1. Introduction

Wood is among the most widely used natural materials in construction, furniture, and interior design, valued for its unique aesthetic, structural versatility, and renewable nature. However, its organic composition and hydrophilic character make it highly sensitive to moisture fluctuations and biological deterioration, significantly limiting its long-term performance, especially in exterior and high-humidity environments. Dimensional instability, fungal decay, discoloration, and surface degradation are common challenges associated with untreated wood [

1,

2,

3]. The demand is continuously on the increase for chemical-free and eco-friendly non-toxic methods of wood preservation, in which heattreatment (thermal modification) is being widely applied due to its significant improvement in durability, stability, aesthetic appeal, and ease of maintenance [

4,

5,

6].

Heat treatment involves exposing wood to elevated temperatures, typically between 160 °C and 230 °C, in an oxygen-limited environment to prevent combustion. This thermal exposure induces profound chemical transformations in the wood matrix, most notably in hemicelluloses, the most thermally labile component of the cell wall, followed by partial alterations in lignin and cellulose [

2,

7,

8]. The degradation of hemicelluloses leads to the formation of volatile by-products and non-crystalline residues, resulting in reduced hygroscopicity, lower equilibrium moisture content, and increased resistance to fungal and insect attack [

4,

9]. There is also simultaneous active color darkening occurs due to the formation of degradation compounds and modification of extractives which also improves the aesthetic appearance alongside the uniformly appealing visual marketable appeal of the wood.

The intensity of these modifications quantified by mass loss, dimensional shrinkage, and chemical changes is directly dependent on the treatment temperature, duration, and wood species [

10,

11]. The key indicator widely recognized for assessing treatment severity is weight loss, which strongly correlates with chemical degradation, particularly of hemicelluloses [

4]. The degree of heat sensitivity of each type of wood is also determined by species-specific anatomical and chemical characteristics. For example, because they contain comparatively more thermally labile polysaccharides, hardwoods like

Quercus (oak) and

Populus (poplar) would probably lose more mass, while softwoods like

Pinus (pine), which contain more lignin and resin, might behave more steadily at similar temperatures [

12,

13].

Chemical analysis methods and technics like Fourier transform infrared spectroscopy (FTIR) have shown that heat-treated wood goes through some major changes. Esteves et al., for instance, reported a reduction in hydroxyl groups and more carbonyl and aromatic compounds in pine and eucalypt after heat treatment [

14]. That happens because the hemicelluloses are breaking down, the lignin is condensing, and oxidation reactions are happening, changing the surface reactivity of the wood. Moreover, Herrera et al. found that industrial heat treatments caused a big drop in polar functional groups, which has a direct impact on the interaction between the wood surface and subsequent coatings or adhesives [

13].

While the benefits of heat treatment are well established in terms of durability, dimensional stability, and biological resistance, there is still limited understanding of how these chemical and structural changes influence the performance of surface coatings. Surface properties such as porosity, roughness, wettability, and brittleness can be significantly altered by heat treatment and directly impact coating adhesion, elasticity, UV protection, and aesthetic longevity [

15,

16,

17]. Moreover, environmental exposure through natural or artificial weathering can exacerbate surface degradation, leading to differential responses in coated versus uncoated wood depending on the species and treatment intensity [

18].

Although there is growing industrial interest in using thermally modified wood for outdoor applications like facades, decking, and cladding, few studies have compared how coatings perform across different wood species treated under the same thermal treatments’ conditions [

15,

17]. This is a major gap in literature, as most existing research tends to focus on individual species or isolated property changes [

6]. For instance, Populus, despite its fast growth and commercial potential, remains understudied, whereas Quercus and Pinus are more commonly used as benchmarks for structural and decorative uses. Gaining a better understanding of how various species respond both chemically and physically to thermal modification is crucial for developing coating systems that offer reliable, long-term surface protection.

Furthermore, the practical importance of species-specific behavior under thermal modification is underlined by research showing variations in mass loss, volume stability, and chemical alteration [

14,

19].

Populus tends to exhibit a continuous decrease in weight and volume due to its porous structure and low-density hemicellulose-rich matrix. In contrast,

Pinus may initially gain density due to structural shrinkage and resin redistribution, with significant chemical degradation occurring only at higher temperatures (around 200 °C).

Quercus, rich in lignin and tannins, tends to display moderate mass loss and gradual volume shrinkage with increased resistance to thermal breakdown, but may develop surface brittleness [

13].

Coating performance is an important factor in determining heat-treated wood’s suitability for exterior applications. However, the relationship between thermal modification and coating systems, such as acrylics, alkyds, oils, and hybrid finishes, is still poorly understood across many species. Surface chemistry and porosity are not the only factors influencing coating adherence and endurance; thermal history and photodegradation resistance are also important [

15,

16]. Moreover, thermally modified wood may experience color fading or microcracking under UV exposure unless adequately protected, which can further compromise mechanical properties and aesthetics [

3,

18,

20,

21].

Despite advances in understanding the overall impacts of thermal modification, there is a significant dearth of comparison data on coating performance across various species under identical thermal regimes. Studies directly comparing Populus, Quercus, and Pinus under controlled heat-treatment conditions are limited. This knowledge gap restricts the optimization of surface finishing systems tailored to the unique surface chemistry and morphology of heat-treated wood.

Taking into consideration the current knowledge gaps and the practical challenges involved, this study aims to establish a systematic analysis of the impacts of heat treatment on the coating performance of three common wood species: Populus, Quercus, and Pinus. The research investigation examines the effects of three treatment temperatures (160, 180, and 200 °C) on mass, volume, surface chemistry, and visual qualities prior to coating. The goal is to discover how species-specific reactions to heat treatment affect coating adhesion, weather resistance, and surface integrity, which will aid in the development of finishing systems for thermally modified wood in both structural and architectural applications. By integrating mass loss, volume change, and surface characterization with an evaluation of coating performance, this work seeks to contribute to the development of thermally modified wood products with enhanced surface functionality and durability for outdoor applications.

3. Results

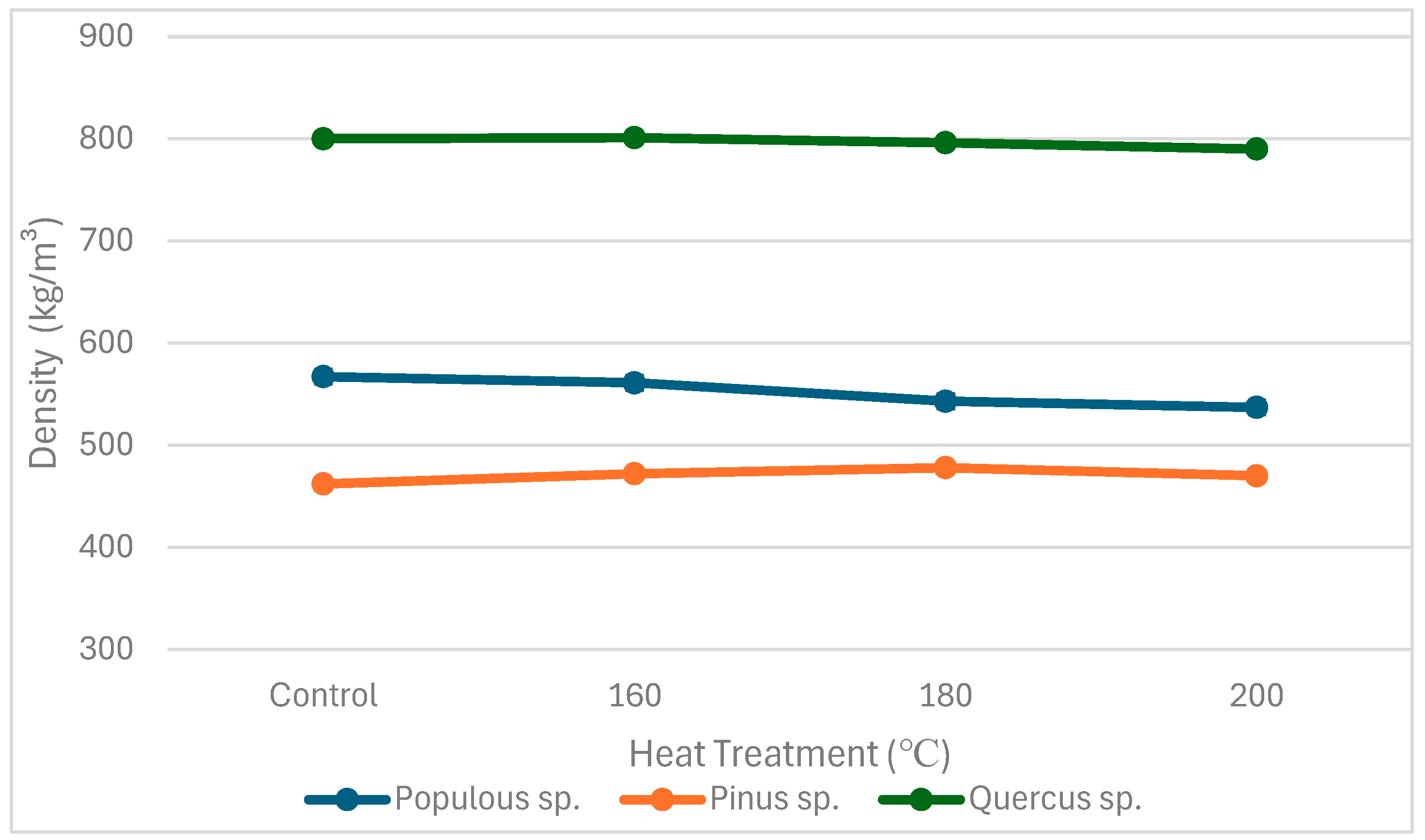

As

Figure 3 shows, the basic density after thermal treatment decreased from 567 kg m

−3 to 537 kg m

−3 in

Populous sp. There was a decrease of 30 kg/m

3 (~5.3%). This decrease is significant and likely results from the degradation of hemicelluloses, which are thermally sensitive components. When hemicelluloses break down, mass is lost without a proportional shrinkage in volume, leading to lower density. In

Quercus, the density decreased from 800 kg m

−3 to 790 kg m

−3, a decrease of 10 kg/m

3 (~1.25%). The reduction in

Quercus is relatively minor, indicating greater thermal stability. This species typically has a higher lignin content, which is more resistant to thermal degradation than hemicelluloses, leading to less mass loss during treatment. Interestingly, the density of

Pinus increased from 462 kg m

−3 to 470 kg m

−3, an increase of 8 kg/m

3 (~1.7%). This might be due to a volume reduction (shrinkage) without significant mass loss. Another possible explanation is chemical reorganization, such as condensation reactions or structural rearrangement of lignin, which may cause the cell walls to become denser and more compact. Different wood species respond uniquely to thermal treatment due to variations in anatomical structure and chemical composition. For instance,

Populus and

Quercus species typically show a reduction in basic density after heat treatment, likely due to degradation of thermally labile compounds such as hemicelluloses [

13,

20], while

Pinus species may exhibit increased density, possibly from structural compaction [

5]. These changes influence how coatings interact with the wood surface, affecting adhesion, penetration, and weathering resistance.

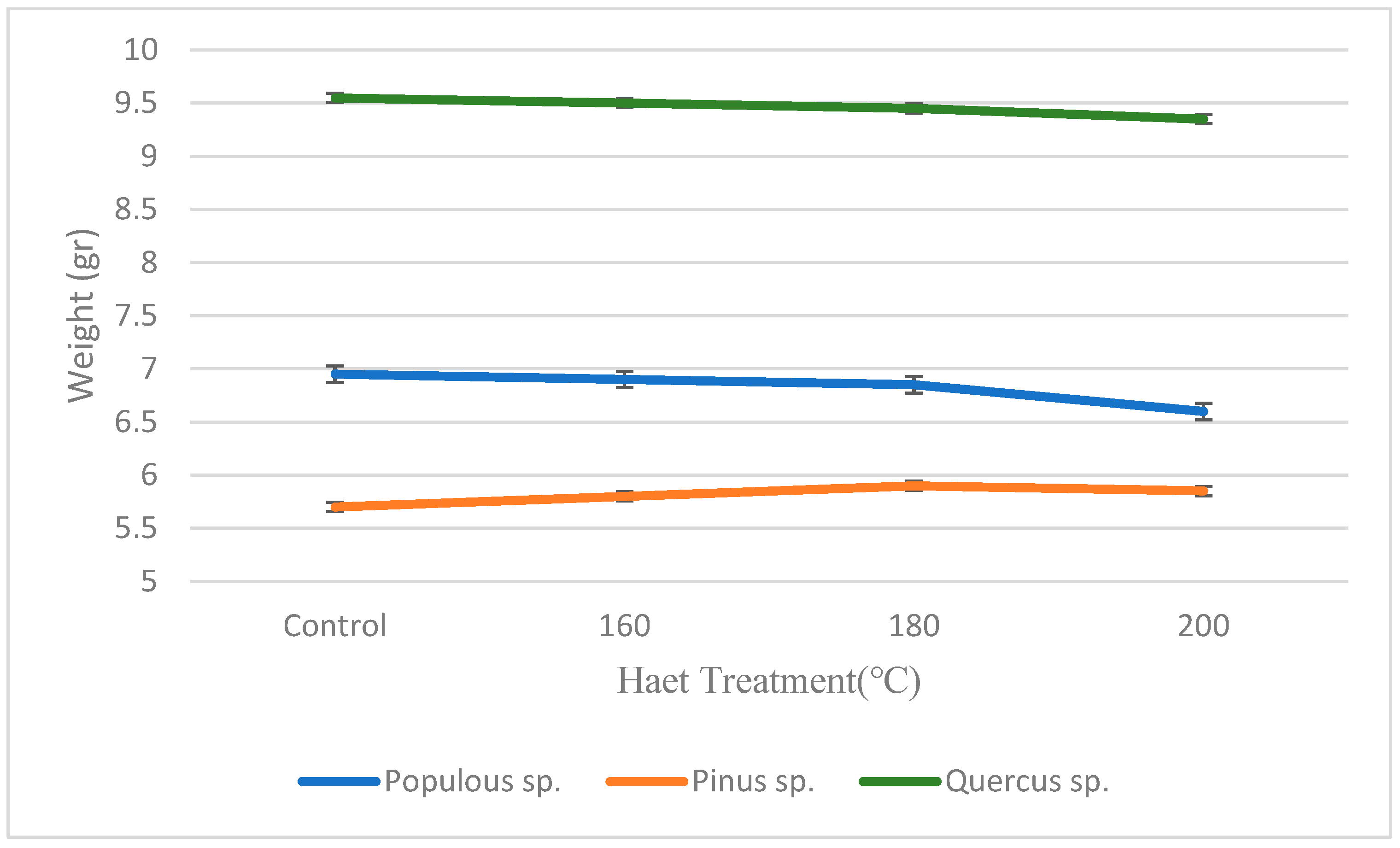

Heat treatment promotes average mass loss in all woods, where hardwoods presented the highest values of mass loss in accordance with the literature. The weight loss is mainly due to the degradation of hemicelluloses, which are the most thermally sensitive of the major wood polymers [

19,

26]. In the case of

Populus sp., the weight decreases steadily with increasing temperature, reflecting continuous hemicellulose breakdown.

Quercus also demonstrates a consistent mass reduction, indicative of progressive thermal degradation. In contrast,

Pinus sp. shows a slight increase in weight up to approximately 180 °C, likely due to moisture loss and structural compaction, followed by a subsequent decrease as thermal decomposition becomes more pronounced (

Figure 4). These patterns highlight species-specific responses to heat and emphasize the importance of tailoring thermal treatment parameters based on wood type.

Wood volume responds differently to thermal treatment depending on the species and the structural changes induced by heat (

Figure 5). Populus sp. exhibits a noticeable increase in volume up to 180 °C, suggesting thermal expansion or internal stress relief, followed by a decline at higher temperatures, likely due to cell wall degradation and collapse. In contrast, Pinus sp. maintains relatively stable volume throughout the heat-treatment range, indicating greater structural resilience and lower sensitivity to thermal-induced dimensional change. Quercus displays a gradual and consistent decrease in volume with increasing temperature, reflecting progressive degradation of cell wall components and shrinkage. These volume trends, in combination with mass loss data, are critical for understanding the density changes and physical stability of heat-treated wood (

Figure 5).

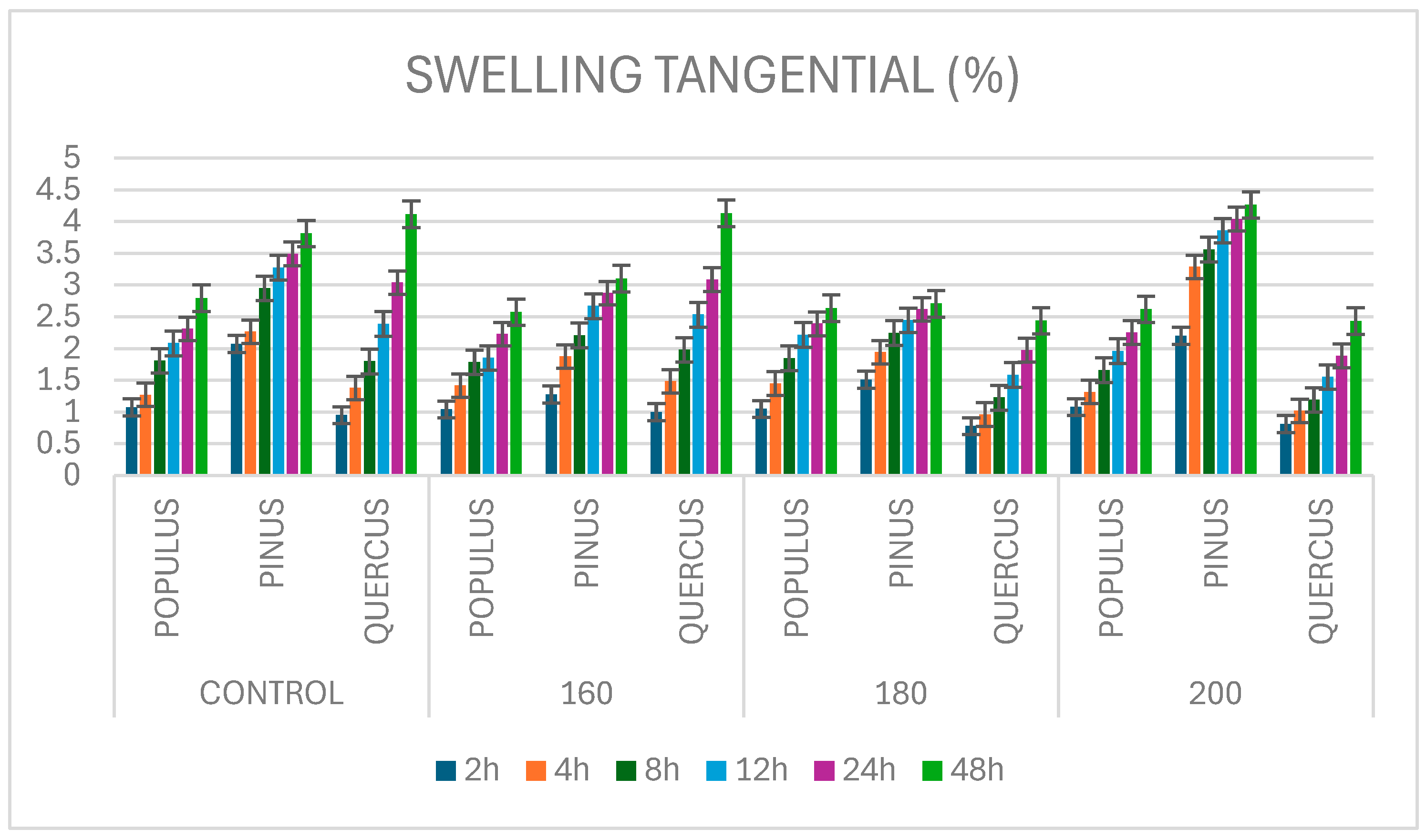

Figure 6 shows tangential swelling (%) over time for three wood types (

Populus,

Pinus, and

Quercus) under different thermal treatments (control, 160 °C, 180 °C, 200 °C).

Pinus generally exhibits the highest swelling, especially at 200 °C, showing a steep increase over time, suggesting it reacts the most under high temperature.

Quercus has the lowest swelling, particularly at 180 °C and 200 °C, suggesting better dimensional stability under heat.

Populus shows moderate swelling, with swelling increasing over time but less influenced by temperature extremes compared to pine [

21].

For statistical analysis, we used two-way ANOVA: dimensional stability (swelling %). The dependent variables were axial swelling (%), tangential swelling (%), and radial swelling (%), and the independent variables (factors) were temperature (control, 160 °C, 180 °C, 200 °C) and species (Populus, Pinus, and Quercus). The following hypotheses were posited:

Main Effects:

H01 (Temperature): No significant difference in swelling across temperatures.

H02 (Species): No significant difference in swelling across species.

Interaction:

H03 (Temperature × Species): No interaction effect between temperature and species on swelling.

The results of the statistical analysis showed that (p < 0.001) thermal treatment significantly affects swelling. Different wood species have significantly different swelling behaviors (p < 0.001). The effect of temperature varies by species consistent with observed trends (e.g., Quercus benefits most at 160 °C, Pinus swells more at 200 °C, and Populus responds moderately) (p = 0.008). From post hoc (Tukey HSD) analysis (tangential swelling), it can be seen that the Quercus groups exhibited significantly lower swelling at 160 °C and 180 °C than all others. Pinus swelling at 200 °C is significantly greater than in other temperature groups.

At 180 °C, Populus shows moderate but statistically significant improvement over the control. Two-way ANOVA confirms that both temperature and species, as well as their interaction, significantly influence dimensional stability. Quercus shows the most stable response, especially at 160–180 °C. Pinus is sensitive to over-treatment at 200 °C, showing increased tangential swelling. Populus benefits from treatment but is less stable at high temperatures.

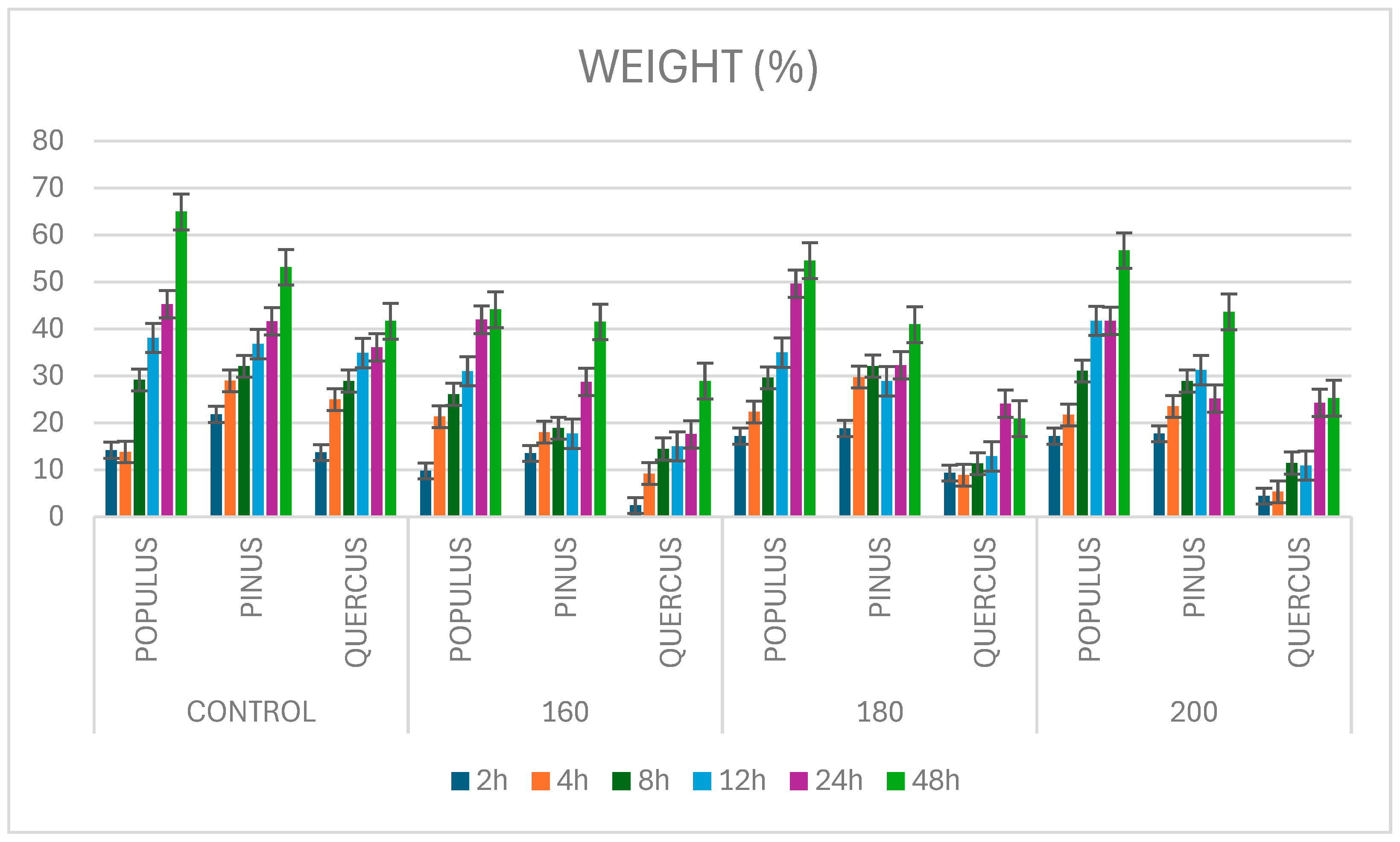

At

Figure 7 the water absorption increases over time in almost all conditions, which is expected as more time typically allows more water penetration into the wood.

Higher temperatures (160 °C, 180 °C, 200 °C) reduce the water absorption compared to the control, indicating that thermal treatment makes the wood less hydrophilic (more hydrophobic). At Populus sp. control samples observed an increase in WA from 14.17 (2 h) to 64.94 (48 h). At 160 °C heat treatment reduced absorption at all times compared to control; final WA at 48 h is ~44.11. At 180 °C & 200 °C further reduction, especially at 2 h and 4 h, but the gap closes at 48h (54.52–56.67). This suggests thermal treatment slows initial absorption but may not fully prevent long-term uptake.

At Pinus control samples show a strong increase, from 21.8 to 53.1. At 160 °C and 180 °C noticeable reduction in early hours, and WA stays consistently lower than control across all time points and at 200 °C heat treatment slightly higher than 160 °C and 180 °C at later stages, suggesting that too high a temperature might reverse some benefits due to structural damage.

At Quercus sp. control species start at 13.66 and go to 41.66. In temperature of 160 °C, the lowest WA among all samples across time, especially at 2 h (2.39) and 4 h (9.17). At 180 °C and 200 °C the WA increases gradually but remains well below control.

Quercus shows the most pronounced reduction from heat treatment, especially at lower exposure durations.

To conclude, heat treatment significantly reduces water absorption, with effectiveness dependent on temperature and wood species. The temperature of 160 °C seems optimal for Quercus, giving minimal WA. The temperature of 180 °C gives a good balance for Populus and pine. A temperature of 200 °C may result in slightly increased WA at later stages for some species (e.g., Populus), possibly due to microcracks or cell wall degradation.

To conclude, thermal modification is effective at reducing the water absorption of wood, which enhances dimensional stability and durability. Quercus responds best to thermal treatment, especially at 160 °C. Populus and pine benefit from treatment at 180 °C but may show higher long-term absorption at 200 °C. For practical applications (e.g., exterior use), treating at 160–180 °C appears optimal, avoiding over-treatment that could reduce structural integrity.

The two-way ANOVA revealed that wood species, heat-treatment temperature, and immersion time all had statistically significant effects on water absorption (WA) (p < 0.001 for all terms). Among the main effects, species was the dominant factor, explaining approximately 63% of the variance (partial η2 = 0.63). This reflects the strong influence of inherent anatomical and chemical properties: Quercus consistently exhibited the lowest WA, Populus the highest, and Pinus showed intermediate behavior.

Temperature was the second most influential factor (η2 ≈ 0.47). Heat treatment led to a substantial reduction in WA, particularly between the untreated control and the 160 °C condition. Further increases to 180 °C provided additional reductions in some species, but rising to 200 °C often reversed the trend, particularly in Populus and Pinus, likely due to thermal degradation or the formation of microcracks that compromise cell wall integrity.

Immersion time also had a strong effect (η2 ≈ 0.54), with longer soaking resulting in greater water uptake, as expected. However, the absorption kinetics varied with species and heat-treatment history, indicating that time effects were not uniform across all conditions.

A significant species × temperature interaction (η2 ≈ 0.61) further confirmed that the response to thermal treatment was species-specific. In Quercus, the most effective reduction occurred at 160 °C, with little additional benefit at higher temperatures. Pinus showed a minimum WA at 180 °C, but WA increased again at 200 °C, suggesting over-treatment. Populus showed a gradual decline in WA up to 180 °C, followed by a rebound at 200 °C, pointing to possible structural damage at high temperatures.

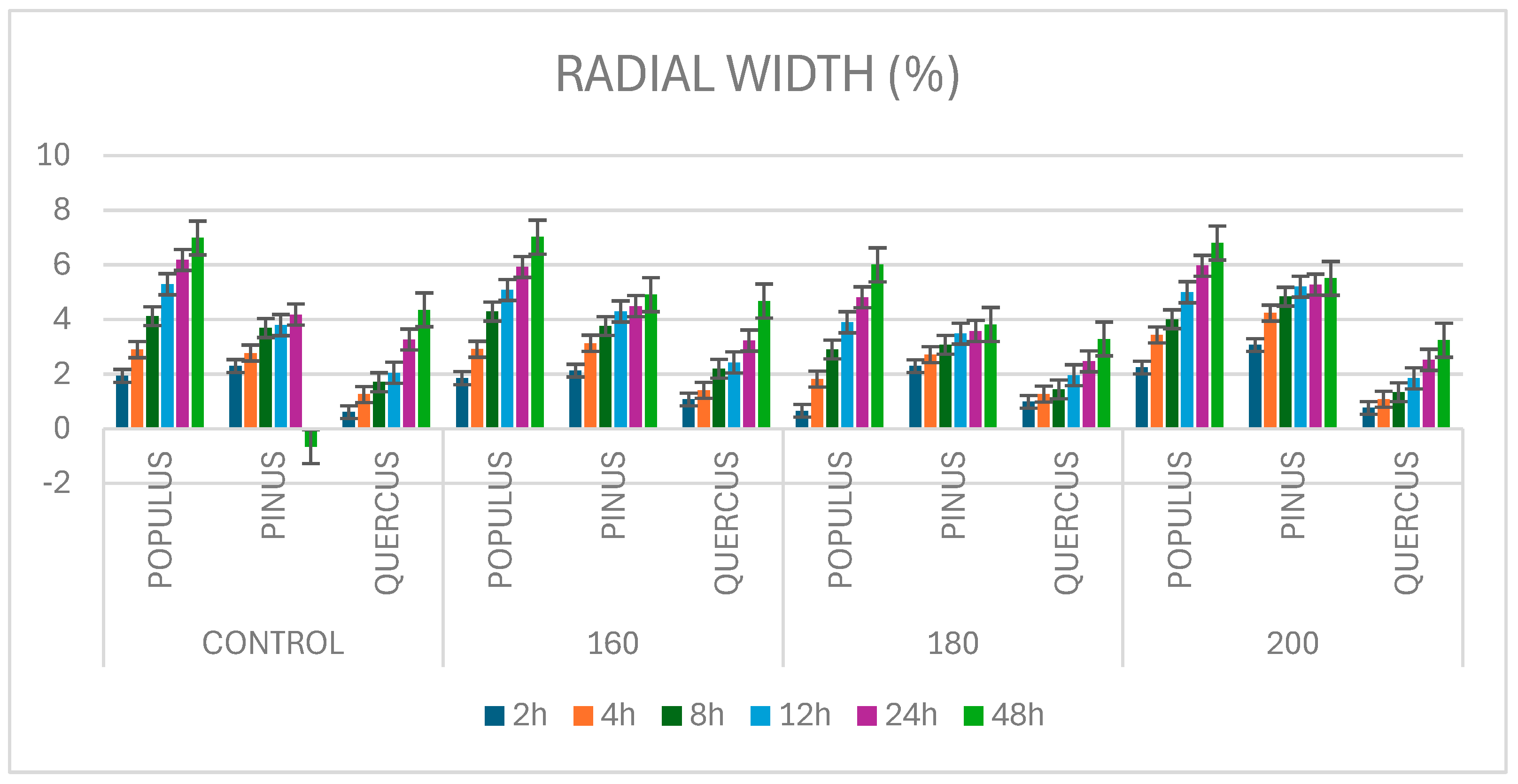

As shown in

Figure 8,

Populus shows the highest average radial swelling across all treatments, especially at 200 °C.

Pinus shows a more moderate response with relatively low variation, especially under thermal treatment.

Quercus exhibits the least radial swelling overall, indicating dimensional stability.

The ANOVA on Radial Swelling (%) shows that the species of wood had the most significant influence on radial swelling (p < 0.001, η2 = 0.57). Populus exhibited the highest swelling, indicating low dimensional stability in the radial direction. Quercus showed the least swelling, confirming its superior radial stability. Pinus was intermediate, but more stable than Populus. This reflects differences in anatomical structure and cell wall composition. Quercus has thicker cell walls and higher lignin content, resisting moisture-driven expansion. Temperature significantly influenced swelling, but less than species (p = 0.016, η2 = 0.17). Swelling decreased at moderate temperatures (160 °C–180 °C) across species. At 200 °C, swelling increased again, especially in Pinus and Populus, likely due to cell wall microcracks and degradation of bonding structures. Moderate heat improves dimensional stability by reducing hygroscopic hemicelluloses, but excessive heat damages structural integrity. Swelling increased with longer water exposure across all species and treatments (p < 0.001, η2 = 0.64). After 48 h, all species showed significant radial expansion, especially under control or low-temperature treatments. However, Quercus remained the most stable, even for longer durations. This confirms that thermal modification delays moisture uptake but cannot fully prevent it with prolonged exposure. Interaction: species × temperature (p = 0.026, η2 = 0.22).

The effect of heat treatment varied across species. Populus benefited most from a temperature of 180 °C, with reduced swelling. Pinus reacted negatively at 200 °C, suggesting degradation. Quercus remained consistently stable, especially at 160 °C. Thermal response is species-specific. What benefits one species may harm another at the same temperature.

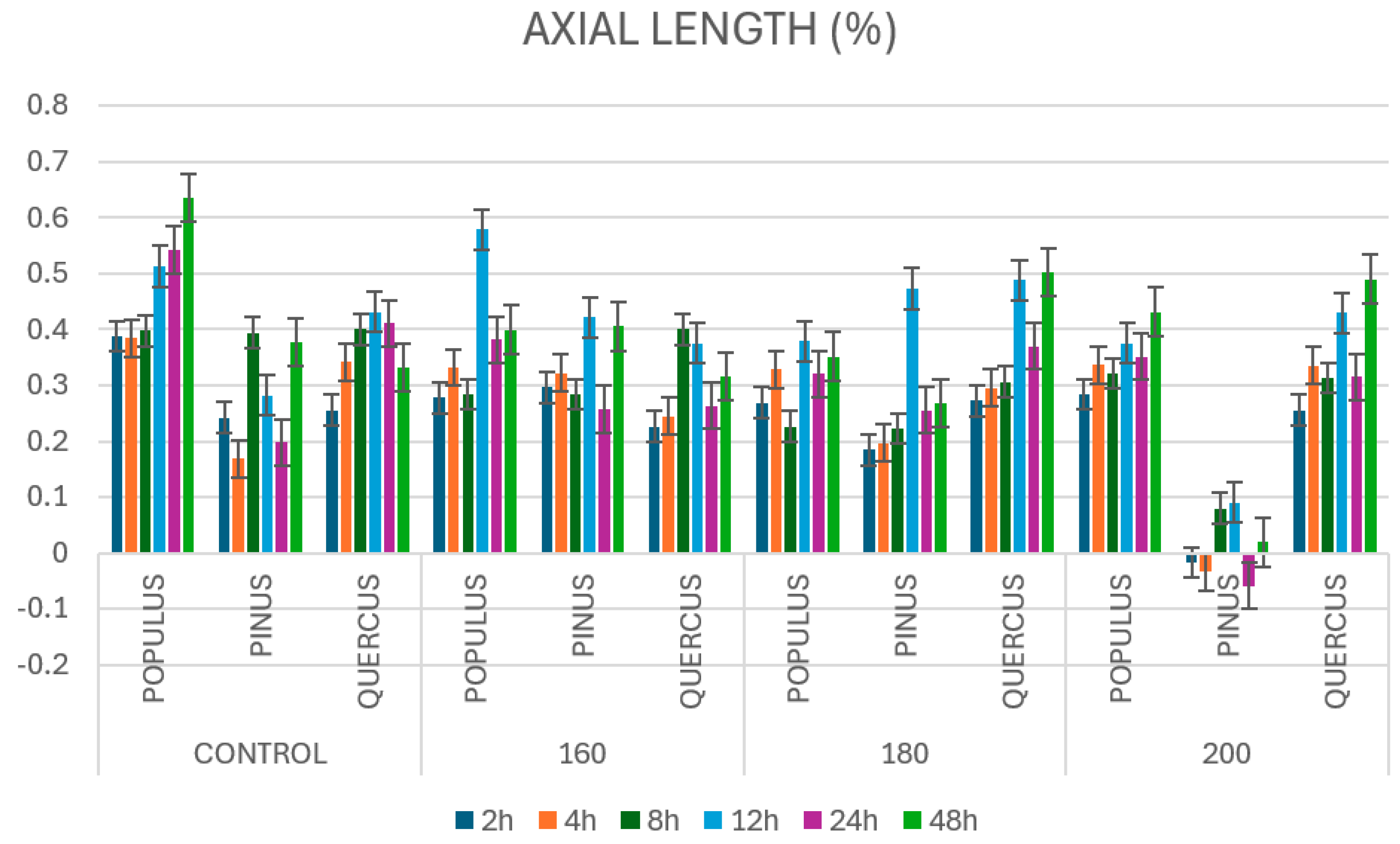

Figure 9 shows the percentage change in axial length over time (2 h to 48 h) for three wood species:

Populus,

Pinus, and

Quercus. Treatments included a control and thermal treatments at 160 °C, 180 °C, and 200 °C.

The control samples for all three species showed positive axial length increases. Populus and Quercus had the highest elongation at 48 h (above 0.6%). Pinus was slightly lower, staying under 0.55%. At 160 °C treatment Populus and Pinus showed slight reduction compared to Control but still growth. Quercus maintains nearly the same performance as the control. At 180 °C treatment, all species showed reduced axial growth. Particularly, pine shows minimal elongation, close to 0.2%–0.3%. Trend suggests moderate thermal inhibition. At 200 °C treatment Populus and Pinus exhibit negative or near-zero axial length change, indicating shrinkage or collapse due to high thermal stress. Quercus retains moderate positive values (up to ~0.5%), suggesting better thermal stability

Axial elongation decreases with increasing temperature. Quercus demonstrates best thermal resilience in axial structure. Populus and Pinus are more susceptible to thermal degradation at higher temperatures (200°C), showing dimensional instability.

In conclusion, Quercus consistently shows better axial stability, especially at 200 °C. Populus and Pinus show clear thermal sensitivity, especially above 180 °C. The 200 °C treatment led to negative or negligible axial changes for Populus and pine, indicating it is unsuitable for maintaining structural integrity. The 160–180 °C treatments offer a balance between modification and structural retention for most species.

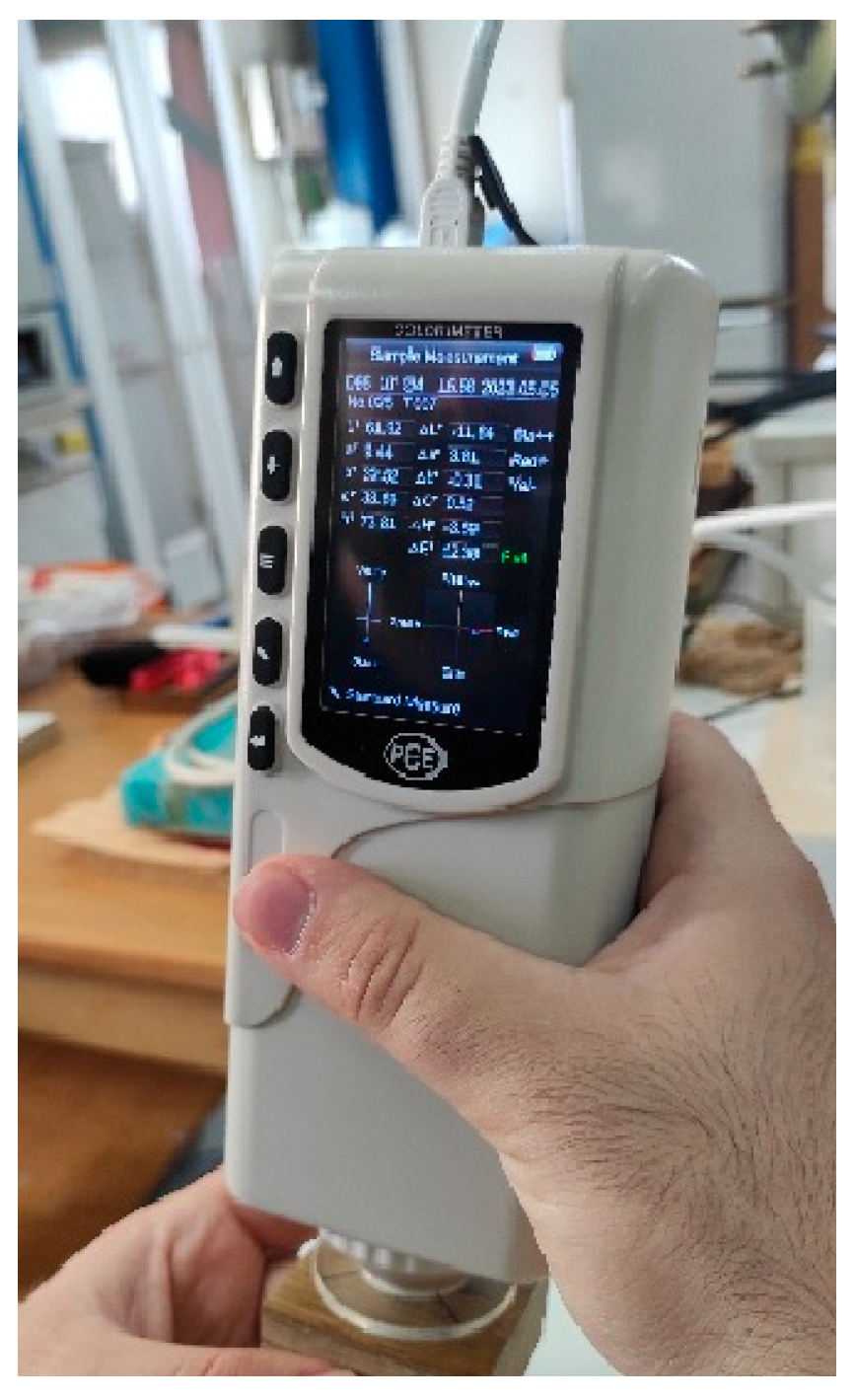

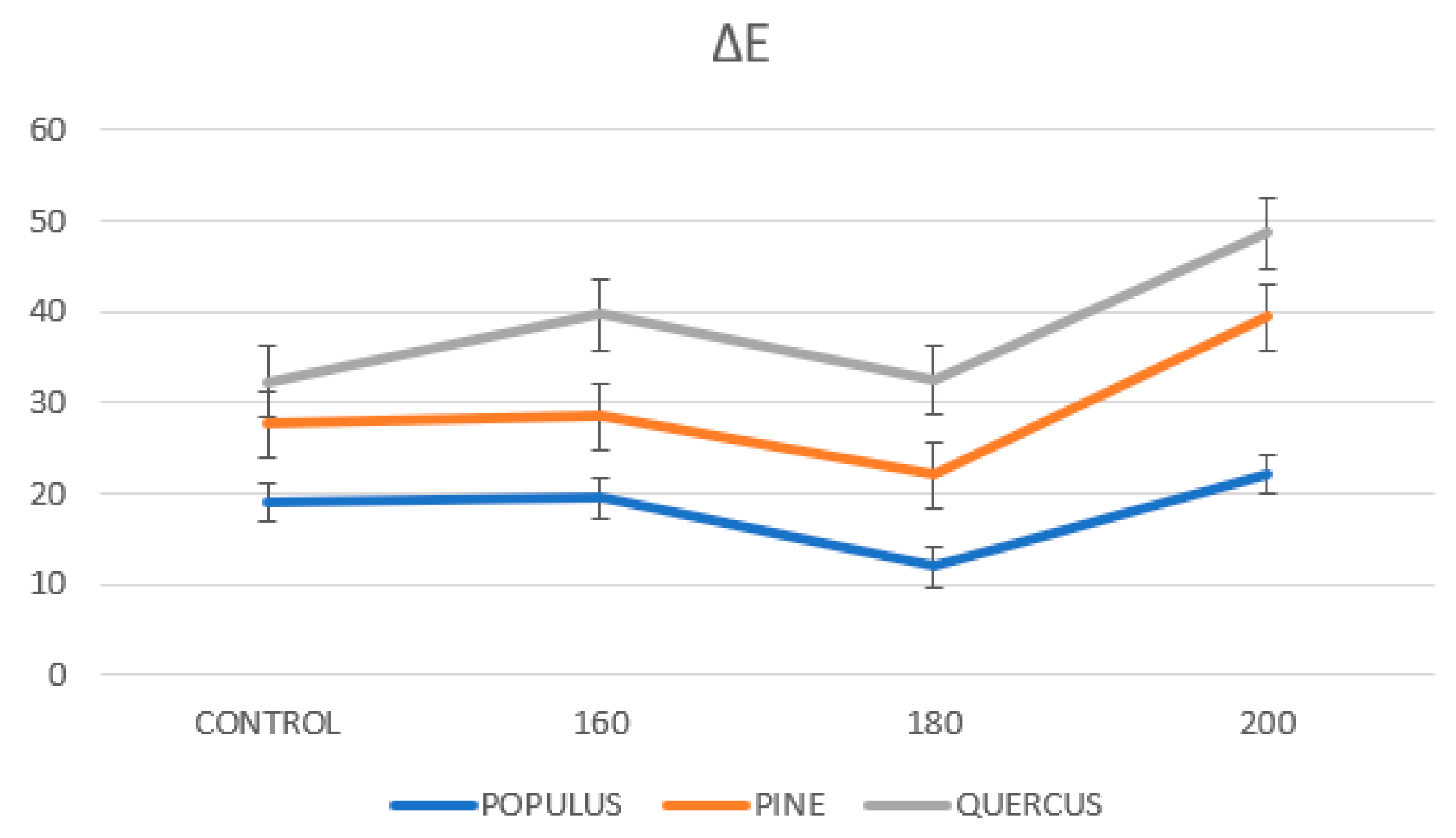

At

Quercus color changes become significantly more noticeable at all treatment levels compared to control. The peak color change is at 160 ℃ (ΔE = 11.27), then stabilizes at slightly lower values at 180 and 200. This suggests saturation point may be around 160–180 ℃ (

Table 1). At

Pinus a very strong reaction at 200 ℃ where ΔE = 17.24, indicating a dramatic color shift. Moderate and gradual increase from 160 ℃ to 180℃. Control already shows moderate ΔE (likely from aging or baseline exposure).

Populus observed high baseline color variability (ΔE = 19.01 at control). Heat treatment at 200 ℃ causes a very high ΔE, meaning extremely noticeable changes. Heat Treatment at 160 ℃ already induces nearly maximum shift (ΔE = 19.46). Which suggests that

Populus is highly sensitive to even moderate treatment levels (

Figure 10).

<1: Not perceptible to the human eye.

1–2: Perceptible through close observation.

2–10: Noticeable at a glance.

>10: Significant color difference.

4. Discussion

The results of this study confirm that thermal modification significantly alters the physical, chemical, and surface properties of wood, with outcomes strongly influenced by species-specific characteristics and treatment parameters. These findings align with earlier studies indicating that thermal degradation primarily affects hemicellulose and cellulose, leading to improved dimensional stability and reduced hygroscopicity across species. However, the extent of these changes and their implications for coating performance and surface integrity vary widely among Populus, Quercus, and Pinus.

All three species exhibited noticeable darkening accompanied by an increase in extractive content. Specifically, the increase in total lignin content and extractives is consistent with the breakdown of hemicellulose and cellulose, resulting in a higher proportion of thermally stable compounds. This chemical reorganization contributes to enhanced resistance to moisture and improved dimensional stability, particularly evident in Quercus, which showed minimal swelling and water uptake, even at the lower treatment temperature of 160 °C.

Quercus demonstrated the highest overall thermal resistance and coating compatibility, likely due to its inherently high lignin content and dense anatomical structure. This supports findings by Poncsak et al. [

20], who noted that hardwoods with higher initial lignin concentrations retain mechanical integrity better during heat treatment. On the other hand, Populus proved to be the most thermally sensitive species, suffering substantial mass loss and surface degradation, especially at 200 °C. These effects negatively influenced coating adhesion and weather resistance, suggesting that light, porous hardwoods require more conservative treatment protocols.

Pinus exhibited the most balanced response at 180 °C, showing improvements in density, color stability, and coating performance without the detrimental effects observed at higher temperatures. This suggests that softwoods with intermediate density and extractives can benefit significantly from mid-range thermal treatments. Interestingly, while 200 °C treatments enhanced dimensional stability across all species, they also introduced surface chemistry changes that impaired coating adhesion, particularly in Populus. This aligns with findings by Sundqvist [

21] who noted surface inactivation and reduced wettability at high treatment temperatures.

Xenon arc aging tests further emphasized species-specific differences in weathering behavior. Pinus retained the most consistent color and gloss, confirming its suitability for outdoor applications after moderate thermal treatment. In contrast, Populus showed marked fading and gloss loss, indicating a lower capacity for UV resistance post-modification.

The findings underscore the need for a species-tailored approach to thermal modification, balancing treatment intensity with desired end-use performance. While 160–180 °C treatments generally provide the optimal combination of structural integrity and surface compatibility, temperatures above 180 °C should be applied with caution, particularly for species with low thermal resistance.

5. Conclusions

This study demonstrates that thermal modification induces species-specific changes in the physical, chemical, and surface properties of wood, contingent upon initial composition and treatment parameters. The response of Populus, Quercus, and Pinus to heat treatment at 160 °C, 180 °C, and 200 °C highlights the necessity for species-optimized processing to achieve targeted performance outcomes.

Quercus exhibited optimal thermal response at 160 °C, with significant gains in dimensional stability, minimal volumetric swelling, and favorable coating adhesion. Its inherent high lignin and extractive content enhanced thermal resilience and surface compatibility without requiring higher thermal exposure. Pinus achieved peak performance at 180 °C, with increased density, moderate improvement in dimensional stability, and enhanced surface properties conducive to coating applications. Treatment at 200 °C, however, resulted in over-degradation of surface polymers, impairing coating adhesion and aesthetic retention. Populus demonstrated limited benefit beyond 160 °C, with progressive mass loss, color instability, and surface degradation at 200 °C compromising both structural and coating performance. As a lower-density, hemicellulose-rich species, Populus is particularly susceptible to thermal over-processing. Across all species, thermal treatment reduced hygroscopicity and increased total lignin and extractive content, primarily due to hemicellulose degradation. Colorimetric analysis confirmed darkening post-treatment, with Populus exhibiting the highest ΔE values. Xenon arc aging revealed superior gloss and color retention in Pinus, while Populus displayed accelerated weathering effects.

Thermal treatments within the 160–180 °C range provide the most favorable balance of structural stability, color development, and coating compatibility. Exceeding this threshold, particularly at 200 °C, may be detrimental for lighter, chemically labile species such as Populus. These findings support a species-specific approach to thermal modification in the design of durable, coated wood products for exterior use.

Future research should explore the interplay between thermal modifications and advanced coating systems, particularly those designed to mitigate the effects of surface degradation at higher temperatures. Additionally, long-term field studies are needed to validate laboratory findings under real environmental conditions and to develop predictive models for performance over time.