Influence of Herbal Fillers Addition on Selected Properties of Silicone Subjected to Accelerated Aging

Abstract

1. Introduction

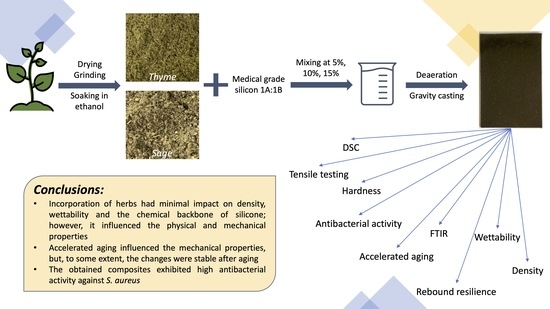

2. Materials and Methods

2.1. Materials Preparation

- Similar polyphenolic compounds composition;

- Similar antimicrobial properties;

- Wide availability.

2.2. Research of the Composites’ Properties

- Grains’ size and morphology;

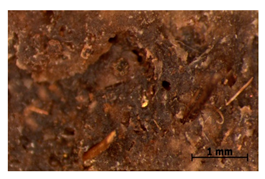

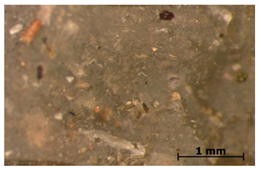

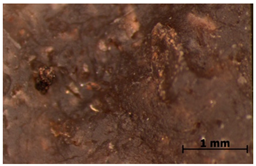

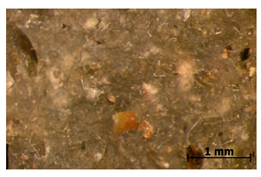

- Microscopic images of composites cross-section;

- Topography microscopy;

- Physicochemical properties (density, wettability, rebound resilience, Fourier transform infrared (FTIR) spectroscopy, and differential scanning calorimetry (DSC) curve analysis);

- Mechanical properties (rebound resilience, stress at break, and elongation at break);

- Biological tests (antibacterial activity).

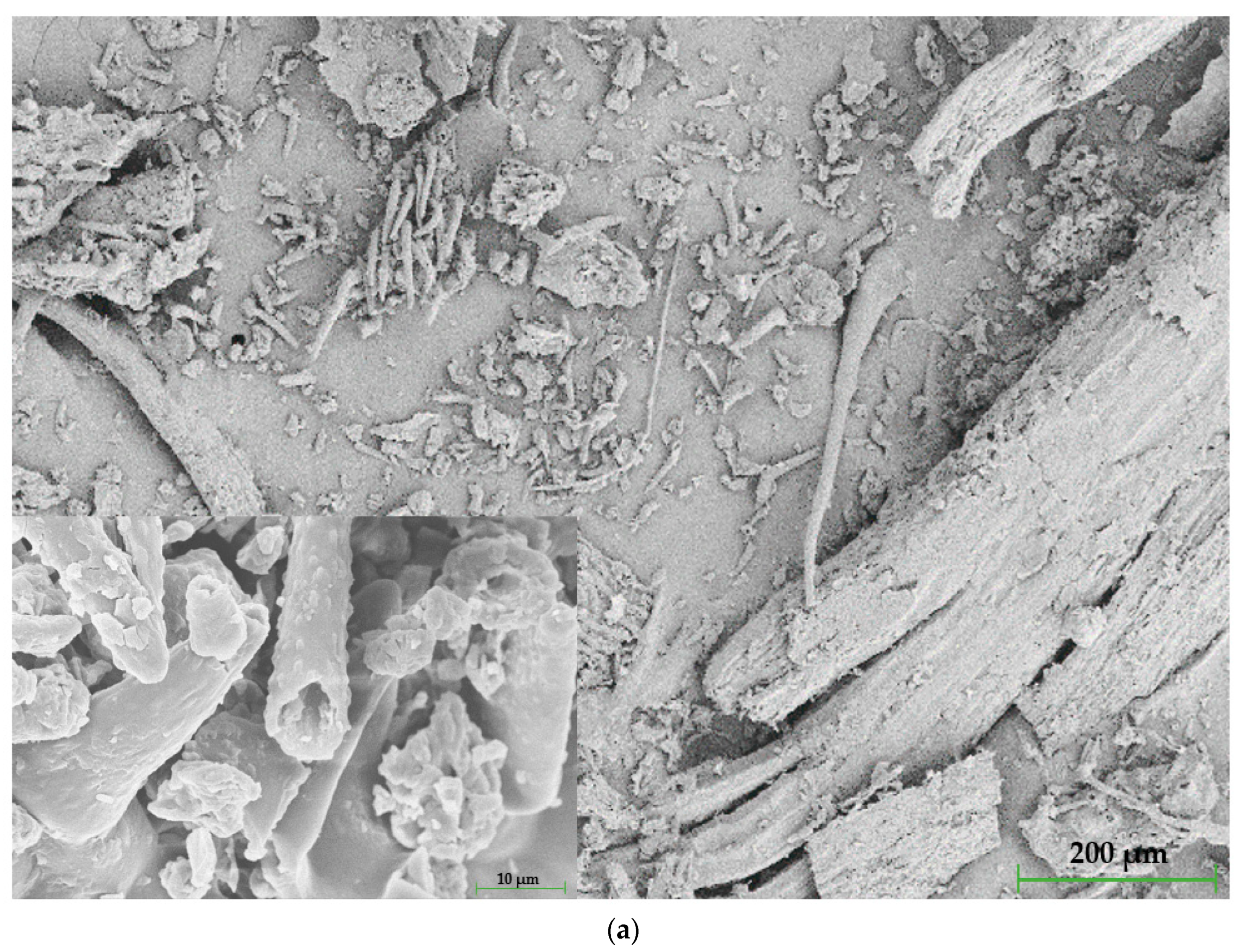

2.2.1. Grain Morphology

2.2.2. Samples Topography

2.2.3. Density

2.2.4. Wettability

2.2.5. Fourier Transform Infrared Spectroscopy

2.2.6. Differential Scanning Calorimetry

2.2.7. Rebound Resilience

2.2.8. Hardness

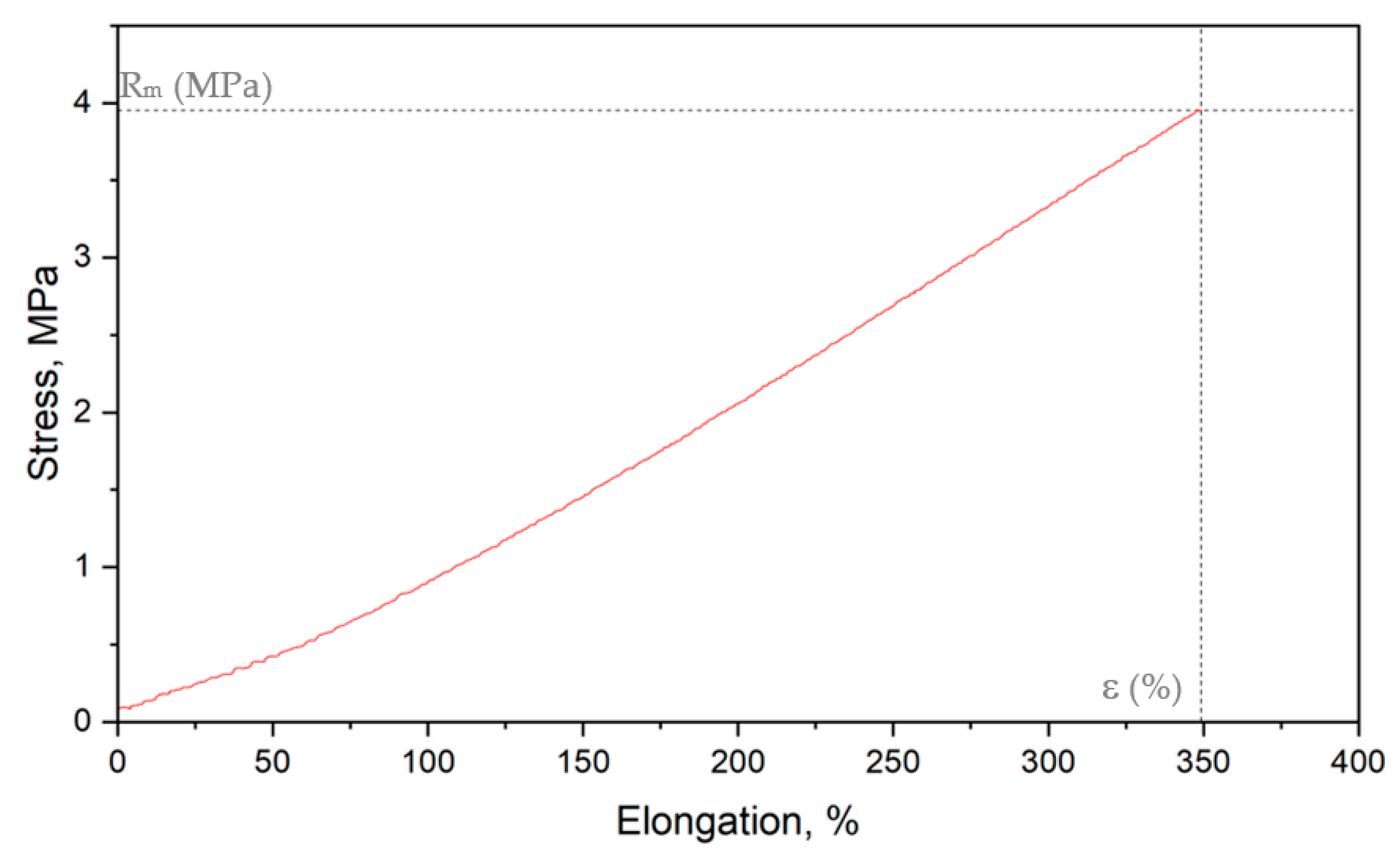

2.2.9. Static Tensile Testing

2.2.10. Antibacterial Activity Assessment

2.3. Accelerated Aging

3. Results and Discussions

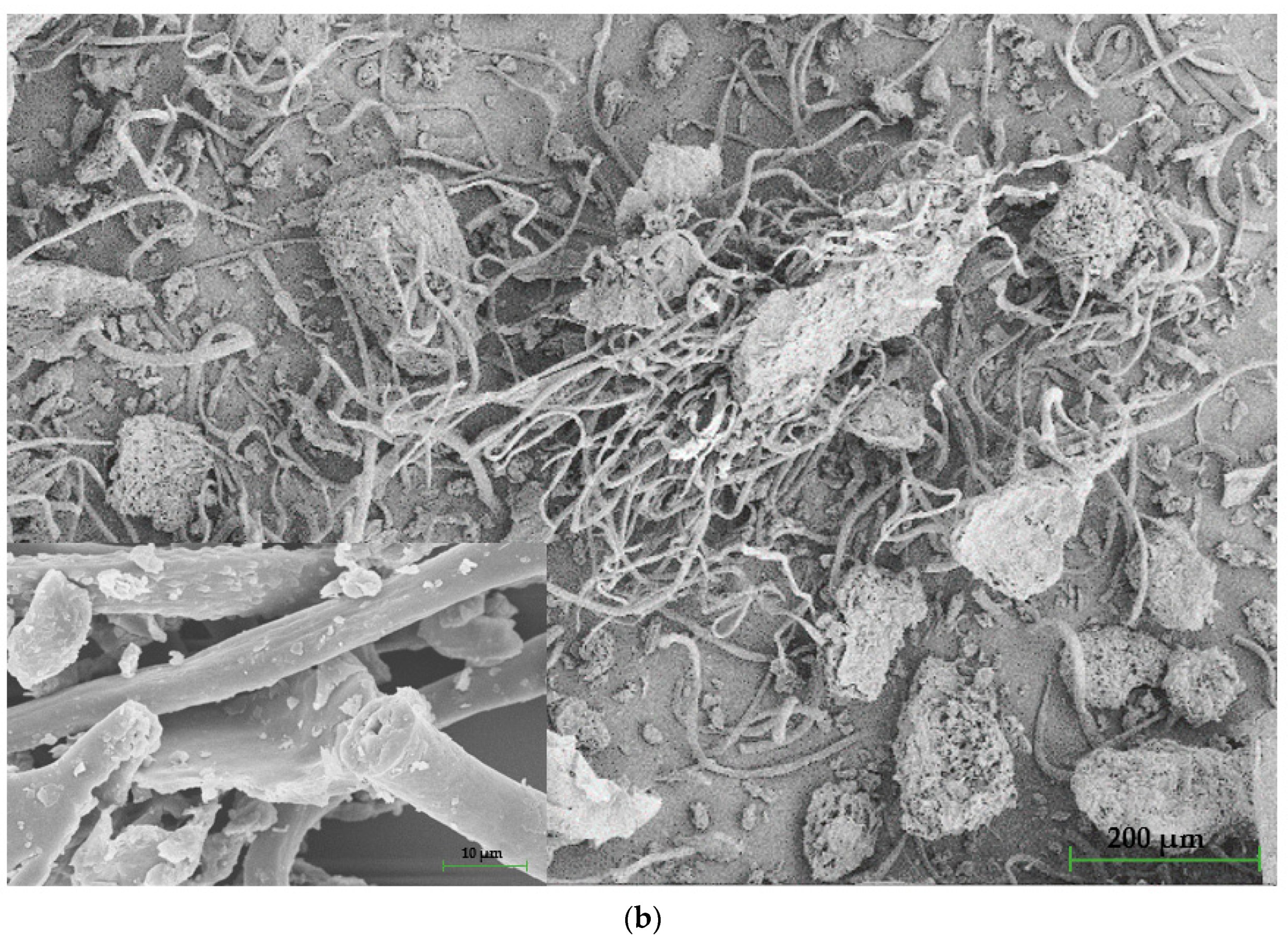

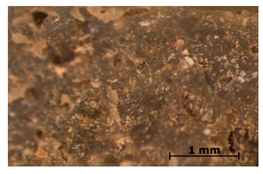

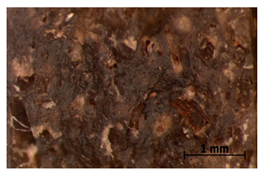

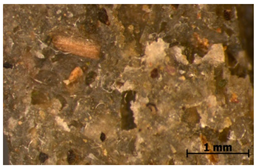

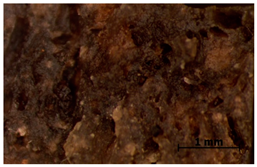

3.1. SEM Observations

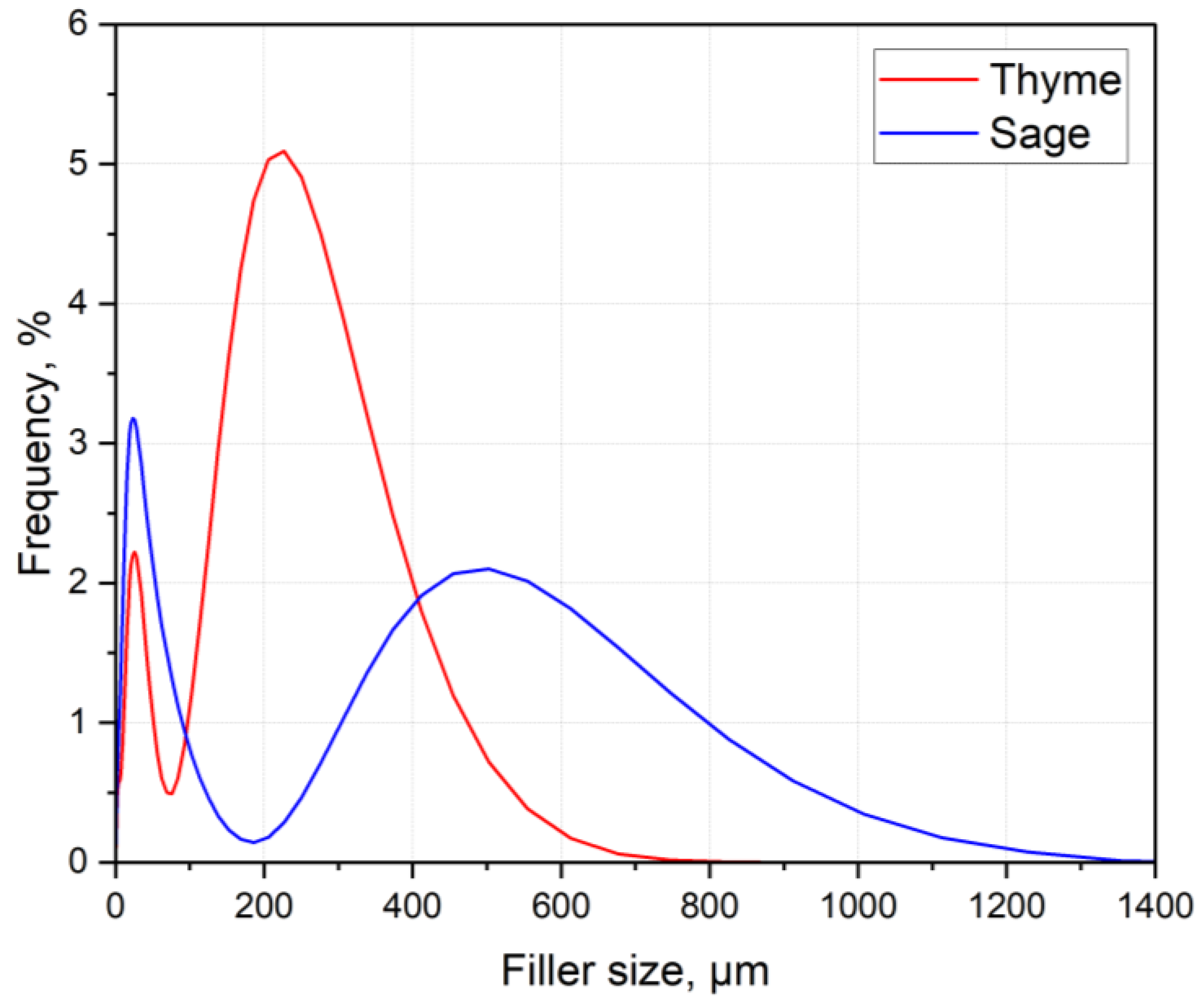

3.2. Grain Size

3.3. Density

3.4. Wettability

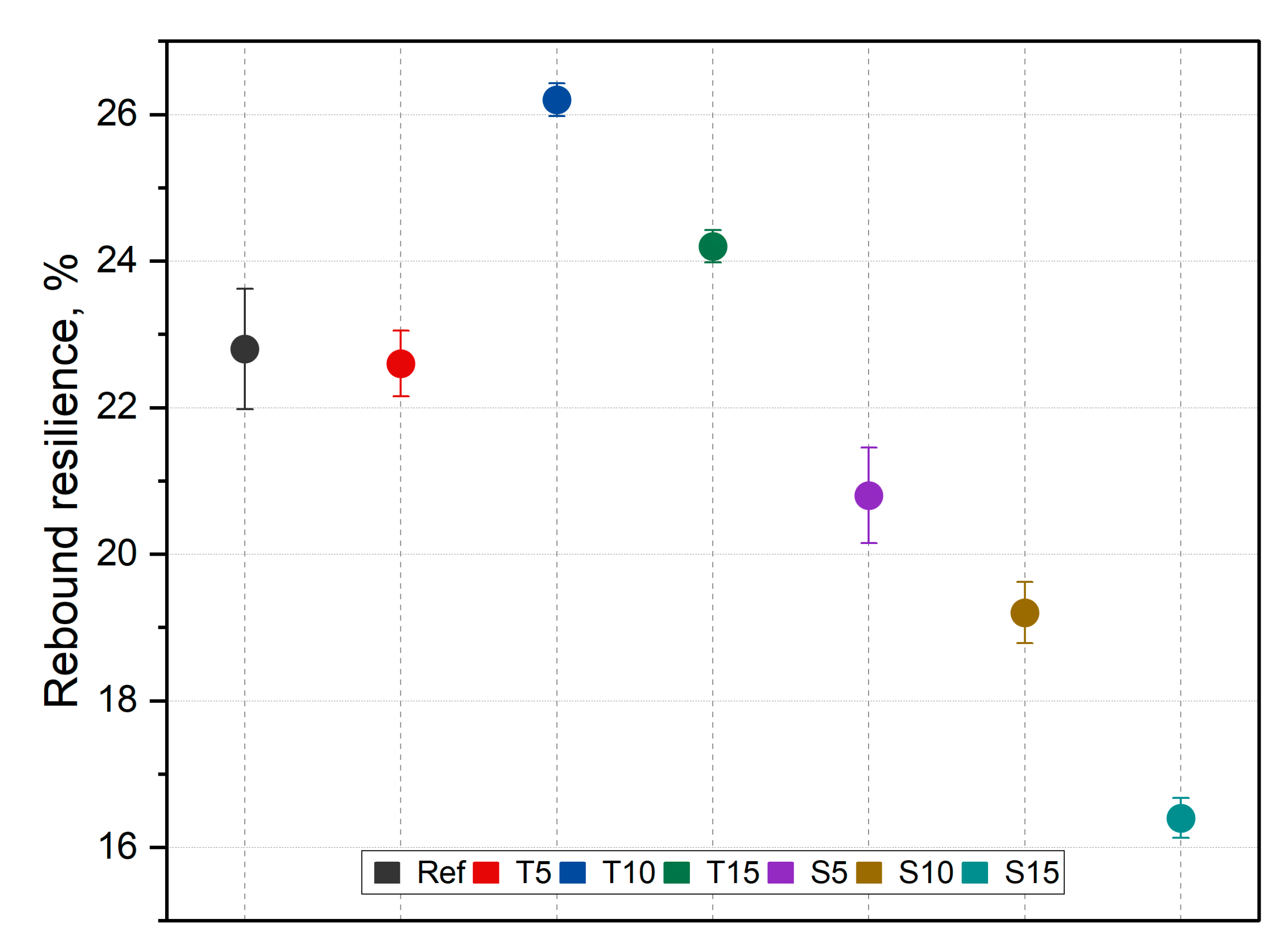

3.5. Rebound Resilience

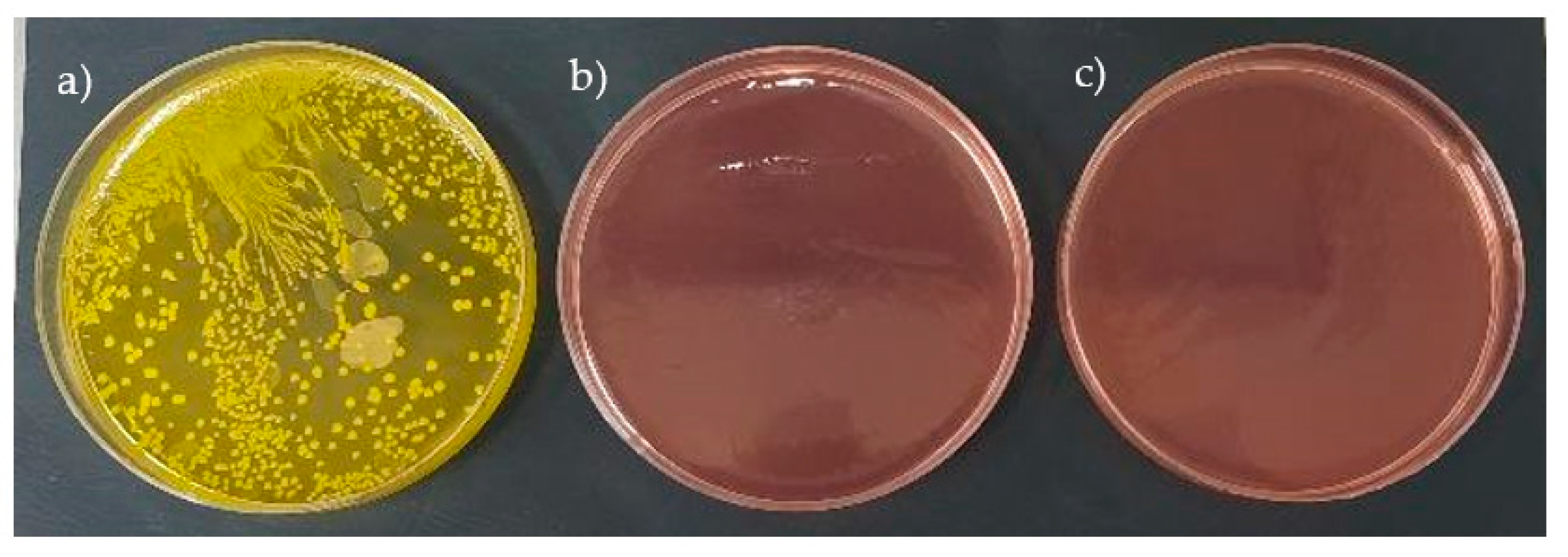

3.6. Antimicrobial Activity Measurements

3.7. Accelerated Aging

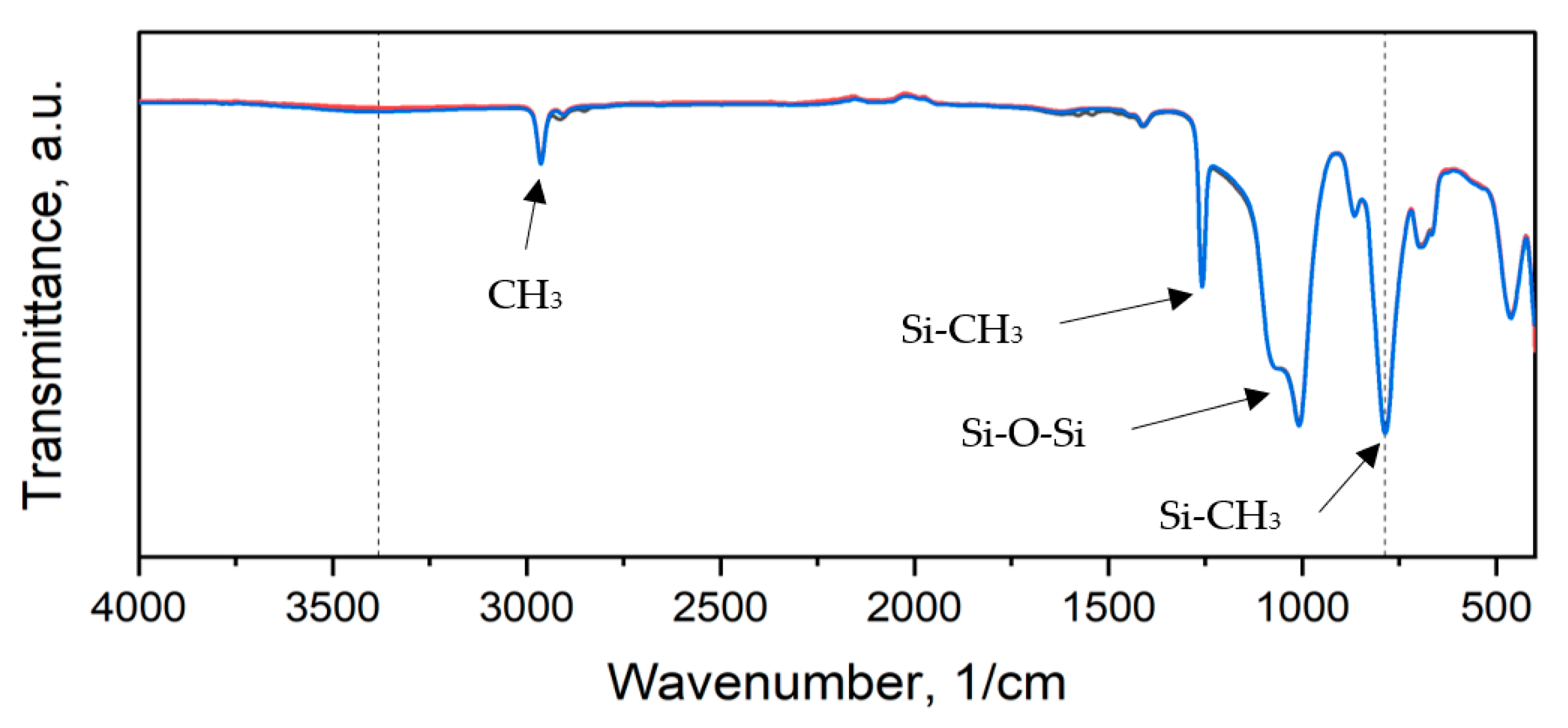

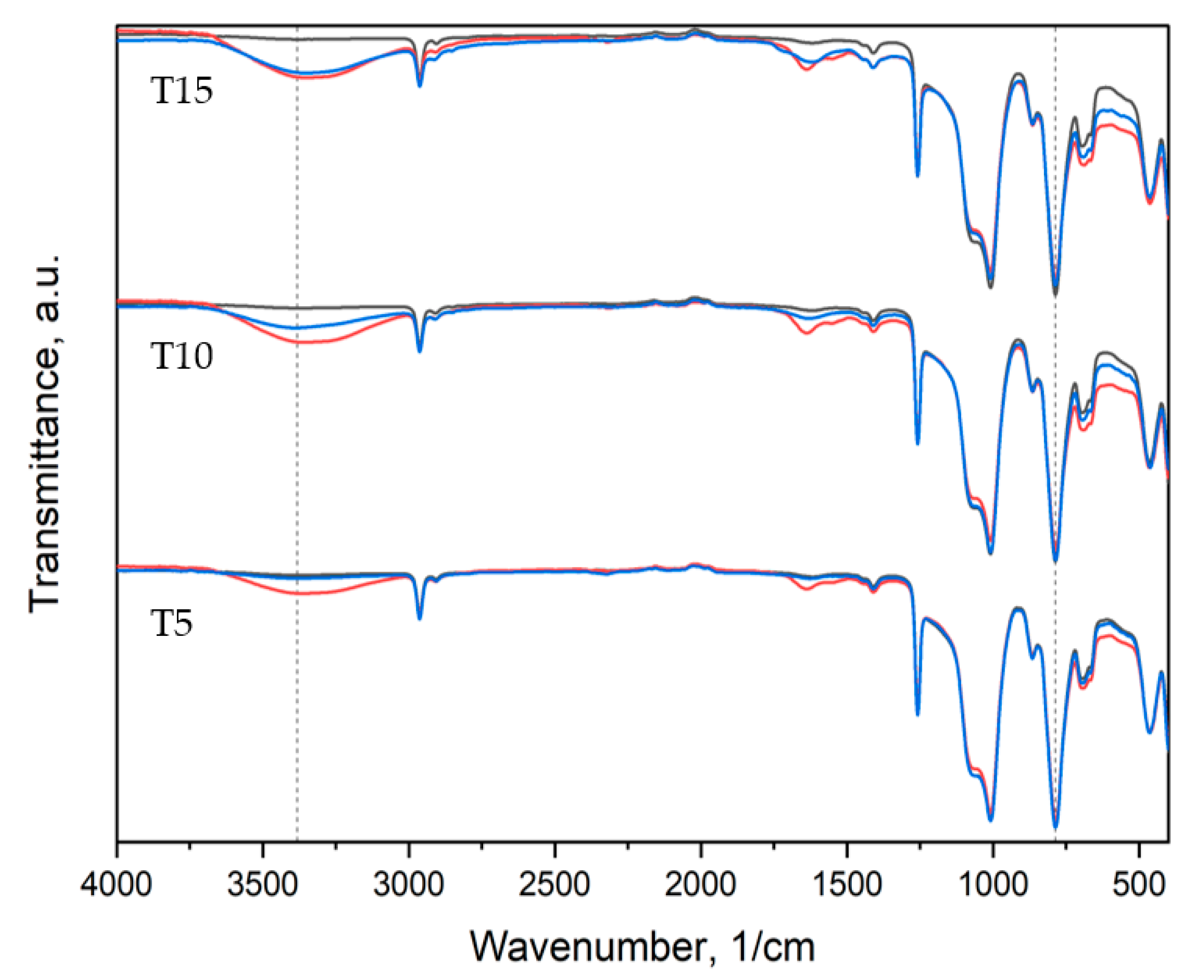

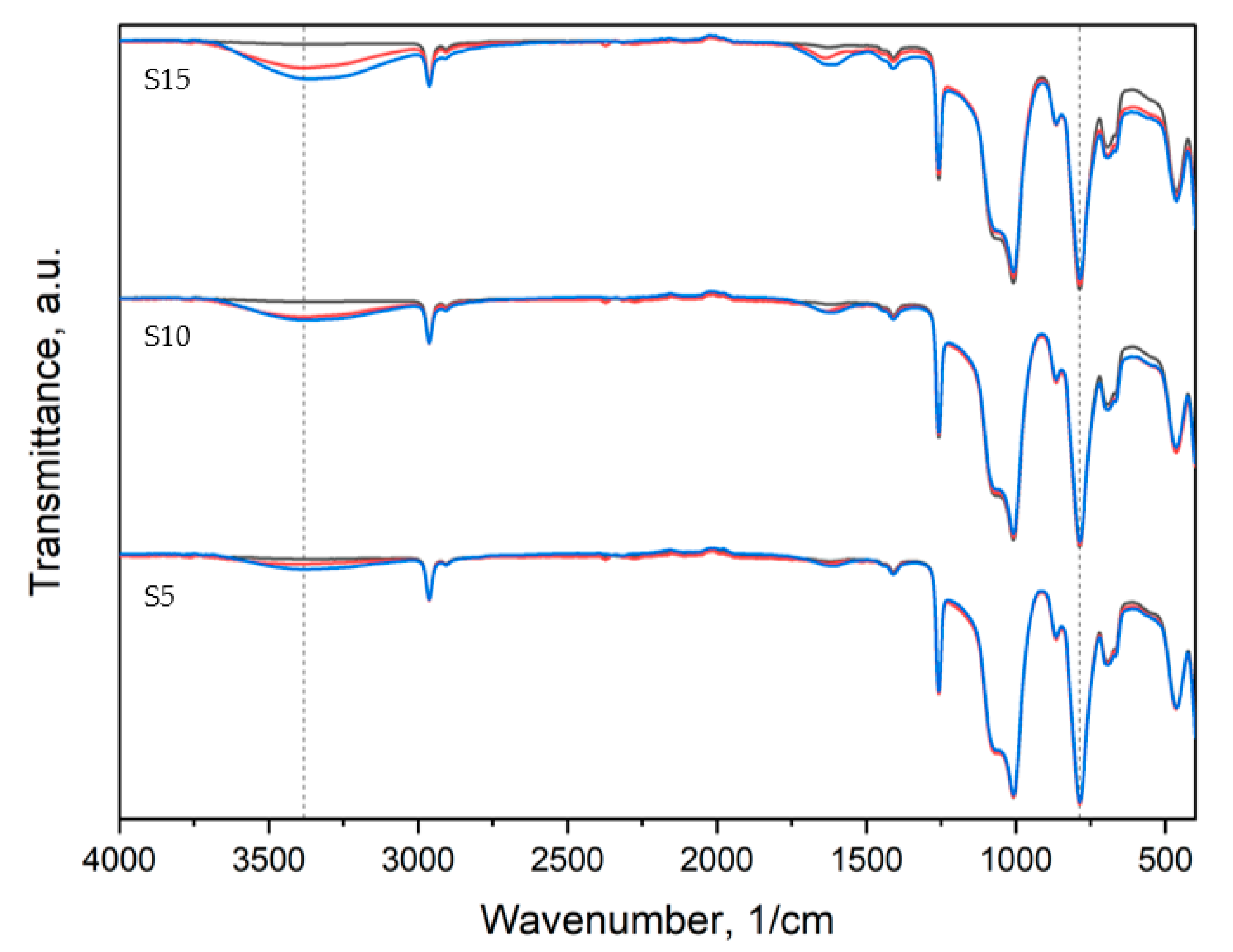

3.8. ATR-FTIR

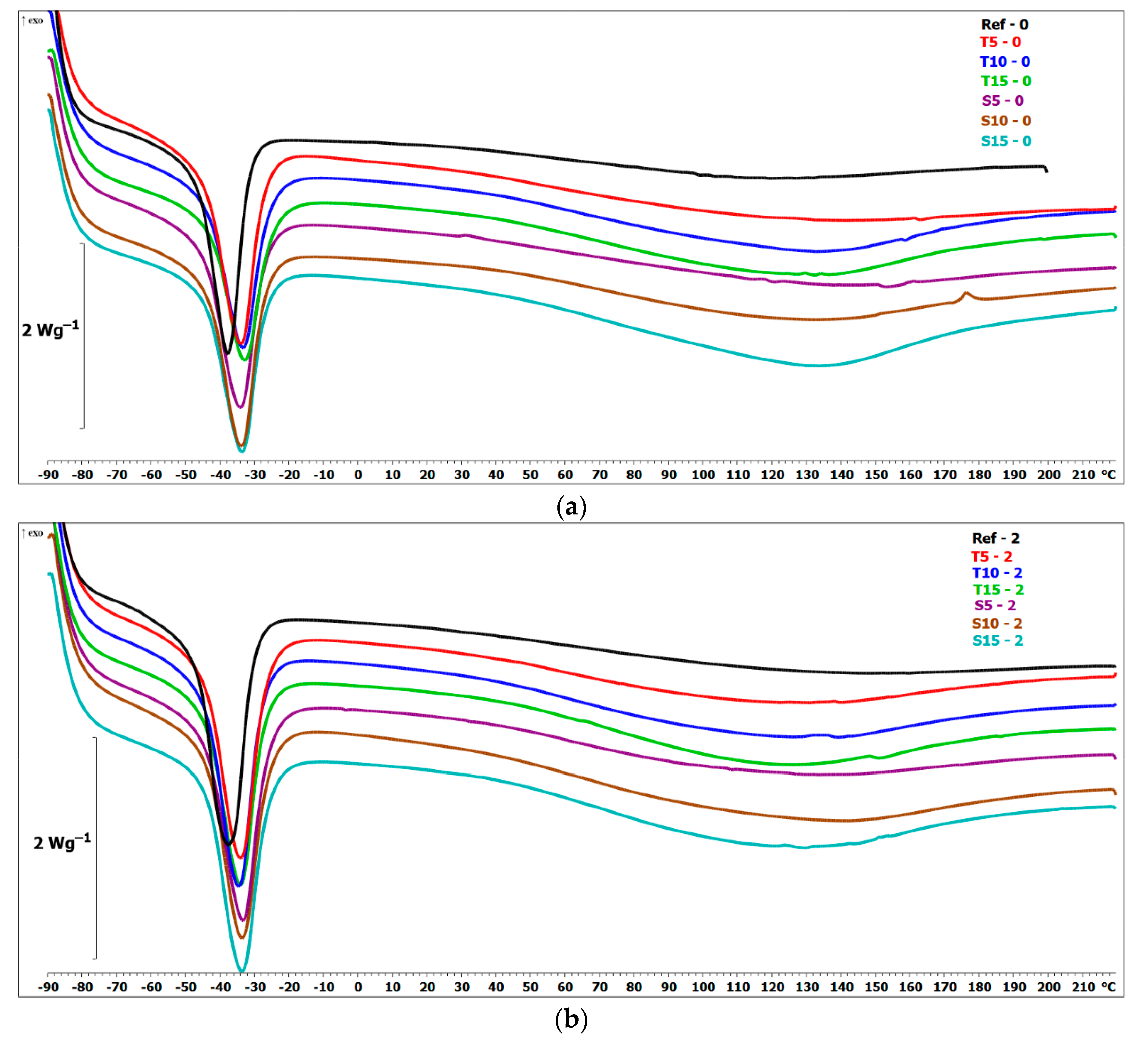

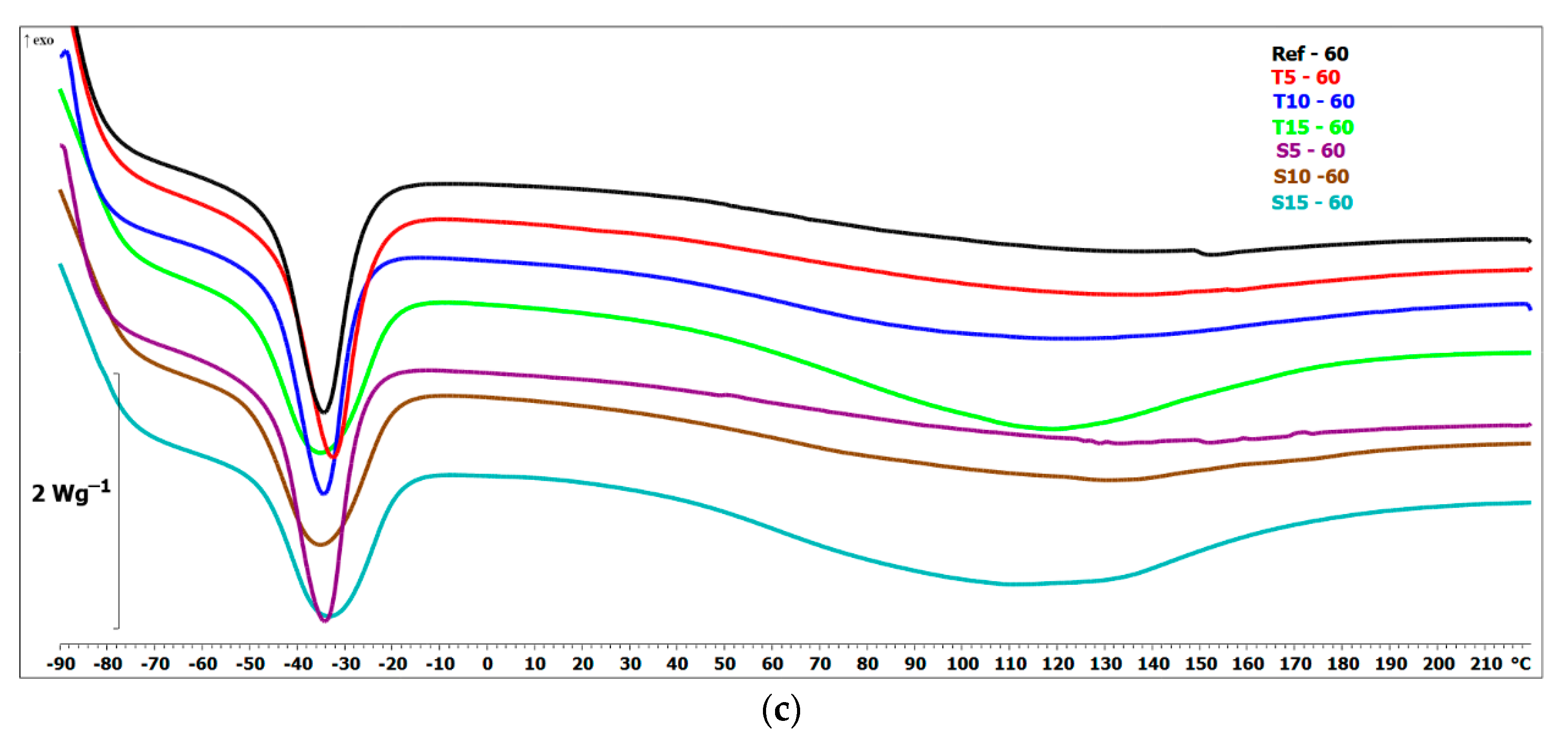

3.9. DSC

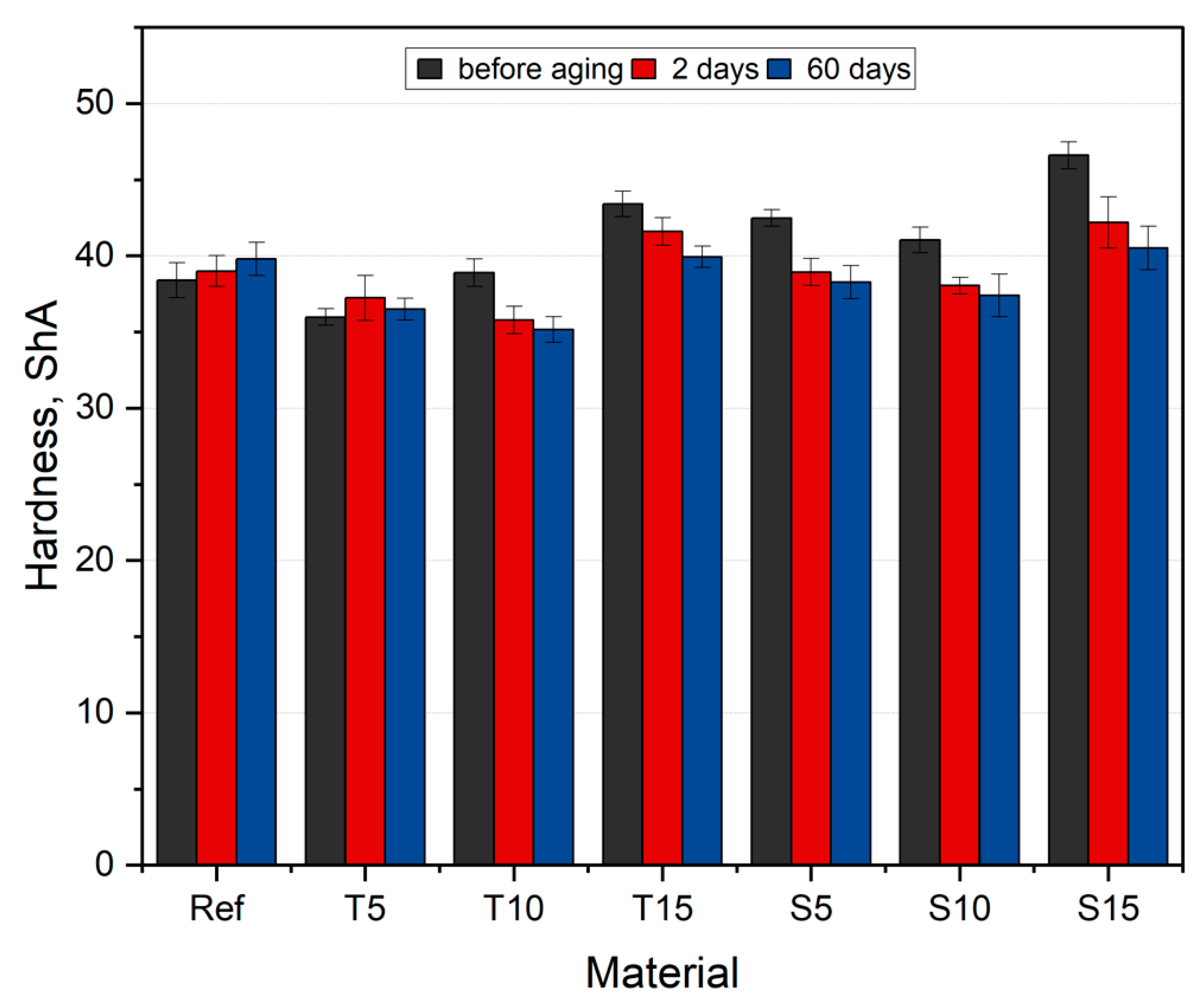

3.10. Hardness

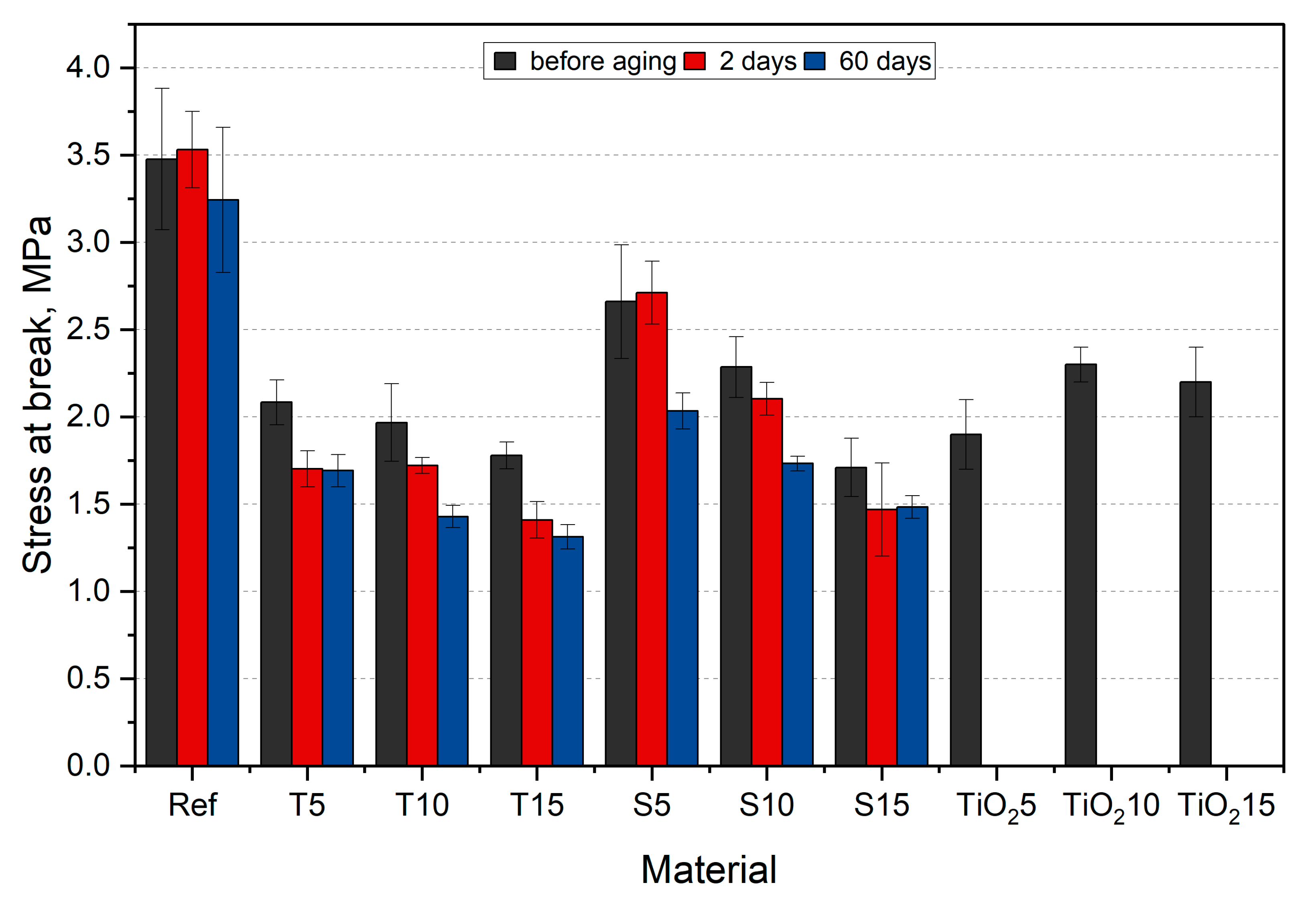

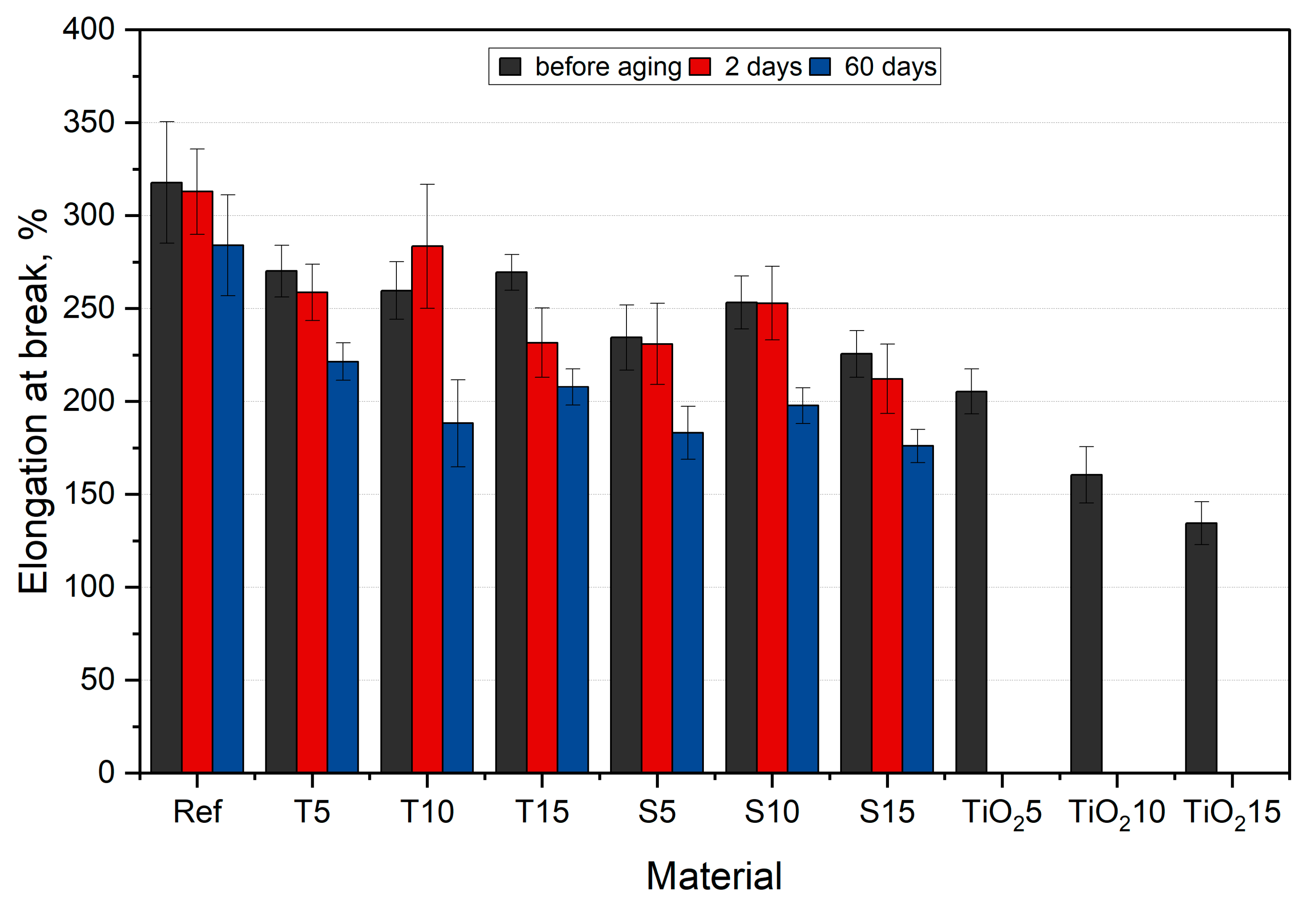

3.11. Tensile Testing

3.12. Multiple-Criteria Analysis

4. Conclusions

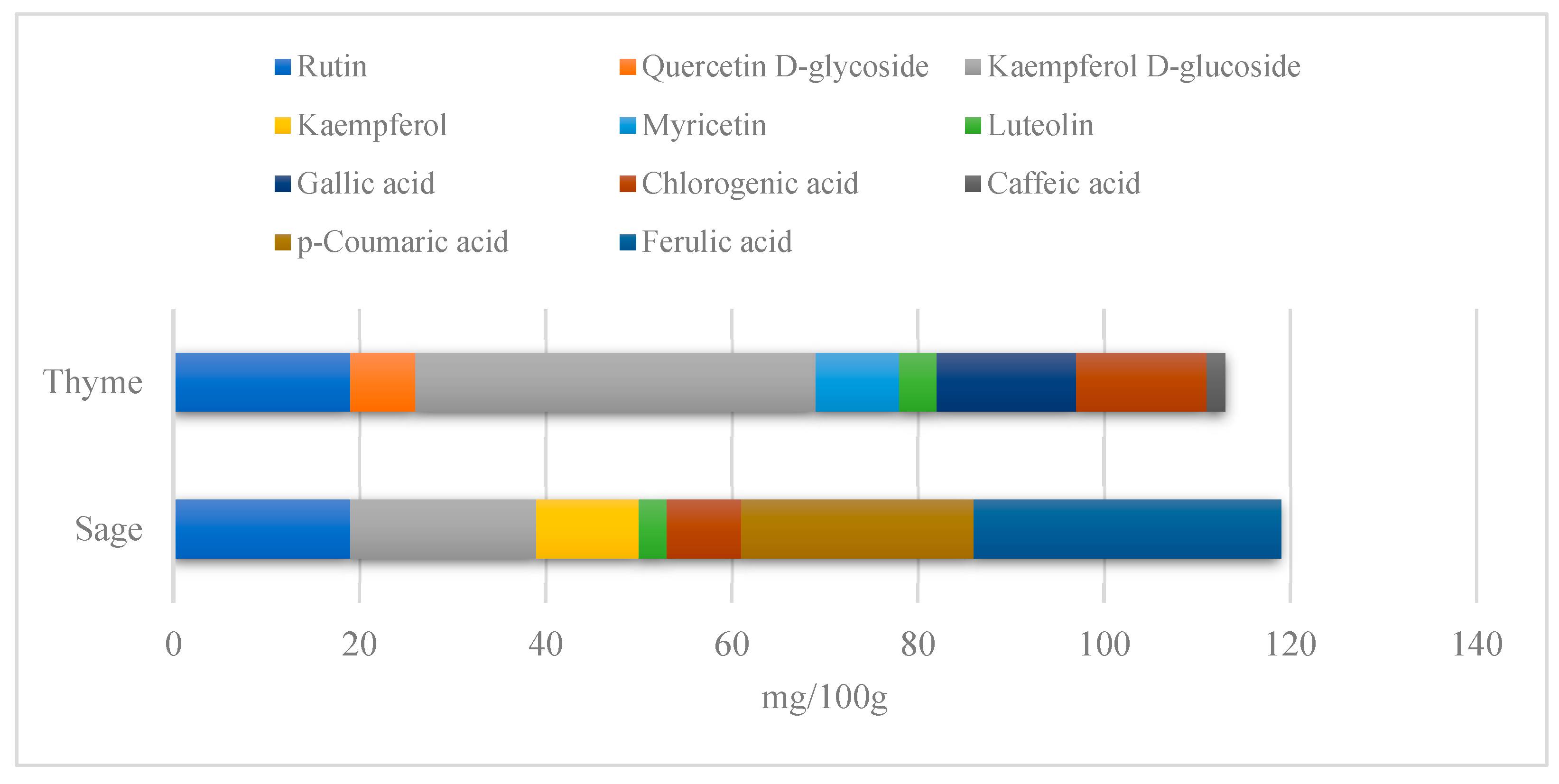

- The inclusion of thyme and sage in various mass fractions influences the chemical, mechanical, and biological properties. This is strongly dependent on the size and morphology of the grain and the chemical composition (acid content)—Figure 2;

- The introduction of the fillers did not significantly change the density and the contact angle. A slight change is observed in the case of density and contact angle measurements. The size and structure of the filler affect the tested properties. Minimal changes in the contact angle of the composite material in relation to the reference samples prove that the modified materials are hydrophobic. However, it should be emphasized that the higher the thyme content, the more the contact angle increases, as opposed to sage;

- Composites with thyme have higher resilience than composites with sage. Moreover, the lower the filler content, the higher the resilience. Adding 5 and 10% of thyme to the matrix positively influences the tested characteristics;

- The developed surface of the fillers influences the absorbency of phosphate-buffered saline (PBS) solution simulating the human extracellular fluid. Significant surface changes are observed after 60 days of aging, as can be seen in Table 4. The higher the filler content, the greater the surface changes after 60 days;

- The hardness, stress at break, and elongation at break decrease with aging time, and the longer the aging time, the smaller the differences between the tested composites, which is caused by the absorption of water by the fillers resulting in a change in their hardness (minimizing the impact of the notch). The results are stable after two days (they do not show surface changes), so they can be used in short-term applications;

- The introduction of fillers does not change silicone’s chemical backbone and melting temperature, regardless of the content. Enthalpy decreases as the filling content increases. During aging, minimal changes in FTIR spectra related to water absorption are observed, and the melting temperature decreases by about 3 °C;

- The applied modification altered the antibacterial properties and exhibited higher efficacy than strong, commonly employed antimicrobial agents;

- Among the obtained composites S5 exhibited the most superior properties based on the multiple-criteria analysis;

- The developed materials can be employed for short-term applications, such as wound dressings or coatings. Further studies will focus on improving the mechanical properties to include high-operational properties demanding applications, i.e., implants.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Curtis, J.; Colas, A. Medical Applications of Silicones. In Biomaterials Science: An Introduction to Materials; Ratner, B., Hoffman, A., Schoen, F., Eds.; Academic: Waltham, MA, USA, 2013; pp. 1106–1116. [Google Scholar]

- Bovis, M.J.; Noimark, S.; Woodhams, J.H.; Kay, C.W.M.; Weiner, J.; Peveler, W.J.; Correia, A.; Wilson, M.; Allan, E.; Parkin, I.P.; et al. Photosensitisation studies of silicone polymer doped with methylene blue and nanogold for antimicrobial applications. RSC Adv. 2015, 5, 54830–54842. [Google Scholar] [CrossRef]

- Tan, Y.; Leonhard, M.; Moser, D.; Ma, S.; Schneider-Stickler, B. Inhibition of mixed fungal and bacterial biofilms on silicone by carboxymethyl chitosan. Colloids Surf. B Biointerfaces 2016, 148, 193–199. [Google Scholar] [CrossRef] [PubMed]

- Unkovskiy, A.; Spintzyk, S.; Brom, J.; Huettig, F.; Keutel, C. Direct 3D printing of silicone facial prostheses: A preliminary experience in digital workflow. J. Prosthet. Dent. 2018, 120, 303–308. [Google Scholar] [CrossRef]

- Gildea, T.R.; Young, B.P.; Machuzak, M.S. Application of 3D Printing for Patient-Specific Silicone Stents: 1-Year Follow-Up on 2 Patients. Respiration 2018, 96, 488–494. [Google Scholar] [CrossRef] [PubMed]

- Qian, W.; Hu, X.; He, W.; Zhan, R.; Liu, M.; Zhou, D.; Huang, Y.; Hu, X.; Wang, Z.; Fei, G.; et al. Polydimethylsiloxane incorporated with reduced graphene oxide (rGO) sheets for wound dressing application: Preparation and characterization. Colloids Surf. B Biointerfaces 2018, 166, 61–71. [Google Scholar] [CrossRef]

- Ceresa, C.; Fracchia, L.; Williams, M.; Banat, I.; De Rienzo, M.D. The effect of sophorolipids against microbial biofilms on medical-grade silicone. J. Biotechnol. 2019, 309, 34–43. [Google Scholar] [CrossRef]

- Ceresa, C.; Tessarolo, F.; Maniglio, D.; Tambone, E.; Carmagnola, I.; Fedeli, E.; Caola, I.; Nollo, G.; Chiono, V.; Allegrone, G.; et al. Medical-Grade Silicone Coated with Rhamnolipid R89 Is Effective against Staphylococcus spp. Biofilms. Molecules 2019, 24, 3843. [Google Scholar] [CrossRef]

- Meran, Z.; Besinis, A.; De Peralta, T.; Handy, R.D. Antifungal properties and biocompatibility of silver nanoparticle coatings on silicone maxillofacial prostheses in vitro. J. Biomed. Mater. Res. Part B Appl. Biomater. 2017, 106, 1038–1051. [Google Scholar] [CrossRef]

- Zong, Y.; Gui, D.; Li, S.; Tan, G.; Xiong, W.; Liu, J. Preparation and thermo-mechanical properties of functionalized graphene/silicone rubber nanocomposites. In Proceedings of the 2015 16th International Conference on Electronic Packaging Technology, Changsha, China, 11–14 August 2015; pp. 30–34. [Google Scholar] [CrossRef]

- Kong, J.; Tong, Y.; Sun, J.; Wei, Y.; Thitsartarn, W.; Jayven, C.C.Y.; Muiruri, J.K.; Wong, S.Y.; He, C. Electrically conductive PDMS-grafted CNTs-reinforced silicone elastomer. Compos. Sci. Technol. 2018, 159, 208–215. [Google Scholar] [CrossRef]

- Englert, M.; Minister, F.; Moussaoui, A.; Pisula, W. Mechanical properties of thermo-oxidative aged silicone rubber thermally stabilized by titanium oxide based fillers. Polym. Test. 2022, 115, 107726. [Google Scholar] [CrossRef]

- Fang, L.; Chen, H. Mechanical and Antibacterial Properties of Silicone Rubber Compounds Filled with Silver-Zirconium Phosphate Modified by Aluminate Coupling Agent. Polym. Technol. Eng. 2017, 56, 1969–1976. [Google Scholar] [CrossRef]

- Sun, D.; Shahzad, M.B.; Li, M.; Wang, G.; Xu, D. Antimicrobial materials with medical applications. Mater. Technol. 2014, 30, B90–B95. [Google Scholar] [CrossRef]

- Felice, B.; Seitz, V.; Bach, M.; Rapp, C.; Wintermantel, E. Antimicrobial polymers: Antibacterial efficacy of silicone rubber–titanium dioxide composites. J. Compos. Mater. 2016, 51, 2253–2262. [Google Scholar] [CrossRef]

- Salih, S.I.; Oleiwi, J.K.; Ali, H.M. Study the Mechanical Properties of Polymeric Blends (SR/PMMA) Using for Maxillofacial Prosthesis Application. IOP Conf. Ser. Mater. Sci. Eng. 2018, 454, 012086. [Google Scholar] [CrossRef]

- Cohrs, N.H.; Schulz-Schönhagen, K.; Jenny, F.; Mohn, D.; Stark, W.J. Bioactive glass containing silicone composites for left ventricular assist device drivelines: Role of Bioglass 45S5® particle size on mechanical properties and cytocompatibility. J. Mater. Sci. 2017, 52, 9023–9038. [Google Scholar] [CrossRef]

- Cohrs, N.H.; Schulz-Schönhagen, K.; Mohn, D.; Wolint, P.; Bürgisser, G.M.; Stark, W.J.; Buschmann, J. Modification of silicone elastomers with Bioglass 45S5® increases in ovo tissue biointegration. J. Biomed. Mater. Res. Part B Appl. Biomater. 2018, 107, 1180–1188. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Li, W.; Liu, Q. Recent development of antifouling polymers: Structure, evaluation, and biomedical applications in nano/micro-structures. WIREs Nanomed. Nanobiotechnol. 2014, 6, 599–614. [Google Scholar] [CrossRef]

- Armentano, I.; Arciola, C.R.; Fortunati, E.; Ferrari, D.; Mattioli, S.; Amoroso, C.F.; Rizzo, J.; Kenny, J.M.; Imbriani, M.; Visai, L. The Interaction of Bacteria with Engineered Nanostructured Polymeric Materials: A Review. Sci. World J. 2014, 2014, 1–18. [Google Scholar] [CrossRef]

- Olmos, D.; González-Benito, J. Polymeric Materials with Antibacterial Activity: A Review. Polymers 2021, 13, 613. [Google Scholar] [CrossRef]

- Bahrain, S.H.K.; Rahim, N.N.C.A.; Mahmud, J.; Mohammed, M.N.; Sapuan, S.M.; Ilyas, R.A.; Alkhatib, S.E.; Asyraf, M.R.M. Hyperelastic Properties of Bamboo Cellulosic Fibre–Reinforced Silicone Rubber Biocomposites via Compression Test. Int. J. Mol. Sci. 2022, 23, 6338. [Google Scholar] [CrossRef]

- Bahrain, S.H.K.; Mahmud, J. Swelling behaviour and morphological analysis of Arenga pinnata–silicone biocomposite. Mater. Lett. 2019, 242, 32–34. [Google Scholar] [CrossRef]

- Sarraj, S.; Szymiczek, M.; Machoczek, T.; Mrówka, M. Evaluation of the Impact of Organic Fillers on Selected Properties of Organosilicon Polymer. Polymers 2021, 13, 1103. [Google Scholar] [CrossRef] [PubMed]

- Pandey, K.B.; Rizvi, S.I. Plant polyphenols as dietary antioxidants in human health and disease. Oxid. Med. Cell. Longev. 2009, 2, 270–278. [Google Scholar] [CrossRef] [PubMed]

- Maroufi, L.Y.; Ghorbani, M.; Mohammadi, M.; Pezeshki, A. Improvement of the physico-mechanical properties of antibacterial electrospun poly lactic acid nanofibers by incorporation of guar gum and thyme essential oil. Colloids Surf. A Physicochem. Eng. Asp. 2021, 622, 126659. [Google Scholar] [CrossRef]

- Koushki, P.; Bahrami, S.H.; Ranjbar-Mohammadi, M. Coaxial nanofibers from poly(caprolactone)/ poly(vinyl alcohol)/Thyme and their antibacterial properties. J. Ind. Text. 2016, 47, 834–852. [Google Scholar] [CrossRef]

- Lin, D.; Zheng, Y.; Wang, X.; Huang, Y.; Ni, L.; Chen, X.; Wu, Z.; Huang, C.; Yi, Q.; Li, J.; et al. Study on physicochemical properties, antioxidant and antimicrobial activity of okara soluble dietary fiber/sodium carboxymethyl cellulose/thyme essential oil active edible composite films incorporated with pectin. Int. J. Biol. Macromol. 2020, 165, 1241–1249. [Google Scholar] [CrossRef]

- Członka, S.; Kairytė, A.; Miedzińska, K.; Strąkowska, A.; Adamus-Włodarczyk, A. Mechanically Strong Polyurethane Composites Reinforced with Montmorillonite-Modified Sage Filler (Salvia officinalis L.). Int. J. Mol. Sci. 2021, 22, 3744. [Google Scholar] [CrossRef]

- Masłowski, M.; Aleksieiev, A.; Miedzianowska, J.; Strzelec, K. Potential Application of Peppermint (Mentha piperita L.), German Chamomile (Matricaria chamomilla L.) and Yarrow (Achillea millefolium L.) as Active Fillers in Natural Rubber Biocomposites. Int. J. Mol. Sci. 2021, 22, 7530. [Google Scholar] [CrossRef]

- Montanes, N.; Garcia-Sanoguera, D.; Segui, V.J.; Fenollar, O.; Boronat, T. Processing and Characterization of Environmentally Friendly Composites from Biobased Polyethylene and Natural Fillers from Thyme Herbs. J. Polym. Environ. 2017, 26, 1218–1230. [Google Scholar] [CrossRef]

- Hamad, Q.A.; Abed, M.S. Investigation of Thyme and Pumpkin Nanopowders Reinforced Epoxy Matrix Composites. J. Mech. Eng. Res. Dev. 2019, 42, 153–157. [Google Scholar] [CrossRef]

- Kashi, S.; Varley, R.; De Souza, M.; Al-Assafi, S.; Di Pietro, A.; de Lavigne, C.; Fox, B. Mechanical, Thermal, and Morphological Behavior of Silicone Rubber during Accelerated Aging. Polym. Technol. Eng. 2018, 57, 1687–1696. [Google Scholar] [CrossRef]

- Lorenz, G.; Kandelbauer, A. Silicones. In Handbook of Thermoset Plastics, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 555–575. [Google Scholar] [CrossRef]

- Kaneko, T.; Ito, S.; Minakawa, T.; Hirai, N.; Ohki, Y. Degradation mechanisms of silicone rubber under different aging conditions. Polym. Degrad. Stab. 2019, 168, 108936. [Google Scholar] [CrossRef]

- Dragon Skin 30. Available online: https://www.smooth-on.com/products/dragon-skin-30/ (accessed on 9 July 2022).

- Sadowska, U.; Kopeć, A.; Kourimska, L.; Zarubova, L.; Kloucek, P. The effect of drying methods on the concentration of compounds in sage and thyme. J. Food Process. Preserv. 2017, 41, e13286. [Google Scholar] [CrossRef]

- Kazimierczak, R.; Hallmann, E.; Sokołowska, O.; Rembiałkowska, E. Bioactive substances content in selected species of medical plants from organic and conventional production. J. Res. Appl. Agric. Eng. 2011, 56, 200–205. [Google Scholar]

- EN ISO 1183-1: 2006; Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method. International Organization of Standardization: Geneva, Switzerland, 2006.

- EN 828:2013; Adhesives. Wettability. Determination by measurement of contact angle and surface free energy of solid surface. European Standard: Pilsen, Czech Republic, 2013.

- EN ISO 11357-1:2016; Plastics—Differential scanning calorimetry (DSC)—Part 1: General principles. International Organization of Standardization: Geneva, Switzerland, 2016.

- EN ISO 4662:2017; Rubber, Vulcanized or Thermoplastic—Determination of Rebound Resilience. International Organization of Standardization: Geneva, Switzerland, 2017.

- ISO 7619-1:2010; Rubber, Vulcanized or Thermoplastic-Determination of Indentation Hardness-Part 1: Durometer Method (Shore Hardness). International Organization of Standardization: Geneva, Switzerland, 2010.

- EN ISO 527-1:2012; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization of Standardization: Geneva, Switzerland, 2012.

- ISO 22196:2011; Measurement of Antibacterial Activity on Plastics and Other Non-Porous Surfaces. International Organization of Standardization: Geneva, Switzerland, 2011.

- EN ISO 10993-13:2010; Biological Evaluation of Medical Devices—Part 13: Identification and Quantification of Degradation Products from Polymeric Medical Devices. International Organization of Standardization: Geneva, Switzerland, 2010.

- Nowak, D. Uprawiamy Rośliny Zielarskie; Centrum Doradztwa Rolniczego w Brwinowie: Poznań, Poland, 2014. [Google Scholar]

- Bulk Densities. Available online: https://www.binmaster.com/_resources/dyn/files/75343622z9caf67af/_fn/Bulk+Density.pdf (accessed on 18 October 2022).

- Zhang, Z.; Pang, G.; Lu, M.; Gao, C.; Jiang, X. Research on Silicone Rubber Sheds of Decay-Like Fractured Composite Insulators Based on Hardness, Hydrophobicity, NMR, and FTIR. Polymers 2022, 14, 3424. [Google Scholar] [CrossRef] [PubMed]

- Ozkan, E.; Ozkan, F.T.; Allan, E.; Parkin, I.P. The use of zinc oxide nanoparticles to enhance the antibacterial properties of light-activated polydimethylsiloxane containing crystal violet. RSC Adv. 2015, 5, 8806–8813. [Google Scholar] [CrossRef]

- Dardouri, M.; Aljnadi, I.M.; Deuermeier, J.; Santos, C.; Costa, F.; Martin, V.; Fernandes, M.H.; Gonçalves, L.; Bettencourt, A.; Gomes, P.S.; et al. Bonding antimicrobial rhamnolipids onto medical grade PDMS: A strategy to overcome multispecies vascular catheter-related infections. Colloids Surfaces B Biointerfaces. 2022, 217, 112679. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Guo, X. Aging Condition Assessment of Silicone Rubber for Composite In-sulators Based on FTIR. High Volt. Appar. 2015, 51, 62–67. [Google Scholar]

- Yang, H.; Nguyen, Q.T.; Ding, Y.; Long, Y.; Ping, Z. Investigation of poly(dimethyl siloxane) (PDMS)–solvent interactions by DSC. J Memb Sci. 2000, 164, 37–43. [Google Scholar] [CrossRef]

- Bosq, N.; Guigo, N.; Persello, J.; Sbirrazzuoli, N. Melt and glass crystallization of PDMS and PDMS silica nanocomposites. Phys. Chem. Chem. Phys. 2014, 16, 7830–7840. [Google Scholar] [CrossRef]

- Mirabedini, S.; Mohseni, M.; PazokiFard, S.; Esfandeh, M. Effect of TiO2 on the mechanical and adhesion properties of RTV silicone elastomer coatings. Colloids Surf. A Physicochem. Eng. Asp. 2008, 317, 80–86. [Google Scholar] [CrossRef]

- Xu, R.; Luo, G.; Xia, H.; He, W.; Zhao, J.; Liu, B.; Tan, J.; Zhou, J.; Liu, D.; Wang, Y.; et al. Novel bilayer wound dressing composed of silicone rubber with particular micropores enhanced wound re-epithelialization and contraction. Biomaterials 2015, 40, 1–11. [Google Scholar] [CrossRef] [PubMed]

| Property | Unit | Value |

|---|---|---|

| Density | (g/cm3) | 1.08 |

| Viscosity | (mPa∙s) | 20 |

| Hardness | (ShA) | 30 |

| Strain at break | (MPa) | 3.45 |

| Elongation at break | (%) | 364 |

| Compound (g/100 g Fresh Weight) | Thyme | Sage |

|---|---|---|

| Protein | 0.59 ± 0.01 | 0.62 ± 0.01 |

| Crude fat | 1.06 ± 0.12 | 5.27 ± 0.33 |

| Total carbohydrates | 22.30 ± 0.69 | 18.45 ± 0.39 |

| Ash | 2.55 ± 0.14 | 2.37 ± 0.07 |

| Filler | Content (%) | Code |

|---|---|---|

| Control group | Ref | |

| Thyme | 5 | T5 |

| 10 | T10 | |

| 15 | T15 | |

| Sage | 5 | S5 |

| 10 | S10 | |

| 15 | S15 |

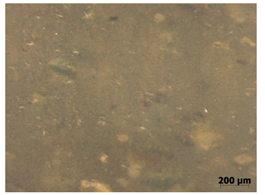

| Material | Aging Days | ||

|---|---|---|---|

| Before Aging | 2 Days | 60 Days | |

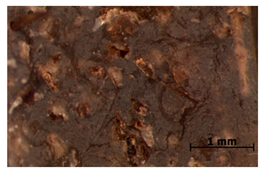

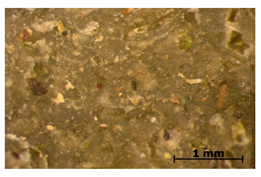

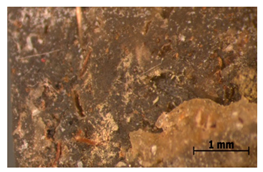

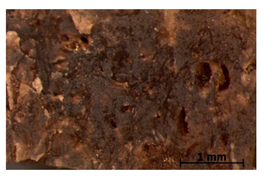

| Ref |  |  |  |

| T5 |  |  |  |

| T10 |  |  |  |

| T15 |  |  |  |

| S5 |  |  |  |

| S10 |  |  |  |

| S15 |  |  |  |

| Material | Aging Days | ||

|---|---|---|---|

| Before Aging | 2 Days | 60 Days | |

| T5 |  |  |  |

| T10 |  |  |  |

| T15 |  |  |  |

| S5 |  |  |  |

| S10 |  |  |  |

| S15 |  |  |  |

| Property | Weight | Material | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ref | T5 | T10 | T15 | S5 | S10 | S15 | |||||||||

| C | W | C | W | C | W | C | W | C | W | C | W | C | W | ||

| Density | 1 | 7 | 7 | 7 | 7 | 7 | 7 | 5 | 5 | 6 | 6 | 6 | 6 | 5 | 5 |

| Wettability | 4 | 2 | 8 | 3 | 12 | 5 | 20 | 7 | 28 | 6 | 24 | 4 | 16 | 1 | 4 |

| Rebound resilience | 2 | 5 | 10 | 7 | 14 | 6 | 12 | 4 | 8 | 5 | 10 | 3 | 6 | 1 | 2 |

| Aging impact | 7 | 7 | 49 | 3 | 21 | 1 | 7 | 2 | 14 | 6 | 42 | 4 | 28 | 5 | 35 |

| Hardness | 3 | 6 | 18 | 7 | 21 | 5 | 15 | 2 | 6 | 3 | 9 | 4 | 12 | 1 | 3 |

| Stress at break | 6 | 7 | 42 | 4 | 24 | 3 | 18 | 2 | 12 | 6 | 36 | 5 | 30 | 1 | 6 |

| Elongation at break | 5 | 7 | 35 | 6 | 30 | 4 | 20 | 5 | 25 | 2 | 10 | 3 | 15 | 1 | 5 |

| Σ | 169 | 129 | 99 | 98 | 137 | 113 | 60 | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarraj, S.; Szymiczek, M.; Jurczyk, S. Influence of Herbal Fillers Addition on Selected Properties of Silicone Subjected to Accelerated Aging. Polymers 2023, 15, 42. https://doi.org/10.3390/polym15010042

Sarraj S, Szymiczek M, Jurczyk S. Influence of Herbal Fillers Addition on Selected Properties of Silicone Subjected to Accelerated Aging. Polymers. 2023; 15(1):42. https://doi.org/10.3390/polym15010042

Chicago/Turabian StyleSarraj, Sara, Małgorzata Szymiczek, and Sebastian Jurczyk. 2023. "Influence of Herbal Fillers Addition on Selected Properties of Silicone Subjected to Accelerated Aging" Polymers 15, no. 1: 42. https://doi.org/10.3390/polym15010042

APA StyleSarraj, S., Szymiczek, M., & Jurczyk, S. (2023). Influence of Herbal Fillers Addition on Selected Properties of Silicone Subjected to Accelerated Aging. Polymers, 15(1), 42. https://doi.org/10.3390/polym15010042