Research on the Influence of Collector Microstructure on the Performance of PEM Electrolyzer

Abstract

:1. Introduction

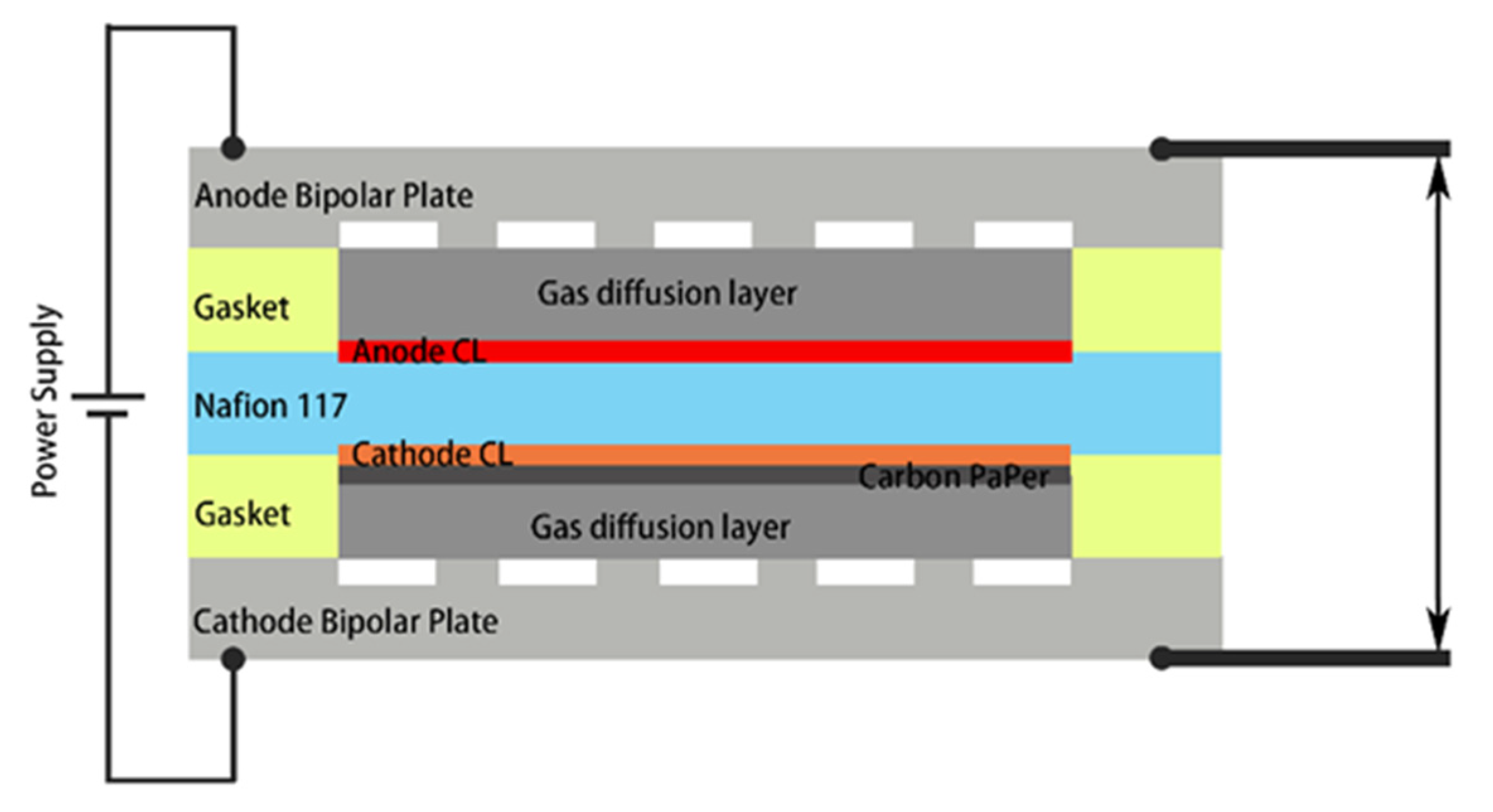

2. Materials and Methods

2.1. Preparation

2.2. Experimental Process

3. Results

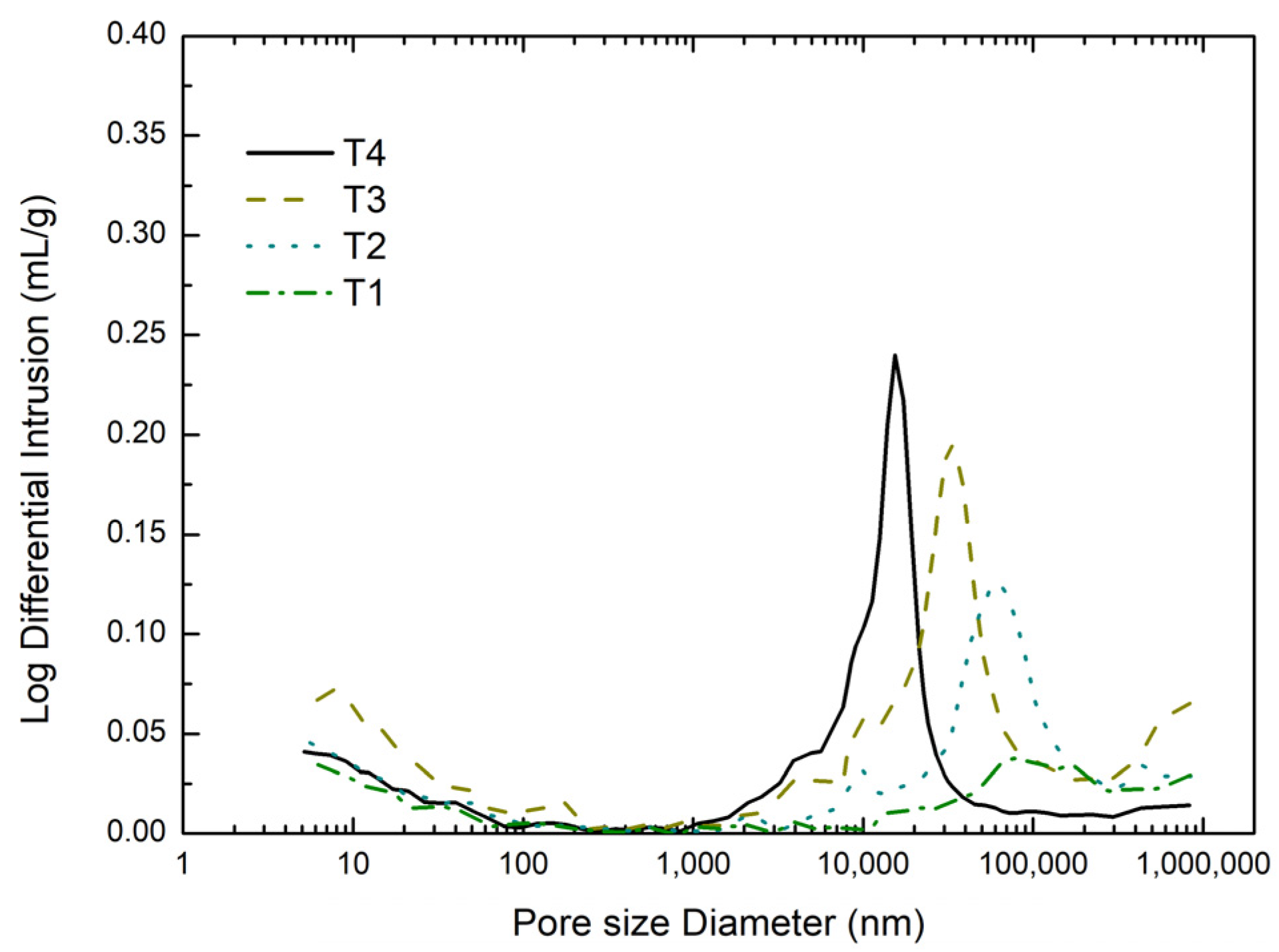

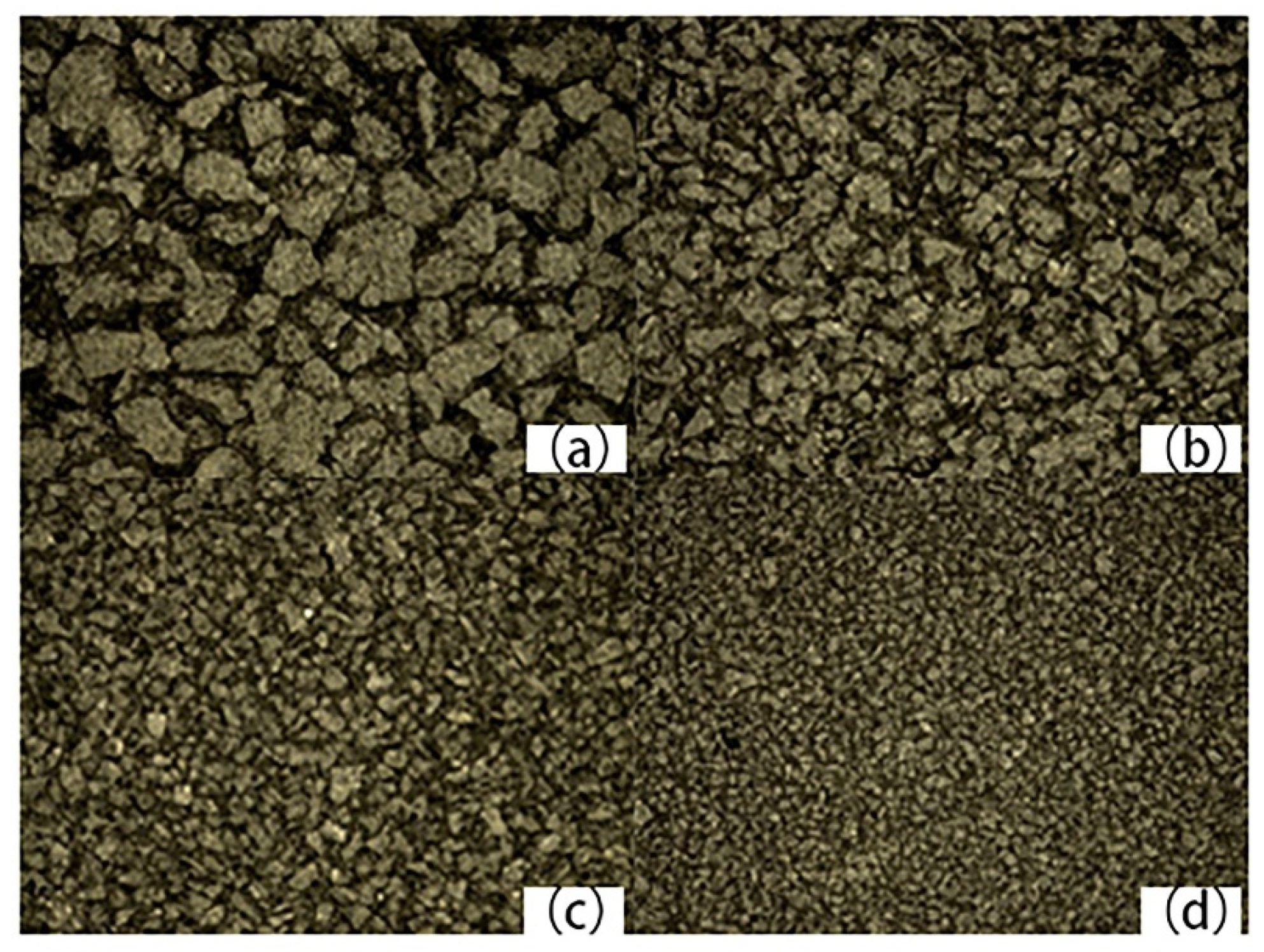

3.1. Characterization of Titanium Plate

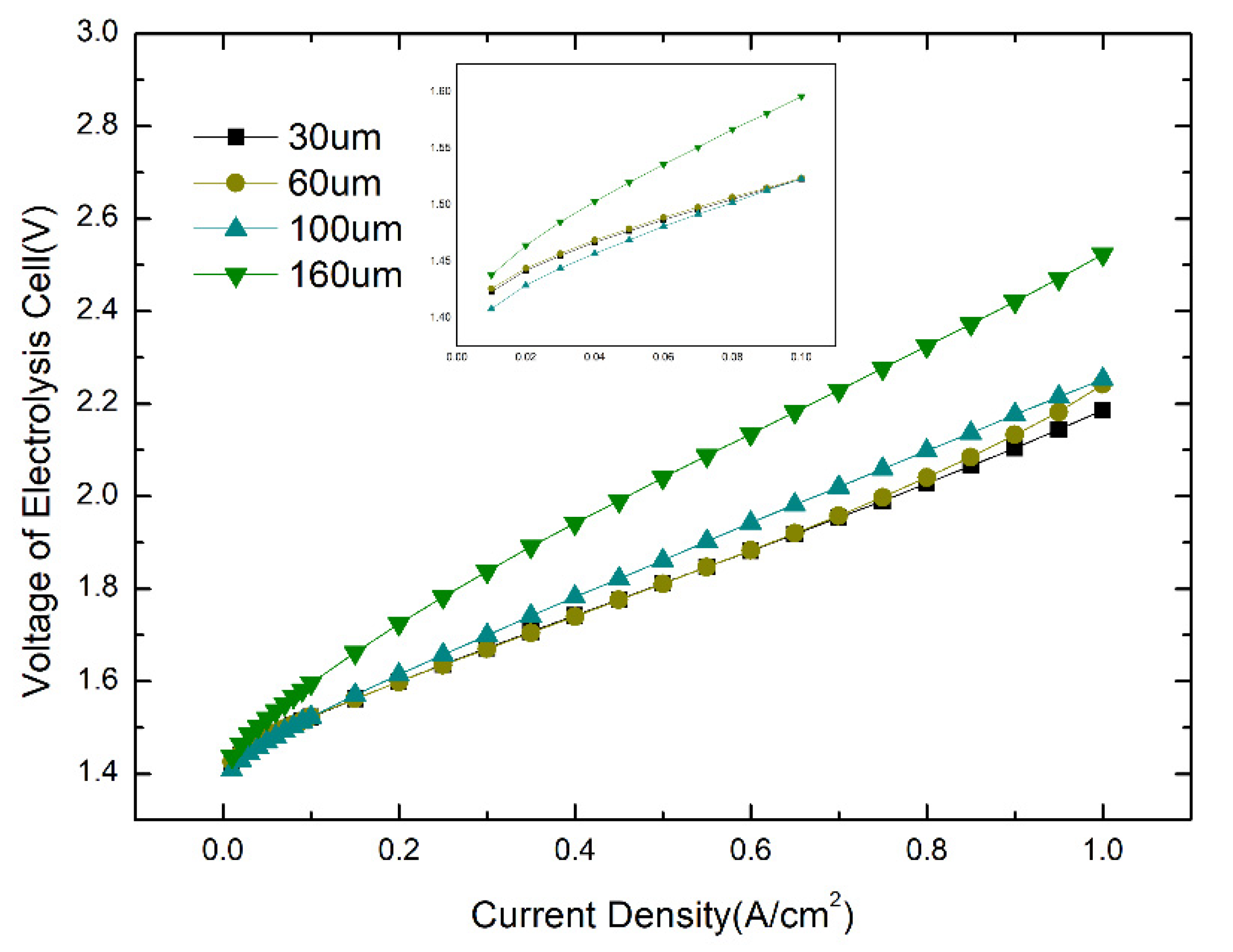

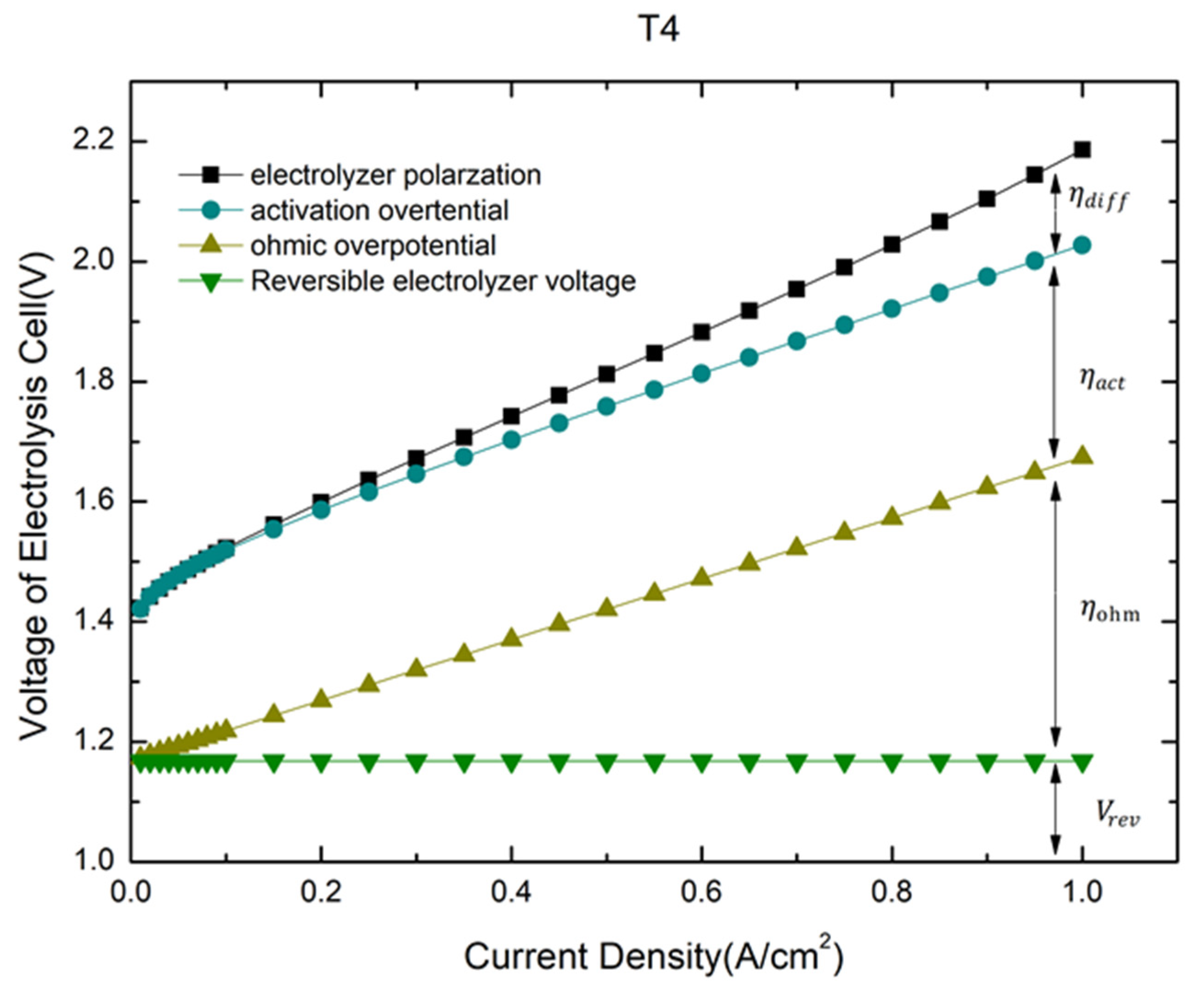

3.2. Electrolytic Cell Performance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dawood, F.; Anda, M.; Shafiullah, G. Hydrogen production for energy: An overview. Int. J. Hydrog. Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Alanne, K.; Cao, S. An overview of the concept and technology of ubiquitous energy. Appl. Energy 2019, 238, 284–302. [Google Scholar] [CrossRef]

- Nemitallah, M.; Imteyaz, B.; Abdelhafez, A.; Habib, M.A. Experimental and computational study on stability characteristics of hydrogen-enriched oxy-methane premixed flames. Appl. Energy 2019, 250, 433–443. [Google Scholar] [CrossRef]

- Ripple, W.; Wolf, C.; Newsome, T.; Galetti, M.; Alamgir, M.; Crist, E.; Ibrahim-Mahmoud, M.; Laurance, W. World scientists’ warning to humanity: A second notice. Bioscience 2017, 67, 1026–1028. [Google Scholar] [CrossRef]

- Tarhan, C.; Çil, M.A. A study on hydrogen, the clean energy of the future: Hydrogen storage methods. J. Energy Storage 2021, 40, 102676. [Google Scholar] [CrossRef]

- Yang, J.; Sudik, A.; Wolverton, C.; Siegel, D. High capacity hydrogen storage materials: Attributes for automotive applications and techniques for materials discovery. Chem. Soc. Rev. 2010, 39, 656–675. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Okolie, J.A.; Patra, B.R.; Mukherjee, A.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Futuristic applications of hydrogen in energy, biorefining, aerospace, pharmaceuticals and metallurgy. Int. J. Hydrog. Energy 2021, 46, 8885–8905. [Google Scholar] [CrossRef]

- Nath, K.; Das, D. Modeling and optimization of fermentative hydrogen production. Bioresour. Technol. 2011, 102, 8569–8581. [Google Scholar] [CrossRef]

- Pethaiah, S.S.; Sadasivuni, K.K.; Jayakumar, A.; Ponnamma, D.; Tiwary, C.S.; Sasikumar, G. Methanol Electrolysis for Hydrogen Production Using Polymer Electrolyte Membrane: A Mini-Review. Energies 2020, 13, 5879. [Google Scholar] [CrossRef]

- Bhawna; Sharma, S. Metal based catalysts for hydrogen production reactions. Mater. Today Proc. 2021, 2–6. [Google Scholar] [CrossRef]

- Ayers, K. High efficiency PEM water electrolysis: Enabled by advanced catalysts, membranes, and processes. Curr. Opin. Chem. Eng. 2021, 33, 100719. [Google Scholar] [CrossRef]

- Qyyum, M.A.; Dickson, R.; Shah, S.F.A.; Niaz, H.; Khan, A.; Liu, J.J.; Lee, M. Availability, versatility, and viability of feedstocks for hydrogen production: Product space perspective. Renew. Sustain. Energy Rev. 2021, 145, 110843. [Google Scholar] [CrossRef]

- Kirk, D.W.; Thorpe, S.J.; Suzuki, H. Ni-base amorphous alloys as electrocatalysts for alkaline water electrolysis. Int. J. Hydrog. Energy 1997, 22, 493–500. [Google Scholar] [CrossRef]

- Holladay, J.D.; Hu, J.; King, D.L.; Wang, Y. An overview of hydrogen production technologies. Catal. Today 2009, 139, 244–260. [Google Scholar] [CrossRef]

- Grigoriev, S.; Porembsky, V.; Fateev, V. Pure hydrogen production by PEM electrolysis for hydrogen energy. Int. J. Hydrog. Energy 2006, 31, 171–175. [Google Scholar] [CrossRef]

- Anwar, S.; Khan, F.; Zhang, Y.; Djire, A. Recent development in electrocatalysts for hydrogen production through water electrolysis. Int. J. Hydrog. Energy 2021, 46, 32284–32317. [Google Scholar] [CrossRef]

- Ito, H.; Maeda, T.; Nakano, A.; Hwang, C.M.; Ishida, M.; Kato, A.; Yoshida, T. Experimental study on porous current collectors of PEM electrolyzers. Int. J. Hydrog. Energy 2012, 37, 7418–7428. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.; Witteman, L.; Wrubel, J.A.; Bender, G. A comprehensive modeling method for proton exchange membrane electrolyzer development. Int. J. Hydrog. Energy 2021, 46, 17627–17643. [Google Scholar] [CrossRef]

- Rahim, A.H.A.; Tijani, A.S.; Kamarudin, S.; Hanapi, S. An overview of polymer electrolyte membrane electrolyzer for hydrogen production: Modeling and mass transport. J. Power Sources 2016, 309, 56–65. [Google Scholar] [CrossRef]

- Lafmejani, S.S.; Olesen, A.C.; Kær, S.K. VOF modelling of gas–liquid flow in PEM water electrolysis cell micro-channels. Int. J. Hydrog. Energy 2017, 42, 16333–16344. [Google Scholar] [CrossRef] [Green Version]

- Fritz, D.L.; Mergel, J.; Stolten, D. PEM Electrolysis Simulation and Validation. ECS Trans. 2014, 58, 1–9. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, Y.; Yang, F.; Xu, H. Two-dimensional multi-physics modeling of porous transport layer in polymer electrolyte membrane electrolyzer for water splitting. Int. J. Hydrog. Energy 2020, 45, 32984–32994. [Google Scholar] [CrossRef]

- Dedigama, I.; Angeli, P.; Ayers, K.; Robinson, J.; Shearing, P.; Tsaoulidis, D.; Brett, D. In situ diagnostic techniques for characterisation of polymer electrolyte membrane water electrolysers-Flow visualisation and electrochemical impedance spectroscopy. Int. J. Hydrog. Energy 2014, 39, 4468–4482. [Google Scholar] [CrossRef]

- Kúš, P.; Ostroverkh, A.; Khalakhan, I.; Fiala, R.; Kosto, Y.; Šmíd, B.; Lobko, Y.; Yakovlev, Y.; Novakova, J.; Matolínová, I.; et al. Magnetron sputtered thin-film vertically segmented Pt-Ir catalyst supported on TiC for anode side of proton exchange membrane unitized regenerative fuel cells. Int. J. Hydrog. Energy 2019, 44, 16087–16098. [Google Scholar] [CrossRef]

- Wu, H.-W. A review of recent development: Transport and performance modeling of PEM fuel cells. Appl. Energy 2016, 165, 81–106. [Google Scholar] [CrossRef]

- Grigoriev, S.; Millet, P.; Volobuev, S.; Fateev, V. Optimization of porous current collectors for PEM water electrolysers. Int. J. Hydrog. Energy 2009, 34, 4968–4973. [Google Scholar] [CrossRef]

- Shaddad, M.N.; Arunachalam, P.; Hezam, M.; Al-Saeedan, N.M.; Gimenez, S.; Bisquert, J.; Al-Mayouf, A.M. Unprecedented solar water splitting of dendritic nanostructured Bi2O3 films by combined oxygen vacancy formation and Na2MoO4 doping. Int. J. Hydrog. Energy 2021, 46, 23702–23714. [Google Scholar] [CrossRef]

- Wrubel, J.A.; Kang, Z.; Witteman, L.; Zhang, F.-Y.; Ma, Z.; Bender, G. Mathematical modeling of novel porous transport layer architectures for proton exchange membrane electrolysis cells. Int. J. Hydrog. Energy 2021, 46, 25341–25354. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, X.; Shuai, S.; Qin, Y.; Yang, J. Effect of micro-porous layer on PEM fuel cells performance: Considering the spatially variable properties. Int. J. Heat Mass Transf. 2021, 178, 121592. [Google Scholar] [CrossRef]

- Wu, M.; Xu, S.; Li, X.; Zhang, T.; Lv, Z.; Li, Z.; Li, X. Pore regulation of wood-derived hierarchical porous carbon for improving electrochemical performance. J. Energy Storage 2021, 40, 102663. [Google Scholar] [CrossRef]

- Ito, H.; Maeda, T.; Nakano, A.; Kato, A.; Yoshida, T. Influence of pore structural properties of current collectors on the performance of proton exchange membrane electrolyzer. Electrochim. Acta 2013, 100, 242–248. [Google Scholar] [CrossRef]

| Titanium Plate | Median Pore Diameter (um) | Thickness (mm) | |

|---|---|---|---|

| T1 | 52.1 | 28.8005 | 1 |

| T2 | 47.4 | 46.1398 | 1 |

| T3 | 25.4 | 62.9010 | 1 |

| T4 | 12.3 | 49.2385 | 1 |

| Titanium Plate | Ohmic Impedance | Charge Transfer Impedance | Conductivity |

|---|---|---|---|

| T1 | 0.656 | 0.112 | 0.1524 |

| T2 | 0.604 | 0.093 | 0.1657 |

| T3 | 0.546 | 0.121 | 0.1832 |

| T4 | 0.506 | 0.099 | 0.1976 |

| Titanium Plate | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| T4 | 1.168 | 53.87 | 0.506 | 23.15 | 0.353 | 16.15 | 0.159 | 7.27 | 2.186 |

| T3 | 1.168 | 54.27 | 0.546 | 24.35 | 0.348 | 15.52 | 0.180 | 8.03 | 2.242 |

| T2 | 1.168 | 51.84 | 0.604 | 26.81 | 0.352 | 15.62 | 0.129 | 5.73 | 2.253 |

| T1 | 1.168 | 46.29 | 0.656 | 26.00 | 0.453 | 17.95 | 0.246 | 9.75 | 2.523 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, W.; Wang, S.; Sun, Y.; Lv, H.; Shen, X.; Zhang, C. Research on the Influence of Collector Microstructure on the Performance of PEM Electrolyzer. World Electr. Veh. J. 2021, 12, 165. https://doi.org/10.3390/wevj12040165

Ji W, Wang S, Sun Y, Lv H, Shen X, Zhang C. Research on the Influence of Collector Microstructure on the Performance of PEM Electrolyzer. World Electric Vehicle Journal. 2021; 12(4):165. https://doi.org/10.3390/wevj12040165

Chicago/Turabian StyleJi, Wenxuan, Sen Wang, Yongwen Sun, Hong Lv, Xiaojun Shen, and Cunman Zhang. 2021. "Research on the Influence of Collector Microstructure on the Performance of PEM Electrolyzer" World Electric Vehicle Journal 12, no. 4: 165. https://doi.org/10.3390/wevj12040165

APA StyleJi, W., Wang, S., Sun, Y., Lv, H., Shen, X., & Zhang, C. (2021). Research on the Influence of Collector Microstructure on the Performance of PEM Electrolyzer. World Electric Vehicle Journal, 12(4), 165. https://doi.org/10.3390/wevj12040165