State of the Art in Humidified Gas Turbine Configurations

Abstract

:1. Introduction

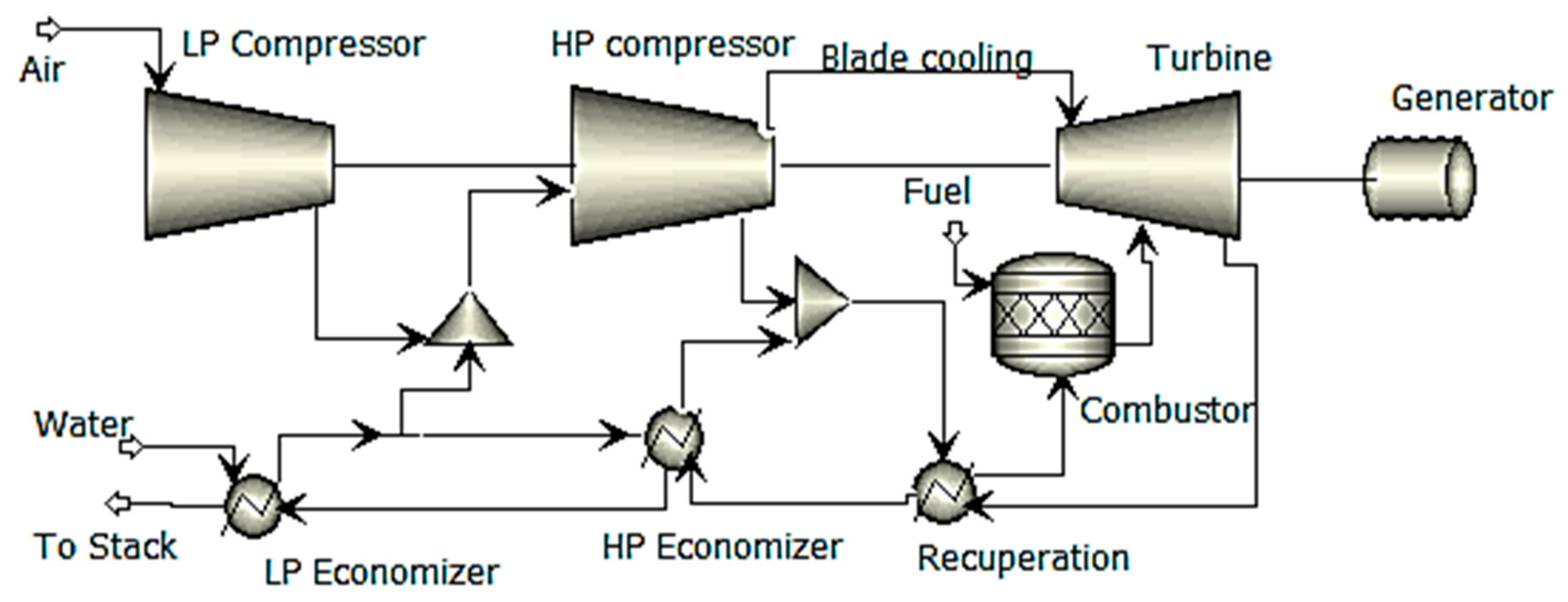

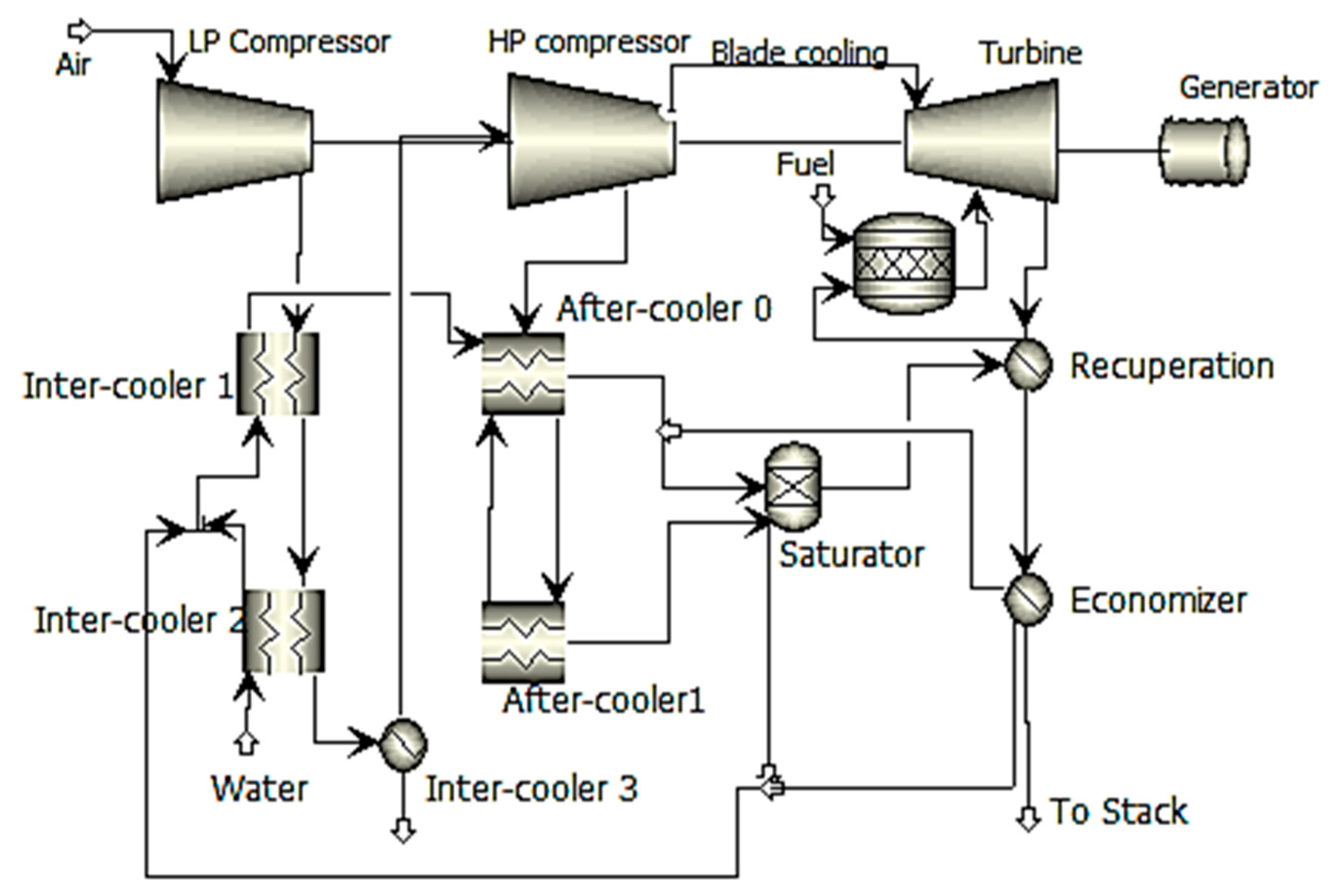

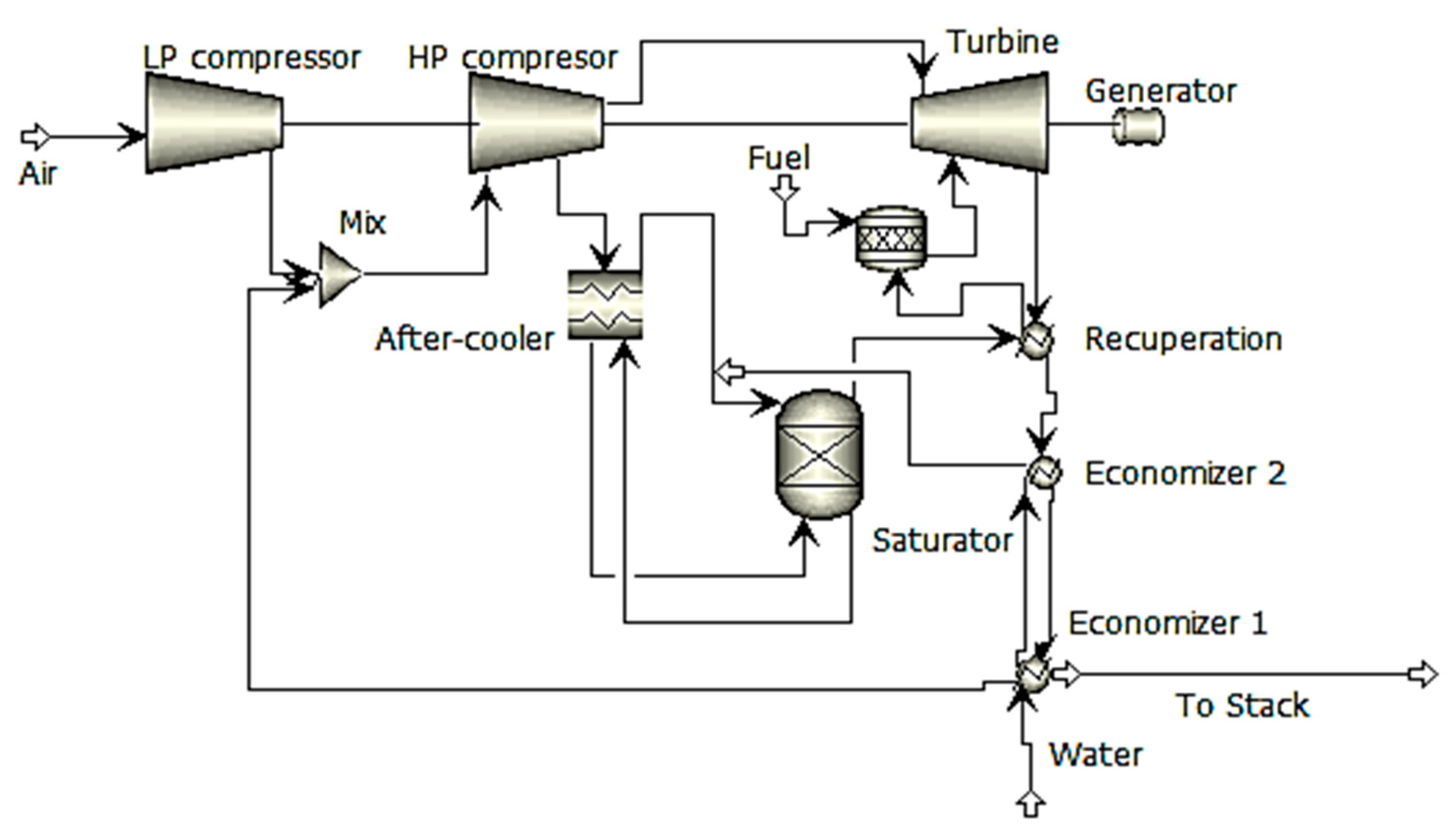

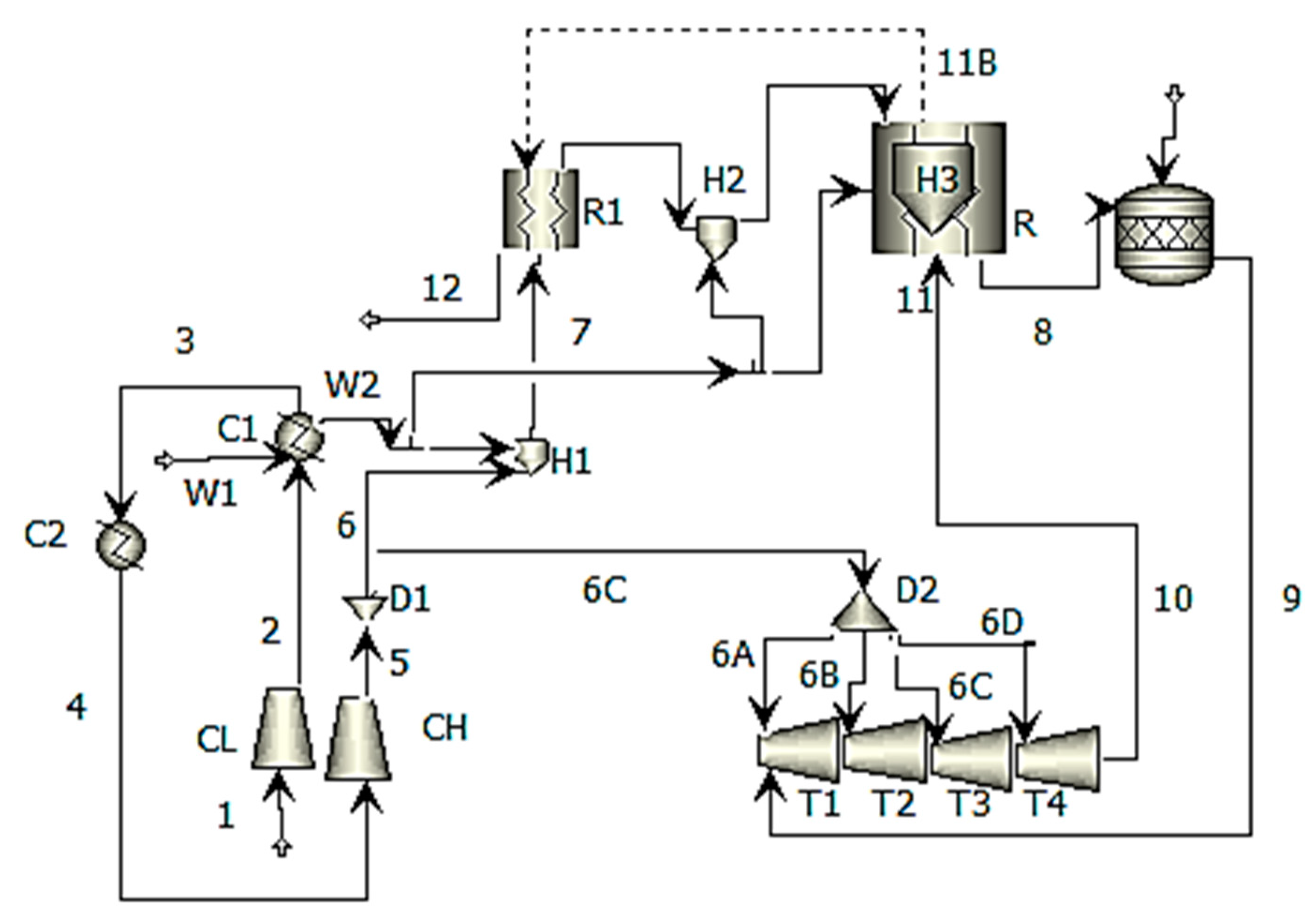

2. Concepts of Humidification-Based Gas Turbines

- Gas turbines with water injection that results in complete evaporation of the water. Systems that have water injected at the compressor intake for the purpose of increasing power output on hot days; systems that have water injected in the compressor for the purpose of intercooling; and systems that have water injected after the compressor in conjunction with recuperation fall under this category. Injection of water or steam into the combustor is a mature strategy for minimizing the formation of nitrogen oxides (NOx), although deployment of the two types of systems that were just discussed has been minimal.

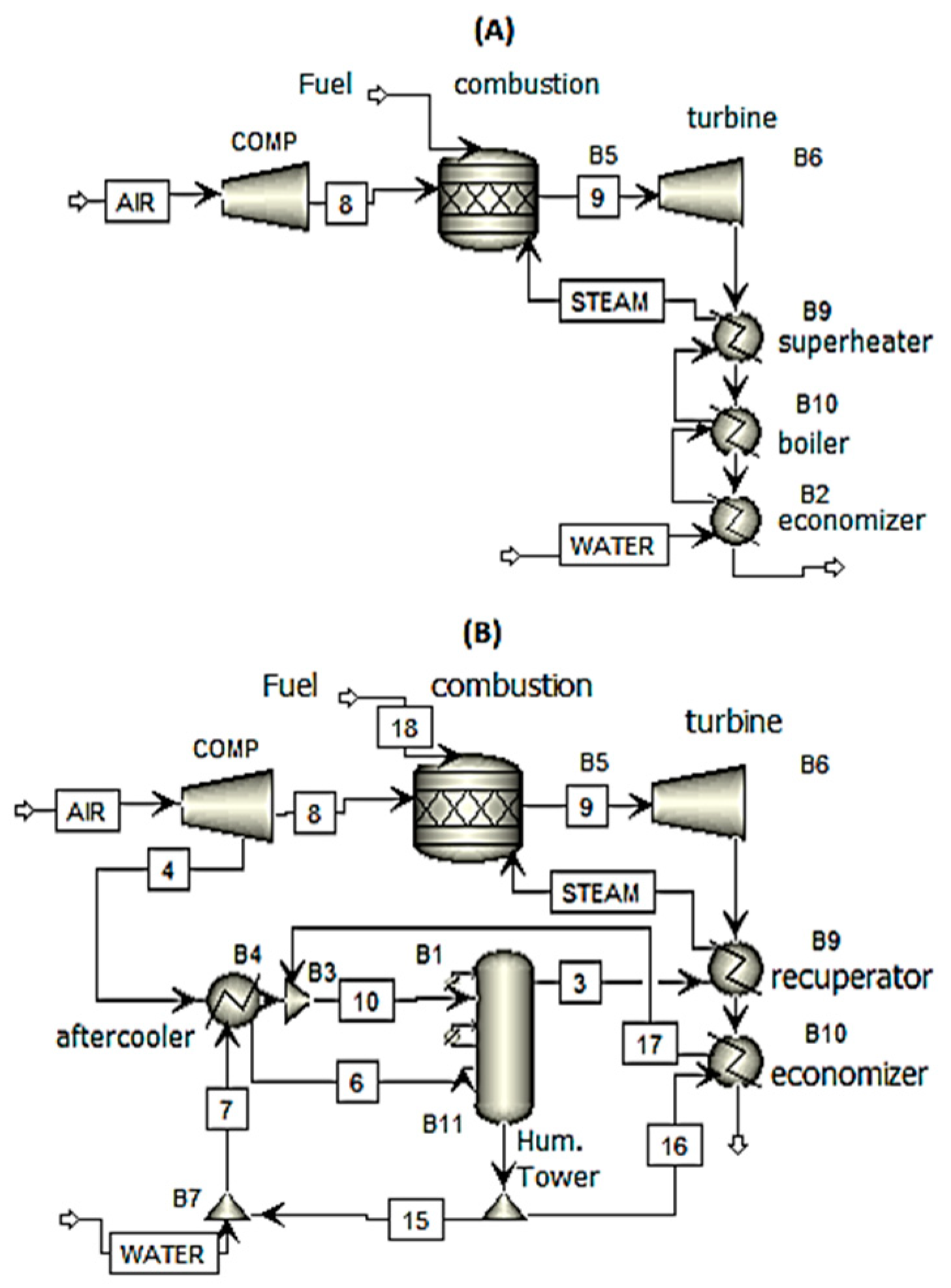

- Gas turbines that get steam injections. This category encompasses a wide variety of commercially available systems.

- The gas turbine that runs while water is injected into a humidification tower and recirculated through the system. The terms evaporation-based power plants (EvGT) and humid-air turbines (HAT) are often used to refer to these cycles. According to the study’s authors, the sole evaporative cycle currently operates at a pilot plant in Sweden [4].

3. Gas Turbines with Water Injection and Full Evaporation

3.1. Injection of Water to Cool the Intake Air

- Evaporative coolers that use various media. In order to humidify the air, water is sprayed onto pads of fibers, which the air then passes through. 1—Cooling systems that use spray and foggers. Using nozzles to inject water into the air creates a fog with water droplets ranging in size from 5 to 20 mm in diameter. The systems may be broken down into two distinct categories: (1) saturable systems, in which the air is already saturated before the compressor, and (2) non-saturable systems. 2—Overspray systems. Systems that inject more water than is necessary for saturation. Evaporation of moisture drops in the compression results in the air being cooled.

- In order to cool the air that is being drawn in, a heat exchanger utilizes either a mechanical vapor compression or absorption chillers. The output of gas turbines may be increased by 15–20%, and their efficiency can be increased by 1–2% if chillers are used (i.e., if energy is retrieved from the exhaust gases of gas turbines). The incoming air may be cooled by a chiller regardless of the temperature of the surrounding environment; nevertheless, purchasing a chiller demands a larger initial expenditure than media and spray coolers do.

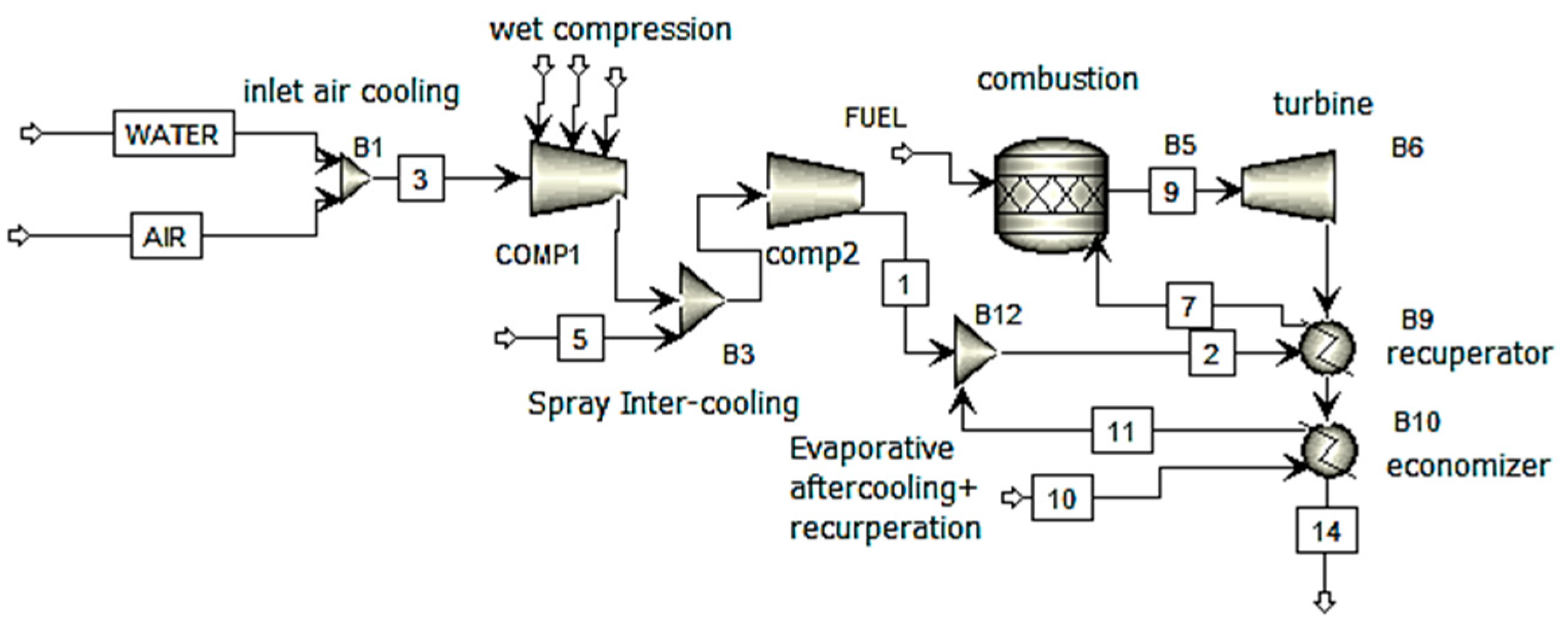

3.2. Wet Compression and Spray Intercooling with Water Injection in the Compressor

3.3. Gas Turbines with Recycled Water Injection

3.4. NOx Management Using the Combustor Injection of Water or Steam

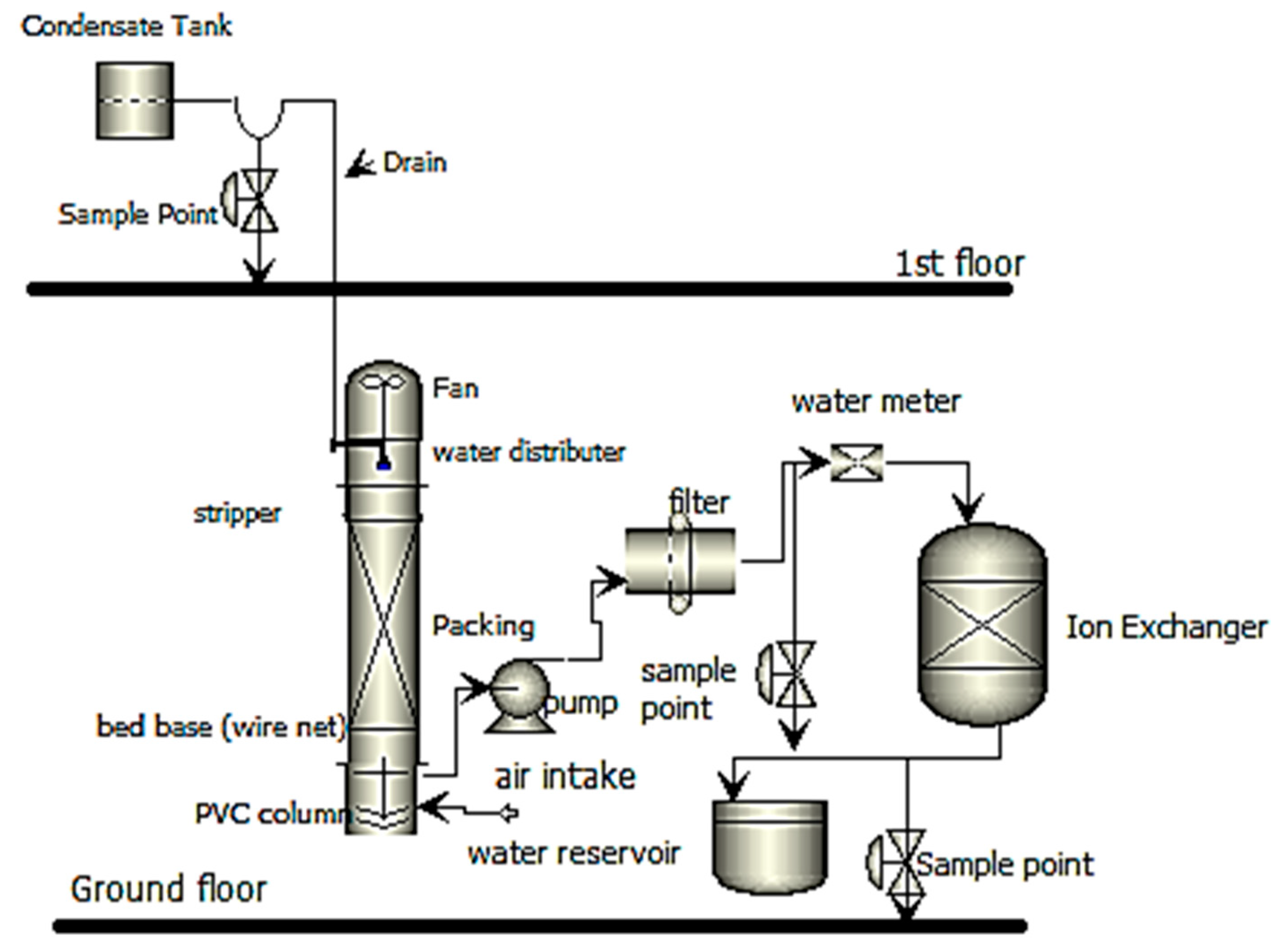

4. Water Recovery and Water Quality

5. A Working Fluid for Gas Turbines, Humid Air

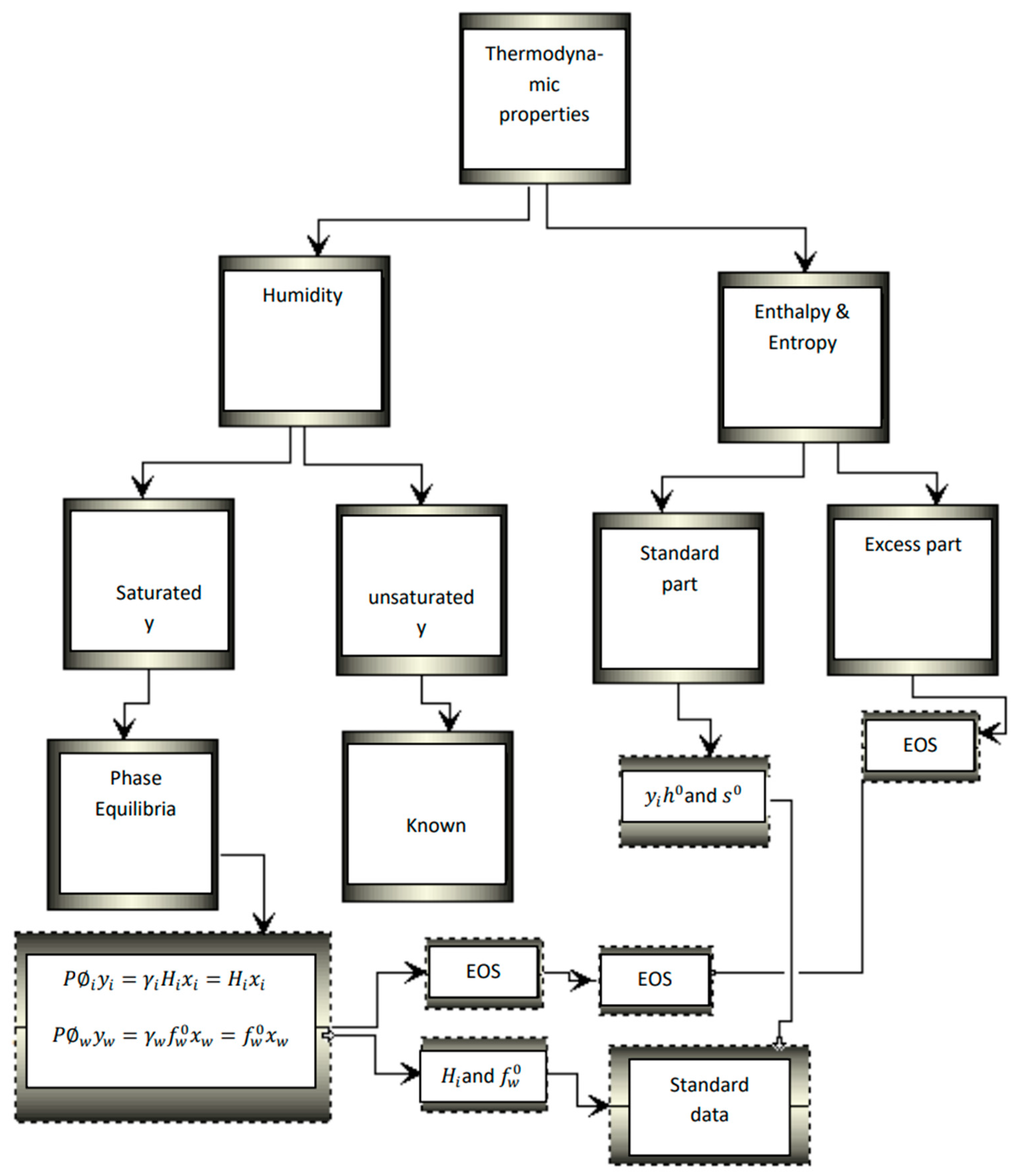

5.1. Thermal Characteristics of Mixes of Air and Water

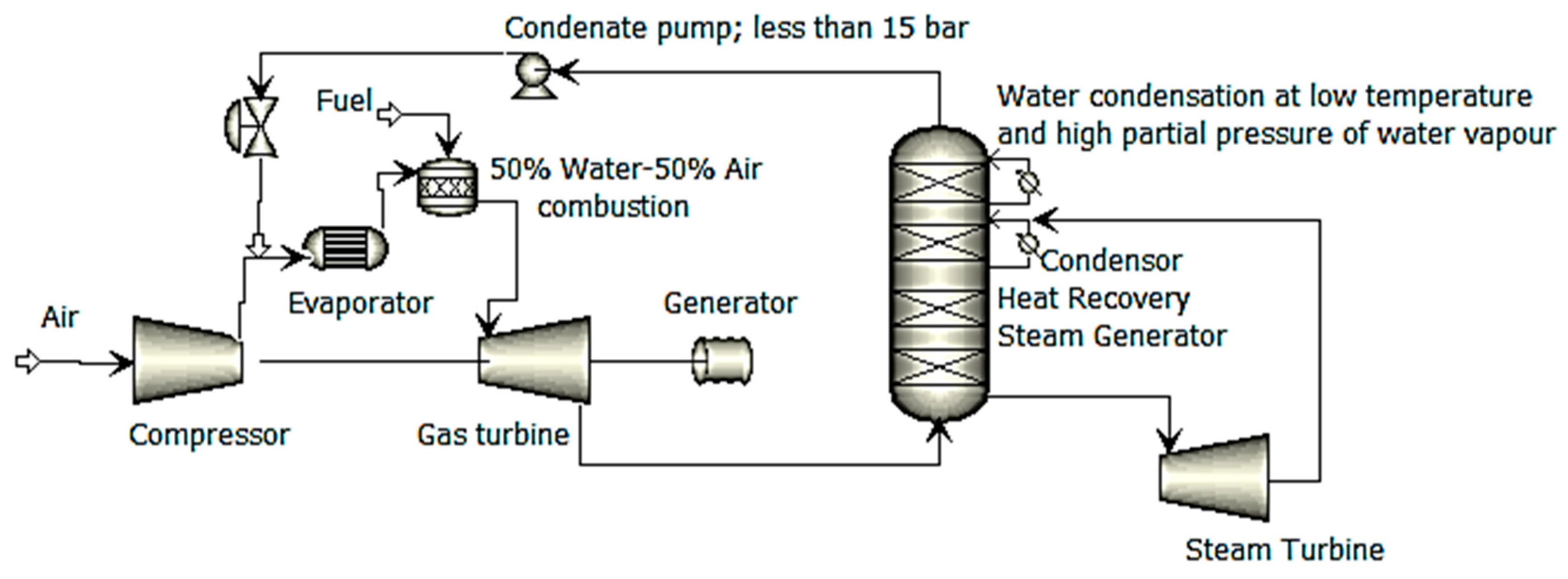

5.2. Humidified Combustion

5.3. The Process of Normalizing Data Collected from Gas Turbines for Humidified Gas Turbines

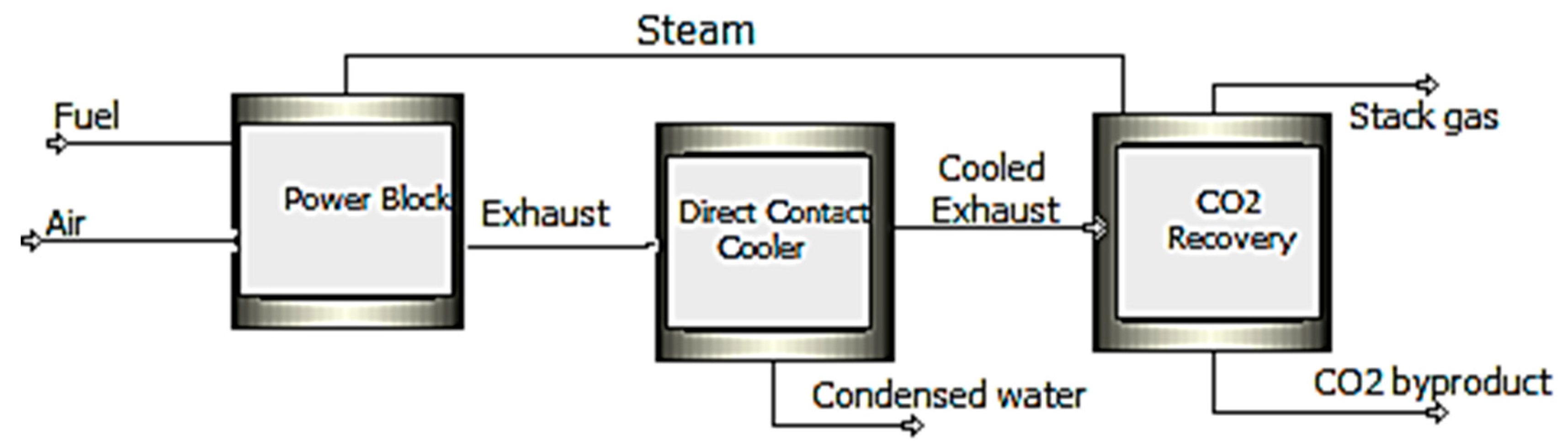

5.4. CO2 Recovery from Humidified Gas Turbines

6. Discussion

6.1. Costs and Applications

6.2. Development Status

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency. World Energy Outlook; OECD/IEA: Paris, France, 2009. [Google Scholar]

- Jänicke, M. Dynamic governance of clean-energy markets: How technical innovation could accelerate climate policies. J. Clean. Prod. 2012, 22, 50–59. [Google Scholar] [CrossRef]

- Walsh, P.P.; Fletcher, P. Gas turbine performance; John Wiley & Sons: Hoboken, NJ, USA, 2004. [Google Scholar]

- Bhargava, R.; Meher-Homji, C.B. Parametric analysis of existing gas turbines with inlet evaporative and overspray fogging. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; Volume 4, pp. 387–401. [Google Scholar]

- Rogers, L.H.; Liese, E.A. Humidification of a high pressure air stream by direct water injection. In Proceedings of the 1997 International Joint Power Generation Conference, Denver, CO, USA, 2–5 November 1997; ASME: New York, NY, USA, 1997; Volume 32. [Google Scholar]

- Mohammad, S.; Mohamed, G. Innovative inlet air cooling technology for gas turbine power plants using integrated solid desiccant and Maisotsenko cooler. Energy 2015, 87, 663–677. [Google Scholar]

- Mahmood, F.-G.; Deymi-Dashtebayaz, M. Effect of various inlet air cooling methods on gas turbine performance. Energy 2011, 36, 1196–1205. [Google Scholar]

- Horlock, J.H. Compressor performance with water injection. In Proceedings of the ASME Turbo Expo 2001: Power for Land, Sea, and Air, New Orleans, LA, USA, 4–7 June 2001; ASME: New York, NY, USA, 2001; Volume 78507. [Google Scholar]

- Härtel, C.; Pfeiffer, P. Model analysis of high-fogging effects on the work of compression. In Proceedings of the ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; Volume 36851. [Google Scholar]

- White, A.J.; Meacock, A.J. An evaluation of the effects of water injection on compressor performance. In Proceedings of the ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; Volume 3686. [Google Scholar]

- Wang, Y.; Wang, G.; Li, S.; Sun, Y. Analysis of effects on wet compression on surge margin of a small gas turbine. In Proceedings of the 2002 International Joint Power Generation Conference, Scottsdale, AZ, USA, 24–26 June 2002; Volume 36177. [Google Scholar]

- Ingistov, S. Interstage Injection into Axial Compressor, Gas Turbine Model 7EA: Part 2. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; Volume 36096. [Google Scholar]

- Zheng, Q.; Sun, Y.; Li, S.; Wang, Y. Thermodynamic analyses of wet compression process in the compressor of gas turbine. J. Turbomach. 2003, 125, 489–496. [Google Scholar] [CrossRef]

- De Paepe, W.; Carrero, M.M.; Bram, S.; Contino, F.; Parente, A. Waste heat recovery optimization in micro gas turbine applications using advanced humidified gas turbine cycle concepts. Appl. Energy 2017, 207, 218–229. [Google Scholar] [CrossRef]

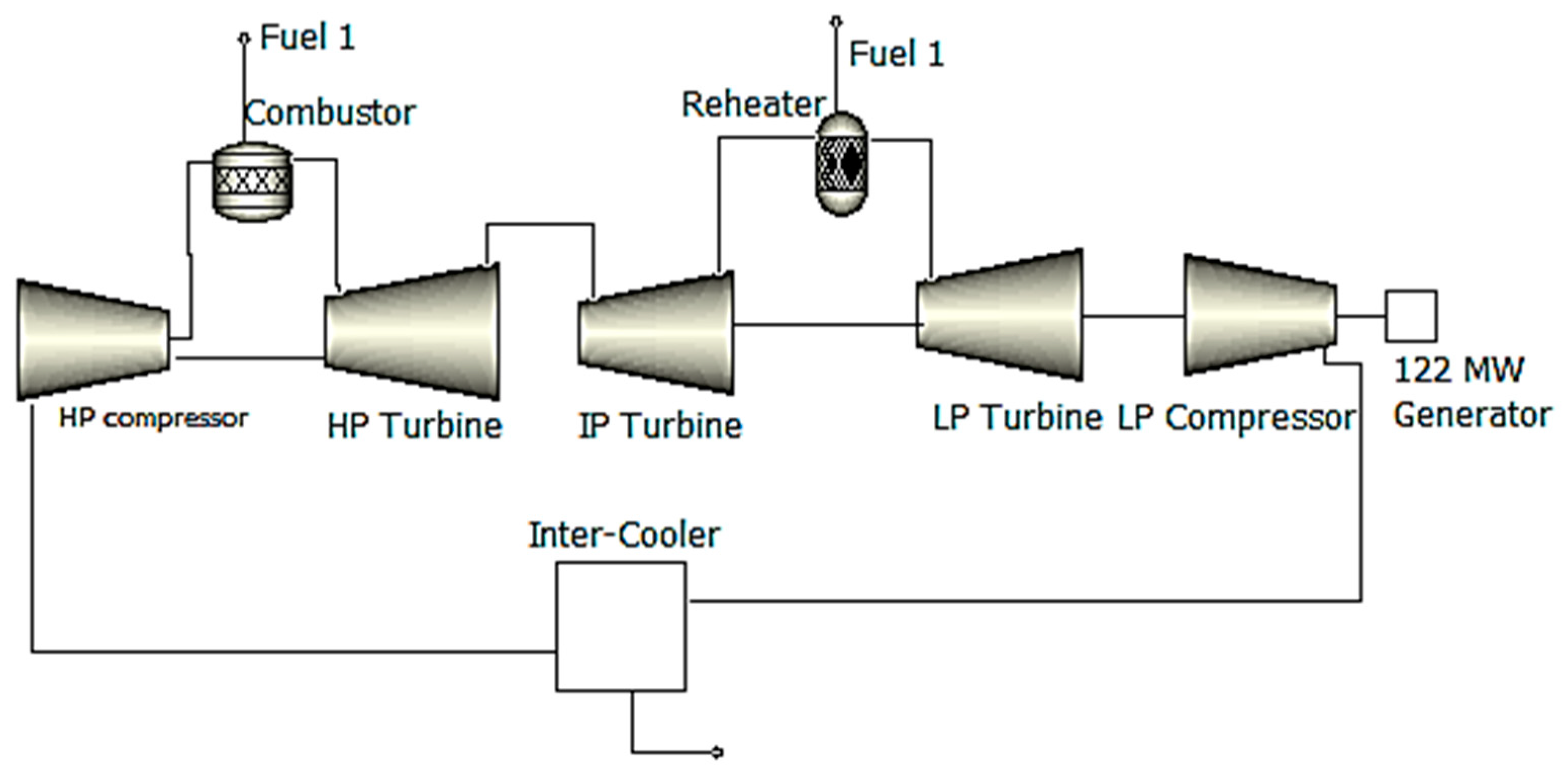

- Takeya, K.; Yasui, H. Performance of the integrated gas and steam cycle (IGSC) for reheat gas turbines. J. Eng. Gas Turbines Power 1988, 110, 220–224. [Google Scholar] [CrossRef]

- Hori, A.; Takeya, K. Outline of plan for advanced reheat gas turbine. J. Eng. Power 1981, 103, 772–775. [Google Scholar] [CrossRef]

- de Biasi, V. LM6000 sprint design enhanced to increase power and efficiency. Gas Turbine World 2000, 30, 16–19. [Google Scholar]

- Najjar, Y.S.H.; Zaamout, M.S. Enhancing gas-turbine engine performance by means of the evaporative regenerative cycle. J. Inst. Energy 1996, 69, 2–8. [Google Scholar] [CrossRef]

- Camporeale, S.M.; Fortunato, B. Aero-thermodynamic simulation of a double-shaft industrial evaporative gas turbine. In Proceedings of the ASME Turbo Expo 2000: Power for Land, Sea, and Air, Munich, Germany, 8–11 May 2000; ASME: New York, NY, USA, 2000; Volume 78552. [Google Scholar]

- Camporeale, S.; Fortunato, B. Design and off-design performance of advanced mixed gas-steam cycle power plants. In Proceedings of the 31st Intersociety Energy Conversion Engineering Conference, IECEC 96. Washington, DC, USA, 11–16 August 1996; IEEE: New York, NY, USA, 1996; Volume 2. [Google Scholar]

- Camporeale, S.M.; Fortunato, B. Performance of a mixed gas–steam cycle power plant obtained upgrading an aero-derivative gas turbine. Energy Convers. Manag. 1998, 39, 1683–1692. [Google Scholar] [CrossRef]

- Manfrida, G.; Bidini, G.; Alessandrello, P.P. Exergy analysis of viable options for steam/water injection in gas turbines. In Proceedings of the ASME 1989 International Gas Turbine and Aeroengine Congress and Exposition, Toronto, ON, Canada, 4–8 June 1989; ASME: New York, NY, USA, 1989; Volume 79160. [Google Scholar]

- Frutschi, H.U.; Plancherel, A.A. Comparison of combined cycles with steam injection and evaporation cycles. Proc. ASME Cogen-Turbo II 1988, 137–145. [Google Scholar]

- Bhargava, R.K.; Bianchi, M.; Campanari, S.; Pascale, A.D.; Montenegro, G.N.D.; Peretto, A. High Efficiency Gas Turbine Based Power Cycles—A Study of the Most Promising Solutions: Part 1—A Review of the Technology. In Proceedings of the ASME Turbo Expo 2008: Power for Land, Sea, and Air, Berlin, Germany, 9–13 June 2008; Volume 43178, pp. 305–314. [Google Scholar]

- Traverso, A.; Massardo, A.F. Thermoeconomic analysis of mixed gas–steam cycles. Appl. Therm. Eng. 2002, 22, 1–21. [Google Scholar] [CrossRef]

- Stambler, I. DOE shifting from design studies to technology oriented programs. Gas Turbine World 2002, 32, 17–18. [Google Scholar]

- Horlock, J.H. The evaporative gas turbine [EGT] cycle. J. Eng. Gas Turbines Power 1998, 120, 336–343. [Google Scholar] [CrossRef]

- Fawwaz Alrebei, O.; Amhamed, A.I.; Mashruk, S.; Bowen, P.; Medina, A.V. Planar laser-induced fluorescence and chemiluminescence analyses of CO2-argon-steam oxyfuel (CARSOXY) combustion. Energies 2021, 15, 263. [Google Scholar] [CrossRef]

- Horlock, J.H. Heat exchanger performance with water injection (with relevance to evaporative gas turbine (EGT) cycles). Energy Convers. Manag. 1998, 39, 1621–1630. [Google Scholar] [CrossRef]

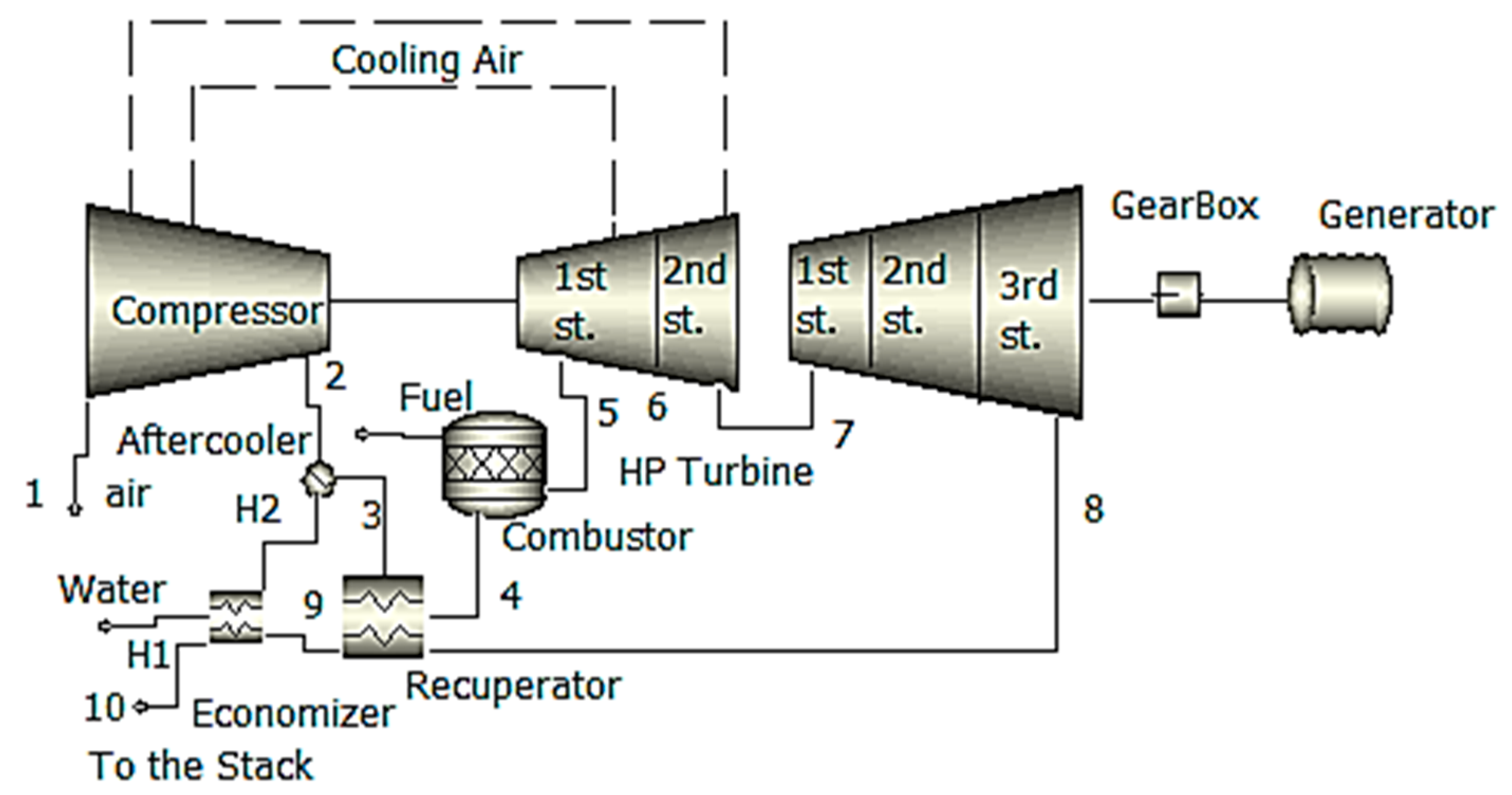

- El-Masri, M.A. A modified, high-efficiency, recuperated gas turbine cycle. J. Eng. Gas Turbines Power 1988, 110, 233–242. [Google Scholar] [CrossRef]

- Wang, F.J.; Chiou, J.-S. Performance improvement for a simple cycle gas turbine GENSET––a retrofitting example. Appl. Therm. Eng. 2002, 22, 1105–1115. [Google Scholar] [CrossRef]

- Szargut, J. Cogeneration of network heat in the set of a humid air turbine. Energy 2002, 27, 1–15. [Google Scholar] [CrossRef]

- Ireneusz, S. Thermodynamic analysis of different humid air turbine schemes. In Proceedings of the 15th International Conference on Efficiency, Costs, Optimization, Simulation and Environmental Impact of Energy Systems, Berlin, Germany, 3–5 July 2002; pp. 719–725. [Google Scholar]

- Mori, Y.; Nakamura, H.; Takahashi, T.; Yamamoto, K. IGTC-38 A highly efficient regenerative gas turbine system by new method of heat recovery with water injection (Session A-12 Cycle Performance). In Proceedings of the 1983 Tokyo International Gas Turbine Congress and Exhibition, The International Gas Turbine Congress: Book of Abstracts. Tokyo, Japan, 23–29 October 1983; pp. 297–303. [Google Scholar]

- Fawwaz Alrebei, O.; Al-Doboon, A.; Bowen, P.; Valera Medina, A. CO2-Argon-Steam Oxy-Fuel production for (CARSOXY) gas turbines. Energies 2019, 12, 3580. [Google Scholar] [CrossRef] [Green Version]

- Omar, H.; Kamel, A.; Alsanousi, M. Performance of Regenerative Gas Turbine Power Plant. Energy Power Eng. 2017, 9, 136. [Google Scholar] [CrossRef] [Green Version]

- Nakamura, H. Heat Exchanging System for a Heat Engine. U.S. Patent 4,532,982, 6 August 1985. [Google Scholar]

- Nakamura, H. Heat Exchanging System for a Heat Engine Using Compressed Gaseous Fuel. European Patent Application 0 051 487 A1, 17 July 1982. [Google Scholar]

- Bram, S.; De Ruyck, J. Exergy analysis tools for ASPEN applied to evaporative cycle design. Energy Convers. Manag. 1997, 38, 1613–1624. [Google Scholar] [CrossRef]

- Fawwaz Alrebei, O.; Bowen, P.; Medina, A.V. Parametric study of various thermodynamic cycles for the use of unconventional blends. Energies 2020, 13, 4656. [Google Scholar] [CrossRef]

- Aronis, N.; Leithner, R. Combined cycle with low-quality heat integration and water injection into the compressed air. Energy 2004, 29, 1929–1943. [Google Scholar] [CrossRef]

- Dodo, S.; Tsubouchi, K.; Yasugahira, N.; Arita, H.; Akatsu, Y.; Hatamiya, S. Heat and Electric Power Supply System and Operation Method Thereof. U.S. Patent 6,477,852, 12 November 2002. [Google Scholar]

- El-Masri, M.A. A flexible, efficient gas-turbine cogeneration cycle with a novel dual mode heat recovery system. In Proceedings of the ASME Cogen-Turbo, 2nd International Symposium on Turbomachinery, Combined-Cycle Technologies and Cogeneration, Montreux, Switzerland, 30 August–1 September 1988; pp. 229–237. [Google Scholar]

- Bolland, O.; Stadaas, J.F. Comparative evaluation of combined cycles and gas turbine systems with water injection, steam injection, and recuperation. J. Eng. Gas Turbines Power 1995, 117, 138–145. [Google Scholar] [CrossRef]

- De Ruyck, J.; Peeters, F.; Bram, S.; Allard, G. An Externally Fired Evaporative Gas Turbine Cycle for Small Scale Biomass CHP Production; Report No. CONF-941024-; American Society of Mechanical Engineers: New York, NY, USA, 1994. [Google Scholar]

- Bechtel, T.F.; Parsons, E.J., Jr. Water Augmented Indirectly-Fired Gas Turbine Systems and Method. U.S. Patent 5,165,239, 24 November 1992. [Google Scholar]

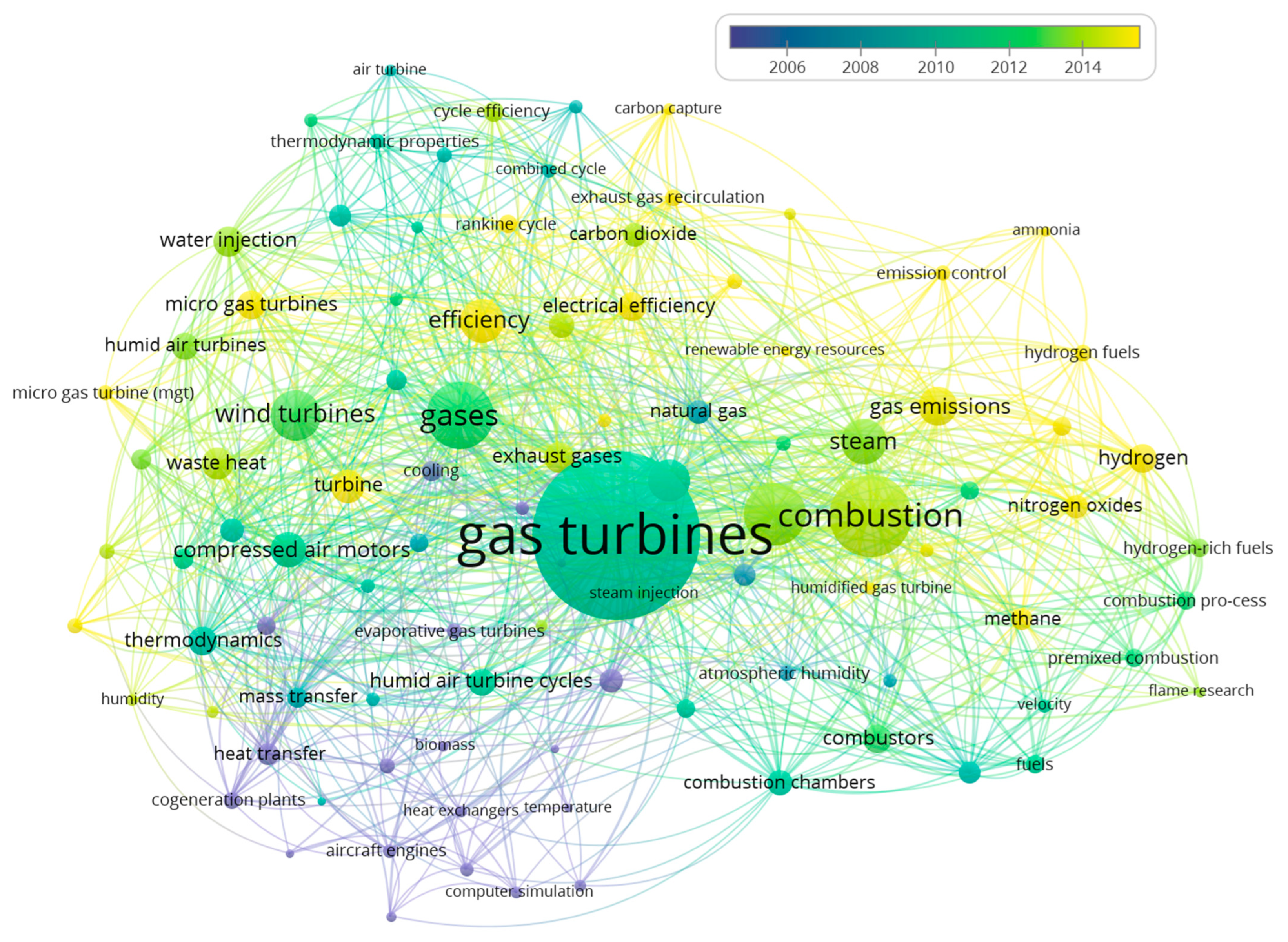

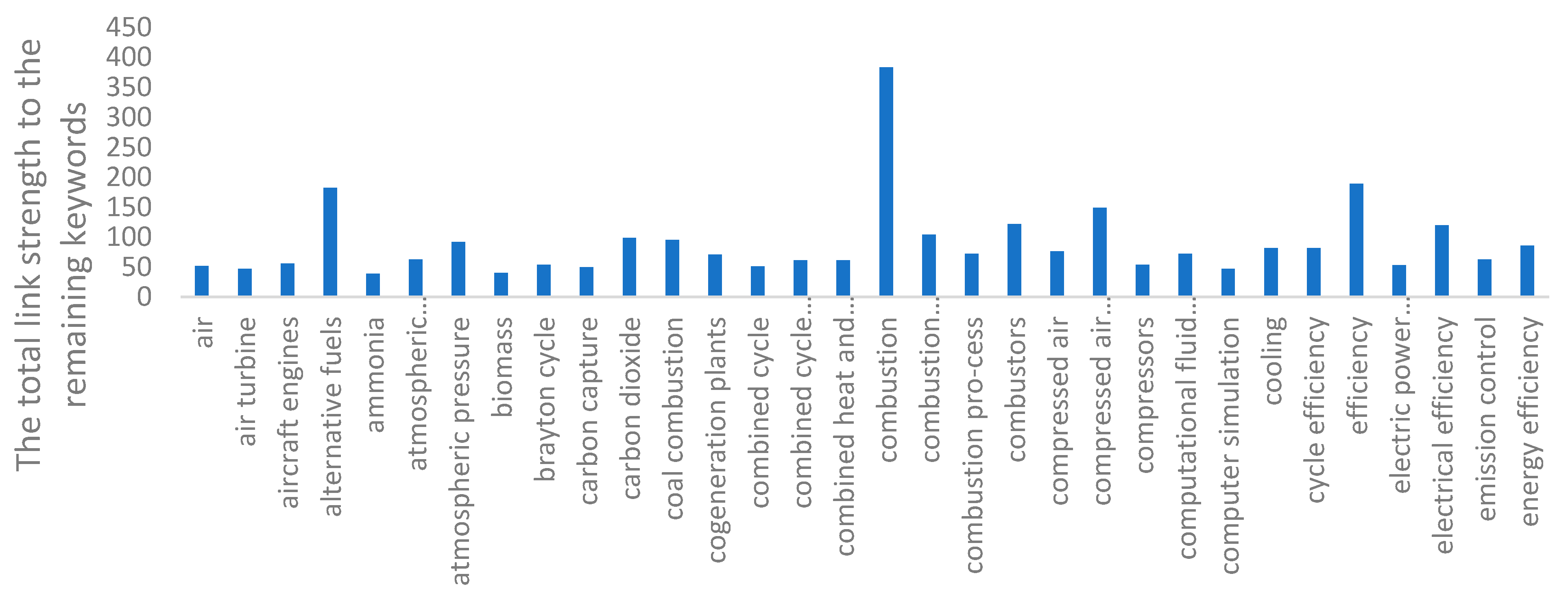

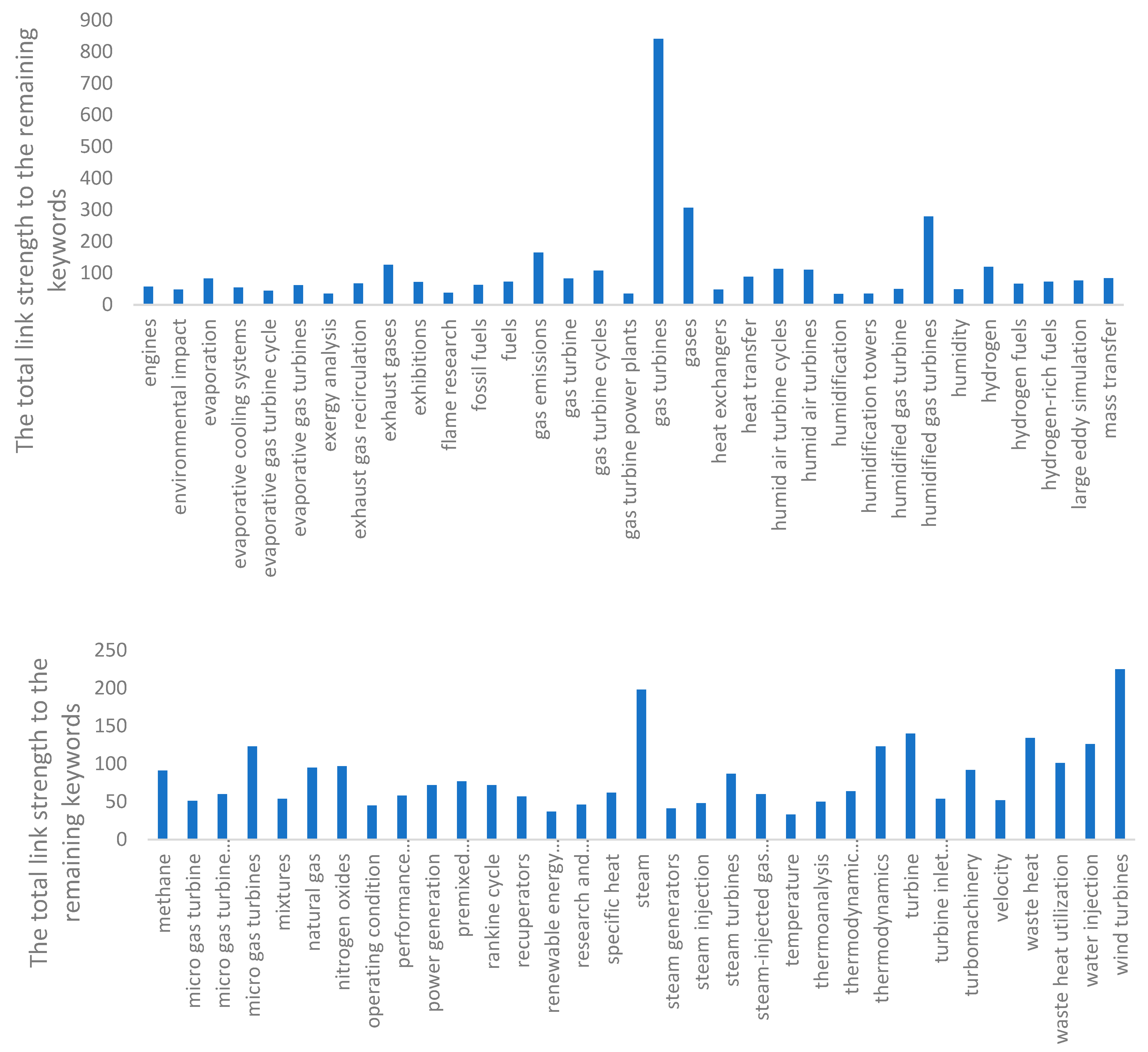

- Yu, A.; Su, W.; Lin, X.; Zhou, N. Recent trends of supercritical CO2 Brayton cycle: Bibliometric analysis and research review. Nucl. Eng. Technol. 2021, 53, 699–714. [Google Scholar] [CrossRef]

- Fawwaz Alrebei, O.; Aldoboon, A.; Bowen, P.; Valera-Medina, A. Techno-Economics of CO2-Argon-Steam Oxy-Fuel (Carsoxy) Gas Turbines. Envion. Energy Earth Sci. [CrossRef]

- Dryer, F.L. Water addition to practical combustion systems—Concepts and applications. Symp. (Int.) Combust. 1977, 16, 279–295. [Google Scholar] [CrossRef]

- Bathie, W.W. Fundamentals of Gas Turbines; Wiley: Hoboken, NJ, USA, 1984. [Google Scholar]

- Jonsson, M.; Yan, J. Humidified gas turbines—A review of proposed and implemented cycles. Energy 2005, 30, 1013–1078. [Google Scholar] [CrossRef]

- Mathioudakis, K. Analysis of the Effects of Water Injection on the Performance of a Gas Turbine. J. Eng. Gas Turbines Power 2002, 124, 489–495. [Google Scholar] [CrossRef]

- de Biasi, V. Aquarius design recovers water from exhaust for steam injection. Gas Turbine World 2000, 30, 14–17. [Google Scholar]

- Macchi, E.; Poggio, A. A cogeneration plant based on a steam injection gas turbine with recovery of the water injected: Design criteria and initial operating experience. In Proceedings of the ASME 1994 International Gas Turbine and Aeroengine Congress and Exposition, The Hague, The Netherlands, 13–16 June 1994; ASME: New York, NY, USA, 1994; Volume 78866. [Google Scholar]

- A˚ gren, N.D.; Westermark, M.O.; Bartlett, M.A.; Lindquist, T. First experiments on an evaporative gas turbine pilot power plant: Water circuit chemistry and humidification evaluation. J. Eng. Gas Turbines Power 2002, 124, 96–102. [Google Scholar] [CrossRef]

- Fawwaz Alrebei, O.; Amhamed, A.I.; El-Naas, M.H.; Hayajnh, M.; Orabi, Y.A.; Fawaz, W.; Al-tawaha, A.S.; Valera Medina, A. State of the art in separation processes for alternative working fluids in clean and efficient power generation. Separations 2022, 9, 14. [Google Scholar] [CrossRef]

- De Paepe, M.; Dick, E. Water recovery in steam injected gas turbines: A technological and economical analysis. Eur. J. Mech. Environ. Eng. 1999, 44, 195–204. [Google Scholar] [CrossRef]

- De Paepe, M.; Huvenne, P.; Dick, E. Economic Analysis of Condensers for Water Recovery in Steam Injected Gas Turbines; Report No. CONF-9806214-; Universiteit Gent: Ghent, Belgium, 1998. [Google Scholar]

- Bettagli, N.; Facchini, B. Water recovery in steam injection cycles. In Proceedings of the Florence World Energy Research Symposium, Florence, Italy, 6–8 July 1994. [Google Scholar]

- Nguyen, H.B.; Den Otter, A. Development of gas turbine steam injection water recovery (SIWR) system. J. Eng. Gas Turbines Power 1994, 116, 68–74. [Google Scholar] [CrossRef]

- Blanco, G.; Ambs, L.L. Water recovery systems for steam-injected gas turbines: Size optimization and life cycle savings. In Proceedings of the 2002 International Joint Power Generation Conference, Scottsdale, AZ, USA, 24–26 June 2002; Volume 36177. [Google Scholar]

- Amhamed, A.I.; Qarnain, S.S.; Hewlett, S.; Sodiq, A.; Abdellatif, Y.; Isaifan, R.J.; Fawwaz Alrebei, O. Ammonia Production Plants—A Review. Fuels 2022, 3, 408–435. [Google Scholar] [CrossRef]

- Cataldi, G. Dry Air-Cooling for Water Recovery in Humidified Gas Turbine Cycles. Master’s Thesis, Department of Chemical Engineering and Technology, Division of Energy Processes, Royal Institute of Technology, Stockholm, Sweden, 2001. [Google Scholar]

- Desideri, U.; Di Maria, F. Water recovery from HAT cycle exhaust gas: A possible solution for reducing stack temperature problems. Int. J. Energy Res. 1997, 21, 809–822. [Google Scholar] [CrossRef]

- Poels, R.P.W.; Gallo, W.L.R. A study on water recovery and reuse for HAT (humid air turbine) cycle. In Proceedings of the 2000 ECOS, Enschede, The Netherlands, 3–7 July 2000; pp. 599–608. [Google Scholar]

- De Paepe, M.; Dick, E. Analysis of efficiency and water recovery in steam injected gas turbines. In Proceedings of the ASME 1997 International Gas Turbine and Aeroengine Congress and Exhibition, Orlando, FL, USA, 2–5 June 1997; ASME: New York, NY, USA, 1997; Volume 78705. [Google Scholar]

- Alrebei, O.F.A. Carbon dioxide-Argon-Steam Oxyfuel (CARSOXY) Gas Turbines. Ph.D. Thesis, Cardiff University, Cardiff, UK, 2019. [Google Scholar]

- Zheng, Q.; Wang, G.; Sun, Y.; Liu, S. Experiments on water and heat recovery of steam injection gas turbine (STIG) power plant. In Proceedings of the ASME 1997 International Gas Turbine and Aeroengine Congress and Exhibition, Orlando, FL, USA, 2–5 June 1997; ASME: New York, NY, USA, 1997; Volume 78705. [Google Scholar]

- Cerri, G.; Arsuffi, G. Steam-injected gas turbine integrated with a self-production demineralized water thermal plant. J. Eng. Gas Turbines Power 1988, 110, 8–16. [Google Scholar] [CrossRef]

- Bartlett, M.A.; Westermark, M.O. Modelling of Alkali Contaminant Flows in Evaporative Gas Turbines. In Proceedings of the ASME Turbo Expo 2001: Power for Land, Sea, and Air, New Orleans, LA, USA, 4–7 June 2001; ASME: New York, NY, USA, 2001; Volume 78514. [Google Scholar]

- Zaba, T.; Lombardi, P. Experience in the operation of air filters in gas turbine installations. In Turbo Expo: Power for Land, Sea, and Air; American Society of Mechanical Engineers: New York, NY, USA, 1984; Volume 79498, p. V004T10A009. [Google Scholar]

- Ji, X.; Lu, X.; Yan, J. Survey of experimental data and assessment of calculation methods of properties for the air–water mixture. Appl. Therm. Eng. 2003, 23, 2213–2228. [Google Scholar] [CrossRef]

- Fawwaz Aalrebei, O.; Al Assaf, A.H.; Amhamed, A.; Swaminathan, N.; Hewlett, S. Ammonia-hydrogen-air gas turbine cycle and control analyses. Int. J. Hydrogen Energy 2022, 47, 8603–8620. [Google Scholar] [CrossRef]

- Farnosh, D.; Andrén, M.; Yan, J.; Westermark, M. The impact of thermodynamic properties of air-water vapor mixtures on design of evaporative gas turbine cycles. In Proceedings of the ASME Turbo Expo 2001: Power for Land, Sea, and Air, New Orleans, LA, USA, 4–7 June 2001; ASME: New York, NY, USA, 2001; Volume 78514. [Google Scholar]

- Hyland, R.W.; Wexter, A. Formulations for the thermodynamic properties of dry air from 173.15 K to 473.15 K, and of saturated moist air from 173.15 K to 372.15 K, at pressures to 5 MPa. ASHRAE Trans. 1983, 89, 520–535. [Google Scholar]

- Yan, J.; Ji, X. Humidity, enthalpy and entropy for the humid air form 298 to 573 K and up to 200 bar. In Proceedings of the 16th European Conference on Thermophysical Properties, Orleans, France, 1–4 September 2002; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Ji, X.; Lu, X.; Yan, J. Saturated humidity, entropy, and enthalpy for the nitrogen-water system at elevated temperatures and pressures. Int. J. Thermophys. 2003, 24, 1681–1696. [Google Scholar] [CrossRef]

- Ji, X.; Yan, J. Saturated thermodynamic properties for the air–water system at elevated temperatures and pressures. Chem. Eng. Sci. 2003, 58, 5069–5077. [Google Scholar] [CrossRef]

- Yan, J.; Ji, X.; Jonsson, M. Thermodynamic property models for the simulation of advanced wet cycles. In Proceedings of the ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; Volume 3686. [Google Scholar]

- Koop, W.E. Advanced Turbine Systems annual program review; No. DOE/METC-96/1023-Vol. 1; CONF-9510109-Vol. 1; USDOE Morgantown Energy Technology Center: Morgantown, WV, USA; USDOE Assistant Secretary for Energy Efficiency and Renewable Energy: Washington, DC, USA, 1995; Office of Industrial Technologies. [Google Scholar]

- Fawwaz Alrebei, O.; Le Page, L.M.; Hewlett, S.; Bicer, Y.; Amhamed, A. Numerical investigation of a first-stage stator turbine blade subjected to NH3–H2/air combustion flue gases. Int. J. Hydrogen Energy 2022, 47, 33479–33497. [Google Scholar] [CrossRef]

- Bhargava, A.; Colket, M.; Sowa, W.; Casleton, K.; Maloney, D. An experimental and modeling study of humid air premixed flames. J. Eng. Gas Turbines Power 2000, 122, 405–411. [Google Scholar] [CrossRef]

- Hermann, F.; Klingmann, J.; Gabrielsson, R. Computational and experimental investigation of emissions in a highly humidified premixed flame. In Proceedings of the Computational and experimental investigation of emissions in a highly humidified premixed flame, Atlanta, GA, USA, 16–19 June 2003; Volume 36843. [Google Scholar]

- Chen, A.G.; Maloney, D.J.; Day, W.H. Humid air NOx reduction effect on liquid fuel combustion. J. Eng. Gas Turbines Power 2002, 126, 69–74. [Google Scholar] [CrossRef]

- Bianco, M.; Camporeale, S.M.; Fortunato, B. Cfd simulation of humid air premixed flame combustion chamber for evaporative gas turbine cycles. In Proceedings of the ASME Turbo Expo 2001: Power for Land, Sea, and Air, New Orleans, LA, USA, 4–7 June 2001; ASME: New York, NY, USA, 2001; Volume 78514. [Google Scholar]

- Belokon, A.A.; Khritov, K.M.; Klyachko, L.A.; Tschepin, S.A.; Zakharov, V.M.; Opdyke, G., Jr. Prediction of combustion efficiency and NOx levels for diffusion flame combustors in HAT cycles. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; Volume 36061. [Google Scholar]

- Lindquist, T.O.; Rosén, P.M.; Torisson, T. Theoretical and experimental evaluation of the EvGT-process. In Proceedings of the ASME 2000 International Mechanical Engineering Congress and Exposition, Orlando, FL, USA, 5–10 November 2000; ASME: New York, NY, USA, 2000; Volume 19074. [Google Scholar]

- Mesbahi, E.; Assadi, M.; Torisson, T.; Lindquist, T. A unique correction technique for evaporative gas turbine (EvGT) parameters. In Proceedings of the ASME Turbo Expo 2001: Power for Land, Sea, and Air, New Orleans, LA, USA, 4–7 June 2001; ASME: New York, NY, USA, 2001; Volume 78538. [Google Scholar]

- Fawwaz Alrebei, O.; Al Assaf, A.H.; Al-Kuwari, M.S.; Amhamed, A. Lightweight methane-air gas turbine controller and simulator. Energy Convers. Manag. X 2022, 15, 100242. [Google Scholar] [CrossRef]

- Mathioudakis, K. Gas turbine test parameters corrections including operation with water injection. J. Eng. Gas Turbines Power 2004, 126, 334–341. [Google Scholar] [CrossRef]

- Rao, A.D.; Day, W.H. Mitigation of greenhouse gases from gas turbine power plants. Energy Convers. Manag. 1996, 37, 909–914. [Google Scholar] [CrossRef]

- Carcasci, C.; Cosi, L.; Fiaschi, D.; Manfrida, G. Semi–Closed Hat (SC-HAT) Power Cycle. In Proceedings of the ASME Turbo Expo 2000: Power for Land, Sea, and Air, Munich, Germany, 8–11 May 2000; ASME: New York, NY, USA, 2000; Volume 78552. [Google Scholar]

- Corti, A.; Failli, L.; Fiaschi, D.; Manfrida, G. Exergy analysis of two second-generation SCGT plant proposals. In Proceedings of the ASME 1998 International Gas Turbine and Aeroengine Congress and Exhibition, Stockholm, Sweden, 2–5 June 1998; ASME: New York, NY, USA, 1998; Volume 78644. [Google Scholar]

- Desideri, U.; Roberto, C. CO2 capture in small size cogeneration plants: Technical and economical considerations. Energy Convers. Manag. 1998, 39, 857–867. [Google Scholar] [CrossRef]

- Bartlett, M. Developing Humidified Gas Turbine Cycles. Ph.D. Thesis, Royal Institute of Technology, Stockholm, Sweden, 2002. [Google Scholar]

- Sanz, W. Basic Principle. Available online: https://www.diva-portal.org/smash/record.jsf?pid=diva2%3A9236&dswid=4266 (accessed on 2 August 2022).

- Jonsson, M.; Yan, J. Economic assessment of evaporative gas turbine cycles with optimized part flow humidification systems. In Proceedings of the ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; Volume 3686. [Google Scholar]

- Al-Assaf, A.H.; Alrebei, O.; Amhamed, A.; Hayajnh, M.A.; Fawaz, W.; Al-tawaha, A.S. PID Power Controller to a Setpoint of Fluid Level Height in a Reservoir for Unattended Human Monitoring. Int. J. Electr. Electron. Eng. Stud. 2021, 8, 1–13. [Google Scholar] [CrossRef]

- Rao, A.D.; Francuz, V.J.; Shen, J.C.; West, E.W. A Comparison of Humid Air Turbine (HAT) Cycle and Combined-Cycle Power Plants; Report No. EPRI-IE-7300; Electric Power Research Inst.: Palo Alto, CA, USA; Fluor Daniel, Inc.: Irvine, CA, USA, 1991. [Google Scholar]

- Rao, A.D.; Francuz; Mulato, F.J.; Sng, B.; West, E.W.; Kana, J.; Perkins, G.; Podolski, D. A Feasibility and Assessment Study for FT 4000 Humid Air Turbine (HAT). Final Report; Report No. EPRI-TR-102156; Electric Power Research Inst.: Palo Alto, CA, USA; Fluor Daniel, Inc.: Irvine, CA, USA; United Technologies Corp.: Farmington, CT, USA; Texaco, Inc.: White Plains, NY, USA, 1993. [Google Scholar]

- Božo, M.G.; Vigueras-Zuniga, M.O.; Buffi, M.; Seljak, T.; Valera-Medina, A. Fuel rich ammonia-hydrogen injection for humidified gas turbines. Appl. Energy 2019, 251, 113334. [Google Scholar] [CrossRef]

- Carmona, J. Gas turbine evaporative cooling evaluation for Lagos–Nigeria. Appl. Therm. Eng. 2015, 89, 262–269. [Google Scholar] [CrossRef]

- Corradetti, A.; Desideri, U.; Rao, A.D. A Novel Concept for Combined Heat and Cooling in Humid Gas Turbine Cycles. In Proceedings of the ASME Turbo Expo 2007: Power for Land, Sea, and Air, Montreal, Canada, 14–17 May 2007; Volume 47926. [Google Scholar]

- McDonald, C.F.; Wilson, D.G. The utilization of recuperated and regenerated engine cycles for high-efficiency gas turbines in the 21st century. Appl. Therm. Eng. 1996, 16, 635–653. [Google Scholar] [CrossRef]

- Lagerström, G.; Xie, M. High performance and cost effective recuperator for micro-gas turbines. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; Volume 36061. [Google Scholar]

- Kesseli, J.; Wolf, T.; Nash, J.; Freedman, S. Micro, industrial, and advanced gas turbines employing recuperators. In Proceedings of the ASME Turbo Expo 2003, collocated with the 2003 International Joint Power Generation Conference, Atlanta, GA, USA, 16–19 June 2003; Volume 3686. [Google Scholar]

- Saidi, A.; Sundén, B.; Eriksson, D. Intercoolers in gas turbine systems and combi-processes for production of electricity. In Proceedings of the ASME Turbo Expo 2000: Power for Land, Sea, and Air, Munich, Germany, 8–11 May 2000; ASME: New York, NY, USA, 2000; Volume 78569. [Google Scholar]

- McCarthy, S.J.; Scott, I. The WR-21 intercooled recuperated gas turbine engine: Operation and integration into the royal navy type 45 destroyer power system. In Proceedings of the ASME Turbo Expo 2002: Power for Land, Sea, and Air, Amsterdam, The Netherlands, 3–6 June 2002; Volume 3607. [Google Scholar]

- Ali, U.; Font-Palma, C.; Hughes, K.J.; Ingham, D.B.; Ma, L.; Pourkashanian, M. Thermodynamic analysis and process system comparison of the exhaust gas recirculated, steam injected and humidified micro gas turbine. In Proceedings of the ASME Turbo Expo 2015, Montreal, QC, Canada, 15–19 June 2015. Paper No. GT2015-42688. [Google Scholar]

- Lee, J.J.; Jeon, M.S.; Kim, T.S. The Influence of Water and Steam Injection on the Performance of a Recuperated Cycle Microturbine for Combined Heat and Power Application. Appl. Energy 2010, 87, 1307–1316. [Google Scholar] [CrossRef]

- De Paepe, W.; Montero Carrero, M.; Bram, S.; Parente, A.; Contino, F. Toward higher micro gas turbine efficiency and flexibility—Humidified micro gas turbines: A review. J. Eng. Gas Turbines Power 2018, 140, 081702. [Google Scholar] [CrossRef]

- Delattin, F.; Bram, S.; Knoops, S.; De Ruyck, J. Effects of Steam Injection on Microturbine Efficiency and Performance. Energy 2008, 33, 241–247. [Google Scholar] [CrossRef]

- Stathopoulos, P.; Paschereit, C. Retrofitting Micro Gas Turbines for Wet Operation. a Way to Increase Operational Flexibility in Distributed CHP Plants. Appl. Energy 2015, 154, 438–446. [Google Scholar] [CrossRef]

- De Paepe, W.; Delattin, F.; Bram, S.; De Ruyck, J. Steam Injection Experiments in a Microturbine—A Thermodynamic Performance Analysis. Appl. Energy 2012, 97, 569–576. [Google Scholar] [CrossRef]

- De Paepe, W.; Delattin, F.; Bram, S.; Contino, F.; De Ruyck, J. A Study on the Performance of Steam Injection in a Typical Micro Gas Turbine. In Proceedings of the ASME Turbo Expo 2013: Turbine Technical Conference and Exposition, San Antonio, TX, USA, 3–7 June 2013. Paper No: GT2013-94569. [Google Scholar]

- Zare, V. Role of modeling approach on the results of thermodynamic analysis: Concept presentation via thermoeconomic comparison of biomass gasification-fueled open and closed cycle gas turbines. Energy Convers. Manag. 2020, 225, 113479. [Google Scholar] [CrossRef]

- Zare, V. Performance improvement of biomass-fueled closed cycle gas turbine via compressor inlet cooling using absorption refrigeration; thermoeconomic analysis and multi-objective optimization. Energy Convers. Manag. 2020, 215, 112946. [Google Scholar] [CrossRef]

- VOSviewer. Available online: https://www.vosviewer.com (accessed on 20 November 2022).

| Reference | Scope of Work and Configuration | Key Findings |

|---|---|---|

| Ingistoov et al. [12] | Analysis of a water injection device that was placed between stages of a compressor |

|

| Zhang et al. [13,14] and Van Liere [7] | The development of the TopHat cycle.This cycle involves the injection of a significant quantity of water that has been preheated by the exhaust gas from the gas turbine into the compressor. |

|

| Hori et al. [16] | The development of the evaporative inter-cooling system was used in order to increase power generation and efficiency while simultaneously reducing NOx emissions. |

|

| de Biasi et al. [17] | Development of Sprint spray inter-cooling system for the LM6000 gas turbine |

|

| Reference | Scope of Work and Configuration | Key Findings |

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Reference | Scope Of Work and Configuration | Key Findings |

|---|---|---|

|

|

|

|

| |

|

|

|

|

| |

|

|

|

|

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamdan Al Assaf, A.; Amhamed, A.; Fawwaz Alrebei, O. State of the Art in Humidified Gas Turbine Configurations. Energies 2022, 15, 9527. https://doi.org/10.3390/en15249527

Hamdan Al Assaf A, Amhamed A, Fawwaz Alrebei O. State of the Art in Humidified Gas Turbine Configurations. Energies. 2022; 15(24):9527. https://doi.org/10.3390/en15249527

Chicago/Turabian StyleHamdan Al Assaf, Anwar, Abdulkarem Amhamed, and Odi Fawwaz Alrebei. 2022. "State of the Art in Humidified Gas Turbine Configurations" Energies 15, no. 24: 9527. https://doi.org/10.3390/en15249527