Development of a Standardized Method for Measuring Bioadhesion and Mucoadhesion That Is Applicable to Various Pharmaceutical Dosage Forms

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Formulations

2.2.1. Pellets

2.2.2. Minitablets

2.2.3. Emulsions

2.3. Gastric Mucoadhesion

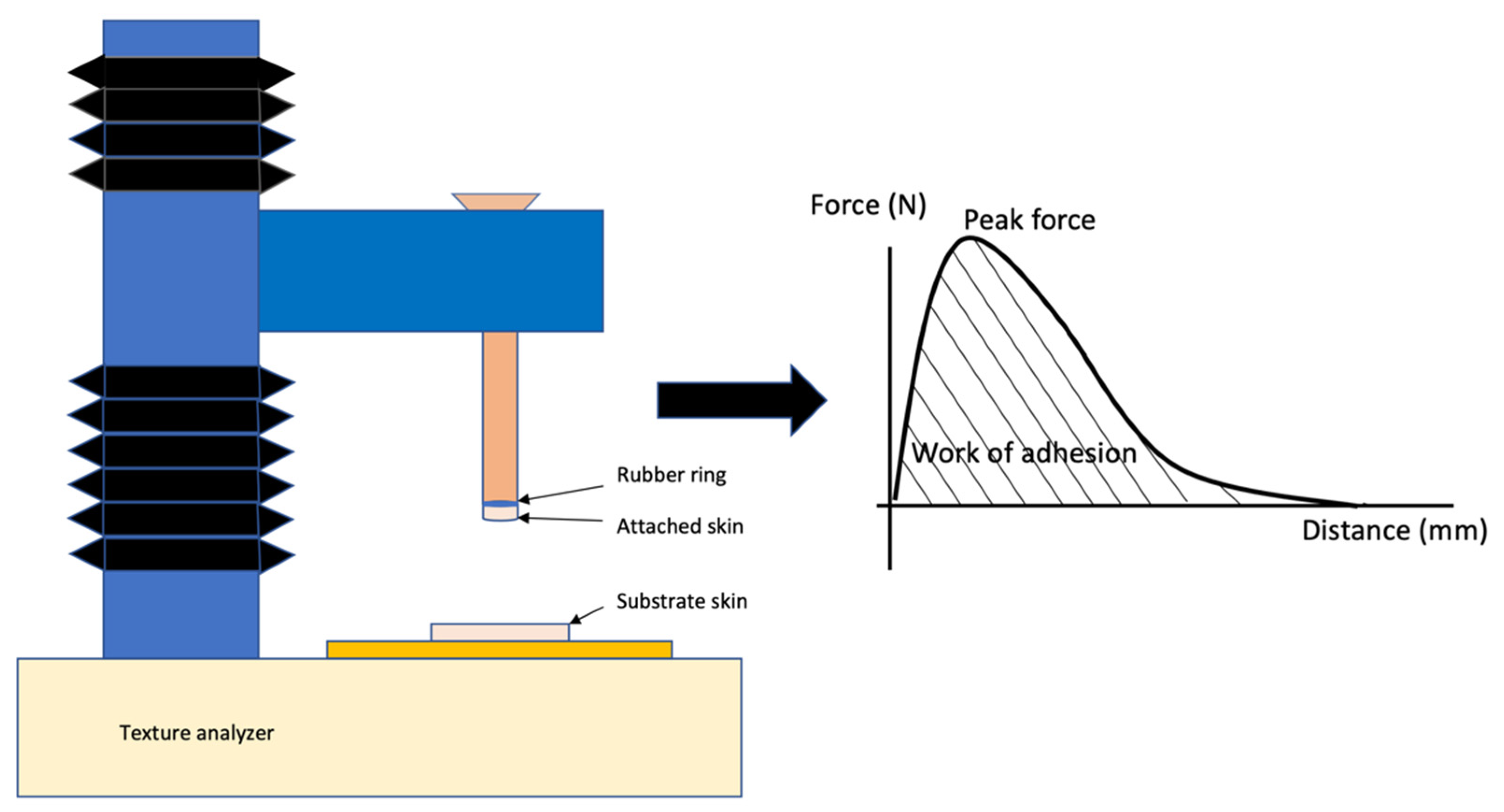

2.4. Topical Bioadhesion

2.5. Texture Analyzer

2.5.1. Experimental Settings

2.5.2. Method Development

2.6. Statistical Analysis

3. Results

3.1. Parameters Analysis

3.2. Gastric Mucoadhesion and Statistical Study

3.2.1. Pellets

3.2.2. Minitablets

3.3. Emulsions

3.4. Case Study

4. Discussions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Force of Adhesion | Work of Adhesion | |||

|---|---|---|---|---|

| Assay Number | No Film (N) | Film (N) | No Film (mJ) | Film (mJ) |

| 1 | 0.031 | 0.056 | 0.058 | 0.137 |

| 2 | 0.014 | 0.049 | 0.011 | 0.273 |

| 3 | 0.012 | 0.043 | 0.003 | 0.260 |

| 4 | 0.046 | 0.21 | 0.150 | 0.299 |

| 5 | 0.038 | 0.058 | 0.210 | 0.063 |

| 6 | 0.029 | 0.07 | 0.042 | 0.085 |

| 7 | 0.014 | 0.08 | 0.038 | 0.061 |

| 8 | 0.019 | 0.051 | 0.069 | 0.230 |

| 9 | 0.026 | 0.042 | 0.015 | 0.260 |

| Average | 0.025 | 0.073 | 0.07 | 0.19 |

| DS | 0.012 | 0.053 | 0.07 | 0.10 |

| CV | 0.460 | 0.720 | 1.05 | 0.53 |

| Fore of Adhesion | Work of Adhesion | |||

|---|---|---|---|---|

| Assay Number | No Film (N) | Film (N) | No Film (mJ) | Film (mJ) |

| 1 | 0.018 | 0.044 | 0.018 | 0.175 |

| 2 | 0.033 | 0.049 | 0.051 | 0.123 |

| 3 | 0.018 | 0.043 | 0.045 | 0.124 |

| 4 | 0.023 | 0.031 | 0.042 | 0.076 |

| 5 | 0.025 | 0.035 | 0.035 | 0.010 |

| 6 | 0.030 | 0.040 | 0.084 | 0.160 |

| Average | 0.025 | 0.040 | 0.046 | 0.111 |

| DS | 0.006 | 0.007 | 0.022 | 0.060 |

| CV | 0.251 | 0.161 | 0.477 | 0.541 |

| Force of Adhesion | Work of Adhesion | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Assay Number | Mock (N) | Non-BE Emulsion (N) | BE (N) | BE 1 Year (N) | BE Wet (N) | Mock (mJ) | Non-BE Emulsion (mJ) | BE (mJ) | BE 1 Year (mJ) | BE Wet (mJ) |

| 1 | 0.080 | 0.080 | 0.320 | 0.330 | 0.170 | 0.01 | 0.007 | 0.21 | 0.178 | 0.09 |

| 2 | 0.160 | 0.470 | 0.420 | 0.230 | 0.020 | 0.37 | 0.480 | 0.08 | ||

| 3 | 0.110 | 0.380 | 0.380 | 0.240 | 0.023 | 0.37 | 0.300 | 0.08 | ||

| 4 | 0.430 | 0.55 | ||||||||

| 5 | 0.400 | 0.46 | ||||||||

| Average | 0.12 | 0.40 | 0.38 | 0.21 | 0.01 | 0.02 | 0.39 | 0.32 | 0.08 | |

| DS | 0.04 | 0.06 | 0.05 | 0.04 | 0.0001 | 0.01 | 0.13 | 0.15 | 0.00 | |

| CV | 0.35 | 0.14 | 0.12 | 0.19 | 0.51 | 0.32 | 0.48 | 0.05 | ||

References

- Kumar, K.; Dhawan, N.; Sharma, H.; Vaidya, S.; Vaidya, B. Bioadhesive Polymers: Novel Tool for Drug Delivery. Artif. Cells Nanomed. Biotechnol. 2014, 42, 274–283. [Google Scholar] [CrossRef] [PubMed]

- Bassi da Silva, J.; de Ferreira, S.B.S.; de Freitas, O.; Bruschi, M.L. A Critical Review about Methodologies for the Analysis of Mucoadhesive Properties of Drug Delivery Systems. Drug Dev. Ind. Pharm. 2017, 43, 1053–1070. [Google Scholar] [CrossRef] [PubMed]

- Hägerström, H.; Edsman, K. Interpretation of Mucoadhesive Properties of Polymer. J. Pharm. Pharmacol. 2001, 53, 1589–1599. [Google Scholar] [CrossRef] [PubMed]

- Djekic, L.; Martinovic, M. In Vitro, Ex Vivo and In Vivo Methods for Characterization of Bioadhesiveness of Drug Delivery Systems. In Bioadhesives in Drug Delivery; Scrivener Publishing LLC: Beverly, MA, USA, 2020. [Google Scholar]

- Carvalho, F.C.; Calixto, G.; Hatakeyama, I.N.; Luz, G.M.; Gremião, M.P.D.; Chorilli, M. Rheological, Mechanical, and Bioadhesive Behavior of Hydrogels to Optimize Skin Delivery Systems. Drug Dev. Ind. Pharm. 2013, 39, 1750–1757. [Google Scholar] [CrossRef] [PubMed]

- Palacio, M.L.B.; Bhushan, B. Bioadhesion: A Review of Concepts and Applications. Philos. Trans. R. Soc. A 2012, 370, 2321. [Google Scholar] [CrossRef] [PubMed]

- Wong, R.; Geyer, S.; Weninger, W.; Guimberteau, J.C.; Wong, J.K. The Dynamic Anatomy and Patterning of Skin. Exp. Dermatol. 2016, 25, 92–98. [Google Scholar] [CrossRef]

- Hägerström, H.; Bergström, C.A.S.; Edsman, K. The Importance of Gel Properties for Mucoadhesion Measurements: A Multivariate Data Analysis Approach. J. Pharm. Pharmacol. 2004, 56, 161–168. [Google Scholar] [CrossRef] [PubMed]

- Duchene, D.; Ponchel, G. Bioadhesion: A New Pharmacotechnical Method for Improving Therapeutic Efficiency. STD Pharma 1989, 5, 830–838. [Google Scholar]

- Dick, I.P.; Scott, R.C. Pig Ear Skin as an In-Vitro Model for Human Skin Permeability. J. Pharm. Pharmacol. 1992, 44, 640–645. [Google Scholar] [CrossRef] [PubMed]

- Bruschi, M.L.; Jones, D.S.; Panzeri, H.; Gremiao, M.P.D.; de Freitas, O.; Lara, E.H.G. Semisolid Systems Containing Propolis for the Treatment of Periodontal Disease: In Vitro Release Kinetics, Syringeability, Rheological, Textural, and Mucoadhesive Properties. J. Pharm. Sci. 2007, 96, 2074–2089. [Google Scholar] [CrossRef] [PubMed]

- 01 General Notices—European Pharmacopoeia 10.8. Available online: https://pheur.edqm.eu/app/10-8/content/10-8/10000E.htm?highlight=on&terms=1.2.3%20temperature&terms=temperature&terms=temperature&terms=temperature&terms=temperature&terms=1.2.3%20temperature&terms=temperature&terms=temperature&terms=temperature&terms=temperature&terms=temperature (accessed on 31 August 2022).

- Woertz, C.; Preis, M.; Breitkreutz, J.; Kleinebudde, P. Assessment of test methods evaluating mucoadhesive polymers and dosage forms: An overview. Eur. J. Pharm. Biopharm. 2013, 85, 843–853. [Google Scholar] [CrossRef] [PubMed]

- Hägerström, H.; Edsman, K. Limitations of the Rheological Mucoadhesion Method: The Effect of the Choice of Conditions and the Rheological Synergism Parameter. Eur. J. Pharm. Sci. 2003, 18, 349–357. [Google Scholar] [CrossRef]

- Gonzalez-Ojer, C.; Costa-Martins, D.; Maria, R.; Miñarro-Carmona, M.; Ticó-Grau, J.R.A.; García-Montoya, E.; Pérez-Lozano, P.; Roig-Carreras, M.; Sánchez-Porqueres, N. ES2608794T3_Original_document_20200610102618.Pdf 2013, 29. Available online: https://worldwide.espacenet.com/patent/search/family/047520732/publication/ES2608794T3?q=ES2608794T3 (accessed on 16 September 2022).

- ISO 24444:2019 (SPF), Cosmetics—Sun Protection Test Methods—In Vivo Determination of the Sun Protection Factor 2019. Available online: https://www.iso.org/standard/72250.html (accessed on 16 September 2022).

- Karakucuk, A.; Tort, S.; Han, S.; Oktay, A.N.; Celebi, N. Etodolac Nanosuspension Based Gel for Enhanced Dermal Delivery: In Vitro and in Vivo Evaluation. J. Microencapsul. 2021, 38, 218–232. [Google Scholar] [CrossRef] [PubMed]

- Ivarsson, D.; Wahlgren, M. Comparison of in Vitro Methods of Measuring Mucoadhesion: Ellipsometry, Tensile Strength and Rheological Measurements. Colloids Surf. B Biointerfaces 2012, 92, 353–359. [Google Scholar] [CrossRef]

| Ingredients | % |

|---|---|

| Vinylpyrrolidone–vinyl acetate copolymer | 5.0 |

| Hypromellose | 5.0 |

| Sodium bibarbonate | 30.0 |

| Barium sulfate | 20.0 |

| Microcrystalline cellulose | 40.0 |

| Ingredients | % |

|---|---|

| Pellets in Table 1 | 70 |

| Acrylic acid polymer solution (10%) (polycarbophil USP) | 30 |

| Ingredients | % |

|---|---|

| Sodium croscarmellose | 2.0 |

| Magnesium stearate | 2.0 |

| Talc | 4.0 |

| Isomaltose | ad 100 |

| Ingredients | % |

|---|---|

| Non-bioadhesive minitablets | 98.0 |

| Acrylic acid polymer solution (1%) (polycarbophil USP) | 2.0 |

| Phase | Ingredients | % |

|---|---|---|

| A | Behenyl alcohol | 3.0 |

| Caprylic/capric trigliceride | 3.0 | |

| Dodecyl benzoate | 3.0 | |

| 7-methyloctanoate | 4.0 | |

| Phenoxyethanol | 0.8 | |

| Benzoic acid 2-ethylhexyl ester | 5.0 | |

| B | Distilled water | ad 100 |

| Disodium EDTA | 1.0 | |

| Tris(hydroxymethyl)aminomethane | 2.4 | |

| Glycerine | 0.8 | |

| Acrylic acid polymer (polycarbophil USP) | X 1 | |

| C | Ethylhexyloxy hydroxyphenyl methoxyphenyl triazine | 7.0 |

| Benzotriazolyl tetramethylbutylphenol | 7.0 | |

| Ethanol | 10.0 | |

| Propylenglycol | 24.0 |

| Pellets | F (N) | W (mJ) |

|---|---|---|

| No film | 0.025 ± 0.012 | 0.066 ± 0.070 |

| Film | 0.073 ± 0.053 | 0.185 ± 0.135 |

| Difference (film−no film) | 0.048 | 0.119 |

| Increase (%) | 187.8 | 179.8 |

| Minitablets | F (N) | W (mJ) |

|---|---|---|

| No film | 0.025 ± 0.006 | 0.046 ± 0.022 |

| Film | 0.040 ± 0.007 | 0.111 ± 0.060 |

| Difference (film−no film) | 0.015 | 0.065 |

| Increase (%) | 60 | 141.3 |

| Samples | F (N) | W (mJ) |

|---|---|---|

| Non-BE | 0.117 ± 0.040 | 0.017 ± 0.009 |

| BE | 0.400 ± 0.056 | 0.392 ± 0.126 |

| Difference (BE−Non-BE) | 0.283 | 0.375 |

| Increase (%) | 241.9 | 2205.9 |

| Samples | F (N) | W (mJ) |

|---|---|---|

| Mock | 0.080 | 0.011 |

| Non-BE | 0.117 ± 0.040 | 0.017 ± 0.009 |

| BE | 0.400 ± 0.056 | 0.392 ± 0.126 |

| Difference (BE−mock) | 0.320 | 0.381 |

| Increase (%) | 400.0 | 3463.6 |

| Difference (BE−Non-BE) | 0.283 | 0.375 |

| Increase (%) | 241.8 | 2205.9 |

| BE after 1 year | 0.377 ± 0.045 | 0.319 ± 0.152 |

| Difference (ba.em-1y−mock) | 0.297 | 0.308 |

| Increase (%) | 371.3 | 2803.0 |

| Difference (ba.em-1y−Non-BE) | 0.260 | 0.302 |

| Increase (%) | 222.2 | 1776.0 |

| Bioadhesive emulsion wet | 0.212 ± 0.041 | 0.081 ± 0.004 |

| Difference (ba. em-wet−mock) | 0.132 | 0.070 |

| Increase (%) | 165.0 | 638.8 |

| Difference (ba. em-wet−Non-BE) | 0.095 | 0.064 |

| Increase (%) | 81.2 | 376.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amorós-Galicia, L.; Nardi-Ricart, A.; Verdugo-González, C.; Arroyo-García, C.M.; García-Montoya, E.; Pérez-Lozano, P.; Suñé-Negre, J.M.; Suñé-Pou, M. Development of a Standardized Method for Measuring Bioadhesion and Mucoadhesion That Is Applicable to Various Pharmaceutical Dosage Forms. Pharmaceutics 2022, 14, 1995. https://doi.org/10.3390/pharmaceutics14101995

Amorós-Galicia L, Nardi-Ricart A, Verdugo-González C, Arroyo-García CM, García-Montoya E, Pérez-Lozano P, Suñé-Negre JM, Suñé-Pou M. Development of a Standardized Method for Measuring Bioadhesion and Mucoadhesion That Is Applicable to Various Pharmaceutical Dosage Forms. Pharmaceutics. 2022; 14(10):1995. https://doi.org/10.3390/pharmaceutics14101995

Chicago/Turabian StyleAmorós-Galicia, Lola, Anna Nardi-Ricart, Clara Verdugo-González, Carmen Martina Arroyo-García, Encarna García-Montoya, Pilar Pérez-Lozano, Josep Mª Suñé-Negre, and Marc Suñé-Pou. 2022. "Development of a Standardized Method for Measuring Bioadhesion and Mucoadhesion That Is Applicable to Various Pharmaceutical Dosage Forms" Pharmaceutics 14, no. 10: 1995. https://doi.org/10.3390/pharmaceutics14101995

APA StyleAmorós-Galicia, L., Nardi-Ricart, A., Verdugo-González, C., Arroyo-García, C. M., García-Montoya, E., Pérez-Lozano, P., Suñé-Negre, J. M., & Suñé-Pou, M. (2022). Development of a Standardized Method for Measuring Bioadhesion and Mucoadhesion That Is Applicable to Various Pharmaceutical Dosage Forms. Pharmaceutics, 14(10), 1995. https://doi.org/10.3390/pharmaceutics14101995