The Optimum Slash Pile Size for Grinding Operations: Grapple Excavator and Horizontal Grinder Operations Model Based on a Sierra Nevada, California Survey

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Site and Treatment

2.2. Description of Slash Pile and Element Operation

- Loading means grabbing logging residues out of a slash pile and then pivoting with load;

- Unloading means releasing the residues at the conveyor of a horizontal grinder and then pivoting with no load;

- Shaking means shaking waste material off in order to facilitate the feeding of grabbed residues;

- Waiting means waiting for feeding the material; the grinding operation was carried out by the interaction of excavator and grinder, so the waiting operation was essential for the excavator;

- Pushing means pushing the material into the grinder when it could not ‘swallow’ the residues because of their bulkiness;

- Reorienting or repositioning means reorienting or repositioning the scattered material in order to increase the amount of residue per grab when the operation proceeded and the bulk volume of pile became smaller;

- Loading with moving means that the loading operation shown above was done with moving;

- Unloading with moving means that unloading operation shown above was done with moving.

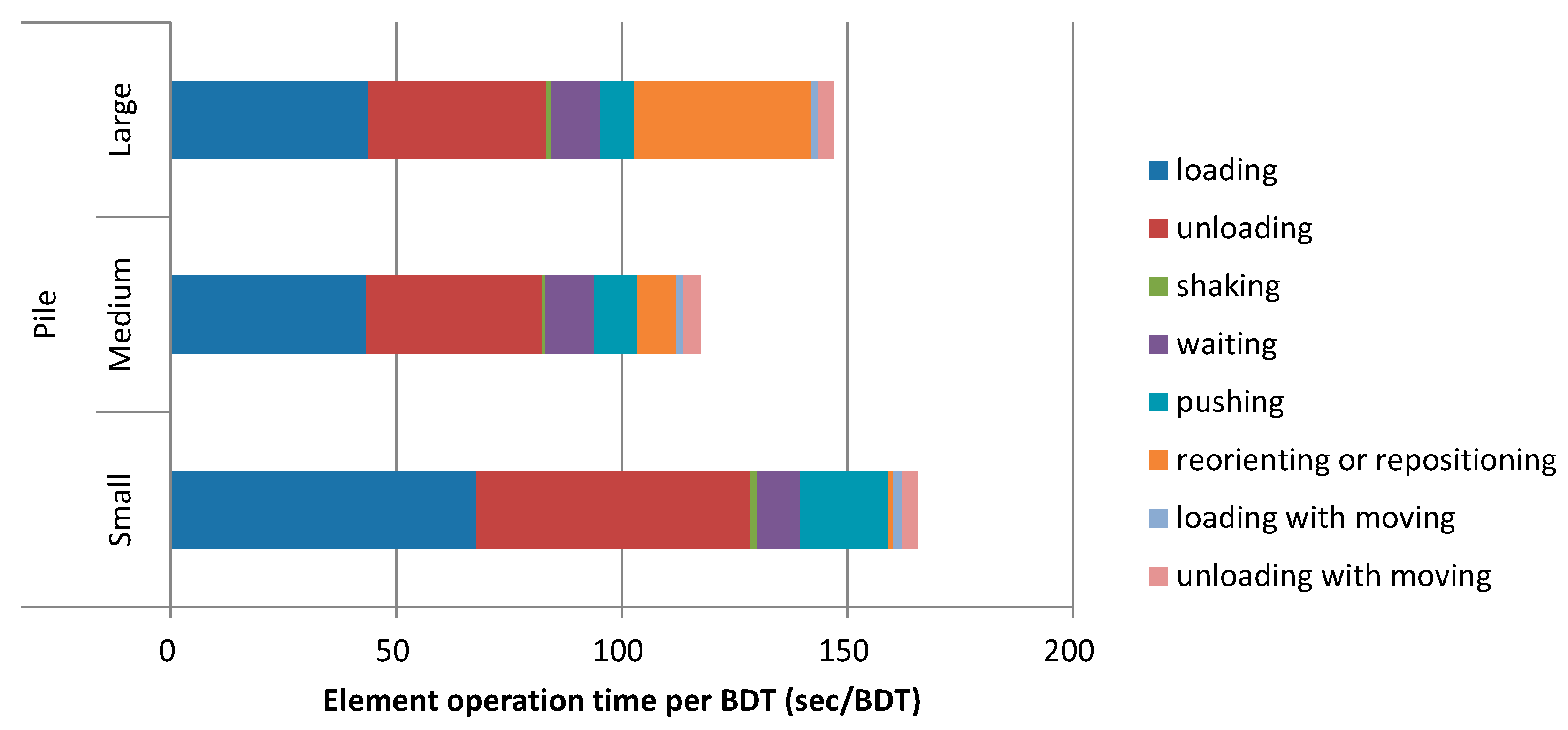

3. Results of the Time Study and the Monitored Productivity of a Grinder

4. Discussion by the Simulation Model

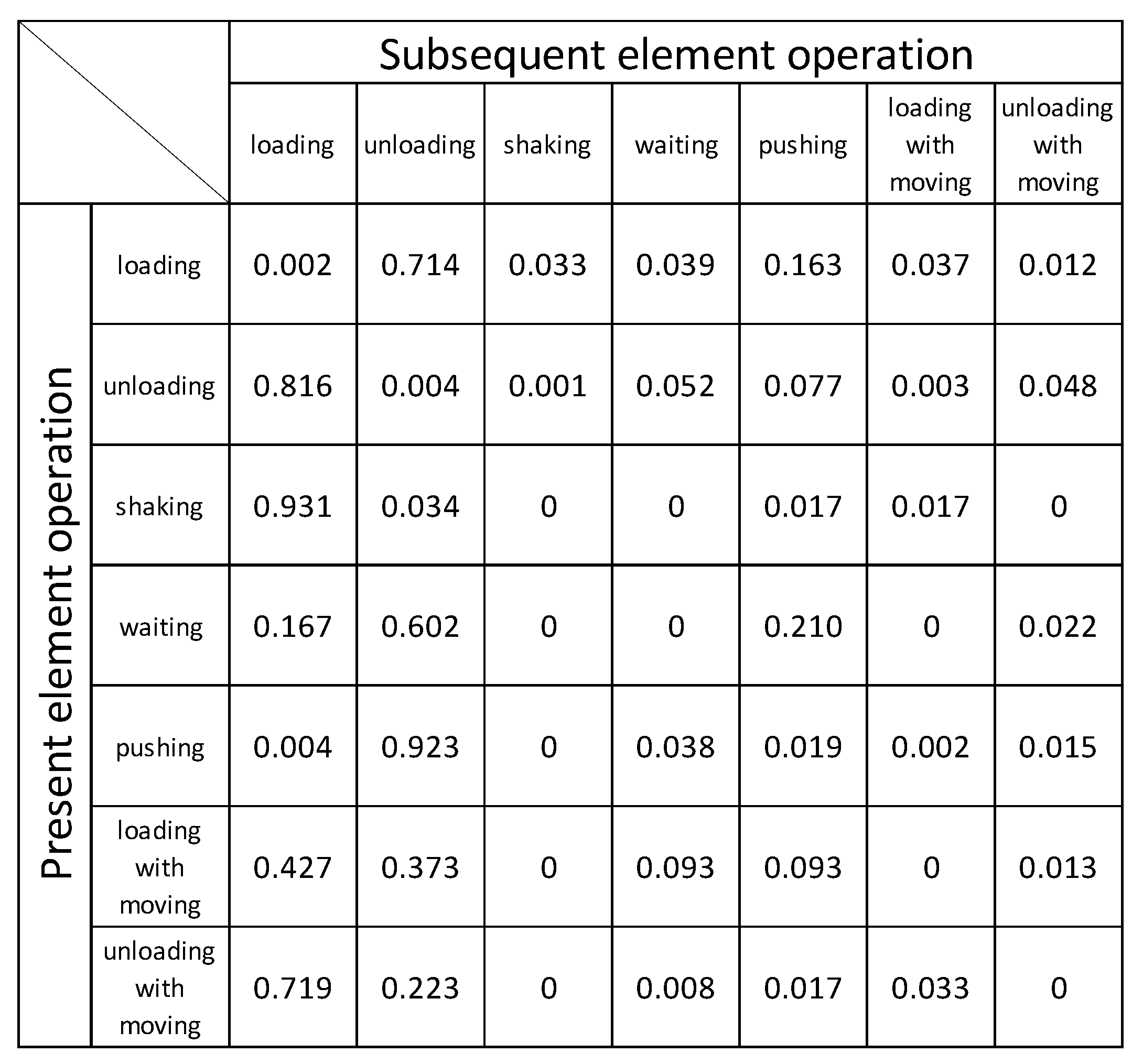

4.1. Modeling a Grapple Excavator Operation

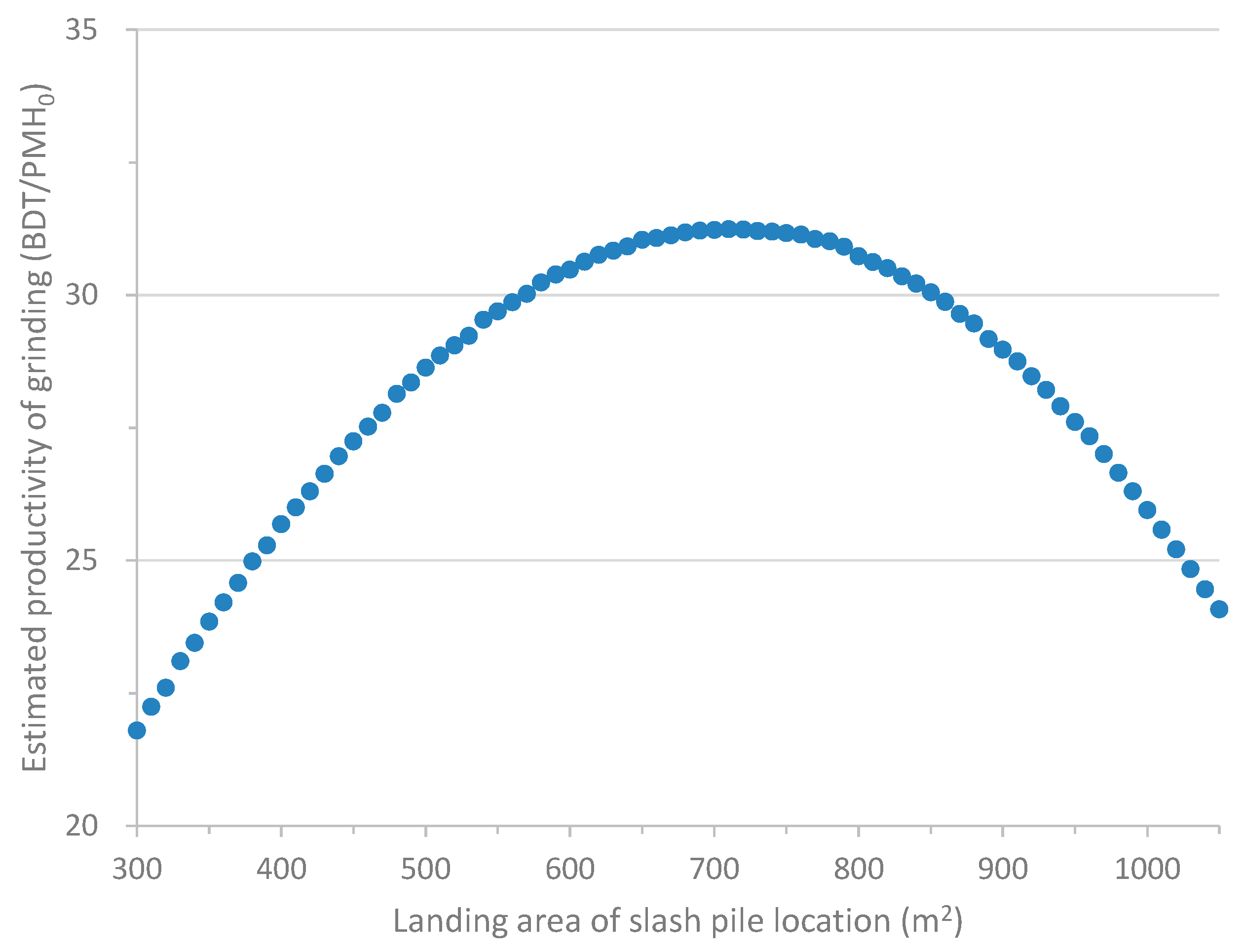

4.2. Verification of the Replicability of the Model and an Optimum Slash Pile Size

- The shape of each landing, i.e., the ratio of its length to its width, was not considered in the simulation model;

- The theoretical formulae of (1) and (2) were both approximated from only three samples;

- The optimum size of the slash pile for a grinding operation will also depend in part on aspects of the machines used, e.g., their size, engine output, and grinding capacity.

5. Conclusions

- The energy (diesel fuel) expended for processing and transport was 2.5% of the biomass fuel (energy equivalent);

- Based on measurements from a large pile burn, air emission reductions of 98–99% for PM2.5, CO, NMOC, CH4, and BC, and 20% for NOX and CO2-equivalent greenhouse gases were observed;

- The delivered cost of $70/BDT exceeds the biomass plant gate price of $45/BDT. Under typical conditions, the break-even haul distance would be approx. 48 km.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- McIntyre, P.J.; Thorne, J.H.; Dolanc, C.R.; Flint, A.L.; Flint, L.E.; Kelly, M.; Ackerly, D.D. Twentieth-century shifts in forest structure in California: Denser forests, smaller trees, and increased dominance of oaks. Proc. Natl. Acad. Sci. USA 2015, 112, 1458–1463. [Google Scholar] [CrossRef] [PubMed]

- Kocher, S. Californians must learn from the past and work together to meet the forest and fire challenges of the next century. Calif. Agric. 2015, 69, 5–9. [Google Scholar] [CrossRef]

- North, M.; Collins, B.; Stephens, S. Using fire to increase the scale, benefits, and future maintenance of fuels treatments. J. For. 2012, 110, 392–401. [Google Scholar] [CrossRef]

- Springsteen, B.; Christofk, T.; Eubanks, S.; Mason, T.; Clavin, C.; Storey, B. Emission reductions from woody biomass waste for energy as an alternative to open burning. J. Air Waste Manag. Assoc. 2011, 61, 63–68. [Google Scholar] [CrossRef] [PubMed]

- Present Status and Promotion Measures for the Introduction of Renewable Energy in Japan. Available online: http://www.meti.go.jp/english/policy/energy_environment/renewable/index.html (accessed on 26 October 2017).

- Forestry Agency of Japan (Ed.) FY 2016 White Paper in Forest and Forestry; Zenrinkyou: Tokyo, Japan, 2017; p. 236. (In Japanese)

- Tomari, M. (Ed.) Biomass White Paper 2017; Biomass Industrial Society Network (BIN), NPO: Kashiwa, Japan, 2017; p. 28. (In Japanese) [Google Scholar]

- Seymour, G.; Tecle, A. Impact of slash pile size and burning on ponderosa pine forest soil physical properties. J. Ariz. Nev. Acad. Sci. 2004, 37, 74–82. [Google Scholar] [CrossRef]

- Seymour, G.; Tecle, A. Impact of slash pile size and burning on soil chemical characteristics in ponderosa pine forests. J. Ariz. Nev. Acad. Sci. 2005, 38, 6–20. [Google Scholar] [CrossRef]

- Kim, D.-W.; Murphy, G. Forecasting air-drying rates of small Douglas-fir and hybrid poplar stacked logs in Oregon, USA. Int. J. For. Eng. 2013, 24, 137–147. [Google Scholar] [CrossRef]

- Lin, Y.; Pan, F. Effect of in-woods storage of unprocessed logging residue on biomass feedstock quality. For. Prod. J. 2013, 63, 119–124. [Google Scholar] [CrossRef]

- Bisson, J.A.; Han, H.-S. Quality of feedstock produced from sorted forest residues. Am. J. Biomass Bioenerg. 2016, 5, 81–97. [Google Scholar] [CrossRef]

- Zamora-Cristales, R.; Sessions, J.; Marrs, G. Economic implications of grinding, transporting, and pretreating fresh versus aged forest residues for biofuel production. Can. J. For. Res. 2017, 47, 269–276. [Google Scholar] [CrossRef]

- Hartsough, B.; Nakamura, G. Harvesting eucalyptus for fuel chips. Calif. Agric. 1990, 44, 7–8. [Google Scholar]

- Yoshioka, T.; Aruga, K.; Sakai, H.; Kobayashi, H.; Nitami, T. Cost, energy and carbon dioxide (CO2) effectiveness of a harvesting and transporting system for residual forest biomass. J. For. Res. 2002, 7, 157–163. [Google Scholar] [CrossRef]

- Yoshioka, T.; Aruga, K.; Nitami, T.; Sakai, H.; Kobayashi, H. A case study on the costs and the fuel consumption of harvesting, transporting, and chipping chains for logging residues in Japan. Biomass Bioenerg. 2006, 30, 342–348. [Google Scholar] [CrossRef]

- Yoshioka, T.; Sakurai, R.; Aruga, K.; Nitami, T.; Sakai, H.; Kobayashi, H. Comminution of logging residues with a tub grinder: Calculation of productivity and procurement cost of wood chips. Croat. J. For. Eng. 2006, 27, 103–114. [Google Scholar]

- Iwaoka, M.; Aruga, K.; Sakurai, R.; Cho, K.-H.; Sakai, H.; Kobayashi, H. Performance of small harvester head in a thinning operation. J. For. Res. 1999, 4, 195–200. [Google Scholar] [CrossRef]

- Sakurai, R.; Iwaoka, M.; Sakai, H.; Kobayashi, H. Studies on yarding and hauling system of mobile-yarder, processor, and forwarder with simulation methods. Bull. Tokyo Univ. For. 1999, 102, 113–132, (In Japanese with English Summary). [Google Scholar]

- Nitami, T. Modeling of timber harvesting operation by system dynamics and the productivity estimation function. J. Jpn. For. Eng. Soc. 2006, 20, 281–284. (In Japanese) [Google Scholar] [CrossRef]

- Sugimoto, K.; Niinaga, S.; Hasegawa, H. Consideration on flow harvesting system utilizing system dynamics. J. Jpn. For. Eng. Soc. 2010, 25, 5–14, (In Japanese with English Summary). [Google Scholar] [CrossRef]

- Yoshimura, T.; Hartsough, B. Conceptual evaluation of harvesting systems for fuel reduction and biomass collection on steep terrain using system dynamics. In Proceedings of the International Mountain Logging and 13th Pacific Northwest Skyline Symposium, Corvallis, OR, USA, 1–6 April 2007; Sessions, J., Havill, Y., Eds.; Department of Forest Engineering, Oregon State University: Corvallis, OR, USA, 2007; pp. 94–102. Available online: http://www.cof.orst.edu/cof/ferm/pdf/skyproceedings.pdf (accessed on 22 September 2017).

- Springsteen, B.; Christofk, T.; York, R.; Mason, T.; Baker, S.; Lincoln, E.; Hartsough, B.; Yoshioka, T. Forest biomass diversion in the Sierra Nevada: Energy, economics and emissions. Calif. Agric. 2015, 69, 142–149. [Google Scholar] [CrossRef]

- Nilsson, B. Costs, CO2-emissions and energy balance for applying Nordic methods of forest biomass utilization in British Columbia. M.Sc. Thesis, Department of Forest Resource Management, Swedish University of Agricultural Sciences, Umeå, Sweden, 13 April 2009. Available online: http://ex-epsilon.slu.se/id/eprint/3244 (accessed on 22 September 2017).

| Equipment | Grapple Excavator | Horizontal Grinder |

|---|---|---|

| Vendor, model | Link-Belt, 290 LX | Bandit, Beast 3680 |

| Engine, horsepower | Isuzu CC-6BG1TC, 132 kW | Caterpillar C18 Tier III, 522 kW |

| Length | 10.41 m | 11.89 m |

| Width | 3.400 m | 2.845 m |

| Height | 3.270 m | 4.115 m |

| Weight | 29,211 kg | 28,122 kg |

| Maximum reach | 10.54 m | - |

| Maximum feed height | - | 0.890 m |

| Infeed conveyor | - | 6.110 m × 1.520 m |

| Element Operation | Pile | |||

|---|---|---|---|---|

| Small | Medium | Large | ||

| Loading | Time (s) | 3484 | 5312 | 7614 |

| Frequency | 359 | 550 | 802 | |

| Avg. (s) | 9.70 | 9.66 | 9.49 | |

| Std. Dev. (s) | 5.55 | 4.29 | 4.56 | |

| Unloading | Time (s) | 3114 | 4776 | 6848 |

| Frequency | 383 | 594 | 863 | |

| Avg. (s) | 8.13 | 8.04 | 7.94 | |

| Std. Dev. (s) | 3.09 | 3.00 | 2.73 | |

| Shaking | Time (s) | 92 | 95 | 201 |

| Frequency | 14 | 15 | 29 | |

| Avg. (s) | 6.57 | 6.33 | 6.93 | |

| Std. Dev. (s) | 3.08 | 2.50 | 2.84 | |

| Waiting | Time (s) | 479 | 1314 | 1875 |

| Frequency | 29 | 71 | 88 | |

| Avg. (s) | 16.52 | 18.51 | 21.31 | |

| Std. Dev. (s) | 18.06 | 19.95 | 19.32 | |

| Pushing | Time (s) | 1013 | 1190 | 1316 |

| Frequency | 132 | 168 | 180 | |

| Avg. (s) | 7.67 | 7.08 | 7.31 | |

| Std. Dev. (s) | 5.02 | 4.83 | 7.06 | |

| Reorienting or repositioning | Time (s) | 52 | 1056 | 6826 |

| Frequency | 3 | 11 | 21 | |

| Avg. (s) | 17.33 | 96.00 | 325.05 | |

| Std. Dev. (s) | 2.31 | 126.17 | 732.85 | |

| Loading with moving | Time (s) | 100 | 201 | 284 |

| Frequency | 13 | 29 | 33 | |

| Avg. (s) | 7.69 | 6.93 | 8.61 | |

| Std. Dev. (s) | 3.82 | 2.25 | 3.19 | |

| Unloading with moving | Time (s) | 185 | 464 | 581 |

| Frequency | 18 | 47 | 56 | |

| Avg. (s) | 10.28 | 9.87 | 10.38 | |

| Std. Dev. (s) | 6.95 | 5.44 | 9.28 | |

| Total | 8519 | 14,408 | 25,545 |

| Element Operation | Chi-Square Test | Theoretical Formula 1 | ||

|---|---|---|---|---|

| χ2 | df | p-Value | ||

| Loading | 5.416 | 5 | 0.367 | eN(2.140, 0.485) |

| Unloading | 10.985 | 5 | 0.052 | eN(2.023, 0.370) |

| Shaking | 4.422 | 5 | 0.490 | eN(1.825, 0.383) |

| Waiting | 6.314 | 5 | 0.277 | eN(2.625, 0.800) |

| Pushing | 10.238 | 5 | 0.069 | eN(1.819, 0.539) |

| Loading with moving | 8.353 | 5 | 0.138 | eN(1.987, 0.363) |

| Unloading with moving | 8.009 | 5 | 0.156 | eN(2.153, 0.530) |

| Pile | Monitored | Estimated Productivity | ||||

|---|---|---|---|---|---|---|

| Area of Landing (m2) | Amount of Slashes (BDT) | Productivity (BDT/PMH0) | Calculation Frequency | Avg. ± Std. Dev. (BDT/PMH0) | Rate of Avg. Value to Monitored (%) | |

| Small | 300 | 51.41 | 21.73 | 1000 | 21.78 ± 0.70 | 100.2 |

| Medium | 720 | 122.66 | 30.65 | 1000 | 31.17 ± 0.75 | 101.7 |

| Large | 1050 | 173.78 | 24.49 | 1000 | 24.27 ± 0.38 | 99.10 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoshioka, T.; Sakurai, R.; Kameyama, S.; Inoue, K.; Hartsough, B. The Optimum Slash Pile Size for Grinding Operations: Grapple Excavator and Horizontal Grinder Operations Model Based on a Sierra Nevada, California Survey. Forests 2017, 8, 442. https://doi.org/10.3390/f8110442

Yoshioka T, Sakurai R, Kameyama S, Inoue K, Hartsough B. The Optimum Slash Pile Size for Grinding Operations: Grapple Excavator and Horizontal Grinder Operations Model Based on a Sierra Nevada, California Survey. Forests. 2017; 8(11):442. https://doi.org/10.3390/f8110442

Chicago/Turabian StyleYoshioka, Takuyuki, Rin Sakurai, Shohei Kameyama, Koki Inoue, and Bruce Hartsough. 2017. "The Optimum Slash Pile Size for Grinding Operations: Grapple Excavator and Horizontal Grinder Operations Model Based on a Sierra Nevada, California Survey" Forests 8, no. 11: 442. https://doi.org/10.3390/f8110442

APA StyleYoshioka, T., Sakurai, R., Kameyama, S., Inoue, K., & Hartsough, B. (2017). The Optimum Slash Pile Size for Grinding Operations: Grapple Excavator and Horizontal Grinder Operations Model Based on a Sierra Nevada, California Survey. Forests, 8(11), 442. https://doi.org/10.3390/f8110442