Cell Density Effects in Different Cell Culture Media and Their Impact on the Propagation of Foot-And-Mouth Disease Virus

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cells and Cell Culture Media

2.2. Viruses and Virus Titrations

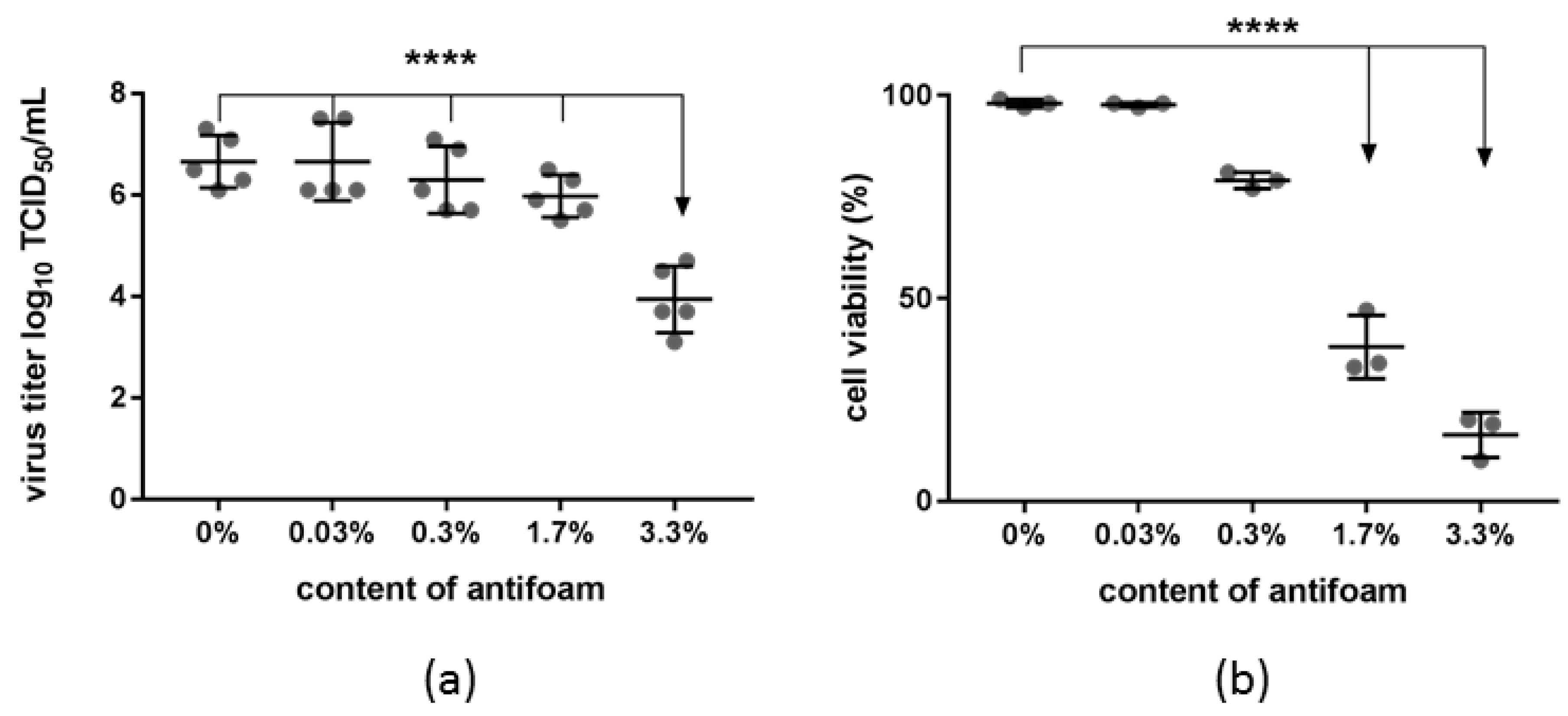

2.3. Antifoam Studies

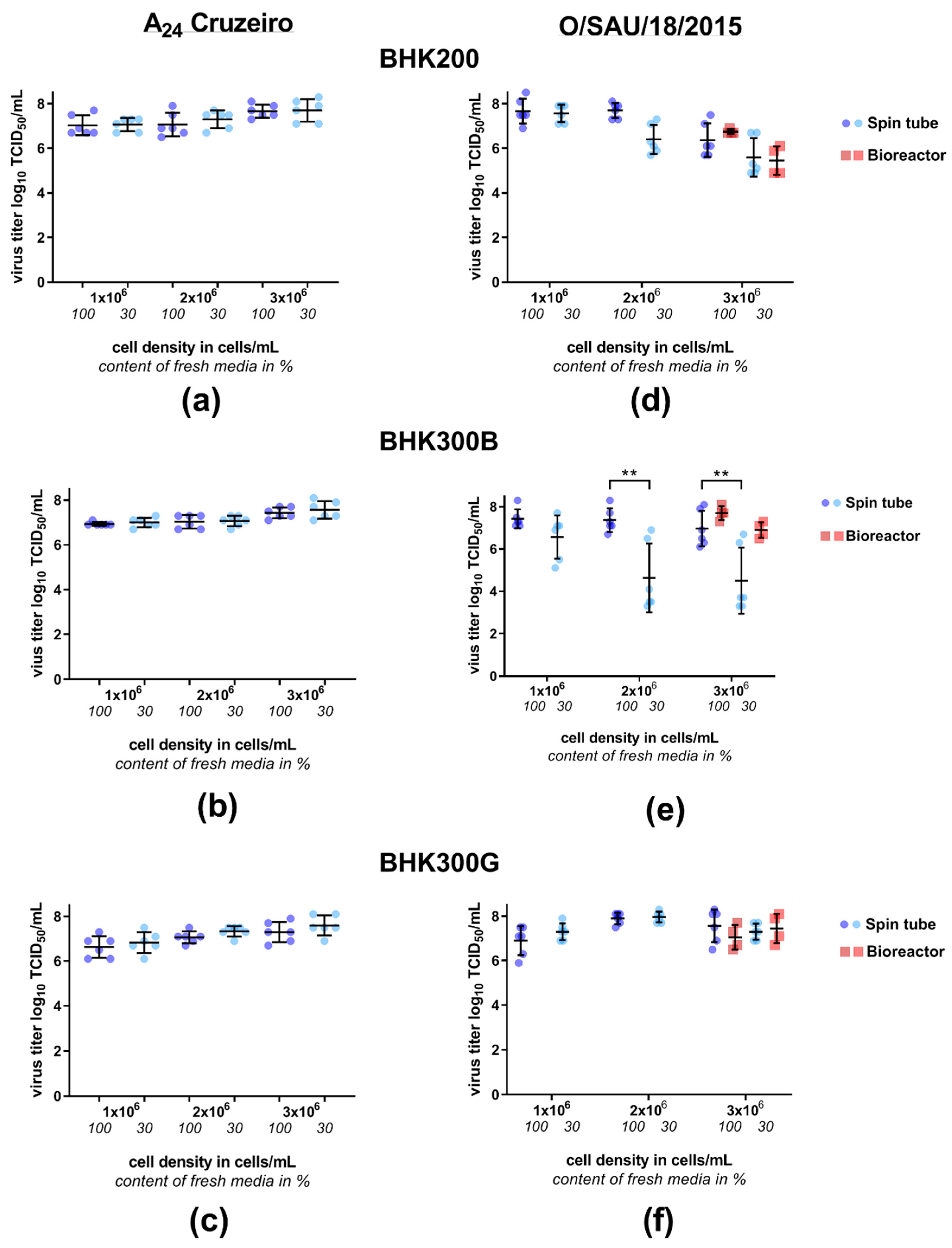

2.4. Cell Density Experiments

2.4.1. Spin Tube Experiments

2.4.2. Bioreactor Experiments

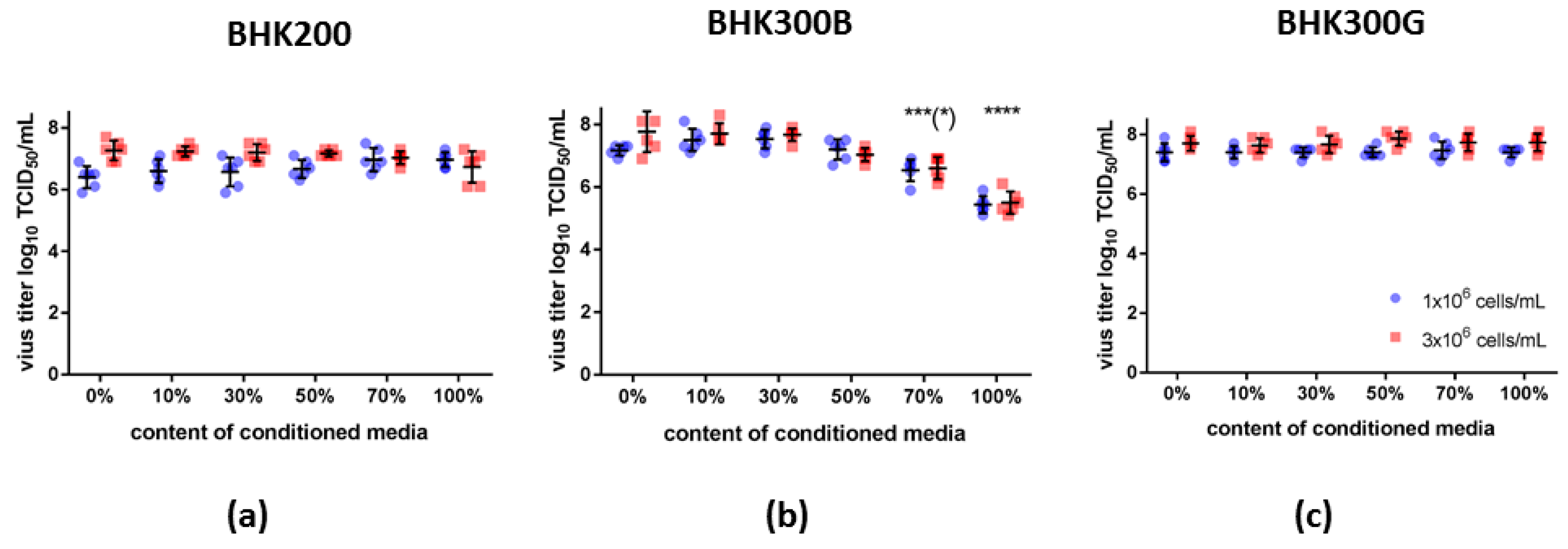

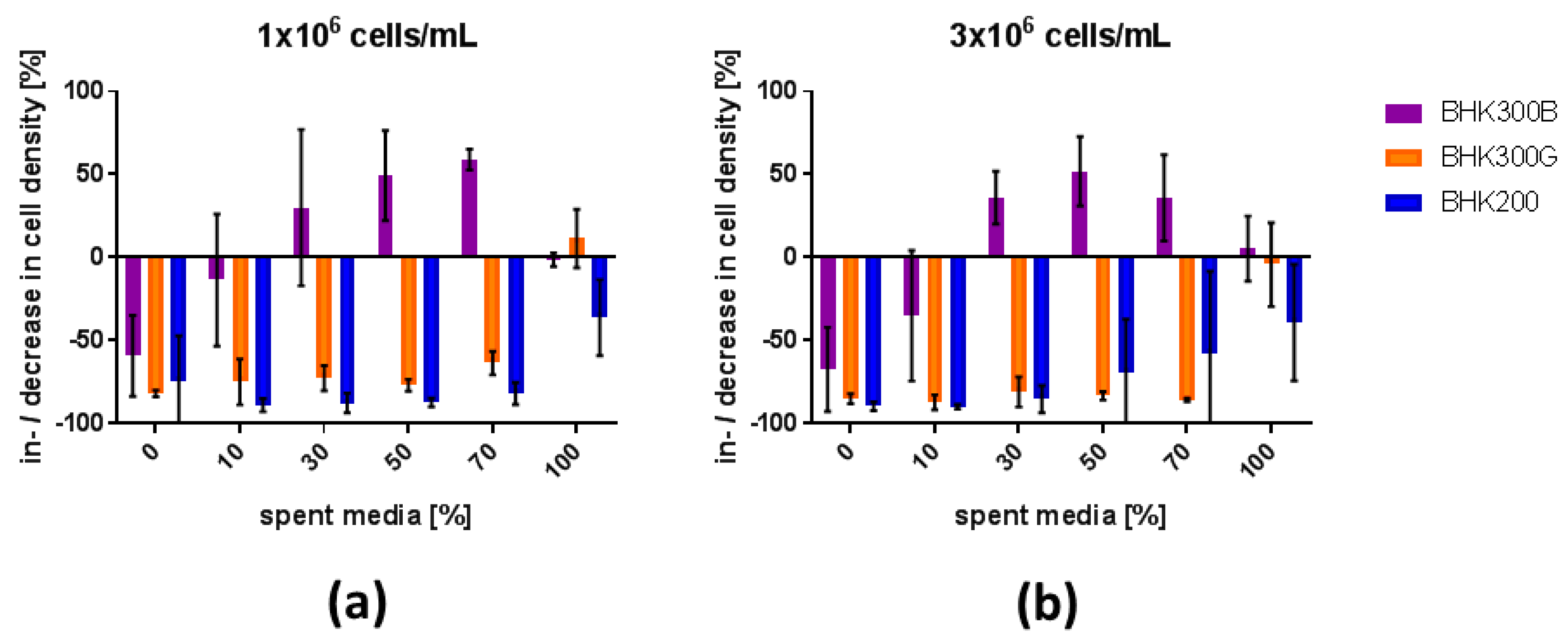

2.5. Effect of Conditioned Culture Media on Virus Propagation

2.6. Batch Culture Experiments

2.7. Calculations

2.7.1. Specific Growth Rate: μ (h−1)

2.7.2. Cell Division Number (Cd):

2.8. Statistical Analysis

3. Results

3.1. Antifoam Studies

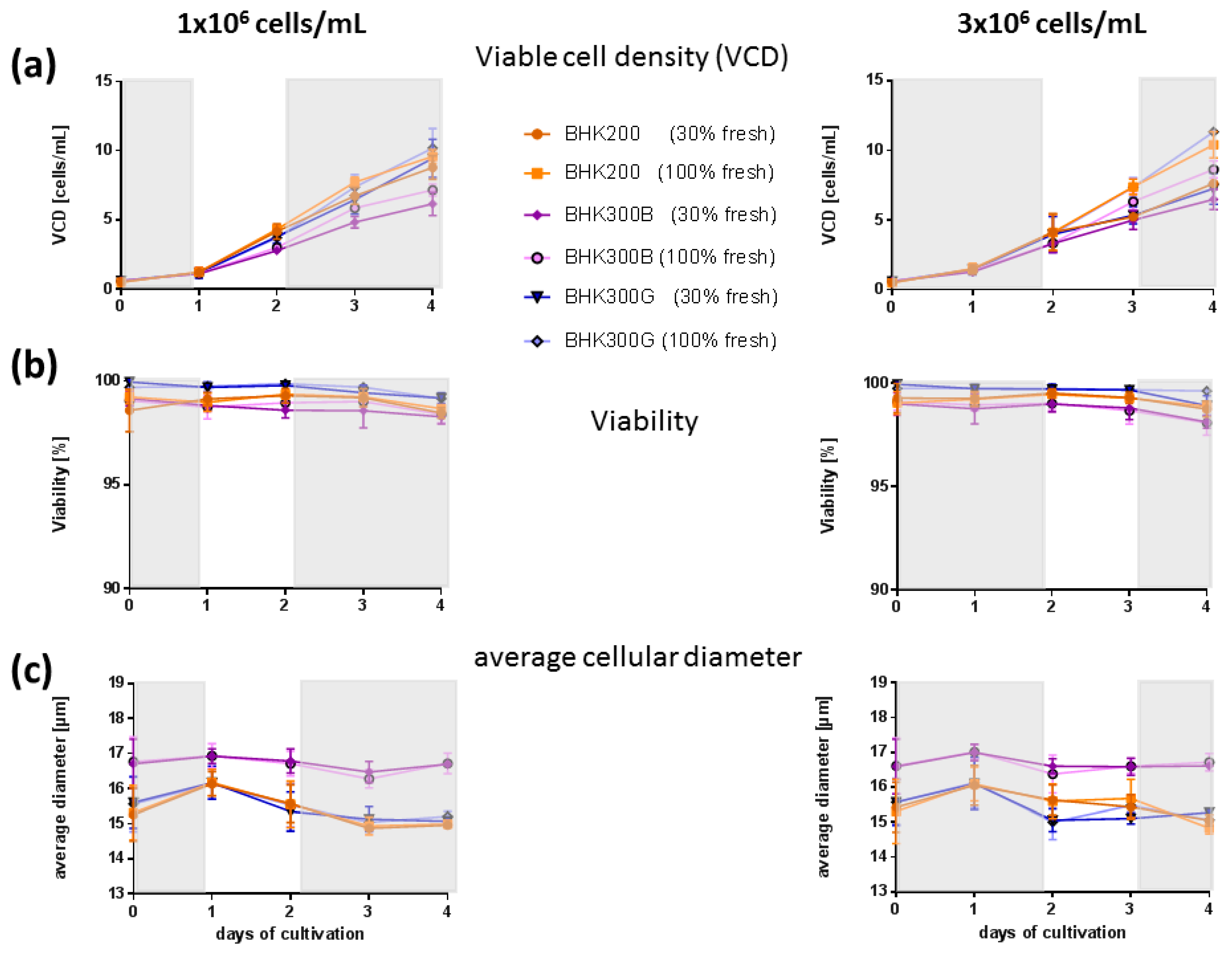

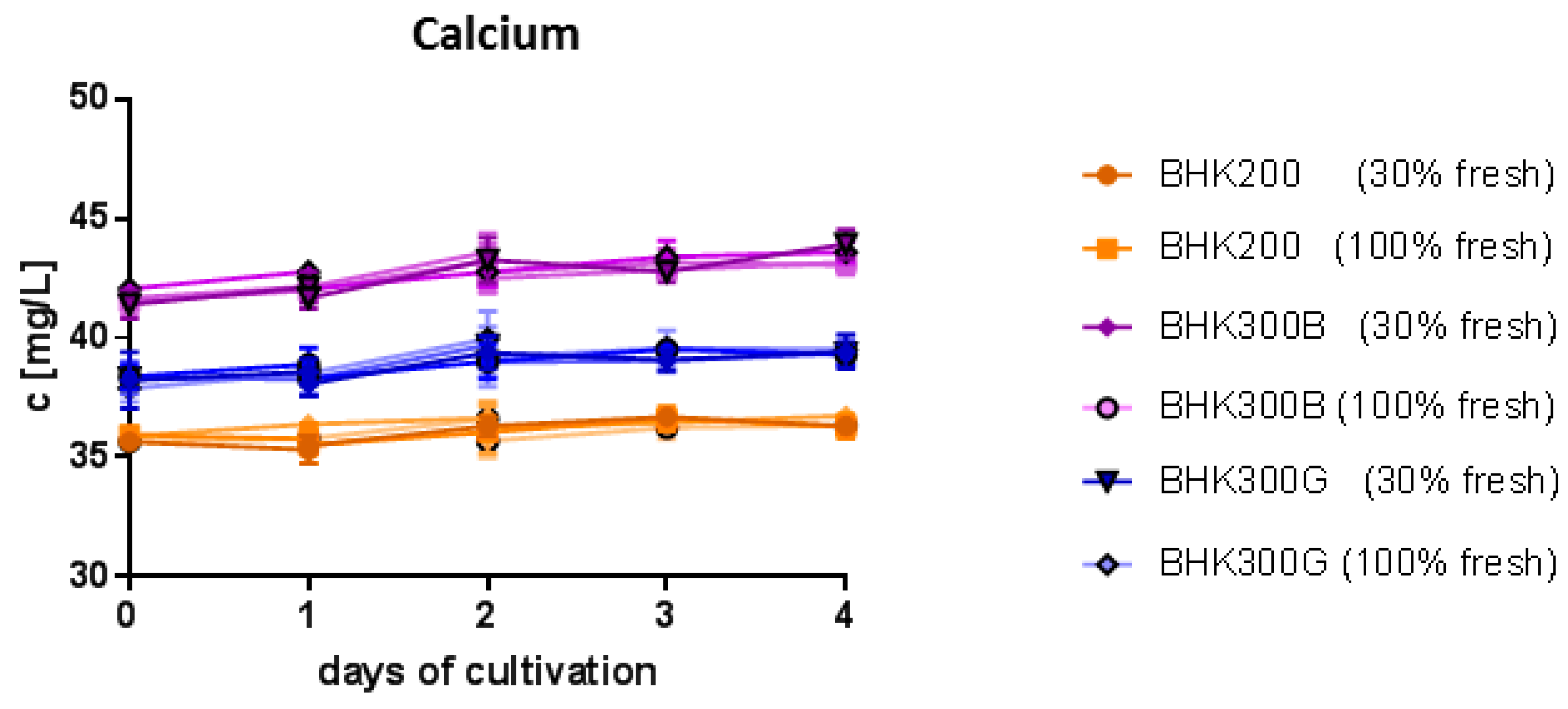

3.2. Cell Density Effects

3.3. Conditioned Media

3.4. Batch Culture Experiments

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jamal, S.M.; Belsham, G.J. Foot-and-mouth disease: Past, present and future. Vet. Res. 2013, 44, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Samuel, A.R.; Knowles, N.J. Foot-and-mouth disease virus: Cause of the recent crisis for the UK livestock industry. Trends Genet. Tig. 2001, 17, 421–424. [Google Scholar] [CrossRef]

- Brito, B.P.; Rodriguez, L.L.; Hammond, J.M.; Pinto, J.; Perez, A.M. Review of the Global Distribution of Foot-and-Mouth Disease Virus from 2007 to 2014. Transbound. Emerg. Dis. 2017, 64, 316–332. [Google Scholar] [CrossRef] [PubMed]

- Doel, T.R. FMD vaccines. Virus Res. 2003, 91, 81–99. [Google Scholar] [CrossRef]

- Parida, S. Vaccination against foot-and-mouth disease virus: Strategies and effectiveness. Expert Rev. Vaccines 2009, 8, 347–365. [Google Scholar] [CrossRef]

- Barteling, S.J. Development and performance of inactivated vaccines against foot and mouth disease. Rev. Sci. Tech. 2002, 21, 577–588. [Google Scholar] [CrossRef] [PubMed]

- Genzel, Y.; Fischer, M.; Reichl, U. Serum-free influenza virus production avoiding washing steps and medium exchange in large-scale microcarrier culture. Vaccine 2006, 24, 3261–3272. [Google Scholar] [CrossRef]

- Thomassen, Y.E.; Rubingh, O.; Wijffels, R.H.; van der Pol, L.A.; Bakker, W.A. Improved poliovirus D-antigen yields by application of different Vero cell cultivation methods. Vaccine 2014, 32, 2782–2788. [Google Scholar] [CrossRef]

- van der Pol, L.; Tramper, J. Shear sensitivity of animal cells from a culture-medium perspective. Trends Biotechnol. 1998, 16, 323–328. [Google Scholar] [CrossRef]

- Bock, A.; Schulze-Horsel, J.; Schwarzer, J.; Rapp, E.; Genzel, Y.; Reichl, U. High-density microcarrier cell cultures for influenza virus production. Biotechnol. Prog. 2011, 27, 241–250. [Google Scholar] [CrossRef]

- Kamen, A.; Henry, O. Development and optimization of an adenovirus production process. J. Gene Med. 2004, 6, S184–S192. [Google Scholar] [CrossRef] [PubMed]

- Lindsay, D.A.; Betenbaugh, M.J. Quantification of cell culture factors affecting recombinant protein yields in baculovirus-infected insect cells. Biotechnol. Bioeng 1992, 39, 614–618. [Google Scholar] [CrossRef] [PubMed]

- Perrin, P.; Madhusudana, S.; Gontier-Jallet, C.; Petres, S.; Tordo, N.; Merten, O.W. An experimental rabies vaccine produced with a new BHK-21 suspension cell culture process: Use of serum-free medium and perfusion-reactor system. Vaccine 1995, 13, 1244–1250. [Google Scholar] [CrossRef]

- Rourou, S.; van der Ark, A.; van der Velden, T.; Kallel, H. A microcarrier cell culture process for propagating rabies virus in Vero cells grown in a stirred bioreactor under fully animal component free conditions. Vaccine 2007, 25, 3879–3889. [Google Scholar] [CrossRef] [PubMed]

- Chen, A.; Poh, S.L.; Dietzsch, C.; Roethl, E.; Yan, M.L.; Ng, S.K. Serum-free microcarrier based production of replication deficient influenza vaccine candidate virus lacking NS1 using Vero cells. BMC Biotechnol. 2011, 11, 81. [Google Scholar] [CrossRef] [PubMed]

- Carrillo, C.; Tulman, E.R.; Delhon, G.; Lu, Z.; Carreno, A.; Vagnozzi, A.; Kutish, G.F.; Rock, D.L. Comparative genomics of foot-and-mouth disease virus. J. Virol. 2005, 79, 6487–6504. [Google Scholar] [CrossRef] [PubMed]

- Spearman, C. The Method of “Right and Wrong Cases” (Constant Stimuli) without Gauss’s Formula. Br. J. Psychol. 1908, 2, 227–242. [Google Scholar]

- Kärber, G. Beitrag zur kollektiven Behandlung pharmakologischer Reihenversuche. Arch. f Exp. Pathol u Pharmakol 1931, 162, 480–483. [Google Scholar] [CrossRef]

- Brückner, G.; Saraiva-Vieira, V.E. OIE strategy for the control and eradication of foot-and-mouth disease at reginal and global levels. In Proceedings of the OIE/FAO Global Conference on Foot-and-Mouth Disease, Asunción, Paraguay, 24–26 June 2009; pp. 187–198. [Google Scholar]

- Chisti, Y. Animal Cell Culture in Stirred Bioreactors: Observations on Scale-up. Process. Biochem. 1992, 28, 511–517. [Google Scholar] [CrossRef]

- Etoc, A.; Delvigne, F.; Lecomte, J.P.; Thonart, P. Foam control in fermentation bioprocess: From simple aeration tests to bioreactor. Appl. Biochem. Biotechnol. 2006, 129–132, 392–404. [Google Scholar] [CrossRef]

- Velugula-Yellela, S.R.; Williams, A.; Trunfio, N.; Hsu, C.J.; Chavez, B.; Yoon, S.; Agarabi, C. Impact of media and antifoam selection on monoclonal antibody production and quality using a high throughput micro-bioreactor system. Biotechnol. Prog. 2018, 34, 262–270. [Google Scholar] [CrossRef] [PubMed]

- Committee for Medicinal Products for Veterinary Use (CVMP) of the European Medicines Agency. Substances Considered as Not Falling within the Scope of Regulation (EC) No. 470/20091, with Regard to Residues of Veterinary Medicinal Products in Foodstuffs of Animal Origin. EMA/CVMP/519714/2009 Rev. 39 of 24 January 2019. Available online: https://www.ema.europa.eu/en/documents/regulatory-procedural-guideline/substances-considered-not-falling-within-scope-regulation-ec-no-470/20091-regard-residues-veterinary-medicinal-products-foodstuffs-animal-origin_.pdf (accessed on 2 June 2019).

- Maranga, L.; Brazao, T.F.; Carrondo, M.J. Virus-like particle production at low multiplicities of infection with the baculovirus insect cell system. Biotechnol. Bioeng. 2003, 84, 245–253. [Google Scholar] [CrossRef] [PubMed]

- Doverskog, M.; Bertram, E.; Ljunggren, J.; Ohman, L.; Sennerstam, R.; Haggstrom, L. Cell cycle progression in serum-free cultures of Sf9 insect cells: Modulation by conditioned medium factors and implications for proliferation and productivity. Biotechnol. Prog. 2000, 16, 837–846. [Google Scholar] [CrossRef] [PubMed]

- Dill, V.; Zimmer, A.; Beer, M.; Eschbaumer, M. Nutritional requirements of cell culture media for optimal foot-and-mouth disease virus production. BMC Biotechnol. 2019, submitted. [Google Scholar]

- Curry, S.; Abrams, C.C.; Fry, E.; Crowther, J.C.; Belsham, G.J.; Stuart, D.I.; King, A.M. Viral RNA modulates the acid sensitivity of foot-and-mouth disease virus capsids. J. Virol. 1995, 69, 430–438. [Google Scholar] [PubMed]

- Martin-Acebes, M.A.; Rincon, V.; Armas-Portela, R.; Mateu, M.G.; Sobrino, F. A single amino acid substitution in the capsid of foot-and-mouth disease virus can increase acid lability and confer resistance to acid-dependent uncoating inhibition. J. Virol. 2010, 84, 2902–2912. [Google Scholar] [CrossRef] [PubMed]

- Bjorklund, M.; Marguerat, S. Editorial: Determinants of Cell Size. Front. Cell Dev. Biol. 2017, 5, 115. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mould, A.P.; Garratt, A.N.; Askari, J.A.; Akiyama, S.K.; Humphries, M.J. Regulation of integrin alpha 5 beta 1 function by anti-integrin antibodies and divalent cations. Biochem. Soc. Trans. 1995, 23, 395S. [Google Scholar] [CrossRef] [PubMed]

- Hamazaki, H. Ca2+-mediated association of human serum amyloid P component with heparan sulfate and dermatan sulfate. J. Biol. Chem. 1987, 262, 1456–1460. [Google Scholar] [PubMed]

- Jackson, T.; Clark, S.; Berryman, S.; Burman, A.; Cambier, S.; Mu, D.; Nishimura, S.; King, A.M. Integrin alphavbeta8 functions as a receptor for foot-and-mouth disease virus: Role of the beta-chain cytodomain in integrin-mediated infection. J. Virol. 2004, 78, 4533–4540. [Google Scholar] [CrossRef]

- Jackson, T.; Ellard, F.M.; Ghazaleh, R.A.; Brookes, S.M.; Blakemore, W.E.; Corteyn, A.H.; Stuart, D.I.; Newman, J.W.; King, A.M. Efficient infection of cells in culture by type O foot-and-mouth disease virus requires binding to cell surface heparan sulfate. J. Virol. 1996, 70, 5282–5287. [Google Scholar] [PubMed]

- Jackson, T.; Mould, A.P.; Sheppard, D.; King, A.M. Integrin alphavbeta1 is a receptor for foot-and-mouth disease virus. J. Virol. 2002, 76, 935–941. [Google Scholar] [CrossRef] [PubMed]

- Mould, A.P.; Akiyama, S.K.; Humphries, M.J. Regulation of integrin alpha 5 beta 1-fibronectin interactions by divalent cations. Evidence for distinct classes of binding sites for Mn2+, Mg2+, and Ca2+. J. Biol. Chem. 1995, 270, 26270–26277. [Google Scholar] [CrossRef] [PubMed]

- Takeuchi, Y.; Sakaguchi, K.; Yanagishita, M.; Aurbach, G.D.; Hascall, V.C. Extracellular calcium regulates distribution and transport of heparan sulfate proteoglycans in a rat parathyroid cell line. J. Biol. Chem. 1990, 265, 13661–13668. [Google Scholar] [PubMed]

- Tazi, L.M.; Jayawickreme, S. Determination of residual dextran sulfate in protein products by SEC-HPLC. J. Chromatogr B Anal. Technol Biomed. Life Sci. 2016, 1011, 89–93. [Google Scholar] [CrossRef] [PubMed]

- Luscher-Mattli, M.; Gluck, R.; Kempf, C.; Zanoni-Grassi, M. A comparative study of the effect of dextran sulfate on the fusion and the in vitro replication of influenza A and B, Semliki Forest, vesicular stomatitis, rabies, Sendai, and mumps virus. Arch. Virol 1993, 130, 317–326. [Google Scholar] [CrossRef] [PubMed]

- Baba, M.; Pauwels, R.; Balzarini, J.; Arnout, J.; Desmyter, J.; De Clercq, E. Mechanism of inhibitory effect of dextran sulfate and heparin on replication of human immunodeficiency virus in vitro. Proc. Natl. Acad. Sci. USA 1988, 85, 6132–6136. [Google Scholar] [CrossRef] [PubMed]

- Mastromarino, P.; Seganti, L.; Petruzziello, R.; Gabrieli, R.; Divizia, M.; Pana, A.; Orsi, N. Influence of polyions on the early steps of enterovirus infection. J. Chemother 1991, 3, 203–208. [Google Scholar] [CrossRef]

- Totsuka, A.; Mukoyama, A.; Tagaya, I. Strain-specific aggregation of enterovirus by dextran sulfate. Arch. Virol. 1981, 70, 123–135. [Google Scholar] [CrossRef]

- Yamamoto, S.; Maruta, H.; Shingu, M. Effects of Dextran Sulfate on Plaque Formation of Enteroviruses. Kurume Med. J. 1964, 11, 182–187. [Google Scholar] [CrossRef]

| Cell Density | Media Exchange | Growth Rate μ (h−1) | Cell Division Number (cd) | |||||

|---|---|---|---|---|---|---|---|---|

| s | N | s | N | |||||

| BHK200 | 1 × 106 cells/mL | +30% | 0.06 | 0.00 | 6 | 1.92 | 0.16 | 6 |

| 1 × 106 cells/mL | +100% | 0.06 | 0.01 | 6 | 2.05 | 0.18 | 6 | |

| 3 × 106 cells/mL | +30% | 0.03 | 0.00 | 6 | 0.87 | 0.12 | 6 | |

| 3 × 106 cells/mL | +100% | 0.04 | 0.00 | 6 | 1.36 | 0.12 | 6 | |

| BHK300B | 1 × 106 cells/mL | +30% | 0.04 | 0.00 | 6 | 1.47 | 0.10 | 6 |

| 1 × 106 cells/mL | +100% | 0.04 | 0.00 | 6 | 1.54 | 0.07 | 6 | |

| 3 × 106 cells/mL | +30% | 0.02 | 0.00 | 6 | 0.83 | 0.16 | 6 | |

| 3 × 106 cells/mL | +100% | 0.03 | 0.00 | 6 | 1.13 | 0.10 | 6 | |

| BHK300G | 1 × 106 cells/mL | +30% | 0.06 | 0.00 | 6 | 2.07 | 0.16 | 6 |

| 1 × 106 cells/mL | +100% | 0.06 | 0.00 | 6 | 2.02 | 0.17 | 6 | |

| 3 × 106 cells/mL | +30% | 0.03 | 0.01 | 6 | 0.94 | 0.17 | 6 | |

| 3 × 106 cells/mL | +100% | 0.04 | 0.00 | 4 | 1.40 | 0.07 | 4 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dill, V.; Ehret, J.; Zimmer, A.; Beer, M.; Eschbaumer, M. Cell Density Effects in Different Cell Culture Media and Their Impact on the Propagation of Foot-And-Mouth Disease Virus. Viruses 2019, 11, 511. https://doi.org/10.3390/v11060511

Dill V, Ehret J, Zimmer A, Beer M, Eschbaumer M. Cell Density Effects in Different Cell Culture Media and Their Impact on the Propagation of Foot-And-Mouth Disease Virus. Viruses. 2019; 11(6):511. https://doi.org/10.3390/v11060511

Chicago/Turabian StyleDill, Veronika, Janike Ehret, Aline Zimmer, Martin Beer, and Michael Eschbaumer. 2019. "Cell Density Effects in Different Cell Culture Media and Their Impact on the Propagation of Foot-And-Mouth Disease Virus" Viruses 11, no. 6: 511. https://doi.org/10.3390/v11060511