Abstract

In order to rationally utilize wood materials, increase wood quality, and mitigate drawbacks, research on industrial techniques for timber protection and preservation is essential on a European and global scale. When high-quality timber enters the market, it offers structures and objects that have considerable added value. This study examines the performance of thermally treated (6 h at 170 °C and 200 °C) softwood species (fir wood) when exposed outdoors and applied on wooden building structures as cladding timber, among other structures. International standards were applied for the characterization of the untreated and thermally treated wooden boards after the treatments in terms of physical, hygroscopic, and surface properties. In contrast, all the boards (of dimensions 390 × 75 × 20 mm in length, width, thickness respectively) were exposed outdoors to direct sunlight and a combination of biotic and abiotic factors for a six-month period to mainly investigate the thermal properties (heat transfer analysis/insulation properties) using a real-time test in situ, as well as to investigate their potential resistance to natural weathering (color, surface roughness, visual inspection, etc.). Heat transfer in the thermally treated wood specimens was found to be much slower than that in the untreated specimens, which, combined with lower hygroscopicity and higher dimensional stability, reveals the high potential of thermally treated wood utilization in outdoor applications, such as cladding, facades, frames, and other outdoor elements.

Keywords:

cladding; conductivity; fir wood; heat; hygroscopicity; insulation; modification; thermal transmittance; treatment 1. Introduction

Rapid population growth has made wood consumption exceed the natural forests’ productivity rate [1]. The problem becomes particularly noticeable and intensifies because of the lack of knowledge of wood properties and cost-effective technologies to convert this precious resource into competitive end products. The increasing environmental concerns of recent years have led to significant changes in the timber sector and, in particular, in the field of wood preservation. In the past, abundant quantities of high-quality wood were harvested from natural forests, but nowadays, this is not feasible. Subsequently, the timber-based product industry is based on low-value species and plantation wood, which is also considered of lower quality and requires the application of protective techniques/treatments prior to exposure to the outdoor environment [2].

In parallel, environmental concerns regarding toxic chemicals that are usually impregnated into wood, aiming to enhance its properties, have turned the research towards alternative and more environmentally friendly methods of wood modification treatments. In this direction, wood modification treatments aim to improve the properties and increase their application range, increasing the service life of the wood and its structures without worsening the environment. One such practice is thermal modification [3], which was invented in ancient times when indigenous people in Africa applied it to make their sticks durable, or Vikings to make their ships durable, etc. [4]. Therefore, this method is one of the first methods of wood improvement and protection that permanently modifies the material and creates a “new” substrate material of similar appearance, though of different properties [5].

During thermal treatment, wood with a low moisture content is exposed to high temperatures (160–250 °C) for relatively short periods [3], resulting in permanent changes to the wood’s physical/chemical properties in terms of its equilibrium moisture content (EMC), wood surface color, odor [6], other physical and mechanical properties, and chemical composition [7,8]. In general, after thermal treatment, light-colored wood species tend to acquire darker shades, resembling naturally dark-colored hardwoods of high quality [9]. Esteves and Pereira [10] explain how these changes are attributed to the increase in phenolic groups and the stabilization of lignin. Additionally, wood’s resistance to biodegradation by fungi, microfungi, and bacteria is being improved [11,12], as well as its resistance to the deterioration caused by insect attacks [13], attributed to the chemical changes and the lower hygroscopicity and moisture content (EMC) [8,14]. The chemical changes in the wood substrate induced by thermal treatment are as follows: depolymerization of hemicelluloses and the amorphous parts of cellulose, plasticization of lignin, and an increase in the lignin network, loss/alteration of extractives, followed by an increase in extractives as the treatment duration progresses.

Each wood species responds differently to specific thermal treatment conditions [3]. The temperature level, treatment duration, moisture content, and oxygen level in the chamber’s atmosphere constitute the most critical factors [15]. When wood is exposed to high temperatures, some of its hemicelluloses are depolymerized (the chemical component bearing the highest number of hydroxyl groups among the structural components of wood), and the moisture and volatile components gradually evaporate. At the same time, other extractives are being modified [16]. Some polysaccharides degrade, demonstrating a noticeable weight and density reduction, while some new compounds (extracts) are produced. During treatment, especially under humid conditions, carbonic acids, mainly acetic acid, are initially formed as a result of the breakdown of acetyl groups, particularly from hemicelluloses [17], which further promotes the structural components’ depolymerization. In parallel, wood plasticizes between 170 °C and 200 °C, while at temperatures higher than 200 °C, exothermic reactions take place. At the temperature range responsible for a lignin–glass transition, the network of lignin slightly increases through a cross-linking bond development. In general, wood that contains a higher percentage of lignin exhibits lower hygroscopicity and dimensional changes. Therefore, thermal modification provides a more dimensionally stable material [18] by reducing the EMC by approximately 0%–50%, depending on the treatment conditions [19]. Even relatively low-intensity heat treatments result in lower EMC values, with the effect being higher with an increase in temperature [20,21,22].

Previous studies have shown that the modulus of rupture (MOR) and modulus of elasticity (MOE) of wood change, depending on the temperature and duration of treatment, with a higher temperature inducing higher strength loss [23]. The density of wood decreases by 5%–15% during heat treatment, negatively affecting its strength, though without totally explaining the strength reduction. The loss of strength is due to the degradation of the cell wall due to the degradation of the hemicelluloses and is mainly reflected in a reduction in hardness of 5%–10%, flexural strength of 10%–20%, modulus of elasticity of 5%–20%, and impact bending of 30%–80%. This suggests that heat-treated wood in its current form is not suitable for load-bearing use [24]. Thermally treated wood also exhibits superior color stability compared to untreated wood based on experiments that involve artificial UV exposure [25,26]. Furthermore, when exposed to natural weathering conditions, thermally treated wood seems to be less prone to discoloration and fungal colonization staining [27]. Several other researchers have shown that reduced hygroscopicity accompanies increased dimensional stability and increased durability. However, the use of thermally treated wood in contact with the ground is not recommended [28]. Regarding thermal conductivity, wood that has undergone thermal modification exhibits 20 to 25% lower thermal conductivity [28], while resistance to ultraviolet radiation seems to be unaffected by thermal modification [29].

Most thermally modified wood is used in cladding, decking, window frames, garden furniture, indoor furniture, cabinets, posts, fences, poles, and packaging. Each application has specific property requirements. For example, cladding, flooring, and utility poles for outdoor exposure require very high resistance to weathering, ultraviolet radiation, decay, mold, and insects [30]. According to Hortobágyi et al. [31], the heat transfer intensity of thermally modified specimens decreases after heat treatment compared to untreated wood. When wood is used outdoors, heat transfer seems to be more affected by atmospheric conditions (humidity, ultraviolet radiation, air pressure, airflow intensity, etc.). Heat transfer seems to depend on the temperature differences that occur at the interface and, especially, the change in seasons and the alternation of days and nights [31]. The thermal conductivity of wood depends on several factors. Some of the most important variables that affect the rate of heat flow in wood (insulation properties) are the wood density, moisture content, direction of heat flow, species and their anatomical characteristics, and the amount and distribution of extractives or chemical substances (gums, tannins, oils, etc.) [29].

According to the literature, the impact of weathering or aging observed on the appearance and physical, thermal, and chemical characteristics of wood constitutes an intriguing area of study [2,32,33]. Furthermore, there is a conflict in the literature, with some researchers regarding the impact of weathering conditions on thermally treated wood as negligible [34], while others have pointed out that treated wood used as cladding on buildings changes color over time towards gray shades or demonstrates surface cracking [22,35,36]. Notably, a considerable lack of studies, information, and data focusing on the abiotic factors has been detected and pointed out in recently published studies [37].

The aim of this study is to investigate the effects of thermal modification on a non-durable, fast-growing and light-colored softwood species, such as fir wood, and the impact this has on its physical and thermal properties (heat transfer analysis) as well as its level of resistance to natural weathering, in order to evaluate its suitability as a thermal insulation building material. This research was undertaken in light of today’s urgent need for superior wood and wood-based materials and increased utilization of low-quality timber species to support energy-efficient building construction.

2. Materials and Methods

2.1. Raw Materials

For the purposes of the current experimental work, two trunks of fir species (Abies Borisii-regis L.) were harvested from the University Forest of Pertouli (Trikala), located in the eastern part of Pindos (Central Greece). The trunks were transferred to lab infrastructures and were cut and formed into sawn pieces (Figure 1A) of specific dimensions of 390 mm in length, 75 mm in width, and 20 mm in thickness (Figure 1B). The EMC (ISO13061-1:2014 [38]) and the basic density (dry wood weight/wet wood volume, ISO13061-2:2014 [39]) of all the samples were determined, using 5 replicates per property test, from which the mean values and standard deviation values were based. The mean EMC value of the fir wood was measured to be 11.52% (standard deviation—SD: 0.06), while the density of the wood was found to be 446 kg/m3 (SD: 81).

Figure 1.

(A) Mechanical processing of sawn wood and (B) machined boards (intended for thermal treatment).

2.2. Thermal Treatment

The thermal treatment of fir boards was carried out in a laboratory drying chamber (800 × 500 × 600 mm), in which the boards were placed on two levels. The thermal treatment took place in a pre-heated chamber at 170 °C and 200 °C for 6 h, where 12 boards were used per treatment. Relatively low temperatures were chosen for application in this study in order to allow only limited thermal degradation of the wood mass and to avoid mechanical property deterioration (based on the data from the literature [8,36], as well as previous knowledge and experience of the research team). In the preliminary experimental studies conducted by our team, a duration of 6 h demonstrated the greatest improvement in the wood’s dimensional stability (swelling and absorption percentage) and hydrophobicity, without a high mechanical strength loss [40,41,42]. Therefore, we chose to expose outdoors and continue the experimental work with the samples that had been treated for 6 h at two temperature levels: 170 °C and 200 °C, as well as the untreated samples for comparative purposes.

Upon completion of the thermal treatment, the samples were weighed on a lab scale of high accuracy (four decimals) to determine the weight and mass loss induced by the treatment. Then, all the boards, including the untreated ones, were placed in a conditioning chamber under constant relative humidity and temperature (65% ± 3%, 20 ± 2 °C) until constant weight was achieved; meanwhile, they were also visually checked for any further defects. The EMC (ISO13061-1:2014 [38]) and the basic density (ISO13061-2:2014 [39]) of the treated samples were also determined using 5 replicates.

2.3. Mass Loss

Based on the dry weight before and after treatment, the mass loss (%) of the specimens was determined, which could be attributed to the moisture and volatile extract loss and the loss of some structural chemical components of wood (the most unstable ones), which is calculated by the following equation [40].

Mass loss (%) = [(pre-treatment dry weight − post-treatment dry weight)/pre-treatment dry weight] × 100

2.4. Hygroscopic Properties

According to ISO13061-1:2014 [38], the specimens prepared for the hygroscopic properties test had dimensions of 20 × 20 × 30 mm in width, thickness, and length, respectively. After the weight, length, width, and thickness measurements of all samples, they were immersed in water at room temperature (23 ± 3 °C) using grids and weights. The specimens’ radial, tangential, and longitudinal surface dimensions, as well as weight, were measured accurately, as well after the immersion duration of 1, 3, 6, 24, and 72 h. Additionally, 10–12 specimens/replicates were used in this text per material category in order to determine the percentage of swelling and absorption of the treated and untreated specimens. The following equation was used to calculate the percentage of the radial, tangential, and longitudinal swelling of the samples:

where S is the swelling percentage (%), L1 is the dimension after immersion (mm), and L0 is the dimension prior to immersion.

𝑆 = ((𝐿1 − 𝐿0)/L0) × 100

The following equation was used to calculate the absorption percentage of the samples:

where WA is the percentage of water absorption (%), W1 is the wet weight after immersion (g), and W0 is the weight before immersion (g).

WA = ((W1 − W0)/W0) × 100

2.5. Color Determination

A Minolta colorimeter (Chroma-MeterCR 300 Colourimeter, CHNSpec Technology (Zhejiang) Co., Ltd., Hangzhou, China) was used to examine the color change of the wood samples’ surfaces due to thermal modification. The color was measured on the surface of the wooden panels, and the sensor head diameter was 6 mm, while the measurements were made using a 10-degree observer. The percentage of reflectance was collected at 10 nm intervals over the visible spectrum (from 400 to 700 nm), which were converted into CIELAB color system coordinates (DIN5033-10 [43]). These three color coordinates, L*, a*, and b*, were recorded through the colorimeter (10 measurements/material category), and the values of the color coordinates were used in the calculation of the parameters called “Total Color Difference” (ΔE), “Chroma Index” (C*), and “Color Saturation” (ΔC*).

2.6. Surface Roughness

The roughness of the boards’ surfaces was determined using a profilometer device (Mitutoyo Surftest SJ-301, Mitutoyo Corporation, Kawasaki, Japan), applying the profile method using the diamond stylus of the device. The measuring speed, the diameter of the pin, and the upper angle of the pin tool were 10 mm/min, 4 μm, and 90°, respectively. The values of the roughness indices were determined with an accuracy of ±0.01 pm. The roughness measurement points were randomly selected by marking them on the surface of the samples in a way that points from the whole surface were included. The measurements were made in a direction perpendicular to that of the wood grain (Figure 2A).

Figure 2.

(A) Roughness measurement with the Mitutoyo Surftest SJ-301 profilometer; (B) indicative view of the structure with some of the boards anchored at a fixed 45° inclination bed (the tangential surfaces of the boards were exposed to direct sun irradiation); and (C) a view of the digital infrared thermometer.

Three roughness parameters, the mean arithmetic deviation of profile—Ra, the mean peak-to-valley height—Rz, and the root mean square deviation of the assessed profile—Rq, have been widely used in previous studies to evaluate wood surface roughness [44], as were applied in the present study. The above parameters, defined by ISO 21920-2:2021 [45], were recorded in this work and compared with the respective values of the reference wood boards (untreated ones). The measurements were conducted at ambient temperature (23 ± 2 °C, 65% rh), 12 measurements were implemented on at least 3 boards of each material category, and the small areas of measurement were marked on the wood surface in order to check the same areas, especially during exposure outdoors.

2.7. Exposure of Specimens Outdoors

After the roughness and color measurements of all the boards, 5 boards were selected from each group to be exposed outdoors to the weathering and temperature (heat transfer) measurements (15 boards in total). The specimens were anchored on an improvised structure on the roof of the lab infrastructure so that they would be exposed to direct solar irradiation and all weather phenomena (i.e., sunlight, changes in temperatures and relative humidity, rain, atmospheric pollution, wind, abrasion promoted by windblown particles, salinity, microorganism actions, etc.). Specifically, the wood boards were placed at a constant distance from each other and at an angle of 45° so that one surface (back surface) would remain in the shade and the other (front) surface would come into direct contact with solar irradiation as well as other abiotic factors in a southern exposure (Figure 2B).

After the time of board anchoring, 9 different measurements were carried out on 9 different days, with a total duration of 6 months. On each of the board’s surfaces (front and back), measurements of temperature were conducted at 5 different points of each of the surface areas every two hours (12 h measurement). The measurements were carried out using a digital infrared thermometer with a digital LAZER (Parkside, Lidl Stiftung & Co., Neckarsulm, Germany) (accuracy of ±0.2 °C), keeping a stable distance from the wooden boards, according to EN 60825-1:2014 [46] (Figure 2C).

In parallel, during the period of board monitoring and measurements performed (6-month period of exposure), the ambient temperature was recorded every two hours, and when the boards were measured, at the same time, a closely placed cement reference surface temperature was recorded, as well, in order to have the opportunity to compare the performance of different materials and draw some useful conclusions. The ambient temperature measurements were carried out using a laboratory thermometer.

The boards were exposed from September until the end of February (a 6-month period); therefore, a high-temperature range was covered in terms of ambient temperature since the period from the warmest to the coldest month of the year was covered. Specifically, in the first measurements, the ambient mean temperature was 24.7 °C, while in the last measurements, it was 9.4 °C, a typical temperature level for the Mediterranean climate (Thessaloniki, North Greece) [47,48]. The exact climatic data concerning the months of exposure period from September 2020 till February 2021 (Table 1), concerning the precipitation, relative humidity, and temperature values (mean, minimum, maximum), were obtained from the closest to the exposure location meteorological station (Kalamaria region, Thessaloniki, Greece).

Table 1.

Meteorological data of the mean temperature, mean maximum temperature, mean minimum temperature, precipitation (rain), wind, and mean relative humidity, concerning the exposure period (Meteorological station Kalamaria, Thessaloniki, Greece).

After the 6-month outdoor exposure, the boards were released from the supporting construction frame and placed again in a lab environment under stable temperature and relative humidity conditions. Color and roughness measurements were conducted again, applying the same process as previously described, aiming to compare the values of the modified and unmodified wooden-board specimens before and after exposure to external conditions.

Microsoft Excel software (Microsoft office 16) was used for processing the results and preparing the diagrams/tables of the experimental results, while a one-way ANOVA was conducted through SPSS software (IBM SPSS Statistics 29.0.1.0) in order to detect whether the differences in the mean values of different wood material categories were statistically significant. Differences were considered significant at p ≤ 0.05.

3. Results

The mass loss test results (Table 2) reveal that as the treatment temperature increases, the mass loss of the boards increases as well—a trend that could be attributed mainly to the loss of wood moisture, the evaporation of volatile extracts, as well as to the thermal degradation processes that cause the depolymerization of hemicelluloses and amorphous parts of cellulose [49,50].

Table 2.

The mean percentage values of the mass loss, EMC, and basic density values of the specimens after different thermal treatments, and the respective standard deviation values are inside the parentheses.

Nevertheless, the thermally modified boards demonstrate a higher rate of weight regain during the conditioning process after thermal treatment compared to the untreated specimens. Essentially, the moisture uptake trend of the modified wood specimens was found to be higher compared to that of the untreated ones. Additionally, a significant difference was detected between the two categories of thermally modified wood (170 °C and 200 °C). More specifically, the samples modified at 170 °C presented lower weight regain during the conditioning process compared to the modified ones at 200 °C. This indicates a higher trend of wood to balance its moisture content according to the current relative humidity. The thermally treated wood’s high permeability [37,51] is a factor that could have an association with faster moisture uptake.

The EMC value seemed to decrease after the two thermal modification processes. The higher the treatment temperature, the lower the EMC and density of the wood, which is in agreement with previously conducted studies [49,50].

A statistically significant difference in density was observed between the reference material (untreated specimens) and the thermally modified samples at 170 and 200 °C. The EMC follows a similar trend, as it appears that there is a high difference between the reference and the wood samples of both thermal treatments. The beneficial role of thermal treatment in the mitigation of wood’s hygroscopic nature is apparent.

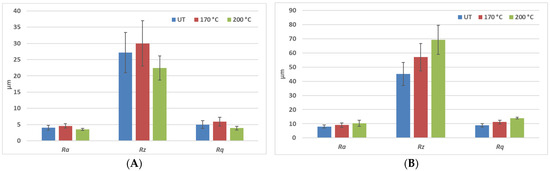

It seems that there was a slight increase in the surface roughness indices when comparing the reference material boards with those of the thermally treated ones. As it is evident, the indices Ra, Rz, and Rq of the wood surfaces increased numerically when the thermal treatment at 170 °C was applied, while the same indices decreased after thermal treatment at 200 °C, approaching the levels of reference/untreated boards’ surface roughness (Figure 3A). This slight increase in roughness was not found to be significant from a statistical point of view (p-value > 0.92) and can be attributed to a potential detachment of fibers in the surface of the wood or the decrease in density induced by the thermal treatment. In contrast, the roughness decrease, recorded at the treatment of 200 °C, could have some association with the transfer of extractives towards the surface of wood [37], the lignin network increase and stabilization, or the loss of moisture [8,52]. Therefore, these surfaces that have been modified via the most intensive treatment (200 °C) presented a lower roughness compared to the reference boards, recording a statistically significant difference (p-value < 0.017). In comparison, they presented much lower roughness than the samples of the first less intensive treatment—170 °C (p < 0.0082). These three indexes (Ra, Rz, and Rq) recorded a parallel trend in most cases, and therefore, in the literature, mainly Ra was chosen to be analyzed statistically [53].

Figure 3.

The mean values of the surface roughness indices (Ra, Rz, and Rq) before (untreated—UT) and after thermal treatment application (treated at 170 °C and 200 °C) (A), and the mean values of the surface roughness indices of the specimens after 6 months of exposure outdoors (B).

Concerning the exposure of the treated and untreated boards outdoors (Figure 3B), it was observed that as the treatment temperature increased, the roughness of the wooden specimens also increased, though this is not significant from a statistical point of view (p-value > 0.09), referring to the difference between treated specimens at 170 °C and reference material. Comparing the surface roughness values of the reference material measured before and after exposure of the specimens outdoors, significant differences were observed (Figure 3). More specifically, there was a strong increase in surface roughness in the untreated boards after being exposed to external conditions. The increase in roughness indices after exposure to external environmental conditions is quite high compared to the values recorded prior to exposure, demonstrating almost doubled values of roughness (Figure 3B). Tomak et al. [54] thermally modified ash, iroko, Scots pine, and oriental spruce at 190 °C and 212 °C for 90 min, and after the weathering tests, concluded that the surface roughness increased as the weathering time increased, that surface quality and color stability were enhanced with the thermal modification for all wood species, and that better results were achieved with hardwoods rather than softwoods.

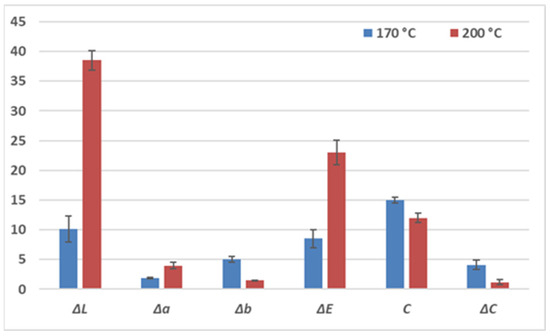

It was observed that as the intensity of the treatment (temperature level) increased, the lightness (L* index) decreased, depicting the darkening of the wood’s surface. According to the results, a decrease in L* was observed already in the mildest treatment at 170 °C compared to the reference material. In comparison, this decrease became more pronounced in the samples treated at 200 °C. This fact indicates the significant influence of treatment temperature on the lightness of the wood specimens. In parallel, it was observed that the value of color index a* tended to increase due to thermal treatments without marking high standard deviation values. Similarly, index b* exhibited similar values among the two different treatment values.

Analyzing the L* index values by measuring the samples after their external exposure, similarities between the current measurement and the pre-exposure measurement of this index were observed (Figure 4). More specifically, L* decreased, going from the mild (170 °C) to more intensive treatment (200 °C). There is a statistically significant difference between the L* of the reference samples compared to the samples of the thermal treatment at 170 °C (p < 0.0049), and an even higher difference is noted between the reference specimens and those treated at 200 °C (p < 0.0011). Likewise, in the case of the pre-exposure samples, the a* and b* indexes did not present major differences between the reference/untreated specimens and the thermally modified ones.

Figure 4.

The mean values of the total color change ΔΕ index before (induced by the thermal treatment) and after exposure outdoors (exposure’s impact on treated and untreated specimens) (Δ refers to the difference in the color indexes).

The total color difference (ΔE) and the saturation index (ΔC) were calculated, as well, in order to draw useful conclusions. The higher the ΔΕ index, the higher the surface color change measured on the wooden boards. This indicates that the samples that had undertaken heat treatment at 200 °C became even darker in color after exposure. Therefore, after the exposure of the wood boards outdoors, the ΔE index increased again, especially going from the mild to more intense treatment, with the thermally treated specimens at 200 °C (the most intensive one) exhibiting the darkest color. Comparing the samples before and after the exposure outdoors, it appears that they became slightly darker in color after the exposure since the ΔE index is numerically higher.

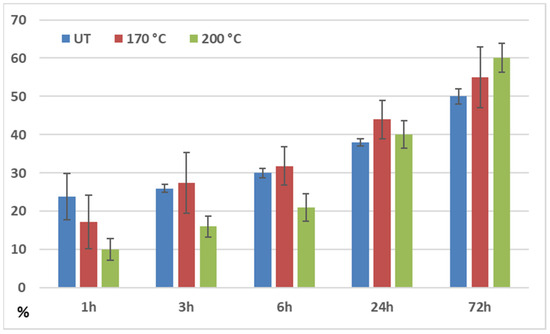

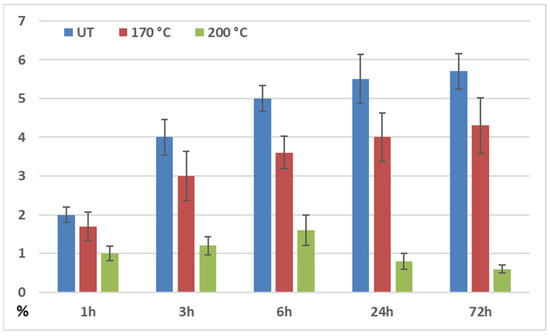

According to the results, the hygroscopic properties of the thermally modified wooden specimens improved compared to the untreated samples and the reference material (Figure 5), marking a significant enhancement in most cases. The absorption test was carried out after 1, 3, 6, 24, and 72 h of immersion in water, using specimens of both thermal treatments (170 °C and 200 °C), as well as the reference specimens. Slightly significant differences were observed in the mildest treatment of 170 °C, which suggests that improvement in the hygroscopic properties of wood begins, even from the temperature level of 170 °C. This is mainly attributed to the potential reduction and degradation of hemicelluloses [8] and the potential subsequent reduction in hydroxyl groups that the hemicelluloses and amorphous parts of cellulose bear [37,55]. Additionally, this tendency could be explained by the depolymerization of the amorphous parts of cellulose and the lignin plasticization at the glass transition temperature point (approximately at 160–180 °C), which leads to a potential increase in the lignin network through thermal degradation product attachment via cross-linking chemical bond development [8,22,37,53]. Therefore, during high-temperature treatments, several changes in the chemical composition occur within the wood mass [8,37].

Figure 5.

The mean percentage values of the absorption (%) of the specimens after immersion in water for 1, 3, 6, 24, and 72 h.

Longitudinal swelling values (Figure 6) presented significant differences between the untreated and treated specimens, highlighting the beneficial action of thermal treatment towards the mitigation of its hygroscopic nature. Even the mildest treatment presented a significantly lower longitudinal swelling percentage (p-value < 0.027), while the specimens treated at 200 °C presented the lowest values of longitudinal swelling (p-value < 0.0097), marking statistical differences in the response of the material compared to the untreated specimens. In conclusion, the thermal treatment significantly and positively affected the wood material, making it less hygroscopic and dimensionally stable.

Figure 6.

The mean values of longitudinal swelling (%) after water immersion for 1, 3, 6, 24, and 72 h.

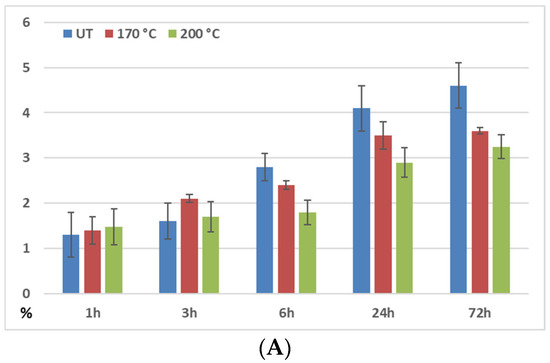

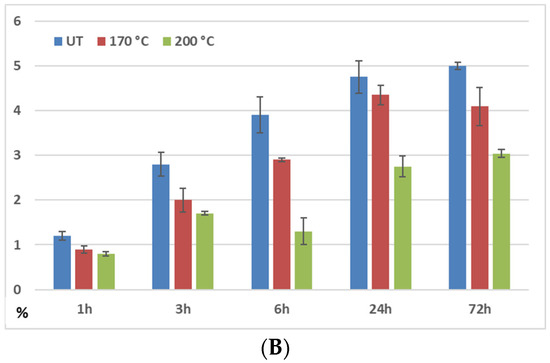

A similar trend of the longitudinal swelling of treated and untreated wood specimens was observed in the tangential (Figure 7A) and radial swelling trends (Figure 7B). The tangential swelling, as well as the radial swelling of thermally treated wood, were found to be much lower than the respective mean values of untreated (reference) wood specimens, marking, in most cases, statistically significant differences. The numerical indices increased substantially at 24 h and 72 h of immersion in water, as was expected. Among the samples of the two treatments, in those that were thermally modified at 200 °C, the tangential and radial swellings were even lower compared to the samples modified at 170 °C. These findings were further evidence of the beneficial influence of thermal treatments on wood material properties. As was expected, the radial swelling values were, in general, found to be lower than the respective values of tangential swelling due to the anatomical characteristics of wood.

Figure 7.

The mean values of tangential swelling (%) (A) and radial swelling (%) (B) after water immersion for 1, 3, 6, 24, and 72 h.

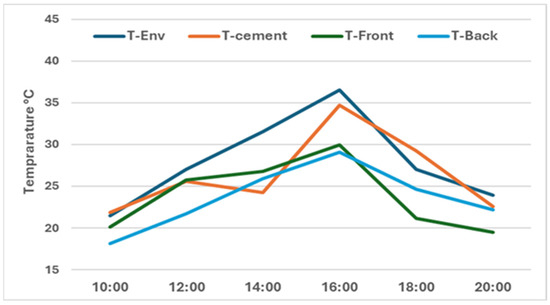

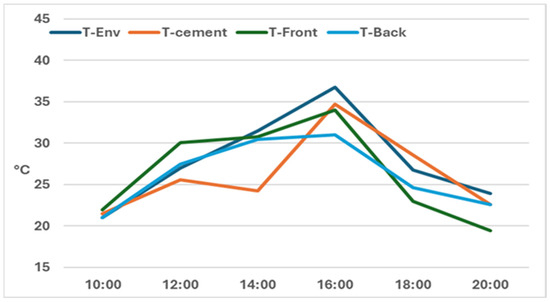

The analysis of the results of the temperatures recorded during the specimens’ exposure to external conditions showed that the ambient temperature increased during the hours between 14:00 and 18:00 in the afternoon. The main differences in the temperatures of the treated specimens and the untreated ones, as well as the specimens of the two treatments, were observed during these hours (14:00 to 18:00). The temperature on the reference specimens increased as the ambient temperature increased during these hours (14:00 to 18:00). The temperature value recorded on the back surfaces remained constant without significant differences occurring during the hours of 14:00 to 18:00, and all these temperature values were found significantly lower than the respective temperature values of the front wooden boards’ surfaces. From 16:00 onwards, it was observed that on the back surface of the wooden boards, there was an increase in temperature, which indicates that the high temperature during the whole day was maintained. The temperature of the cement wall was almost at all time points higher than the respective ones for the untreated specimens since it was affected by the ambient temperature much more intensively and at a faster rate (Figure 8). The advantages of wood, compared to cement, in terms of insulation properties and heat transfer, are apparent—characteristics that are considered very crucial, especially in the construction field.

Figure 8.

The mean values of the temperature of untreated specimens (reference) when exposed outdoors. (T-Env.: temperature of the environment; T-cement: temperature of the reference material of cement wall; T-Front: temperature on the front specimens’ surface; T-Back: temperature on the back specimens’ surface).

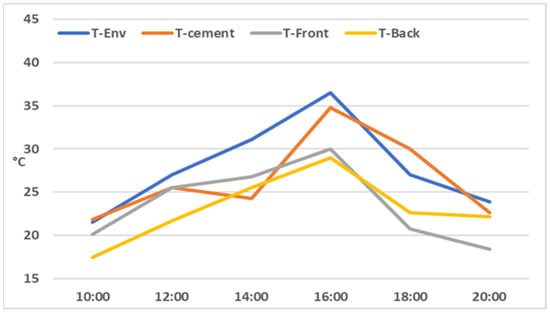

In the specimens that were thermally modified at 170 °C, the temperature (measured during their exposure outdoors) increased during the afternoon hours (14:00 to 18:00). The same was observed in the back surface of the specimens that did not come into direct contact with solar irradiation. The temperature values measured at the back surfaces remained numerically at lower levels than those of the respective front surfaces, with a slight maintenance of the temperature during the afternoon hours. The difference in the temperatures for the front and back surfaces was not numerically high (not statistically significant). Therefore, it can be concluded that the transfer of temperature from the front surface, which is in direct contact with sun irradiation, to the back surface of the specimens occurs relatively quickly. Particular differences were detected between the temperature values of the wall (cement reference) and the specimens treated at 170 °C since high differences were recorded (Figure 9).

Figure 9.

The temperature of the treated specimens (170 °C, 6 h) exposed outdoors. (T-Env.: temperature of the environment; T-cement: temperature of the reference material of cement wall; T-Front: temperature on the front specimens’ surface; T-Back: temperature on the back specimens’ surface).

In the specimens treated at 200 °C, a higher surface temperature during the midday hours was observed, where the effect of solar irradiation is higher, compared to the respective specimens treated at 200 °C and the untreated specimens. During the hours between 12:00–16:00, the temperature of the front surfaces that came into direct contact with the sun irradiation reached up to 40 °C. At these temperature levels, the back surfaces remained at low-temperature levels. We therefore conclude that the transfer of temperature from the front surface of the wooden boards to the back surface, where there is no direct effect of solar irradiation, is slow.

During the afternoon hours, the opposite trend was observed. The temperature on the back surface of the specimens was found to be slightly higher than those recorded on the front surface. Therefore, essentially, during the hours when the ambient temperature declined, the specimens maintained a higher temperature on the back surface. In the case of the wooden boards that were thermally treated at 200 °C, the temperature transfer occurred at a slower rate from the front surface to the back. Therefore, the thermal treatment clearly affects the temperature transfer from one side of the specimen to the other. In the case of the wood samples modified at 200 °C, their temperature values differed from the cement reference surface temperature, mainly in the morning and noon hours. In conclusion, it follows that the untreated, in relation to the thermally treated specimens, present a difference in the uptake and transfer of temperature from one surface to the other. In the untreated specimens (reference), the temperature transfer occurred faster in the direction from the front surface to the back. In contrast, on the treated specimens, and especially those modified at 200 °C, the transfer occurred at a much slower pace/rate, and the temperature maintenance on the back surface was higher (Figure 10).

Figure 10.

The temperature of the treated specimens (200 °C, 6 h) exposed outdoors. (T-Env.: temperature of the environment; T-cement: temperature of the reference material of cement wall; T-Front: temperature on the front specimens’ surface; T-Back: temperature on the back specimens’ surface).

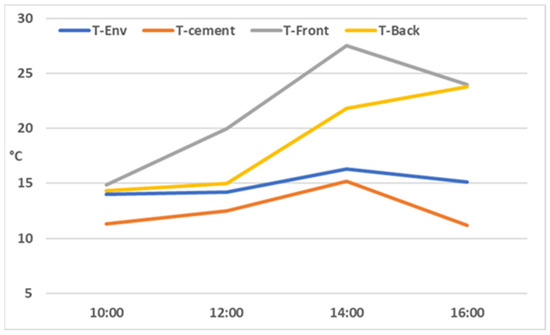

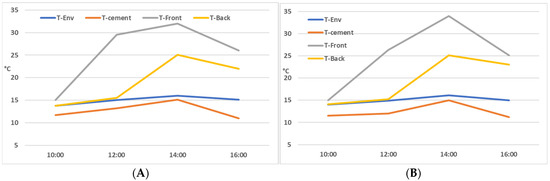

During the month of February, the ambient temperature demonstrated low values, with a maximum temperature of 17 °C (Figure 11). The results showed that the front surface of the untreated samples, which came into contact with solar irradiation, increased in temperature at 14:00, reaching a mean value of 27.7 °C with an ambient temperature between 17 °C and 23.93 °C, with an ambient temperature of 16 °C. The temperature uptake is significant compared to the ambient temperature. At the same time, the back side of the untreated samples maintained a lower temperature compared to the front surfaces.

Figure 11.

The temperature of the untreated specimens (reference) exposed outdoors during the winter month of February. (T-Env.: temperature of the environment; T-cement: temperature of the reference material of cement wall; T-Front: temperature on the front specimens’ surface; T-Back: temperature on the back specimens’ surface).

Essentially, at the relatively low ambient temperatures of the winter months (February), the untreated samples appeared to maintain a satisfying amount of temperature. On the contrary, the temperature on the cement wall surface remained quite low compared to the ambient temperature and the untreated (reference) specimens.

The temperatures on the front surfaces of the specimens that were thermally treated at 170 °C increased during the hours between 12:00 and 16:00. During these hours; the temperature reached the level of 32.2 °C on the front surface. The temperature of the back surfaces of the specimens seemed to be lower by approximately 3 °C during these hours, indicating a relatively low and slow temperature transfer. In parallel, comparing the front surface of the untreated specimens and those treated at 170°, it was observed that the treated specimens demonstrated higher temperatures (Figure 12A).

Figure 12.

The temperature of the specimens exposed outdoors during the winter month of February, treated at 170 °C (A) and 200 °C (B) (T-Env.: temperature of the environment; T-cement: temperature of the reference material of cement wall; T-Front: temperature on the front specimens’ surface; T-Back: temperature on the back specimens’ surface).

In the thermally treated boards at 200 °C, it was observed that the surface that comes into direct contact with solar irradiation increased in temperature between 12:00 and 16:00, as happened with the samples modified at 170 °C. The maximum temperature value recorded was 34.1 °C at an ambient temperature of 17 °C.

The temperature values of the back surfaces that do not have direct contact with solar irradiation were maintained low. Comparing the front and back surfaces, a large difference at a level between 10 and 6 °C was identified. This indicates that between the hours of 12:00 and 14:00, the temperature transfer was quite slow. A fact that changes from 16:00 onwards, though without major differences (Figure 12B).

The specimens of the two treatments, at a low ambient temperature in the month of February, seemed to absorb a high amount of heat (compared to the untreated specimens and to the cement reference material). The differences recorded between the boards of the two thermal treatments are not significant, although, at 200 °C, the samples presented slightly higher temperature values. Even after six months of exposure, it was observed that heat treatment plays an important role in heat absorption and transfer through wood material-based panels. The potential of utilizing wood material and specifically the wood of fir species in outdoor wooden structure elements after the performance of thermal treatments at 170 °C and 200 °C (6 h) has been highlighted through the results of this study. It is undoubtful that wood may offer several advantages over cement in construction regarding heat transfer and insulation, lowering consumption of energy while fostering thermal comfort. The insulating qualities of wood and thermally treated wood enable the construction of walls with a higher degree of thermal resistance while remaining thinner (of lower thickness). Combined with its capacity to absorb CO2, wood’s sustainability and renewable qualities make it a more eco-friendly choice for construction materials [37].

Based on the thorough observation of the specimens of the current study during and at the end of their 6-month exposure to external conditions, both the unmodified and modified wood developed some micro-cracks and, to a small extent, discontinuities in the structure of the material. At the same time, color loss and photodegradation of the wood surfaces caused by UV radiation [37] have also been identified. Nevertheless, all these weathering signs are much more apparent and extended on the untreated (reference) wood specimens compared to the thermally treated ones. Improvements in dimensional stability and mild weathering resistance for fir wood material and its structures appear to be ensured by thermal treatment, which is in agreement with the findings of previous studies in the literature dealing with different thermal treatment conditions and wood species [22,36,37]. It is, though, important to keep in mind that thermally treated wood is not considered highly durable in terms of either mechanical strength (due to the thermal decomposition that has been undertaken during the treatment) or biological strength. Therefore, the need for additional protection is a crucial issue to be addressed according to the conditions in which the treated wood material is being applied. In addition, the increase in construction costs when using thermally modified wood should be taken into account, considering whether the benefits emerging from its use (dimensional stability, slight weathering protection, lower heat transfer rate) outweigh the drawback of the slight increase in production costs.

It is suggested that, in the future, further research should be performed on the insulating properties and heat transfer of wood and thermally treated wood in real-time service applications. Future studies should include an examination of the responses of various wood species for comparative reasons, application/examination of longer periods of exposure of treated and untreated wood samples to outdoor conditions (along with the associated structures of those materials), and an investigation of the optimum combination of protective techniques (surface protection or chemical treatment techniques) to be applied on thermally treated wood before being exposed outdoors towards the increase in wooden construction service life duration.

4. Conclusions

In this study, heat treatment of fir wooden boards was carried out at 170 °C and 200 °C for 6 h. The properties of the modified specimens were examined and compared to the untreated ones, while both treated and untreated specimens were exposed outdoors for 180 days in order to monitor the weathering response and the heat insulation performance (heat transfer) of the boards.

It was observed that as the intensity of the treatment increased from 170 to 200 °C, the mass loss (%) of the fir wood increased as well, and was mainly attributed to a loss of moisture, volatile extractives, and unstable chemical components of the wood. The EMC and density of the samples were found to be both lower after the thermal treatments. The treatment at 170 °C increased the surface roughness of the wood, while the most intense treatment of 200 °C decreased it, providing smoother surfaces. The exposure outdoors increased the roughness significantly, especially that of the heat-treated specimens, with the roughness of the specimens treated at 200 °C being the highest. Before outdoor exposure, the untreated specimens appeared to have the lowest roughness compared to the “after exposure” values of all the specimens. The color indices (L*) of both thermally treated and untreated specimens appeared to decrease after exposure to external environmental conditions. The hygroscopic properties (swelling and absorption) of the specimens improved significantly after both treatments, with the most intensive providing the highest hydrophobicity.

Concerning outdoor exposure, direct contact of the front surfaces of the specimens was affected by solar irradiation. Regarding the heat-treated specimens at 200 °C, the temperature transfer occurred more slowly/gradually compared to the untreated samples, indicating the crucial role of treatment in slowing down the heat transfer in wood.

The natural weathering of the specimens was induced by UV combined with other biotic and abiotic factors, revealing, in parallel, high differences in temperature and heat transfer, even after 6 months of exposure and even at low ambient temperatures. Weathering phenomena were more apparent in the untreated wood compared to the wood that was thermally treated. Thermal treatment seems to benefit wood material’s dimensional stability and provides slight weathering protection. The heat transfer in the samples treated at 200 °C was proved to be much slower than the untreated wood, which reveals that the heat treatment significantly affects the heat absorption and transfer from one side of the wood to the other. Thermally treated wood (even untreated wood) seems to offer several advantages over cement in construction regarding heat transfer and insulation. Thus, there is a great deal of opportunity for using these thermally treated wood products in several applications, including, among others, heat insulation structural components, cladding, facades, doors/windows frames, and other medium- or low-load-bearing applications.

Author Contributions

Conceptualization, I.B. and V.K.; methodology, I.B. and V.K.; software, A.I.; validation, A.I. and V.K.; formal analysis, A.I. and I.B.; investigation, A.I.; resources, I.B.; data curation, A.I. and V.K.; writing—original draft preparation, A.I.; writing—review and editing, V.K. and I.B.; visualization, A.I.; supervision, I.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are available upon request to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Uetimane, E., Jr.; Jebrane, M.; Terziev, N.; Daniel, G. Comparative wood anatomy and chemical composition of Millettiamossambicensis and Millettiastuhlmannii from Mozambique. Biores 2018, 13, 3335–3345. [Google Scholar] [CrossRef]

- Dubey, M.K.; Pang, S.; Walker, J. Color and dimensional stability of oil heat-treated radiata pinewood after accelerated UV weathering. For. Prod. J. 2010, 60, 453–459. [Google Scholar] [CrossRef]

- Hill, C. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons Chichester: Hoboken, NJ, USA, 2006. [Google Scholar]

- Rowell, R. Chemical modification of wood: A short review. Wood Mater. Sci. Eng. 2006, 1, 29–33. [Google Scholar] [CrossRef]

- Younsi, R.; Kocaefe, D.; Poncsak, S.; Kocaefe, Y. Computational and experimental analysis of high temperature thermal treatment of wood based on Thermo Wood technology. Int. Commun. Heat Mass Transf. 2010, 37, 21–28. [Google Scholar] [CrossRef]

- Kotilainen, R.; Toivannen, T.; Alén, R. FTIR monitoring of chemical changes in softwood during heating. J. Wood Chem. Technol. 2008, 20, 307–320. [Google Scholar] [CrossRef]

- Obataya, E. Effects of ageing and heating on the mechanical properties of wood. In Wood Science for Conservation of Cultural Heritage, Proceedings of the International Conference held by COST Action IE0601, Florence, Italy, 8–10 November 2009; Uzielli, L., Ed.; Firenze University Press: Florence, Italy, 2009; pp. 16–23. [Google Scholar]

- Kamperidou, V. Chemical and Structural Characterization of Poplar and Black Pine Wood exposed to Short Thermal Modification. Drv. Ind. 2021, 72, 155–167. [Google Scholar] [CrossRef]

- Barboutis, I.; Kamperidou, V. Impact of Heat Treatment on the Quality of Tree-of-Heaven Wood. Drv. Ind. 2019, 70, 351–358. [Google Scholar] [CrossRef]

- Esteves, B.M.; Pereira, H.M. Wood modification by heat treatment: A review. Biores 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Leithoff, H.; Peek, R. Heat treatment of bamboo. In International Research Group Wood Pre; Section 4-Processes; Nº IRG/WP 01-40216; International Research Group: Lüneburg, Germany, 2001. [Google Scholar]

- Lekounougou, S.; Kocaefe, D.; Oumarou, N.; Kocaefe, Y.; Poncsák, S. Effect of thermal modification on mechanical properties of Canadian white birch (Betula papyrifera). Int. Wood Prod. J. 2011, 2, 101–107. [Google Scholar] [CrossRef]

- Mayes, D.; Oksanen, O. ThermoWood® Handbook, version 1.0; Finnish Thermowood Association: Helsinki, Finland, 2002. [Google Scholar]

- Militz, H.; Altgen, M. Processes and Properties of Thermally Modified Wood Manufactured in Europe. In Deterioration and Protection of Sustainable Biomaterials; Schultz, T.P., Goodell, P., Nicholas, D.D., Eds.; ACS Symposium Series; Oxford University Press: Oxford, UK, 2014; Volume 1158, Chapter 16; pp. 269–285. [Google Scholar]

- Gunduz, G.; Aydemir, D.; Karakas, G. The effects of thermal treatment on the mechanical properties of wild Pear (Pyrus elaeagnifolia Pall.) wood and changes in physical properties. Mater. Des. 2009, 30, 4391–4395. [Google Scholar] [CrossRef]

- Filippou, I. Chemistry and Chemical Products of Wood; Giahoudi, Giapouli: Thessaloniki Greece, 2014. [Google Scholar]

- Bourgois, J.; Guyonnet, R. Characterisation and analysis of torrefied wood. Wood Sci. Technol. 1988, 22, 143–155. [Google Scholar] [CrossRef]

- Liu, S.; Ran, Y.; Cao, J. Comparison on thermally modified beech wood in different mediums: Morphology, chemical change and water-related properties. Ind. Crops Prod. 2024, 209, 117935. [Google Scholar] [CrossRef]

- Militz, H. Processes and properties of thermally modified wood manufactured in Europe. In Development of Commercial Wood Preservatives; Schultz, T.P., Militz, H., Freeman, M.H., Goodell, B., Nicholas, D.D., Eds.; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2008; Chapter 22; Volume 982, pp. 372–388. [Google Scholar]

- Popper, R.; Niemz, P.; Eberle, G. Untersuchungenzum Sorptions- und Quellungsverhalten von thermischbehandeltemHolz. (Investigations on the sorption and swelling properties of thermally treated wood). HolzRohWerkst 2005, 63, 135–148. [Google Scholar]

- Sandberg, D.; Kutnar, A. Thermally modified timber: Recent developments in Europe and North America. Wood Fiber Sci. 2016, 48, 28–39. [Google Scholar]

- Kamperidou, V.; Barboutis, I. Natural Weathering performance of thermally treated poplar and black pine wood. Maderas. Cienc. Tecnol. 2021, 23, 1–21. [Google Scholar] [CrossRef]

- Dagbro, O. Studies on Industrial-Scale Thermal Modification of Wood. Ph.D. Thesis, Department of Engineering Sciences and Mathematics, Luleå University of Technology, Luleå, Sweden, 2016. [Google Scholar]

- Tavassoli, F.; Razzaghi-Kashani, M.; Mohebby, B. Hydrothermally treated wood as reinforcing filler for natural rubber bio-composites. J. Polym. Res. 2018, 25, 3. [Google Scholar] [CrossRef]

- Ayadi, N.; Lejeune, F.; Charrier El Bouhtoury, F.; Charrier, B.; Merlin, A. Color stability of heat-treated wood during artificial weathering. Eur. J. Wood Wood Prod. 2003, 61, 221–226. [Google Scholar] [CrossRef]

- Srinivas, K.; Pandey, K. Photodegradation of thermally modified wood. J. Photochem. Photobiol. 2012, 117, 140–145. [Google Scholar] [CrossRef]

- Tolvaj, L. Optical Properties of Wood. In Measurement Methods and Result Evaluations; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Jämsä, S.; Viitaniemi, P. Heat treatment of wood—Better durability without chemicals. In Proceedings of the Special Seminar, Antibes, France, 9 February 2001. [Google Scholar]

- Rapp, A. Review on heat treatments of wood, COST ACTION E22-Environmental optimisation of wood protection. In Proceedings of the Special Seminar, Antibes, France, 9 February 2001. [Google Scholar]

- Moura, L.F. Effect of thermal treatment on the chemical characteristics of wood from Eucalyptus grandis W. Hill ex Maiden under different atmospheric conditions. CERNE 2012, 18. [Google Scholar] [CrossRef]

- Hortobágyi, Á.; Pivarčiová, E.; Koleda, P. Holographic Interferometry for Measuring the Effect of Thermal Modification on Wood Thermal Properties. Appl. Sci. 2021, 11, 2516. [Google Scholar] [CrossRef]

- Koutsianitis, D.; Ninikas, K.; Mitani, A.; Ntalos, G.; Miltiadis, N.; Vasilios, A.; Taghiyari, H.R.; Papadopoulos, A.N. Thermal Transmittance, Dimensional Stability, and Mechanical Properties of a Three-Layer Laminated Wood Made from Fir and Meranti and Its Potential Application for Wood-Frame Windows. Coatings 2021, 11, 304. [Google Scholar] [CrossRef]

- Yildiz, S.; Tomak, E.D.; Yildiz, U.C.; Ustaomer, D. Effect of artificial weathering on the properties of heat treated wood. Polym. Degrad. Stab. 2013, 98, 1419–1427. [Google Scholar] [CrossRef]

- Nuopponen, M.; Wikberg, H.; Vuorinen, T.; Maunu, S.L.; Jämsä, S.; Viitaniemi, P. Heat-treated softwood exposed to weathering. J. Appl. Polym. Sci. 2004, 91, 2128–2134. [Google Scholar] [CrossRef]

- Humar, M.; Kržišnik, D.; Lesar, B.; Brischke, C. The Performance of Wood Decking after Five Years of Exposure: Verification of the Combined Effect of Wetting Ability and Durability. Forests 2019, 10, 903. [Google Scholar] [CrossRef]

- Herrera, R.; Arrese, A.; de Hoyos-Martinez, P.L.; Labidi, J.; Llano-Ponte, R. Evolution of thermally modified wood properties exposed to natural and artificial weathering and its potential as an element for façades systems. Constr. Build. Mater. 2018, 172, 233–242. [Google Scholar] [CrossRef]

- Godinho, D.; Araújo, S.d.O.; Quilhó, T.; Diamantino, T.; Gominho, J. Thermally Modified Wood Exposed to Different Weathering Conditions: A Review. Forests 2021, 12, 1400. [Google Scholar] [CrossRef]

- ISO13061-1:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens. Part 1: Determination of Moisture Content for Physical and Mechanical Tests. ISO: Geneva, Switzerland, 2014.

- ISO13061-2:2014; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens. Part 2: Determination of Density for Physical and Mechanical Tests. ISO: Geneva, Switzerland, 2014.

- Kamperidou, V.; Barboutis, I.; Vasileiou, V. Response of Colour and Hygroscopic properties of Scots Pine wood to thermal modification. J. For. Res. 2013, 24, 571–575. [Google Scholar] [CrossRef]

- Barboutis, I.; Vassiliou, V.; Mitani, A.; Kamperidou, V. Effects of short time thermal treatment on some properties of lime wood (Tilia cordata). PRO Ligno Int. J. Field Wood Eng. 2011, 7, 39–49. [Google Scholar]

- Mitani, A.; Barboutis, I. Color changes and dimensional stability in fir wood (Abies Borissi-regis Mattf.) Modified by heat treatment. Int. J. Eng. Invent. 2014, 4, 26–32. [Google Scholar]

- DIN5033-10; Colorimetry—Part 10: Reflectance Black Standard for Calibration in Colorimetry and Photometry. DIN: Berlin, Germany, 2022.

- Adamčík, L.; Giudice, V.L.; Todaro, L.; Dudiak, M.; Kminiak, R. Surface roughness of thermally modified and unmodified selected wood species after sanding. Eur. J. Wood Prod. 2025, 83, 105. [Google Scholar] [CrossRef]

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile. Part 2: Terms, Definitions and Surface Texture Parameters. ISO: Geneva, Switzerland, 2021.

- EN 60825-1:2014; Safety of Laser Products—Part 1: Equipment Classification and Requirements. CEN: Brussels, Belgium, 2014.

- Stathi, E.; Kastridis, A.; Myronidis, D. Analysis of Hydrometeorological Characteristics and Water Demand in Semi-Arid Mediterranean Catchments under Water Deficit Conditions. Climate 2023, 11, 137. [Google Scholar] [CrossRef]

- Kastridis, A.; Margiorou, S.; Sapountzis, M. Check-Dams and Silt Fences: Cost-Effective Methods to Monitor Soil Erosion under Various Disturbances in Forest Ecosystems. Land 2022, 11, 2129. [Google Scholar] [CrossRef]

- Kocaefe, D. Effect of thermal treatment on the chemical composition and mechanical properties of birch and aspen. Bioresources 2008, 3, 517–537. [Google Scholar] [CrossRef]

- Kamperidou, V.; Ratajczak, I.; Perdoch, W.; Mazela, B. Impact of thermal modification combined with silicon compounds treatment on wood structure. Wood Res. 2022, 67, 773–784. [Google Scholar] [CrossRef]

- Lesar, B.; Humar, M.; Kržišnik, D.; Thaler, N.; Žlahtič, M. Performance of façade elements made of five different thermally modified wood species on model house in Ljubljana. In Proceedings of the WCTE 2016—World Conference on Timber Engineering, Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Pelit, H.; Korkmaz, M.; Budakci, M. Surface Roughness of Thermally Treated Wood Cut with Different Parameters in CNC Router Machine. BioResources 2021, 16, 5133–5147. [Google Scholar] [CrossRef]

- Moreau, C.; Lemesle, J.; Páez Margarit, D.; Blateyron, F.; Bigerelle, M. A Statistical Approach for Characterizing the Behaviour of Roughness Parameters Measured by a Multi-Physics Instrument on Ground Surface Topographies: Four Novel Indicators. Metrology 2024, 4, 640–672. [Google Scholar] [CrossRef]

- Tomak, E.D.; Ustaomer, D.; Ermeydan, M.A.; Yildiz, S. An investigation of surface properties of thermally modified wood during natural weathering for 48 months. Meas. J. Int. Meas. Confed. 2018, 127, 187–197. [Google Scholar] [CrossRef]

- Schneid, E.; Gonzalez de Cademartori, P.H.; Gatto, D. The effect of thermal treatment on physical and mechanical properties of Luehea divaricata hardwood. Maderas. Cienc. Tecnol. 2014, 16, 413–422. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).