Oil Friction Loss Evaluation of Oil-Immersed Cooling In-Wheel Motor Based on Improved Analytical Method and VOF Model

Abstract

:1. Introduction

2. Methods

2.1. An Improved Analytical Derivation

- (1)

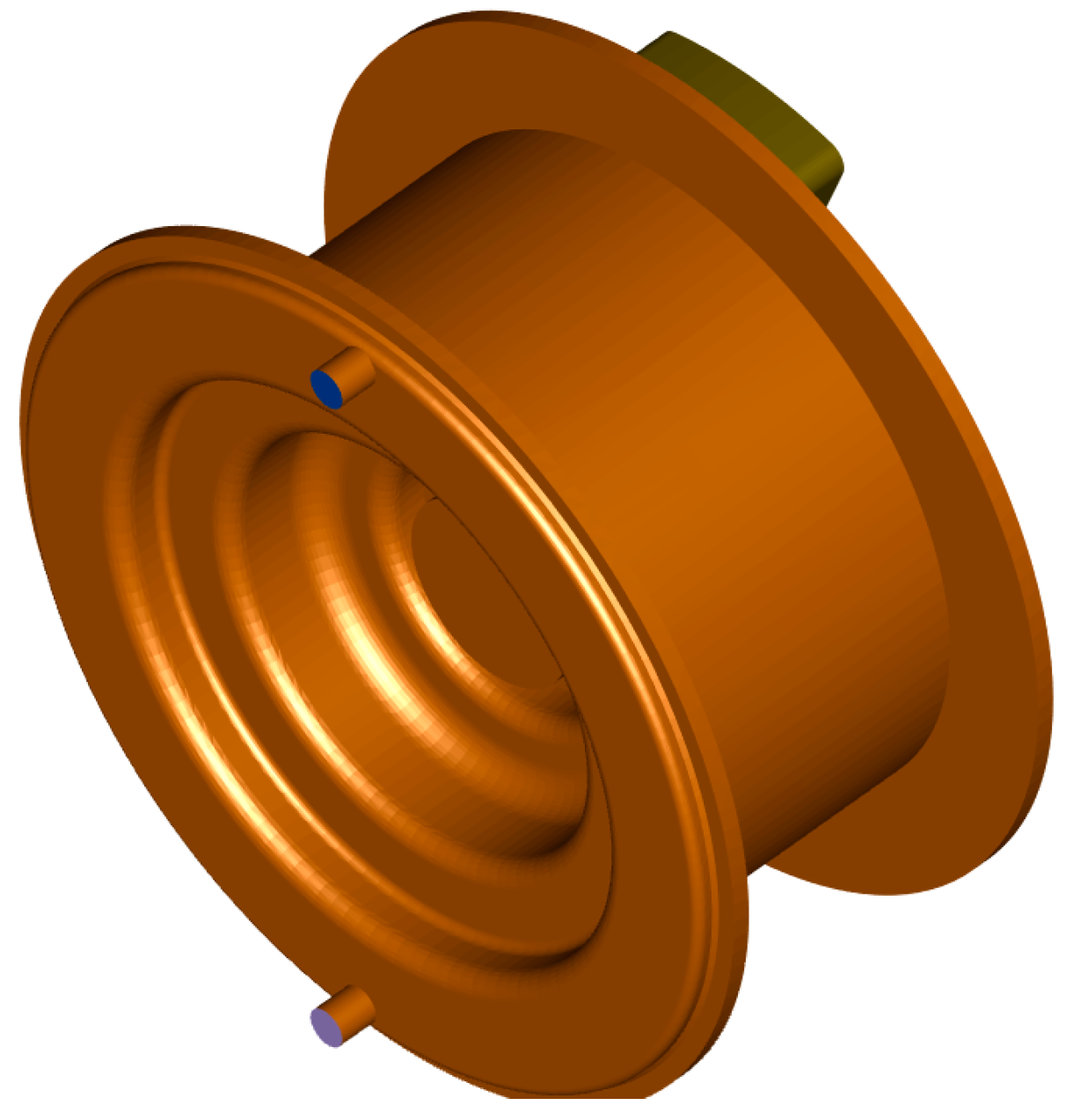

- The rotor and stator are both simplified to cylinders, as shown in Figure 1. The oil friction loss is divided into two parts: oil friction loss generated in air gap and oil friction loss generated at both ends of the bottom of the cylinder, which are calculated respectively.

- (2)

- The fluid motion in the air gap is considered as circular steady laminar flow, so the axial and radial velocities are approximately 0. The mass force is ignored, and there is no pressure difference in the axial direction.

- (3)

- The fluid flow at the end of the cylinder is assumed to be a steady flow, the velocity does not change with θ, and the mass force is ignored.

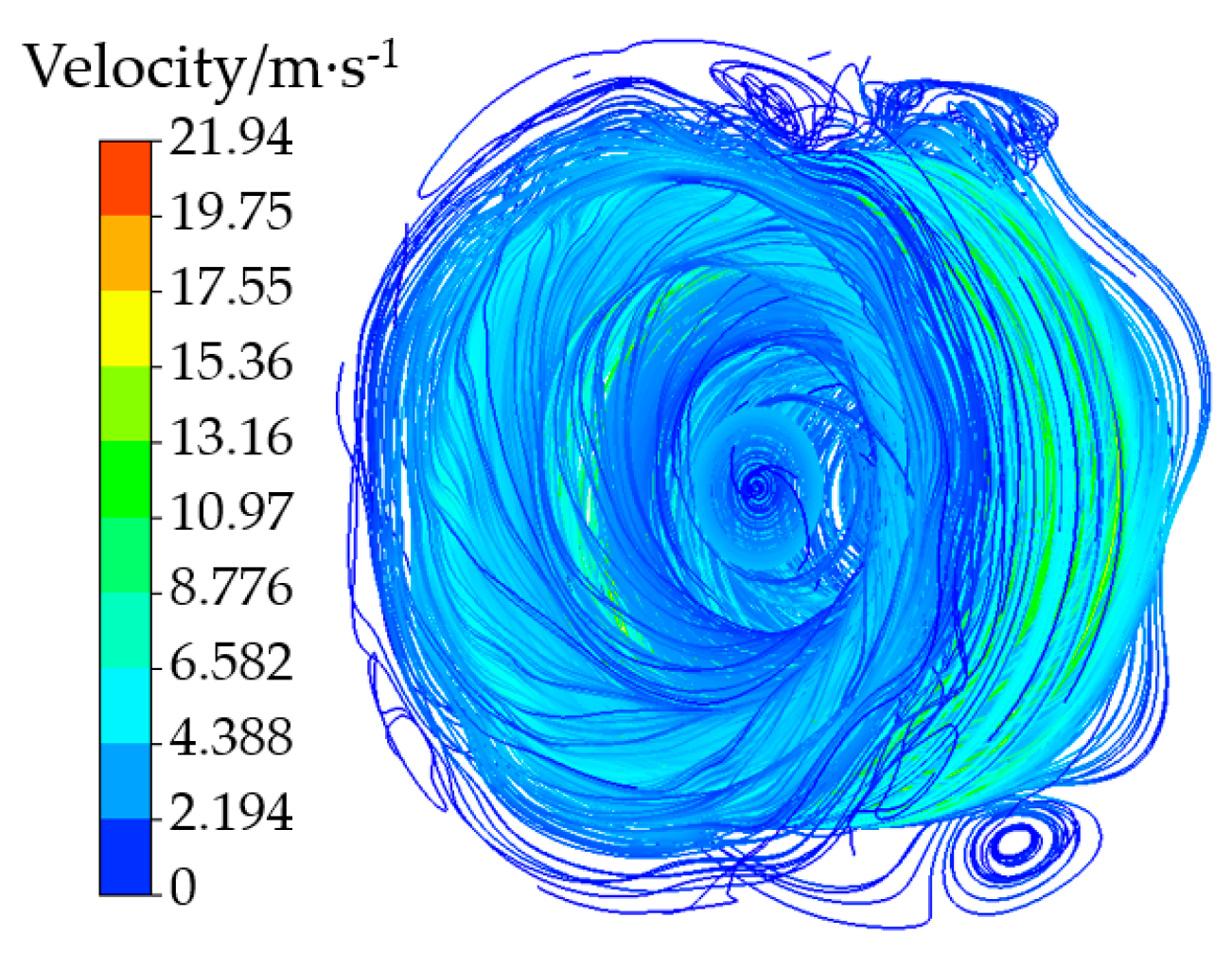

2.2. Numerical Analysis Procedure

2.2.1. Model Definition and Mesh

2.2.2. Governing Equation

2.2.3. Sliding Mesh Method and Boundary Conditions

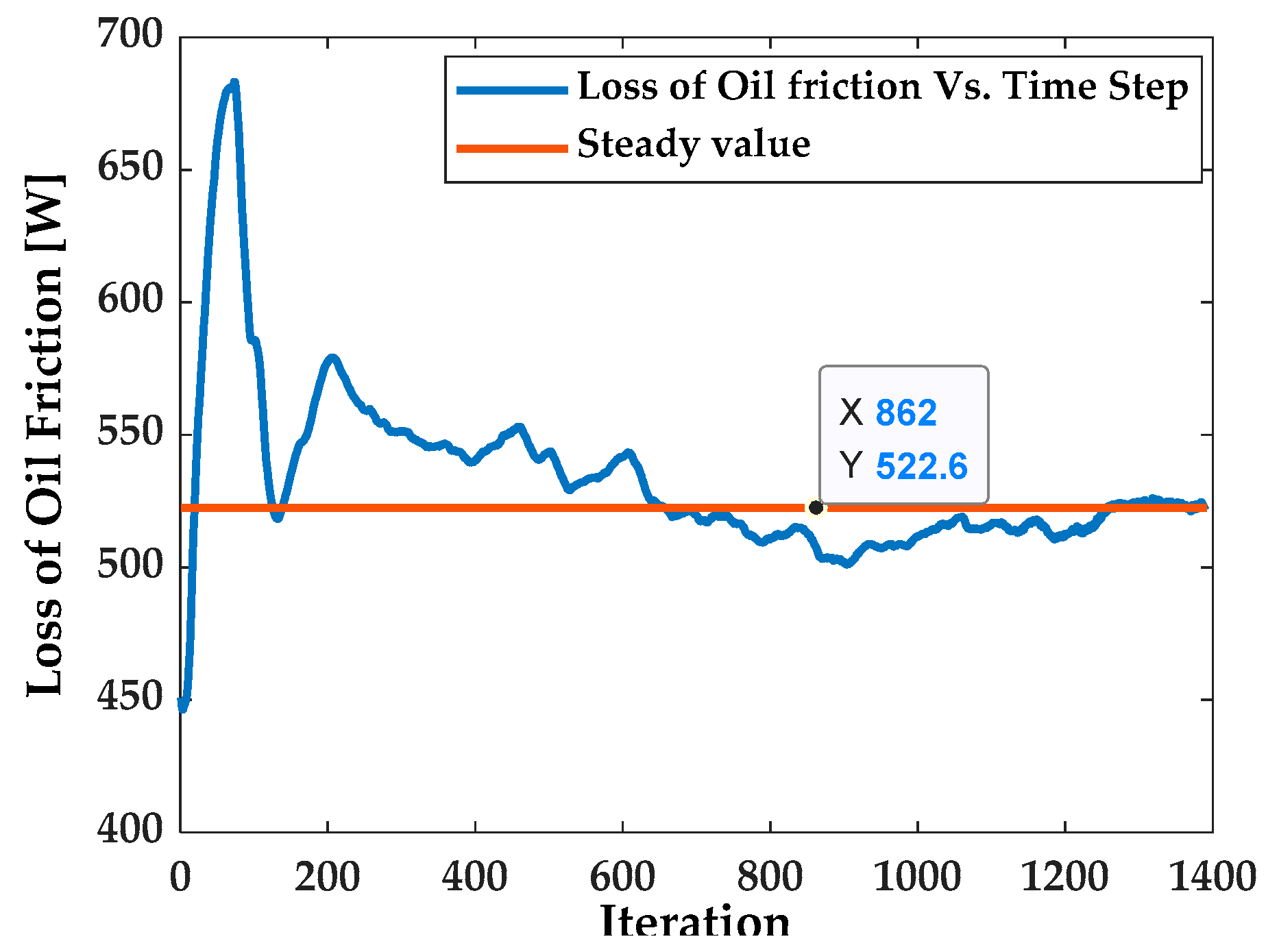

2.2.4. Convergence Criteria

2.3. Experimental Procedure

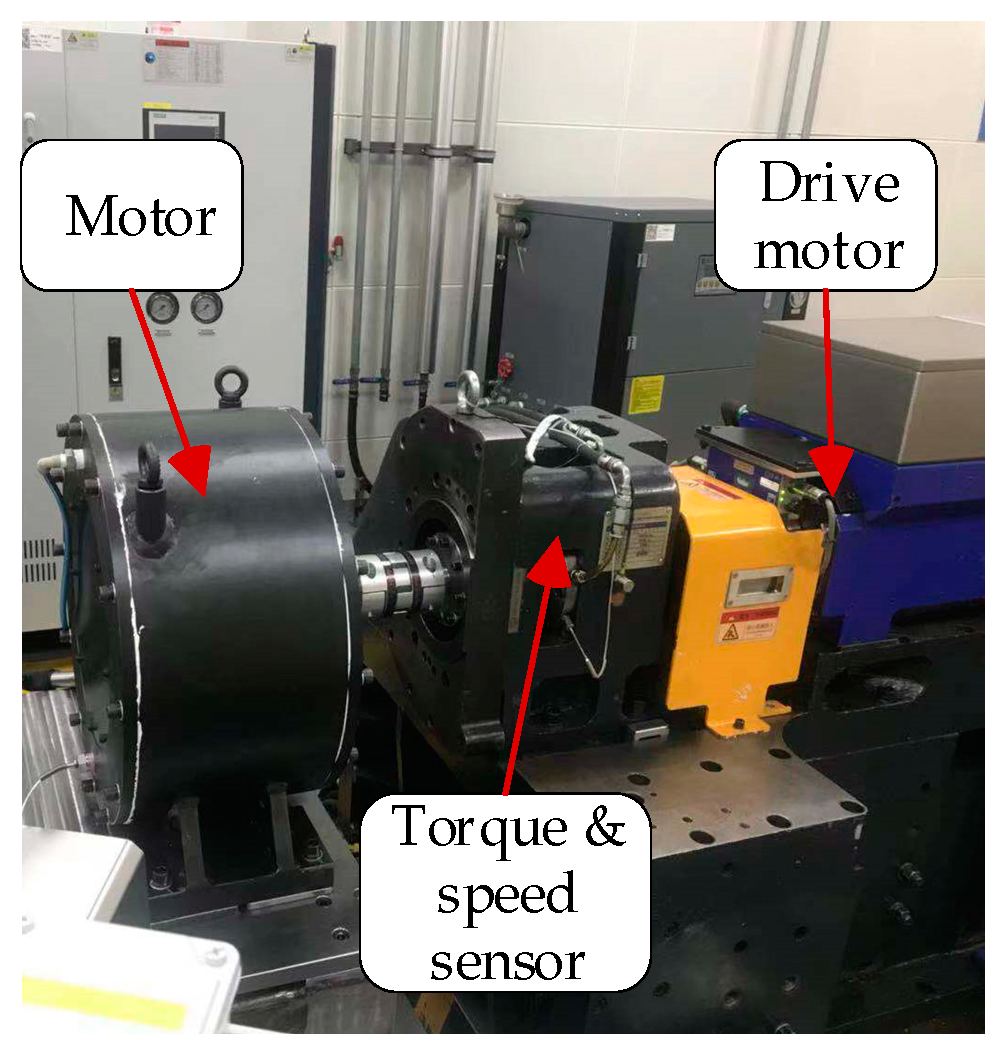

2.3.1. Setup

2.3.2. Loss Measurement

- (1)

- Test the loss with a fixed oil-soaked depth inside the motor. Pour 1500 mL of ATF cooling oil into the testing motor, which is equivalent to the oil-soaked depth of 112.5 mm. The equivalent method can be followed as formula (23), which is obtained by numerical fitting of the fifth-degree polynomial. Record the stable torque with different speeds.

- (2)

- Testing the loss with different oil-soaked depths. Set a fixed speed of 1000 rpm, pour 800 mL of ATF cooling oil into the testing motor firstly, and record the stable torque. Then, change the oil quantity and record the stable torque:

2.3.3. Uncertainly Analysis

3. Results

4. Conclusions

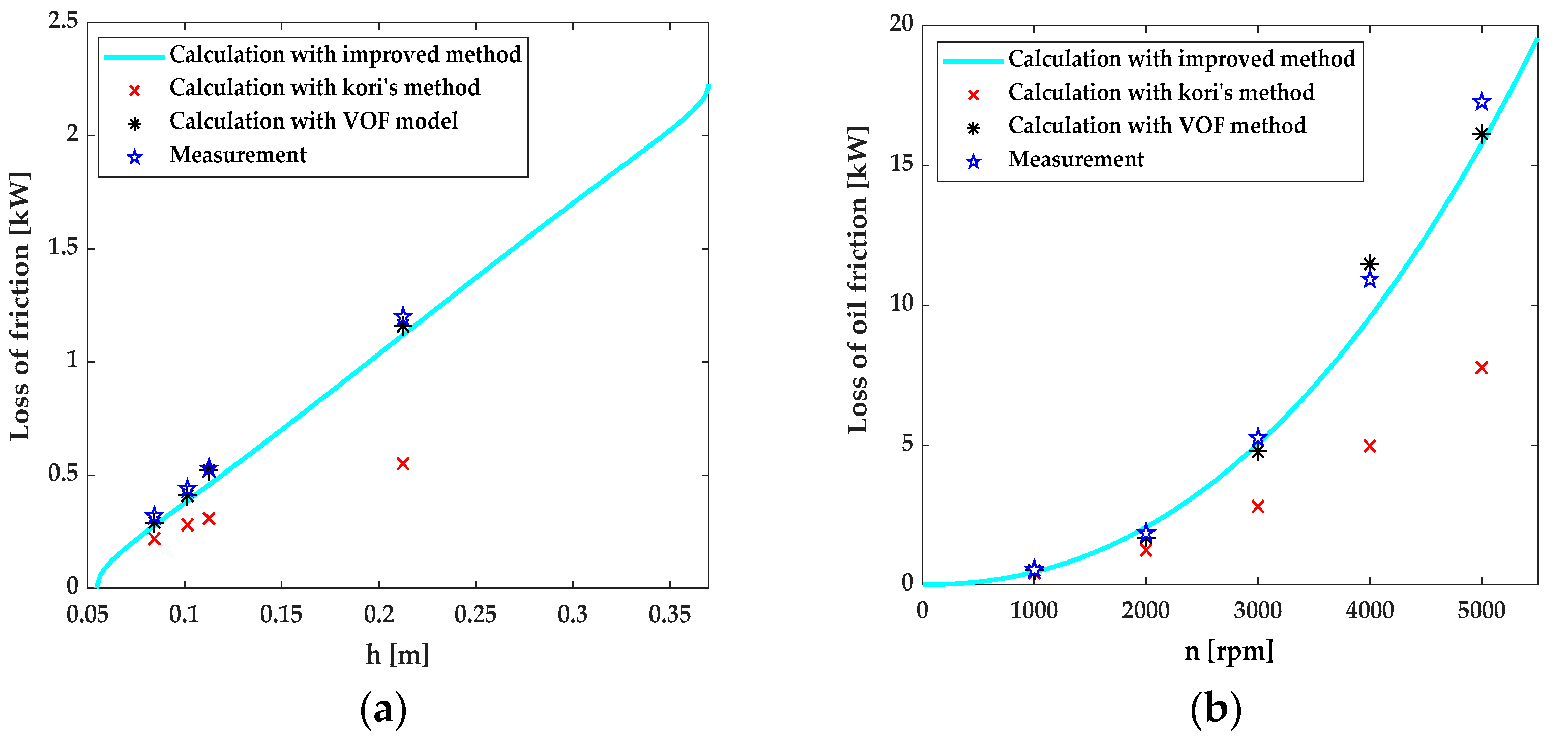

- The improved method analytical has higher computational accuracy than those previously studied. It is suitable for the early design of an oil-immersed cooling motor. When the design parameters need to be adjusted, the designer can quickly calculate the oil friction loss.

- The VOF model can accurately reflect the law of oil friction loss under the rotation speed and oil-soaked depth. The maximum error between theoretical calculation and testing data is less than 10%. It is useful in the later optimization design of the oil-immersed cooling motor, and the oil friction loss caused by the variation of local structure can be calculated by the model.

- The oil friction loss is proportional to the first power of the oil-soaked depth and the 2nd–3rd power of the rotational speed.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, X.; Gao, P. Application of Equivalent Thermal Network Method and Finite Element Method in Temperature Calculation of in-Wheel Motor. Electr. Mach. Control 2016, 31, 26–33. [Google Scholar]

- Guo, F.; Zhang, C. Oil-Cooling Method of the Permanent Magnet Synchronous Motor for Electric Vehicle. Energies 2019, 12, 2984. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Gerada, D.; Xu, Z.; Chong, Y.C.; Michon, M.; Goss, J.; Zhang, H. Estimation of Oil Spray Cooling Heat Transfer Coefficients on Hairpin Windings with Reduced-parameter Models. IEEE Trans. Transp. Electrif. 2020, 7, 793–803. [Google Scholar] [CrossRef]

- Ponomarev, P.; Polikarpova, M.; Pyrhonen, J. Thermal modeling of directly-oil-cooled permanent magnet synchronous machine. In Proceedings of the XXth International Conference on Electrical Machines, Marseille, France, 2–5 September 2012; IEEE: Manhattan, NY, USA; pp. 1882–1887. [Google Scholar]

- Zeng, J.; Sun, X.; Qian, Z. Thermal simulation of an oil-cooled permanent magnet synchronous motor. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017; pp. 1–7. [Google Scholar]

- Ponomarev, P.; Polikarpova, M.; Pyrhonen, J. Conjugated fluid-solid heat transfer modeling of a directly-oil-cooled PMSM using CFD. In Proceedings of the International Symposium on Power Electronics Power Electronics, Electrical Drives, Automation and Motion, Sorrento, Italy, 20–22 June 2012; IEEE: Manhattan, NY, USA, 2012; pp. 141–145. [Google Scholar]

- Kim, S.C.; Kim, W.; Kim, M.S. Cooling performance of 25 kW in-wheel motor for electric vehicles. Int. J. Automot. Technol. 2013, 14, 559–567. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, Y.H.; Zhang, W.M. Multi-Objective Optimization Analysis of Motor Cooling System in Articulated Dump Truck. Adv. Mater. Res. 2012, 383–390, 4715–4720. [Google Scholar] [CrossRef]

- Ye, L.; Tao, F.; Qi, L.; Xuhui, W. Experimental investigation on heat transfer of directly-oil-cooled permanent magnet motor. In Proceedings of the 2016 19th International Conference on Electrical Machines and Systems (ICEMS), Chiba, Japan, 13–16 November 2016; IEEE: Manhattan, NY, USA, 2017; pp. 1–4. [Google Scholar]

- Davin, T.; Pellé, J.; Harmand, S.; Yu, R. Experimental study of oil cooling systems for electric motors. Appl. Therm. Eng. 2015, 75, 1–13. [Google Scholar] [CrossRef]

- Sugimoto, S.; Kori, D. Cooling Performance and Loss Evaluation for Water- and Oil-Cooled without Pump for Oil. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 1136–1141. [Google Scholar]

- Montonen, J.; Nerg, J.; Polikarpova, M.; Pyrhönen, J. Integration Principles and Thermal Analysis of an Oil-Cooled and -Lubricated Permanent Magnet Motor Planetary Gearbox Drive System. IEEE Access 2019, 7, 69108–69118. [Google Scholar] [CrossRef]

- Nutakor, C.; Montonen, J.; Nerg, J.; Heikkinen, J.; Sopanen, J.; Pyrhönen, J. Development and validation of an integrated planetary gear set permanent magnet electric motor power loss model. Tribol. Int. 2018, 124, 34–45. [Google Scholar] [CrossRef]

- Ponomarev, P.; Polikarpova, M.; Heinikainen, O.; Pyrhönen, J. Design of integrated electro-hydraulic power unit for hybrid mobile working machines. In Proceedings of the 2011 14th European Conference on Power Electronics and Applications, Birmingham, UK, 30 August–1 September 2011; IEEE: Manhattan, NY, USA, 2011. [Google Scholar]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

- Park, M.H.; Kim, S.C. Thermal characteristics and effects of oil spray cooling on in-wheel motors in electric vehicles. Appl. Therm. Eng. 2019, 152, 582–593. [Google Scholar] [CrossRef]

- Liu, M.; Li, Y.; Ding, H.; Sarlioglu, B. Study on ATF Oil Resistant Insulating Material and System for Electric Vehicle Motors. Insul. Mater. 2018, 2, 18–22. [Google Scholar]

| Parameter | Value |

|---|---|

| Rated power/kW | 200 |

| Peak power/kW | 445 |

| Rated power/rpm | 1000 |

| Maximum speed/rpm | 5000 |

| Slots | 36 |

| Stator Diameter/mm | 430 |

| Air gap/mm | 2 |

| Rotor Diameter/mm | 316 |

| Axial length of iron core/mm | 104 |

| inner cavity volume/mL | 8300 |

| Medium | Density (kg/m3) | Dynamic Viscosity (Pa × s) |

|---|---|---|

| Oil-ATF220 | 867.2 | 0.07805 |

| air | 1.205 | 1.81 × 10−5 |

| Speed (rpm) | 1000 | 2000 | 3000 | 4000 | 5000 |

|---|---|---|---|---|---|

| Kori’s method/kW [Error/%] | 0.31 [42] | 1.24 [33] | 2.80 [47] | 4.97 [54] | 7.77 [55] |

| Improved method/kW [Error/%] | 0.46 [13] | 2.06 [−11] | 5.04 [4.0] | 9.56 [12] | 15.8 [8.7] |

| VOF model/kW [Error/%] | 0.52 [1.8] | 1.70 [8.6] | 4.78 [8.9] | 11.5 [−5.2] | 16.1 [6.9] |

| Testing value/kW | 0.53 | 1.86 | 5.25 | 10.93 | 17.3 |

| h (m) | 0.0843 | 0.1014 | 0.1125 | 0.2125 |

|---|---|---|---|---|

| Kori’s method/kW [Error/%] | 0.22 [30] | 0.28 [36] | 0.31 [42] | 0.55 [54] |

| Improved method/kW [Error/%] | 0.28 [12] | 0.39 [11] | 0.46 [13] | 1.12 [6.7] |

| VOF model/kW [Error/%] | 0.29 [9.0] | 0.41 [6.8] | 0.52 [1.8] | 1.16 [3.3] |

| Testing value/kW | 0.32 | 0.44 | 0.53 | 1.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, Y.; Li, H.; Xiang, X. Oil Friction Loss Evaluation of Oil-Immersed Cooling In-Wheel Motor Based on Improved Analytical Method and VOF Model. World Electr. Veh. J. 2021, 12, 164. https://doi.org/10.3390/wevj12040164

Yin Y, Li H, Xiang X. Oil Friction Loss Evaluation of Oil-Immersed Cooling In-Wheel Motor Based on Improved Analytical Method and VOF Model. World Electric Vehicle Journal. 2021; 12(4):164. https://doi.org/10.3390/wevj12040164

Chicago/Turabian StyleYin, Yi, Hui Li, and Xuewei Xiang. 2021. "Oil Friction Loss Evaluation of Oil-Immersed Cooling In-Wheel Motor Based on Improved Analytical Method and VOF Model" World Electric Vehicle Journal 12, no. 4: 164. https://doi.org/10.3390/wevj12040164

APA StyleYin, Y., Li, H., & Xiang, X. (2021). Oil Friction Loss Evaluation of Oil-Immersed Cooling In-Wheel Motor Based on Improved Analytical Method and VOF Model. World Electric Vehicle Journal, 12(4), 164. https://doi.org/10.3390/wevj12040164