Spatial Distribution of Cocoa Quality: Relationship between Physicochemical, Functional and Sensory Attributes of Clones from Southern Colombia

Abstract

1. Introduction

2. Materials and Methods

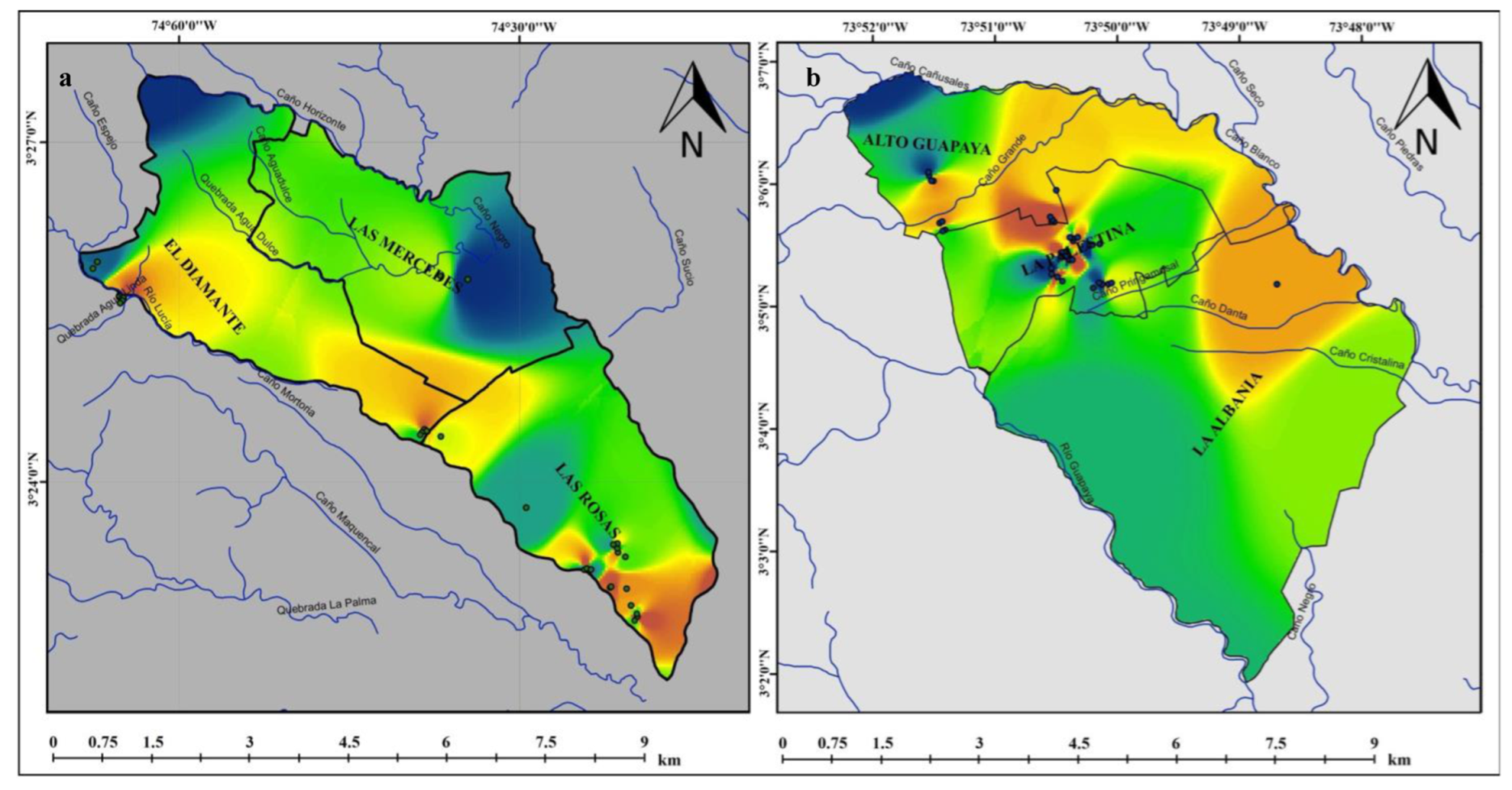

2.1. Description of the Study Area and Identified Cocoa Clones

2.2. Postharvest Sample Handling

2.3. Determination of Physicochemical and Functional Properties of Cocoa Clones

2.4. Sensory Evaluation of Cocoa Clones

2.5. Data Analysis

3. Results

3.1. Physicochemical and Functional Properties of Cocoa Clones

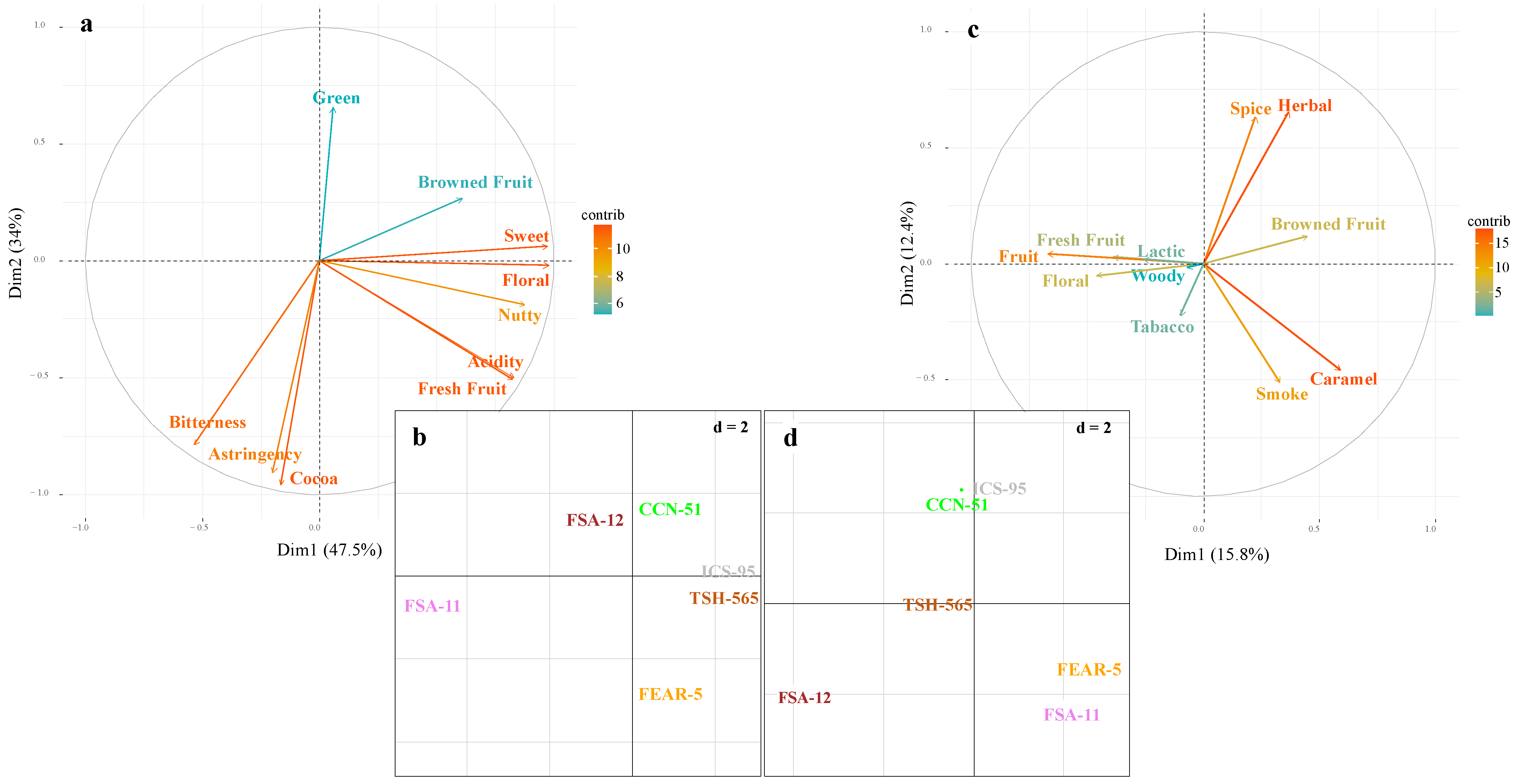

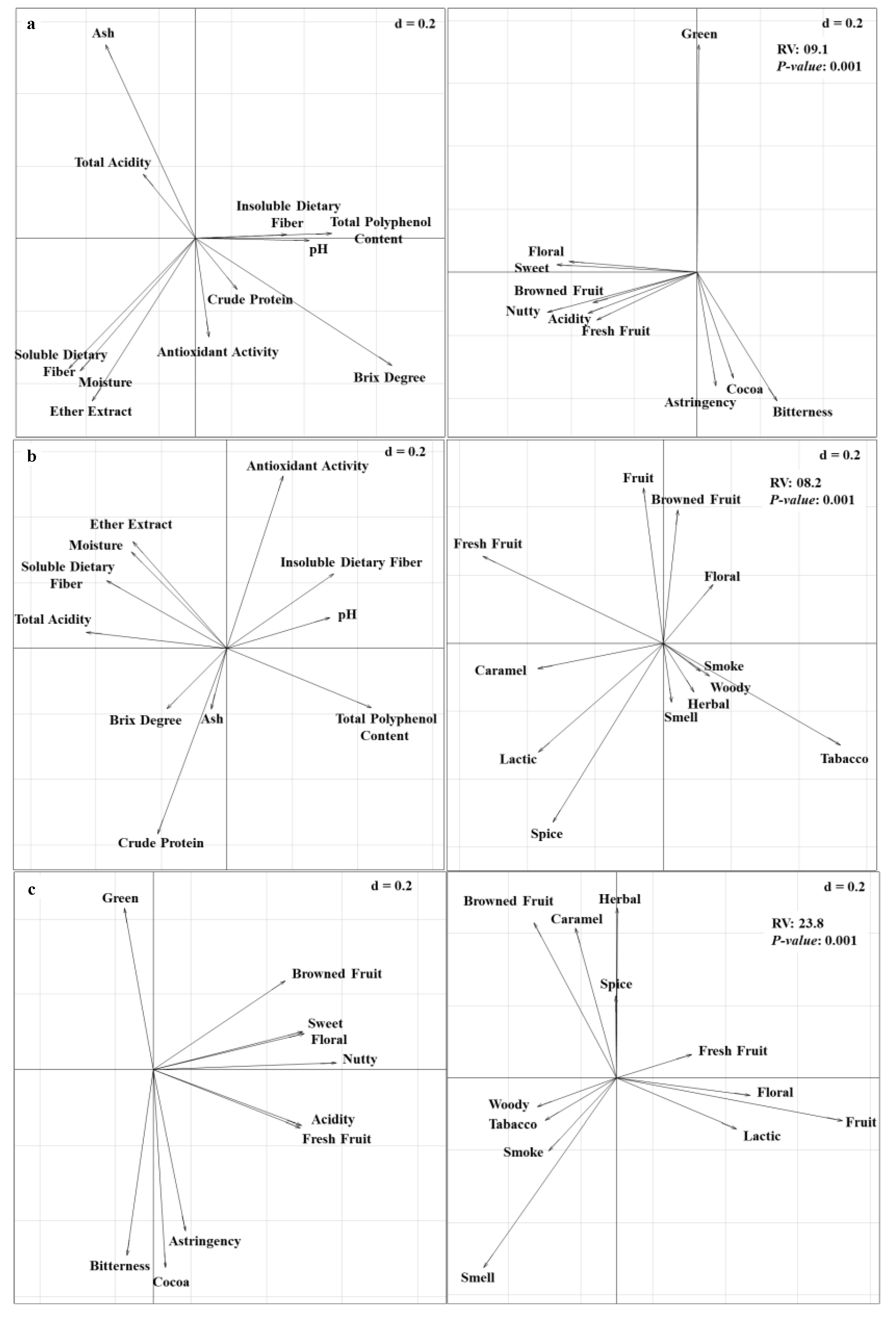

3.2. Sensory Attributes of Cocoa Clones

4. Discussion

4.1. Physicochemical Properties, Phenolic and Antioxidant Contents

4.2. Sensory Attributes

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ICCO. ICCO Quarterly Bulletin of Cocoa Statistics. The International Cocoa Organization (ICCO) Cocoa Producing and Cocoa Consuming Countries. Supply & Demand. Available online: https://www.icco.org/statistics/ (accessed on 26 July 2022).

- Fibrianto, K.; Fajrul Azhar, L.O.M.; Widyotomo, S.; Harijono, H. Effect of cocoa bean origin and conching time on the physicochemical and microstructural properties of Indonesian dark chocolate. Braz. J. Food Technol. 2021, 24, 1–14. [Google Scholar] [CrossRef]

- Perez, M.; Lopez-Yerena, A.; Vallverdú-Queralt, A.; Vallverd U-Queralt, A. Traceability, authenticity and sustainability of cocoa and chocolate products: A challenge for the chocolate industry. Crit. Rev. Food Sci. Nutr. 2021, 62, 475–489. [Google Scholar] [CrossRef]

- Frauendorfer, F.; Schieberle, P. Changes in Key Aroma Compounds of Criollo Cocoa Beans During Roasting. J. Agric. Food Chem. 2008, 56, 10244–10251. [Google Scholar] [CrossRef]

- Luna, F.; Crouzillat, D.; Cirou, L.; Bucheli, P. Chemical Composition and Flavor of Ecuadorian Cocoa Liquor. J. Agric. Food Chem. 2002, 50, 3527–3532. [Google Scholar] [CrossRef]

- González, Y.; Pérez, E.; Palomino, C. Factores que inciden en la calidad sensorial del chocolate. Actual Nutr. 2012, 13, 314–331. [Google Scholar]

- Pino Alea, J.A.; Llera, L.; Roncal, E. Caracterización del perfil de compuestos volátiles de licores de cacao cubanos. Cienc. Tecnol. Aliment. 2011, 21, 41–49. [Google Scholar]

- Brito-Vega, H.; Salaya-Domínguez, J.M.; Gómez-Méndez, E.; Gómez-Vázquez, A.; Antele-Gómez, J.B. Physico-chemical properties of soil and pods (Theobroma cacao L.) in cocoa agroforestry systems. J. Agron. 2018, 17, 48–55. [Google Scholar] [CrossRef][Green Version]

- Sánchez Vargas, A.D.P.; Castellanos Domínguez, O.F.; Domínguez Martínez, K.P. Mejoramiento de la poscosecha del cacao a partir del roadmapping. Rev. Ing. Investig. 2008, 28, 150–158. [Google Scholar]

- Cuellar, L.M.; Espinosa, C.M.O.; Sánchez, Y.K.A.; Cruz, L.G.; Salazar, J.C.S. Organoleptic quality assessment of Theobroma cacao L. in cocoa farms in northern Huila, Colombia. Acta Agron. 2018, 67, 46–52. [Google Scholar] [CrossRef]

- Fernández, R.D.R.; Gallo, F.W.M.; Cedeño, Á.M.G.; Galeas, M.M.P.; Quinteros, H.N.M.; Ferrín, L.M.C.; Álvarez, A.E.B.; Morante, P.E.N. Efecto del Tipo y Tiempo de Fermentación en la Calidad Física y Química del Cacao (Theobroma cacao L.) Tipo Nacional. Available online: https://dialnet.unirioja.es/descarga/articulo/4149700.pdf (accessed on 18 October 2022).

- Alean, J.; Chejne, F.; Rojano, B. Degradation of polyphenols during the cocoa drying process. J. Food Eng. 2016, 189, 99–105. [Google Scholar] [CrossRef]

- Rodriguez-Campos, J.; Escalona-Buendía, H.B.; Orozco-Avila, I.; Lugo-Cervantes, E.; Jaramillo-Flores, M.E. Dynamics of volatile and non-volatile compounds in cocoa (Theobroma cacao L.) during fermentation and drying processes using principal components analysis. Food Res. Int. 2011, 44, 250–258. [Google Scholar] [CrossRef]

- Cubillos, G.C.; Merizalde, G.; Correa, E. Manual de Beneficio del Cacao: Para Técnicos, Profesionales del Sector Agropecuario y Productores (No. 16057); Gobernación de Antioquia: Medellin, Colombia, 2008. [Google Scholar]

- Martinez, N. Evaluación de Componentes Físicos, Químicos, Organolépticos y de Rendimiento de Clones Universales y Regionales de Cacao (Theobroma cacao L.) En Las Zonas Productoras de Santander, Arauca y Huila. Master’s Thesis, Universidad Nacional de Colombia, Bogotá, Columbia, 2016. [Google Scholar]

- Magalhães da Veiga Moreira, I.; Gabriela da Cruz Pedrozo Miguel, M.; Lacerda Ramos, C.; Ferreira Duarte, W.; Efraim, P.; Freitas Schwan, R. Influence of Cocoa Hybrids on Volatile Compounds of Fermented Beans, Microbial Diversity during Fermentation and Sensory Characteristics and Acceptance of Chocolates. J. Food Qual. 2016, 39, 839–849. [Google Scholar] [CrossRef]

- Marcucci, M.C.; Gonç, A.; Gonç, C.P.; Sawaya, A.C.H.F.; Alonso, R.C.B.; de Oliveira, M.M.; Barbin, D.F. Quality Parameters, Caffeine and Theobromine Contents and Antioxidant Activity of Artisan and Commercial Chocolate from Brazil. Open Access Libr. J. 2021, 8, 1–18. [Google Scholar] [CrossRef]

- Kumar, M.; Kumar, P.; Tewari, J.C.; Pandey, C.B. Changes in Soil Fertility under Multipurpose Tree Species in Thar Desert of Rajasthan. Available online: https://www.researchgate.net/publication/323445344 (accessed on 22 March 2022).

- Castro-Nunez, A.; Charry, A.; Castro-Llanos, F.; Sylvester, J.; Bax, V. Reducing deforestation through value chain interventions in countries emerging from conflict: The case of the Colombian cocoa sector. Appl. Geogr. 2020, 123, 102280. [Google Scholar] [CrossRef]

- Benjamin, T.; Burniske, G.; Croft, M.; Fenton, M.C. An Analysis of the Supply Chain of Cacao in Colombia View Project. 2018. Available online: https://cgspace.cgiar.org/bitstream/handle/10568/96636/Cacao_Final_Report.pdf?sequence=1 (accessed on 18 October 2022).

- Hernández-Núñez, H.E.; Gutiérrez-Montes, I.; Bernal-Núñez, A.P.; Gutiérrez-García, G.A.; Suárez, J.C.; Casanoves, F.; Flora, C.B. Cacao cultivation as a livelihood strategy: Contributions to the well-being of Colombian rural households. Agric. Hum. Values 2022, 39, 201–216. [Google Scholar] [CrossRef]

- Calvo, A.M.; Botina, B.L.; García, M.C.; Cardona, W.A.; Montenegro, A.C.; Criollo, J. Dynamics of cocoa fermentation and its effect on quality. Sci. Rep. 2021, 11, 16746. [Google Scholar] [CrossRef]

- Perea, A.; Martínez, N.; Aranzazu, F.; Cadena, T. Características de calidad del cacao de Colombia. Catálogo de 26 Cultivares; Universidad Industrial de Santander—Fedecacao: Bucaramanga, Colombia, 2013; p. 107. [Google Scholar]

- Zambrano, A.; Gómez, Á.; Ramos, G.; Romero, C.; Lacruz, C.; Rivas, E. Characterization of physical quality parameters in criollo, trinitario and forastero cocoa beans during the drying process. Inst. Nac. Investig. Agrícolas 2010, 60, 389–396. [Google Scholar]

- Ortiz de Bertorelli, L.; Rovedas, L.G.; Graziani de Fariñas, L. Influencia de varios factores sobre índices físicos del grano de cacao en fermentación. Agron. Trop. 2009, 59, 81–88. [Google Scholar]

- ICONTEC. Norma Técnica Colombiana Cacao en Grano 1252. NTC 1252; ICONTEC: Bogotá, Colombia, 2012. [Google Scholar]

- Zyzelewicz, D.; Budryn, G.; Krysiak, W.; Oracz, J.; Nebesny, E.; Bojczuk, M. Influence of roasting conditions on fatty acid composition and oxidative changes of cocoa butter extracted from cocoa bean of Forastero variety cultivated in Togo. Food Res. Int. 2014, 63, 328–343. [Google Scholar] [CrossRef]

- Nazaruddin, R.; Seng, L.K.; Hassan, O.; Said, M. Effect of pulp preconditioning on the content of polyphenols in cocoa beans (Theobroma Cacao) during fermentation. Ind. Crops Prod. 2006, 24, 87–94. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International (939.05); Association of Official Analytical Chemists International: Rockville, MD, USA, 1995. [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International (31.5.13); Association of Official Analytical Chemists International: Rockville, MD, USA, 1990. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber and Nonstarch Polysaccharides in Relation to Animal Nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, (970.22), 19th ed.; Association of Official Analytical Chemists International: Rockville, MD, USA, 2012. [Google Scholar]

- Wollgast, J. The Contents and Effects of Polyphenols in Chocolate: Qualitative and Quantitative Analyses of Polyphenols in Chocolate and Chocolate Raw Products as Well as Evaluation of Potential Implications of Chocolate Consumption in Human Health. Ph.D. Thesis, University of Giessen, Giessen, Germany, 2004. [Google Scholar]

- Benzie, I.F.F.; Strain, J.J. The Ferric Reducing Ability of Plasma (FRAP) as a Measure of “Antioxidant Power”: The FRAP Assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef]

- ICONTEC. Análisis Sensorial. Guía General Para la Selección y Seguimiento de Evaluadores. Parte 1 Evaluadores Seleccionados; ICONTEC: Bogotá, Columbia, 1997. [Google Scholar]

- Ramos, G.; González, N.; Zambrano, A. Olores y sabores de cacaos (Theobroma cacao L.) venezolanos obtenidos usando un panel de catación entrenado. Rev. Cient. UDO Agríc. 2013, 13, 114–117. [Google Scholar]

- Khan, N.; Motilal, L.A.; Sukha, D.A.; Bekele, F.L.; Iwaro, A.D.; Bidaisee, G.G.; Umaharan, P.; Grierson, L.H.; Zhang, D. Variability of butterfat content in cacao (Theobroma cacao L.): Combination and correlation with other seed-derived traits at the International Cocoa Genebank, Trinidad. Plant Genet. Resour. 2008, 6, 175–186. [Google Scholar] [CrossRef]

- ICONTEC. Análisis Sensorial. Metodología. Guía General. GTC 165; ICONTEC: Bogotá, Columbia, 2014; p. 26. [Google Scholar]

- ICONTEC. Análisis Sensorial. Metodología. Métodos del Perfil del Sabor. Norma Técnica Colombiana NTC 3929; ICONTEC: Bogotá, Columbia, 2009. [Google Scholar]

- Braudeau, J. El Cacao: Tecnicas Agricolas y Producciones Tropicales; Blume: Barcelona, Spain, 1970; p. 299. [Google Scholar]

- Dray, S.; Chessel, D.; Thioulouse, J. Co-inertia analysis and the linking of ecological data tables. Ecology 2003, 84, 3078–3089. [Google Scholar] [CrossRef]

- R Development Core Team. R: The R Project for Statistical Computing. Available online: https://www.r-project.org/ (accessed on 29 July 2022).

- Thioulouse, J.; Dray, S.; Dufour, A.B.; Siberchicot, A.; Jombart, T.; Pavoine, S. Description of Species-Environment Relationships. In Multivariate Analysis of Ecological Data with ade4; Springer: New York, NY, USA, 2018; pp. 141–166. [Google Scholar]

- Kotsaki, E.; Reynolds, A.G.; Brown, R.; Jollineau, M.; Lee, H.S.; Aubie, E. Proximal Sensing and Relationships to Soil and Vine Water Status, Yield, and Berry Composition in Ontario Vineyards. Am. J. Enol. Vitic. 2020, 71, 114–131. [Google Scholar] [CrossRef]

- Radovic, D.I.; Lazarević, K.B.; Trifković, J.; Andrić, F.; Tešić, Ž.L.; Anđelković, I.; Nedic, N.M.; Stanimirovic, Z.; Stevanovic, J.; Curcic, B.P.M.; et al. Gis techology in regional recognition of the distribution pattern of multifloral honey: The chemical traits in Serbia. Arch. Biol. Sci. 2014, 66, 935–946. [Google Scholar] [CrossRef]

- Del Aguila, E. Determinación de Cadmio y Plomo en Granos de Cacao, Frescos, Secos y en Licor de Cacao (Theobroma cacao). Available online: http://repositorio.unas.edu.pe/handle/UNAS/1269 (accessed on 19 October 2022).

- Portillo, E.; Labarca, M.; Grazziani, L.; Cros, E.; Assemat, S.; Davrieux, F.; Boulager, R. Influencia de las condiciones del tratamiento poscosecha sobre la temperatura y acidez en granos de cacao Criollo (Theobroma cacao L.). Rev. Fac. Agron. 2011, 28, 646–660. [Google Scholar]

- Álvarez, R.; Portillo, E.; Portillo, A.; Villasmil, R. Evaluación de las propiedades sensoriales del licor de cacao (Theobroma cacao L.) obtenido en forma artesanal e industrial. Rev. Agrollanía 2018, 15, 1690–8066. [Google Scholar]

- Del Valle González-Canache, A.; Orlando-Álvarez, C.; Durand-Cos, I.; Utria-Borges, C. Evaluación de diferentes tipos de fermentadores y frecuencia de remoción en la calidad del grano de Theobroma cacao L. Hombre Cienc. Tecnol. 2014, 18, 36–45. [Google Scholar]

- Vera Chang, J.F.; Vallejo Torres, C.; Párraga Morán, D.E.; Macías Véliz, J.; Ramos Remache, R.; Morales Rodríguez, W. Atributos físicos-químicos y sensoriales de las almendras de quince clones de cacao nacional (Theobroma cacao L.) en el Ecuador. Cienc. Tecnol. 2015, 7, 21–34. [Google Scholar] [CrossRef]

- Calderón, D. Caracterización y Evaluación de Accesiones de Cacao Amazónico con Énfasis en su Comportamiento Sanitario Productivo. Available online: http://repositorio.iniap.gob.ec/bitstream/41000/3959/7/iniaptpC146c.PDF (accessed on 8 August 2022).

- Wood, G. Cacao, Trad. por Marino, Primera edición en español, Compañía Editorial Continental S.A., México D.F. Available online: https://scirp.org/reference/referencespapers.aspx?referenceid=3098065 (accessed on 8 August 2022).

- Lemus, M.; Graziani de Farinas, L.; Ortiz de Bertorelli, L.; Trujillo de Leal, Y.A. Efecto del mezclado de cacaos tipos Criollo y Forastero de la localidad de Cumboto sobre algunas características físicas de los granos durante la fermentacion. Agron. Trop. 2002, 52, 45–58. [Google Scholar]

- Juran, J.M.; Bingham, R.S.; Gryna, F.M. Manual de Control de la Calidad, 2nd ed.; Reverte: Barcelona, Spain, 2005; p. 1534. [Google Scholar]

- Tanska, M.; Rotkiewicz, D. Quality of fat from oilseeds used to produce selected kinds of bread. ZYWNOSC Nauka Technol. JAKOSC 2011, 18, 62–74. [Google Scholar]

- Nogales, J.; Graziani de Fariñas, L.; Ortiz de Bertorelli, L. Cambios físicos y químicos durante el secado al sol del grano de cacao fermentado en dos diseños de cajones de madera. Agron. Trop. 2006, 56, 5–20. [Google Scholar]

- García-Alamilla, P.; Salgado-Cervantes, M.A.; Barel, M.; Berthomieu, G.; Rodríguez-Jimenes, G.C.; García-Alvarado, M.A. Moisture, acidity and temperature evolution during cacao drying. J. Food Eng. 2007, 79, 1159–1165. [Google Scholar] [CrossRef]

- Krysiak, W.; Iciek, J.; Motyl-Patelska, L. Wpływ warunków prażenia na wybrane właściwości fizykochemiczne ziarna kakaowego. Inż. Chem. Proces 2003, 24, 9–23. [Google Scholar]

- Guerron, V. Elaboracion de Pasta a Partir de Mezclas de Cacao Nacional (Theobroma cacao L.) y CCN-51 Producidos en Quevedo. Ph.D. Thesis, Universidad Tecnica Estatal de Quevedo, Quevedo, Ecuador, 2009; pp. 38–40. [Google Scholar]

- Steinkamp, J.A.; Lehnert, B.E.; Lehnert, N.M. Discrimination of damaged/dead cells by propidium iodide uptake in immunofluorescently labeled populations analyzed by phase-sensitive flow cytometry. J. Immunol. Methods 1999, 226, 59–70. [Google Scholar] [CrossRef]

- Perea, J.A.; Ramirez, O.L.; Villamizar, A.R. Caracterización fisicoquimica de materiales regionales de cacao colombiano. Biotecnol. Sect. Agropecu Agroind. 2011, 9, 35–42. [Google Scholar]

- Álvarez, C.; Pérez, E.; Lares, M.C. Caracterización física y química de almendras de cacao fermentadas, secas y tostadas cultivadas en la región de Cuyagua, estado Aragua. Agron. Trop. 2007, 57, 249–256. [Google Scholar]

- ICONTEC. Chocolate de Mesa. NTC 793; ICONTEC: Bogotá, Columbia, 2008. [Google Scholar]

- Graziani de Fariñas, L.; Ortiz de Bertorelli, L.; Parra, P. Características químicas de la semilla de diferentes tipos de cacao de la localidad de cumboto, aragua. Agron. Trop. 2003, 53, 133–144. [Google Scholar]

- Bekele, F.; Butler, D.R. Proposed short list of cocoa descriptors for characterization. In Working Procedures for Cocoa Germplasm Evaluation and Selection. Proceedings of the CFC/ICCO/IPGRI Project Workshop, Montpellier, France, 1–6 February, 1998; International Plant Genetic Resources Institute (IPGRI): Rome, Italy, 2000. [Google Scholar]

- Clough, Y.; Dwi Putra, D.; Pitopang, R.; Tscharntke, T. Local and landscape factors determine functional bird diversity in Indonesian cacao agroforestry. Biol. Conserv. 2009, 142, 1032–1041. [Google Scholar] [CrossRef]

- Jahurul, M.H.A.; Zaidul, I.S.M.; Norulaini, N.A.N.; Sahena, F.; Jinap, S.; Azmir, J.; Sharif, K.M.; Omar, A.M. Cocoa butter fats and possibilities of substitution in food products concerning cocoa varieties, alternative sources, extraction methods, composition, and characteristics. J. Food Eng. 2013, 117, 467–476. [Google Scholar] [CrossRef]

- Enriquez, G. Cacao Organico. Guia para Productores Ecuatorianos; Instituto Nacional de Investigaciones Agropecuarias: Quito, Ecuador, 2004; p. 54. [Google Scholar]

- Vera, J. Origen del Cacao, Botanica y Clasificacion del Cacao en Manual del Cultivo de Cacao. Segunda Edicion, Manual Numero 25; Estacion Experimental Tropical Pichilingue, INIAP: Quito, Ecuador, 1993; pp. 8–16. [Google Scholar]

- Bertazzo, A.; Comai, S.; Brunato, I.; Zancato, M.; Costa, C.V.L. The content of protein and non-protein (free and protein-bound) tryptophan in Theobroma cacao beans. Food Chem. 2011, 124, 93–96. [Google Scholar] [CrossRef]

- Sandesh, K.; Shishir, R.K.; Vaman Rao, C. Optimization and Comparison of Induction Heating and LPG Assisted Acid Pretreatment of Cocoa Pod for ABE Fermentation. Available online: https://www.sciencedirect.com/science/article/pii/S0016236119318538 (accessed on 20 July 2022).

- Serra Bonvehí, J.; Aragay Benería, M. Composition of Dietary fibre in Cocoa Husk. Z. Lebensm. Forsch. A 1998, 207, 105–109. [Google Scholar] [CrossRef]

- Baena, L.; Cardona, N.G. Obtención y Caracterización de Fibra Dietaría a Partir de Cascarilla de las Semillas Tostadas de Theobroma cacao L. de Una Industria Chocolatera Colombiana. Bachelor’s Thesis, Universidad Tecnológica de Pereira, Pereira, Colombia, 2012. [Google Scholar]

- Efraim, P. Estudo para Minimizar as Perdas de Flavonóides Durante a Fermentação de Sementes de Cacau para Produção de Chocolate. Master’s Thesis, Faculdade de Engenharia de Alimentos, Universidade Estadual de Campinas, Campinas, Brazil, 2004. [Google Scholar]

- Zuñiga, G. Propiedades Bromatológicas y Funcionales de Diferentes Accesiones de Theobroma Cacao L. del Departamento del Huila; Universidad de la Amazonia: Florencia, Colombia, 2019. [Google Scholar]

- Sangronis, E.; Soto, M.J.; Valero, Y.; Buscema, I. Husk of Venezuelan cocoa as raw material of infusions. Arch. Latinoam. Nutr. 2014, 64, 123–130. [Google Scholar]

- Quiroz-Reyes, C.N.; Aguilar-Méndez, M.A.; Ramírez-Ortíz, M.E.; Ronquillo-De Jesús, E. Comparative study of ultrasound and maceration techniques for the extraction of polyphenols from cocoa beans (Theobroma cacao L.). Rev. Mex.Ing. Quim. 2013, 12, 11–18. [Google Scholar]

- Ardhana, M.M.; Fleet, G.H. The microbial ecology of cocoa bean fermentations in Indonesia. Int. J. Food Microbiol. 2003, 86, 87–99. [Google Scholar] [CrossRef]

- Cros, E. Factores que afectan el desarrollo del sabor a cacao bases bioquimicas del perfil aromatico. In Memoria. Taller Internacional Calidad Integral del Cacao: Teoría y Práctica; INIAP/EET-P: Quevedo, Ecuador, 2004. [Google Scholar]

- Sukha, D.A.; Butler, D.R.; Umaharan, P.; Boult, E. The use of an optimised organoleptic assessment protocol to describe and quantify different flavour attributes of cocoa liquors made from Ghana and Trinitario beans. Eur. Food Res. Technol. 2008, 226, 405–413. [Google Scholar] [CrossRef]

- Amoa-Awua, W.K. Methods of Cocoa Fermentation and Drying. In Cocoa and Coffee Fermentations; CRC Press: Boca Raton, FL, USA, 2020; pp. 90–147. [Google Scholar]

- Batista, N.N.; Ramos, C.L.; Dias, D.R.; Pinheiro, A.C.M.; Schwan, R.F. The impact of yeast starter cultures on the microbial communities and volatile compounds in cocoa fermentation and the resulting sensory attributes of chocolate. J. Food Sci. Technol. 2016, 53, 1101–1110. [Google Scholar] [CrossRef]

- Menezes, A.G.T.; Batista, N.N.; Ramos, C.L.; e Silva, A.R.D.A.; Efraim, P.; Pinheiro, A.C.M.; Schwan, R.F. Investigation of chocolate produced from four different Brazilian varieties of cocoa (Theobroma cacao L.) inoculated with Saccharomyces cerevisiae. Food Res. Int. 2016, 81, 83–90. [Google Scholar] [CrossRef]

- Ramos, C.L.; Dias, D.R.; Miguel, M.G.D.C.P.; Schwan, R.F. Impact of different cocoa hybrids (Theobroma cacao L.) and S. cerevisiae UFLA CA11 inoculation on microbial communities and volatile compounds of cocoa fermentation. Food Res. Int. 2014, 64, 908–918. [Google Scholar] [CrossRef] [PubMed]

- Afoakwa, E.; Quao, J.; Takrama, F.; Budu, A.; Saalia, F. Changes in Total Polyphenols, O-diphenols and Anthocyanin Concentrations during Fermentation of Pulp Pre-Conditioned Cocoa (Theobroma cacao) Beans. 2012. Available online: http://ugspace.ug.edu.gh/handle/123456789/26792 (accessed on 8 August 2022).

- Cedeño, P. Determinación de Perfiles Organolépticos en Ocho Grupos de Cacao Mediante la Degustación de Licor de Cacao y Chocolates Oscuros Elaborados Artesanalmente. Bachelor’s Thesis, Escuela Superior Agronómica de Manabí, Facultad de Ingeniería Agroindustrial, Calceta, Ecuador, 2010. [Google Scholar]

- Cros, E.; Mermet, G.; Jeanjean, N.; Georges, G. Relation Précurseurs—Développement de l’arôme Cacao; Cocoa Producers’ Alliance: Lagos, Nigeria, 1993; pp. 723–726. [Google Scholar]

- Cros, E. Factores condicionantes de la calidad del cacao. In Memorias del Primer Congreso Venezolano del Cacao y su Industria Maracay, Estado Aragua; Fundacite: Mérida, Venezuela, 2000; pp. 16–32. [Google Scholar]

- Alvis, A.; Pérez, L.; Arrazola, G. Determinación de las propiedades de textura de tabletas de chocolate mediante técnicas instrumentales. Inf. Tecnol. 2011, 22, 11–18. [Google Scholar] [CrossRef]

- Augusto, P.P.C.; Bolini, H.M.A. The role of conching in chocolate flavor development: A review. Compr. Rev. Food Sci. Food Saf. 2022, 21, 3274–3296. [Google Scholar] [CrossRef] [PubMed]

- Spada, F.P.; de Alencar, S.M.; Purgatto, E. Comprehensive chocolate aroma characterization in beverages containing jackfruit seed flours and cocoa powder. Future Foods 2022, 6, 100158. [Google Scholar] [CrossRef]

- Gutiérrez-Ríos, H.G.; Suárez-Quiroz, M.L.; Hernández-Estrada, Z.J.; Castellanos-Onorio, O.P.; Alonso-Villegas, R.; Rayas-Duarte, P.; Cano-Sarmiento, C.; Figueroa-Hernández, C.Y.; González-Rios, O. Yeasts as Producers of Flavor Precursors during Cocoa Bean Fermentation and Their Relevance as Starter Cultures: A Review. Fermentation 2022, 8, 331. [Google Scholar] [CrossRef]

- Sioriki, E.; Tuenter, E.; Van de Walle, D.; Lemarcq, V.; Cazin, C.S.; Nolan, S.P.; Pieters, L.; Dewettinck, K. The effect of cocoa alkalization on the non-volatile and volatile mood-enhancing compounds. Food Chem. 2022, 381, 132082. [Google Scholar] [CrossRef] [PubMed]

- Pinzón, J. Guía Técnica para el Cultivo del Cacao, 5th ed.; FEDECACAO: Bogotá, Columbia, 2012; p. 192. [Google Scholar]

- Quintero, R.M.L.; Díaz Morales, K.M. El mercado mundial del cacao. Agroalimentaria 2004, 9, 47–59. [Google Scholar]

- Reineccius, G.A. Flavor Technology. Second Edition. In Flavour Chemistry and Technology; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Liu, M.; Liu, J.; He, C.; Song, H.; Liu, Y.; Zhang, Y.; Wang, Y.; Guo, J.; Yang, H.; Su, X. Characterization and comparison of key aroma-active compounds of cocoa liquors from five different areas. Int. J. Food Prop. 2017, 20, 2396–2408. [Google Scholar] [CrossRef]

- Torres-Moreno, M.; Tarrega, A.; Costell, E.; Blanch, C. Dark chocolate acceptability: Influence of cocoa origin and processing conditions. J. Sci. Food Agric. 2012, 92, 404–411. [Google Scholar] [CrossRef]

- Cambrai, A.; Marcic, C.; Morville, S.; Houer, P.S.; Bindler, F.; Marchioni, E. Differentiation of Chocolates According to the Cocoa’s Geographical Origin Using Chemometrics. J. Agric. Food Chem. 2010, 58, 1478–1483. [Google Scholar] [CrossRef]

- Sukha, D.A.; Butler, D.R.; Comissiong, E.A.; Umaharan, P. The impact of processing location and growing environment on flavor in cocoa (Theobroma cacao L.)—Implications for “terroir” and certification—Processing location study. Acta Hortic. 2014, 1047, 255–262. [Google Scholar] [CrossRef]

- Bertoldi, D.; Barbero, A.; Camin, F.; Caligiani, A.; Larcher, R. Multielemental fingerprinting and geographic traceability of Theobroma cacao beans and cocoa products. Food Control 2016, 65, 46–53. [Google Scholar] [CrossRef]

| Variable | CCN-51 | FEAR-5 | FSA-11 | FSA-12 | ICS-95 | TSH-565 | General Average | p-Value | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| pH | 5.74 ± 0.05 | 5.66 ± 0.06 | 5.7 ± 0.1 | 5.79 ± 0.04 | 5.84 ± 0.03 | 5.77 ± 0.04 | 5.78 ± 0.02 | NS | ||||||

| Titratable acidity | 16.29 ± 0.32 | b | 18.72 ± 0.96 | a | 15.58 ± 0.74 | b | 20.02 ± 0.63 | a | 18.93 ± 0.42 | a | 16.54 ± 0.53 | b | 17.82 ± 0.24 | <0.0001 |

| Ash | 2.95 ± 0.08 | b | 3.39 ± 0.34 | a | 2.82 ± 0.18 | b | 2.91 ± 0.04 | b | 3.22 ± 0.08 | a | 2.8 ± 0.12 | b | 3.04 ± 0.05 | 0.0081 |

| Crude Protein | 10.34 ± 0.18 | b | 11.52 ± 0.47 | a | 11.96 ± 0.35 | a | 10.98 ± 0.41 | b | 10.54 ± 0.12 | b | 10.46 ± 0.29 | b | 10.65 ± 0.1 | 0.0029 |

| °Brix | 2.69 ± 0.04 | b | 2.76 ± 0.1 | b | 3.68 ± 0.26 | a | 3.4 ± 0.15 | a | 2.91 ± 0.06 | b | 3.01 ± 0.1 | b | 2.95 ± 0.04 | <0.0001 |

| Moisture | 2.67 ± 0.08 | a | 2.12 ± 0.11 | b | 2.29 ± 0.26 | b | 2.68 ± 0.08 | a | 2.75 ± 0.08 | a | 2.75 ± 0.16 | a | 2.66 ± 0.05 | 0.0404 |

| Ether extract | 52.22 ± 0.09 | a | 51.53 ± 0.18 | b | 51.81 ± 0.28 | b | 52.24 ± 0.08 | a | 52.26 ± 0.08 | a | 52.33 ± 0.18 | a | 52.2 ± 0.05 | 0.0274 |

| Insoluble D. Fiber | 46.2 ± 0.3 | 45.24 ± 0.62 | 45.73 ± 0.64 | 45.87 ± 0.26 | 45.5 ± 0.19 | 46.24 ± 0.29 | 45.84 ± 0.13 | NS | ||||||

| Soluble D. Fiber | 54.8 ± 0.52 | 53.4 ± 0.69 | 53.64 ± 1.02 | 54.97 ± 0.55 | 55.57 ± 0.31 | 55.1 ± 0.44 | 55.02 ± 0.21 | NS | ||||||

| Total polyphenol | 210.4 ± 1.82 | 209.52 ± 3.11 | 214.77 ± 3.99 | 207.59 ± 2.09 | 210.09 ± 1.24 | 210.82 ± 1.47 | 210.18 ± 0.78 | NS | ||||||

| FRAP | 2671 ± 48.1 | a | 2235.5 ± 126.5 | b | 2395.1 ± 126.8 | b | 2501.8 ± 82.8 | b | 2468.3 ± 40.6 | b | 2693.2 ± 85.4 | a | 2544.8 ± 28.1 | 0.0009 |

| Organoleptic Qualities | CCN-51 | FEAR-5 | FSA-11 | FSA-12 | ICS-95 | TSH-565 | General Average | p-Value | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cocoa | 3.9 ± 0.2 | a | 4.0 ± 0.0 | a | 4.0 ± 0.5 | a | 4.3 ± 0.2 | a | 3.3 ± 0.1 | b | 3.3 ± 0.2 | b | 3.7 ± 0.1 | 0.0004 |

| Acidity | 4.1 ± 0.3 | 3.7 ± 0.7 | 2.0 ± 0.0 | 3.6 ± 0.4 | 3.6 ± 0.2 | 3.7 ± 0.4 | 3.7 ± 0.1 | NS | ||||||

| Astringency | 3.7 ± 0.2 | a | 2.7 ± 0.2 | b | 4.0 ± 0.5 | a | 4.0 ± 0.3 | a | 2.9 ± 0.1 | b | 2.7 ± 0.1 | b | 3.3 ± 0.1 | <0.0001 |

| Bitterness | 4.0 ± 0.2 | a | 3.7 ± 0.3 | a | 4.7 ± 0.7 | a | 4.4 ± 0.4 | a | 3.0 ± 0.1 | b | 3.0 ± 0.2 | b | 3.5 ± 0.1 | <0.0001 |

| Fresh fruit | 4.0 ± 0.3 | 3.7 ± 0.7 | 2.0 ± 0.0 | 3.7 ± 0.5 | 3.6 ± 0.2 | 3.8 ± 0.4 | 3.7 ± 0.1 | NS | ||||||

| Browned Fruit | 3.1 ± 0.2 | a | 1.7 ± 0.2 | b | 2.7 ± 0.3 | a | 3.1 ± 0.3 | a | 3.1 ± 0.1 | a | 3.0 ± 0.2 | a | 3.0 ± 0.1 | 0.0135 |

| Floral | 4.0 ± 0.3 | a | 3.7 ± 0.7 | a | 2.0 ± 0.5 | b | 3.6 ± 0.5 | a | 4.3 ± 0.2 | a | 4.4 ± 0.3 | a | 4.0 ± 0.1 | 0.0117 |

| Nutty | 3.4 ± 0.2 | a | 2.3 ± 0.3 | b | 2.3 ± 0.2 | b | 3.0 ± 0.3 | a | 3.2 ± 0.1 | a | 3.0 ± 0.2 | a | 3.1 ± 0.1 | 0.0097 |

| Sweet | 4.2 ± 0.3 | a | 4.3 ± 0.3 | a | 2.0 ± 0.5 | b | 3.6 ± 0.5 | a | 4.5 ± 0.2 | a | 4.7 ± 0.2 | a | 4.2 ± 0.1 | 0.0008 |

| Green | 0.3 ± 0.1 | a | 0.7 ± 0.3 | a | 0.1 ± 0.1 | b | 0.3 ± 0.2 | a | 0.6 ± 0.1 | a | 0.4 ± 0.2 | a | 0.5 ± 0.1 | 0.0378 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramón, V.; Hernández, H.E.; Polania, P.; Suárez, J.C. Spatial Distribution of Cocoa Quality: Relationship between Physicochemical, Functional and Sensory Attributes of Clones from Southern Colombia. Agronomy 2023, 13, 15. https://doi.org/10.3390/agronomy13010015

Ramón V, Hernández HE, Polania P, Suárez JC. Spatial Distribution of Cocoa Quality: Relationship between Physicochemical, Functional and Sensory Attributes of Clones from Southern Colombia. Agronomy. 2023; 13(1):15. https://doi.org/10.3390/agronomy13010015

Chicago/Turabian StyleRamón, Vivian, Héctor Eduardo Hernández, Paola Polania, and Juan Carlos Suárez. 2023. "Spatial Distribution of Cocoa Quality: Relationship between Physicochemical, Functional and Sensory Attributes of Clones from Southern Colombia" Agronomy 13, no. 1: 15. https://doi.org/10.3390/agronomy13010015

APA StyleRamón, V., Hernández, H. E., Polania, P., & Suárez, J. C. (2023). Spatial Distribution of Cocoa Quality: Relationship between Physicochemical, Functional and Sensory Attributes of Clones from Southern Colombia. Agronomy, 13(1), 15. https://doi.org/10.3390/agronomy13010015