A block diagram is a complete visual language for scientists and engineers. As shown in

Figure 3, it provides the systematics and logic of the vehicle design, and was applied to the software analysis and design. In the vehicle body, velocity, weight, and elevation are the main parameters. Input from the powertrain is then coupled through the transmission before entering the differential. From this, the rotation is divided into wheels. In two-wheel drive vehicles, the power is transmitted to the front wheels via the trans-axle. The rolling coefficient is another crucial parameter, following Equation (1).

3. Results and Discussion

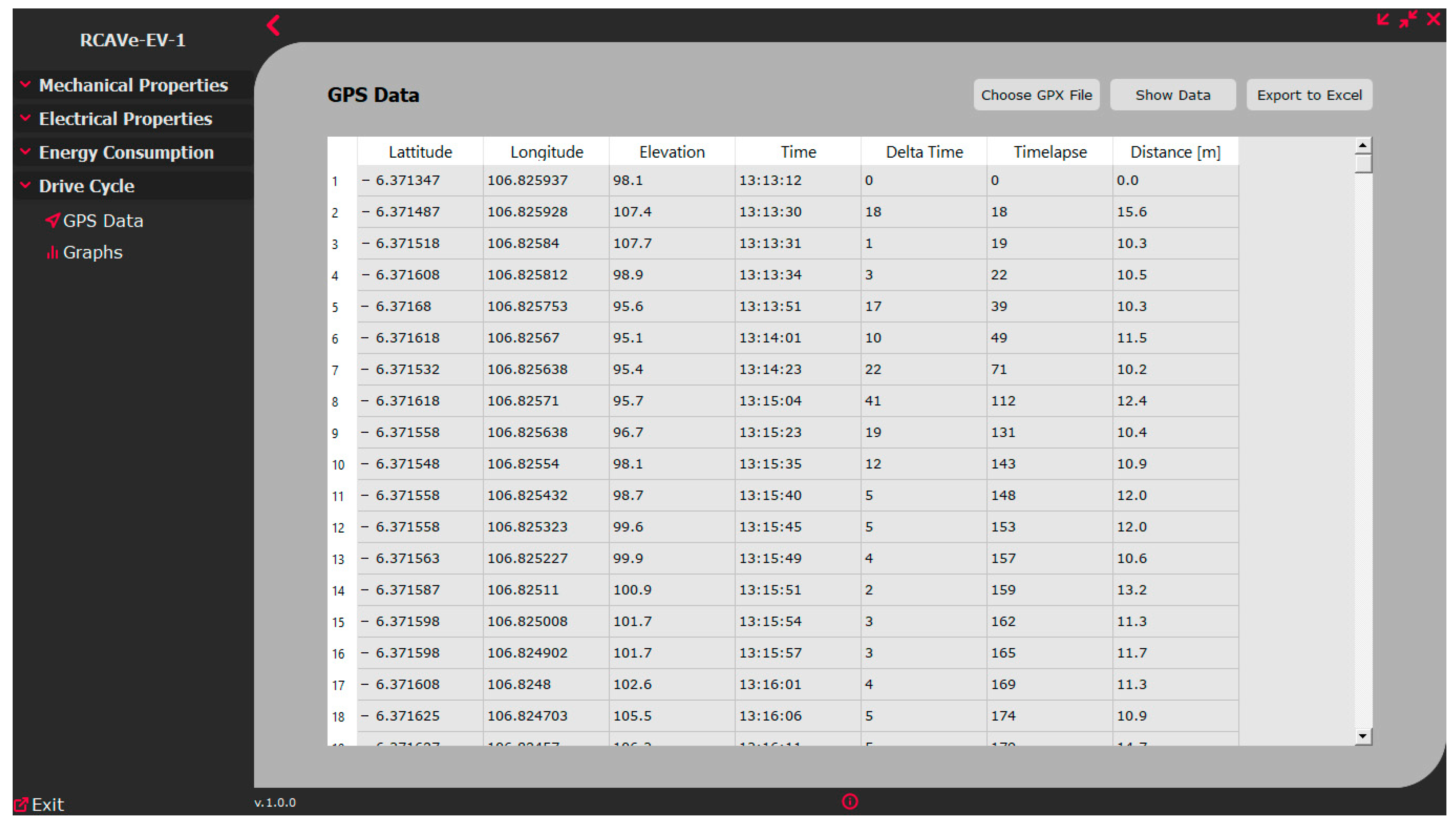

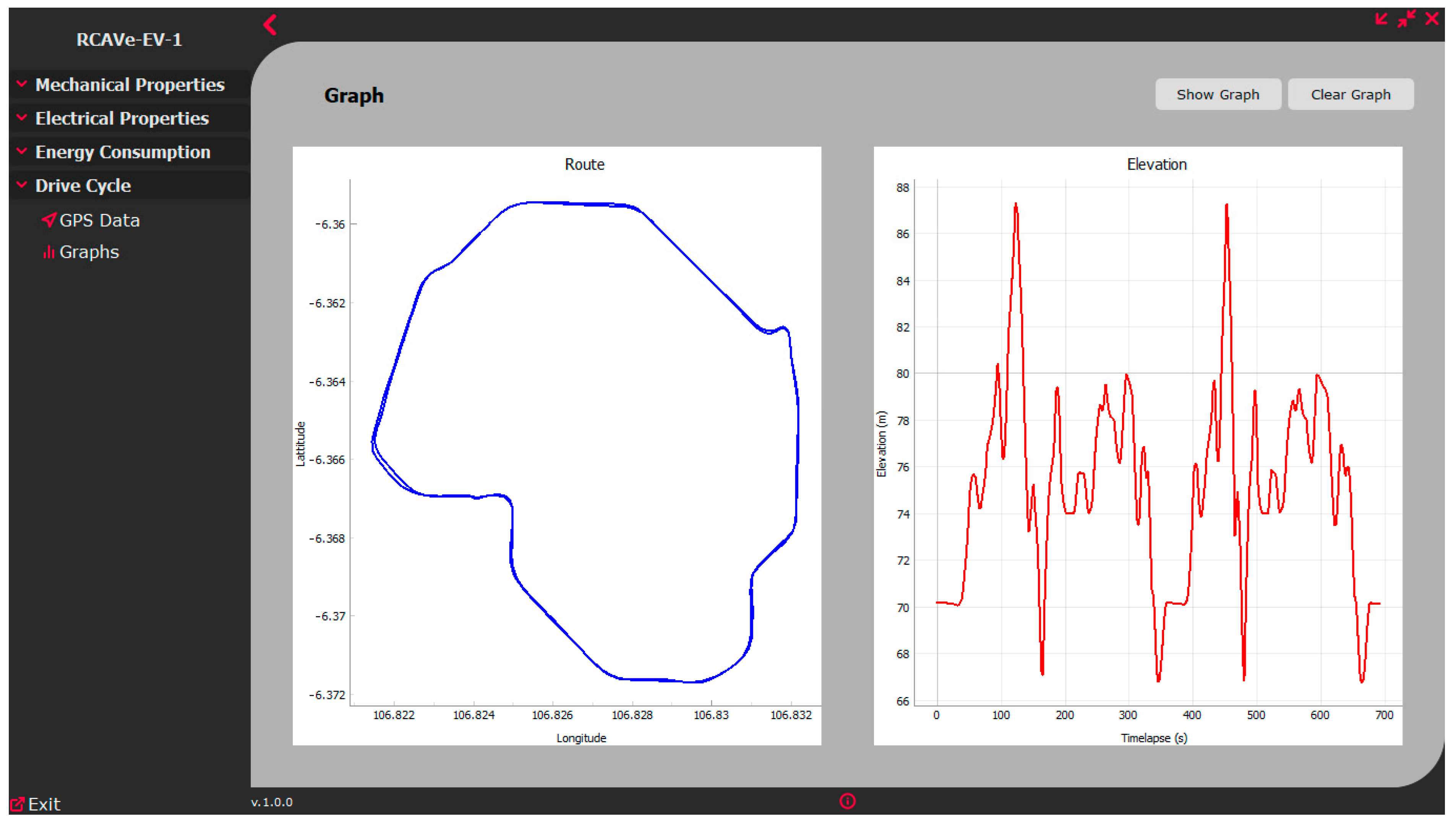

The vehicle testing was carried out in the area of the University of Indonesia. GPS data from GeoTrack were processed and remapped into a display of the route traversed by the vehicle using RCAVe-EV1 software (

Figure 4 and

Figure 5). This software analyzes the power needed by electric vehicles, and is still being developed and improved by the Mechanical Engineering Department of the University of Indonesia. In this study, the feature used in RCAVe-EV1 was the conversion of GPS data into graphs.

By inputting the vehicle parameters into the RCAVe-EV1 software, it is known that the motor capacity followed the needs of the route taken. The maximum acceleration achieved also followed the calculations on RCAVe-EV1.

These results confirm that the selected motor capacity is appropriate. In general, the vehicle’s performance was sufficient for use on the test route, which represents the route within the city. The quantitative results are discussed later.

In addition, these results also provide initial verification that the software can help in the initial planning of the required motor and battery capacity. In the future, by combining experimental testing using a power analyzer and GPS software to obtain speed, acceleration, and elevation simulation data, adequate data can be obtained for designing the capacity requirements of a motor and its battery. Furthermore, these data can also be developed to obtain the drive cycle.

The use of this software dramatically saved time and cost in the testing of the electric vehicle.

From the graphs of

Figure 5, it can be seen that the vehicle traveled routes with different elevations. Due to the limited width of the chart, the difference in elevation looks very steep, but in actuality, it is not so. The graph above used all data, including the test preparation data.

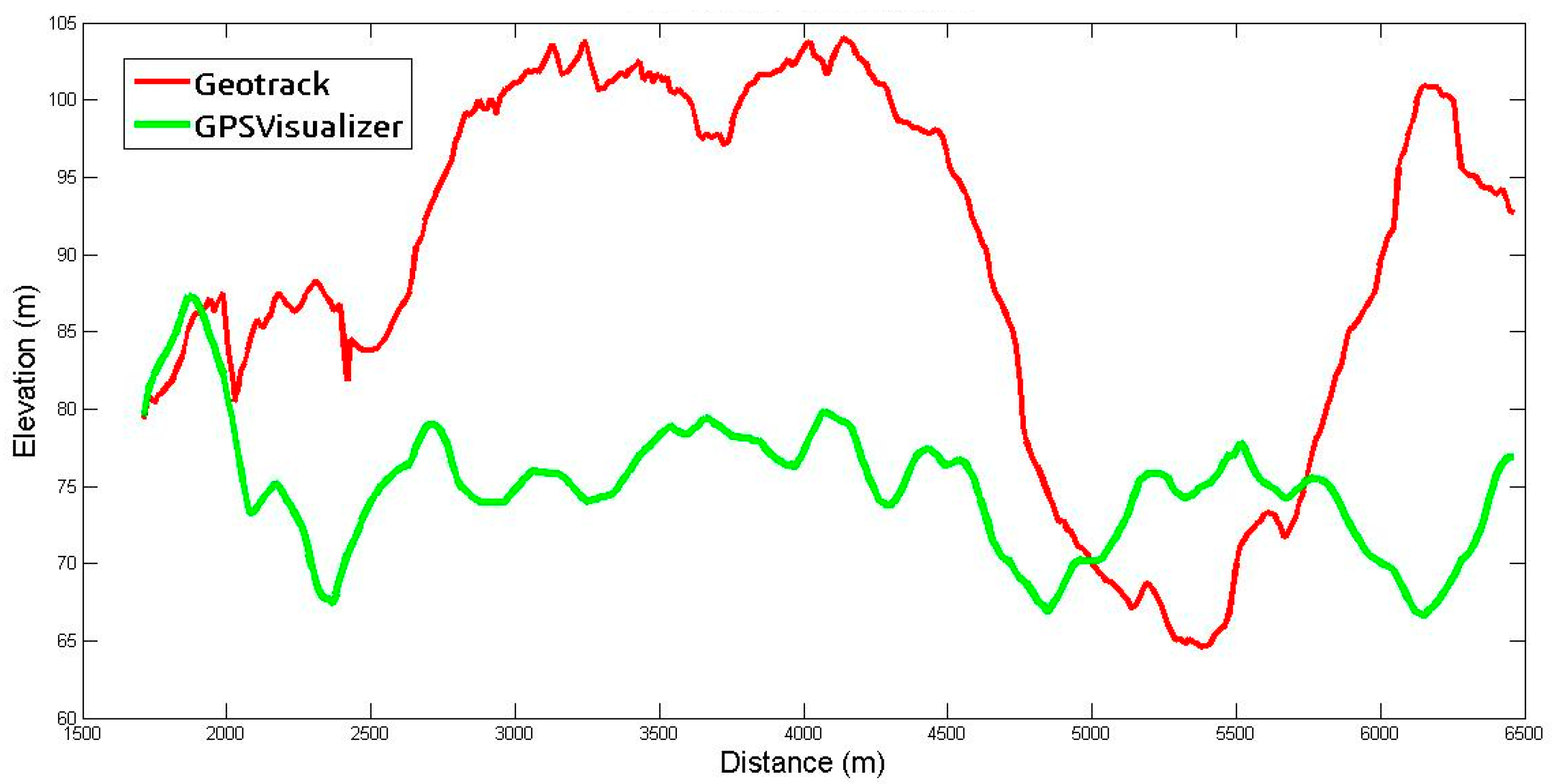

To ensure verification of the data from GeoTrack, two other software were used. As a result, for the latitude and longitude, all data demonstrated similarities. However, for elevation, the GeoTrack data were different from those of the two comparison software, namely, GPSVisualizer and Strava. Therefore, the author decided that the data to be used for the theoretical calculations were those of GPSVisualizer.

GPSVisualizer is an online software that is very helpful in finding the elevation of many point coordinates of a route. This software can also help to convert data maps, create maps, and others [

21].

Strava is a software that functions the same as GeoTrack. This software is installed on gadgets widely used by cyclists, runners, and e-bikers. This software can acquire movement data, including speed, distance, and elevation, as well as their derivatives [

22].

In

Figure 6, the data of GPSVisualizer (green line) show that the altitude range of the road being traversed was between 65 and 85 m above sea level. No uphill or downhill path was too extreme. These results solve the problem of unreasonable power requirement calculation results using RCAVe-EV1. The elevation reading errors significantly affected the power and torque requirements when climbing.

Figure 6 displays an elevation chart with a mileage comparison. These data (green line) also corrected and verified the error when calculating the elevation angle using RCAVe-EV1. The elevation angle is the ratio between the elevation and distance traveled per point read by the sensor and recorded by the data logger.

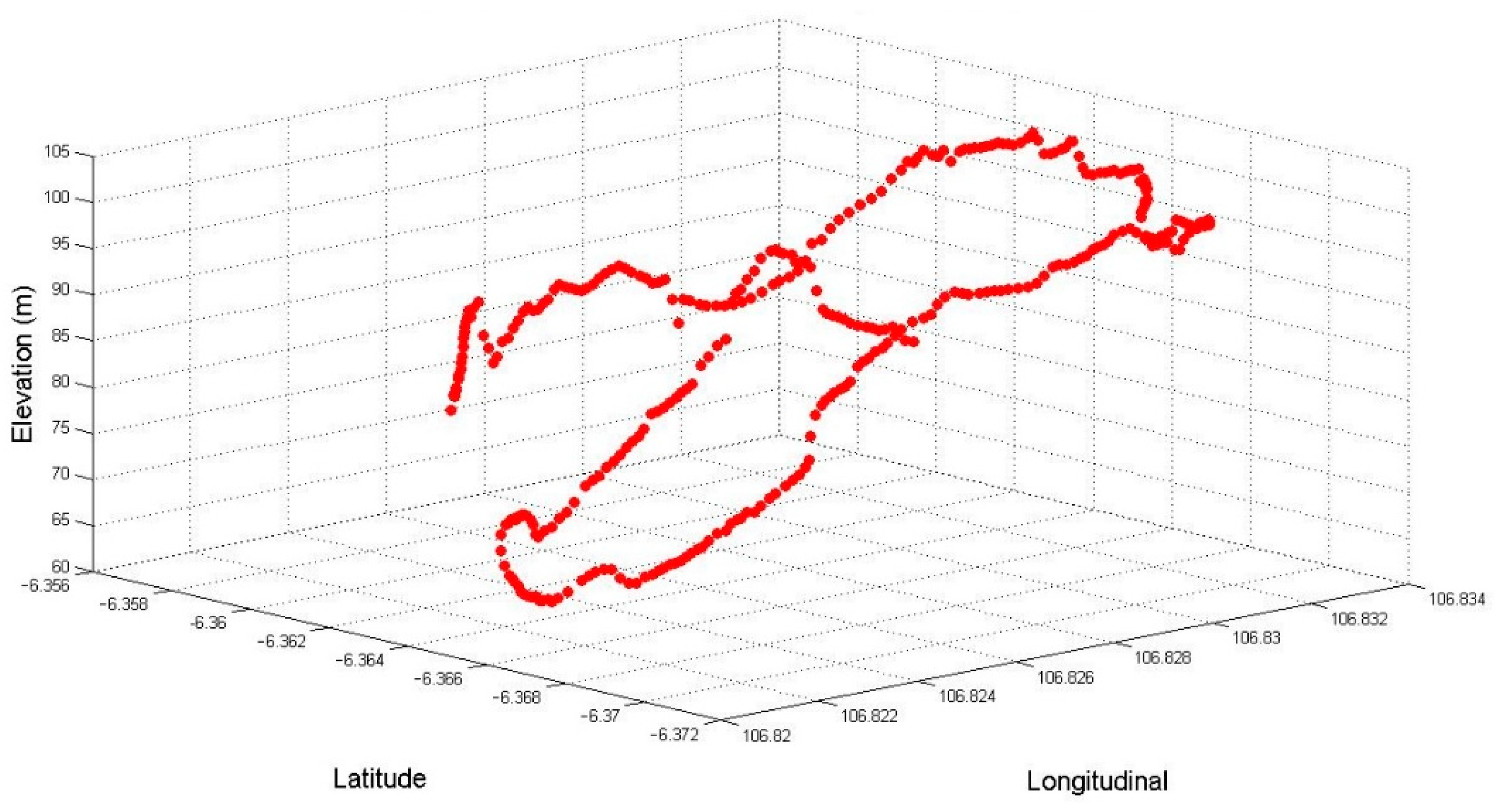

As a comparison, the data were processed using MATLAB with the results, as shown in

Figure 7, indicating the relationship between latitude, longitudinal, and elevation.

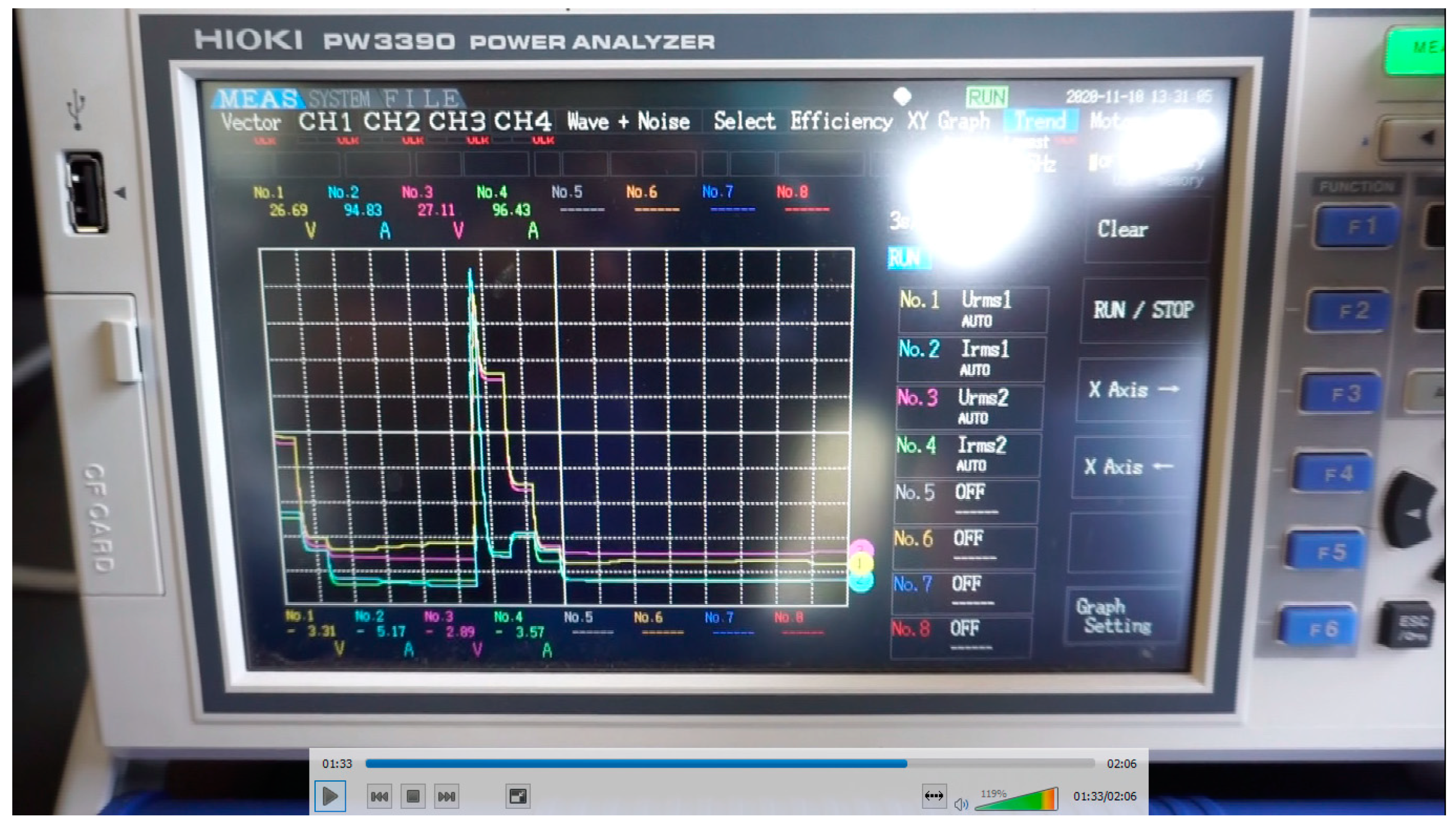

The measurement and data acquisition of energy use during the test were achieved using the power analyzer (

Figure 8), which is specifically designed for applications in electric vehicles. In addition to the data recorded and acquired during the test, we also monitored it second-by-second through the monitor. The primary data obtained were the current and voltage. Simultaneously, GPS was acquired from longitudinal, latitude, elevation, distance, speed, and others.

Data from the power analyzer and GPS were synchronized and further processed to obtain research conclusions.

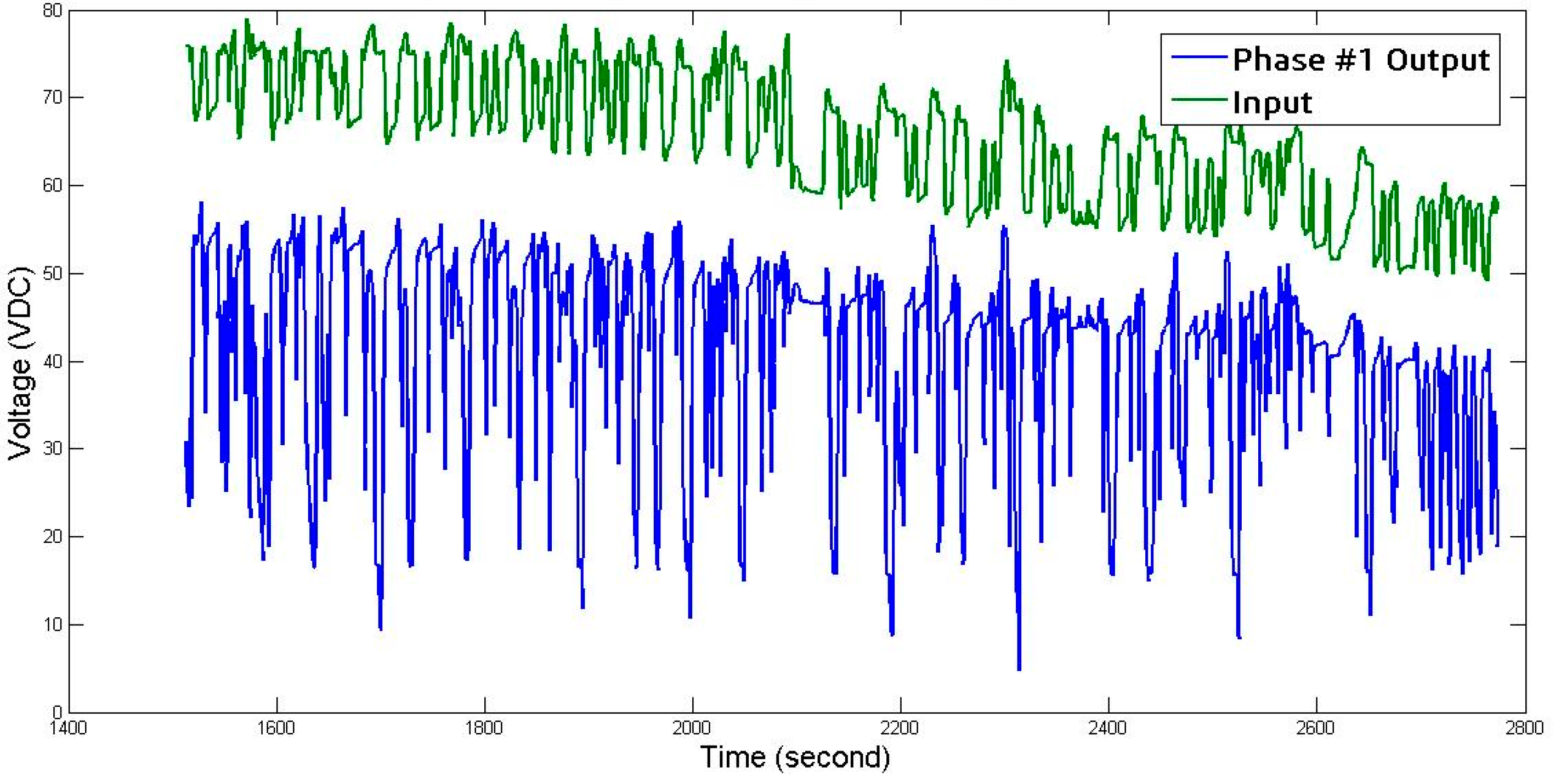

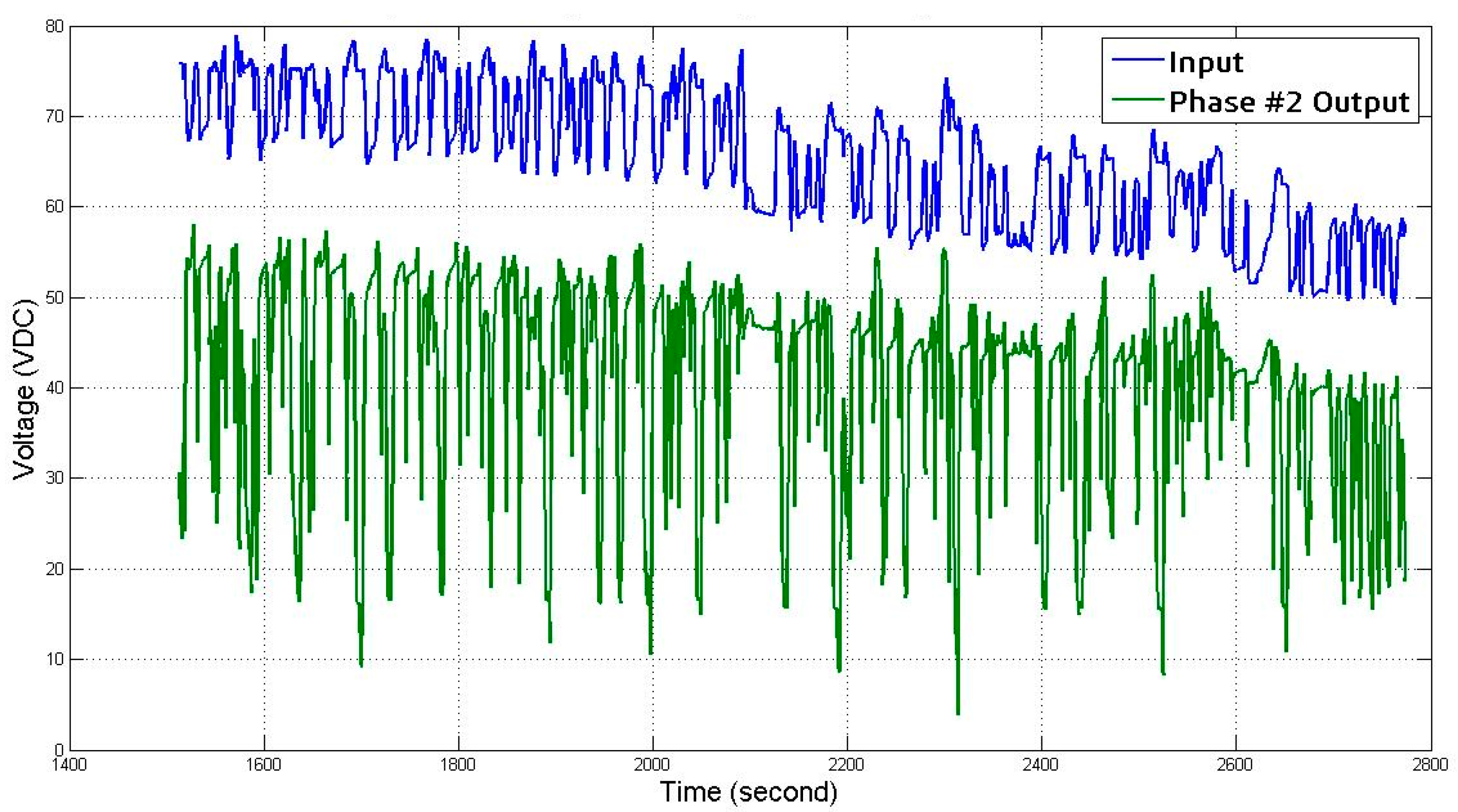

The voltage drop trend was obtained from the voltage and current data processing results, as presented in

Figure 9 and

Figure 10. This decrease is normal for vehicles with battery energy sources.

From these graphs, it can be seen how efficient the system built on the test electric vehicle is. Of course, efficiency depends on the quality of the motor, controller, cables, and the selected high-voltage class.

Figure 8 shows data acquired when the SoC (state of charge) of the battery was around 90%, starting from the 1500th second to the 2800th second. The starting voltage was almost 80 VDC. After more than 20 min of running, the voltage reduced to approximately 50 VDC. The distance covered was approximately 4.4 km.

Figure 9, which displays data from phase #2, shows results that are in line with phase #1. These data also validate the voltage sensor installed on the battery output cable and motor input cable.

Figure 11 shows the voltage drop during the vehicle’s test run. Until the 2700th second, the voltage was still sufficient to provide energy to the inverter to be transmitted to the motor. The current issue was relatively the same or stable. A current below zero indicates an attempt by the motor to become a generator (regenerative), which is read by the current sensor. However, this current does not recharge the battery, because the vehicle is not equipped with a generator or regenerative system.

The vehicle was able to run on the specified test route at the desired speed. Due to the voltage drop, logically and theoretically, the power generated decreased. In other words, the power and battery capacity decreased. When the voltage reached the minimum voltage required by the inverter, the motor was no longer able to drive the vehicle. It is a fact that at a voltage up to approximately 50 VDC, an inverter can still drive a motor.

In

Figure 12, we can see a graph of the voltage drop compared to the accumulated clock current used. The chart of accumulated current hours is close to linear form.

From the experimental results, during acceleration, a large current was required. The amount of current can reach three times the rate of the converter and electric motor. Therefore, current surges are unavoidable, must be accommodated, and are common in electric vehicles.

The surge current can be set or limited by the battery management system, taking into consideration the ability of the battery, converter, and motor. On the battery side, current surges or over-discharge can cause battery swelling, electrolyte leakage, smoke, fire, and even an explosion [

23].

In the era of electric vehicles, the demand for electricity from the grid will increase. Therefore, in-depth analysis and research are needed to overcome power surges when many electric cars are charging. Furthermore, the policy to limit the power of electric vehicles is strategic. Thus, electric vehicles not only contribute to a green environment, but also save energy [

24].

4. Conclusions

The first contribution of this paper is helping researchers determine the right powertrain for road and traffic conditions, the vehicle is not only environmentally friendly, but also energy efficient. Efficiency comparisons should not only involves comparing EVs with ICEs, but also EVs and other EVs.

The second contribution involves illustrating to the government and the automotive industry that their investments thus far will not be in vain. The existing vehicle designs are still very relevant and can be developed into electric vehicles. In general, of all current vehicle designs, only the ICE part is missing, which is replaced by an electric motor.

The third contribution is the provision of an overview to researchers of batteries, inverters, converters, electric ACs, and EPS regarding the importance of designing the right proportion of power to support the cruising range, comfort, and efficiency of EVs.

From the test results, it can be concluded that a 7.5 KW electric motor is able to drive a vehicle properly. With a system ratio of approximately 1:5, a car can travel at a maximum speed of 58 km/h. The ratio and speed were obtained in gear shift 3. However, the ability of the battery used was still minimal. At less than 50% DoD, the battery could barely provide any more energy.

With these results, it is projected that a vehicle can cover a distance of 50 km in one charge. Regarding convenience, this will be discussed in a separate paper, where ir is related to the presence of batteries, whose placement must be considered so that passengers remain comfortable, the vehicle’s center of gravity remains ideal, and safety is maintained.

Motor power and torque can be recommended for a small four-passenger vehicle for daily use in the city with a maximum speed of less than 60 km/h. For the record, the test did not include activation of the air conditioner and power steering, or regenerative braking. The cost of the conversion, as well as the necessary materials, of this vehicle was around thirty million rupiahs, or approximately a quarter of the price of the vehicle.

Apart from the battery, the inverter and motor to transmission converter functioned very well.

The authors realize that there is still much to be improved in this research, including the limited materials and resources. Research can be continued by adding a torque sensor. Thus, the efficiency of torque and mechanical power with electric power can be further analyzed.

Then, to make the time synchronization more accurate, the power, voltage, and current data collector must be integrated with GPS. The tool can also be implemented with a gear position sensor.

Further research should include activating all devices that require electricity, specifically air conditioning and power steering. If this comprehensive test is to be carried out, the number of voltage and current sensors must be increased.

After the prototype is successful, research should test the durability of the vehicle.