Design of an Improved IoT-Based PV-Powered Soil Remote Monitoring System with Low Data Acquisition Failure Rate

Abstract

1. Introduction

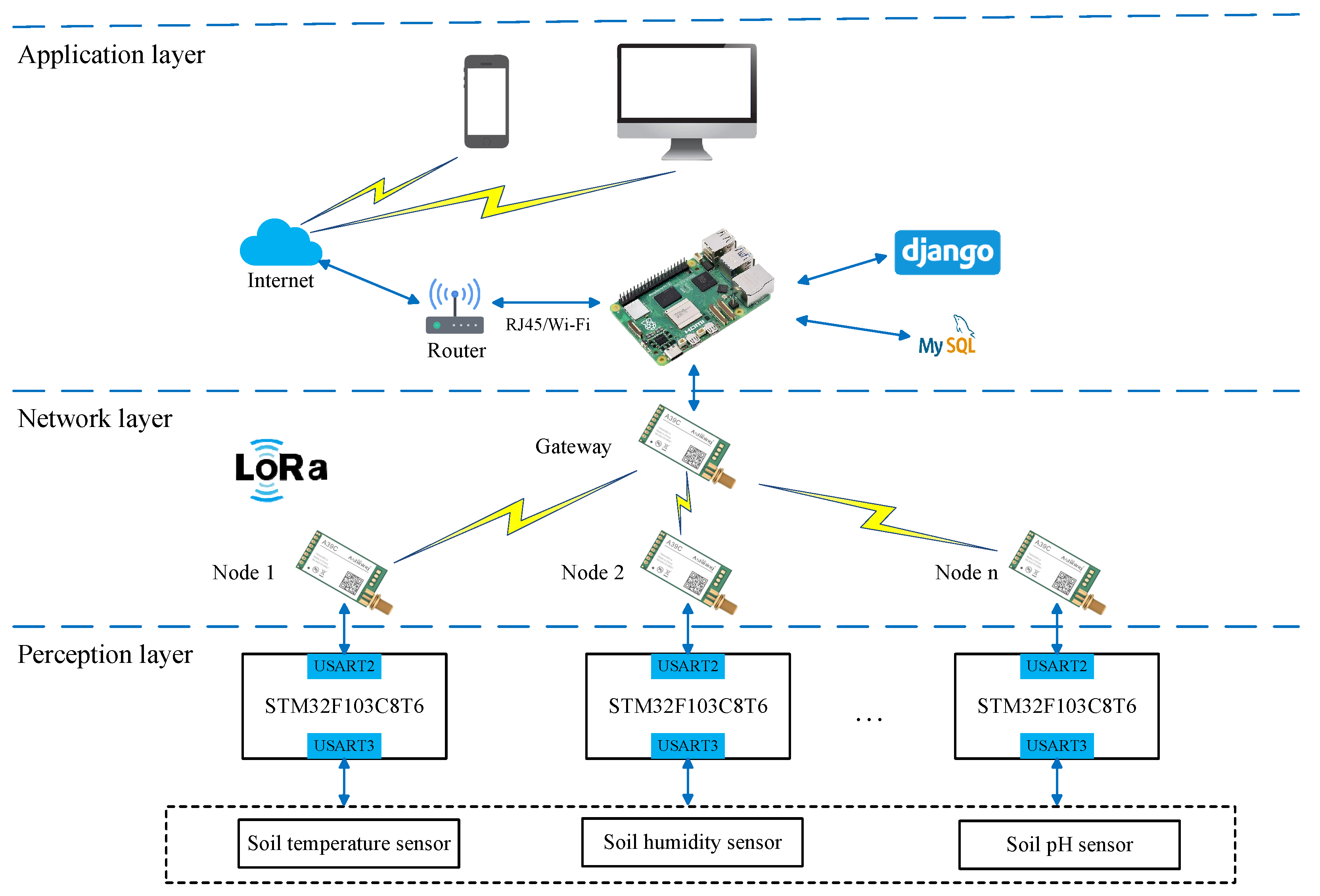

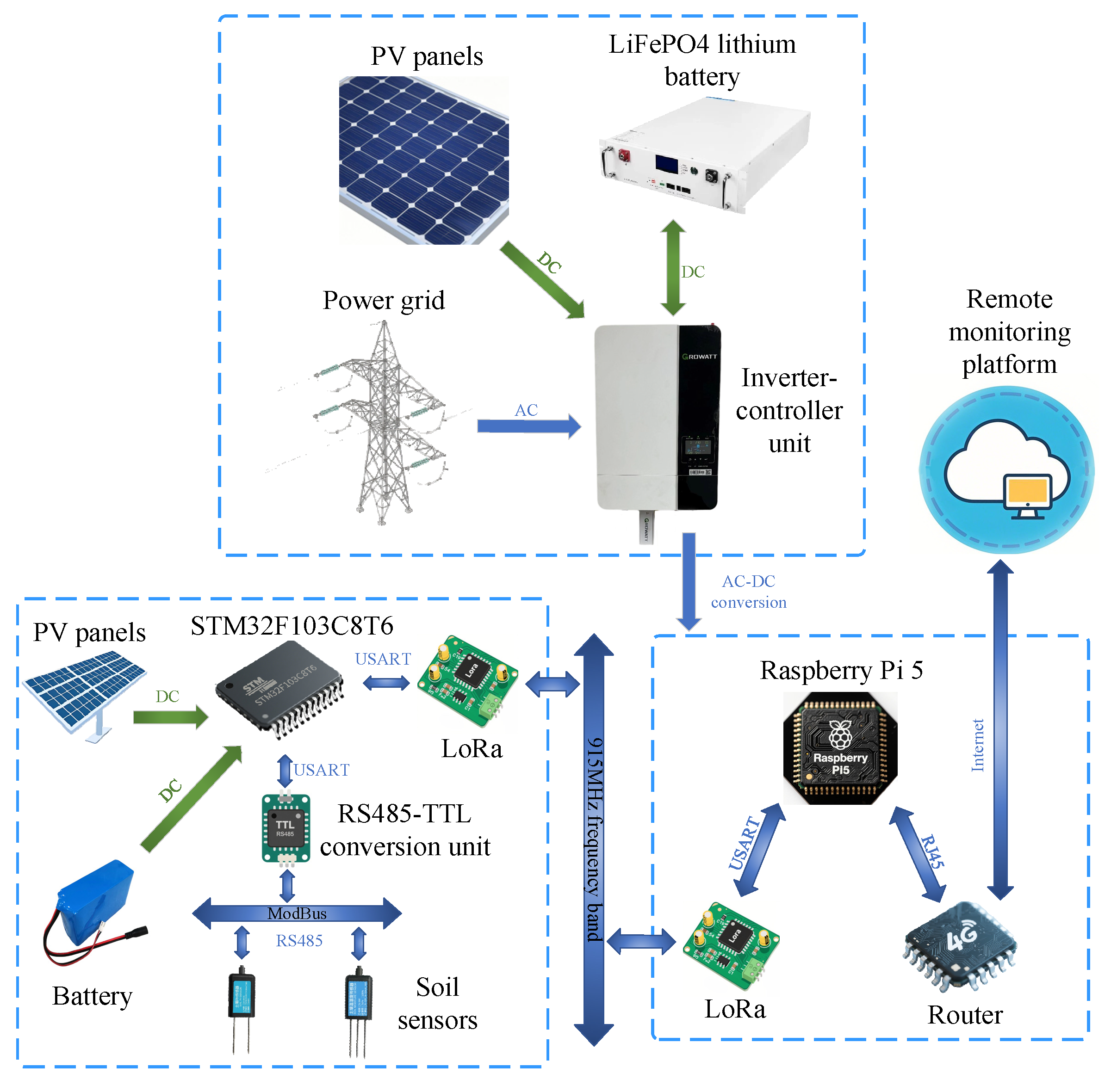

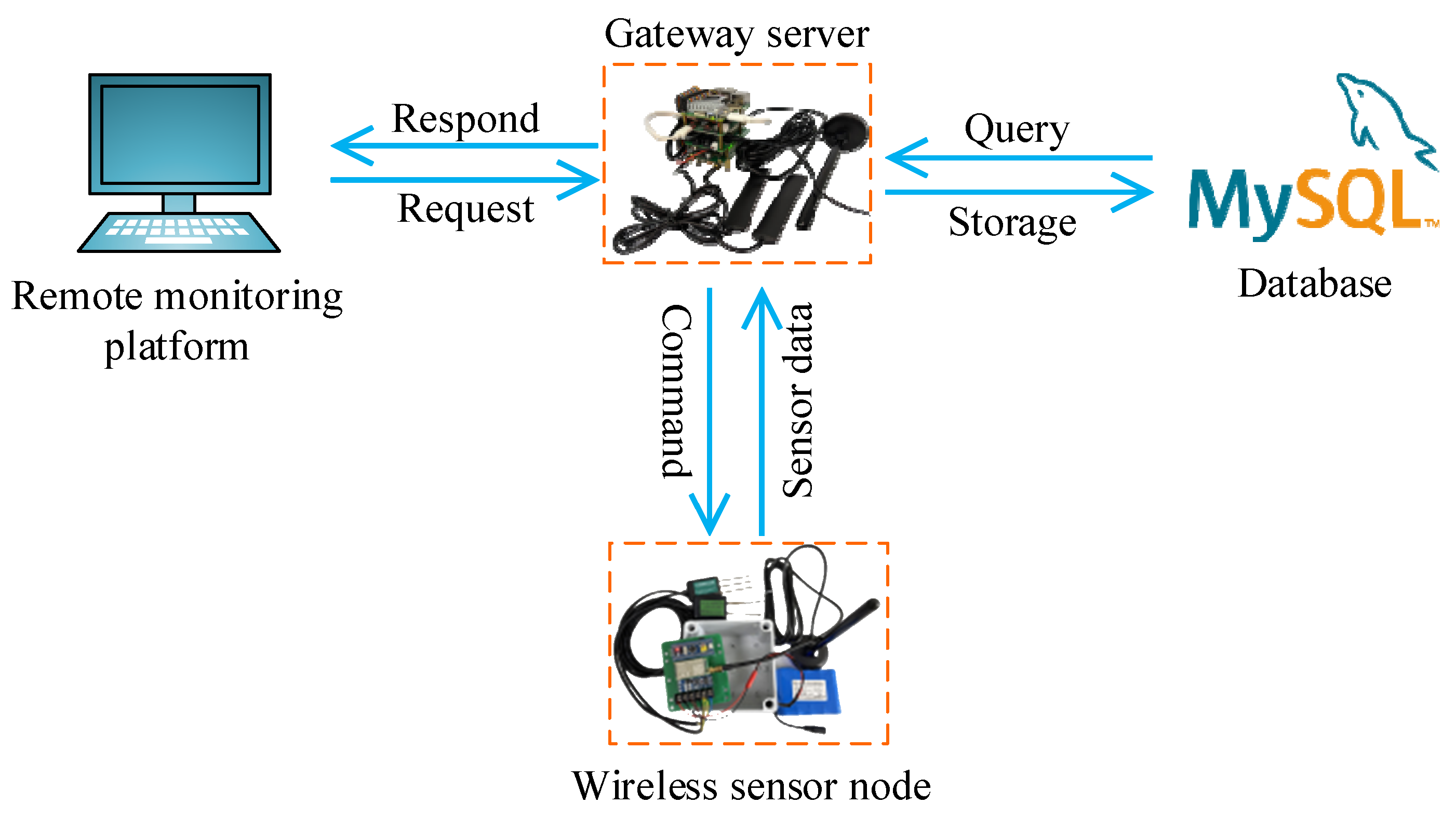

2. System Architecture

3. System Hardware Design

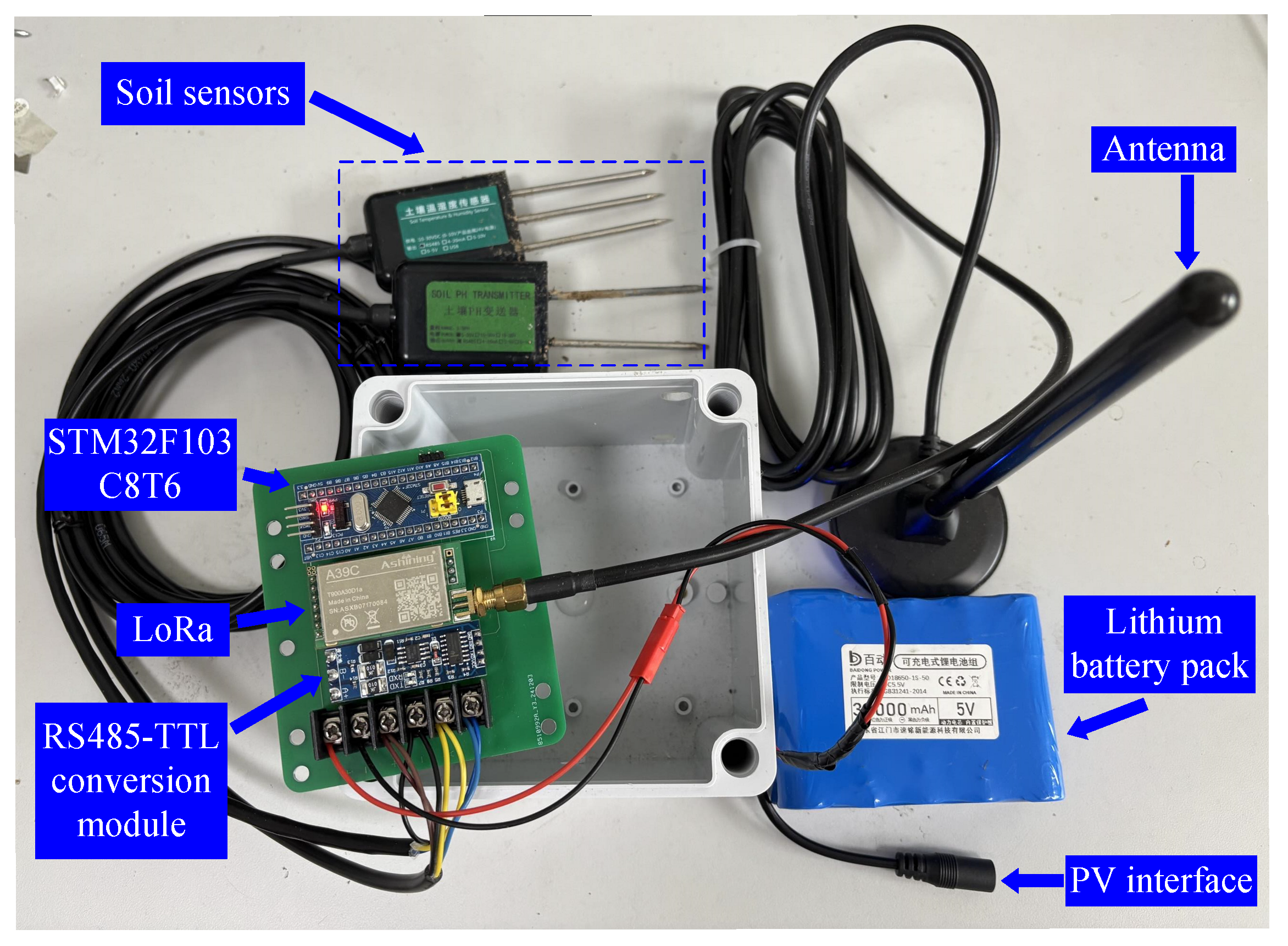

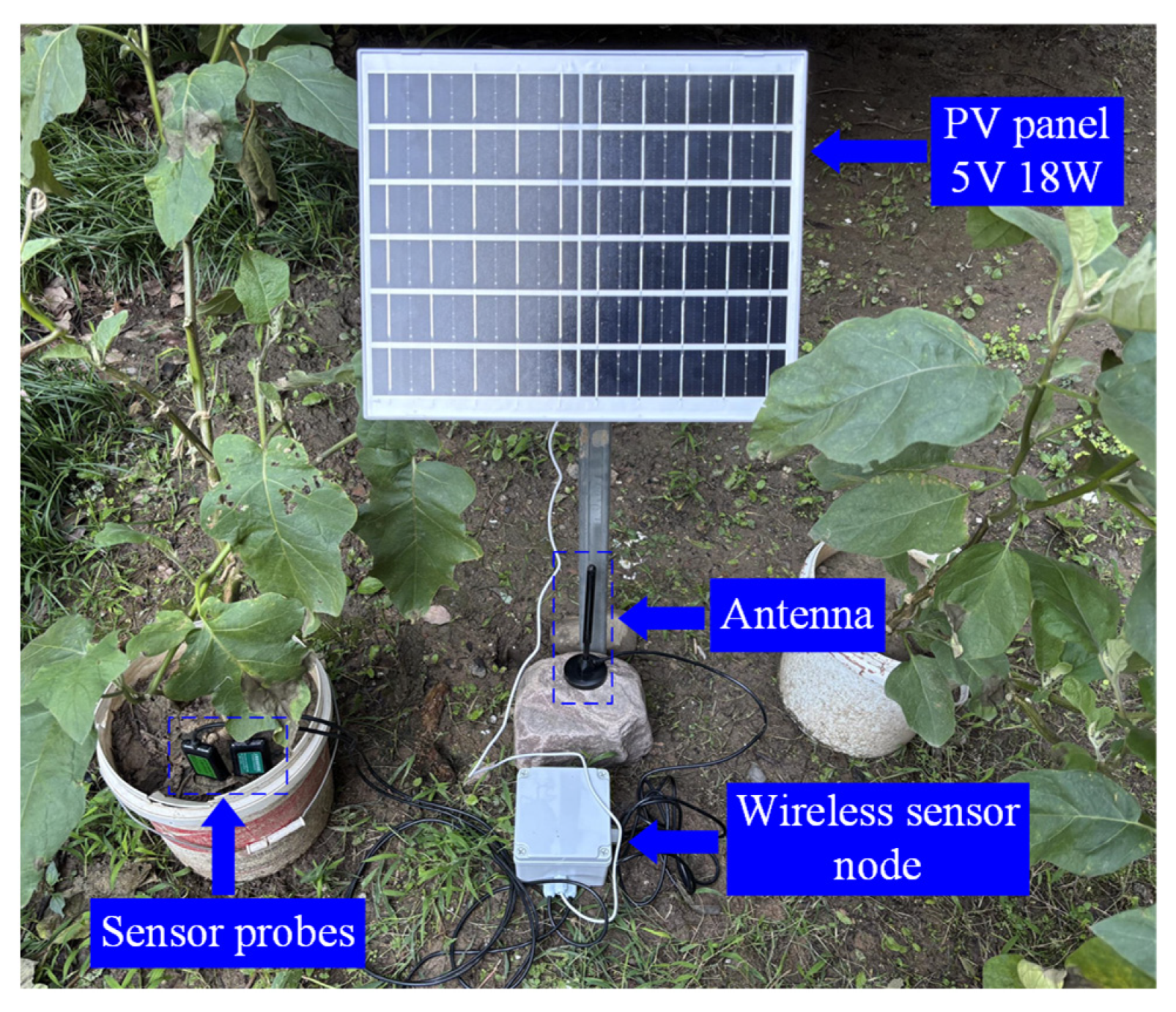

3.1. Wireless Sensor Node

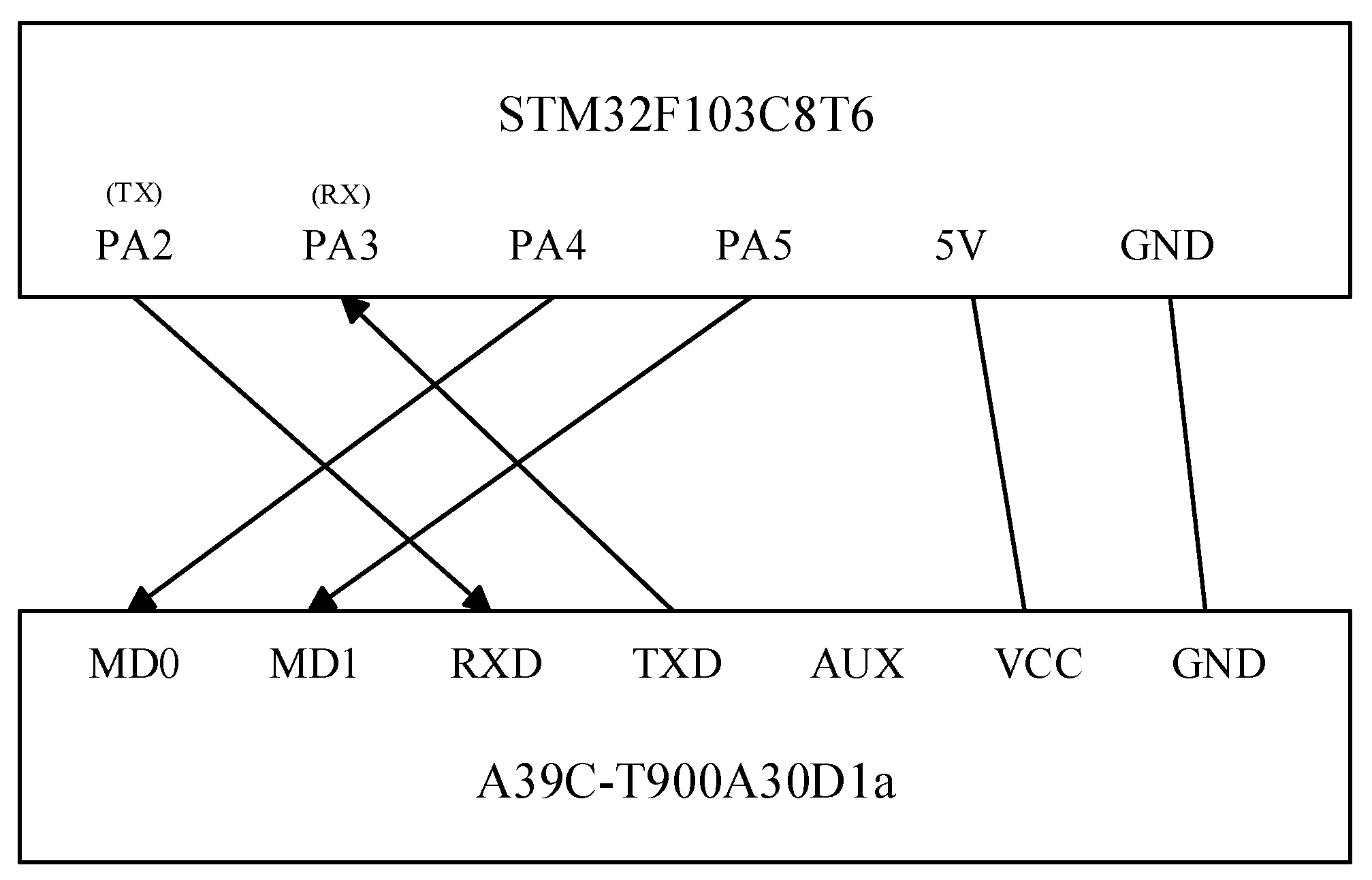

3.2. LoRa Communication Unit

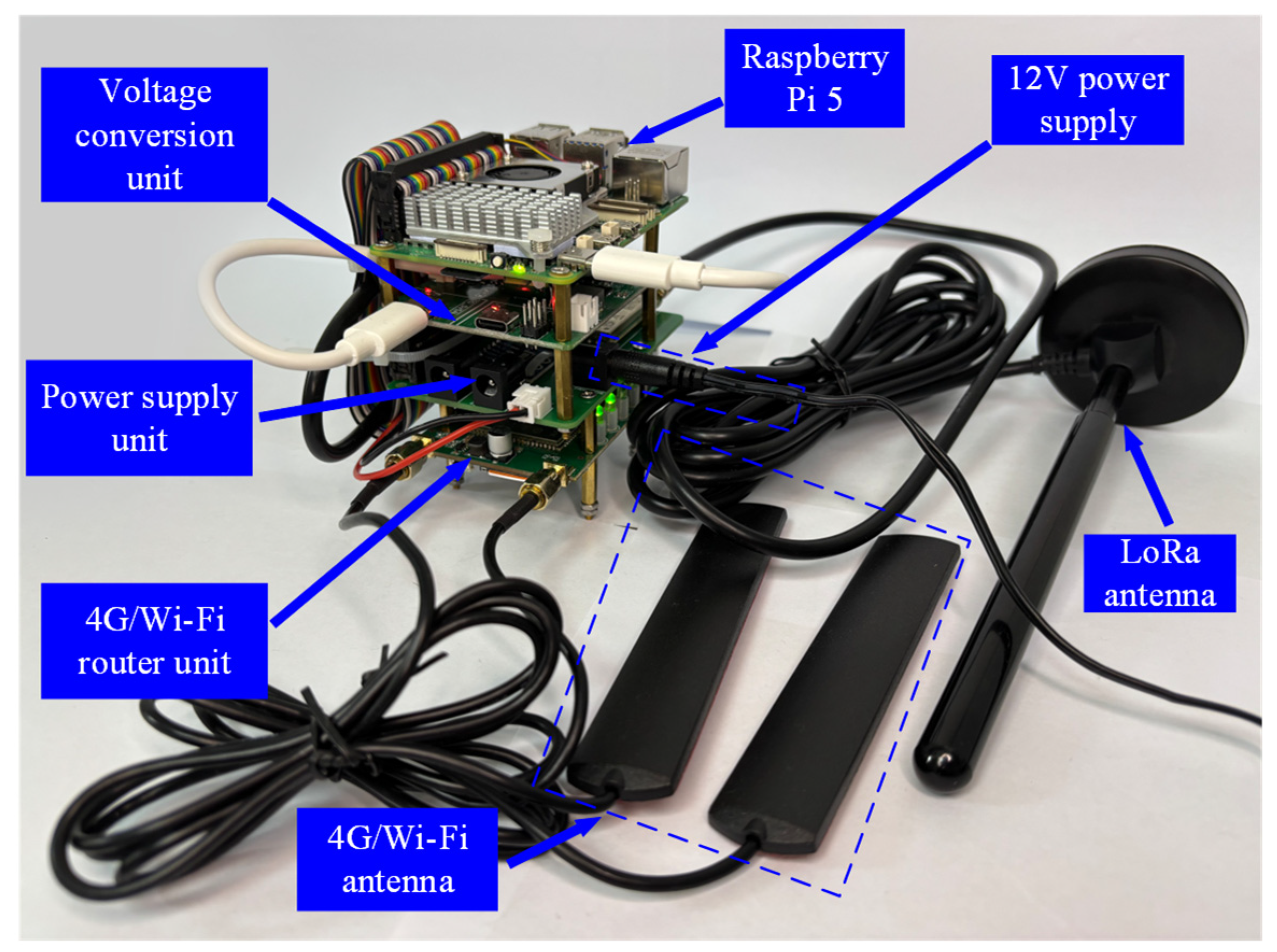

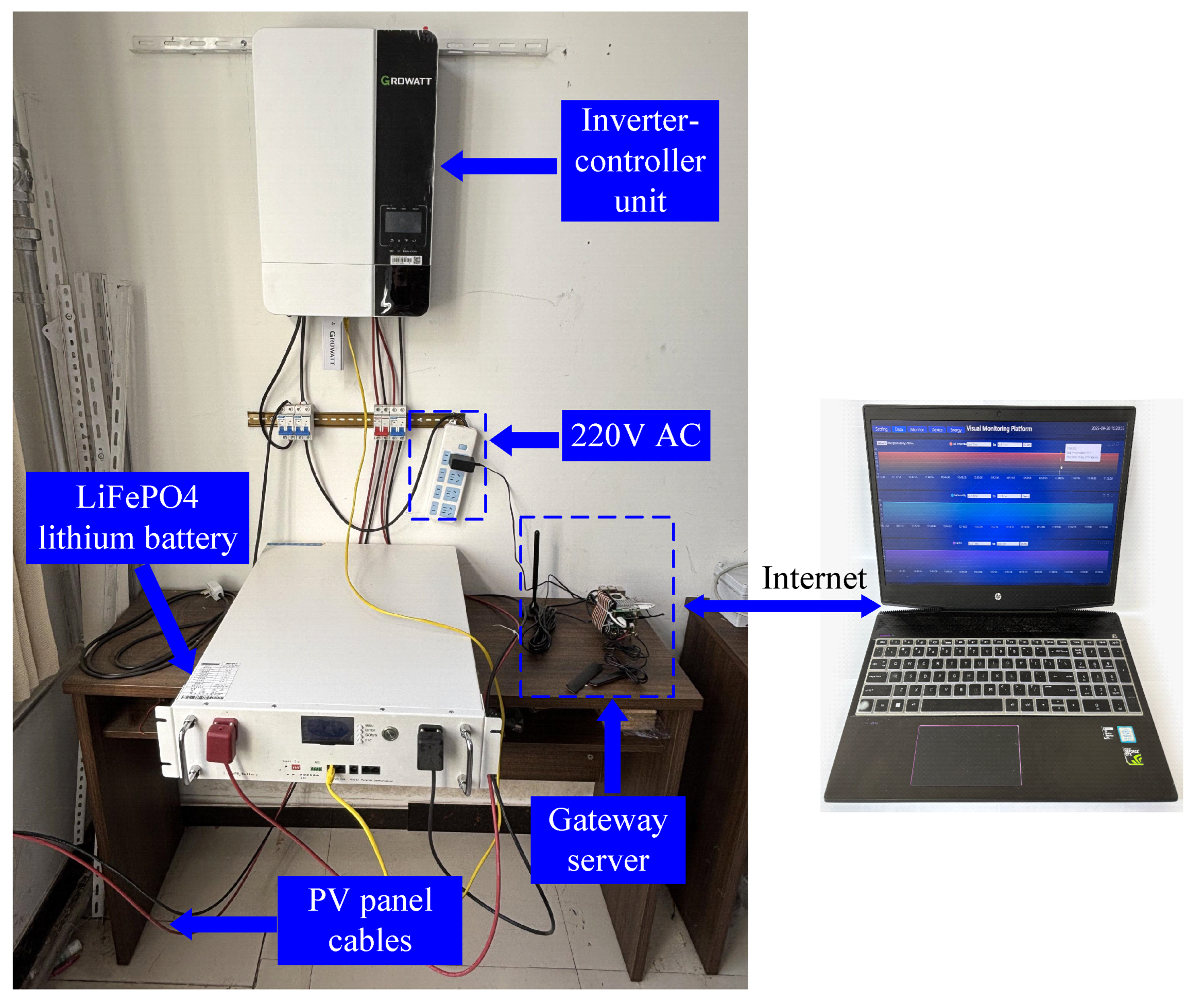

3.3. Gateway Server Node

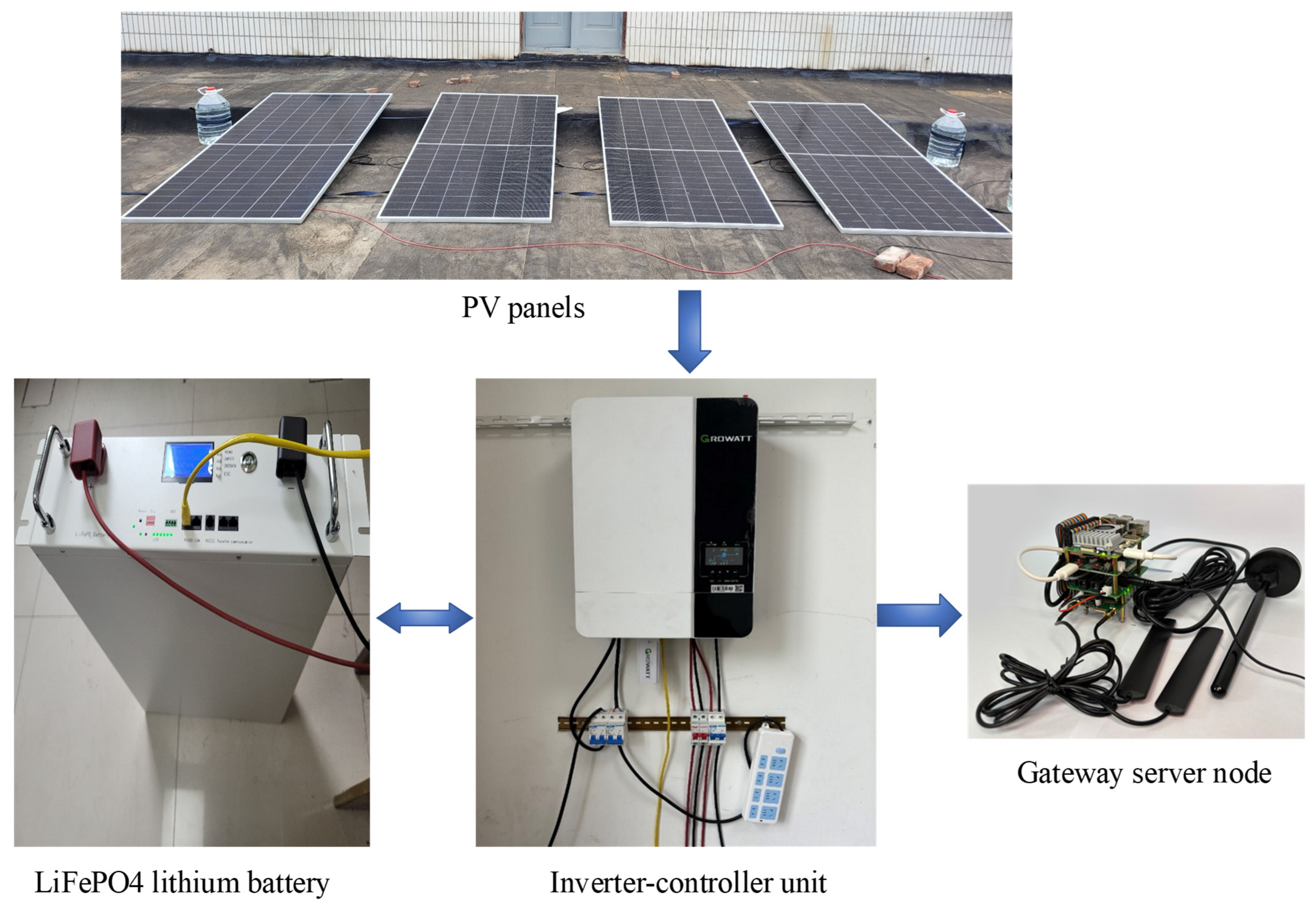

3.4. PV Power Module

4. System Software Design

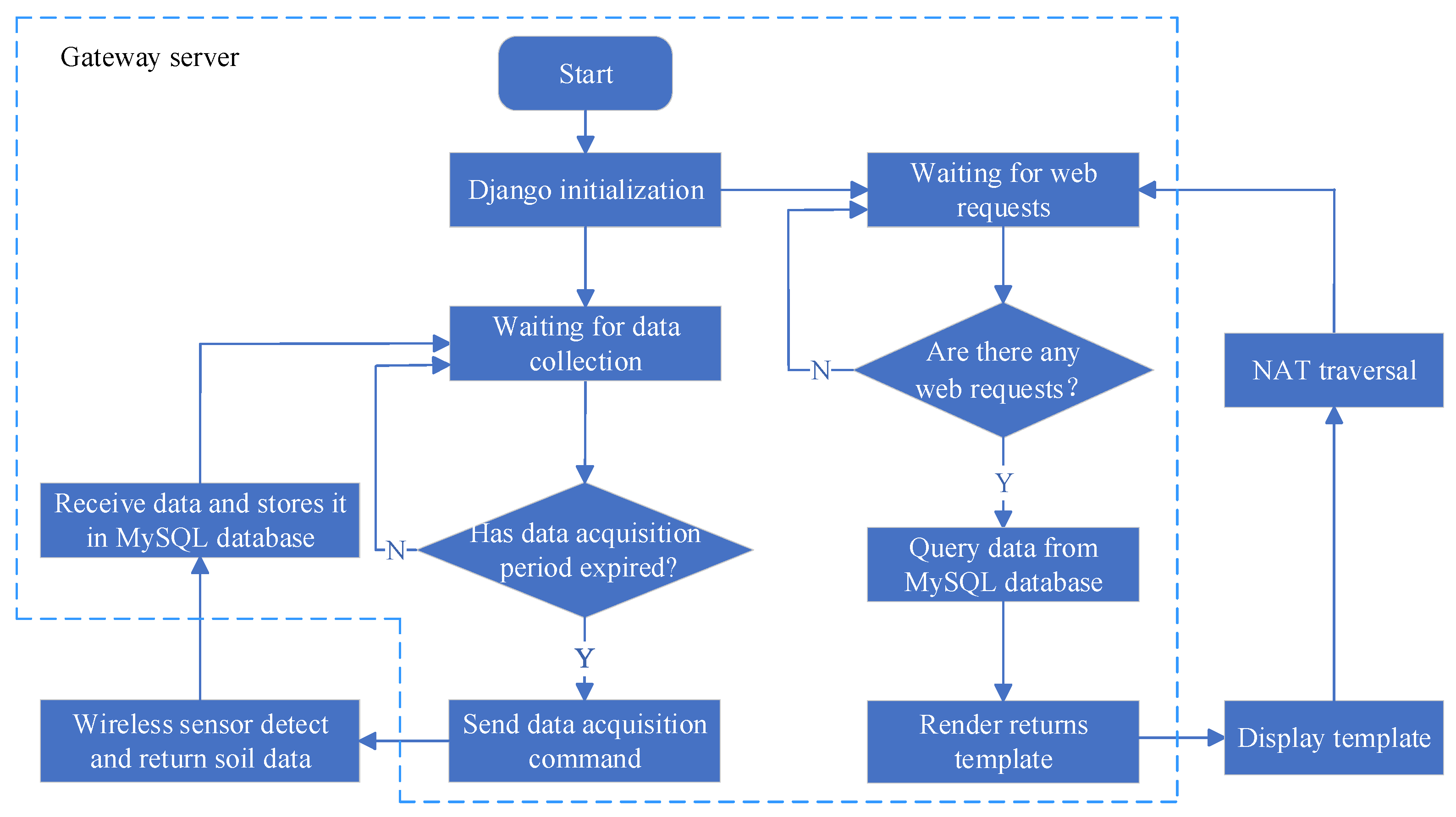

4.1. Software Design for Gateway Server

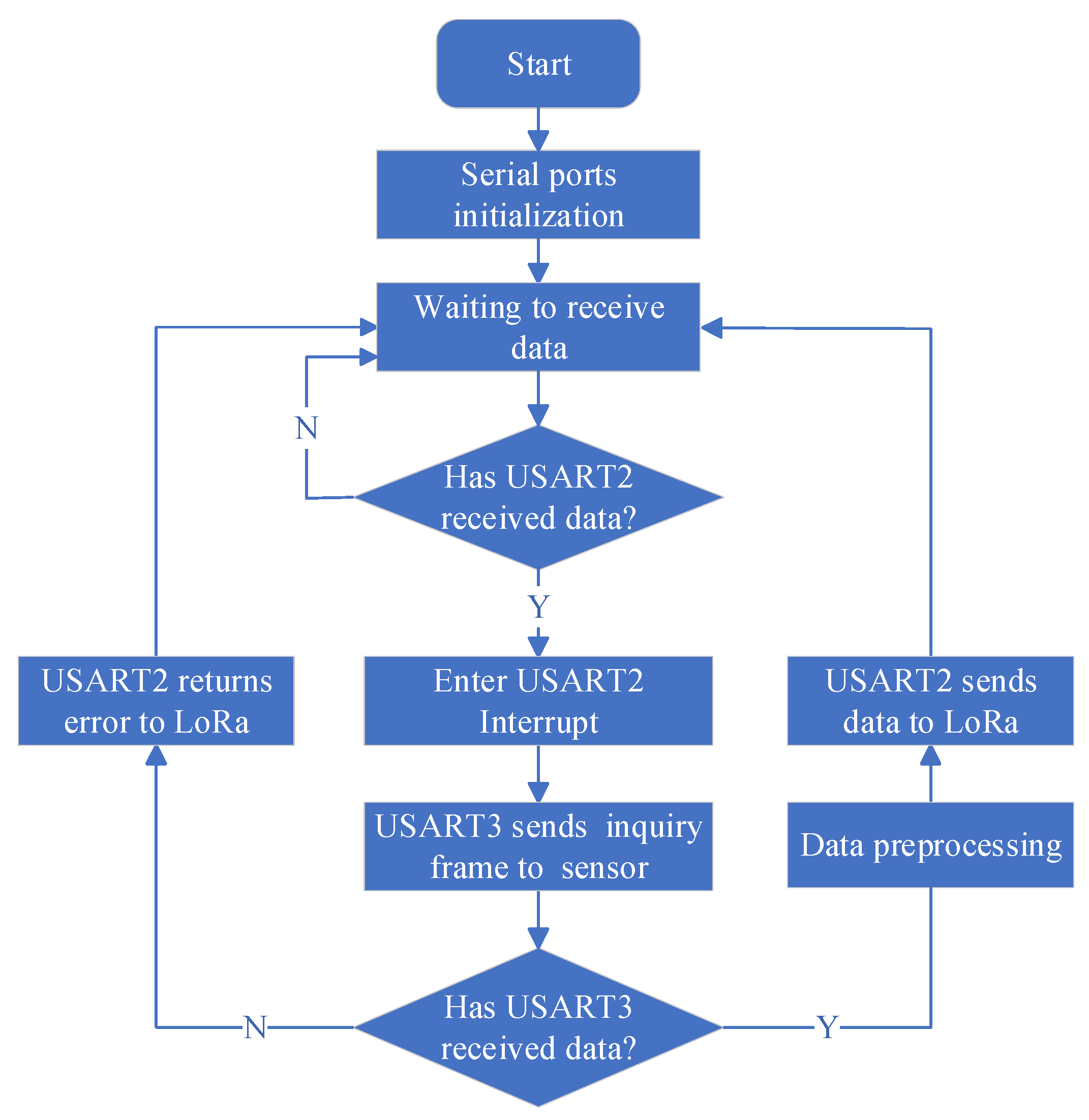

4.2. Software Design for Wireless Sensor Node

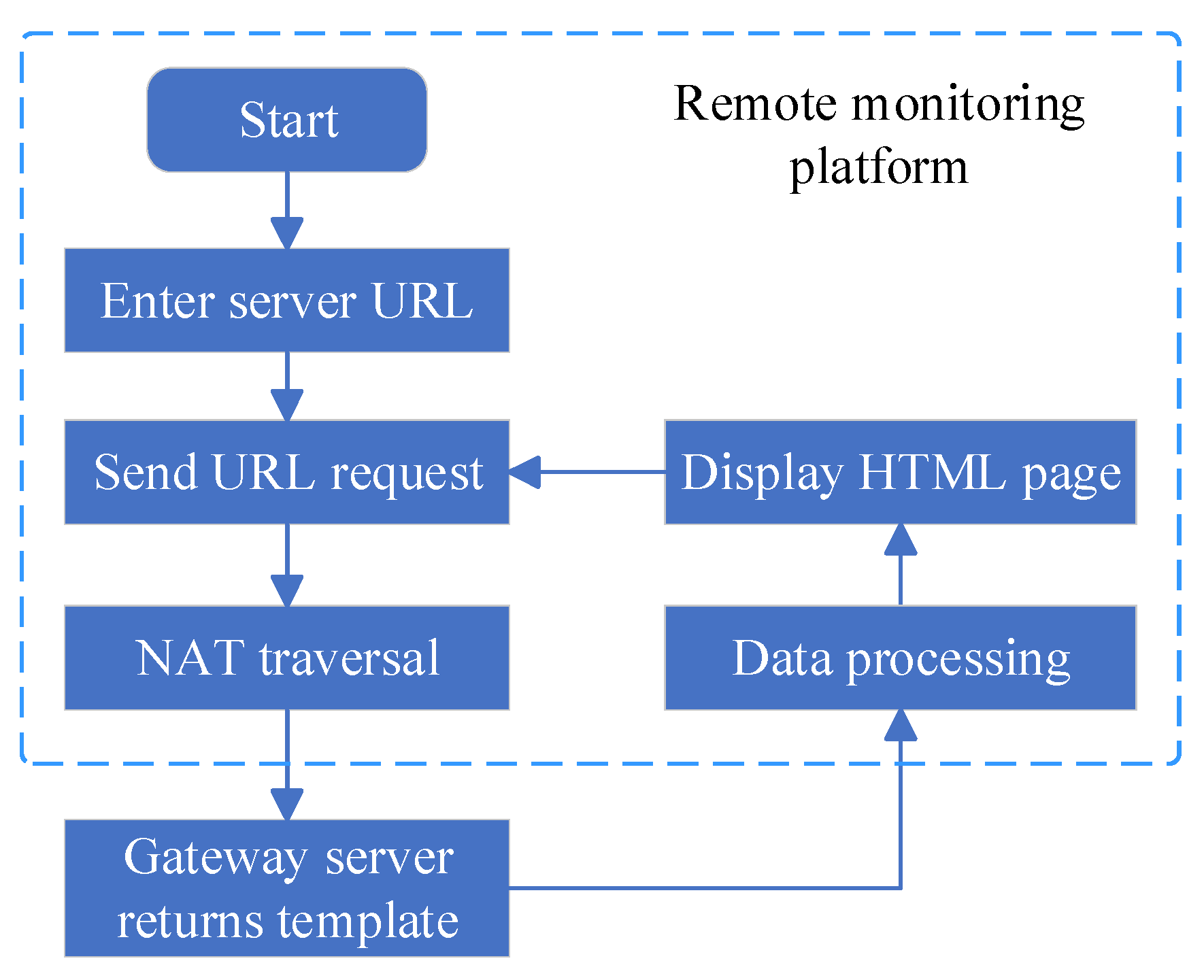

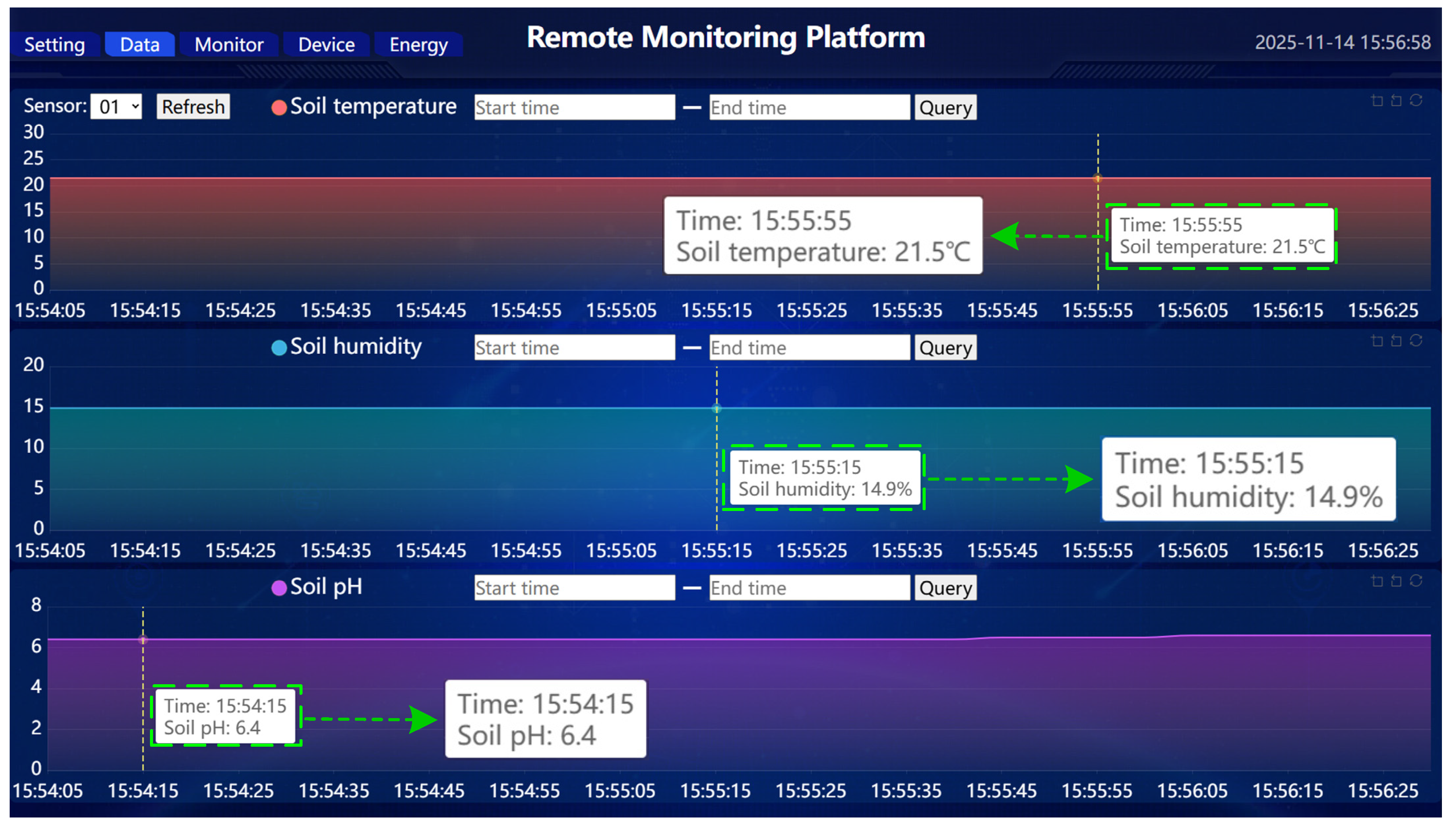

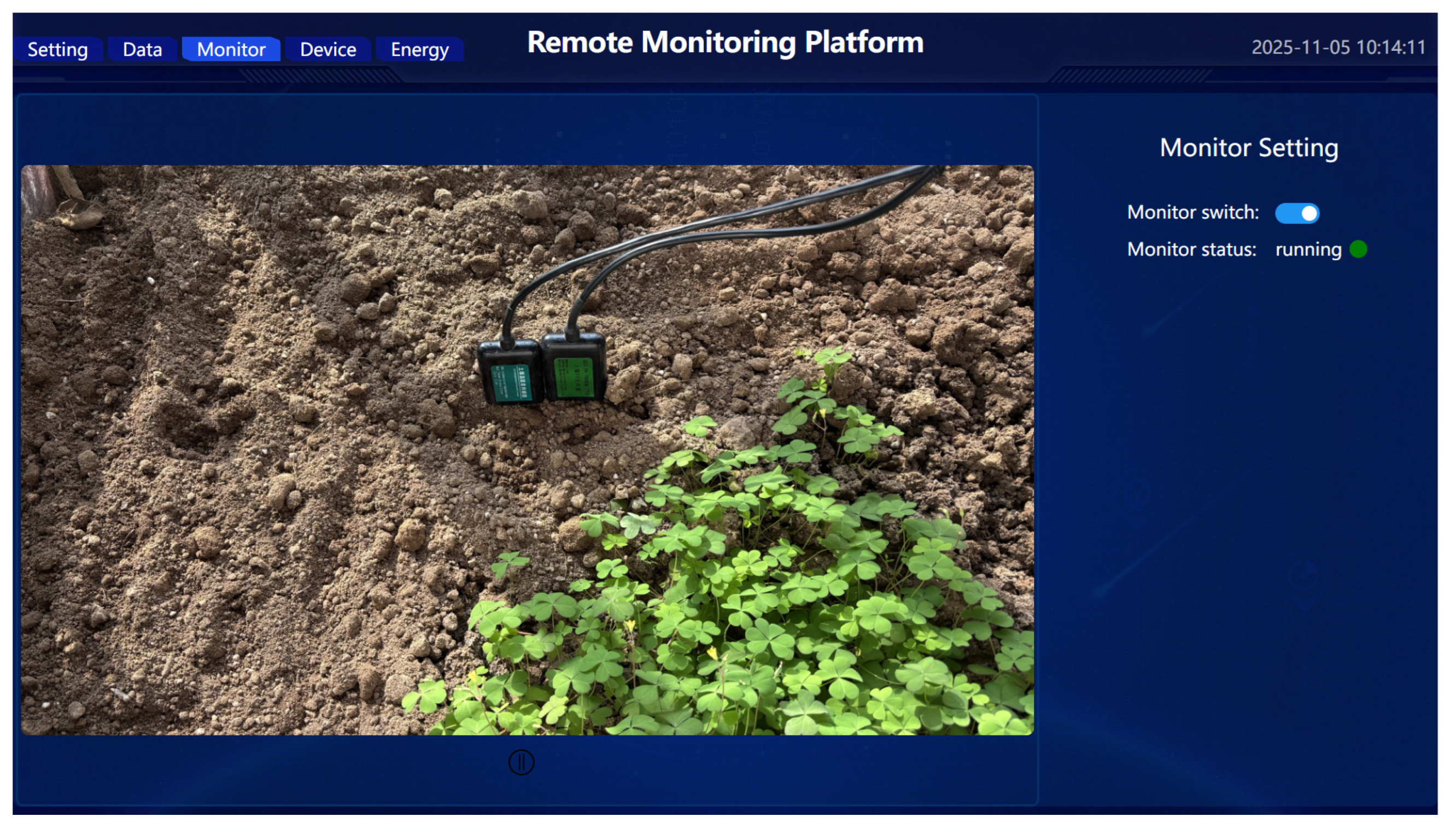

4.3. Remote Monitoring Platform

5. System Test and Performance Analysis

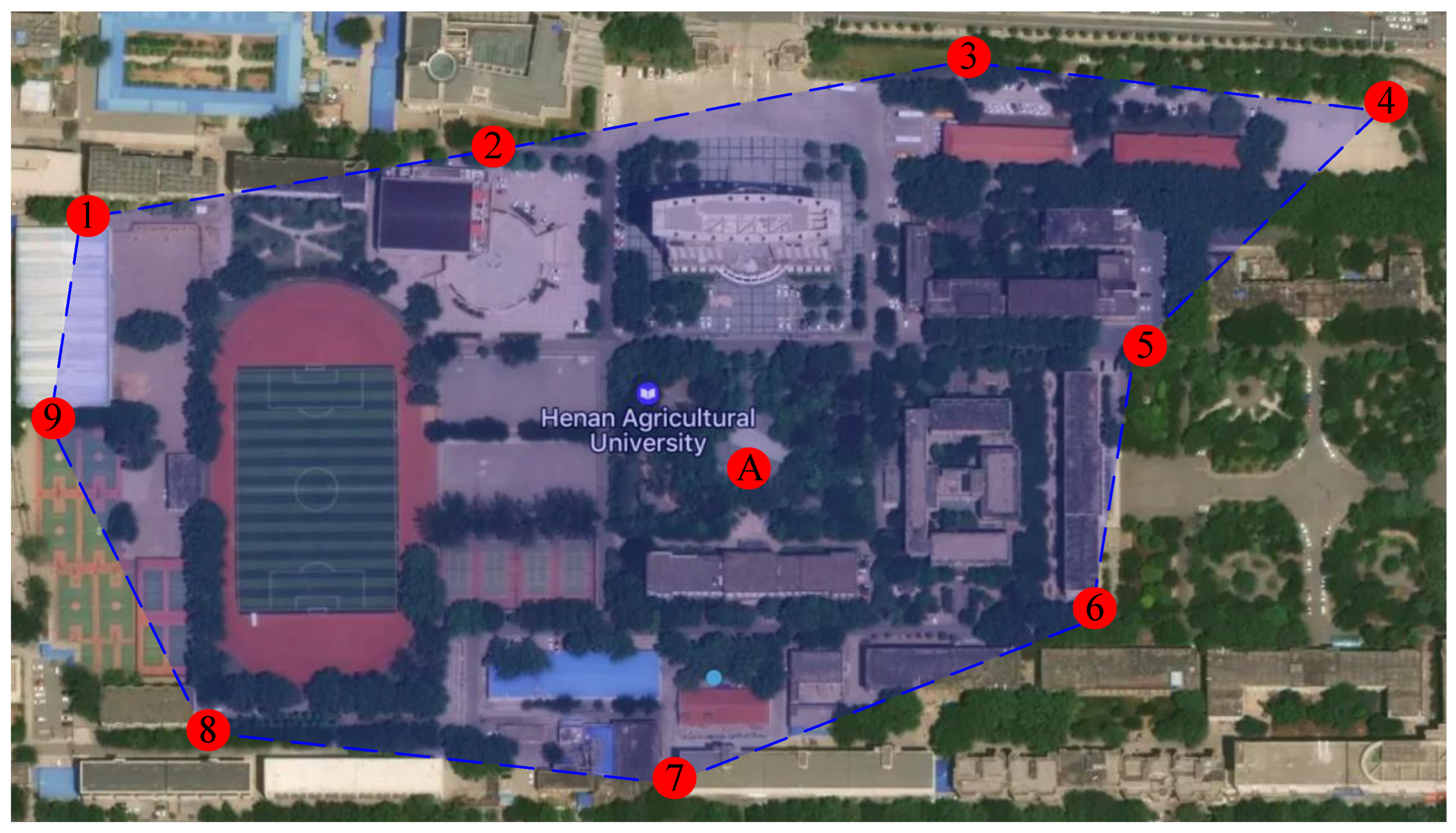

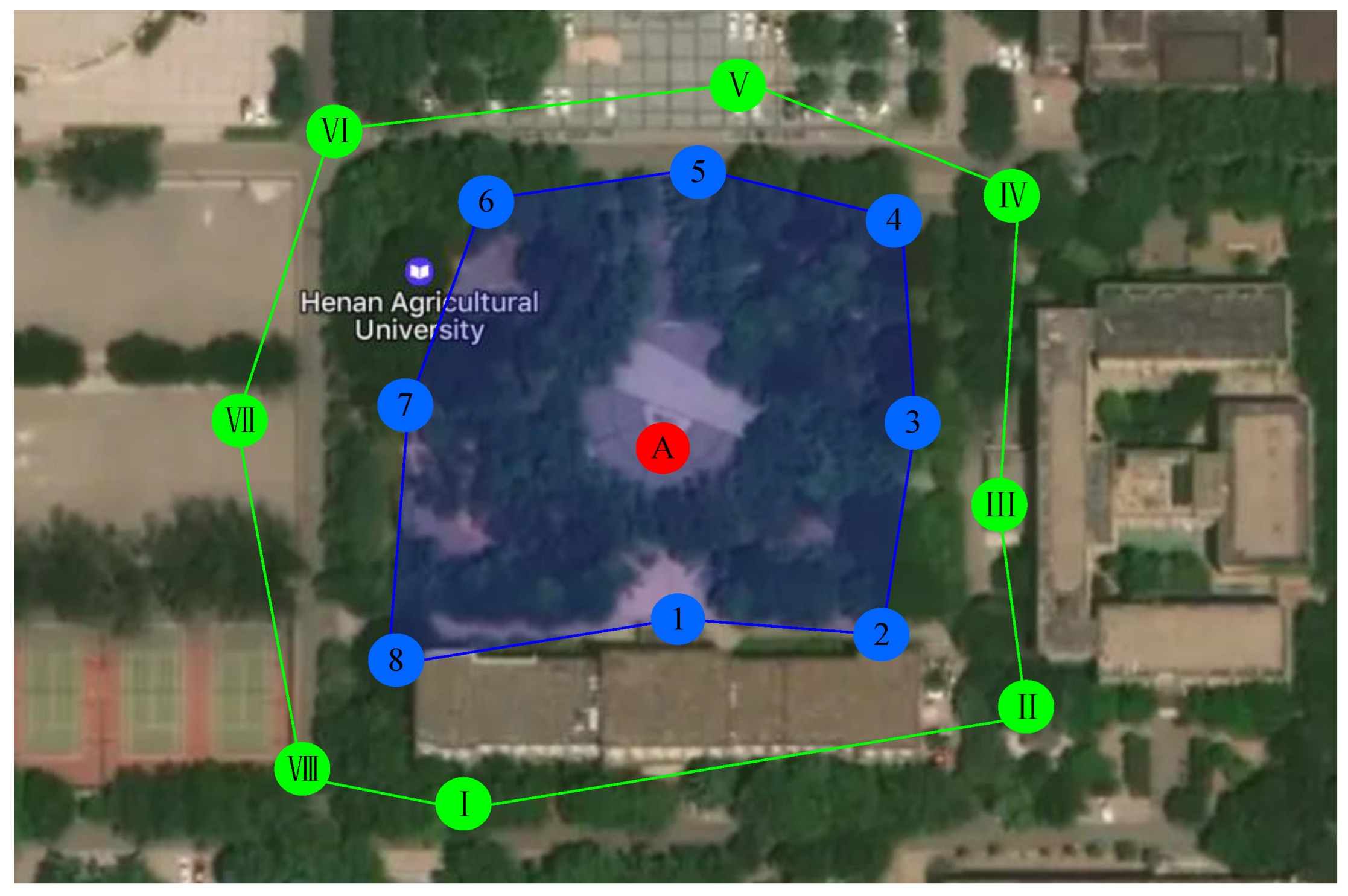

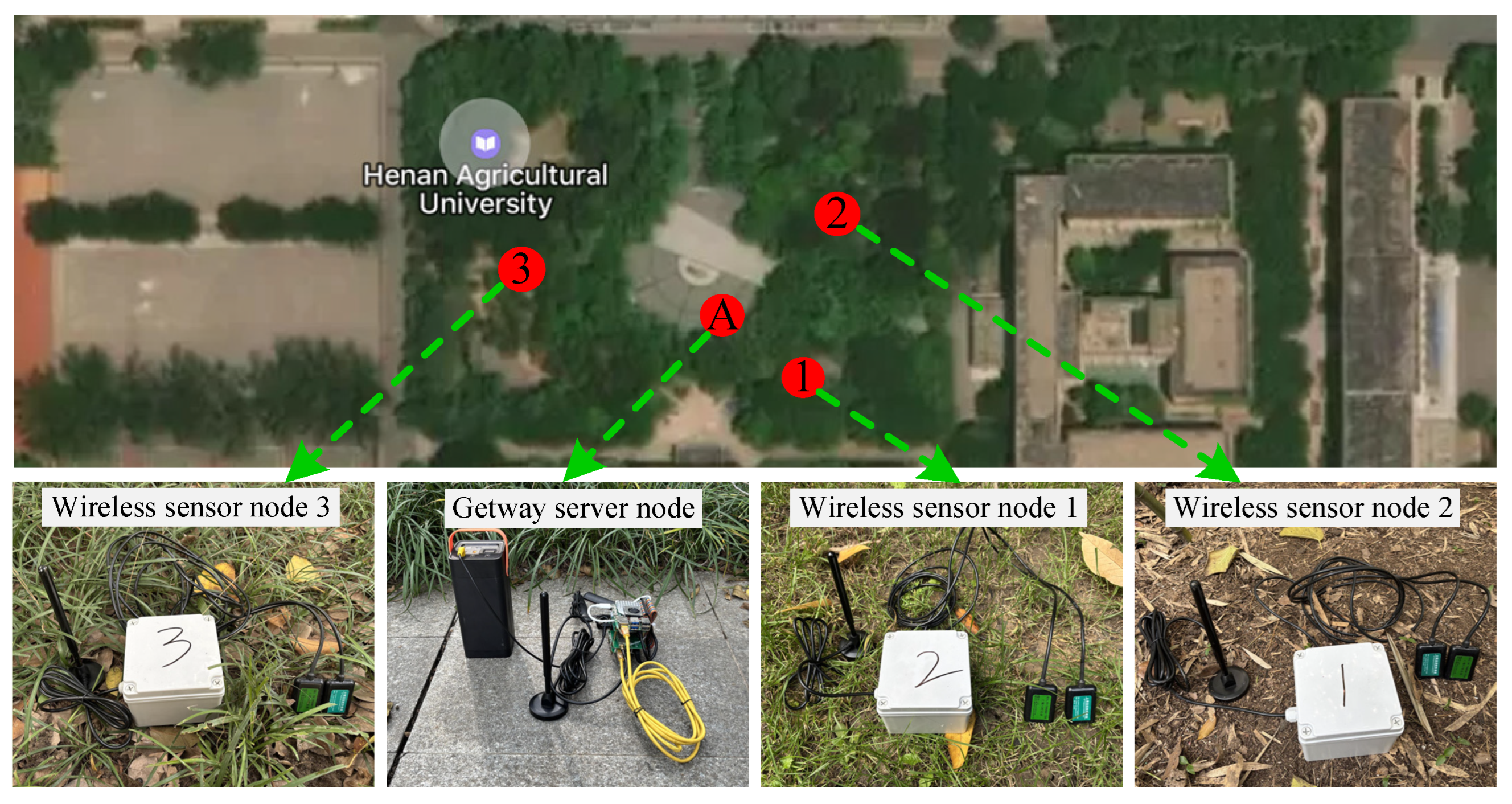

5.1. System Test

5.2. Data Acquisition Failure Rate

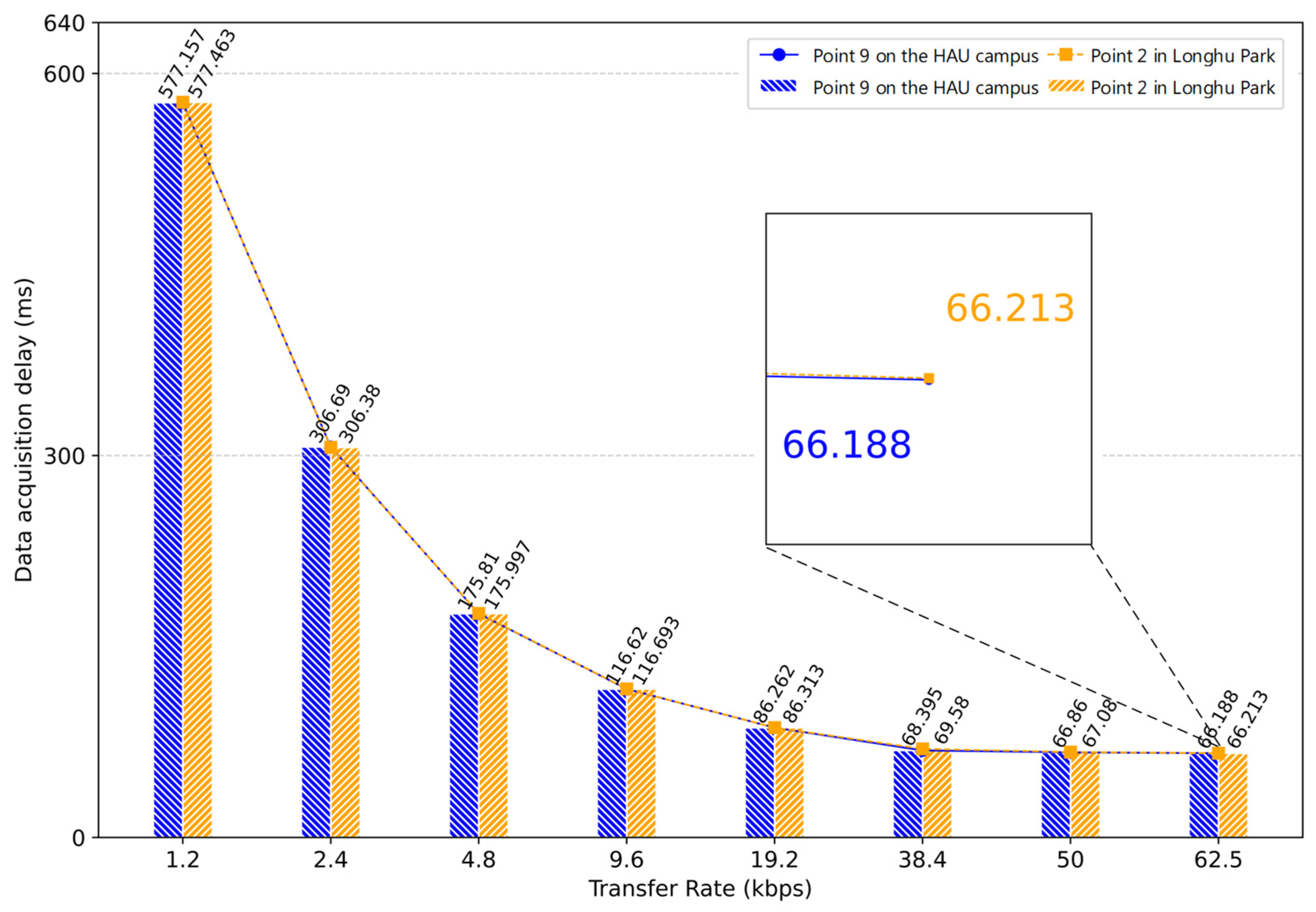

5.3. Data Acquisition Delay

5.4. Comparison with the Zigbee Method

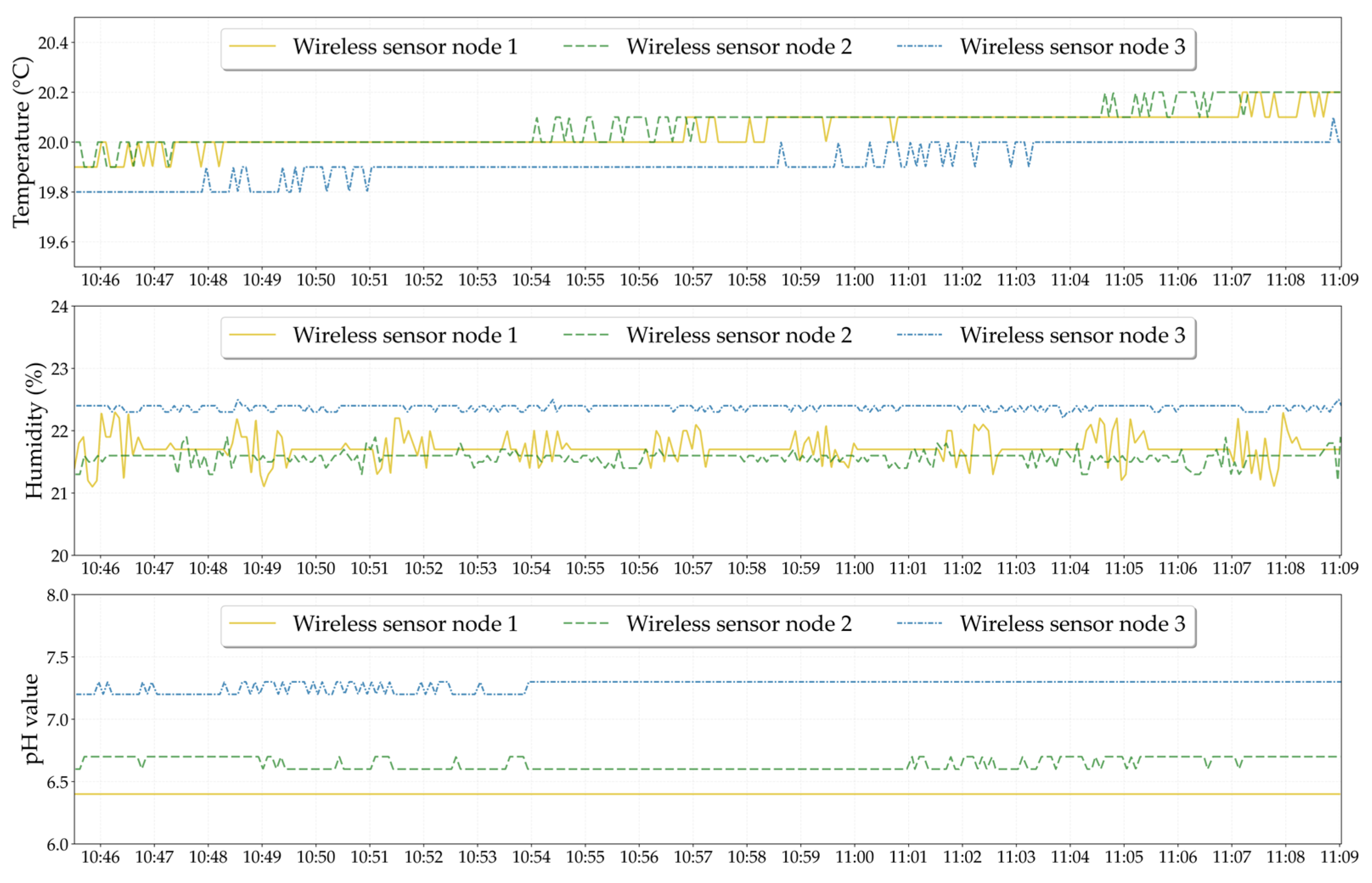

5.5. Multi-Node Soil Detecting System

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Qian, M.; Qian, C.; Xu, G.; Tian, P.; Yu, W. Smart irrigation systems from Cyber–Physical perspective: State of art and future directions. Future Internet 2024, 16, 234. [Google Scholar] [CrossRef]

- Loukatos, D.; Fragkos, A.; Kargas, G.; Arvanitis, K.G. Implementation and evaluation of a low-cost measurement platform over LoRa and applicability for soil monitoring. Future Internet 2024, 16, 443. [Google Scholar] [CrossRef]

- Volosciuc, C.; Bogdan, R.; Blajovan, B.; Stângaciu, C.; Marcu, M. GreenLab, An IoT-based small-scale smart greenhouse. Future Internet 2024, 16, 195. [Google Scholar] [CrossRef]

- Chereches, I.A.; Gaspar, F.; Danci, I.A. Designing and calibration of a low-cost multi-point soil moisture monitoring system for precision agriculture. INMATEH Agric. Eng. 2024, 72, 245–254. [Google Scholar] [CrossRef]

- Cotrim, R.; Assis, F.; Brito, A.D.S.; Peixouto, Y.S.; Peixouto, L.S. Multi-hop LoRa-based underground network for monitoring soil moisture in agriculture. Comput. Electron. Agric. 2024, 227, 109592. [Google Scholar] [CrossRef]

- Rueda-Delgado, D.; Cuellar-Torres, F.; Martinez, D.; Narducci, M.S. Instrumentation system for monitoring of soil variables in precision agriculture applications. IEEE Access 2025, 13, 49777–49787. [Google Scholar] [CrossRef]

- Awais, M.; Chen, Y.; Zhang, W.; Naqvi, S.M.Z.A.; Zhang, H.; Raghavan, V.; Hu, J.; Tlili, I. Experimental validation of an automated soil leachate monitoring system for agricultural non-point source pollution and nutrient run-off to water bodies. Ain Shams Eng. J. 2025, 16, 103713. [Google Scholar] [CrossRef]

- Gao, Y.; Hu, Q.; Hui, J.; Chang, L.; Zeng, M.; Jiang, Q. Real-time monitoring of soil moisture in cotton fields using electromagnetic induction technology. Agric. Water Manag. 2025, 313, 109466. [Google Scholar] [CrossRef]

- Baumbauer, C.L.; Baumbauer, D.A.; Arias, A.C. The effect of soil water content and crop canopy on passive UHF-RFID wireless links. Comput. Electron. Agric. 2025, 237, 110506. [Google Scholar] [CrossRef]

- Mashhadany, Y.A.; Alsanad, H.R.; Al-Askari, M.A.; Algburi, S.; Taha, B.A. Irrigation intelligence-enabling a cloud-based Internet of Things approach for enhanced water management in agriculture. Environ. Monit. Assess. 2024, 196, 438. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Yu, H.; Muller, E.; Askey, S.; Van Der Markt, M.; Sukkarieh, S. A heterogeneous sensing system for soil moisture mapping in agricultural environments. Comput. Electron. Agric. 2025, 239, 110932. [Google Scholar] [CrossRef]

- Kamarianakis, Z.; Perdikakis, S.; Daliakopoulos, I.N.; Papadimitriou, D.M.; Panagiotakis, S. Design and implementation of a low-cost, linear robotic camera system, targeting greenhouse plant growth monitoring. Future Internet 2024, 16, 145. [Google Scholar] [CrossRef]

- Akilan, T.; Baalamurugan, K.M. Automated weather forecasting and field monitoring using GRU-CNN model along with IoT to support precision agriculture. Expert Syst. Appl. 2024, 249, 123468. [Google Scholar] [CrossRef]

- Sonata, I.; Arifin, Y. Enhancing smart agriculture using Internet of Things and transformer model. Int. J. Innov. Comput. Inf. Control. 2025, 21, 515–531. [Google Scholar]

- Kaur, A.; Bhatt, D.P.; Raja, L. Developing a hybrid irrigation system for smart agriculture using IoT sensors and machine learning in Sri Ganganagar, Rajasthan. J. Sens. 2024, 2024, 676907. [Google Scholar] [CrossRef]

- Oguz, F.E.; Ekersular, M.N.; Sunnetci, K.M.; Alkan, A. Enabling smart agriculture: An IoT-based framework for real-time monitoring and analysis of agricultural data. Agric. Res. 2024, 13, 574–585. [Google Scholar] [CrossRef]

- Gómez-Gijón, S.; Salmerón, J.F.; Falco, A.; Loghin, F.C.; Lugli, P.; Morales, D.P.; Rodríguez, N.; Rivadeneyra, A. Printed RFID sensing system: The cost-effective way to IoT smart agriculture. Comput. Electron. Agric. 2025, 232, 110116. [Google Scholar] [CrossRef]

- Maity, T.; Paul, S.; Samanta, J.; Saha, P. Design and development of IoT-based SmartTech-Agri devices for smart agriculture crop field. J. Inst. Eng. Ser. B 2024, 105, 753–762. [Google Scholar] [CrossRef]

- Afzal, M.; Saeed, I.A.; Sohail, M.N.; Saad, M.H.M.; Sarker, M.R. IoT-enabled adaptive watering system with ARIMA-based soil moisture prediction for smart agriculture. IEEE Access 2025, 13, 27714–27728. [Google Scholar] [CrossRef]

- Manzano, J.M.; Orihuela, L.; Pacheco, E.; Pereira, M. Data-driven spatio-temporal estimation of soil moisture and temperature based on lipschitz interpolation. ISA Trans. 2025, 156, 535–550. [Google Scholar] [CrossRef]

- Balasubramanian, A.; Elangeswaran, S.V.J. A novel power aware smart agriculture management system based on RNN-LSTM. Electr. Eng. 2025, 107, 2347–2368. [Google Scholar] [CrossRef]

- Malone, B.; Biggins, D.; Sharman, C.; Searle, R.; Glover, M.; Brown, S. An experiential account with recommendations for the design, installation, operation and maintenance of a farm-scale soil moisture sensing and mapping system. Soil Res. 2024, 62, SR24004. [Google Scholar] [CrossRef]

- Dafonte, J.; González, M.Á.; Comesaña, E.; Teijeiro, M.T.; Cancela, J.J. Soil water status monitoring system with proximal low-cost sensors and LoRa technology for smart water irrigation in woody crops. Sensors 2024, 24, 8104. [Google Scholar] [CrossRef] [PubMed]

- Diaz, F.J.; Ahmad, A.; Parra, L.; Sendra, S.; Lloret, J. Low-cost optical sensors for soil composition monitoring. Sensors 2024, 24, 1140. [Google Scholar] [CrossRef] [PubMed]

- Raina, R.; Singh, K.J.; Kumar, S. Power efficient and long range precision agriculture monitoring system. IEEE J. Radio Freq. Identif. 2025, 9, 330–339. [Google Scholar] [CrossRef]

- Comegna, A.; Hassan, S.B.M.; Coppola, A. Recent technological upgrades to the SHYPROM IoT-based system for monitoring soil water status. Sensors 2025, 25, 4934. [Google Scholar] [CrossRef]

- Mansour, M.; Gamal, A.; Ahmed, A.I.; Said, L.A.; Elbaz, A.; Herencsar, N.; Soltan, A. Internet of Things: A comprehensive overview on protocols, architectures, technologies, simulation tools, and future directions. Energies 2023, 16, 3465. [Google Scholar] [CrossRef]

- Abdelwahed, S.H.; Hefny, I.M.; Hegazy, M.; Said, L.A.; Soltan, A. Survey of IoT multi-protocol gateways: Architectures, protocols and cybersecurity. Internet Things 2025, 33, 101703. [Google Scholar] [CrossRef]

- Tang, P.; Liang, Q.; Li, H.; Pang, Y. Application of Internet-of-Things Wireless Communication Technology in Agricultural irrigation Management: A review. Sustainability 2024, 16, 3575. [Google Scholar] [CrossRef]

- Xu, Z.; Yu, G.; Luo, Y.; Jiang, H. An energy-efficient scheme for waking co-channel TDMA in LoRa networks via the integration of bidirectional timestamp correction and address recognition. Future Internet 2025, 17, 369. [Google Scholar] [CrossRef]

- Luo, Y.-Y.; Chiu, Y.-H.; Cheng, C.-H. Detection and mitigation in IoT ecosystems using One M2M architecture and edge-based machine learning. Future Internet 2025, 17, 411. [Google Scholar] [CrossRef]

- Salunke, S.V.; Ouda, A. A performance benchmark for the PostgreSQL and MySQL databases. Future Internet 2024, 16, 382. [Google Scholar] [CrossRef]

- Zhang, P.; Wang, R.; Shi, N. IgA nephropathy prediction in children with machine learning algorithms. Future Internet 2020, 12, 230. [Google Scholar] [CrossRef]

- Fahrudin, T.M.; Funabiki, N.; Brata, K.C.; Naing, I.; Aung, S.T.; Muhaimin, A.; Prasetya, D.A. An improved reference paper collection system using web scraping with three enhancements. Future Internet 2025, 17, 195. [Google Scholar] [CrossRef]

- Yang, H.; Peng, C.; Cao, Z. Attack-model-independent stabilization of networked control systems under a jump-like TOD scheduling protocol. Automatica 2023, 152, 110982. [Google Scholar] [CrossRef]

- Lin, S.; Costello, D.J.; Miller, M.J. Automatic-repeat-request error-control schemes. IEEE Commun. Mag. 1984, 22, 5–17. [Google Scholar] [CrossRef]

- Yang, H.; Peng, C.; Cao, Z.; Zhang, X.-M. A novel semantic-based multi-packet parallel transmission scheme for networked control systems. Automatica 2025, 174, 112120. [Google Scholar] [CrossRef]

- Yan, R.; He, X.; Wang, Z.; Wang, Y.; Li, Z.; Li, X. A compact autonomous inspection system for greenhouse environmental information sensing and three-dimensional visualization. Comput. Electron. Agric. 2025, 231, 109976. [Google Scholar] [CrossRef]

- Luo, Y.; Pu, L. UAV Remotely-Powered Underground IoT for soil Monitoring. IEEE Trans. Ind. Inform. 2023, 20, 972–983. [Google Scholar] [CrossRef]

| References | Contributions | Open Issues or Limits |

|---|---|---|

| [5] | A wireless underground sensor network is proposed to monitor soil moisture using a multi-hop routing protocol. | The maximum round-trip delay was 190 s. |

| [6] | Wireless sensor nodes are used to acquire and transmit georeferenced soil information. | It presents high levels of error in measuring nutrients. |

| [7] | A soil leachate monitoring system is designed to evaluate phosphorus and nitrogen in agricultural runoff. | Wired signal transmission and on-site analysis are required. |

| [8] | A soil moisture monitoring system for cotton fields is designed using electromagnetic induction technology, and the Kalman filter algorithm is employed to enhance the model precision. | The precision of the global model and its applicability across broader areas still require extensive research. |

| [9] | Passive ultra-high frequency (UHF) radio frequency identification (RFID) is used for sensor nodes to enable continuous soil monitoring. | The read range only exceeds 2 m, and no external sensors are used. |

| [10] | The work designs a remote monitoring system for agricultural environmental information, including soil, weather and crops, and introduces a fuzzy PID controller to optimize water management. | The controller practical implementation faces challenges such as complexity and computing resources. |

| [11] | A heterogeneous sensing system for soil moisture mapping is proposed, which contains wireless sensor networks for large-scale continuous detection, mobile robots for in situ monitoring, and portable probes for flexible sampling. | Environmental factors such as soil salinity, greatly affect radio frequency signal transmission. |

| [12] | A cost-efficient linear robotic camera system with one degree of freedom is designed for automatic plant photography utilizing Wi-Fi communication. | The wireless communication performance is not investigated. |

| [13] | The work uses sensor nodes to detect agricultural information, including soil moisture and temperature, and send sensor data to the gateway node via Wi-Fi. | The communication distance of Wi-Fi limits the coverage range of the monitoring system. |

| [14] | The Internet of Things (IoT) and the Transformer model are employed to monitor agricultural soil moisture, temperature, and air humidity, as well as predict temperature and air humidity data. | The application faces the challenge of a lack of communication infrastructure such as the Internet and Wi-Fi. |

| [15,16] | The works use the Arduino-based sensor nodes to acquire agricultural information including soil moisture and send data to a cloud server via Wi-Fi. | Soil pH is not monitored [15] and the method [16] is only evaluated in a short period of time. |

| [17] | The work designs printed RFID sensor tags to collect soil parameters, uses a UHF reader on a robot to collect sensor data, and sends data to a web server via Wi-Fi and Bluetooth. | The reading distance of the tags buried in the soil is 70 cm, and a longer reading range is expected. |

| [18] | A low-cost agriculture monitoring system is designed to collect information such as soil moisture, which contains Arduino-based hardware using Wi-Fi, and server and phone applications. | The communication distance of the used Wi-Fi protocol is limited. |

| [19] | Two monitoring systems are developed based on Wi-Fi and global systems for mobile communication (GSM) to collect crop, soil, and outdoor information. | Soil pH is not monitored, and environmental changes are not used to improve prediction accuracy. |

| [20] | The work designs a monitoring system with sensor nodes connecting with the gateway via LoRa, and makes spatio-temporal estimation of soil moisture and temperature. | The outliers have a significant impact on the estimated value. |

| [21] | The work designs an agricultural irrigation management system, where sensors transmit data such as soil moisture to the gateway via LoRa. | The inconsistent power supply in rural regions can cause disruptions to the system operation. |

| [22] | The work develops a farm monitoring system, where soil moisture probes communicate with a base station via radio link, the base station sends data to the gateway via LoRa, and the gateway connects with the server via GSM. | The communication performance, such as data transmission success rate and delays, is not investigated. |

| [23] | The work develops a monitoring system for woody crops, where Arduino-based sensor nodes for soil parameters communicate with the gateway via LoRa, and the gateway sends data to an FTP server via a router. | The sensor accuracy for soil water content is low, and the communication between the sensor and the gateway is unidirectional. |

| [24] | An optical wireless sensor network is designed to monitor changes in soil composition, and the gateway nodes forward sensor data to a cloud server. | Its limitations lie in the use of artificial samples and the relatively small sample size. |

| [25] | The work studies the power consumption of an agriculture monitoring system, where sensor nodes for soil moisture connect to the gateway via Bluetooth, and the gateway sends data to a cloud server via GSM. | The Bluetooth communication range and battery lifetimes are limited. |

| [26] | The work develops sensor nodes to monitor soil moisture, matric potential, and hydraulic conductivity, and sends data to a cloud server via GSM. | Wireless communication performance is not given enough attention. |

| Soil Sensor Type | Model | Operating Voltage | Measure Range | Resolution | Accuracy |

|---|---|---|---|---|---|

| temperature sensor | SN-3000-TR-N01 | 4.5–30 V DC | −40~80 °C | 0.1 °C | 0.5 °C |

| humidity sensor | SN-3000-TR-N01 | 4.5–30 V DC | 0–100% | 0.1% | 3% |

| pH sensor | ZTS-3000-TR-pH | 5–30 V DC | 3–9 pH | 0.1 pH | 0.3 pH |

| Protocol | Transmission Range | Power Consumption | Data Rate | Cost |

|---|---|---|---|---|

| LoRa | 15 km | Ultra-low | 62 kbps | Low |

| Zigbee | 10–100 m | Low | 250 kbps | Low |

| Wi-Fi | 100 m | Medium | 11–9600 Mbps | Low |

| Bluetooth | 15–30 m | Low | 1–2 Mbps | Low |

| Fifth generation | 100–300 m | Medium | <1 × 107 kbps | High |

| Sensor Location | Distance from Point A | Data Acquisition Failure Rate Under the Traditional Method | Data Acquisition Failure Rate Under the Proposed QADA Method |

|---|---|---|---|

| Point 1 | 304 m | 24% | 0 |

| Point 2 | 174 m | 23% | 0.33% |

| Point 3 | 198 m | 25% | 0 |

| Point 4 | 315 m | 21% | 0.33% |

| Point 5 | 171 m | 25% | 0 |

| Point 6 | 164 m | 25% | 0 |

| Point 7 | 145 m | 25% | 0.33% |

| Point 8 | 266 m | 23% | 0 |

| Point 9 | 307 m | 22% | 0 |

| Sensor Location | Distance from Point B | Data Acquisition Failure Rate |

|---|---|---|

| Point 1 | 1780 m | 0 |

| Point 2 | 1696 m | 0.33% |

| Sensor Location | Distance from Point A | Data Acquisition Failure Rate | Sensor Location | Distance from Point A | Data Acquisition Failure Rate |

|---|---|---|---|---|---|

| Point 1 | 37 m | 3.5% | Point I | 77 m | 49.5% |

| Point 2 | 54 m | 4.0% | Point II | 81 m | 33.0% |

| Point 3 | 47 m | 3.5% | Point III | 66 m | 39.5% |

| Point 4 | 60 m | 3.0% | Point IV | 87 m | 27.0% |

| Point 5 | 47 m | 2.0% | Point V | 69 m | 32.0% |

| Point 6 | 56 m | 3.5% | Point VI | 86 m | 42.0% |

| Point 7 | 52 m | 3.5% | Point VII | 85 m | 33.5% |

| Point 8 | 68 m | 3.0% | Point VIII | 83 m | 42.0% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Li, Z.; Gao, L.; Peng, C. Design of an Improved IoT-Based PV-Powered Soil Remote Monitoring System with Low Data Acquisition Failure Rate. Future Internet 2025, 17, 538. https://doi.org/10.3390/fi17120538

Li F, Li Z, Gao L, Peng C. Design of an Improved IoT-Based PV-Powered Soil Remote Monitoring System with Low Data Acquisition Failure Rate. Future Internet. 2025; 17(12):538. https://doi.org/10.3390/fi17120538

Chicago/Turabian StyleLi, Fuqiang, Zhe Li, Lisai Gao, and Chen Peng. 2025. "Design of an Improved IoT-Based PV-Powered Soil Remote Monitoring System with Low Data Acquisition Failure Rate" Future Internet 17, no. 12: 538. https://doi.org/10.3390/fi17120538

APA StyleLi, F., Li, Z., Gao, L., & Peng, C. (2025). Design of an Improved IoT-Based PV-Powered Soil Remote Monitoring System with Low Data Acquisition Failure Rate. Future Internet, 17(12), 538. https://doi.org/10.3390/fi17120538