Abstract

As industries continue to prioritize sustainability and resource efficiency, Paulownia stands out as a sustainable candidate for replacing Balsa in engineered wood products, offering a lighter, cost-effective solution with the added benefit of reduced ecological impact. The aim of this research is to manufacture 7 mm- and 15 mm-thick plywood from Paulownia tomentosa x elongata veneers (as an alternative for balsa veneers) using polyurethane (PUR) and melamine–urea–formaldehyde (MUF) adhesives, and to analyze their physical and mechanical properties. Panels with five and seven layers and thicknesses from 0.8 to 3 mm were tested for bulk density (247–385 kg/m3), thickness swelling (2.47%–5.34%), and water absorption (35%–68%) according to European standards. Mechanical properties assessed included three-point bending strength (MOR) parallel (22–35.8 N/mm2) and perpendicular to the fiber/grain (13.4–21.8 N/mm2), three-point modulus of elasticity (MOE) in longitudinal (2824–3799 N/mm2) and transverse directions (1183–1825 N/mm2), tensile shear strength (1.76–2.52 N/mm2), and screw withdrawal resistance (41.9–60.6 N/mm). Results indicate that Paulownia plywood has significant potential for lightweight construction due to its low density and favorable properties, with MUF adhesive showing superior performance in terms of density and panel properties. This positions Paulownia plywood as a strong contender in the ongoing evolution of lightweight construction materials.

1. Introduction

The Paulownia genus (Paulownia spp.), also known as the “European Balsa”, has gained significant attention in recent decades. Increasing Paulownia cultivation is now a trend across various countries, even in regions outside its Asian natural habitat [1], due to its impressive growth rate and large trunk sizes achievable within just a few years [2]. This rapid growth makes it possible to produce sufficient timber for advantageous processing. However, while there is a wide-spread interest in Paulownia, species such as Paulownia tomentosa are considered invasive in some areas, necessitating ongoing monitoring and management of their cultivation [3].

Research on different hybrids of Paulownia in European plantations suggests a density below 300 kg/m3 and mechanical properties such as bending strength and compression strength that are lower than those of many traditional hardwoods [4]. Comparable studies on Paulownia harvested in Portugal [5], Turkey [6], Bulgaria [7], and Hungary [8] support these findings, indicating a range of bending strength from around 36 to 44 MPa, as well as a modulus of elasticity (MOE) that reflects its lightweight nature.

Despite its relatively low mechanical strength, Paulownia wood is prized for its lightness, making it an ideal candidate for crafting lightweight products. Its favorable density-to-strength ratio renders it especially suitable for manufacturing lightweight household items and furnishings, particularly those that do not require structural integrity. These features offer an abundant supply of raw material suitable for a variety of applications [9], including single-layered [10] and three-layered particleboard [11], solid wood panels [12], laminated strand lumber and oriented strand lumber [13], and plywood [14]. Paulownia has been evaluated in sandwich panels [15].

Paulownia has also been recognized also for its role in carbon sequestration, providing environmental benefits in the context of climate change [16].

Increasing interest in producing Paulownia wood has spurred expansion and the development of advanced utilization processes. This includes exploring its entire tree for renewable resources, emphasizing minor fractions as low-cost sources of valuable compounds [17].

Designing future processes that consider the tree’s integral utilization is essential. Particularly appealing is the extraction of high-value compounds with biological properties [18], achievable in the initial stages without impacting on the potential uses of the remaining residual solid. Initially, many Paulownia plantations were established for biomass production, yielding promising results in terms of both growth dimensions and biomass accumulation [19]. Subsequently, studies conducted in several countries investigated the potential of Paulownia for bio-ethanol production [20].

Recent research of Paulownia fortunei, particularly in combination with poplar wood, have led to the production of thin, flexible plywood that is well-suited for applications requiring curvature [14]. In this study of Sedighizadeh et al. (2023) [14], various layer thicknesses and adhesives were utilized to assess the suitability of Paulownia flexible plywood for innovative designs. The research revealed that plywood panels comprising Paulownia exhibited densities ranging from 487 kg/m3 to 530 kg/m3, with mechanical properties heavily influenced by the species of wood used rather than the thickness of the layers [14].

Paulownia is emerging in plywood production as a favorable alternative to traditional Balsa wood. The lightweight nature of Paulownia plywood positions it uniquely well for applications requiring materials that lower overall weight without compromising on durability. Paulownia’s advantage in the manufacturing of plywood stems not only from its lightness but also from its potential cost-effectiveness compared to Balsa [9]. Furthermore, the vast growing regions (with few exceptions all over Europe, Asia, The U.S. and Australia [21]), low demands on soil quality to growth (mostly the light level influencing the fast growth [22]), and ability to reproduce vegetatively in plantations [23] are vastly superior to traditionally used balsa. Yet fast growth comes with challenges in terms of inhomogeneity and more growing defects compared to, for example, poplar [24], which must be researched thoroughly for Paulownia to be considered a suitable alternative in lightweight plywood manufacturing.

The aim of this study is to assess the production of five- and seven-layered plywood using Paulownia sliced veneers, with a focus on evaluating its physical and mechanical properties for potential industrial applications. The methodology entails the formulation of a process for the fabrication of plywood panels utilizing Paulownia veneers and incorporating polyurethane (PU) and melamine–urea–formaldehyde (MUF) adhesives. The resulting plywood will undergo a series of tests to characterize its physical and mechanical properties, enabling a comparative analysis with other lightweight panels and similar products.

2. Materials and Methods

The raw material, comprising Paulownia tomentosa (Tub.) x elongata (S.Y. Hu) wood, was supplied by Glendor Holding GmbH Company (Kilb, Austria) for the initial experimental series conducted with samples originating from Sueca, Spain, and for the subsequent series utilizing samples from Petrinja, Croatia. The source trees, cultivated on Glendor’s plantations, were harvested at five years of age. Veneer processing was carried out by Furnierwerk Merkscha GmbH (Gratwein, Austria), wherein logs were sliced into veneers and delivered with specified thicknesses of 0.9 mm, 1 mm, 2 mm, and 3 mm.

Paulownia veneers were conditioned at 20 °C and 65% relative humidity for at least 60 days, until constant weight was achieved. Plywood panels with a final thickness of 7 and 15 mm and dimensions of 600 × 600 mm were produced at the company Europlac (Topoľčany, Slowakia) with a glue application of 150 g/m2 (Table 1). Layering is also depicted in Table 1, furthermore a scheme showing the layer setup is presented in Figure 1. For the first batch, the veneers, glued with 1-component polyurethane adhesive PUR 501.1 (Kleiberit, Weingarten, Germany), were sourced from Sueca (Valencia, Spain), and for the second batch, the veneers, glued with melamine–urea–formaldehyde resin MUF (LignuPro Zero A211/2545, Akzo Nobel, Elixhausen, Austria), were obtained from Petrinja (Banovina, Croatia).

Table 1.

Overview of the plywood panels (7 and 15 mm thickness) produced with PUR and MUF adhesive and Paulownia tomentosa x elongata veneers.

Figure 1.

Overview of the cross-sections of 7 and 15 mm-thick plywood boards produced from Paulownia tomentosa x elongata veneers with exact layer details with PUR und MUF adhesive.

The mechanical tests were conducted using a Zwick/Roell Z250 universal testing machine (Ulm, Germany) equipped with testXpert III, measuring deflection to 0.1 mm accuracy, equipped with a 25 kN load cell. The tests included the measurement of the modulus of rupture (bending strength, MOR) and the modulus of elasticity (MOE), in accordance with EN 310:2005 [25] in parallel (‖) and perpendicular (ꓕ) directions; tensile shear strength (τs), following EN 314-1:2005 [26]; and axial screw withdrawal resistance (SW), as specified by EN 320:2011 [27]. Thickness swelling (TS) and water absorption (WA) were assessed according to EN 317:2005 [28], while density was determined in accordance with EN 323:2005 [29]. Specimen dimensions for each test were chosen in accordance with each corresponding standard.

Results are reported as the mean ± standard deviation of all test specimens, rounded to 10 N for ≥15 mm thickness and 1 N/mm for <15 mm thickness. ANOVA was performed using OriginPro 2024b; missing data was accounted for by the software. Tuckey’s post hoc test was performed at a significance level of 0.05%.

3. Results

A summary of all results is listed in Table 2 as mean ± standard deviation, including number of test specimens as well as the results of the ANOVA. Rows with the same letters indicate no significant difference at a level of p = 0.05.

Table 2.

Results of mechanical and physical tests given as mean ± standard deviation. Number of specimens n per test as well as results from the post hoc test.

3.1. Physical Properties of Paulownia Plywood

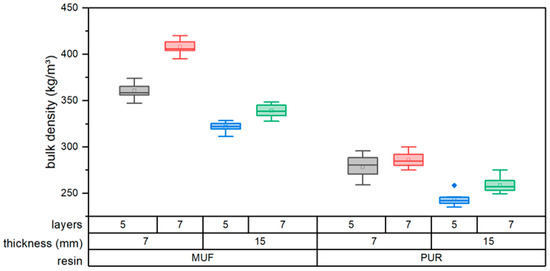

Whilst the solid Paulownia timber has a density in the range of around 260 kg/m3, plywood made from Paulownia veneers is significantly higher, due to the adhesive application. Figure 2 shows a comparison of the bulk density for MUF- and PUR-bonded Paulownia plywood investigated in this study. Overall, the PUR-bonded samples show a lower density of 240–290 kg/m3 for 15 mm five-layer and 7 mm seven-layer boards, respectively. The MUF plywood showed density in the range of 320 kg/m3 (15 mm five-layer) to 410 kg/m3 (7 mm seven-layer). This corresponds well with the relative amount of adhesive present in the boards, as well as the overall higher skeletal density of MUF resin compared to PUR. Furthermore, the difference can be attributed to the variation in origin of the used veneers. ANOVA revealed significant differences between all groups.

Figure 2.

Bulk density of 7 and 15 mm-thick Paulownia plywood bonded with PUR and MUF.

The bulk density of the panels glued with MUF adhesive application is greater than that of the panels glued with PU. This is due to the higher water content of the MUF adhesive, which facilitates greater compaction during pressing and enhances the adhesive’s setting properties. Conversely, it seems reasonable to posit that the production process utilizing the PU adhesive did not proceed as anticipated, resulting in incomplete setting. One potential explanation for this is the relatively low pressing temperature of 60 °C.

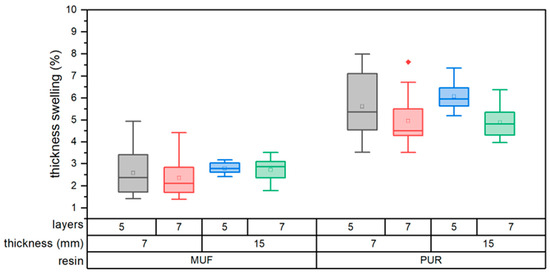

The degree of thickness swelling observed after 24 h of water storage (Figure 3) is less pronounced for the panels glued with MUF (around 2.5%) in comparison to those glued with PU (between 5% and 6%). It is important to note that the five-layer variants of the 7 and 15 mm-thick boards swell slightly more than the other variants due to the lower adhesive content. Again, the PUR-bonded plywood sheets show slightly lower performance, possibly attributed to a less pronounced penetration of the veneers with the adhesive. No significant differences were found for all boards bonded with MUF resin, whilst a difference at 0.05 was found between the seven- and the five-layer PUR-bonded boards.

Figure 3.

Thickness swelling after 24 h water storage for 7 and 15 mm-thick Paulownia plywood.

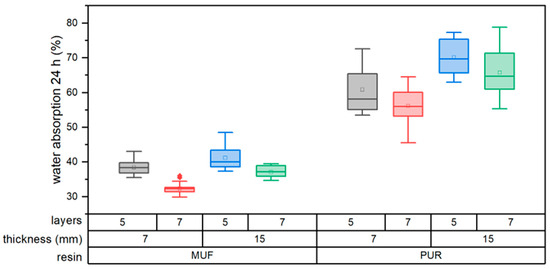

Analogous to the water absorption, thickness swelling after 24 h water immersion shows similar results (Figure 4), where the MUF-bonded plywood outperformed the PUR-bonded ones independent of thickness or layers. Again, the higher amount of adhesive in the seven-layer boards has a positive influence on the thickness swelling, reducing it from 70% (15 mm, five-layer, PUR) to 56% (7 mm, seven-layer, PUR) and 41% (15 mm, five-layer, MUF) to 32% (7 mm, seven-layer, MUF). Thickness and layer amount show a significant influence on the moisture behavior of Paulownia plywood bonded with PUR, but not for those produced with MUF adhesive. Again, no significant differences could be detected for the MUF-bonded boards, whilst all PUR-bonded ones were different from each other.

Figure 4.

Water absorption after 24 h water storage of 7 mm- and 15 mm-thick Paulownia plywood glued with PU and MUF.

3.2. Mechanical Properties of Paulownia Plywood

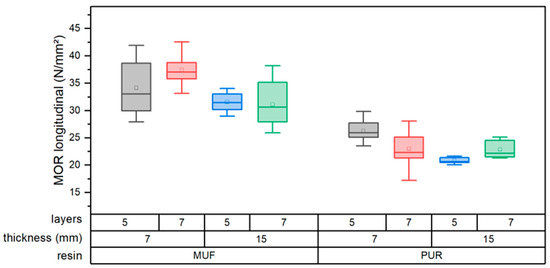

The density of the polyurethane-glued boards is less than 300 kg/m3. This consequently results in lower values for the bending strength in the longitudinal direction. The panels that have been glued with MUF have a bulk density of over 300 kg/m3, which results in higher values of 31 to 37 N/mm2 for MUF and 21 to 26 N/mm2 for PUR-bonded boards, respectively (Figure 5). The 7 mm-thick five-layer PUR-bonded plywood shows significantly higher bending strength (MOR) (26.3 N/mm2) compared to the three other PUR-bonded variants. Conversely, for MUF-bonded boards, only the 7 mm-thick seven-layer boards show significantly improved strength (37.5 N/mm2) compared to the others. The better performance of the MUF 7 mm seven-layer board can be attributed to its overall highest density of 408 kg/m3. Modulus of elasticity was not significantly different within the MUF-bonded boards (3740–3960 N/mm2), whilst there were significant differences in the PUR-bonded ones (15 mm and five-layer with 3160 N/mm2 compared to 2750 N/mm2 for the 7 mm variant with the same number of layers. For MUF-bonded plywood, only the 7 mm and seven-layer-thick boards were different from the others. Due to the high standard deviation, the five-layer, 7 mm-thick PUR-bonded ones were also different from the others in this group.

Figure 5.

Three-point longitudinal bending strength longitudinal to the grain of 7 mm- and 15 mm-thick Paulownia plywood glued with PUR and MUF adhesive.

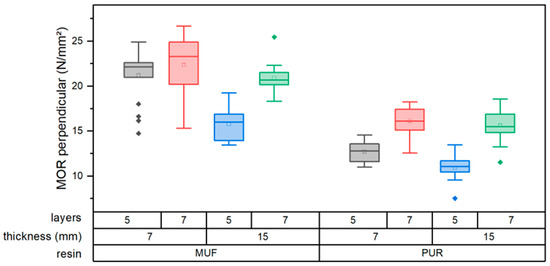

When evaluating three-point bending properties perpendicular to the grain orientation of the outermost layer, a strong dependency on the number of veneers can be observed for both MUF- and PUR-bonded plywood, respectively (Figure 6). Although, ANOVA did not indicate significant differences for 7 mm-thick MUF-bonded plywood, the five-layer board shows high variation (21 ± 2.8 N/mm2). For PUR-bonded boards, the difference is more pronounced and statistically significant, with around 12 N/mm2 for the five-layer variant compared to roughly 16 N/mm2 for the seven-layer boards. In terms of modulus of elasticity, the seven-layer MUF boards show significant higher values (around 1900 and 2000 N/mm2) compared to the five-layer MUF boards (roughly 1750 and 1280 N/mm2) for the 7 mm and the 15 mm, respectively. The same is true for PUR-bonded Paulownia plywood with seven-layers (roughly 1400 N/mm2 for both thicknesses) and five-layers (around 1220 and 920 N/mm2) for 7 and 15 mm, respectively. The overall lower performance perpendicular to the grain in contrast to parallel to the grain can be attributed to the orientation of the fibers, and therefore higher section modulus of the surface layers, as it grows raised to the third power dependent on the distance from the neutral fiber.

Figure 6.

Three-point longitudinal bending strength (MOR) in perpendicular of 7 mm- and 15 mm-thick Paulownia plywood glued with PUR and MUF adhesive.

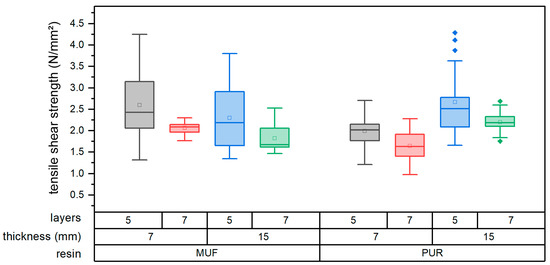

For both types of resin, the seven-layer plywood shows higher consistency across the tensile shear test, as shown in Figure 7. The highest variations were observed for the five-layer boards bonded with MUF resin independent of the thickness. This might be attributed to weak veneer layer, or density variations within the single veneer sheets due to varying growth ring thickness. Overall, the highest average strength was achieved by the five-layer and 15 mm-thick PUR-bonded plywood, with 2.7 N/mm2. The other PUR-bonded boards ranged from 1.6 to 2.2 N/mm2.

Figure 7.

Tensile shear of 7 mm- and 15 mm-thick Paulownia plywood glued with PUR and MUF adhesive.

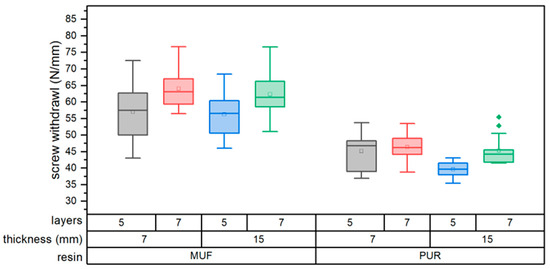

Overall, MUF-bonded boards show a higher screw withdrawal resistance (56–64 N/mm) compared to the PUR-bonded ones (40–46 N/mm), and a seven-layer construction performs better than the five-layer constructions (Figure 8). With 64 N/mm, the seven-layer 5 mm-thick MUF-bonded Paulownia plywood showed the best results, whilst the lowest strength was once more achieved by the five-layer and 15 mm-thick PUR-bonded boards. For both adhesive types employed, the screw withdrawal resistance increases with higher layer numbers independently of the individual layer thickness. As shown previously, an increased amount of hard, yet brittle, glue lines have a beneficial effect on screw withdrawal.

Figure 8.

Screw withdrawal resistance of 7 mm- and 15 mm-thick Paulownia plywood glued with PUR and MUF adhesive.

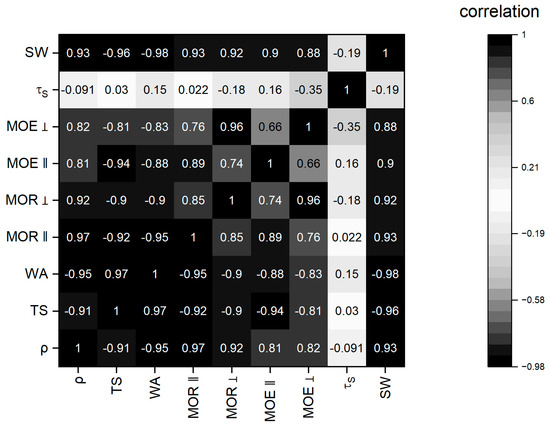

3.3. Correlations

As most mechanical properties are strongly dependent on the density of a material, in-depth correlation analysis was performed. Color-coded results are shown in Figure 9. With the exception of the tensile shear strength, all properties are mostly influenced by density (as expected). Therefore, the higher density MUF-bonded plywood panels also outperform the PUR-bonded ones. Interestingly, the MOE in both the longitudinal and parallel direction is not as strongly correlated to density as the modulus of rupture in both directions.

Figure 9.

Correlation matrix.

4. Discussion

The market of lightweight building and construction materials increases steadily, as weight can be directly converted to additional costs for transport and emissions. In this study, we investigated the feasibility of utilizing low-density wood from Paulownia tomentosa x elongata for the manufacture of plywood bonded with MUF and PUR adhesive.

The investigation reveals that Paulownia plywood has a low density, around 283.54 kg/m3 for 7 mm PU-bonded panels and 385.13 kg/m3 for MUF-bonded panels. For 15 mm panels, densities are 247.93 kg/m3 (PU) and 326.16 kg/m3 (MUF). Improved physical and mechanical properties correlate with higher density; MUF adhesive outperforms PU in enhancing these properties. Increased layer count marginally improves panel properties due to additional high-density glue lines. Specifically, in a three-point bending test perpendicular to the grain, 15 mm MUF-bonded panels with seven layers achieve 20.92 N/mm2, compared to 15.78 N/mm2 for five-layer panels. The lower performance of PU-bonded panels is attributed to potential incomplete curing, possibly due to a pressing temperature of 60 °C or a pressing time of 15 min per panel. Future studies should explore higher temperatures and longer pressing times for PU-bonded panels.

Currently, for lightweight construction, poplar veneer-based plywood is usually employed. When a higher focus is set on reduced weight than on resistance, balsa is a viable alternative. In Table 3 we compare the mechanical properties of different poplar and balsa-based plywood boards with those produced from Paulownia in this study. It is evident from the values in Table 3 that the higher density of poplar plywood has beneficial effects on mechanical performance. But it is worth mentioning that the lab-made Paulownia plywood from this study has similar values or even exceeds them for travers bending strength when compared to the denser poplar plywood. When compared to poplar plywood with a density of 420 kg/m3, MOE in the parallel direction also meets the marked product for the MUF-bonded Paulownia boards.

Table 3.

Comparisons of various properties of lightweight plywood made from poplar, balsa, and Paulownia.

Another possibility for lightweight construction would be solid wood panels made from balsa. Depending on the growth region, properties of balsa variate strongly, as shown by Kotlarewski et al. [25,26]. MOE, for example, depending on density, can be found between 1155 and almost 5900 MPa parallel to the grain [30]. On the other hand, Wu et al. [31] investigated the properties of balsa veneer-based composites with an average density of 180–240 kg/m3 and reported that the orientation of the layers has the biggest influence on the properties [31].

If taking into account other factors, e.g., the relatively fast growth of Paulownia (47 m3/ha·a [21]) compared to balsa (7–30 m3/ha·a [32]) or poplar (20–45 m3/ha·a [33]), and due to the good relation between density and mechanical strength applications in aerospace, train, or maritime industries, Paulownia holds a high potential. Nevertheless, some limitations and drawbacks go hand-in-hand with the low weight and fast growth, such as inconsistency and huge variability between different veneers, strong influence of growth ring thickness, etc. Therefore, more research in this direction and how to overcome homogeneity issues is needed.

This research underscores the viability and significance of Paulownia plywood for the furniture industry. Further investigation into industrial manufacturing processes, alternative adhesives, and property optimization is recommended. The results indicate that Paulownia plywood holds promise for sustainable and lightweight applications such as furniture, model construction, and thermal insulation. Continued development of Paulownia-based materials is essential for advancing ecological and innovative applications.

5. Conclusions

In this study we explored veneers made from Paulownia tomentosa x elongata for the production of 5 and 15 mm-thick, five- and seven-layer plywood boards. The results of mechanical and physical analyses have shown the basic feasibility of this wood species for plywood production. Low densities in the range of 240 kg/m3 are possible, but to achieve competitive mechanical strength, a density of around 280–300 kg/m3 should be targeted. The choice of adhesives has a significant influence on almost all properties. MUF, in this study, was the better choice, yet it should be explored in the future if adaptation of the PUR system and the pressing parameters can further enhance performance.

Author Contributions

Conceptualization, M.C.B. and E.M.T.; methodology, M.C.B. and K.B.; validation, E.M.T.; formal analysis, K.B.; investigation, K.B.; resources, M.C.B.; data curation, K.B., E.M.T. and T.S.; writing—original draft preparation, E.M.T. and T.S.; writing—review and editing, E.M.T. and T.S.; visualization, T.S.; supervision, M.C.B. and E.M.T.; project administration, M.C.B. and E.M.T.; funding acquisition, M.C.B., All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the federal state of Salzburg, grant number 20102/F2300703-KZP, Salzburg Center for Smart Materials 2.0 (SCSM2.0).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Koman, S.; Feher, S. Physical and Mechanical Properties of Paulownia Clone in Vitro 112. Eur. J. Wood Wood Prod. 2020, 78, 421–423. [Google Scholar] [CrossRef]

- Huber, C.; Moog, D.; Stingl, R.; Pramreiter, M.; Stadlmann, A.; Baumann, G.; Praxmarer, G.; Gutmann, R.; Eisler, H.; Müller, U. Paulownia (Paulownia elongata S.Y.Hu)—Importance for Forestry and a General Screening of Technological and Material Properties. Wood Mater. Sci. Eng. 2023, 18, 1663–1675. [Google Scholar] [CrossRef]

- Barbu, M.C.; Tudor, E.M.; Buresova, K.; Petutschnigg, A. Assessment of Physical and Mechanical Properties Considering the Stem Height and Cross-Section of Paulownia tomentosa (Thunb.) Steud. x Elongata (S.Y.Hu) Wood. Forests 2023, 14, 589. [Google Scholar] [CrossRef]

- Lachowicz, H.; Giedrowicz, A. Characteristics of the Technical Properties of Paulownia COTE−2 Wood. Sylwan J. 2020, 5, 414–423. [Google Scholar]

- Esteves, B.; Cruz-Lopes, L.; Viana, H.; Ferreira, J.; Domingos, I.; Nunes, L.J.R. The Influence of Age on the Wood Properties of Paulownia tomentosa (Thunb.) Steud. Forests 2022, 13, 700. [Google Scholar] [CrossRef]

- Kalaycioglu, H.; Deniz, I.; Hiziroglu, S. Some of the Properties of Particleboard Made from Paulownia. J. Wood Sci. 2005, 51, 410–414. [Google Scholar] [CrossRef]

- Barbu, M.C.; Buresova, K.; Tudor, E.M.; Petutschnigg, A. Physical and Mechanical Properties of Paulownia tomentosa x elongata Sawn Wood from Spanish, Bulgarian and Serbian Plantations. Forests 2022, 13, 1543. [Google Scholar] [CrossRef]

- Komán, S.; Feher, S.; Vityi, A. Physical and Mechanical Properties of Paulownia tomentosa Wood Planted In Hungaria. Wood Res. 2017, 62, 335–340. [Google Scholar]

- Avram, A.; Lunguleasa, A.; Spirchez, C.; Ionescu, C.S. Differences and Similarities between the Wood of Three Low-Density and Homogenous Species: Linden, Balsa, and Paulownia. Appl. Sci. 2023, 13, 10209. [Google Scholar] [CrossRef]

- Röllig, P.; Tudor, E.M.; Barbu, M.C.; Direske, M. Effect of the Particle Geometry on Lightweight Particleboard from Paulownia Using High-Frequency Pressing Technology. Wood Mater. Sci. Eng. 2024, 19, 683–690. [Google Scholar] [CrossRef]

- Nelis, P.A.; Mai, C. The Influence of Low-Density (Paulownia Spp.) and High-Density (Fagus sylvatica L.) Wood Species on Various Characteristics of Light and Medium-Density Three-Layered Particleboards. Wood Mater. Sci. Eng. 2021, 16, 21–26. [Google Scholar] [CrossRef]

- Barbu, M.C.; Radauer, H.; Petutschnigg, A.; Tudor, E.M.; Kathriner, M. Lightweight Solid Wood Panels Made of Paulownia Plantation Wood. Appl. Sci. 2023, 13, 11234. [Google Scholar] [CrossRef]

- Bayatkashkoli, A.; Faegh, M. Evaluation of Mechanical Properties of Laminated Strand Lumber and Oriented Strand Lumber Made from Poplar Wood (Populus deltoides) and Paulownia (Paulownia fortunei) with Urea Formaldehyde Adhesive Containing Nanoclay. Int. Wood Prod. J. 2014, 5, 192–195. [Google Scholar] [CrossRef]

- Sedighizadeh, P.; Moradpour, P.; Hosseinabadi, H.Z. Possibility of Making Flexible Three-Ply Plywood Using Poplar (Populus deltoides) and Paulownia (Paulownia fortunei) Veneers. Eur. J. Wood Wood Prod. 2023, 81, 209–221. [Google Scholar] [CrossRef]

- Nelis, P.A.; Henke, O.; Mai, C. Comparison of Blockboards with Core Layers Made of Kiri (Paulownia spp.) and of Spruce (Picea abies) Regarding Mechanical Properties. Eur. J. Wood Wood Prod. 2019, 77, 323–326. [Google Scholar] [CrossRef]

- Ghazzawy, H.S.; Bakr, A.; Mansour, A.T.; Ashour, M. Paulownia Trees as a Sustainable Solution for CO2 Mitigation: Assessing Progress toward 2050 Climate Goals. Front. Environ. Sci. 2024, 12, 1307840. [Google Scholar] [CrossRef]

- Rodríguez-Seoane, P.; Díaz-Reinoso, B.; Moure, A.; Domínguez, H. Potential of Paulownia sp. for Biorefinery. Ind. Crops Prod. 2020, 155, 112739. [Google Scholar] [CrossRef]

- Guo, N.; Zhai, X.-Q.; Fan, G.-Q. Chemical Composition, Health Benefits and Future Prospects of Paulownia Flowers: A Review. Food Chem. 2023, 412, 135496. [Google Scholar] [CrossRef]

- Domínguez, E.; Romaní, A.; Domingues, L.; Garrote, G. Evaluation of Strategies for Second Generation Bioethanol Production from Fast Growing Biomass Paulownia within a Biorefinery Scheme. Appl. Energy 2017, 187, 777–789. [Google Scholar] [CrossRef]

- López, F.; Pérez, A.; Zamudio, M.A.M.; De Alva, H.E.; García, J.C. Paulownia as Raw Material for Solid Biofuel and Cellulose Pulp. Biomass Bioenergy 2012, 45, 77–86. [Google Scholar] [CrossRef]

- Jakubowski, M. Cultivation Potential and Uses of Paulownia Wood: A Review. Forests 2022, 13, 668. [Google Scholar] [CrossRef]

- Icka, P.; Damo, R.; Icka, E. Paulownia Tomentosa, a Fast Growing Timber. Ann. Valahia Univ. Targoviste—Agric. 2016, 10, 14–19. [Google Scholar] [CrossRef]

- Stuepp, C.A.; Zuffellato-Ribas, K.C.; Koehler, H.S.; Wendling, I. Rooting Mini-Cuttings of Paulownia fortunei Var. Mikado Derived From Clonal Mini-Garden. Rev. Árvore 2015, 39, 497–504. [Google Scholar] [CrossRef]

- Nocetti, M.; Brunetti, M.; Criscuoli, I.; Mazzanti, P.; Murrone, P.; Stefanini, F.M.; Goli, G. Technological Properties of Paulownia and Mixed Poplar-Paulownia Plywood. Eur. J. Wood Wood Prod. 2025, 83, 142. [Google Scholar] [CrossRef]

- EN 310:2005; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bend-ing Strength. Austrian Standards: Vienna, Austria, 2005.

- EN 314-1:2005; Plywood—Bonding quality—Part 1: Test methods. Austrian Standards: Vienna, Austria, 2005.

- EN 320:2011; Particleboards and Fibreboards—Determination of Resistane to Axial Withdrawal of Screws. Austrian Standards: Vienna, Austria, 2011.

- EN 317:2005; Particleboards and Fibreboards—Determination of Swelling in Thickness After Immersion in Water. Austrian Standards: Vienna, Austria, 2005.

- EN 323:2005; Wood-Based Panels—Determination of Density. Austrian Standards: Vienna, Austria, 2005.

- Kotlarewski, N.J.; Belleville, B.; Gusamo, B.K.; Ozarska, B. Mechanical Properties of Papua New Guinea Balsa Wood. Eur. J. Wood Wood Prod. 2016, 74, 83–89. [Google Scholar] [CrossRef]

- Wu, C.; Vahedi, N.; Vassilopoulos, A.P.; Keller, T. Mechanical Properties of a Balsa Wood Veneer Structural Sandwich Core Material. Constr. Build. Mater. 2020, 265, 120193. [Google Scholar] [CrossRef]

- Cañadas-López, Á.; Rade-Loor, D.; Siegmund-Schultze, M.; Moreira-Muñoz, G.; Vargas-Hernández, J.J.; Wehenkel, C. Growth and Yield Models for Balsa Wood Plantations in the Coastal Lowlands of Ecuador. Forests 2019, 10, 733. [Google Scholar] [CrossRef]

- Thevs, N.; Fehrenz, S.; Aliev, K.; Emileva, B.; Fazylbekov, R.; Kentbaev, Y.; Qonunov, Y.; Qurbonbekova, Y.; Raissova, N.; Razhapbaev, M.; et al. Growth Rates of Poplar Cultivars across Central Asia. Forests 2021, 12, 373. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).