Performance of Oriented Strand Boards Made with Jack Pine Strands Produced by an Innovative Strander-Canter

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparation

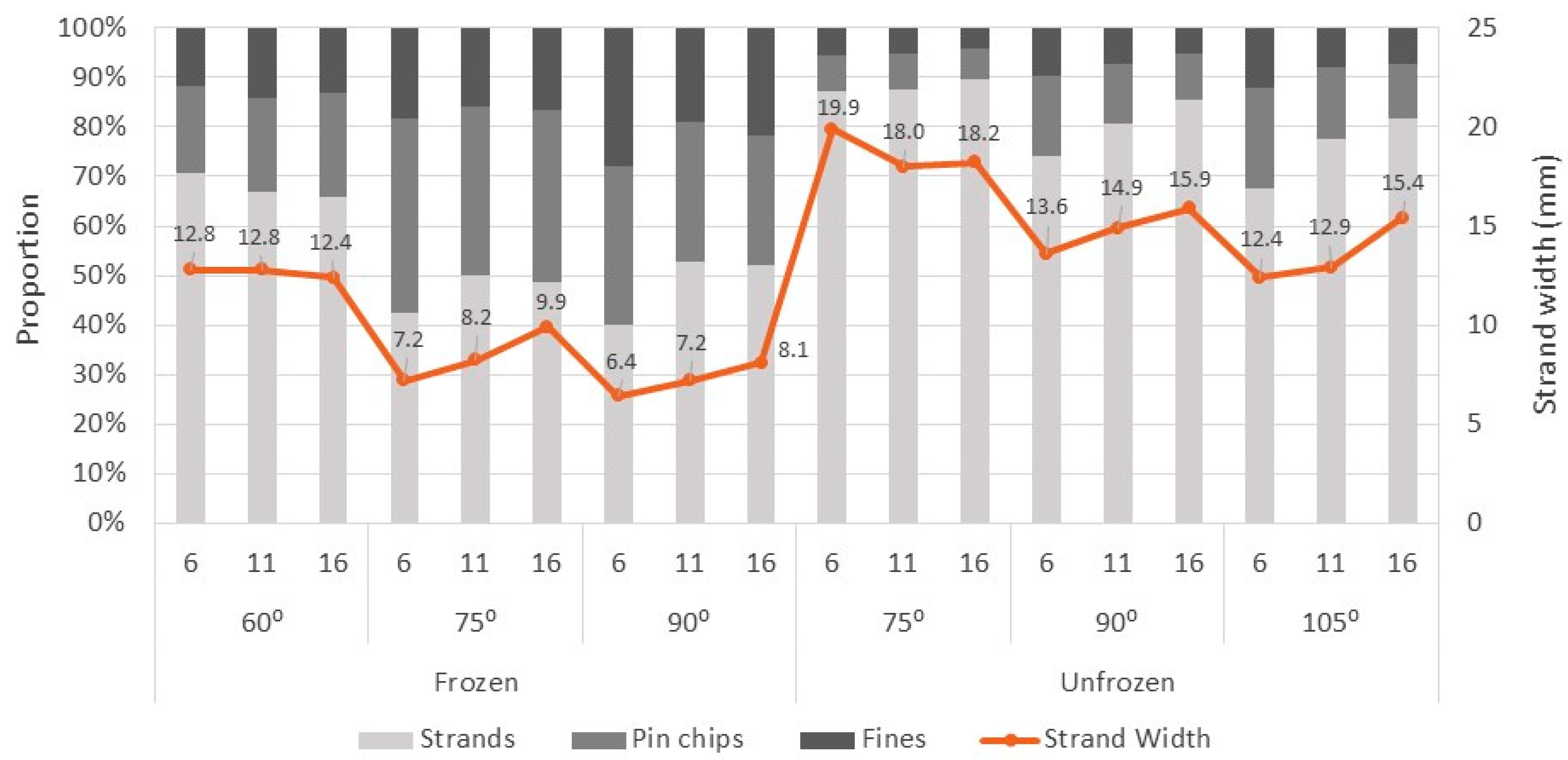

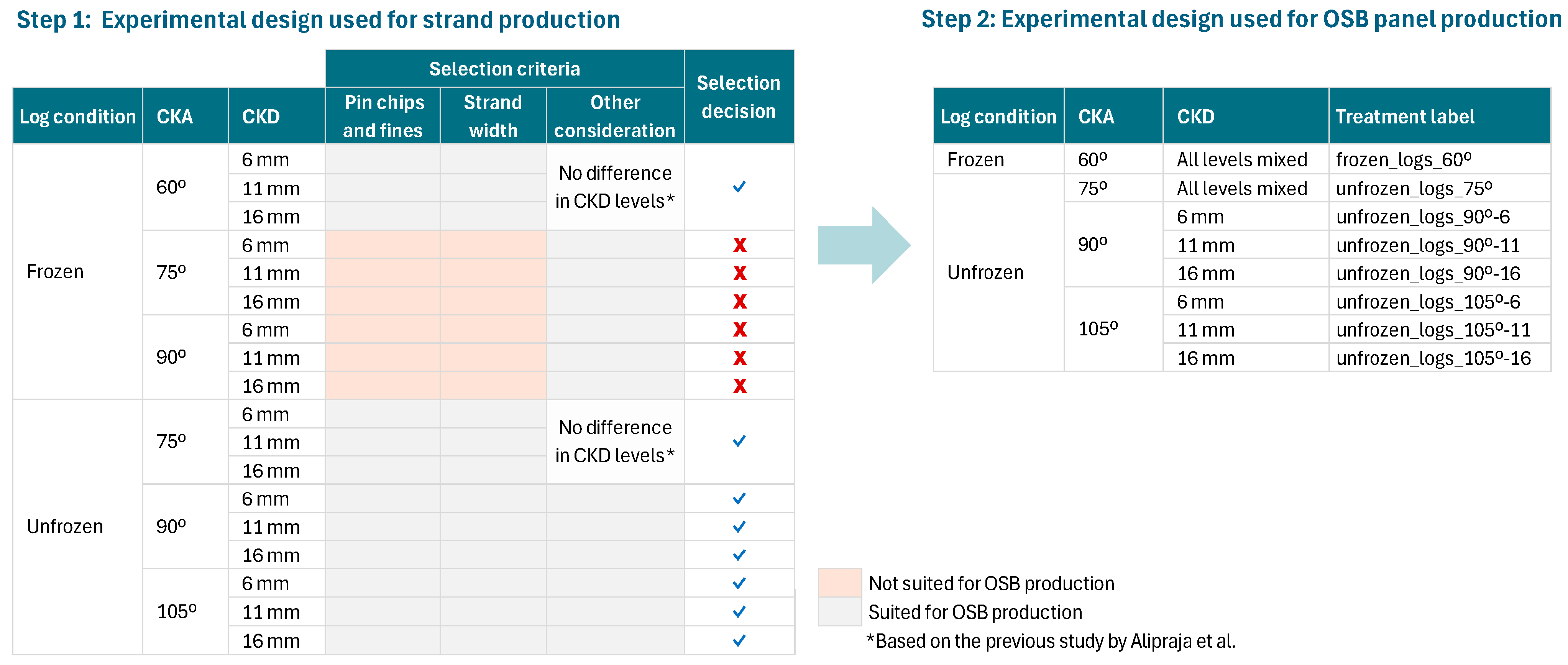

2.2. Treatment Selection and Strand Size Distribution

2.3. OSB Panel Manufacturing

2.4. Vertical Density Profile Measurements

2.5. Measurement of Mechanical and Physical Properties

2.6. Statistical Analysis

3. Results and Discussion

3.1. Strand Size Distribution

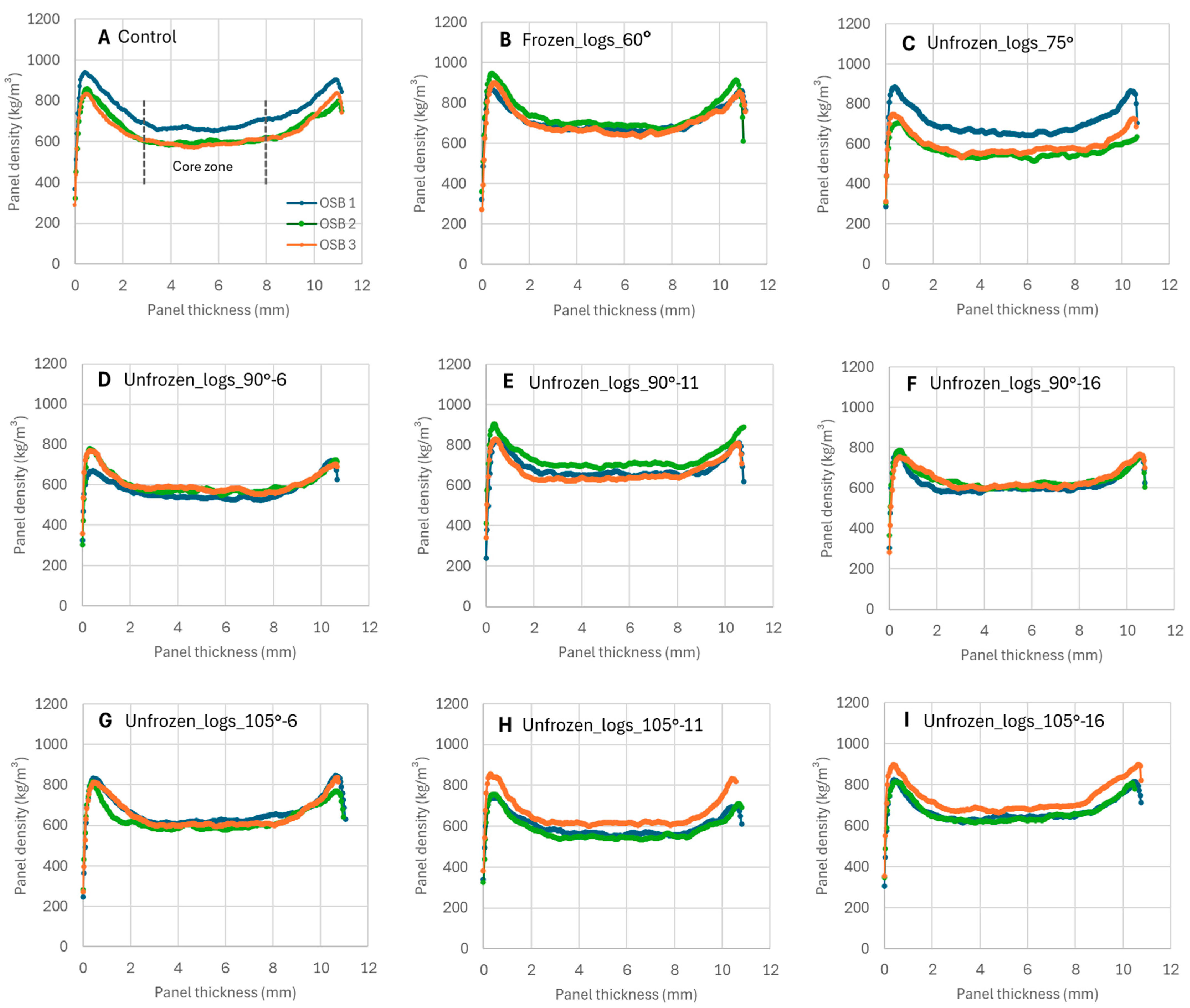

3.2. Vertical Density Profile

3.3. Mechanical Properties

3.3.1. Static Bending Properties

3.3.2. Internal Bond Strength

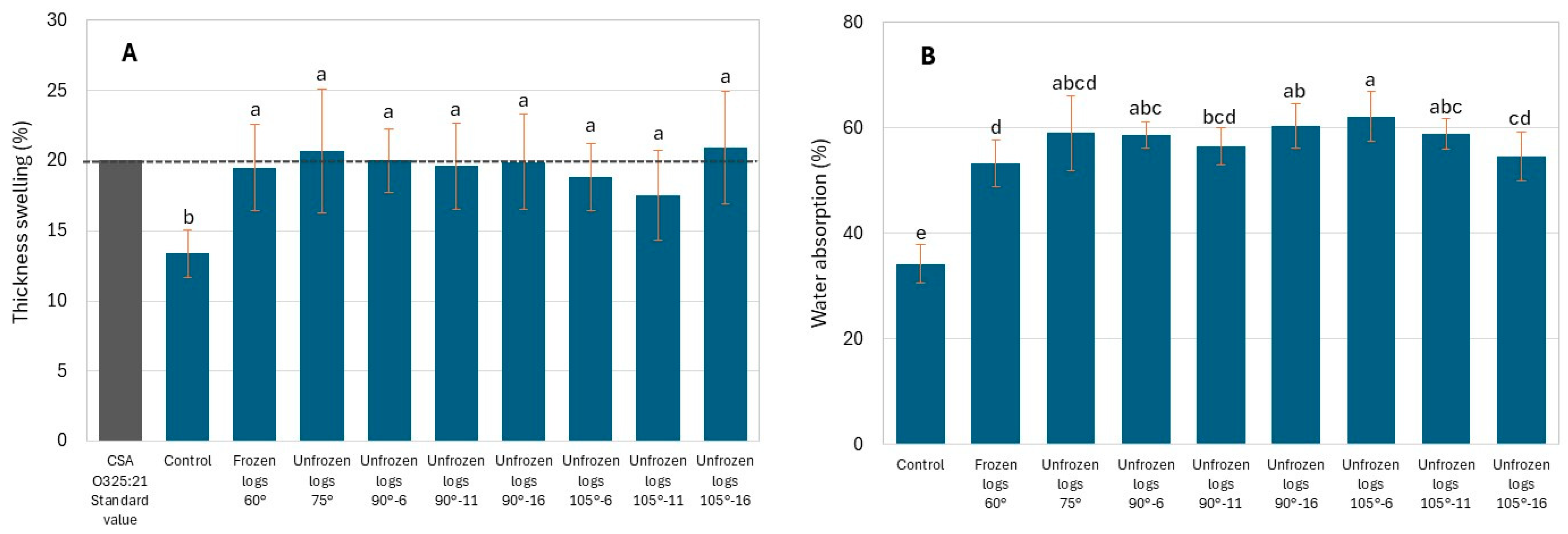

3.4. Dimensional Stability

3.4.1. Thickness Swelling and Water Absorption After a 24 h Soak

3.4.2. Linear Expansion and Thickness Expansion

4. Conclusions

- The strander-canter produced a greater proportion of medium-size strands, whereas the industrial process exhibited a higher proportion of coarse strands.

- The use of jack pine strands in the core layer had no significant effect on the vertical density profiles of the OSB panels.

- All panels, regardless of log conditions or cutting parameters, far exceeded the CSA O325:21 standard requirements for bending properties. In certain instances, the jack pine strands improved bending performance. It is also important to note the dominance of industrial strands in the surface layer. Further research on OSB panels made from jack pine strands in different proportions is recommended.

- Panels containing jack pine strands exhibited IB strength comparable to control panels. Notably, the unfrozen_logs_90°-11 and unfrozen_logs_105°-16 treatments showed higher IB values, likely due to reduced strand specific surface area and greater adhesive coverage per unit of surface area.

- Panels containing jack pine strands showed significantly higher thickness swelling and water absorption than control panels. This is likely due to the anatomical structure of jack pine (latewood vs. earlywood) and the thicker strands produced, which probably increased panel porosity. To improve dimensional stability, it is recommended to adjust cutting parameters to produce thinner strands, consider softwood species with more uniform wood structure, and explore pressing strategies to reduce density gradients between surface and core layers.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ANOVA | Analysis of variance |

| CKA | Counter-knife angle |

| CKD | Counter-knife and knife-edge distance |

| Core_dens | Average core density |

| _par | Bending stiffness per mm specimen width in the parallel direction |

| _per | Bending stiffness per mm specimen width in the perpendicular direction |

| IB | Internal bond |

| LE_par | Linear expansion in the parallel direction |

| LE_per | Linear expansion in the perpendicular direction |

| MOE_par | Modulus of elasticity parallel to the strength axis |

| MOE_per | Modulus of elasticity perpendicular to the strength axis |

| MOR_par | Modulus of rupture parallel to the strength axis |

| MOR_per | Modulus of rupture perpendicular to the strength axis |

| OSB | Oriented strand board |

| Overall_dens | Average overall density |

| PF | Phenol-formaldehyde |

| _par | Maximum bending moment per mm specimen width in the parallel direction |

| _per | Maximum bending moment per mm specimen width in the perpendicular direction |

| Surface_dens | Maximum surface density |

| TE_par | Thickness expansion in the parallel direction |

| TE_per | Thickness expansion in the perpendicular direction |

| TS_24h | Thickness swelling after 24 h water soaking |

| WA_24h | Water absorption after 24 h water soaking |

References

- FAO. FAOSTAT: Forestry Production and Trade. Available online: https://www.fao.org/faostat/en/#data (accessed on 23 May 2025).

- Zhuang, B.; Cloutier, A.; Koubaa, A. Effects of strands geometry on the physical and mechanical properties of oriented strand boards (OSBs) made from black spruce and trembling aspen. BioResources 2022, 17, 3929–3943. [Google Scholar] [CrossRef]

- Zhuang, B.; Cloutier, A.; Koubaa, A. Physical and mechanical properties of oriented strand board made from eastern Canadian softwood species. Forests 2022, 13, 523. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Koubaa, A. Les Résineux de l’Est du Canada: Écologie Forestière, Caractéristiques, Transformation et Usages; Publication Spéciale SP-526F, FPInnovations: Québec, QC, Canada, 2009. (In French) [Google Scholar]

- Gouvernement du Québec. La Forêt Démystifiée: Comment les Arbres Récoltés au Québec Sont-Ils Utilisés. 2021. Available online: https://www.quebec.ca/nouvelles/actualites/details/foret-demystifiee-comment-arbres-recoltes-utilises-32864 (accessed on 15 July 2025).

- Ghosh, S.C.; Hernández, R.E.; Blais, C. Effect of knife wear on surface quality of black spruce cants produced by a chipper-canter. Wood Fiber Sci. 2015, 47, 355–364. [Google Scholar]

- Alipraja, I.; Hernández, R.E.; Cáceres, C.B.; Koubaa, A. Towards strand production in primary log breakdown: Effects of the counter-knife and temperature on size distribution of jack pine strands. BioResources 2022, 17, 2632–2651. [Google Scholar] [CrossRef]

- Alipraja, I.; Hernández, R.E.; Koubaa, A. Effects of wood species on the energy requirements and size distribution of strands produced by a strander-canter. BioResources 2023, 18, 5873–5886. [Google Scholar] [CrossRef]

- Beck, K.; Cloutier, A.; Salenikovih, A.; Beauregard, R. Effect of strand geometry and wood species on strandboard mechanical properties. Wood Fiber Sci. 2009, 41, 267–278. [Google Scholar]

- Xing, C.; Matuan, L.M.; Dawson-Andoh, B.E. Effect of processing parameters on the quality of red oak flakes. Inter. Wood Prod. J. 2017, 8, 139–143. [Google Scholar] [CrossRef]

- Pipíška, T.; Nociar, M.; Král, P.; Ráheľ, J.; Bekhta, P.; Réh, R.; Krišťák, Ľ.; Jopek, M.; Pijáková, B.; Wimmer, R.; et al. Characterization of randomly oriented strand boards manufactured from juvenile wood of underutilized wood species. Eur. J. Wood Prod. 2024, 82, 927–941. [Google Scholar] [CrossRef]

- Dai, C.; Yu, C.; Zhou, X. Heat and mass transfer in wood composite panels during hot pressing. Part II. modeling void formation and mat permeability. Wood Fiber Sci. 2005, 37, 242–257. [Google Scholar]

- Li, P.; Wang, S.; Chen, S.; Wang, F. A three-dimensional solid model for OSB mat. Forest Prod. J. 2008, 58, 53–58. [Google Scholar]

- Pham Van, T.; Schöpper, C.; Klüppel, A.; Mai, C. Effect of wood and panel density on the properties of lightweight strand boards. Wood Mater. Sci. Eng. 2019, 16, 237–245. [Google Scholar] [CrossRef]

- Lunguleasa, A.; Dumitrascu, A.-E.; Spirchez, C.; Ciobanu, V.-D. Influence of the strand characteristics on the properties of oriented strand boards obtained from resinous and broad-leaved fast-growing species. Appl. Sci. 2021, 11, 1784. [Google Scholar] [CrossRef]

- Alipraja, I. Fabrication de Copeaux en Forme de Lamelles à l’aide d’une Équarrisseuse-Fragmenteuse. Ph.D. Thesis, Université Laval, Québec, QC, Canada, 2023. [Google Scholar]

- ASTM D1037-12 (Reapproved 2020); Standard Test Methods for Evaluating Properties of Wood-Based Fiber and Particle Panel Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- CSA O325:21; Construction Sheathing (NIST PS 2-18, MOD). Canadian Standard Association (CSA): Toronto, ON, Canada, 2021.

- ASTM D3043-17; Standard Test Methods for Structural Panels in Flexure. ASTM International: West Conshohocken, PA, USA, 2017.

- Chang, W. Thickness Swelling Behaviour of Oriented Strand Board. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 1999. [Google Scholar]

- Garcia, R.A.; Rosero-Alvarado, J.; Hernández, R.E. Moisture-induced strains in earlywood and latewood of mature and juvenile woods in jack pine from 3D-DIC measurements. Wood Mater. Sci. Eng. 2022, 18, 570–579. [Google Scholar] [CrossRef]

- Lube, V.M. Effects of Moisture-Induced Thickness Swelling on the Microstructure of Oriented Strand Board. Master’s Thesis, University of British Columbia, Vancouver, BC, Canada, November 2016. [Google Scholar]

- Tao, Y.; Li, P. Analyzing the relationships between processing parameters and fractal dimension of void size on cross-sections of oriented strandboards. BioResources 2016, 11, 9154–9161. [Google Scholar] [CrossRef]

- Han, G.; Wu, Q.; Lu, J.Z. The influence of fines content and panel density on properties of mixed hardwood oriented strandboard. Wood Fiber Sci. 2007, 39, 2–15. [Google Scholar]

| OSB Manufacturing Parameters | Condition | |

|---|---|---|

| PF resin (liquid) | Solid content | 55% |

| Brookfield viscosity at 25 °C | 140 cPs | |

| pH at 25 °C | 10.8 | |

| Emulsion wax | Solid wax content | 58% |

| Brookfield viscosity, at 25 °C | 93 cPs | |

| pH at 25 °C | 8.67 | |

| Mat formation | Target mat moisture content 1 | 8% |

| Panel dimensions (length × width × thickness) | 760 mm × 760 mm × 11 mm | |

| Target panel density | 630 kg/m3 | |

| Mass proportion of layers (surface/core/surface) | 30:40:30 | |

| Moisture content 1 (surface/core) | 10%/7% | |

| PF resin content 1 (surface/core) | 7%/5% | |

| Emulsion wax content 1 (surface/core) | 1%/0.5% | |

| Hot-pressing conditions | Press platen temperature | 200 °C |

| Press closing time | 10 s | |

| Resin curing time | 310 s | |

| Press opening time at multi-step | 87 s | |

| Total pressing time | 407 s | |

| Strand Size | Screen Holes | Control | Frozen _logs_60° | Unfrozen _logs_75° | Unfrozen _logs_ 90°-6 | Unfrozen _logs_ 90°-11 | Unfrozen _logs_ 90°-16 | Unfrozen _logs_ 105°-6 | Unfrozen _logs_ 105°-11 | Unfrozen _logs_ 105°-16 |

|---|---|---|---|---|---|---|---|---|---|---|

| Coarse | 70 mm | 2.1 | 0.2 | 0.7 | 0.1 | 0.5 | 0.1 | 0.1 | 0.1 | 0 |

| 45 mm | 38.5 | 12.5 | 22.1 | 10.0 | 14.2 | 11,7 | 7.7 | 9.7 | 13.2 | |

| 28.6 mm | 20.8 | 18.9 | 29.3 | 20.1 | 23.2 | 27.6 | 17.3 | 21.4 | 25.4 | |

| Medium | 22.2 mm | 19.9 | 18.9 | 18.7 | 19.1 | 18.9 | 22.3 | 18.4 | 20.1 | 20.4 |

| 15.9 mm | 10.0 | 20.5 | 15.3 | 21.7 | 19.9 | 19.1 | 22.7 | 21.2 | 19.5 | |

| 9.5 mm | 8.7 | 29.0 | 14.0 | 29.0 | 23.3 | 19.1 | 33.8 | 27.4 | 21.5 |

| Densities (kg/m3) | F-Values | Control | Frozen _logs_60° | Unfrozen _logs_75° | Unfrozen _logs_ 90°-6 | Unfrozen _logs_ 90°-11 | Unfrozen _logs_ 90°-16 | Unfrozen _logs_ 105°-6 | Unfrozen _logs_ 105°-11 | Unfrozen _logs_ 105°-16 |

|---|---|---|---|---|---|---|---|---|---|---|

| Overall_dens | 3.81 * [0.009] | 681 ab (6.9) | 718 a (2.6) | 622 ab (11.5) | 594 b (3.1) | 695 ab (5.3) | 635 ab (2.1) | 648 ab (2.7) | 614 ab (6.5) | 690 ab (5.1) |

| Surface_dens | 3.63 * [0.011] | 914 ab (4.1) | 935 a (3.7) | 811 ab (10.7) | 791 b (3.5) | 895 ab (5.4) | 815 ab (1.9) | 865 ab (3.8) | 818 ab (7.8) | 894 ab (4.7) |

| Core_dens | 3.97 * [0.007] | 619 ab (7.1) | 672 a (2.6) | 587 ab (10.7) | 561 b (3.7) | 642 ab (1.8) | 605 ab (1.5) | 605 ab (2.7) | 574 b (6.3) | 651 ab (4.3) |

| Treatment | MOE (MPa) | Bending Stiffness per mm Specimen Width, EI/b × 103 (N-mm2/mm) | MOR (MPa) | Maximum Bending Moment per mm Specimen Width, (N-mm/mm) | ||||

|---|---|---|---|---|---|---|---|---|

| Par | Per | Par | Per | Par | Per | Par | Per | |

| CSA O325:21 [18] reference value for 7/16 performance category 1 | 3561 | 1271 | 395 | 141 | 19.3 | 10.9 | 390 | 220 |

| Control | 7151 bc (4.8) | 2050 (13.7) | 900 abc (6.2) | 229 (20) | 39.4 ab (5.9) | 15.4 b (10.3) | 865 ab (8.1) | 312 ab (11.1) |

| Frozen_logs_60° | 6770 c (7.5) | 1945 (19.9) | 869 bc (10.8) | 205 (20.6) | 35.6 b (18.5) | 14.6 b(20.0) | 793 b (20.3) | 283 b (19.7) |

| Unfrozen_logs_75° | 8185 ab (9.3) | 2215 (16.8) | 958 ab (9.1) | 229 (19.9) | 41.0 ab (11.7) | 19.6 ab (18.0) | 855 ab (9.5) | 377 ab (20.6) |

| Unfrozen_logs_90°-6 | 7785 abc (7.2) | 2024 (17.1) | 926 abc (10.1) | 212 (14.5) | 41.7 ab (9.5) | 18.2 ab (23.3) | 882 ab (12.5) | 352 ab (20.2) |

| Unfrozen_logs_90°-11 | 7321 abc (8.0) | 2504 (16.7) | 807 c (9.8) | 264 c(18.8) | 38.7 ab (12.7) | 21.7 a (19.0) | 778 b (14.8) | 422 a (20.5) |

| Unfrozen_logs_90°-16 | 7599 abc (8.4) | 1930 (8.8) | 863 bc (8.5) | 201 (6.3) | 37.9 ab (11.1) | 16.2 ab (10.4) | 777 b (12.1) | 314 ab (10.4) |

| Unfrozen_logs_105°-6 | 8557 a (10.4) | 1841 (16.7) | 1037 a (10.0) | 198 (15.0) | 46.8 a (11.3) | 16.5 ab (15.0) | 1001 a (11.0) | 326 ab (14.2) |

| Unfrozen_logs_105°-11 | 7654 abc (10.0) | 1958 (20.1) | 872 bc (5.7) | 214 (25.3) | 38.2 ab (17.2) | 15.9 ab (21.4) | 785 b (15.7) | 317 ab (24.5) |

| Unfrozen_logs_105°-16 | 7679 abc (10.3) | 2146 (30.4) | 848 bc (6.5) | 211 (34.6) | 39.2 ab (13.5) | 16.3 ab(26.6) | 789 b (10.8) | 302 ab (27.1) |

| Dependent Variables | F-Value | p-Value |

|---|---|---|

| MOE_par | 3.79 | 0.0017 * |

| MOE_per | 1.57 | 0.1597 NS |

| _par | 4.47 | 0.0005 * |

| _per | 1.19 | 0.3270 NS |

| MOR_par | 6.36 | <0.0001 * |

| MOR_per | 2.08 | 0.0131 * |

| _par | 2.81 | 0.0130 * |

| _per | 2.56 | 0.0216 * |

| IB | 8.84 | <0.0001 * |

| TS_24h | 6.62 | <0.0001 * |

| WA_24h | 52.21 | <0.0001 * |

| LE_par | 0.61 | 0.765 NS |

| LE_per | 1.84 | 0.099 NS |

| TE_par | 2.01 | 0.067 NS |

| TE_per | 2.04 | 0.063 NS |

| Variable (%) | Control | Frozen _logs_60° | Unfrozen _logs_75° | Unfrozen _logs_ 90°-6 | Unfrozen _logs_ 90°-11 | Unfrozen _logs_ 90°-16 | Unfrozen _logs_ 105°-6 | Unfrozen _logs_ 105°-11 | Unfrozen _logs_ 105°-16 |

|---|---|---|---|---|---|---|---|---|---|

| LE_par | 0.07 (40.5) | 0.05 (38.6) | 0.08 (44.7) | 0.07 (34.0) | 0.07 (8.1) | 0.07 (27.4) | 0.07 (34.7) | 0.08 (34.2) | 0.06 (23.2) |

| LE_per | 0.11 (40.7) | 0.07 (48.9) | 0.06 (47.9) | 0.08 (44.0) | 0.10 (33.8) | 0.09 (23.3) | 0.08 (62.2) | 0.10 (34.3) | 0.04 (68.7) |

| TE_par | 8.5 (12.1) | 9.8 (11.0) | 7.8 (16.9) | 7.8 (12.2) | 8.9 (10.6) | 9.4 (15.9) | 8.8 (7.6) | 8.3 (11.7) | 8.1 (12.2) |

| TE_per | 9.0 (12.5) | 7.7 (13.2) | 8.4 (13.2) | 7.4 (8.5) | 7.9 (15.0) | 7.8 (10.5) | 7.2 (8.1) | 8.2 (10.3) | 8.4 (15.1) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia, R.; Cloutier, A.; Alipraja, I.; Hernández, R.E.; Koubaa, A. Performance of Oriented Strand Boards Made with Jack Pine Strands Produced by an Innovative Strander-Canter. Forests 2025, 16, 1227. https://doi.org/10.3390/f16081227

Garcia R, Cloutier A, Alipraja I, Hernández RE, Koubaa A. Performance of Oriented Strand Boards Made with Jack Pine Strands Produced by an Innovative Strander-Canter. Forests. 2025; 16(8):1227. https://doi.org/10.3390/f16081227

Chicago/Turabian StyleGarcia, Rosilei, Alain Cloutier, Irsan Alipraja, Roger E. Hernández, and Ahmed Koubaa. 2025. "Performance of Oriented Strand Boards Made with Jack Pine Strands Produced by an Innovative Strander-Canter" Forests 16, no. 8: 1227. https://doi.org/10.3390/f16081227

APA StyleGarcia, R., Cloutier, A., Alipraja, I., Hernández, R. E., & Koubaa, A. (2025). Performance of Oriented Strand Boards Made with Jack Pine Strands Produced by an Innovative Strander-Canter. Forests, 16(8), 1227. https://doi.org/10.3390/f16081227