New Operating Strategies for an On-the-Road Modular, Electric and Autonomous Vehicle Concept in Urban Transportation †

Abstract

1. Introduction

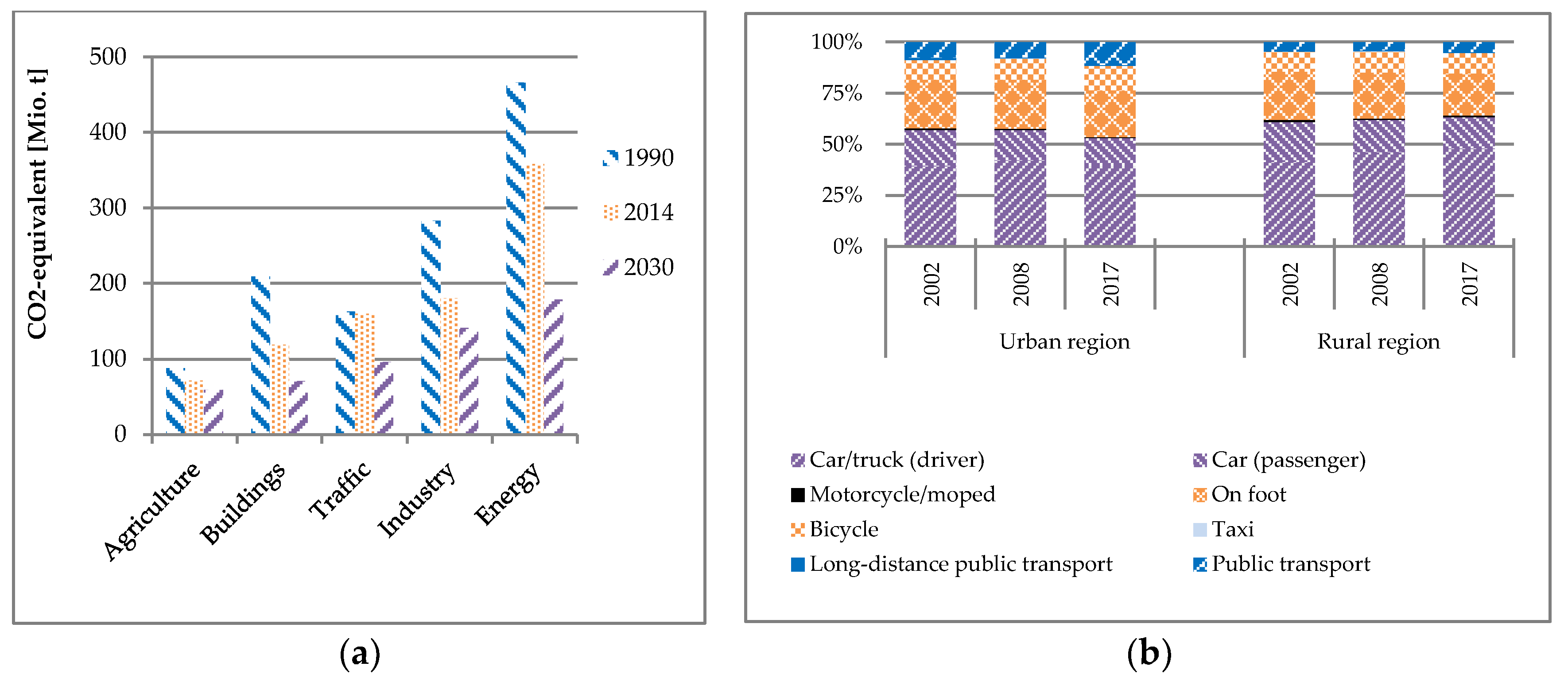

1.1. Urban Transport Challanges

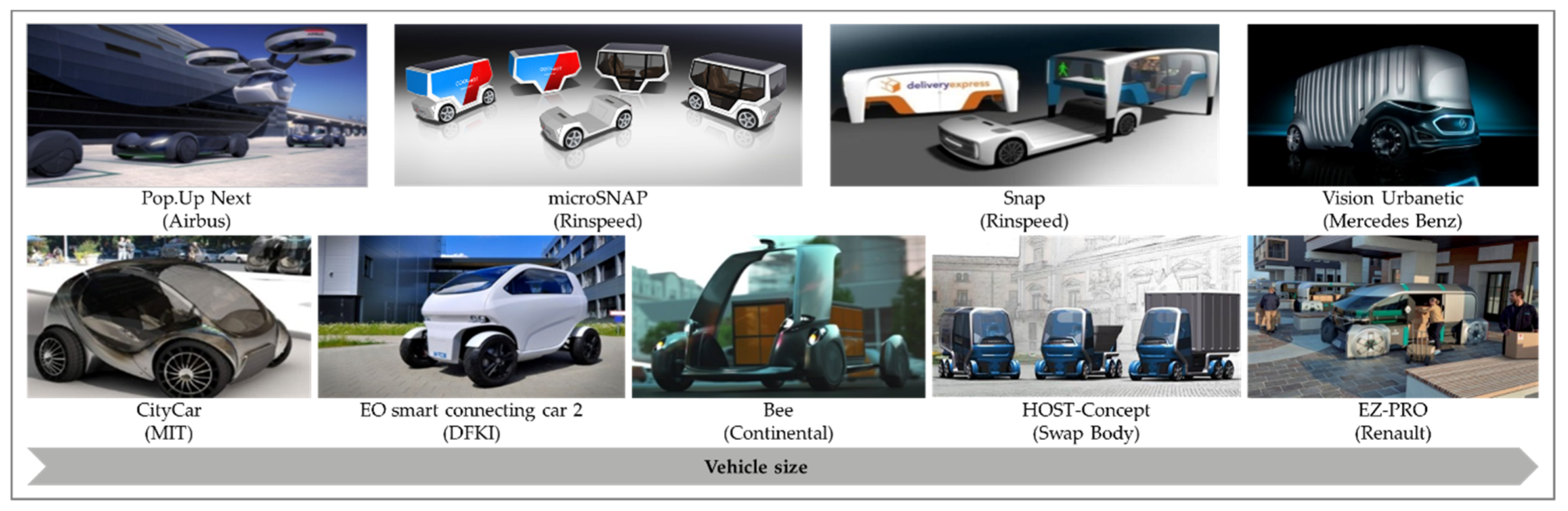

1.2. Modular Road Vehicle Concepts as a Possible Contribution to Improving Urban Transport

2. Methodology

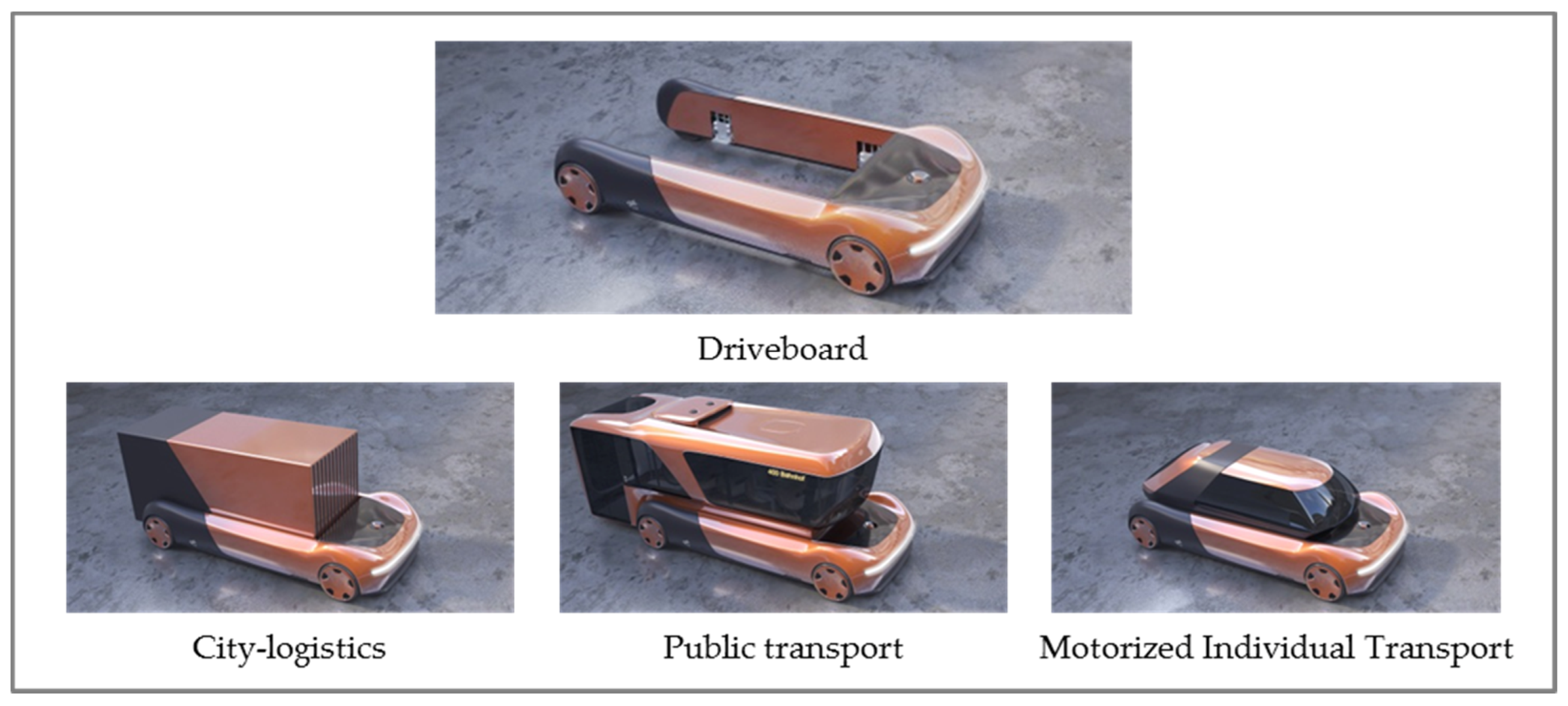

3. MAUDE: An On-The-Road (OTR) Modular Vehicle Concept

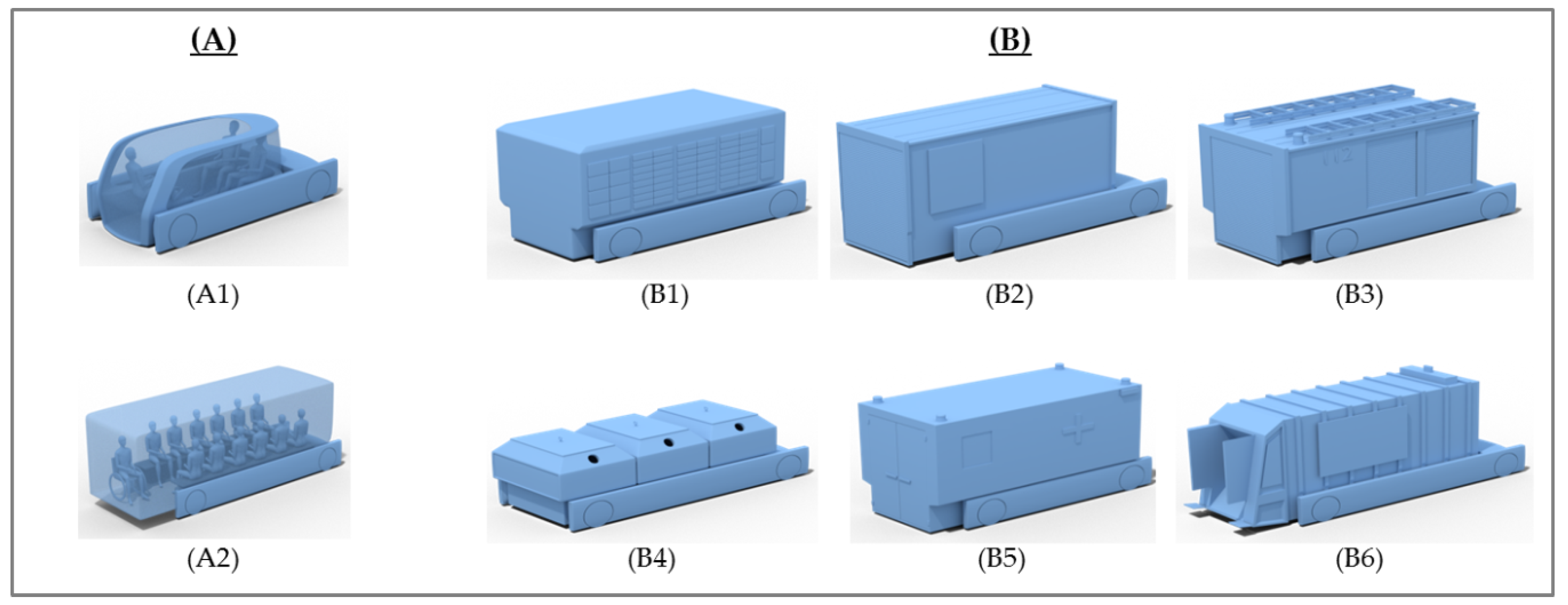

3.1. Driveboard

3.2. Capsule

3.3. Automation

3.4. Energy Management and Sector Coupling

3.5. Legislative Considerations of the Vehicle Concept

3.6. Analysis of Different OTR Modular Vehicle Concepts

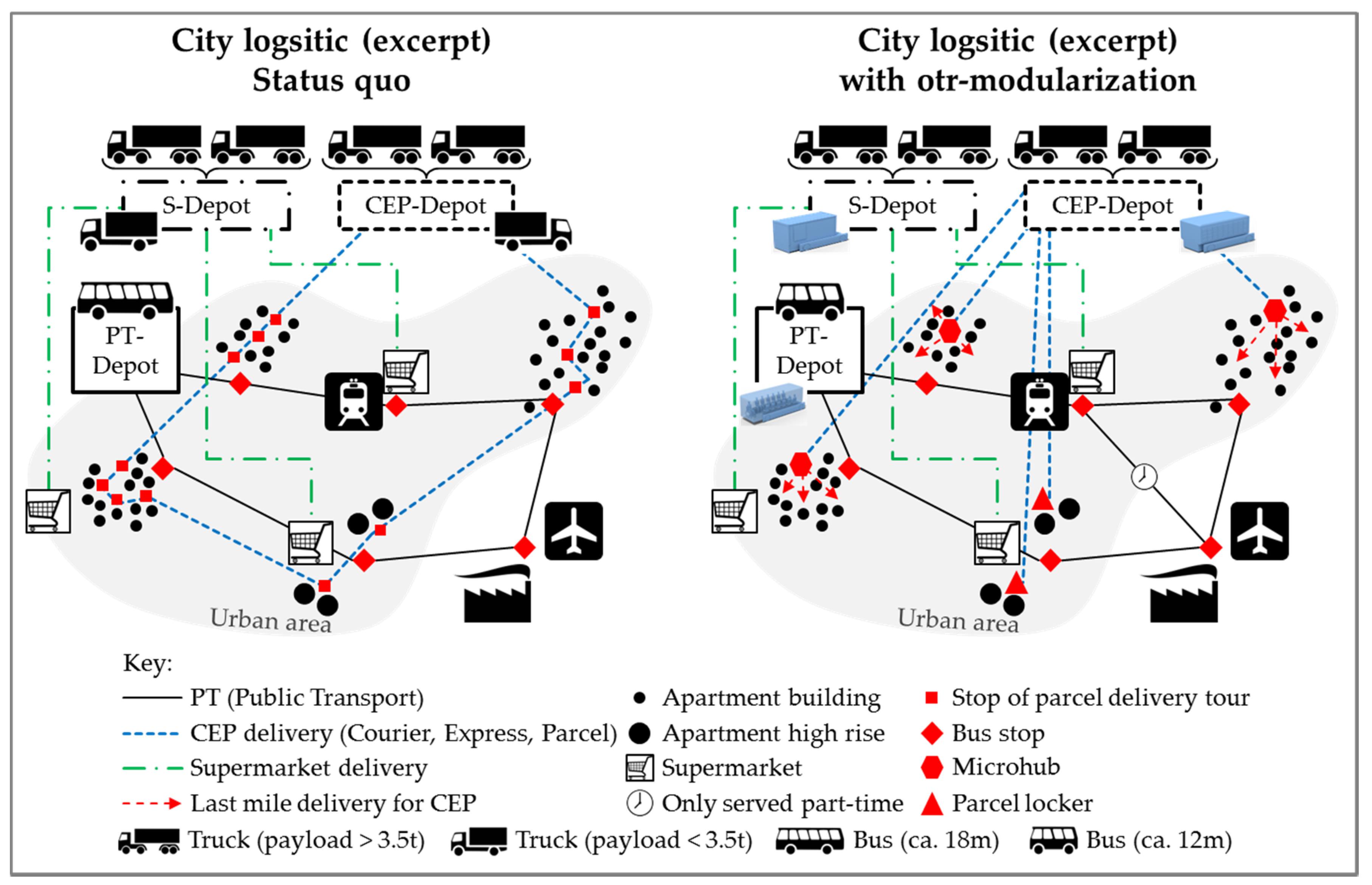

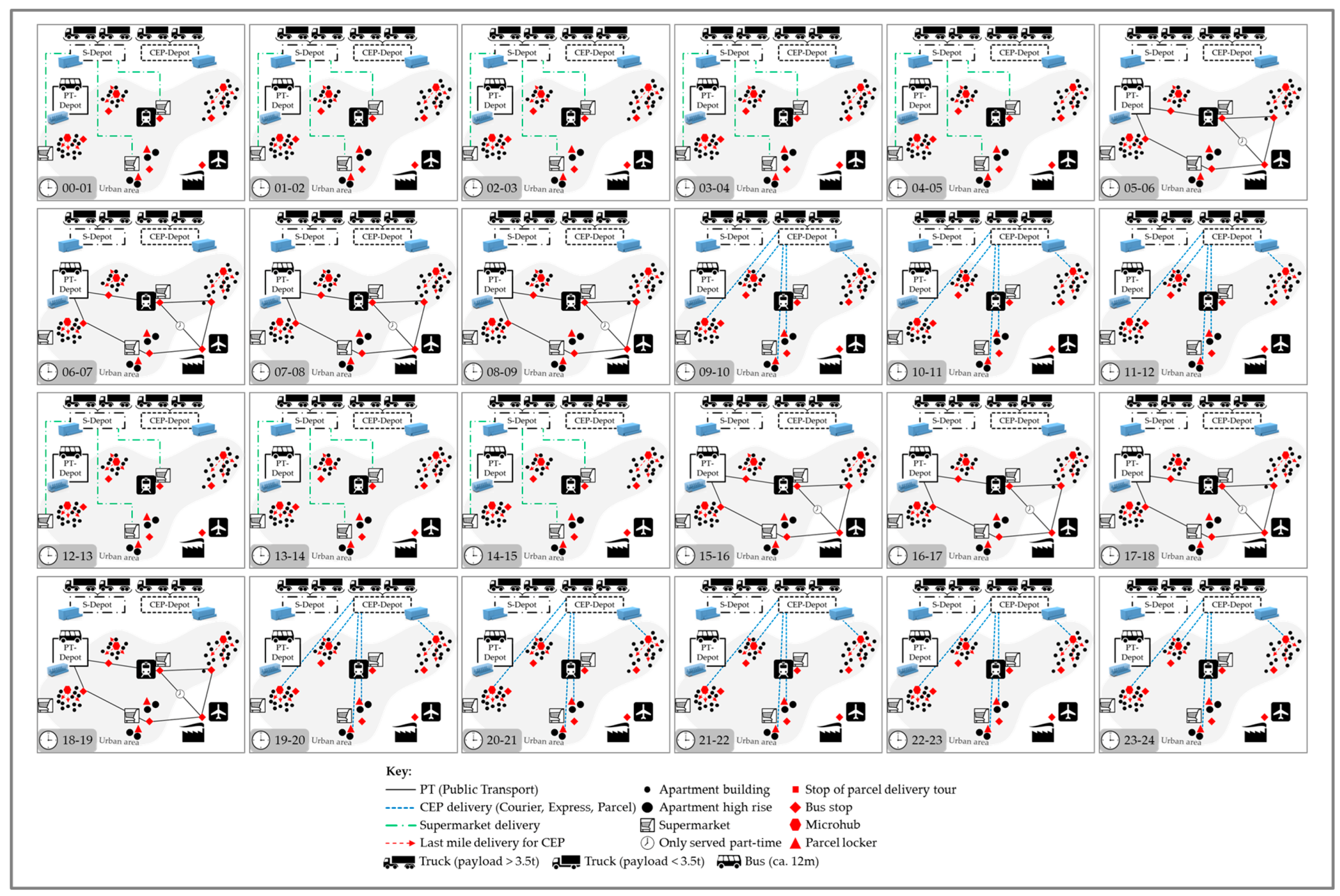

4. Business Models and Operational Concepts for MAUDE

4.1. Preliminary Considerations on the Current Supermarket and Parcel Delivery Situation

4.2. Exemplary Use Case “Urban PT Operator with MAUDE Vehicles Offering LaaS”

5. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ulrich, C.; Friedrich, H.; Weimer, J.; Schmid, S. A highly innovative on-the-road modular vehicle and operation concept to solve today traffic issues. In Proceedings of the 32nd Electric Vehicle Symposium (EVS32), Lyon, France, 19–22 May 2019. [Google Scholar]

- Ulrich, C.; Friedrich, H.E.; Weimer, J.; Hahn, R.; Kopp, G.; Münster, M. Technologies for a modular vehicle concept used in passenger and goods transport. In 19. Internationales Stuttgarter Symposium; Bargende, M., Reuss, H.-C., Wagner, A., Wiedemann, J., Eds.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2019; pp. 587–598. ISBN 978-3-658-25938-9. [Google Scholar]

- Winkel, R.; Cuijpers, M.; Jerram, L. Overcoming the Barriers of Mass EV Introduction. In Proceedings of the EVS30 Symposium, Stuttgart, Germany, 9–11 October 2017. [Google Scholar]

- Lutsey, N.; Grant, M.; Wappelhorst, S.; Zhou, H. Power Play: How Governments are Spurring the Electric Vehicle Industry; The International Council on Clean Transportation (ICCT): Washington, DC, USA, 2018. [Google Scholar]

- McKinsey & Company. Automotive Revolution—Perspective Towards 2030; Advanced Industries: Valenzuela, Metro Manila, 2016. [Google Scholar]

- Falcocchio, J.C.; Levinson, H.S. Historical Perspective of Urban Traffic Congestion. In Road Traffic Congestion: A Concise Guide; Springer: Cham, Switzerland, 2015; Volume 7, pp. 19–31. ISBN 978-3-319-15164-9. [Google Scholar]

- European Commission Urban. Air Pollution—What Are the Main Sources Across the World? Available online: https://ec.europa.eu/jrc/en/news/what-are-main-sources-urban-air-pollution (accessed on 8 December 2019).

- United Nations. World Urbanization Prospects: The 2018 Revision; United Nations Economic & Social Affairs: New York, NY, USA, 2018. [Google Scholar]

- United Nations. Paris Agreement; United Nations: San Francisco, CA, USA, 2015. [Google Scholar]

- Der Klimaschutzplan 2050; BMU: Bonn, Germany, 2016.

- Roadmap to a Single European Transport Area; European Commission: Brussels, Belgium, 2011.

- ADAC. Dieselfahrverbot: Alle Fragen und Antworten. Available online: https://www.adac.de/rund-ums-fahrzeug/abgas-diesel-fahrverbote/fahrverbote/dieselfahrverbot-faq/ (accessed on 14 December 2018).

- Landeshauptstadt Stuttgart Diesel-Verkehrsverbot. Available online: https://www.stuttgart.de/diesel-verkehrsverbot (accessed on 8 December 2019).

- Mobilität in Deutschland 2002; BMVI: Berlin, Germany, 2003.

- Mobilität in Deutschland 2008; BMVI: Berlin, Germany, 2010.

- Mobilität in Deutschland 2017; BMVI: Berlin, Germany, 2018.

- Bates, J.; Leibing, D. Spaced Out: Perspectives on Parking Policy; RAC Foundation: London, UK, 2012. [Google Scholar]

- Urban Mobility System Upgrade; OECD—International Transport Forum: Paris, France, 2015.

- Bogdanski, R. Nachhaltige Stadtlogistik Warum das Lastenfahrrad die letzte Meile gewinnt; Huss-Verlag: Munich, Germany, 2019; ISBN 978-3-948001-02-5. [Google Scholar]

- KEP-Studie 2018—Analyse des Marktes in Deutschland; BIEK: Karachi, Pakistan, 2018.

- Parcel Delivery. The future of last Mile; McKinsey & Company: New York, NY, USA, 2016. [Google Scholar]

- Kopp, G.; Klötzke, M.; Gebhardt, L.; Friedrich, H.E. A Mixed-Methods Approach to Derive Vehicle Concepts for Urban Mobility; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Friedrich, H.E.; Ulrich, C.; Schmid, S. New vehicle concepts for future business model. In 19. Internationales Stuttgarter Symposium; Bargende, M., Reuss, H.-C., Wagner, A., Wiedemann, J., Eds.; Springer: Wiesbaden, Germany, 2019; pp. 815–829. ISBN 978-3-658-25938-9. [Google Scholar]

- Braess, H.-H.; Seiffert, U. (Eds.) Vieweg Handbuch Kraftfahrzeugtechnik; Springer: Wiesbaden, Germany, 2013; ISBN 978-3-658-01690-6. [Google Scholar]

- Vohrer, S.; Münster, M.; Kriescher, M.; Kopp, G.; Kopp, G.; Friedrich, H.E. DLR Next Generation Vehicle Concepts-Urban-Regional-Interurban. In 18 Internationales Stuttgarter Symposium; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Barbucha, D. A Multi-agent Approach to the Dynamic Vehicle Routing Problem with Time Windows. In Computational Collective Intelligence, Technologies and Applications; Bǎdicǎ, C., Nguyen, N.T., Brezovan, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 8083, pp. 467–476. ISBN 978-3-642-40494-8. [Google Scholar]

- Bianchessi, N.; Righini, G. Heuristic algorithms for the vehicle routing problem with simultaneous pick-up and delivery. Comput. Oper. Res. 2007, 34, 578–594. [Google Scholar] [CrossRef]

- Dethloff, J. Vehicle routing and reverse logistics: The vehicle routing problem with simultaneous delivery and pick-up: Fahrzeugeinsatzplanung und Redistribution: Tourenplanung mit simultaner Auslieferung und Rückholung. OR Spektrum 2001, 23, 79–96. [Google Scholar] [CrossRef]

- Liu, R.; Jiang, Z.; Geng, N. A hybrid genetic algorithm for the multi-depot open vehicle routing problem. OR Spectrum 2014, 36, 401–421. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 668:2013: Series 1 Freight Containers—Classification, Dimensions and Ratings; ISO: London, UK, 2013. [Google Scholar]

- Straßenverkehrs-Zulassungs-Ordnung (StVZO) § 32 Abmessungen von Fahrzeugen und Fahrzeugkombinationen; BMJV: Berlin, Germany, 2019.

- SAE. SAE J3016 Taxonomy and Definitions for Terms Related to Driving Automation Systems for On-Road Motor Vehicles; SAE International: Warrendale, Germany, 2018. [Google Scholar]

- Meck, G. Spediteure werben um Migranten—Interview mit Bernhard Simon. Frankfurter Allgemeine Sonntagszeitung, 9 December 2018. [Google Scholar]

- Völklein, M. Nahverkehr: Lokführer Werden Dringend Gesucht. Süddeutsche Zeitung, 30 November 2018. [Google Scholar]

- Automated Valet Parking. Available online: https://www.bosch-mobility-solutions.de/de/highlights/automatisierte-mobilit%C3%A4t/automated-valet-parking/ (accessed on 15 January 2019).

- Li, Y.; Cao, Y.; Qiu, H.; Gao, L.; Du, Z.; Chen, S. Big wave of the intelligent connected vehicles. China Commun. 2016, 13, 27–41. [Google Scholar] [CrossRef]

- Becker, J. Weltkonzerne—Hallo, Robo-Taxi! Süddeutsche Zeitung, 10 July 2018. [Google Scholar]

- ERTRAC. Connected Automated Driving Roadmap; ERTRAC Working Group “Connectivity and Automated Driving”: Brussels, Belgium, 2019. [Google Scholar]

- Bundesregierung Erneuerbare Energien und stabile Netze. Available online: https://www.bundesregierung.de/breg-de/aktuelles/erneuerbare-energien-und-stabile-netze-422384 (accessed on 16 July 2019).

- HAW. Hamburg Speicherregelkraftwerk am Windpark Curslack ist Messehighlight. Available online: https://www.haw-hamburg.de/fileadmin/user_upload/Presse_und_Kommunikation/Downloads/Faktenblatt_NEW4-0_20181123_NEUES-TITELBILD.pdf (accessed on 16 July 2019).

- Komarnicki, P.; Haubrock, J.; Styczynski, Z.A. Elektromobilität und Sektorenkopplung: Infrastruktur- und Systemkomponenten; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 978-3-662-56248-2. [Google Scholar]

- Chapman, N.; Corchero, C.; Sanmarti, M. Task 28: Home Grids and V2X Technologies Final Report (2014–2018); HEV-TCP; IEA: Paris, France, 2019; p. 24. [Google Scholar]

- European Parliament and of the Council. Commission Regulation (EU) No 678/2011 of 14 July 2011. Off. J. Eur. Union 2011, 40, 274–300. [Google Scholar]

- Demiridi, E.; Kopelias, P.; Nathanail, E.; Skabardonis, A. Connected and Autonomous Vehicles—Legal Issues in Greece, Europe and USA. In Data Analytics: Paving the Way to Sustainable Urban Mobility; Nathanail, E.G., Karakikes, I.D., Eds.; Springer: Cham, Switzerland, 2019; Volume 879, pp. 756–763. ISBN 978-3-030-02304-1. [Google Scholar]

- Fafoutellis, P.; Mantouka, E.G. Major Limitations and Concerns Regarding the Integration of Autonomous Vehicles in Urban Transportation Systems. In Data Analytics: Paving the Way to Sustainable Urban Mobility; Nathanail, E.G., Karakikes, I.D., Eds.; Springer: Cham, Switzerland, 2019; Volume 879, pp. 739–747. ISBN 978-3-030-02304-1. [Google Scholar]

- Schreurs, M.A.; Steuwer, S.D. Autonomous Driving—Political, Legal, Social, and Sustainability Dimensions. In Autonomous Driving; Maurer, M., Gerdes, J.C., Lenz, B., Winner, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 149–171. ISBN 978-3-662-48845-4. [Google Scholar]

- Smith, B.W. Model Legislation for Automated Driving. In Road Vehicle Automation 4; Meyer, G., Beiker, S., Eds.; Springer: Cham, Switzerland, 2018; pp. 79–88. ISBN 978-3-319-60933-1. [Google Scholar]

- Van Audenhove, F.-J.; Rominger, G.; Kom, A.; Bettati, A.; Steylemans, N.; Zintel, M.; Smith, A.; Haon, S. The Future of Mobility 3.0; Arthur D. Little: Paris, France, 2018. [Google Scholar]

- Tyrinopoulos, Y.; Antoniou, C. Review of factors affecting transportation systems adoption and satisfaction. In Demand for Emerging Transportation Systems; Elsevier: Amsterdam, The Netherlands, 2019; pp. 11–36. ISBN 978-0-12-815018-4. [Google Scholar]

- Yashiro, R.; Kato, H. Success factors in the introduction of an intermodal passenger transportation system connecting high-speed rail with intercity bus services. Case Stud. Transp. Policy 2019, 7, 708–717. [Google Scholar] [CrossRef]

- Cornet, A.; Mohr, D.; Weig, F.; Zerlin, B.; Hein, A.-P. Mobility of the Future; McKinsey & Company: Munich, Germany, 2012. [Google Scholar]

- Transportation, Tourism and Logistics. Available online: https://www.rolandberger.com/en/Expertise/Industries/Transportation/ (accessed on 7 December 2019).

- Li, Y.; May, A.; Cook, S. Mobility-as-a-Service: A Critical Review and the Generalized Multi-modal Transport Experience. In Cross-Cultural Design. Culture and Society; Rau, P.-L.P., Ed.; Springer: Cham, Switzerland, 2019; Volume 11577, pp. 186–206. ISBN 978-3-030-22579-7. [Google Scholar]

- Kostiainen, J.; Tuominen, A. Mobility as a Service—Stakeholders’ Challenges and Potential Implications. In Towards User-Centric Transport in Europe; Müller, B., Meyer, G., Eds.; Springer: Cham, Switzerland, 2019; pp. 239–254. ISBN 978-3-319-99755-1. [Google Scholar]

- Stopka, U.; Pessier, R.; Günther, C. Mobility as a Service (MaaS) Based on Intermodal Electronic Platforms in Public Transport. In Human-Computer Interaction. Interaction in Context; Kurosu, M., Ed.; Springer: Cham, Switzerland, 2018; Volume 10902, pp. 419–439. ISBN 978-3-319-91243-1. [Google Scholar]

- Nitsche, B.; Figiel, A. Zukunftstrends in der Lebensmittellogistik: Herausforderungen und Lösungsimpulse; Straube, F., Ed.; Schriftenreihe Logistik der Technischen Universität Berlin Sonderband; Universitätsverlag der TU Berlin: Berlin, Germany, 2016; ISBN 978-3-7983-2833-4. [Google Scholar]

- NDR. Wie geht Das? Nachschub für den Supermarkt; NDR: Hamburg, Germany, 2019. [Google Scholar]

- Krampe, H.; Lucke, H.-J.; Schenk, M. Grundlagen der Logistik; Huss-Verl.: München, Germany, 2012; ISBN 978-3-944281-27-8. [Google Scholar]

- Deutscher Logistik-Kongress. Digitales trifft Reales: 35. Deutscher Logistik-Kongress: Kongressband = Digitalization Meets Reality; Wimmer, T., Grotemeier, C., Eds.; DVV Media Group, Deutscher Verkehrs-Verlag: Hamburg, Germany, 2018; ISBN 978-3-87154-632-7. [Google Scholar]

- Van Duin, J.H.R.; de Goffau, W.; Wiegmans, B.; Tavasszy, L.A.; Saes, M. Improving Home Delivery Efficiency by Using Principles of Address Intelligence for B2C Deliveries. Transp. Res. Procedia 2016, 12, 14–25. [Google Scholar] [CrossRef]

- Müller, S.; Lunkeit, S.; Thaller, C. ATLaS—Szenarien des Automatisierten Fahrens in der Logistik; DLR Institut für Verkehrsforschung: Berlin, Germany, 2018. [Google Scholar]

- Deutschepost DHL Versandmarken Deutschland. Available online: https://shop.deutschepost.de/paketversand/dhl-paketmarken/dhl-paeckchenmarken-paketmarken-deutschland (accessed on 8 December 2019).

- Statista Research Department. Anzahl der Paketlieferungen pro Person in ausgewählten Ländern Europas in den Jahren 2012 und 2018; Statista Research Department: Hamburg, Germany, 2018. [Google Scholar]

- Statista Research Department. Anzahl der beförderten Pakete durch die Deutsche Post in Deutschland von 2016 bis 2018; Statista Research Department: Hamburg, Germany, 2019. [Google Scholar]

- Van Duin, J.H.; Wiegmans, B.; Arem, B. From home delivery to parcel lockers: A case study in amsterdam. In Proceedings of the 11th International Conference on City Logistics, Dubrovnik, Croatia, 12–14 June 2019. [Google Scholar]

- Iwan, S.; Kijewska, K.; Lemke, J. Analysis of Parcel Lockers’ Efficiency as the Last Mile Delivery Solution—The Results of the Research in Poland. Transp. Res. Procedia 2016, 12, 644–655. [Google Scholar] [CrossRef]

- Vastag, A.; Bernsmann, A. (Eds.) Urbane Logistik: Schnell, Stadtverträglich und Wirtschaftlich; Logistik Praxis 1. Auflage.; Huss: München, Germany, 2018; ISBN 978-3-946350-78-1. [Google Scholar]

- Ewert, A.; Brost, M.; Schmid, S. Fostering small electric vehicles on a municipal level. In Proceedings of the 32nd Electric Vehicle Symposium (EVS32), Lyon, France, 19–22 May 2019. [Google Scholar]

- Ninnemann, J.; Tesch, T.; Thyssen, R.; Beecken, W.; Hölter, A.-K. Smart Last Mile Solutions; Logistik schafft Lösungen: Hamburg, Germany, 2017. [Google Scholar]

- Ripa, F.; Lozzi, G.; Mourey, T.; Dondi, S. NOVELOG—Cities & Regions—Factsheets; European Union: Brussels, Belgium, 2018. [Google Scholar]

- Dreier, D.; Silveira, S.; Khatiwada, D.; Fonseca, K.V.O.; Nieweglowski, R.; Schepanski, R. The influence of passenger load, driving cycle, fuel price and different types of buses on the cost of transport service in the BRT system in Curitiba, Brazil. Transportation 2019, 46, 2195–2242. [Google Scholar] [CrossRef]

- Regulation (EC) NO 1370/2007 of the European Parliament and of the Council of 23 October 2007 on public Passenger Transport Services by Rail and by Road and Repealing Council Regulations (EEC) Nos 1191/69 and 1107/70; European Union: Brussels, Belgium, 2007.

- Osterwalder, A.; Pigneur, Y.; Clark, T. Business Model Generation: A Handbook for Visionaries, Game Changers, and Challengers; Wiley: Hoboken, NJ, USA, 2010; ISBN 978-0-470-87641-1. [Google Scholar]

- Ickin, S.; Petersen, K.; Gonzalez-Huerta, J. Why Do Users Install and Delete Apps? A Survey Study. In Software Business; Ojala, A., Holmström Olsson, H., Werder, K., Eds.; Springer: Cham, Switzerland, 2017; Volume 304, pp. 186–191. ISBN 978-3-319-69190-9. [Google Scholar]

- Jain, A. Apps marketplaces and the telecom value chain. IEEE Wirel. Commun. 2011, 18, 4–5. [Google Scholar] [CrossRef]

- Laugesen, J.; Yuan, Y. What Factors Contributed to the Success of Apple’s iPhone? In Proceedings of the 2010 Ninth International Conference on Mobile Business and 2010 Ninth Global Mobility Roundtable (ICMB-GMR), Athens, Greece, 13–15 June 2010; pp. 91–99. [Google Scholar]

- Nirmal, S.; Pathare, A. Swarm intelligence for logistics controlling. IRJET 2017, 4, 5. [Google Scholar]

- Zhang, S.; Lee, C.K.M.; Chan, H.K.; Choy, K.L.; Wu, Z. Swarm intelligence applied in green logistics: A literature review. Eng. Appl. Artif. Intell. 2015, 37, 154–169. [Google Scholar] [CrossRef]

| Use | Standardization | Loading | Module Change | |

|---|---|---|---|---|

| Snap (Rinspeed) | Flexible (various purposes) | Individual solution | Lateral | Vertical, lifting system in the capsule |

| MicroSNAP (Rinspeed) | Flexible (various purposes) | Individual solution | Lateral | Vertical, auxiliary robots needed |

| Vision Urbanetic (Mercedes Benz) | Flexible (various purposes) | Medium potential | Back, at ground | Forward (gauge actuation) |

| BEE (Continental) | People- and cargo-movers | Individual solution | Front | Auxiliary robots needed |

| Pop.Up Next (Airbus, Audi, Italdesign) | People-movers | Individual solution | Lateral | In the air, lifting done by a drone |

| MAUDE (DLR) | Flexible (various purposes) | High potential | Back or side, at ground | Forward, lifting system integrated in the driveboard |

| Key Partners Manufacturers of driveboards and capsules; municipalities | Key Activities Operate and maintain the fleet for PT 1 and LaaS 1 in B2B 1 | Value Proposition LaaS 1; lower risk for B2B 1 partners; increased efficiency; new time windows for delivery; use-case-optimized capsules | Customer Relationships B2C 1: Individual B2B 1: Contracts | Customer Segment B2C 1: people using PT 1 B2B 1: parcel service operators, haulers for supermarket goods | |

| Key Resources Fleet of drive boards and PT 1 capsules; fleet management skills | Channels B2C 1: apps, website B2B 1: personal contacts | ||||

| Cost Structure Purchase costs for driveboards and PT 1 capsules; low personnel costs (no driver, maintenance and operational staff); maintenance and operating costs; remote control equipment | Revenue Streams B2C 1: pay-per-ride for PT 1 B2B 1: cargo transport either on pay-per-use or contractual basis | ||||

| Time vs. Capsule Type | Public Transport | Supermarket Delivery | Parcel Delivery |

|---|---|---|---|

| 00:00–05:00 | × | ||

| 05:00–09:00 (peak) | × | ||

| 09:00–12:00 | × | ||

| 12:00–15:00 | × | ||

| 15:00–19:00 (peak) | × | ||

| 19:00–24:00 | × |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ulrich, C.; Friedrich, H.E.; Weimer, J.; Schmid, S.A. New Operating Strategies for an On-the-Road Modular, Electric and Autonomous Vehicle Concept in Urban Transportation. World Electr. Veh. J. 2019, 10, 91. https://doi.org/10.3390/wevj10040091

Ulrich C, Friedrich HE, Weimer J, Schmid SA. New Operating Strategies for an On-the-Road Modular, Electric and Autonomous Vehicle Concept in Urban Transportation. World Electric Vehicle Journal. 2019; 10(4):91. https://doi.org/10.3390/wevj10040091

Chicago/Turabian StyleUlrich, Christian, Horst E. Friedrich, Jürgen Weimer, and Stephan A. Schmid. 2019. "New Operating Strategies for an On-the-Road Modular, Electric and Autonomous Vehicle Concept in Urban Transportation" World Electric Vehicle Journal 10, no. 4: 91. https://doi.org/10.3390/wevj10040091

APA StyleUlrich, C., Friedrich, H. E., Weimer, J., & Schmid, S. A. (2019). New Operating Strategies for an On-the-Road Modular, Electric and Autonomous Vehicle Concept in Urban Transportation. World Electric Vehicle Journal, 10(4), 91. https://doi.org/10.3390/wevj10040091