Physical–Mechanical Properties of Innovative Biobased Particleboards for Application in External Building Façades

Abstract

1. Introduction

- Miscanthus boards and cork (raw or expanded), employed for thermal buffering, moisture regulation, and esthetic cladding [11];

- Environmental sustainability through carbon reduction and the use of renewable or recycled resources;

- Enhanced technical performance via improved thermal, acoustic, and structural properties;

- Material innovation that supports lighter, modular, and code-compliant façade designs.

2. Materials and Methods

2.1. Raw Materials

2.2. Steam Explosion Pretreatment

2.3. Binder Preparation

2.4. Production of Particleboards

2.5. Evaluation of Particleboards

3. Results and Discussion

3.1. Physical–Mechanical Properties of the Boards

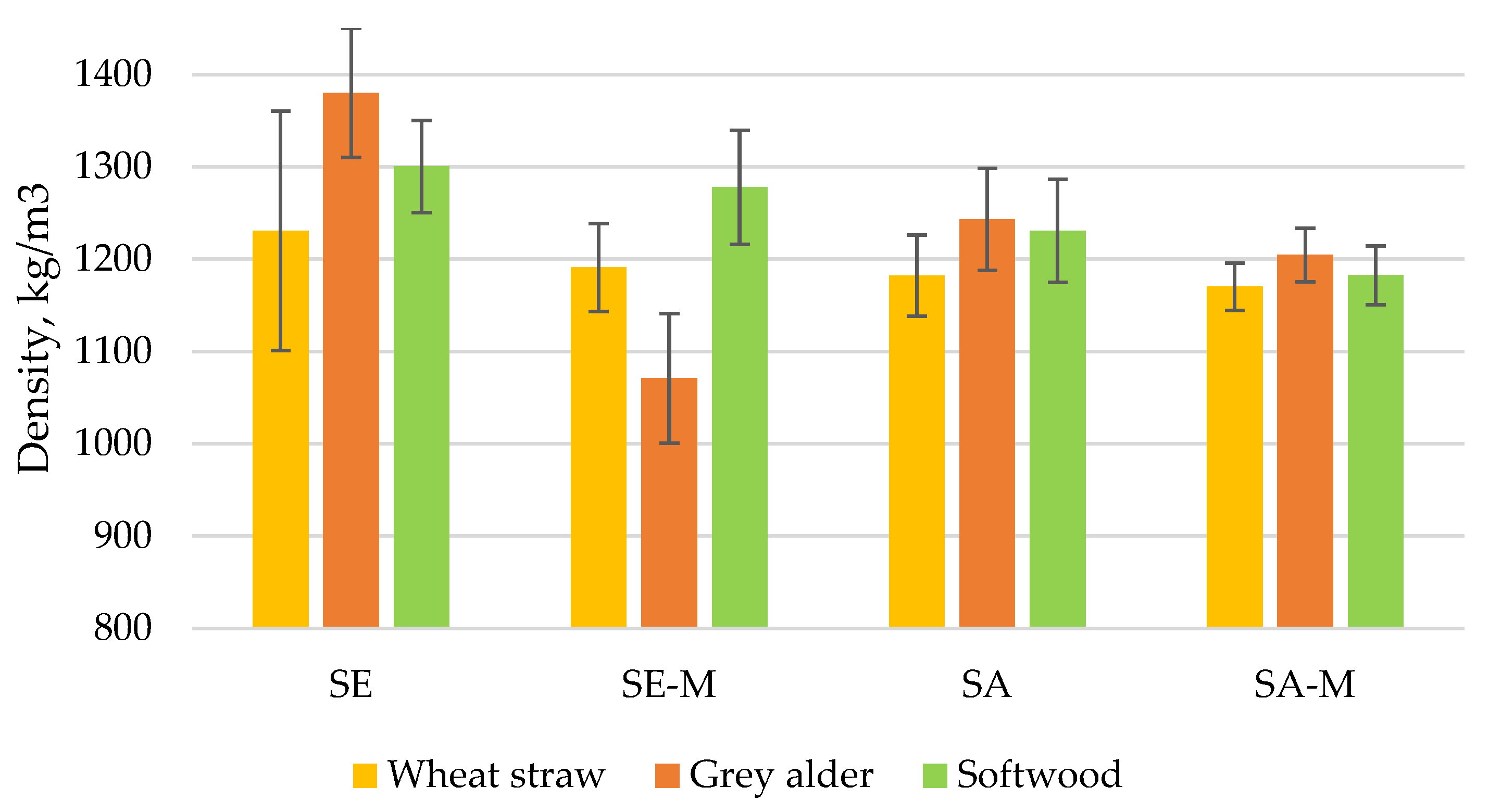

3.1.1. Density

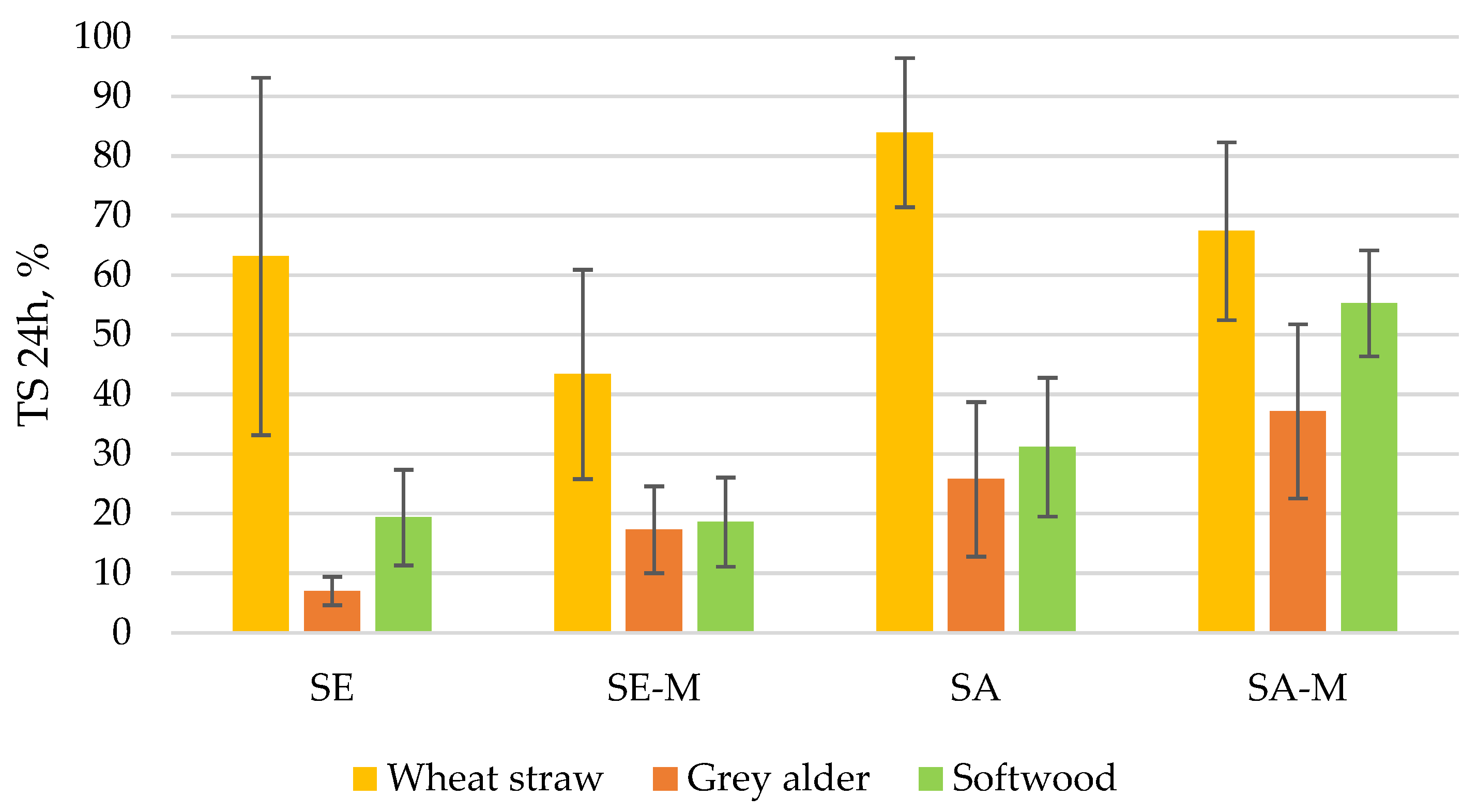

3.1.2. Water Resistance

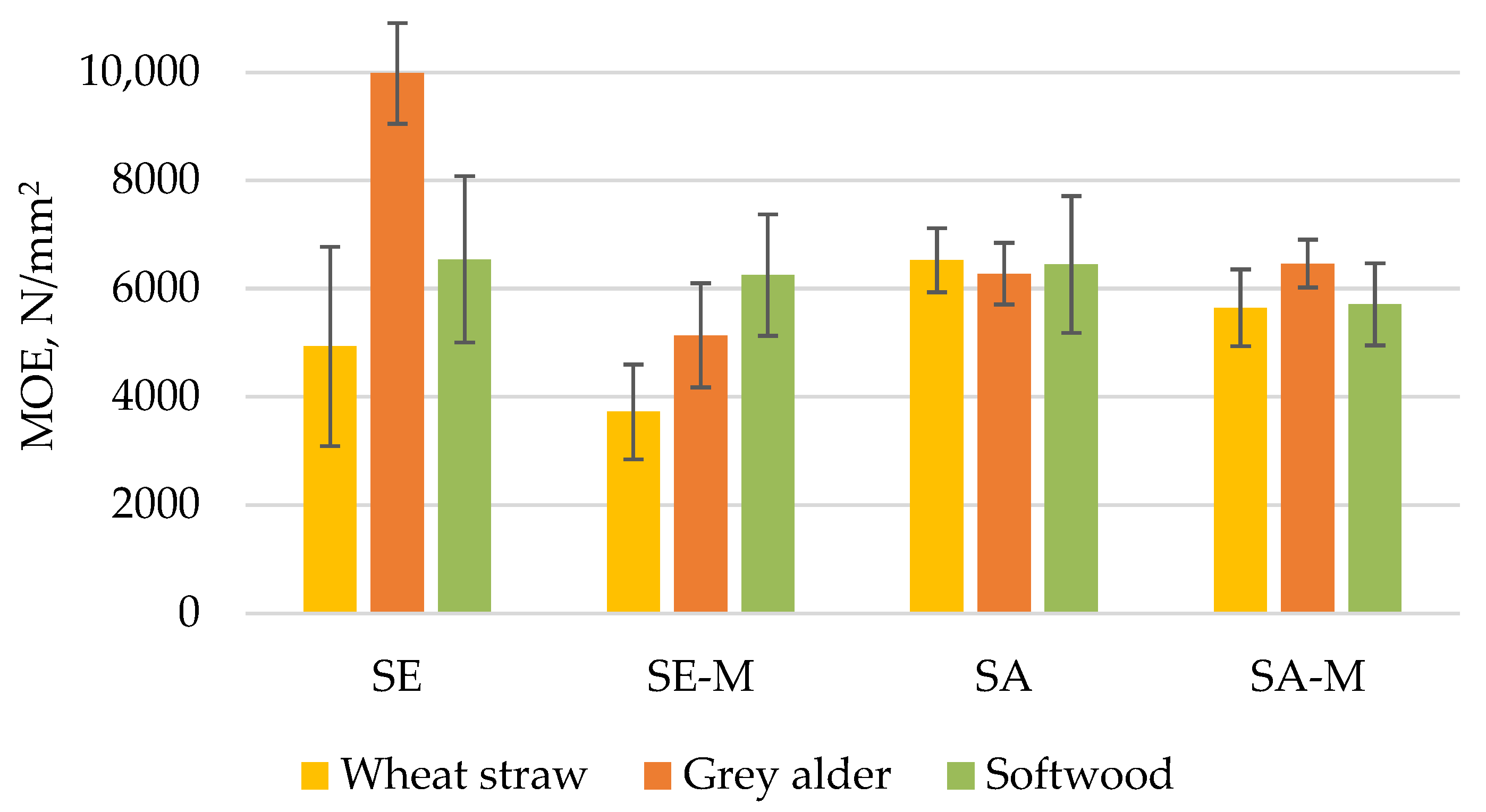

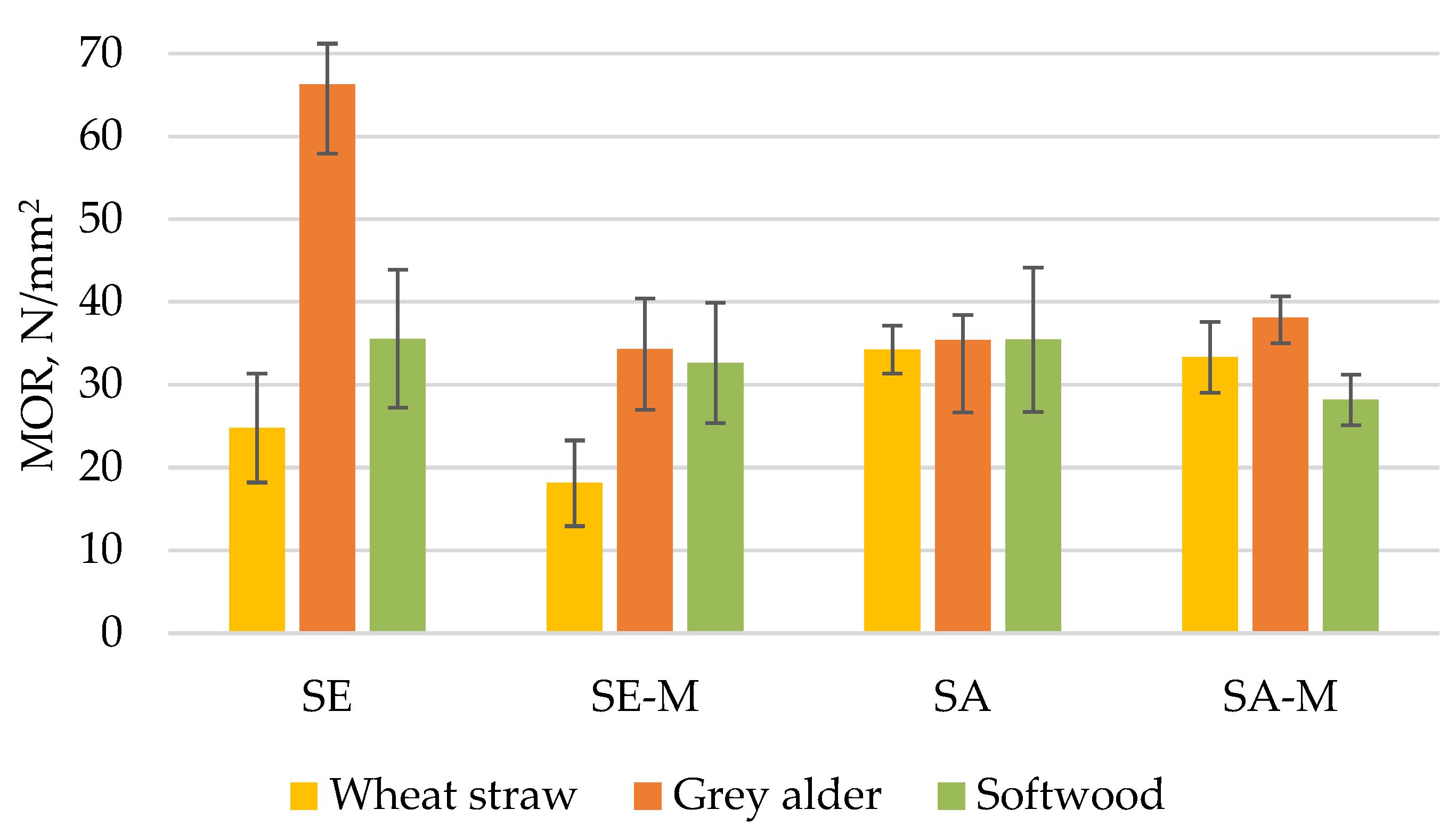

3.1.3. Bending Properties

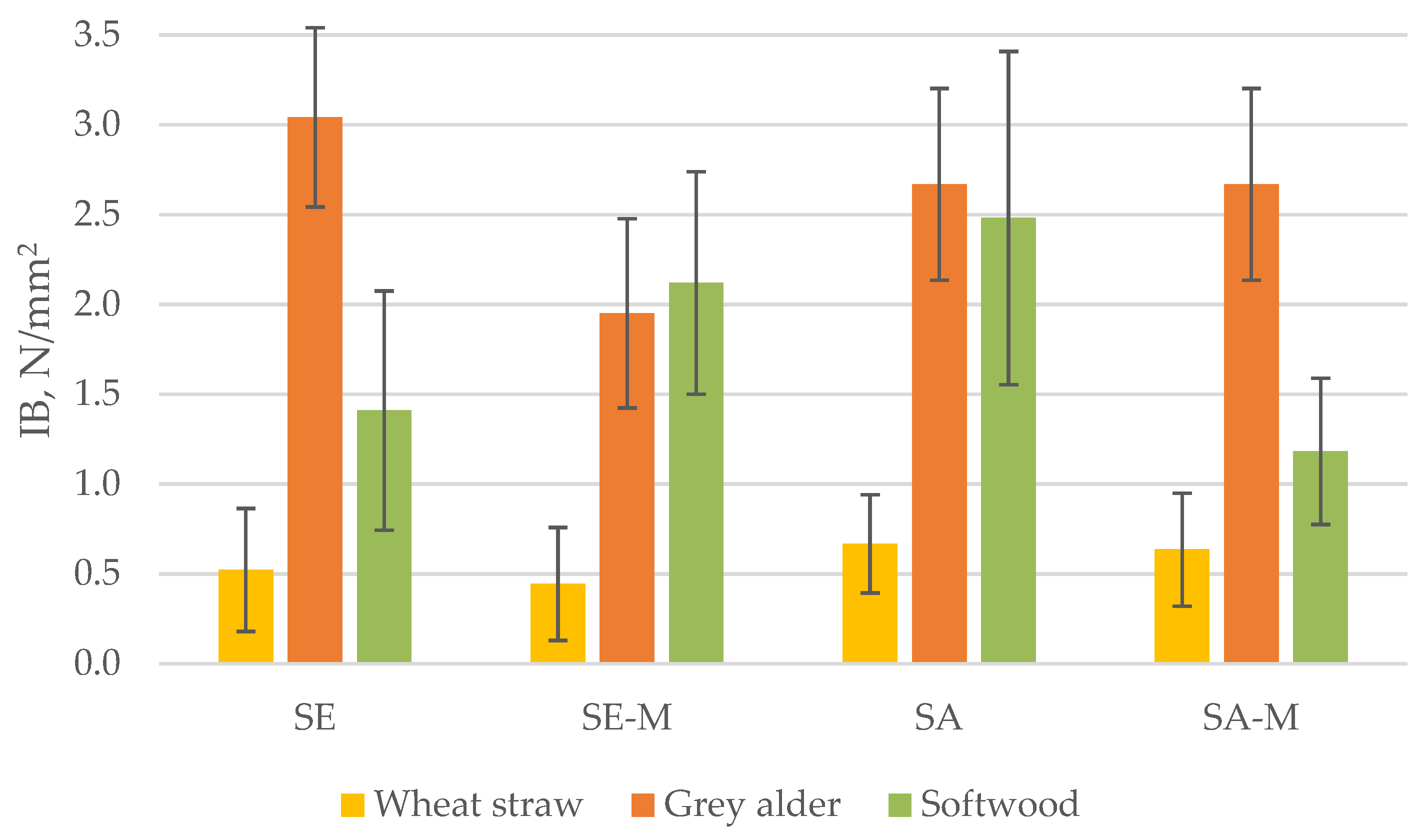

3.1.4. Internal Bonding

3.2. Relation of the Boards’ Properties to Density and IB

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| GHG | Greenhouse gases |

| CO2 | Carbon dioxide |

| LCB | Lignocellulosic biomass |

| SE | Steam explosion treatment |

| SA | Suberinic acids |

| WS | Wheat straw |

| GA | Grey alder wood |

| SW | Softwood |

| EN | European norm |

| MOE | Modulus of elasticity according to EN 310 |

| MOR | Modulus of rupture according to EN 310 |

| WA | Water absorption |

| TS | Thickness swelling according to EN 317 |

| IB | Internal bonding according to EN 319 |

References

- Benduski, M. Paris Agreement vs. Kyoto Protocol [Comparison Chart]. Available online: https://www.careaboutclimate.org/blog/paris-agreement-vs-kyoto-protocol-comparison-chart (accessed on 20 June 2025).

- Liobikiene, G.; Butkus, M. The European Union Possibilities to Achieve Targets of Europe 2020 and Paris Agreement Climate Policy. Renew. Energy 2017, 106, 298–309. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Labrincha, J.A. The Future of Construction Materials Research and the Seventh UN Millennium Development Goal: A Few Insights. Constr. Build. Mater. 2013, 40, 729–737. [Google Scholar] [CrossRef]

- Bikas, D.; Tsikaloudaki, K.; Kontoleon, K.J.; Giarma, C.; Tsoka, S.; Tsirigoti, D. Ventilated Facades: Requirements and Specifications Across Europe. Procedia Environ. Sci. 2017, 38, 148–154. [Google Scholar] [CrossRef]

- Grand View Research Facade Market Size, Share & Trends Analysis Report, ID: GVR-1-68038-221-1. 2023. Available online: https://www.grandviewresearch.com/industry-analysis/facade-market (accessed on 25 July 2025).

- Daly, P.; Barril, P.G. Biobased Construction from Agricultural Crops: Paper 1-A State of Play of Commercial Solutions in Europe. Int. J. Archit. Eng. Technol. 2024, 11, 17–35. [Google Scholar] [CrossRef]

- Maalouf, C.; Ingrao, C.; Scrucca, F.; Moussa, T.; Tricase, C.; Asdrubali, F. Bio-Based and Recycled-Waste Materials in Buildings: A Study of Energy Performance of Hemp-Lime Concrete and Recycled-Pet Façades for Office Facilities in France and Italy. Build. Simul. Appl. 2017, 2017, 393–401. [Google Scholar]

- Alao, P.; Visnapuu, K.; Kallakas, H.; Poltimäe, T.; Kers, J. Natural Weathering of Bio-Based Facade Materials. Forests 2020, 11, 642. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. Portfolio of Bio-Based Façade Materials; Springer: Cham, Switzerland, 2019; ISBN 9789811337468. [Google Scholar]

- Lafond, C.; Blanchet, P. Technical Performance Overview of Bio-Based Expanded Polystyrene. Buildings 2020, 10, 81. [Google Scholar] [CrossRef]

- Miranda, I.; Pereira, H. Cork Façades as an Innovative and Sustainable Approach in Architecture: A Review of Cork Materials, Properties and Case Studies. Materials 2024, 17, 4414. [Google Scholar] [CrossRef]

- Astudillo, J.; Garcia, M.; Sacristan, J.; Uranga, N.; Leivo, M.; Mueller, M.; Roig, I.; Langer, S.; Gemignani, G.; Vilkki, M.; et al. New Biocomposites for Innovative Construction Façades and Interior Partitions. J. Facade Des. Eng. 2018, 6, 67–85. [Google Scholar] [CrossRef]

- Pujadas-Gispert, E.; Alsailani, M.; van Dijk, K.C.A.; Rozema, A.D.K.; ten Hoope, J.P.; Korevaar, C.C.; Moonen, S.P.G. Design, Construction, and Thermal Performance Evaluation of an Innovative Bio-Based Ventilated Façade. Front. Archit. Res. 2020, 9, 681–696. [Google Scholar] [CrossRef]

- Pracucci, A.; Vandi, L.; Morganti, L.; Fernández, A.G.; Nunez Diaz, M.; Navarro Muedra, A.; Győri, V.; Kouyoumji, J.L.; Astudillo Larraz, J. Design and Simulation for Technological Integration of Bio-Based Components in Façade System Modules. Buildings 2024, 14, 1114. [Google Scholar] [CrossRef]

- Romano, A.; Bras, A.; Grammatikos, S.; Wylie, S.; Kot, P.; Shaw, A. On the Development of Self-Controlled Bio-Based Panels for Building’s Thermal Management. In Proceedings of the ECCM 2018-18th European Conference on Composite Materials, Athens, Greece, 24–28 June 2018; pp. 24–28. [Google Scholar]

- Nazrun, T.; Hassan, M.K.; Hossain, M.D.; Ahmed, B.; Hasnat, M.R.; Saha, S. Application of Biopolymers as Sustainable Cladding Materials: A Review. Sustainability 2024, 16, 27. [Google Scholar] [CrossRef]

- Veeger, M.; Prieto, A.; Ottelé, M. Exploring the Possibility of Using Bioreceptive Concrete in Building Facądes. J. Facade Des. Eng. 2021, 9, 73–86. [Google Scholar] [CrossRef]

- Mahrous, R.; Giancola, E.; Osman, A.; Asawa, T.; Mahmoud, H. Review of Key Factors That Affect the Implementation of Bio-Receptive Façades in a Hot Arid Climate: Case Study North Egypt. Build. Environ. 2022, 214, 108920. [Google Scholar] [CrossRef]

- Talaei, M.; Mahdavinejad, M.; Azari, R. Thermal and Energy Performance of Algae Bioreactive Façades: A Review. J. Build. Eng. 2020, 28, 101011. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Gravitis, J.; Belkova, L.; Tuherm, H. Grey Alder Fibreboard Processed by Modified Steam Explosion Unit. In Proceedings of the Research for Rural Development, Jelgava, Latvia, 19–21 May 2010; Volume 1, pp. 248–254. [Google Scholar]

- Tupciauskas, R.; Rizhikovs, J.; Grinins, J.; Paze, A.; Andzs, M.; Brazdausks, P.; Puke, M.; Plavniece, A. Investigation of Suberinic Acids-Bonded Particleboard. Eur. Polym. J. 2019, 113, 176–182. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Rizhikovs, J.; Andzs, M.; Bikovens, O. Influence of Manufacturing Conditions on Binder-Less Boards from Steam-Exploded Hemp Shives and Wheat Straw. Materials 2022, 15, 3141. [Google Scholar] [CrossRef] [PubMed]

- Makars, R.; Paze, A.; Rizikovs, J.; Berzins, R.; Godina, D.; Puke, M.; Stankus, K.; Virsis, I. Changes in Composition of Birch Outer Bark Extractives After Changes in Composition of Birch Outer Bark Extractives After Recrystallization with C2-C5 Alkanols. Key Eng. Mater. 2020, 850, 3–8. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Rizhikovs, J.; Brazdausks, P.; Fridrihsone, V.; Andzs, M. Influence of Steam Explosion Pre-Treatment Conditions on Binder-Less Boards from Hemp Shives and Wheat Straw. Ind. Crop. Prod. 2021, 170, 8. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Irbe, I.; Janberga, A.; Buksans, E. Moisture and Decay Resistance and Reaction to Fire Properties of Self-Binding Fibreboard Made from Steam-Exploded Grey Alder Wood. Wood Mater. Sci. Eng. 2017, 12, 63–71. [Google Scholar] [CrossRef]

- Anglès, M.N.; Ferrando, F.; Farriol, X.; Salvadó, J. Suitability of Steam Exploded Residual Softwood for the Production of Binderless Panels. Effect of the Pre-Treatment Severity and Lignin Addition. Biomass Bioenergy 2001, 21, 211–224. [Google Scholar] [CrossRef]

- Mancera, C.; El Mansouri, N.E.; Ferrando, F.; Salvado, J. The Suitability of Steam Exploded Vitis Vinifera and Alkaline Lignin for the Manufacture of Fiberboard. BioResources 2011, 6, 4439–4453. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Berzins, A.; Pavlovics, G.; Bikovens, O.; Filipova, I.; Andze, L.; Andzs, M. Optimization of Thermal Conductivity vs Bulk Density of Steam Exploded Loose-Fill Annual Lignocellulosics. Materials 2023, 16, 3654. [Google Scholar] [CrossRef] [PubMed]

- EN 323; Wood-Based Panels-Determination of Density. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 310; Wood-Based Panels-Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319; Particleboards and Fibreboards-Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 317; Particleboards and Fibreboards-Determination of Swelling in Thickness after Immersion in Water. European Committee for Standardization: Brussels, Belgium, 1993.

- EN 312; Particleboards-Specifications. European Committee for Standardization: Brussels, Belgium, 2010.

- Shao, S.; Jin, Z.; Wen, G.; Iiyama, K. Thermo Characteristics of Steam-Exploded Bamboo (Phyllostachys pubescens) Lignin. Wood Sci. Technol. 2009, 43, 643–652. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, A.; Xue, L. A Review of Preparation of Binderless Fiberboards and Its Self-Bonding Mechanism. Wood Sci. Technol. 2015, 49, 661–679. [Google Scholar] [CrossRef]

- Korai, H.; Ling, N. Effects of Sealed Press on Improving the Properties of Particleboard. J. Wood Sci. 2011, 57, 208–213. [Google Scholar] [CrossRef]

| LCB | Board Type | Hot-Pressing | Temperature/Time * °C/min | Designation |

|---|---|---|---|---|

| WS | Crushing + SE | Conventional | 160/20 | WSSE |

| Mold | WSSE-M | |||

| Milling + SA | Conventional | 180/20 | WSSA | |

| Mold | WSSA-M | |||

| GA | Crushing + SE | Conventional | 160/20 | GASE |

| Mold | GASE-M | |||

| Milling + SA | Conventional | 180/20 | GASA | |

| Mold | GASA-M | |||

| SW | Crushing + SE | Conventional | 165/20 | SWSE |

| Mold | SWSE-M | |||

| Milling + SA | Conventional | 180/20 | SWSA | |

| Mold | SWSA-M |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tupciauskas, R.; Berzins, A.; Andzs, M.; Berzins, R.; Rizikovs, J.; Pavlovics, G. Physical–Mechanical Properties of Innovative Biobased Particleboards for Application in External Building Façades. Forests 2025, 16, 1359. https://doi.org/10.3390/f16081359

Tupciauskas R, Berzins A, Andzs M, Berzins R, Rizikovs J, Pavlovics G. Physical–Mechanical Properties of Innovative Biobased Particleboards for Application in External Building Façades. Forests. 2025; 16(8):1359. https://doi.org/10.3390/f16081359

Chicago/Turabian StyleTupciauskas, Ramunas, Andris Berzins, Martins Andzs, Rudolfs Berzins, Janis Rizikovs, and Gunars Pavlovics. 2025. "Physical–Mechanical Properties of Innovative Biobased Particleboards for Application in External Building Façades" Forests 16, no. 8: 1359. https://doi.org/10.3390/f16081359

APA StyleTupciauskas, R., Berzins, A., Andzs, M., Berzins, R., Rizikovs, J., & Pavlovics, G. (2025). Physical–Mechanical Properties of Innovative Biobased Particleboards for Application in External Building Façades. Forests, 16(8), 1359. https://doi.org/10.3390/f16081359