3D-Printing of Silk Nanofibrils Reinforced Alginate for Soft Tissue Engineering

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of Silk Nanofibrils (SNFs)

2.3. Fabrication of 3D-Printed Alginate-SNF Scaffold

2.4. Characterization of Alginate-SNF Hybrid Hydrogel

2.5. Cell Culture Investigations

2.6. Statistical Analysis

3. Results and Discussion

3.1. Chemical Characterization of 3D-Printed Alg-SNF Scaffolds

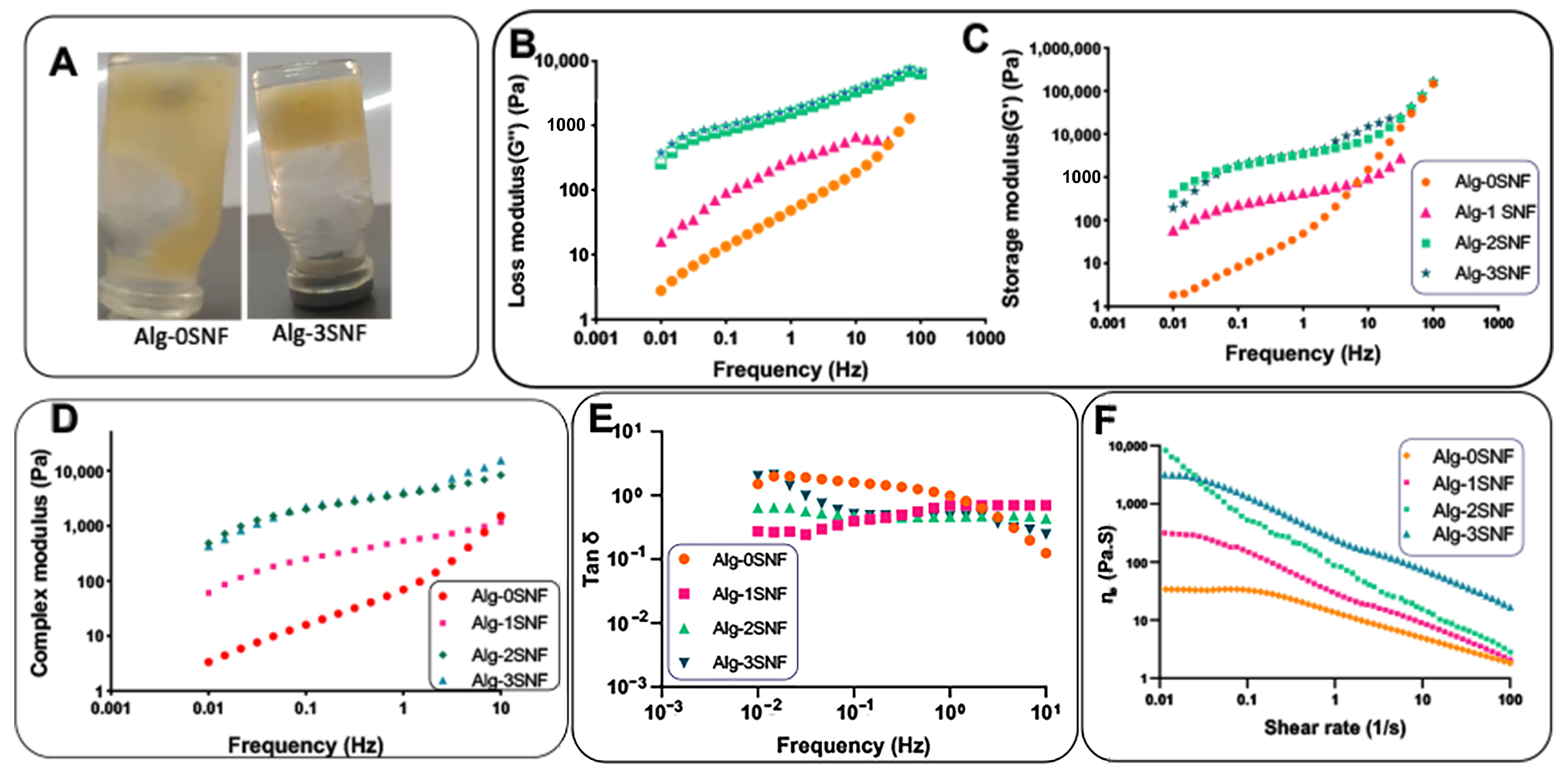

3.2. Rheological Behavior of 3D-Printed Alg-SNF Scaffolds

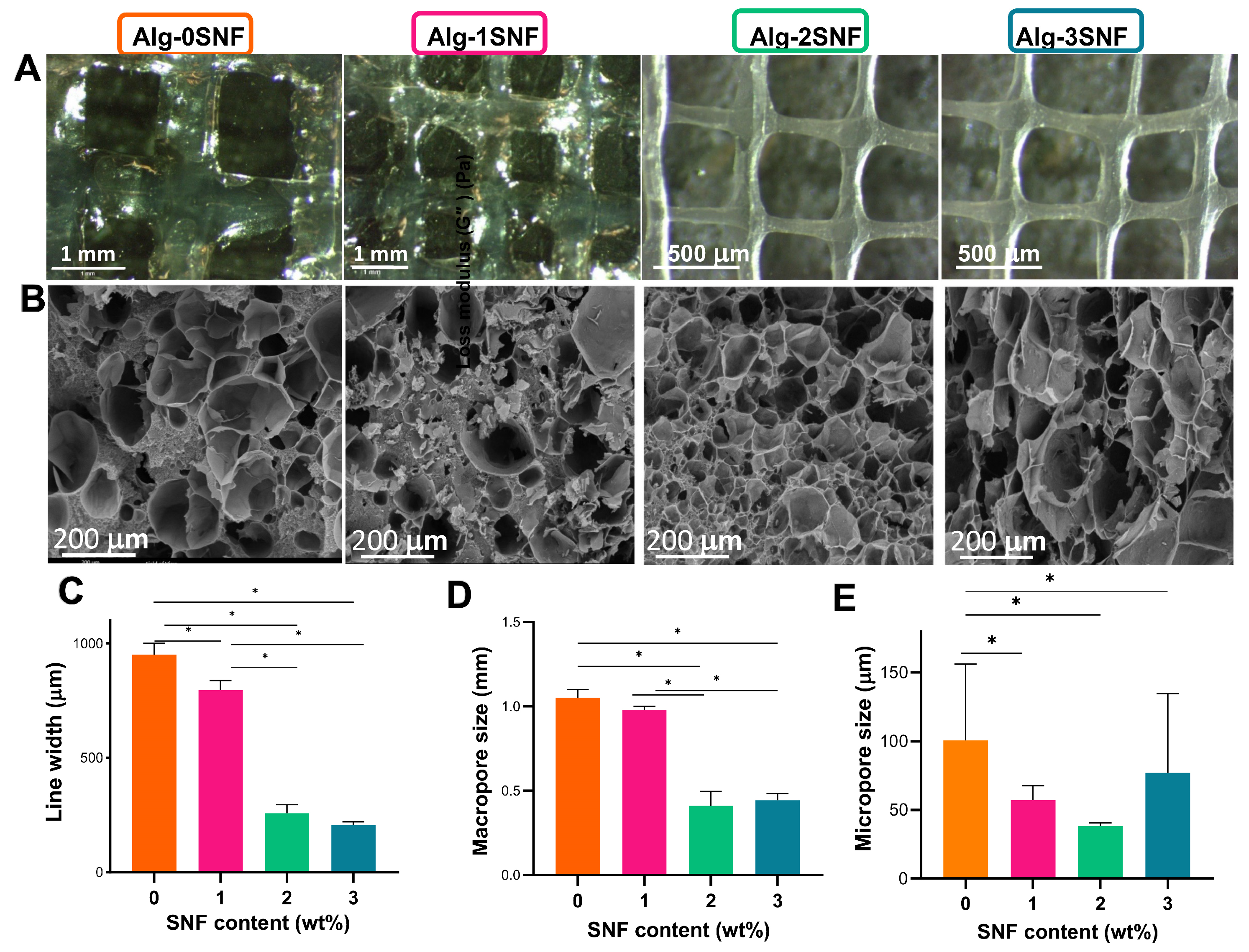

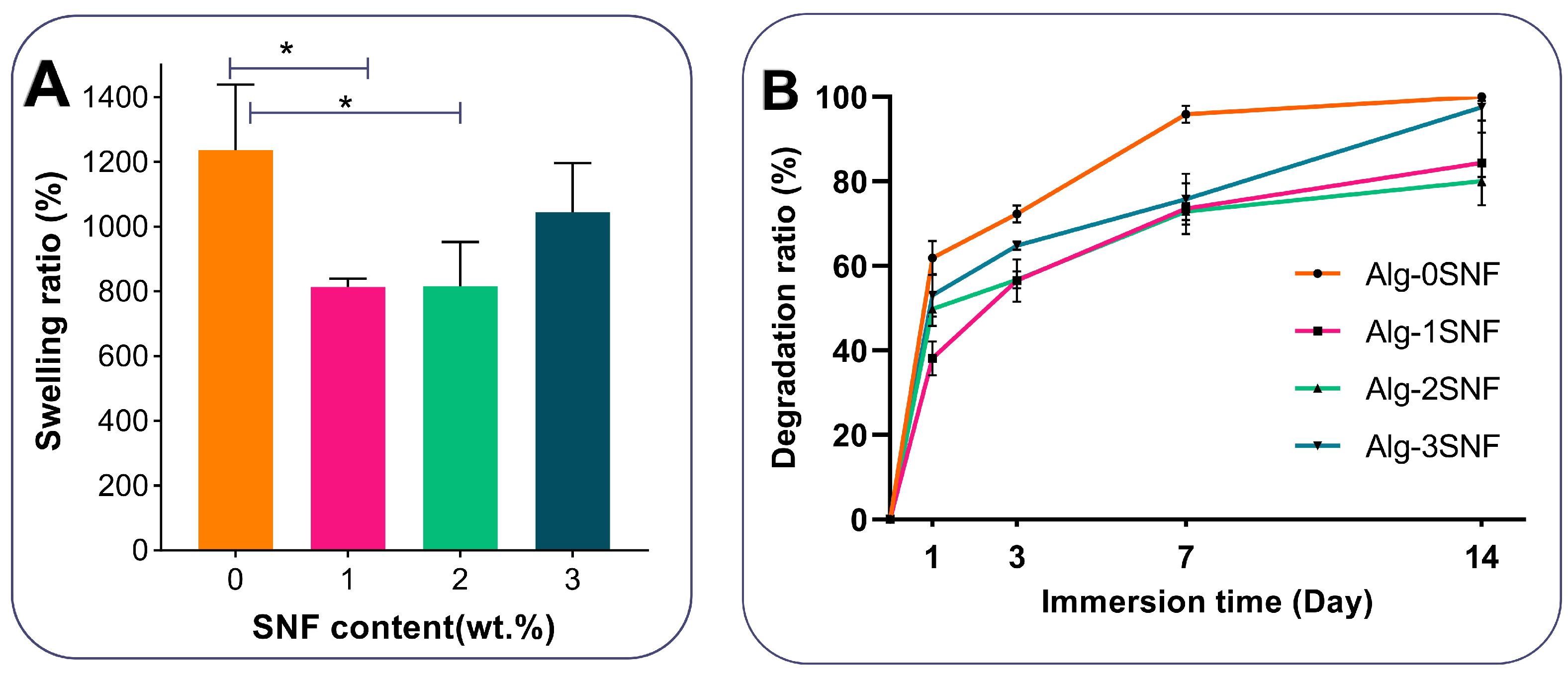

3.3. Structural Properties of 3D-Printed Alg-SNF Scaffolds

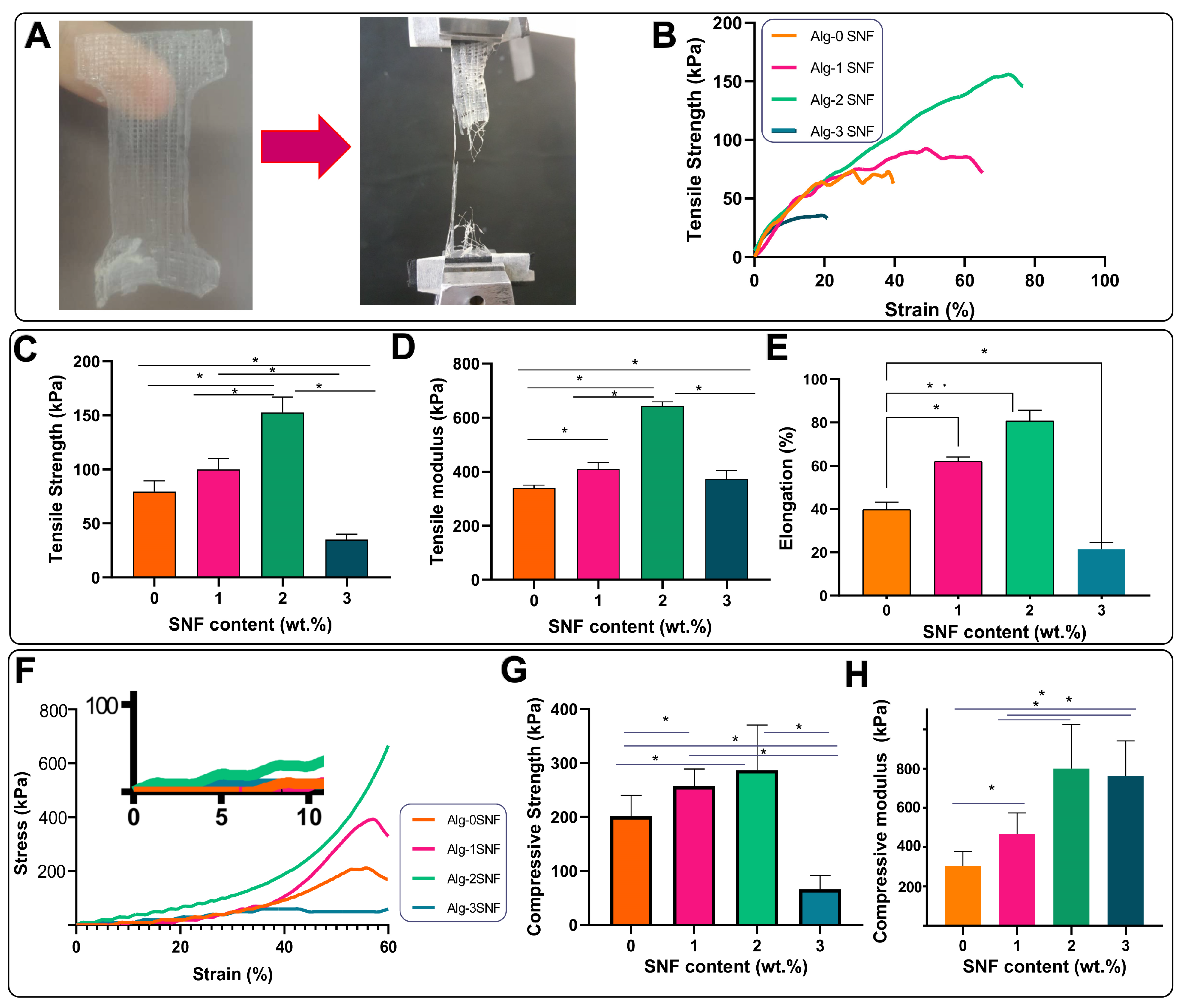

3.4. Mechanical Properties of 3D-Printed Alg-SNF Scaffolds

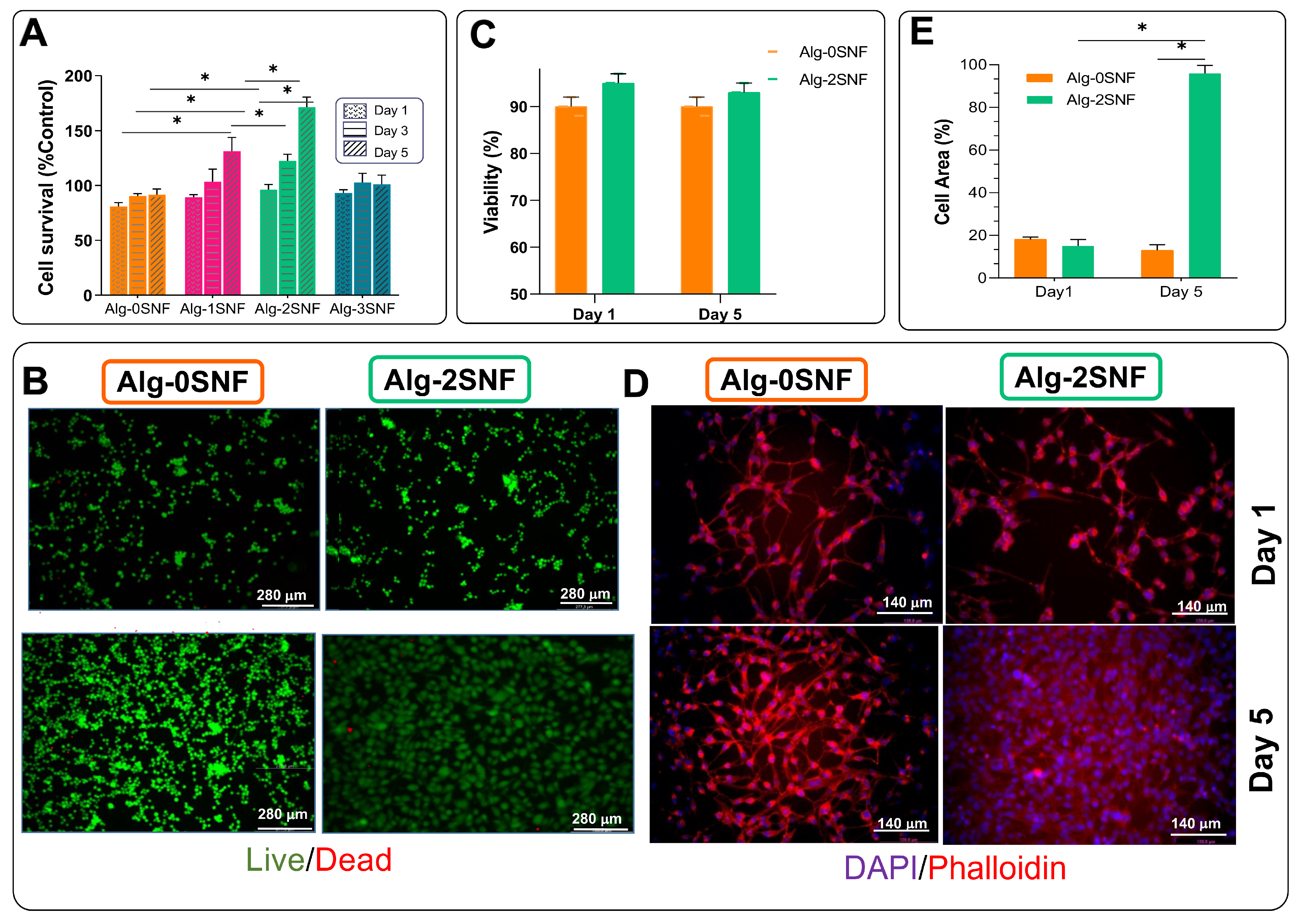

3.5. Cell Culture Investigation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, P.; Gu, H.; Mi, H.; Rao, C.; Fu, J.; Turng, L. Fabrication of scaffolds in tissue engineering: A review. Front. Mech. Eng. 2018, 13, 107–119. [Google Scholar] [CrossRef]

- Du, X. 3D bio-printing review. In Proceedings of theThe 5th Annual International Conference on Material Science and Environmental Engineering, Xiamen, China, 15–17 December 2017; IOP Publishing: Bristol, UK, 2018; Volume 301, p. 12023. [Google Scholar]

- Mandrycky, C.; Phong, K.; Zheng, Y. Tissue engineering toward organ-specific regeneration and disease modeling. MRS Commun. 2017, 7, 332–347. [Google Scholar] [CrossRef]

- Dey, M.; Ozbolat, I.T. 3D bioprinting of cells, tissues and organs. Sci. Rep. 2020, 10, 14023. [Google Scholar] [CrossRef] [PubMed]

- Leberfinger, A.N.; Dinda, S.; Wu, Y.; Koduru, S.V.; Ozbolat, V.; Ravnic, D.; Ozbolat, I.T. Bioprinting functional tissues. Acta Biomater. 2019, 95, 32–49. [Google Scholar] [CrossRef]

- Askari, M.; Naniz, M.; Kouhi, M.; Saberi, A.; Zolfagharian, A.; Bodaghi, M. Recent progress in extrusion 3D bioprinting of hydrogel biomaterials for tissue regeneration: A comprehensive review with focus on advanced fabrication techniques. Biomater. Sci. 2021, 9, 535–573. [Google Scholar] [CrossRef]

- Schwab, A.; Levato, R.; Este, M.; Piluso, S.; Eglin, D.; Malda, J. Printability and Shape Fidelity of Bioinks in 3D Bioprinting. Chem. Rev. 2020, 120, 11028–11055. [Google Scholar] [CrossRef]

- Li, Z.; Hojati, M.; Wu, Z.; Piasente, J.; Ashrafi, N.; Duarte, J.P.; Nazarian, S.; Bilén, S.G.; Memari, A.M.; Radlińska, A. Fresh and hardened properties of extrusion-based 3D-printed cementitious materials: A review. Sustainability 2020, 12, 5628. [Google Scholar] [CrossRef]

- Heid, S.; Boccaccini, A.R. Advancing bioinks for 3D bioprinting using reactive fillers: A review. Acta Biomater. 2020, 113, 1–22. [Google Scholar] [CrossRef]

- Cooke, M.E.; Rosenzweig, D.H. The rheology of direct and suspended extrusion bioprinting. APL Bioeng. 2021, 5, 011502. [Google Scholar] [CrossRef]

- Jia, J.; Richards, D.; Pollard, S.; Tan, Y.; Rodriguez, J.; Visconti, R.; Trusk, T.; Yost, M.; Yao, H.; Markwald, R.; et al. Engineering alginate as bioink for bioprinting. Acta Biomater. 2014, 10, 4323–4331. [Google Scholar] [CrossRef]

- Rastogi, P. Review on Alginate-based Hydrogel Bio-Printing for Application in Tissue Engineering. Biofabrication 2019, 11, 042001. [Google Scholar] [CrossRef]

- Gungor-Ozkerim, P.S.; Inci, I.; Zhang, Y.; Khademhosseini, A.; Dokmeci, M.R. Bioinks for 3D bioprinting: An overview. Biomater. Sci. 2018, 6, 915–946. [Google Scholar] [CrossRef]

- Aarstad, O.; Heggset, E.; Pedersen, I.; Bjørnøy, S.; Syverud, K.; Strand, B.L. Mechanical properties of composite hydrogels of alginate and cellulose nanofibrils. Polymers 2017, 9, 378. [Google Scholar] [CrossRef]

- Markstedt, K.; Mantas, A.; Tournier, I.; Ávila, H.M.; Hagg, D.; Gatenholm, P. 3D bioprinting human chondrocytes with nanocellulose–alginate bioink for cartilage tissue engineering applications. Biomacromolecules 2015, 16, 1489–1496. [Google Scholar] [CrossRef] [PubMed]

- Kambe, Y. Functionalization of silk fi broin-based biomaterials for tissue engineering. Polym. J. 2021, 53, 1345–1351. [Google Scholar] [CrossRef]

- Rockwood, D.N.; Gil, E.; Park, S.-H.; Kluge, J.; Grayson, W.; Bhumiratana, S.; Rajkhowa, R.; Wang, X.; Kim, S.; Vunjak-Novakovic, G. Ingrowth of human mesenchymal stem cells into porous silk particle reinforced silk composite scaffolds: An in vitro study. Acta Biomater. 2011, 7, 144–151. [Google Scholar] [CrossRef]

- Baek, H.S.; Park, Y.; Ki, C.; Park, J.-C.; Rah, D.K. Enhanced chondrogenic responses of articular chondrocytes onto porous silk fibroin scaffolds treated with microwave-induced argon plasma. Surf. Coat. Technol. 2008, 202, 5794–5797. [Google Scholar] [CrossRef]

- Lovett, M.L.; Cannizzaro, C.; Vunjak-Novakovic, G.; Kaplan, D.L. Gel spinning of silk tubes for tissue engineering. Biomaterials 2008, 29, 4650–4657. [Google Scholar] [CrossRef]

- Vepari, C.; Kaplan, D.L. Silk as a Biomaterial. Prog. Polym. Sci. 2007, 32, 991–1007. [Google Scholar] [CrossRef]

- Chawla, S.; Midha, S.; Sharma, A.; Ghosh, S. Silk-Based Bioinks for 3D Bioprinting. Adv. Healthc. Mater. 2018, 7, 1701204. [Google Scholar] [CrossRef]

- Nguy, T.T.; Ratanavaraporn, J.; Yodmuang, S. Alginate-silk fibroin Bioink: A printable hydrogel for tissue engineering. In Proceedings of the 2019 12th Biomedical Engineering International Conference, Ubon Ratchathani, Thailand, 19–22 November 2019; pp. 1–4. [Google Scholar]

- Joshi, A.; Kaur, T.; Singh, N. 3D Bioprinted Alginate-Silk-Based Smart Cell-Instructive Scaffolds for Dual Differentiation of Human Mesenchymal Stem Cells. ACS Appl. Bio Mater. 2022, 5, 2870–2879. [Google Scholar] [CrossRef]

- Aharonov, A.; Mordechai, H.; Sharon, S.; Sharabi, M. The mechanical behavior of silk-fibroin reinforced alginate hydrogel biocomposites-Toward functional tissue biomimetics. J. Mech. Behav. Biomed. Mater. 2023, 138, 105598. [Google Scholar] [CrossRef] [PubMed]

- Qiu, W.; Patil, A.; Hu, F.; Liu, X.Y. Hierarchical structure of silk materials versus mechanical performance and mesoscopic engineering principles. Small 2019, 15, 1903948. [Google Scholar] [CrossRef] [PubMed]

- Ling, S.; Kaplan, D.; Buehler, M.J. Nanofibrils in nature and materials engineering. Nat. Rev. Mater. 2018, 3, 1–15. [Google Scholar] [CrossRef]

- Niu, Q.; Peng, Q.; Lu, L.; Fan, S.; Shao, H.; Zhang, H.; Wu, R.; Hsiao, B.; Zhang, Y. Single molecular layer of silk nanoribbon as potential basic building block of silk materials. ACS Nano 2018, 12, 11860–11870. [Google Scholar] [CrossRef] [PubMed]

- Tan, X.; Zhao, W.; Mu, T. Controllable exfoliation of natural silk fibers into nanofibrils by protein denaturant deep eutectic solvent: Nanofibrous strategy for multifunctional membranes. Green Chem. 2018, 20, 3625–3633. [Google Scholar] [CrossRef]

- Liu, Q.; Ying, G.; Jiang, N.; Yetisen, A.; Yao, D.; Xie, X.; Fan, Y.; Liu, H. Three-dimensional silk fi broin microsphere-nano fi ber scaffolds for vascular tissue engineering. Med. Nov. Technol. Devices 2021, 9, 100051. [Google Scholar] [CrossRef]

- Farasatkia, A.; Kharaziha, M. Robust and double-layer micro-patterned bioadhesive based on silk nanofibril/GelMA-alginate for stroma tissue engineering. Int. J. Biol. Macromol. 2021, 183, 1013–1025. [Google Scholar] [CrossRef]

- Sultan, S.; Siqueira, G.; Zimmermann, T.; Mathew, A.P. 3D printing of nano-cellulosic biomaterials for medical applications. Curr. Opin. Biomed. Eng. 2017, 2, 29–34. [Google Scholar] [CrossRef]

- Li, Y.; Wang, J.; Qian, D.; Chen, L.; Mo, X.; Wang, L.; Wang, Y.; Cui, W. Electrospun fibrous sponge via short fiber for mimicking 3D ECM. J. Nanobiotechnol. 2021, 19, 1–15. [Google Scholar] [CrossRef]

- Sah, M.K.; Pramanik, K. Regenerated silk fibroin from B. mori silkcocoon for tissue engineering applications. Int. J. Environ. Sci. Dev. 2010, 1, 404. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Y.; Shao, H.; Hu, X. Hybrid Silk Fibers Dry-Spun from Regenerated Silk Fibroin/Graphene Oxide Aqueous Solutions. ACS Appl. Mater. Interfaces 2016, 8, 3349–3358. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Long, H.; Chen, L.; Liu, Y.; Li, Q. Ultrasonics induced variations in molecular structure and tensile properties of silk fibers in a chemical free environment. Nano Sel. 2021, 2, 1962–1967. [Google Scholar] [CrossRef]

- Leppiniemi, J.; Lahtinen, P.; Paajanen, A.; Mahlberg, R.; Metsä-kortelainen, S.; Pajari, H.; Vikholm-lundin, I.; Pursula, P.; Hytönen, V.P. 3D Printable Bioactivated Nanocellulose-Alginate Hydrogels. ACS Appl. Mater. Interfaces 2017, 9, 21959–21970. [Google Scholar] [CrossRef]

- Alexa, R.L.; Ianchis, R.; Savu, D.; Temelie, M.; Trica, B.; Serafim, A.; Vlasceanu, G.; Alexandrescu, E.; Preda, S.; Iovu, H. 3D Printing of Alginate-Natural Clay Hydrogel—Based Nanocomposites. Gels 2021, 7, 211. [Google Scholar] [CrossRef] [PubMed]

- Atrian, M.; Kharaziha, M.; Emadi, R.; Alihosseini, F. Silk-Laponite® fibrous membranes for bone tissue engineering. Appl. Clay Sci. 2019, 174, 90–99. [Google Scholar] [CrossRef]

- Baniasadi, H.; Madani, Z.; Ajdary, R.; Rojas, O.; Seppälä, J. Ascorbic acid-loaded polyvinyl alcohol/cellulose nanofibril hydrogels as precursors for 3D printed materials. Mater. Sci. Eng. C 2021, 130, 112424. [Google Scholar] [CrossRef]

- Park, H.; Guo, X.; Temenoff, J.; Tabata, Y.; Caplan, A.; Kasper, F.; Mikos, A.G. Effect of swelling ratio of injectable hydrogel composites on chondrogenic differentiation of encapsulated rabbit marrow mesenchymal stem cells in vitro. Biomacromolecules 2009, 10, 541–546. [Google Scholar] [CrossRef]

- Sindhu, K.R.; Bansode, N.; Rémy, M.; Morel, C.; Bareille, R.; Hagedorn, M.; Hinz, B.; Barthélémy, P.; Chassande, O.; Boiziau, C. New injectable self-assembled hydrogels that promote angiogenesis through a bioactive degradation product. Acta Biomater. 2020, 115, 197–209. [Google Scholar] [CrossRef]

- Li, Q.; Xu, S.; Feng, Q.; Dai, Q.; Yao, L.; Zhang, Y.; Gao, H.; Dong, H.; Chen, D.; Cao, X. 3D printed silk-gelatin hydrogel scaffold with different porous structure and cell seeding strategy for cartilage regeneration. Bioact. Mater. 2021, 6, 3396–3410. [Google Scholar] [CrossRef]

- Mokhtari, H.; Kharaziha, M.; Karimzadeh, F.; Tavakoli, S. An injectable mechanically robust hydrogel of Kappa-carrageenan-dopamine functionalized graphene oxide for promoting cell growth. Carbohydr. Polym. 2019, 214, 234–249. [Google Scholar] [CrossRef] [PubMed]

- Onuwaje, I.; Phillips, J.B. Chapter 16—Three-dimensional culture systems in central nervous system research. In Handbook of Innovations in Central Nervous System Regenerative Medicine; Salgado, A.J., Ed.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 571–601. [Google Scholar] [CrossRef]

- Bai, S.; Zhang, X.; Lu, Q.; Sheng, W.; Liu, L.; Dong, B.; Kaplan, D.; Zhu, H. Reversible hydrogel–solution system of silk with high beta-sheet content. Biomacromolecules 2014, 15, 3044–3051. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Shi, J.; Zhu, R.; Zhang, J.; Zhang, Z.; Ma, D.; Hou, Y.; Lin, F.; Yang, J.; et al. A Biomimetic Silk Fibroin/Sodium Alginate Composite Scaffold for Soft Tissue Engineering. Sci. Rep. 2016, 6, 39477. [Google Scholar] [CrossRef]

- Kolev, A.; Vassileva, V.; Georgiev, H. Interaction Between Fibroin and Alginate in the Corresponding Blended Films. J. Chem. Technol. Metall. 2017, 52, 449–456. [Google Scholar]

- Liu, Q.; Jain, T.; Peng, C.; Peng, F.; Narayanan, A.; Joy, A. Introduction of Hydrogen Bonds Improves the Shape Fidelity of Viscoelastic 3D Printed Scaffolds while Maintaining Their Low-Temperature Printability. Macromolecules 2020, 53, 3690–3699. [Google Scholar] [CrossRef]

- Farasatkia, A.; Kharaziha, M.; Ashrafizadeh, F.; Salehi, S. Transparent silk/gelatin methacrylate (GelMA) fibrillar film for corneal regeneration. Mater. Sci. Eng. C 2021, 120, 111744. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Wang, X.; Rnjak, J.; Weiss, A.; Kaplan, D.L. Biomaterials derived from silk–tropoelastin protein systems. Biomaterials 2010, 31, 8121–8131. [Google Scholar] [CrossRef]

- Xue, Y.; Lofland, S.; Hu, X. Comparative Study of Silk-Based Magnetic Materials: Effect of Magnetic Particle Types on the Protein Structure and Biomaterial Properties. Int. J. Mol. Sci. 2020, 21, 7583. [Google Scholar] [CrossRef]

- Hua, S.; Ma, H.; Li, X.; Yang, H.; Wang, A. pH-sensitive sodium alginate/poly(vinyl alcohol) hydrogel beads prepared by combined Ca2+ crosslinking and freeze-thawing cycles for controlled release of diclofenac sodium. Int. J. Biol. Macromol. 2010, 46, 517–523. [Google Scholar] [CrossRef]

- Gianak, O.; Pavlidou, E.; Sarafidis, C.; Karageorgiou, V.; Deliyanni, E. Silk Fibroin Nanoparticles for Drug Delivery: Effect of Bovine Serum Albumin and Magnetic Nanoparticles Addition on Drug Encapsulation and Release. Separations 2018, 5, 25. [Google Scholar] [CrossRef]

- Fahad, M.; Khan, M.; Gilbert, M. Investigation of thermal gel formation of methylcellulose in glycols using dsc and xrd. Gels 2021, 7, 205. [Google Scholar] [CrossRef]

- Abhilash, V.; Rajender, N. X-ray diffraction spectroscopy of polymer nanocomposites. In Spectroscopy of Polymer Nanocomposites; Elsevier: Amsterdam, The Netherlands, 2016; pp. 410–451. [Google Scholar]

- Mouritz, A.P. Polymers for aerospace structures. In Introduction to Aerospace Materials; Elsevier: Amsterdam, The Netherlands, 2012; pp. 268–302. [Google Scholar]

- Liang, J.; Wang, R.; Chen, R. The impact of cross-linking mode on the physical and antimicrobial properties of a chitosan/bacterial cellulose composite. Polymers 2019, 11, 491. [Google Scholar] [CrossRef]

- Deshmukh, K.; Kovářík, T.; Muzaffar, A.; Ahamed, M.B.; Pasha, S.K. Mechanical analysis of polymers. In Polymer Science and Innovative Applications; Elsevier: Amsterdam, The Netherlands, 2020; pp. 117–152. [Google Scholar]

- Kyle, S.; Jessop, Z.; Al-Sabah, A.; Whitaker, I.S. Printability of candidate biomaterials for extrusion based 3D printing: State-of-the-art. Adv. Healthc. Mater. 2017, 6, 1700264. [Google Scholar] [CrossRef] [PubMed]

- Than, Y.M.; Suriyarak, S.; Titapiwatanakun, V. Rheological Investigation of Hydroxypropyl Cellulose–Based Filaments for Material Extrusion 3D Printing. Polymers 2022, 14, 1108. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhou, J.; Feng, C.; Shi, H.; Zhao, G.; Bian, Y. Rheological behavior, 3D printability and the formation of scaffolds with cellulose nanocrystals/gelatin hydrogels. J. Mater. Sci. 2020, 55, 15709–15725. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Q.; Xu, S.; Zheng, Q.; Cao, X. Preparation and properties of 3D printed alginate–chitosan polyion complex hydrogels for tissue engineering. Polymers 2018, 10, 664. [Google Scholar] [CrossRef]

- Rasoulianboroujeni, M.; Kiaie, N.; Tabatabaei, F.; Yadegari, A.; Fahimipour, F.; Khoshroo, K.; Tayebi, L. Dual Porosity Protein-based Scaffolds with Enhanced Cell Infiltration and Proliferation. Sci. Rep. 2018, 8, 14889. [Google Scholar] [CrossRef] [PubMed]

- Anguiano, M.; Castilla, C.; Maška, M.; Ederra, C.; Peláez, R.; Morales, X.; Munoz-Arrieta, G.; Mujika, M.; Kozubek, M.; Munoz-Barrutia, A. Characterization of three-dimensional cancer cell migration in mixed collagen-Matrigel scaffolds using microfluidics and image analysis. PLoS ONE 2017, 12, e0171417. [Google Scholar] [CrossRef]

- Vincent, A. Study of Porosity of Gelatin-Alginate Hydrogels to Model Brain Matter for Studying Traumatic Brain Injuries Study of Porosity of Gelatin-Alginate Hydrogels to Model Brain Matter for Studying Traumatic Brain Injuries. Ph.D Thesis, University of Connecticut, Stamford, CT, USA, 2022. [Google Scholar]

- Svagan, A.J.; Samir, M.; Berglund, L.A. Biomimetic foams of high mechanical performance based on nanostructured cell walls reinforced by native cellulose nanofibrils. Adv. Mater. 2008, 20, 1263–1269. [Google Scholar] [CrossRef]

- Nge, T.T.; Nogi, M.; Yano, H.; Sugiyama, J. Microstructure and mechanical properties of bacterial cellulose/chitosan porous scaffold. Cellulose 2010, 17, 349–363. [Google Scholar] [CrossRef]

- de Moraes, M.A.; Silva, M.; Weska, R.; Beppu, M.M. Silk fibroin and sodium alginate blend: Miscibility and physical characteristics. Mater. Sci. Eng. C 2014, 40, 85–91. [Google Scholar] [CrossRef] [PubMed]

- Gharasoo, M.; Elsner, M.; Van Cappellen, P.; Thullner, M. Pore-Scale Heterogeneities Improve the Degradation of a Self-Inhibiting Substrate: Insights from Reactive Transport Modeling. Environ. Sci. Technol. 2022, 56, 13008–13018. [Google Scholar] [CrossRef] [PubMed]

- Barcel, X.; Eichholz, K.; Garcia, O.; Kelly, D.J. Tuning the Degradation Rate of Alginate-Based Bioinks for Bioprinting Functional Cartilage Tissue. Biomedicines 2022, 10, 1621. [Google Scholar] [CrossRef]

- Baniasadi, M.; Minary-Jolandan, M. Alginate-collagen fibril composite hydrogel. Materials 2015, 8, 799–814. [Google Scholar] [CrossRef]

- Keten, S.; Buehler, M.J. Geometric confinement governs the rupture strength of H-bond assemblies at a critical length scale. Nano Lett. 2008, 8, 743–748. [Google Scholar] [CrossRef]

- Drury, J.L.; Dennis, R.; Mooney, D.J. The tensile properties of alginate hydrogels. Biomaterials 2004, 25, 3187–3199. [Google Scholar] [CrossRef]

- Liling, G.; Di, Z.; Jiachao, X.; Xin, G.; Xiaoting, F.; Qing, Z. Effects of ionic crosslinking on physical and mechanical properties of alginate mulching films. Carbohydr. Polym. 2016, 136, 259–265. [Google Scholar] [CrossRef]

- Barros, A.A.; Oliveira, C.; Lima, E.; Duarte, A.; Reis, R.L. Gelatin-based biodegradable ureteral stents with enhanced mechanical properties. Appl. Mater. Today 2016, 5, 9–18. [Google Scholar] [CrossRef]

- Feng, Y.; Li, X.; Li, M.; Ye, D.; Zhang, Q.; You, R.; Xu, W. Facile preparation of biocompatible silk fibroin/cellulose nanocomposite films with high mechanical performance. ACS Sustain. Chem. Eng. 2017, 5, 6227–6236. [Google Scholar] [CrossRef]

- Hassanzadeh, P.; Kazemzadeh-Narbat, M.; Rosenzweig, R.; Zhang, X.; Khademhosseini, A.; Annabi, N.; Rolandi, M. Ultrastrong and flexible hybrid hydrogels based on solution self-assembly of chitin nanofibers in gelatin methacryloyl (GelMA). J. Mater. Chem. B 2016, 4, 2539–2543. [Google Scholar] [CrossRef] [PubMed]

- Yin, K.; Divakar, P.; Wegst, U.G. Plant-derived nanocellulose as structural and mechanical reinforcement of freeze-cast chitosan scaffolds for biomedical applications. Biomacromolecules 2019, 20, 3733–3745. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Zheng, H.; Chen, J.; Li, S.; Huang, J.; Zhou, C. Chitosan-chitin nanocrystal composite scaffolds for tissue engineering. Carbohydr. Polym. 2016, 152, 832–840. [Google Scholar] [CrossRef] [PubMed]

- Caliari, S.R.; Burdick, J.A. A practical guide to hydrogels for cell culture. Nat. Methods 2016, 13, 405–414. [Google Scholar] [CrossRef] [PubMed]

- Handorf, A.M.; Zhou, Y.; Halanski, M.; Li, W.-J. Tissue stiffness dictates development, homeostasis, and disease progression. Organogenesis 2015, 11, 1–15. [Google Scholar] [CrossRef]

- Thiele, J.; Ma, Y.; Bruekers, S.; Ma, S.; Huck, W.T.S. 25th anniversary article: Designer hydrogels for cell cultures: A materials selection guide. Adv. Mater. 2014, 26, 125–147. [Google Scholar] [CrossRef]

- Kim, I.L.; Mauck, R.; Burdick, J.A. Hydrogel design for cartilage tissue engineering: A case study with hyaluronic acid. Biomaterials 2011, 32, 8771–8782. [Google Scholar] [CrossRef]

- Temple-Wong, M.M.; Bae, W.; Chen, M.; Bugbee, W.; Amiel, D.; Coutts, R.; Lotz, M.; Sah, R.L. Biomechanical, structural, and biochemical indices of degenerative and osteoarthritic deterioration of adult human articular cartilage of the femoral condyle. Osteoarthr. Cartil. 2009, 17, 1469–1476. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, X.; Su, T.; Lu, F.; Chang, Q.; Gao, J. Recent Advances in Macroporous Hydrogels for Cell Behavior and Tissue Engineering. Gels 2022, 8, 606. [Google Scholar] [CrossRef]

- Nikam, V.S.; Punde, D.; Bhandari, R.S. Silk fibroin nanofibers enhance cell adhesion of blood-derived fibroblast-like cells: A potential application for wound healing. Indian J. Pharmacol. 2020, 52, 306–312. [Google Scholar] [CrossRef]

- Yu, D.; Wang, J.; Qian, K.; Yu, J.; Zhu, H. Effects of nanofibers on mesenchymal stem cells: Environmental factors affecting cell adhesion and osteogenic differentiation and their mechanisms. J. Zhejiang Univ. B 2020, 21, 871–884. [Google Scholar] [CrossRef]

- Holzwarth, J.M.; Ma, P.X. Biomimetic nanofibrous scaffolds for bone tissue engineering. Biomaterials 2011, 32, 9622–9629. [Google Scholar] [CrossRef] [PubMed]

- Tong, X.; Jiang, J.; Zhu, D.; Yang, F. Hydrogels with dual gradients of mechanical and biochemical cues for deciphering cell-niche interactions. ACS Biomater. Sci. Eng. 2016, 2, 845–852. [Google Scholar] [CrossRef] [PubMed]

- Janmey, P.A.; Miller, R.T. Mechanisms of mechanical signaling in development and disease. J. Cell Sci. 2011, 124, 9–18. [Google Scholar] [CrossRef] [PubMed]

- Kai, D.; Prabhakaran, M.; Stahl, B.; Eblenkamp, M.; Wintermantel, E.; Ramakrishna, S. Mechanical properties and in vitro behavior of nanofiber-hydrogel composites for tissue engineering applications. Nanotechnology 2012, 23, 95705. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.M.; Sultan, M.; Kim, S.; Kumar, V.; Yeon, Y.; Lee, O.; Park, C.H. Artificial auricular cartilage using silk fibroin and polyvinyl alcohol hydrogel. Int. J. Mol. Sci. 2017, 18, 1707. [Google Scholar] [CrossRef]

- Griffin, M.F.; Premakumar, Y.; Seifalian, A.; Szarko, M.; Butler, P.E.M. Biomechanical Characterisation of the Human Auricular Cartilages; Implications for Tissue Engineering. Ann. Biomed. Eng. 2016, 44, 3460–3467. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammadpour, Z.; Kharaziha, M.; Zarrabi, A. 3D-Printing of Silk Nanofibrils Reinforced Alginate for Soft Tissue Engineering. Pharmaceutics 2023, 15, 763. https://doi.org/10.3390/pharmaceutics15030763

Mohammadpour Z, Kharaziha M, Zarrabi A. 3D-Printing of Silk Nanofibrils Reinforced Alginate for Soft Tissue Engineering. Pharmaceutics. 2023; 15(3):763. https://doi.org/10.3390/pharmaceutics15030763

Chicago/Turabian StyleMohammadpour, Zahra, Mahshid Kharaziha, and Ali Zarrabi. 2023. "3D-Printing of Silk Nanofibrils Reinforced Alginate for Soft Tissue Engineering" Pharmaceutics 15, no. 3: 763. https://doi.org/10.3390/pharmaceutics15030763

APA StyleMohammadpour, Z., Kharaziha, M., & Zarrabi, A. (2023). 3D-Printing of Silk Nanofibrils Reinforced Alginate for Soft Tissue Engineering. Pharmaceutics, 15(3), 763. https://doi.org/10.3390/pharmaceutics15030763