Internet of Things Driven Digital Twin for Intelligent Manufacturing in Shipbuilding Workshops

Abstract

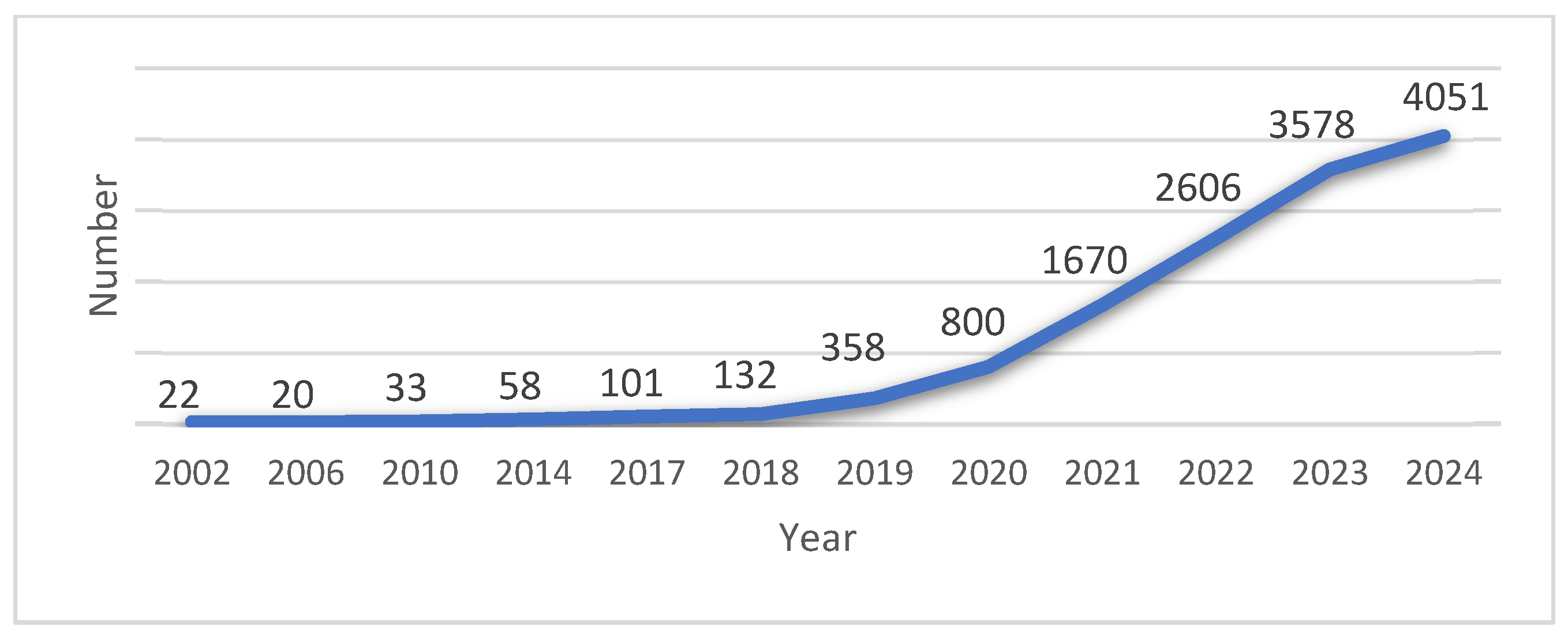

1. Introduction

2. Overview of Internet of Things

2.1. Definition and Development of Internet of Things

- Comprehensive perception denotes the collection and assessment of object information using sensors, radio frequency (RF) technology, and other approaches to record physical characteristics [17].

- Reliable transmission guarantees uninterrupted and trustworthy information flow across interconnected devices, terminals, or systems over IoT networks, facilitating real-time data sharing beyond geographical and temporal limitations [18].

- Intelligent processing entails the analysis and interpretation of acquired data with sophisticated computational approaches, such as edge computing, to extract actionable insights and facilitate data-driven decision-making [19].

2.2. Current Application Status of Internet of Things

2.3. IoT Protocols

2.3.1. TCP

- Connection Establishment: The client sends an SYN request to the server, which replies with SYN + ACK. Upon receipt, the client transmits an ACK, finalizing the connection establishment.

- Data Transmission: Upon establishment, data is exchanged between the client and server until one party terminates the connection or an interruption transpires.

- Connection Termination: Either party may issue an FIN to terminate the connection. The recipient confirms receipt with an ACK and then sends their own FIN and a subsequent ACK, completing the closure.

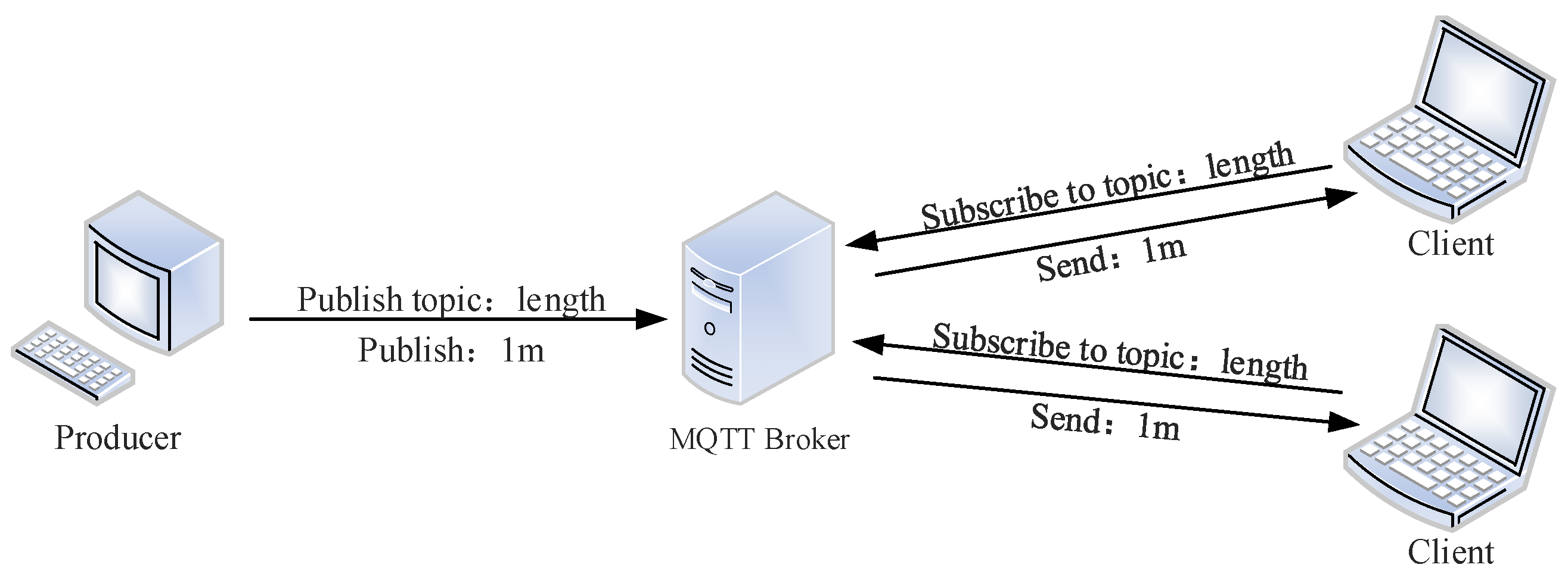

2.3.2. MQTT

2.3.3. XMPP

2.3.4. OPC UA

2.3.5. IoT Protocol Adaptability Analysis

3. Overview of Digital Twin Technology

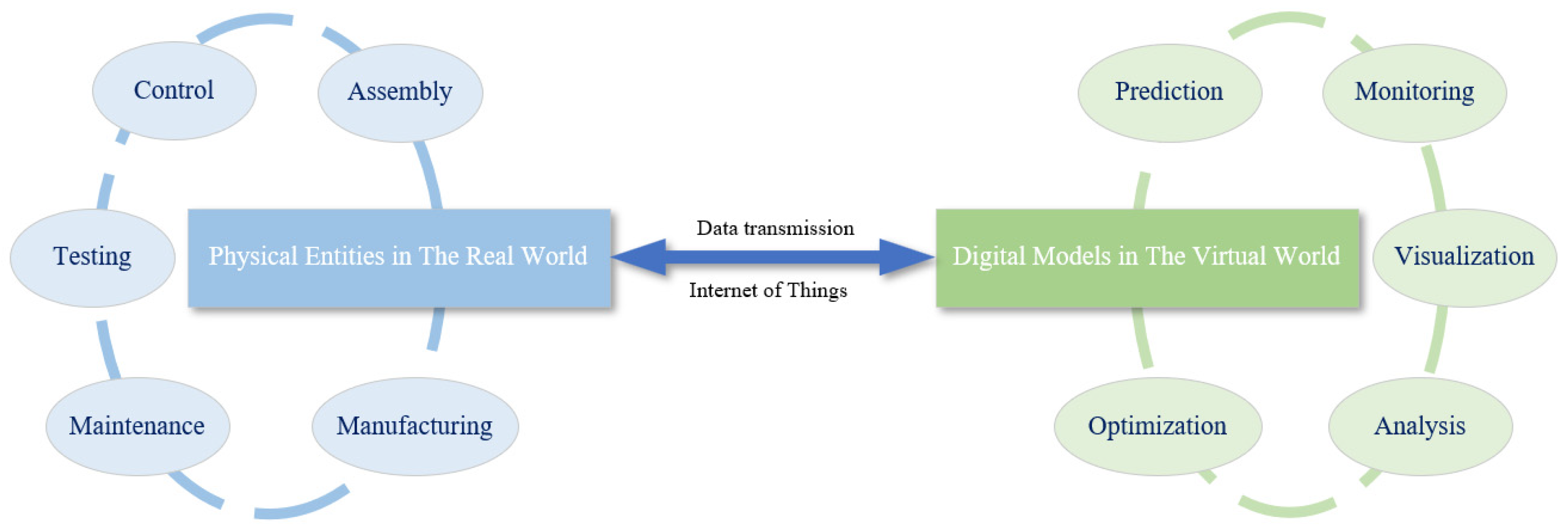

3.1. Definition and Development of DT Technology

- Physical objects: This includes real-world products, systems, facilities, or environments.

- Virtual models: This includes virtual representations of physical entities created in a computer environment.

- Interconnection: This represents a bidirectional connection between the virtual and physical entities, enabling real-time data exchange, synchronization, and feedback.

3.2. Technologies Related to Achieving DTs

3.2.1. Big Data Analysis

3.2.2. Cloud Computing

3.2.3. Summary of Key Technologies

3.3. Specific Applications Related to DTs

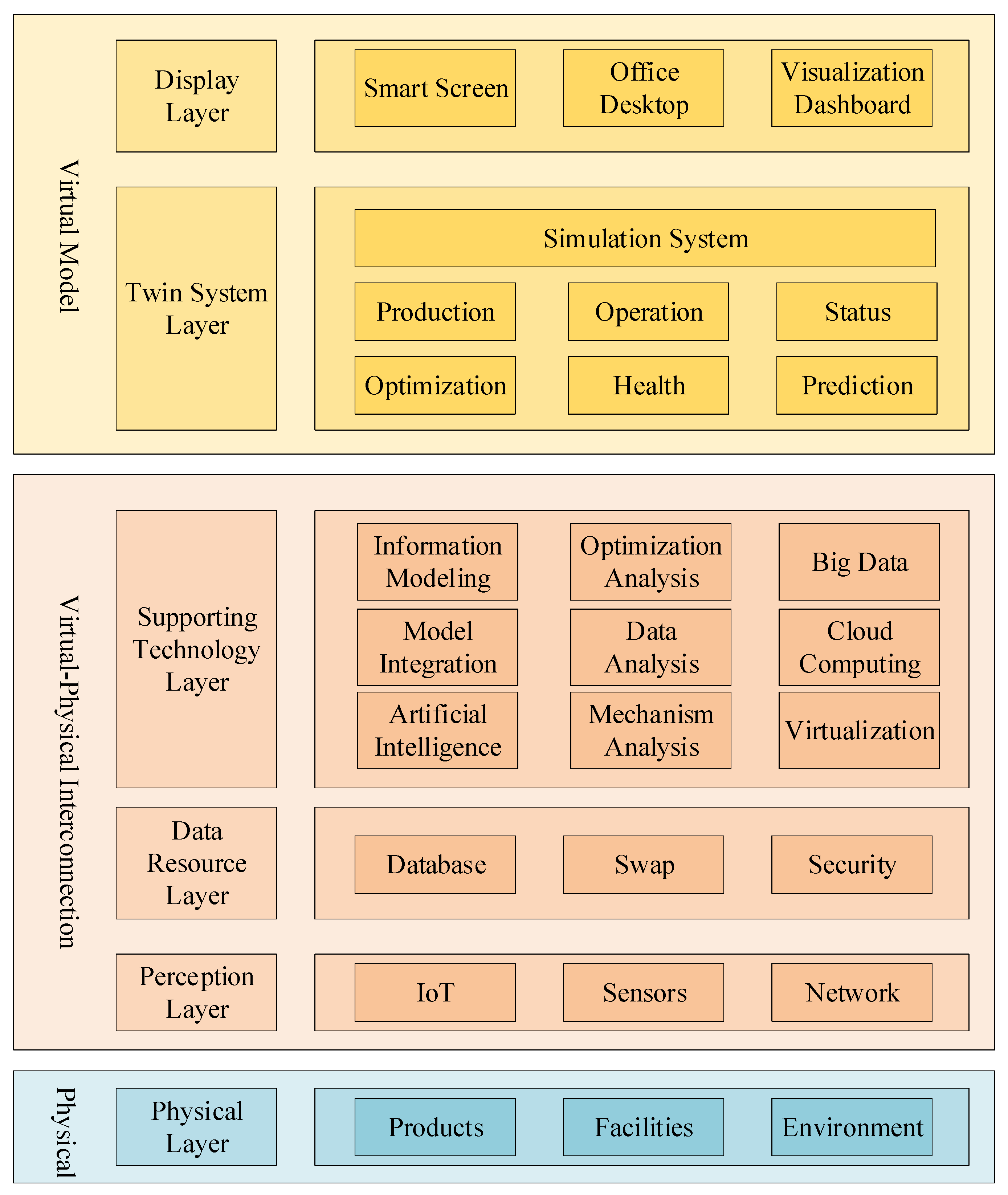

- Display Layer: This layer offers an interface for users to engage with and visualize the DT model.

- Twin System Layer: This layer oversees the fundamental operations of the DT, encompassing data processing and simulation.

- Supporting Technology Layer: This layer includes the foundational technologies that facilitate the use of the DT, such as IoT, big data analytics, and cloud computing.

- Data Resource Layer: This layer pertains to the acquisition, storage, and administration of data vital for the functionality of the DT.

- Perception Layer: This layer is tasked with the real-time gathering of data from the physical system, guaranteeing precise sensory feedback.

- Physical Layer: This layer denotes the tangible components and entities of the system represented by the DT.

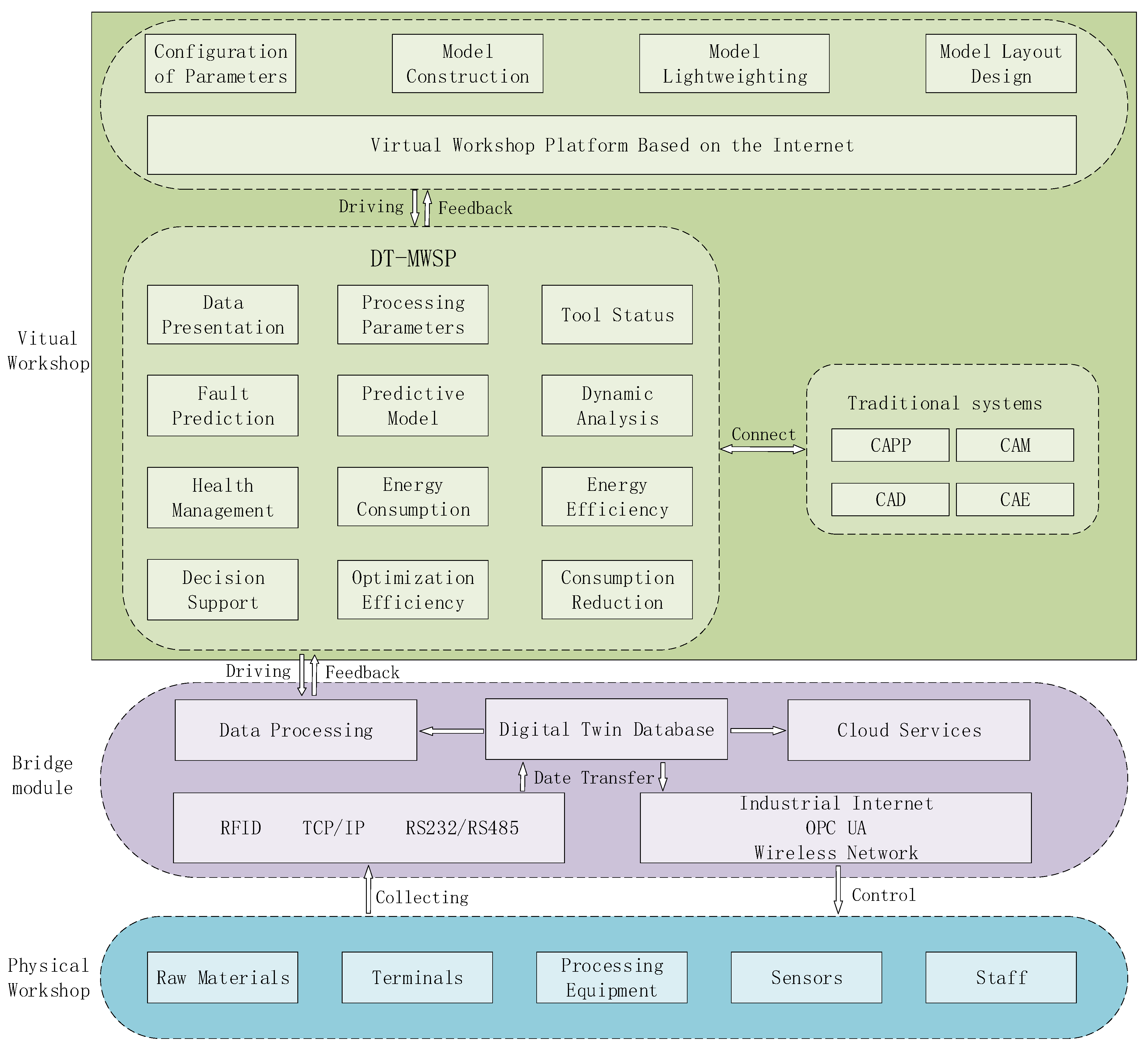

4. IoT-Driven DT for Intelligent Manufacturing Applications in Shipbuilding Workshops

4.1. Intelligent Development of Shipbuilding

- Miniature welding robots designed for operation in restricted environments, versatile for cutting and spraying via modular software;

- Advanced welding systems for real-time surveillance of process parameters to enhance quality and efficiency;

- A robotic system for processing double-curved plates that standardizes intricate shaping procedures;

- A virtual sea trial system for LNG carriers, certified by Lloyd’s Register (LR) with an Approval in Principle (AIP) certificate, which simulates actual sea trial circumstances in a virtual setting to assess dual-fuel engines, fuel supply systems, and control units in extreme situations, thereby decreasing sea trial duration and expenses by up to 30% [87].

4.2. DT of Shipbuilding Workshops

4.3. A DT Taking the Cutting Workshop as an Example

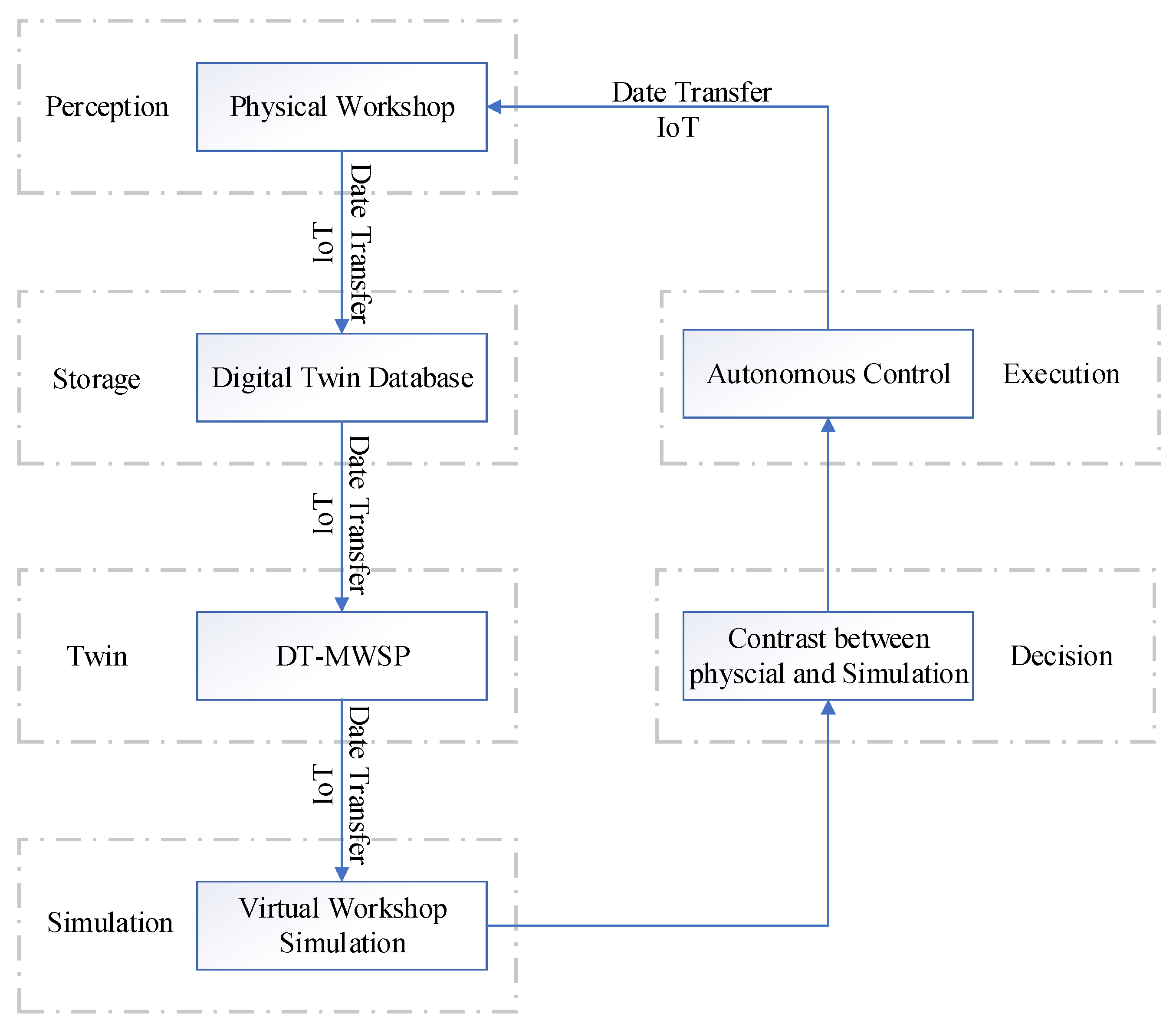

4.4. Cyber-Physical Integration

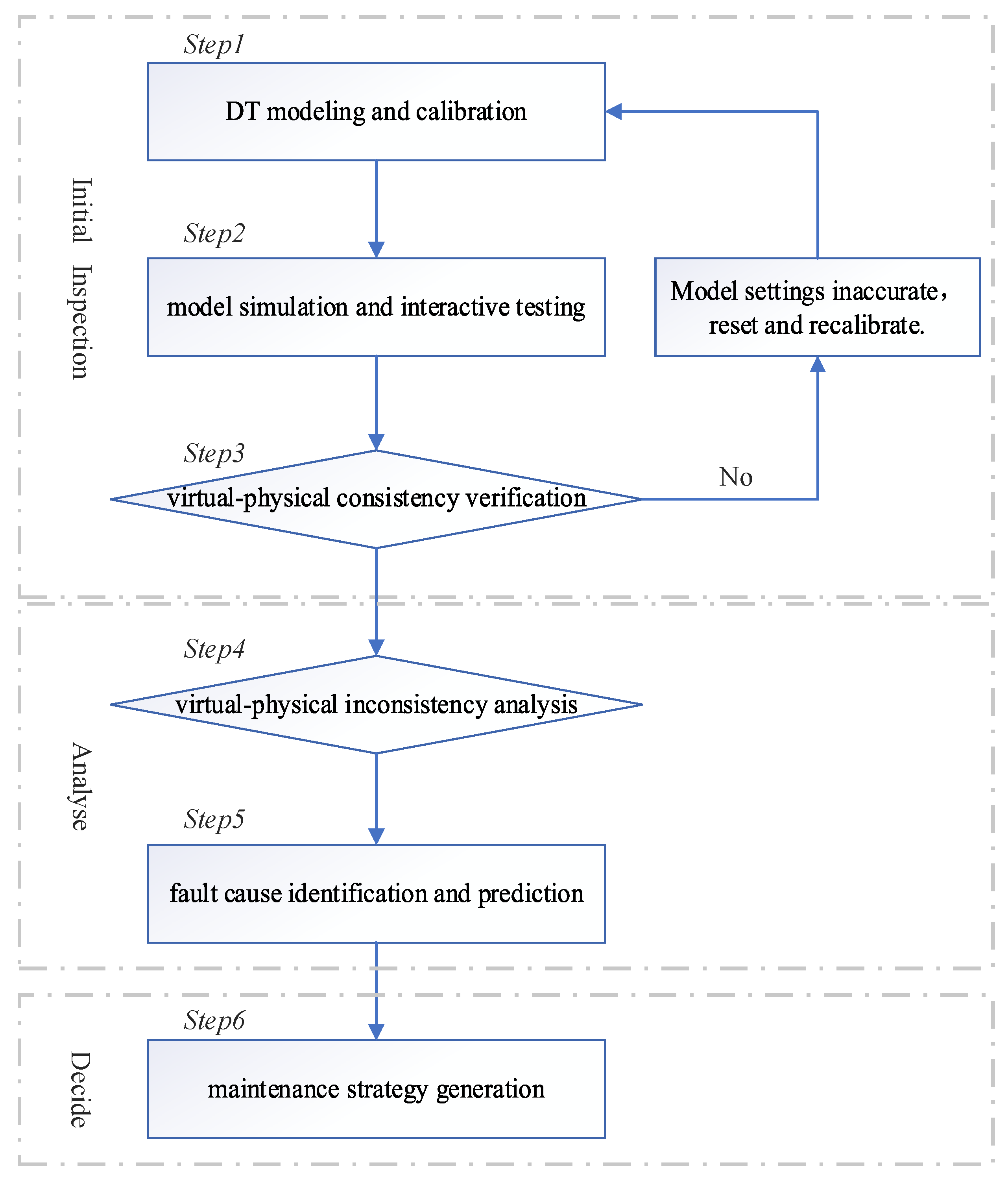

4.5. Fault Prediction and Health Management

4.6. IoT-Driven DT Feedback

5. Technical Challenges

5.1. Standardization and Unification

5.2. Communication Security

5.3. Real-Time Performance and Reliability

5.4. Cross-Workshop Collaboration

5.5. Artificial Intelligence

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yao, J.-F.; Yang, Y.; Wang, X.-C.; Zhang, X.-P. Systematic review of digital twin technology and applications. Vis. Comput. Ind. Biomed. Art 2023, 6, 10. [Google Scholar] [CrossRef]

- Grieves, M. Intelligent digital twins and the development and management of complex systems. Digit. Twin 2022, 2, 8. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A.Y.C. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Söderberg, R.; Wärmefjord, K.; Carlson, J.S.; Lindkvist, L. Toward a Digital Twin for real-time geometry assurance in individualized production. CIRP Ann. 2017, 66, 137–140. [Google Scholar] [CrossRef]

- Zaccaria, V.; Stenfelt, M.; Aslanidou, I.; Kyprianidis, K.G. Fleet Monitoring and Diagnostics Framework Based on Digital Twin of Aero-Engines. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, Z.; Li, F.; Zhao, Y.; Zhang, C.; Li, X.; Zhang, Y. The rapid construction method of the digital twin polymorphic model for discrete manufacturing workshop. Robot. Comput. Integr. Manuf. 2023, 84, 102600. [Google Scholar] [CrossRef]

- Cai, Y.; Starly, B.; Cohen, P.; Lee, Y.-S. Sensor Data and Information Fusion to Construct Digital-twins Virtual Machine Tools for Cyber-physical Manufacturing. Procedia Manuf. 2017, 10, 1031–1042. [Google Scholar] [CrossRef]

- Iliuţă, M.-E.; Moisescu, M.-A.; Pop, E.; Ionita, A.-D.; Caramihai, S.-I.; Mitulescu, T.-C. Digital Twin—A Review of the Evolution from Concept to Technology and Its Analytical Perspectives on Applications in Various Fields. Appl. Sci. 2024, 14, 5454. [Google Scholar] [CrossRef]

- Del Rosal, I. Trade effects of liner shipping across world regions. Marit. Bus. Rev. 2024, 9, 2–16. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, D. Shipbuilding 4.0: A Systematic Literature Review. Appl. Sci. 2024, 14, 6363. [Google Scholar] [CrossRef]

- Billey, A.; Wuest, T. Energy digital twins in smart manufacturing systems: A case study. Robot. Comput. Integr. Manuf. 2024, 88, 102729. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Liu, Z.; Leng, J.; Zhou, H.; Gu, S.; Liu, X. Digital twins enable shipbuilding. Alex. Eng. J. 2024, 107, 915–931. [Google Scholar] [CrossRef]

- Ng, I.C.L.; Wakenshaw, S.Y.L. The Internet-of-Things: Review and research directions. Int. J. Res. Mark. 2017, 34, 3–21. [Google Scholar] [CrossRef]

- Ray, P.P. A survey on Internet of Things architectures. J. King Saud Univ.-Comput. Inf. Sci. 2018, 30, 291–319. [Google Scholar] [CrossRef]

- Sharma, M.; Tomar, A.; Hazra, A. Edge Computing for Industry 5.0: Fundamental, Applications, and Research Challenges. IEEE Internet Things J. 2024, 11, 19070–19093. [Google Scholar] [CrossRef]

- Zijie, F.; Al-Shareeda, M.A.; Saare, M.A.; Manickam, S.; Karuppayah, S. Wireless sensor networks in the internet of things: Review, techniques, challenges, and future directions. Indones. J. Electr. Eng. Comput. Sci. 2023, 31, 1190–1200. [Google Scholar] [CrossRef]

- Khan, M.Z.; Alhazmi, O.H.; Javed, M.A.; Ghandorh, H.; Aloufi, K.S. Reliable Internet of Things: Challenges and Future Trends. Electronics 2021, 10, 2377. [Google Scholar] [CrossRef]

- Li, B.; He, D.; Jiang, Y. Research on the Application of Artificial Intelligence and Computational Intelligence in the Internet of Things. J. Phys. Conf. Ser. 2021, 1915, 042020. [Google Scholar] [CrossRef]

- Soori, M.; Jough, F.K.G.; Dastres, R.; Arezoo, B. AI-Based Decision Support Systems in Industry 4.0, A Review. J. Econ. Technol. 2024; in press. [Google Scholar] [CrossRef]

- Netinant, P.; Utsanok, T.; Rukhiran, M.; Klongdee, S. Development and Assessment of Internet of Things-Driven Smart Home Security and Automation with Voice Commands. IoT 2024, 5, 79–99. [Google Scholar] [CrossRef]

- Zeng, F.; Pang, C.; Tang, H. Sensors on Internet of Things Systems for the Sustainable Development of Smart Cities: A Systematic Literature Review. Sensors 2024, 24, 2074. [Google Scholar] [CrossRef]

- Mathkor, D.M.; Mathkor, N.; Bassfar, Z.; Bantun, F.; Slama, P.; Ahmad, F.; Haque, S. Multirole of the internet of medical things (IoMT) in biomedical systems for managing smart healthcare systems: An overview of current and future innovative trends. J. Infect. Public Health 2024, 17, 559–572. [Google Scholar] [CrossRef] [PubMed]

- Wan, J.; Chen, B.; Imran, M.; Tao, F.; Li, D.; Liu, C.; Ahmad, S. Toward Dynamic Resources Management for IoT-Based Manufacturing. IEEE Commun. Mag. 2018, 56, 52–59. [Google Scholar] [CrossRef]

- Kasera, R.K.; Gour, S.; Acharjee, T. A comprehensive survey on IoT and AI based applications in different pre-harvest, during-harvest and post-harvest activities of smart agriculture. Comput. Electron. Agric. 2024, 216, 108522. [Google Scholar] [CrossRef]

- Cai, Q.; Jing, X.; Chen, Y.; Liu, J.; Kang, C.; Li, B. Online Monitoring of Ship Block Construction Equipment Based on the Internet of Things and Public Cloud: Take the Intelligent Tire Frame as an Example. KSII Trans. Internet Inf. Syst. 2021, 15, 3970–3990. [Google Scholar] [CrossRef]

- Choi, T.; Seo, Y. A Real-Time Physical Progress Measurement Method for Schedule Performance Control Using Vision, an AR Marker and Machine Learning in a Ship Block Assembly Process. Sensors 2020, 20, 5386. [Google Scholar] [CrossRef]

- Lee, S.; Eun, S.; Jung, J.J.; Song, H. Application of Sensor Technology for the Efficient Positioningand Assembling of Ship Blocks. Int. J. Nav. Archit. Ocean. Eng. 2010, 2, 171–176. [Google Scholar] [CrossRef]

- Cil, I.; Arisoy, F.; Kilinç, H. Visibility of resources and assets in the shipyard through industrial internet of things. Glob. J. Comput. Sci. Theory Res. 2021, 11, 88–101. [Google Scholar] [CrossRef]

- Wang, X.; Zou, H.; Li, H.; Qian, H.; He, X. Diversified Intelligent Terminal Devices Unified Access and Data Communication Technology. IEEE Access 2024, 12, 8096–8109. [Google Scholar] [CrossRef]

- Parween, S.; Hussain, S.Z. TCP Performance Enhancement in IoT and MANET: A Systematic Literature Review. Int. J. Comput. Netw. Appl. 2023, 10, 543. [Google Scholar] [CrossRef]

- Kovtun, V.; Grochla, K.; Połys, K. Investigation of the Information Interaction of the Sensor Network End IoT Device and the Hub at the Transport Protocol Level. Electronics 2023, 12, 4662. [Google Scholar] [CrossRef]

- Lakshminarayana, S.; Praseed, A.; Thilagam, P.S. Securing the IoT Application Layer From an MQTT Protocol Perspective: Challenges and Research Prospects. IEEE Commun. Surv. Tutor. 2024, 26, 2510–2546. [Google Scholar] [CrossRef]

- Hintaw, A.J.; Manickam, S.; Aboalmaaly, M.F.; Karuppayah, S. MQTT Vulnerabilities, Attack Vectors and Solutions in the Internet of Things (IoT). IETE J. Res. 2023, 69, 3368–3397. [Google Scholar] [CrossRef]

- Busboom, A. Automated generation of OPC UA information models—A review and outlook. J. Ind. Inf. Integr. 2024, 39, 100602. [Google Scholar] [CrossRef]

- Kocamuftuoglu, A.; Akbay, O.; Kaba, S. A Comparative Study on Industrial Communication Protocols Using IoT Platforms. Eurasia Proc. Sci. Technol. Eng. Math. 2021, 14, 57–65. [Google Scholar] [CrossRef]

- Cho, Y.; Noh, S.D. Design and Implementation of Digital Twin Factory Synchronized in Real-Time Using MQTT. Machines 2024, 12, 759. [Google Scholar] [CrossRef]

- Wu, M.; Ying, W. Research and application of OPC UA-based digital twin smoke alarm calibration workshop information model. PLoS ONE 2024, 19, e0307801. [Google Scholar] [CrossRef] [PubMed]

- Silva, D.; Carvalho, L.I.; Soares, J.; Sofia, R.C. A Performance Analysis of Internet of Things Networking Protocols: Evaluating MQTT, CoAP, OPC UA. Appl. Sci. 2021, 11, 4879. [Google Scholar] [CrossRef]

- Kim, H.-K.; Ko, D.-E. A Study on the Conceptual Design of Quay Process Monitoring System. J. Korea Acad. Ind. Coop. Soc. 2016, 17, 426–431. [Google Scholar] [CrossRef]

- Jung, W.S.; Yoon, T.H.; Yoo, D.S.; Park, J.H.; Choi, H.K. Limitation of LoRaWAN in the Smart HSE System for Shipbuilding and Onshore Plant. In Proceedings of the 2018 IEEE International Symposium on Dynamic Spectrum Access Networks (DySPAN), Seoul, Republic of Korea, 22–25 October 2018; pp. 1–2. [Google Scholar] [CrossRef]

- Fraga-Lamas, P.; Lopez-Iturri, P.; Celaya-Echarri, M.; Blanco-Novoa, O.; Azpilicueta, L.; Varela-Barbeito, J.; Falcone, F.; Fernandez-Carames, T.M. Design and Empirical Validation of a Bluetooth 5 Fog Computing Based Industrial CPS Architecture for Intelligent Industry 4.0 Shipyard Workshops. IEEE Access 2020, 8, 45496–45511. [Google Scholar] [CrossRef]

- Fraga-Lamas, P.; Varela-Barbeito, J.; Fernandez-Carames, T.M. Next Generation Auto-Identification and Traceability Technologies for Industry 5.0: A Methodology and Practical Use Case for the Shipbuilding Industry. IEEE Access 2021, 9, 140700–140730. [Google Scholar] [CrossRef]

- Perez-Garrido, C.; Gonzalez-Castano, F.J.; Chaves-Dieguez, D.; Rodriguez-Hernandez, P.S. Wireless remote monitoring of toxic gases in shipbuilding. Sensors 2014, 14, 2981–3000. [Google Scholar] [CrossRef]

- Dai, R.; Kerber, E.; Reuter, F.; Stumm, S.; Brell-Cokcan, S. The digitization of the automated steel construction through the application of microcontrollers and MQTT. Constr. Robot. 2020, 4, 251–259. [Google Scholar] [CrossRef]

- Xu, J.; Ji, Z.; Jing, X.; Zhou, H.; Ma, H.; Wang, S. Digital twin based intelligent coating film thickness monitoring system. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2025. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems; Springer International Publishing: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar] [CrossRef]

- Atalay, M.; Murat, U.; Oksuz, B.; Parlaktuna, A.M.; Pisirir, E.; Testik, M.C. Digital twins in manufacturing: Systematic literature review for physical–digital layer categorization and future research directions. Int. J. Comput. Integr. Manuf. 2022, 35, 679–705. [Google Scholar] [CrossRef]

- Schuh, G.; Kelzenberg, C.; Wiese, J.; Ochel, T. Data Structure of the Digital Shadow for Systematic Knowledge Management Systems in Single and Small Batch Production. Procedia CIRP 2019, 84, 1094–1100. [Google Scholar] [CrossRef]

- Lee, C.G.; Park, S.C. Survey on the virtual commissioning of manufacturing systems. J. Comput. Des. Eng. 2014, 1, 213–222. [Google Scholar] [CrossRef]

- West, T.D.; Blackburn, M. Is Digital Thread/Digital Twin Affordable? A Systemic Assessment of the Cost of DoD’s Latest Manhattan Project. Procedia Comput. Sci. 2017, 114, 47–56. [Google Scholar] [CrossRef]

- Rosen, R.; von Wichert, G.; Lo, G.; Bettenhausen, K.D. About The Importance of Autonomy and Digital Twins for the Future of Manufacturing. IFAC-Pap. 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Schroeder, G.; Steinmetz, C.; Pereira, C.E.; Muller, I.; Garcia, N.; Espindola, D.; Rodrigues, R. Visualising the digital twin using web services and augmented reality. In Proceedings of the 2016 IEEE 14th International Conference on Industrial Informatics (INDIN), Poitiers, France, 19–21 July 2016; pp. 522–527. [Google Scholar] [CrossRef]

- Brenner, B.; Hummel, V. Digital Twin as Enabler for an Innovative Digital Shopfloor Management System in the ESB Logistics Learning Factory at Reutlingen—University. Procedia Manuf. 2017, 9, 198–205. [Google Scholar] [CrossRef]

- Graessler, I.; Poehler, A. Integration of a digital twin as human representation in a scheduling procedure of a cyber-physical production system. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 289–293. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Liu, Y.; Nee, A.Y.C. Digital twin driven prognostics and health management for complex equipment. CIRP Ann. 2018, 67, 169–172. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F.; Zuo, Y.; Zhao, D. Digital Twin Service towards Smart Manufacturing. Procedia CIRP 2018, 72, 237–242. [Google Scholar] [CrossRef]

- Tao, F.; Qi, Q. New IT Driven Service-Oriented Smart Manufacturing: Framework and Characteristics. IEEE Trans. Syst. Man Cybern. Syst. 2019, 49, 81–91. [Google Scholar] [CrossRef]

- Lee, H.; Kim, T. Smart factory use case model based on digital twin. ICIC Express Lett. Part B Appl. 2018, 9, 931–936. [Google Scholar] [CrossRef]

- Luo, W.; Hu, T.; Zhu, W.; Tao, F. Digital twin modeling method for CNC machine tool. In Proceedings of the 2018 IEEE 15th International Conference on Networking, Sensing and Control (ICNSC), Zhuhai, China, 27–29 March 2018; pp. 1–4. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Qi, Q.; Tao, F. Digital Twin and Big Data Towards Smart Manufacturing and Industry 4.0: 360 Degree Comparison. IEEE Access 2018, 6, 3585–3593. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.K.; Huang, H.; Xu, X. Digital Twin-driven smart manufacturing: Connotation, reference model, applications and research issues. Robot. Comput.-Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. A digital supply chain twin for managing the disruption risks and resilience in the era of Industry 4.0. Prod. Plan. Control 2021, 32, 775–788. [Google Scholar] [CrossRef]

- Maddikunta, P.K.R.; Pham, Q.-V.; B, P.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Ghani, N.A.; Hamid, S.; Targio Hashem, I.A.; Ahmed, E. Social media big data analytics: A survey. Comput. Hum. Behav. 2019, 101, 417–428. [Google Scholar] [CrossRef]

- Dang, H.V.; Tatipamula, M.; Nguyen, H.X. Cloud-Based Digital Twinning for Structural Health Monitoring Using Deep Learning. IEEE Trans. Ind. Inform. 2022, 18, 3820–3830. [Google Scholar] [CrossRef]

- Butt, U.A.; Mehmood, M.; Shah, S.B.H.; Amin, R.; Shaukat, M.W.; Raza, S.M.; Suh, D.Y.; Piran, M.J. A Review of Machine Learning Algorithms for Cloud Computing Security. Electronics 2020, 9, 1379. [Google Scholar] [CrossRef]

- Wermann, A.G.; Wickboldt, J.A. KTWIN: A serverless Kubernetes-based Digital Twin platform. Comput. Netw. 2025, 259, 111095. [Google Scholar] [CrossRef]

- Csukás, M.S.; Szabó, R.Z. The many faces of the smart city: Differing value propositions in the activity portfolios of nine cities. Cities 2021, 112, 103116. [Google Scholar] [CrossRef]

- Elayan, H.; Aloqaily, M.; Guizani, M. Digital Twin for Intelligent Context-Aware IoT Healthcare Systems. IEEE Internet Things J. 2021, 8, 16749–16757. [Google Scholar] [CrossRef]

- Tuegel, E.J.; Ingraffea, A.R.; Eason, T.G.; Spottswood, S.M. Reengineering Aircraft Structural Life Prediction Using a Digital Twin. Int. J. Aerosp. Eng. 2011, 2011, 154798. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Motlagh, N.H.; Jaribion, A.; Werner, L.C.; Holmström, J. Digital Twin: Vision, Benefits, Boundaries, and Creation for Buildings. IEEE Access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Wang, Z.; Liao, X.; Zhao, X.; Han, K.; Tiwari, P.; Barth, M.J.; Wu, G. A Digital Twin Paradigm: Vehicle-to-Cloud Based Advanced Driver Assistance Systems. In Proceedings of the 2020 IEEE 91st Vehicular Technology Conference (VTC2020-Spring), Antwerp, Belgium, 25–28 May 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Yan, M.; Gan, W.; Zhou, Y.; Wen, J.; Yao, W. Projection method for blockchain-enabled non-iterative decentralized management in integrated natural gas-electric systems and its application in digital twin modelling. Appl. Energy 2022, 311, 118645. [Google Scholar] [CrossRef]

- Zheng, Y.; Yang, S.; Cheng, H. An application framework of digital twin and its case study. J. Ambient. Intell. Humaniz. Comput. 2019, 10, 1141–1153. [Google Scholar] [CrossRef]

- Schroeder, G.N.; Steinmetz, C.; Pereira, C.E.; Espindola, D.B. Digital Twin Data Modeling with AutomationML and a Communication Methodology for Data Exchange. IFAC-Pap. 2016, 49, 12–17. [Google Scholar] [CrossRef]

- Fuller, A.; Fan, Z.; Day, C.; Barlow, C. Digital Twin: Enabling Technologies, Challenges and Open Research. IEEE Access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Ding, K.; Fan, L.; He, C. Orchestration constraints BlockChained smart contract and integrated digital twins manufacturing systems: ManuChain4.0-based application paradigm and case study. J. Manuf. Syst. 2024, 74, 606–632. [Google Scholar] [CrossRef]

- Wang, L.; Chen, J.; Zhang, Y.; Tian, Y.; Li, Z.; Wang, C. Research on data mapping and fusion method of ship production workshop based on digital twins. Meas. Control 2024, 57, 1255–1267. [Google Scholar] [CrossRef]

- Hadžić, N.; Ložar, V.; Opetuk, T.; Keser, R. Towards Digital Twinning of Fabrication Lines in Shipyards. J. Mar. Sci. Eng. 2023, 11, 1053. [Google Scholar] [CrossRef]

- Wu, Q.; Mao, Y.; Chen, J.; Wang, C. Application Research of Digital Twin-Driven Ship Intelligent Manufacturing System: Pipe Machining Production Line. J. Mar. Sci. Eng. 2021, 9, 338. [Google Scholar] [CrossRef]

- Hyundai Heavy Industries Group Takes a Leap Toward Smart Shipyard. Available online: https://esg.hd.com/en/news/575 (accessed on 11 July 2025).

- Hyundai Heavy Industries Receives AiP|LR. Available online: https://www.lr.org/en/knowledge/press-room/press-listing/press-release/2018/hhi-receives-approval-in-principle-from-lr-for-lng-fuelled-250000-dwt-vloc (accessed on 11 July 2025).

- Jung, M.-h. Hyundai Heavy Industries to Harness 5G Technology to Build a Smart Shipyard. Available online: https://www.businesskorea.co.kr/news/articleView.html?idxno=39312 (accessed on 11 July 2025).

- Japanese Firms Collaborate on Digital Twin Data Sharing Project. Available online: https://smartmaritimenetwork.com/2024/05/22/japanese-firms-collaborate-on-digital-twin-data-sharing-project (accessed on 11 July 2025).

- lidar. Ship Building Is Making the Transition to 3D. Available online: https://blog.lidarnews.com/ship-building-making-transition-3d (accessed on 11 July 2025).

- MEYER WERFT: Customised Production for Tailored Products. Available online: https://www.meyerwerft.de/en/technologies/tailored_products/index.jsp (accessed on 11 July 2025).

- MIIT Promote the Action Plan for the Intelligent Transformation of Ship Assembly and Construction. Available online: https://www.gov.cn/zhengce/zhengceku/2018-12/31/content_5442949.htm (accessed on 11 July 2025).

- Hu, Z.; Fang, X.; Zhang, J. A digital twin-based framework of manufacturing workshop for marine diesel engine. Int. J. Adv. Manuf. Technol. 2021, 117, 3323–3342. [Google Scholar] [CrossRef]

- Wang, X.; Hu, X.; Ren, Z.; Tian, T.; Wan, J. Knowledge-graph-based multi-domain model integration method for digital-twin workshops. Int. J. Adv. Manuf. Technol. 2023, 128, 405–421. [Google Scholar] [CrossRef]

- VanDerHorn, E.; Mahadevan, S. Digital Twin: Generalization, characterization and implementation. Decis. Support Syst. 2021, 145, 113524. [Google Scholar] [CrossRef]

- Zhong, D.; Xia, Z.; Zhu, Y.; Duan, J. Overview of predictive maintenance based on digital twin technology. Heliyon 2023, 9, e14534. [Google Scholar] [CrossRef]

- Dapkute, A.; Siozinys, V.; Jonaitis, M.; Kaminickas, M.; Siozinys, M. Enhancing Industrial Process Control: Integrating Intelligent Digital Twin Technology with Proportional-Integral-Derivative Regulators. Machines 2024, 12, 319. [Google Scholar] [CrossRef]

- Sun, M.; Liang, C.; Chang, D. Enhancing shipyard transportation efficiency through dynamic scheduling using digital twin technology. PLoS ONE 2024, 19, e0297069. [Google Scholar] [CrossRef]

- Wang, J.; Liu, Y.; Ren, S.; Wang, C.; Ma, S. Edge computing-based real-time scheduling for digital twin flexible job shop with variable time window. Robot. Comput.-Integr. Manuf. 2023, 79, 102435. [Google Scholar] [CrossRef]

- Li, L.; Liu, D.; Liu, J.; Zhou, H.G.; Zhou, J. Quality Prediction and Control of Assembly and Welding Process for Ship Group Product Based on Digital Twin. Scanning 2020, 2020, 3758730. [Google Scholar] [CrossRef] [PubMed]

- Climent Giménez, E.M. Developing Real-Time Digital Twins for Industrial Cobots. Available online: https://rua.ua.es/server/api/core/bitstreams/0b58c4de-7257-47c4-871b-9ef60e28af62/content (accessed on 11 July 2025).

- Assani, N.; Matić, P.; Katalinić, M. Ship’s Digital Twin—A Review of Modelling Challenges and Applications. Appl. Sci. 2022, 12, 6039. [Google Scholar] [CrossRef]

- da Rocha, H.; Pereira, J.; Abrishambaf, R.; Espirito Santo, A. An Interoperable Digital Twin with the IEEE 1451 Standards. Sensors 2022, 22, 7590. [Google Scholar] [CrossRef]

- Chui, K.T.; Gupta, B.B.; Liu, J.; Arya, V.; Nedjah, N.; Almomani, A.; Chaurasia, P. A Survey of Internet of Things and Cyber-Physical Systems: Standards, Algorithms, Applications, Security, Challenges, and Future Directions. Information 2023, 14, 388. [Google Scholar] [CrossRef]

- Akpan, F.; Bendiab, G.; Shiaeles, S.; Karamperidis, S.; Michaloliakos, M. Cybersecurity Challenges in the Maritime Sector. Network 2022, 2, 123–138. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, G.; Xue, C.; Wang, J.; Nixon, M.; Han, S. Time-Sensitive Networking (TSN) for Industrial Automation: Current Advances and Future Directions. ACM Comput. Surv. 2024, 57, 30. [Google Scholar] [CrossRef]

- Pan, Y.; Su, Z.; Wang, Y.; Guo, S.; Liu, H.; Li, R.; Wu, Y. Cloud-Edge Collaborative Large Model Services: Challenges and Solutions. IEEE Netw. 2024, 39, 182–191. [Google Scholar] [CrossRef]

- Jiangsu Yangzi Xinfu Shipbuilding Innovation Patent: A Removable Cable Bracket for LNG Transport Ships to Prevent Electromagnetic Interference. Available online: https://www.sohu.com/a/885789951_122066681 (accessed on 12 July 2025).

- Ou, S. Electromagnetic interference analysis and measures of the antenna servo system of ship-borne satellite communication. Highlights Sci. Eng. Technol. 2022, 7, 294–298. [Google Scholar] [CrossRef]

- Sadat, H.; Abaza, M.; Mansour, A.; Alfalou, A. A Survey of NOMA for VLC Systems: Research Challenges and Future Trends. Sensors 2022, 22, 1395. [Google Scholar] [CrossRef] [PubMed]

- Khajavi, S.H.; Tetik, M.; Liu, Z.; Korhonen, P.; Holmström, J. Digital Twin for Safety and Security: Perspectives on Building Lifecycle. IEEE Access 2023, 11, 52339–52356. [Google Scholar] [CrossRef]

- Chang, J.; Yu, D.; Zhou, Z.; He, W.; Zhang, L. Hierarchical Reinforcement Learning for Multi-Objective Real-Time Flexible Scheduling in a Smart Shop Floor. Machines 2022, 10, 1195. [Google Scholar] [CrossRef]

- Zayed, S.M.; Attiya, G.M.; El-Sayed, A.; Hemdan, E.E.-D. A review study on digital twins with artificial intelligence and internet of things: Concepts, opportunities, challenges, tools and future scope. Multimed. Tools Appl. 2023, 82, 47081–47107. [Google Scholar] [CrossRef]

- Abisheva, G.; Goranin, N.; Razakhova, B.; Aidynov, T.; Satybaldina, D. Specifics of Data Collection and Data Processing during Formation of RailVista Dataset for Machine Learning- and Deep Learning-Based Applications. Sensors 2024, 24, 5239. [Google Scholar] [CrossRef]

| IoT Protocol | Situation | Reason | Ref. |

|---|---|---|---|

| Wi-Fi | Connecting the entire shipyard system | Real-time information transmission, high efficiency, high stability | [40] |

| LoRa | Monitoring systems in shipyard environments | Conveniently build private networks, long distance, low power consumption, low cost | [41] |

| Bluetooth | Shipyard pipeline tracking and monitoring | Low cost, fast data transmission speed, large broadcast capacity | [42] |

| RFID | Identification of high-metal-density areas | Metal materials can interfere with wireless signals, but RFID is not affected by metal materials | [43] |

| Zigbee | Monitoring toxic gases in shipyards | Supports self-organizing networks, multi-hop communication, and easy deployment | [44] |

| MQTT | Automated construction of steel structures | Scalable and flexible | [45] |

| OPC UA | Real-time monitoring of the spraying process | High security, reliability, and interoperability | [46] |

| Ref. | Definition | Citation |

|---|---|---|

| [3] | The technology seamlessly integrates the physical and virtual spaces, enabling the realization of intelligent manufacturing and Industry 4.0 goals. | 1588 |

| [61] | DT-driven product services integrate physical and virtual components with connected data to enable real-time monitoring, energy analysis, user behavior insights, predictive maintenance, optimization, and virtual operations, supporting Industry 4.0 goals. | 1421 |

| [62] | A technique that utilizes computational methods to simulate real-world objects or systems. | 864 |

| [63] | A method for modeling physical entities in a virtual environment to simulate their behavior and optimize production processes. | 800 |

| [64] | A technology that employs digital methods to model real-world objects and systems and perform simulation analysis in a virtual environment. | 785 |

| [65] | Establishing a virtual digital model in a computer system that mirrors actual physical systems, enabling simulations, predictions, and optimizations. | 756 |

| [66] | A virtual model created using computer technology based on real system data and information, designed to simulate the behavior and performance of physical systems. | 741 |

| [67] | A computerized model combining method-based and data analysis approaches, offering end-to-end visibility, business continuity, predictive decision-making, and emergency response planning. | 656 |

| [68] | The process of modeling and simulating physical systems using digital technology to predict and optimize their behavior and performance. | 645 |

| [4] | Complex models driven by sensor updates and historical data, reflecting various aspects of products, processes, or services. | 612 |

| Area | Ref. | Content |

|---|---|---|

| AirCraft | [75] | This study employs a high-fidelity DT model for real-time monitoring of aircraft, evaluating their structural health and predicting lifespan. |

| Transportation | [77] | This paper introduces a DT framework utilizing vehicle-to-cloud communication to link vehicles, enhancing advanced driver assistance systems by integrating physical entities and their interactions in a virtual environment for real-time monitoring and synchronization. |

| Energy | [78] | This paper constructs a DT model for energy management in natural gas and power systems using projection transformation methods, enhancing performance and behavior prediction. |

| City | [73] | By analyzing six high-performing and three emerging cities, the paper presents DTs and anticipated benefits for these urban areas. |

| Healthcare | [74] | This study highlights an increasing adoption of DT technology in healthcare, capable of enhancing patient care, prolonging life expectancy, and reducing medical costs. |

| Manufacture | [79] | The paper outlines a DT application framework, demonstrating its practicality and effectiveness using a welding production line as a case study. |

| [80] | This article utilizes the AutomationML standard to create a DT model for simulating and forecasting industrial component behavior. | |

| [81] | Combining DT technology, the study proposes an advanced simulation technique for complex systems, applicable in data processing, behavior analysis, development, optimization, and validation. | |

| [82] | This study presents ManuChain4. 0, a smart manufacturing system architecture integrating blockchain and DT technologies. The system employs BPMN models to configure and monitor manufacturing resources, while an offline caching mechanism ensures rapid data synchronization and enables fully visualized data management. | |

| [83] | A method for mapping and integrating shipbuilding workshop data based on DTs is proposed to address issues such as weak real-time management and control capabilities and long data interaction delays between the physical and virtual worlds that exist in traditional shipbuilding workshops. | |

| Building | [76] | Through experiments collecting over 25,000 sensor readings, this paper presents a DT model for building facade elements, enhancing management and maintenance. |

| Data Type | Characteristics | Storage Requirements | Examples |

|---|---|---|---|

| real-time streams | High frequency, low latency, time-series | Millisecond-level writing speed, rapid querying | Cutting head position, temperature, current |

| structured datasets | Relational, fixed schema | ACID transaction support, relational queries | Equipment metadata, process parameter templates |

| unstructured files | Large files, diverse formats | High throughput, version control | 3D-scanned point clouds, NC code files |

| historical archives | Low-frequency access, long-term retention | Low cost, high compression | Annual production records, equipment logs |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, C.; Li, X.; Niu, W.; Zhang, Y. Internet of Things Driven Digital Twin for Intelligent Manufacturing in Shipbuilding Workshops. Future Internet 2025, 17, 368. https://doi.org/10.3390/fi17080368

Liang C, Li X, Niu W, Zhang Y. Internet of Things Driven Digital Twin for Intelligent Manufacturing in Shipbuilding Workshops. Future Internet. 2025; 17(8):368. https://doi.org/10.3390/fi17080368

Chicago/Turabian StyleLiang, Caiping, Xiang Li, Wenxu Niu, and Yansong Zhang. 2025. "Internet of Things Driven Digital Twin for Intelligent Manufacturing in Shipbuilding Workshops" Future Internet 17, no. 8: 368. https://doi.org/10.3390/fi17080368

APA StyleLiang, C., Li, X., Niu, W., & Zhang, Y. (2025). Internet of Things Driven Digital Twin for Intelligent Manufacturing in Shipbuilding Workshops. Future Internet, 17(8), 368. https://doi.org/10.3390/fi17080368