A System Dynamics Approach to Resilience Analysis in the Sino-Russian Timber Supply Chain

Abstract

1. Introduction

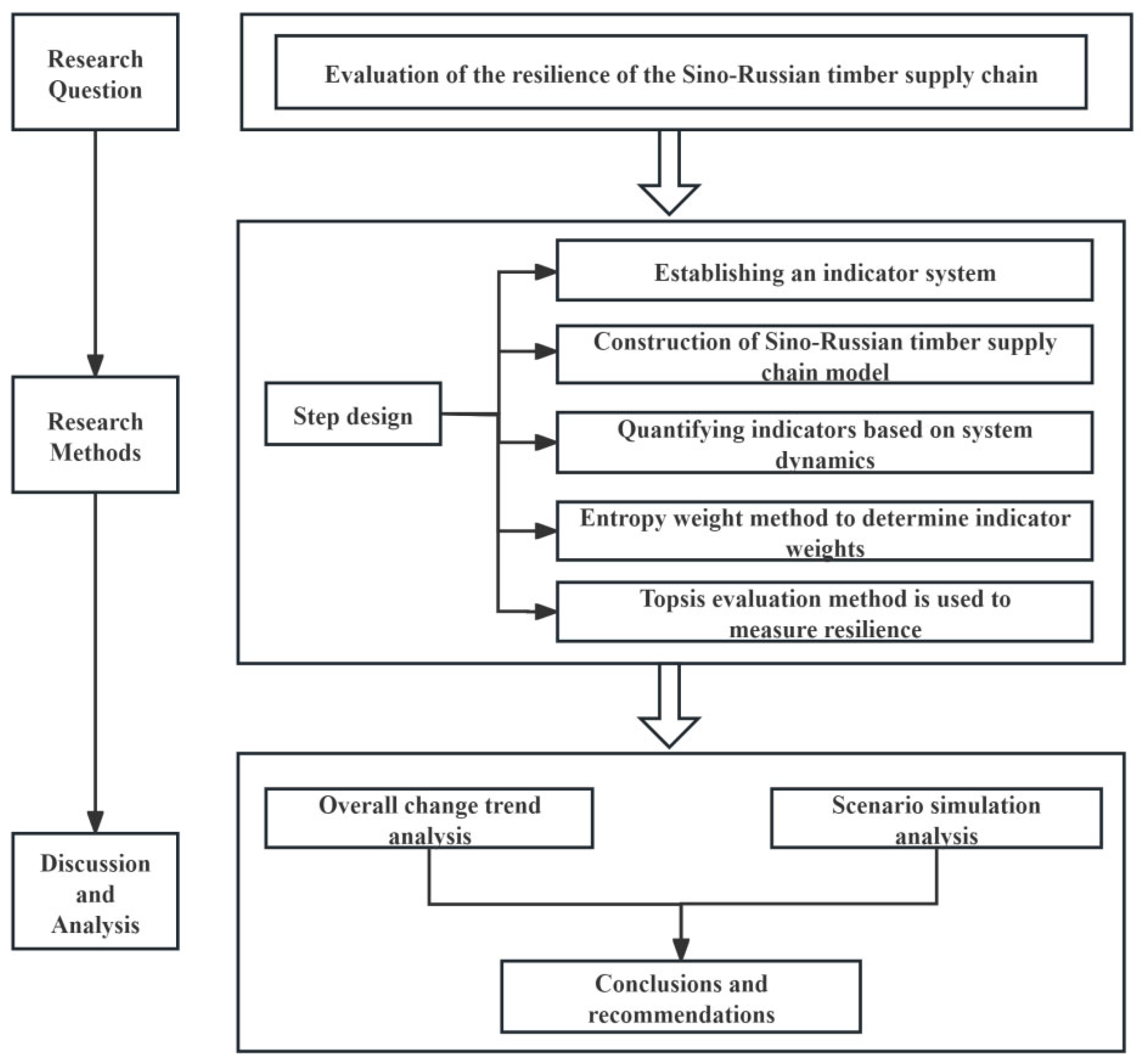

2. Materials and Methods

2.1. Study Area and Data Sources

2.2. Constructing Evaluation Indicators for the Resilience of the Sino-Russian Timber Supply Chain

2.3. Construction of Dynamic Model of Sino-Russian Timber Supply Chain System

2.3.1. System Boundaries and Assumptions

- (1)

- Environmental changes external to the system (such as the global economic environment, political environment, etc.) do not intrinsically affect the internal operation of the system;

- (2)

- The model does not account for low-probability events such as black swan events.

- (3)

- The model focuses on the core sequence of “Russian production—transportation—exportation—Chinese sales”, not including all nodal firms.

- (4)

- Modeling targets the “Russian production–transportation–export–Chinese sales” sequence (partial nodal coverage).

- (5)

- Only the main causal relationships of the influencing factors within the system are considered.

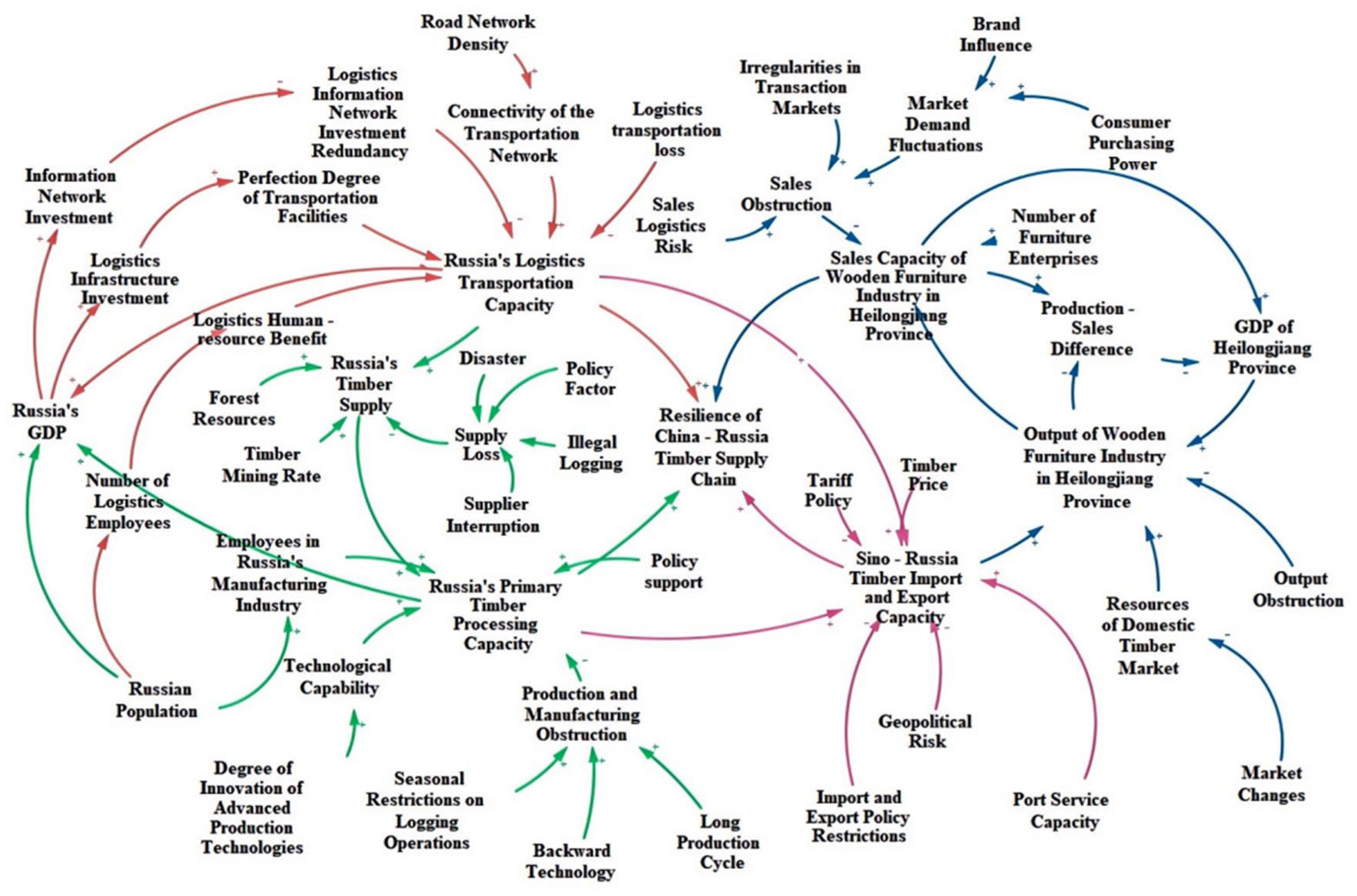

2.3.2. Construction of a Causal Diagram

2.3.3. System Flow Chart and Model Equation Construction

- (1)

- Russian Logistics Transportation Capacity = 7075.328 + 0.15 × Logistics Transportation Capacity Improvement − Logistics Transportation Capacity Consumption − Previous Year’s Russian Logistics Transportation Capacity (Custom Equation Mode, Initial Value: 8072.6 MMT)

- (2)

- Russian Timber Supply = Timber Supply Improvement − Timber Supply Consumption − previous year’s Russian timber supply (Custom Equation Model, Initial Value: 82.8 billion cubic meters)

- (3)

- Russian Primary Processing Capacity = Production And Manufacturing Growth − Production And Manufacturing Obstruction − 0.84 × previous year’s Russian Primary Processing Capacity (Custom Equation Model, Initial Value: 252 thousand cubic meters)

- (4)

- Sino-Russia Timber Import And Export capacity = Timber Import And Export Growth − Timber Import And Export Hindrance (Classic Equation Model, Initial Value: 949.256 million RMB)

- (5)

- Heilongjiang Wooden Furniture Industry Output Capacity = Heilongjiang Wooden Furniture Industry Output Growth − Heilongjiang Wooden Furniture Industry Output Obstruction − previous year’s Heilongjiang Wooden Furniture Industry Output Capacity (Custom Equation Model, Initial Value: 595.5203 million RMB)

- (6)

- Heilongjiang Wooden Furniture Industry Sales Capacity = Heilongjiang Wooden Furniture Industry Sales Growth − Heilongjiang Wooden Furniture Industry Sales Obstruction × Heilongjiang Wooden Furniture Industry Sales Capacity − 0.85 × previous year’s Heilongjiang Wooden Furniture Industry Sales Capacity (Customized Equation Model, Initial Value: 455.7761 million yuan)

- (7)

- Production And Manufacturing Growth = 0.3 × Russian Timber Supply + 0.187 × Human Resources + 0.13 × Technological Capability + 0.105 × Policy Influence − 105

- (8)

- Production And Manufacturing Obstruction = Timber Production Efficiency Impediments × Russian Primary Processing Capacity

- (9)

- Timber import and export growth = 0.73 × Russian Primary Processing Capacity + Transportation Loading Factor × Russian Logistics Transportation Capacity

- (10)

- Timber Import And Export Hindrance = (Geopolitical Riskn + Policy Restriction) × Sino-Russia Timber Import And Export Capacity + 0.4 × Timber Price + 0.6 × Cargo Transportation Tariff

- (11)

- Heilongjiang Wooden Furniture Industry Output Growth = (0.489402 × Domestic timber market resources + 0.0626047 × GDP of Heilongjiang Province + 0.195484 × Sino-Russia Timber Import And Export Capacity) × Market Benefit Factor

- (12)

- Heilongjiang Wooden Furniture Industry Output Obstruction = Production Obstruction Factor × Heilongjiang Wooden Furniture Industry Output Capacity

- (13)

- Heilongjiang Wooden Furniture Industry Sales Growth = 0.35 × Heilongjiang Wooden Furniture Industry Output Capacity × Wooden Furniture Market Adaptability Coefficient + 0.78 × Furniture Enterprise Quantity + 0.1 × Math.log10 (Heilongjiang Wooden Furniture Industry Output Capacity) − 31.81

- (14)

- Heilongjiang Wooden Furniture Industry Sales Obstruction = Sales Obstruction

- (15)

- Growth = Growth Rate × Russian GDP

- (16)

- Hindrance = Hindrance Factor × Russian GDP

- (17)

- Economic Growth = Economic Growth Rate × GDP Of Heilongjiang Province

- (18)

- Economic Obstruction = Economic Obstruction Factor × GDP Of Heilongjiang Province

- (19)

- Timber Production Efficiency Impediments = Industrial Injury Accidents And Occupational Diseases + Seasonal Restrictions On Logging Operations + Long Production Cycle + Lagging Equipment And Production Technology

- (20)

- Sales Obstruction = Transaction Market Disorder + Sales Logistics Risk + Market Demand Fluctuation

- (21)

- Logistics Talent Benefits = Labor Force Conversion Coefficient × Workers

- (22)

- Connectivity Of The Transportation Network = Transportation Benefit Coefficient × Road Network Density

- (23)

- Logistics Information Network Investment Redundancy = Information-based Investment Conversion Coefficient × Information Network Investment

- (24)

- Benefits Of Logistics Infrastructure Construction = Infrastructure Investment And Construction × Infrastructure Investment

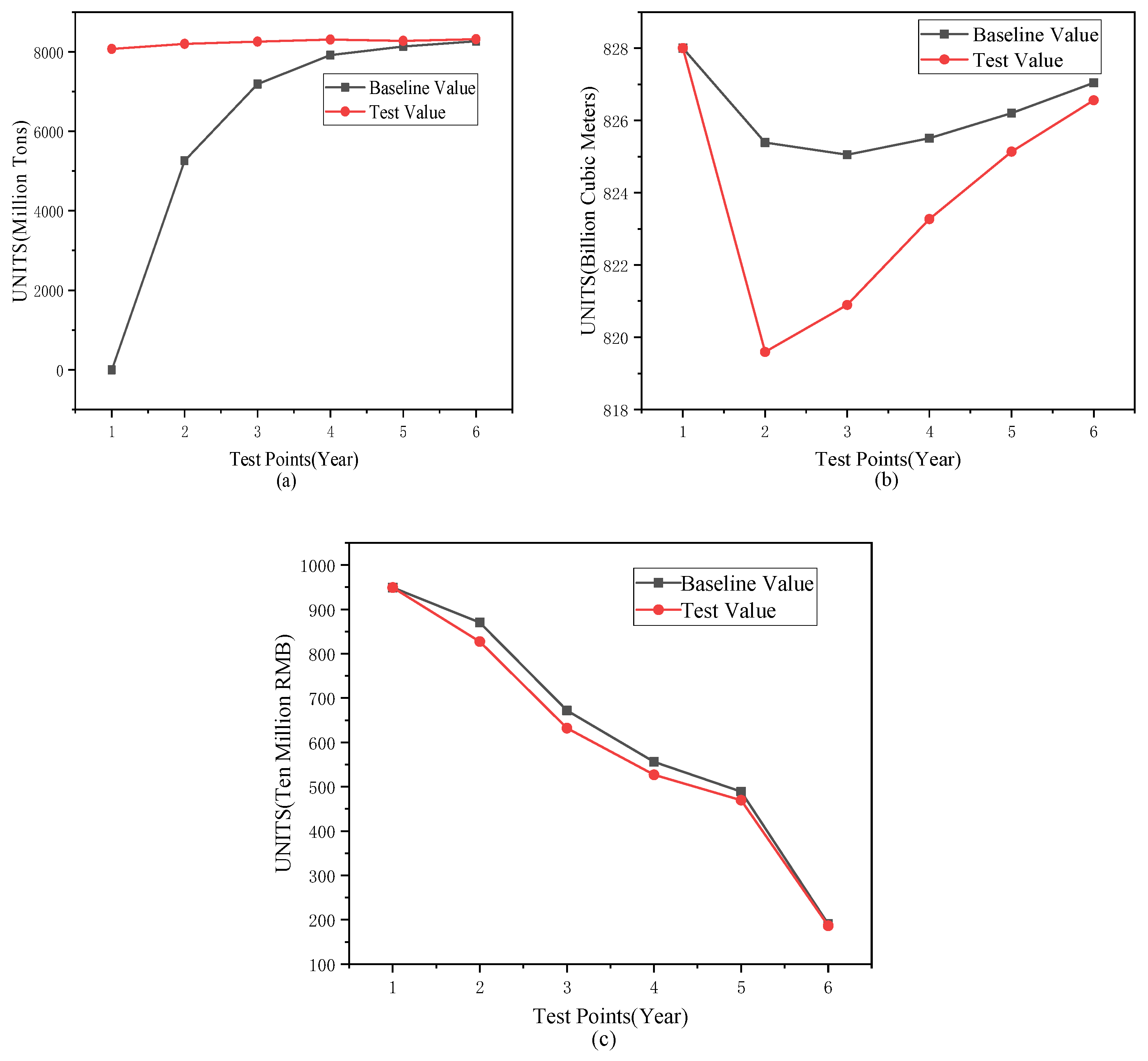

2.3.4. Model Testing

Historicity Test

Stability Test

- (1)

- Single-variable shocks: only extreme disturbances are applied to the logistics and transportation capacity (period 0 = 0), and the rest of the stock (e.g., GDP, etc.) changes normally according to the initial experimental value;

- (2)

- Response test: to verify the resilience of the shocked variable and the mechanism of its dynamic impact on the associated stock.

2.4. Entropy Weight–TOPSIS Evaluation Framework

2.4.1. Entropy Weight Method for Weight Calculation

- Step 1: Construction of the Initial Decision Matrix

- Step 2: Normalization of the Initial Decision Matrix

- Step 3: Calculation of the Entropy

- Step 4: Calculation of the Weight

2.4.2. Integrating Z-Score Normalization and TOPSIS for Overall Supply Chain Resilience Calculation

- (1)

- Z-Score Normalization Method: This method eliminates dimensional differences between indicators and transforms them into standard normal distribution data with a mean of 0 and a standard deviation of 1. The Z-score normalization process involves subtracting the mean from the data and dividing by the standard deviation. This is done for each value in the dataset. For each attribute, the Z-score of an entry is calculated by [48]:

- (2)

- TOPSIS Model Construction: This quantifies the supply chain resilience level by calculating the relative closeness of each evaluation object to positive and negative ideal solutions. Here are the steps [49]:

- Step 1: Construction of the Weighted Normalized Matrix

- Step 2: Determination of the Positive and Negative Ideal Solutions

- Step 3: Calculation of Euclidean Distances

- Step 4: Calculation of Relative Closeness (Resilience Value)

2.5. Scenario Simulation Design

3. Results

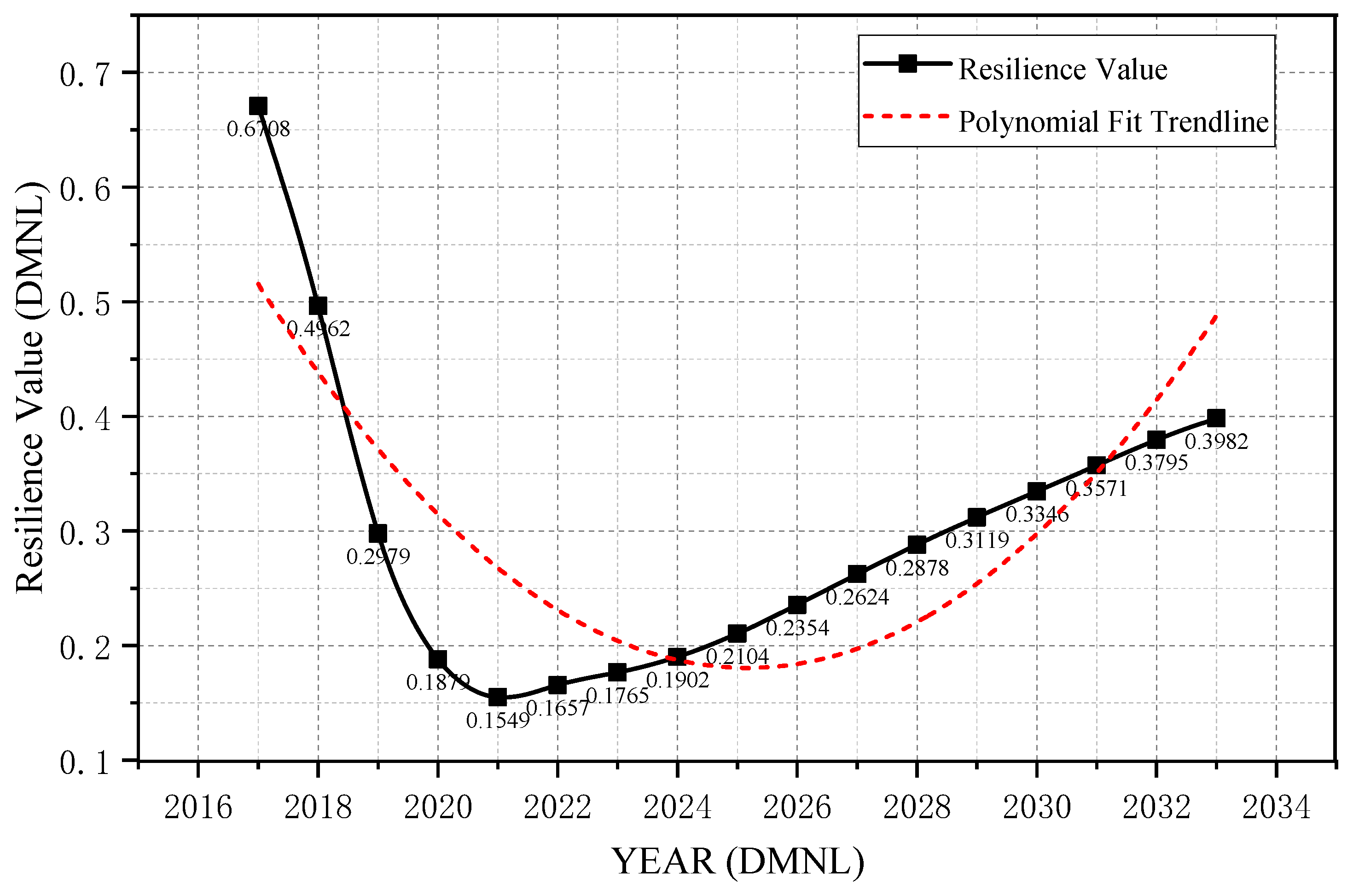

3.1. Trends of Supply Chain Resilience in Sino-Russian Timber Trade

3.1.1. Determination of Evaluation Index Weight

3.1.2. Supply Chain Resilience Trends Change

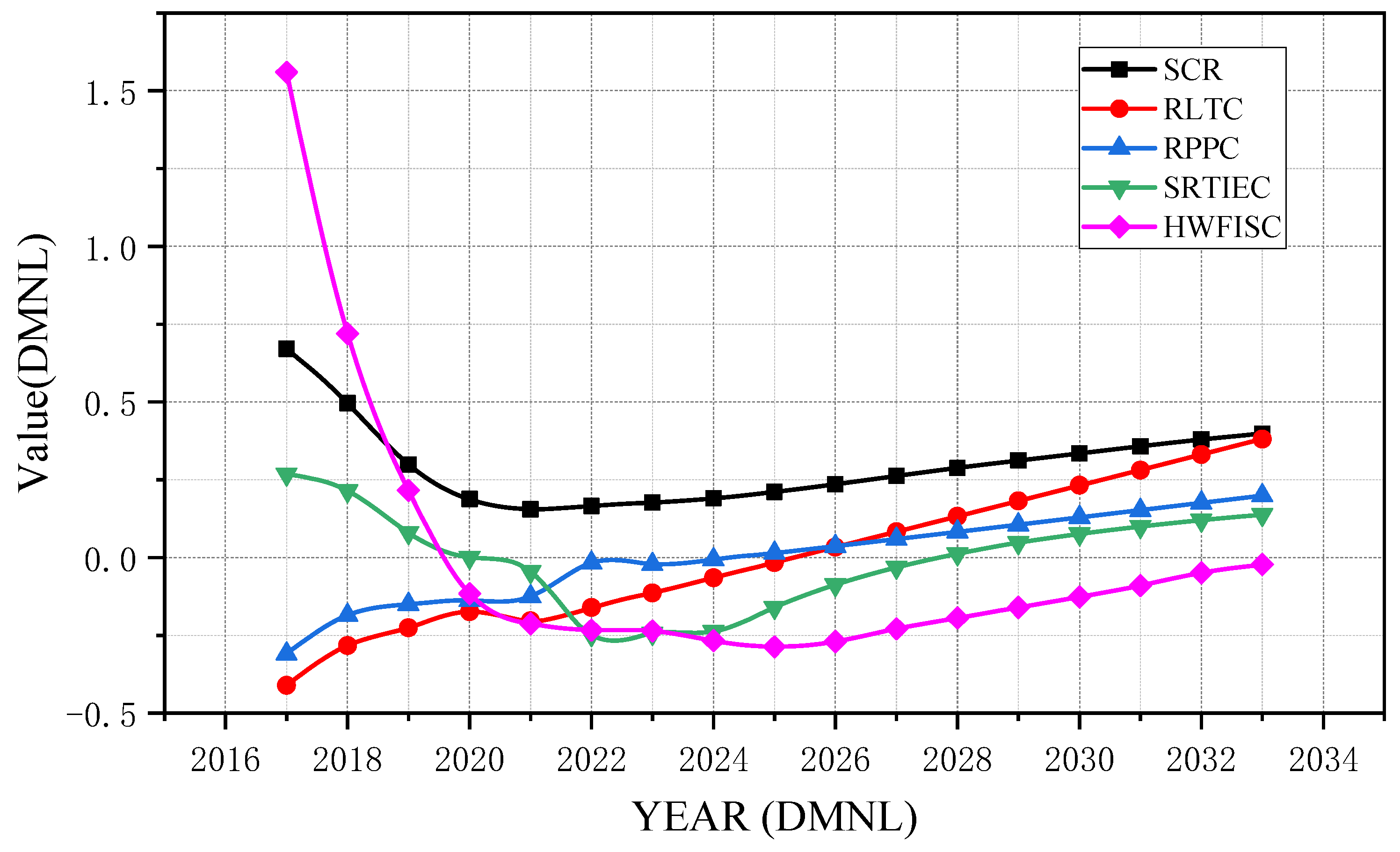

3.1.3. Subsystem Capability and Supply Chain Resilience Trends Change

3.2. Simulation and Specific Analysis of China–Russia Supply Chain Fluctuation Scenarios

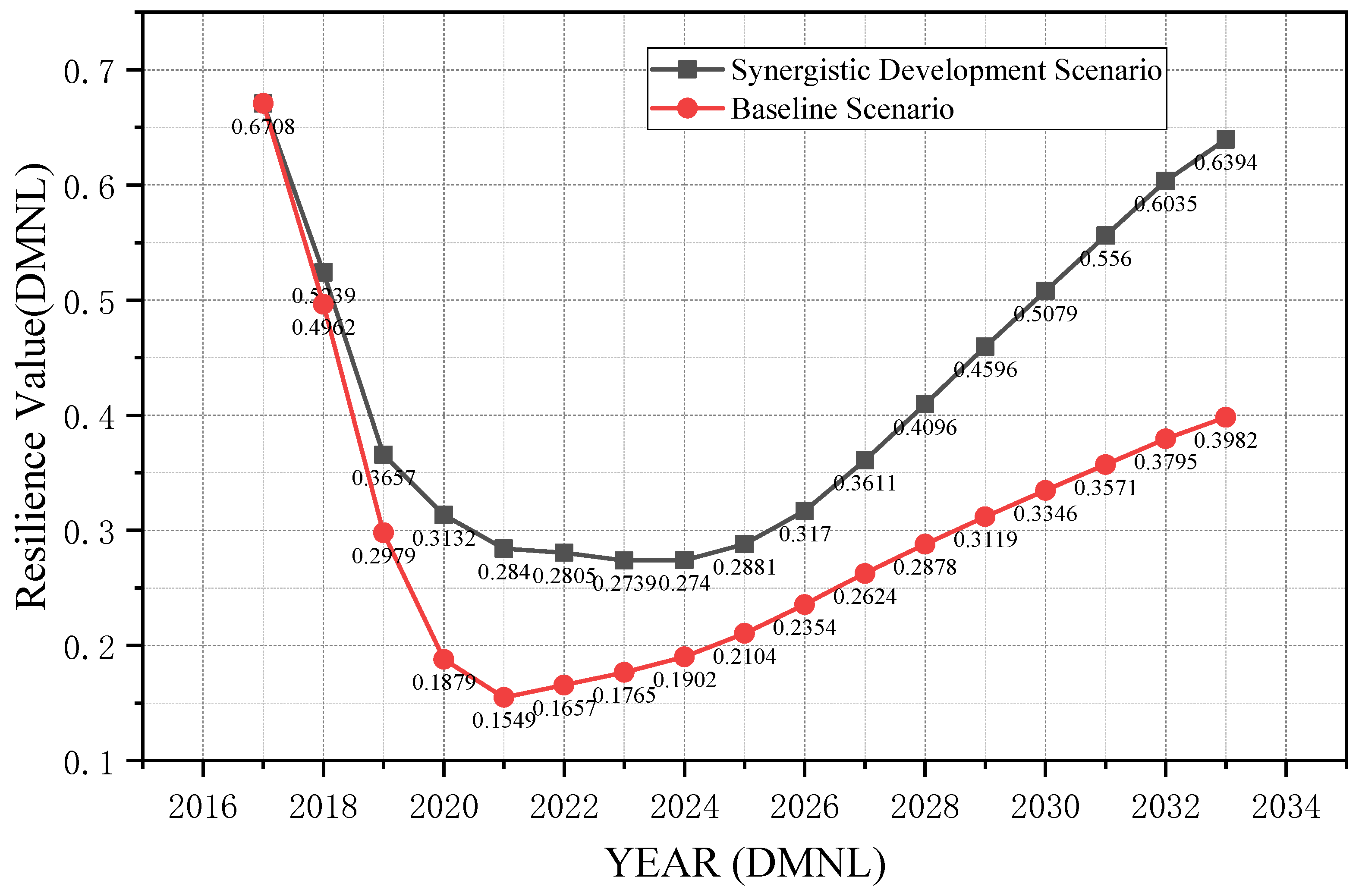

3.2.1. Resilience Analysis in the Context of Collaborative Development

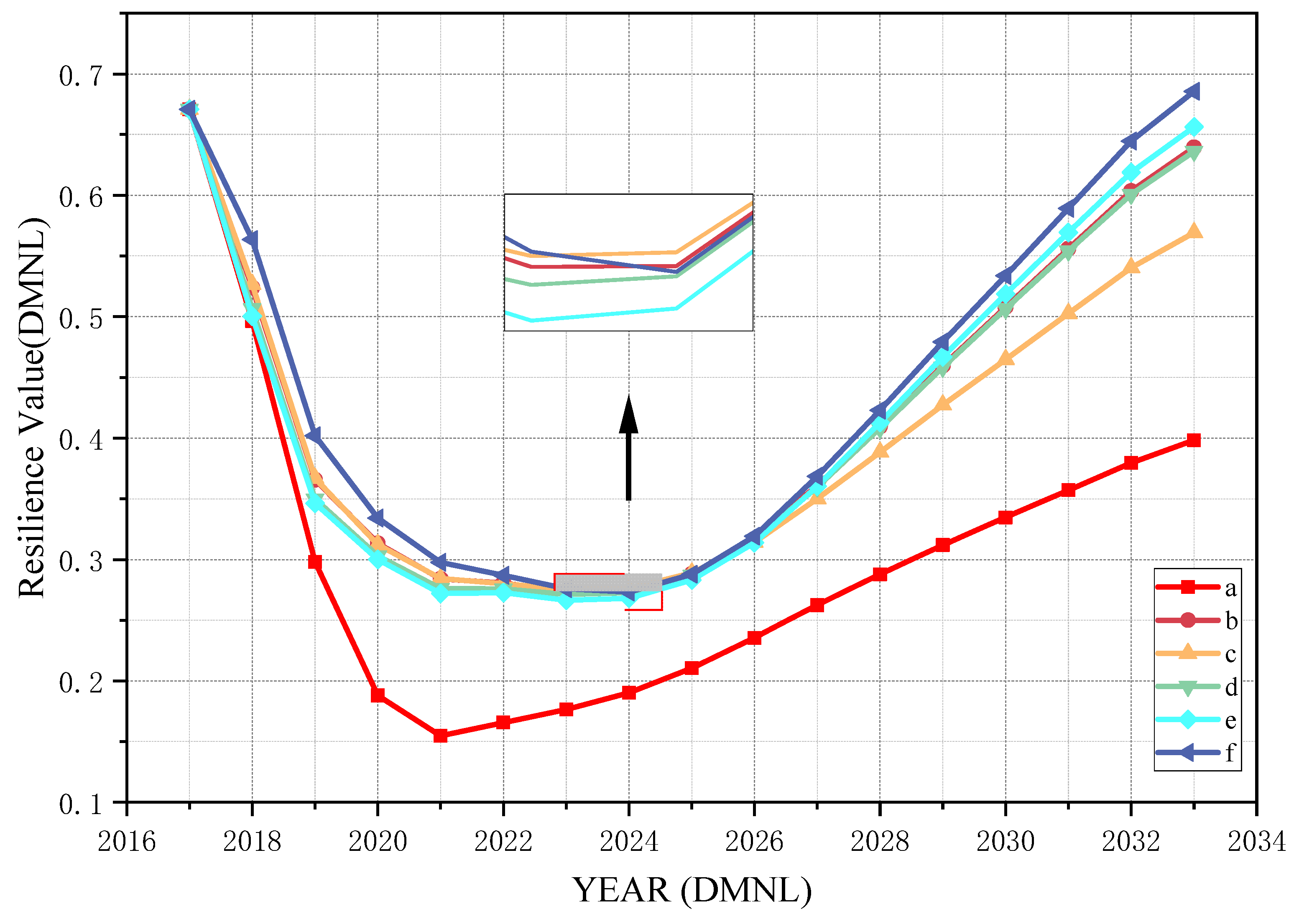

3.2.2. Resilience Change Analysis in All Scenarios

4. Discussion and Limitations

5. Conclusions

- (1)

- Dynamic Evolution of Supply Chain Resilience Characteristics

- (2)

- Resilience Differences Across Multi-Scenario Strategies

- (3)

- Strengthening Core Links for Differentiated Resilience Strategies

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hui, C.; Yue, Z.; Gang, T. Study on Quality Measurement and Influencing Factors of Russian Wood Forest Products Imported from China under the Background of High—Quality Development. Sustainability 2023, 15, 2164. [Google Scholar]

- Qin, Y. Research on Forest Ecological Issues in Russia. Master’s Thesis, Heilongjiang University, Harbin, China, 2024. [Google Scholar]

- Chen, J. China May Be the Only Viable Market for Russian Timber. China For. Ind. 2022, 59. (In Chinese) [Google Scholar]

- Cui, H.; Liu, M. Research on Resource Dynamics in the Ninth National Forest Inventory of China. J. West China For. Sci. 2020, 49, 90–95. (In Chinese) [Google Scholar] [CrossRef]

- Ke, S.; Qiao, D.; Zhang, X.; Feng, Q. Changes of China’s Forestry and Forest Products Industry over the Past 40 Years and Challenges Lying Ahead. For. Policy Econ. 2021, 123, 102352. [Google Scholar] [CrossRef]

- Miao, H. Overview of China’s Timber Imports in 2023 and the Past Decade. Green China 2024, 54, 55. Available online: https://kns.cnki.net/kcms2/article/abstract?v=__pNPjlwk1pO-GMnZQ615DAOZ1H49G_L6-VvBntMM_jUTdjD332Ka-ySAkJQz9W7QlMG0OclNAGMUyoDDhhcBhGrubde-OLnV7uk2OnHw5hW-lNPODkoAVNRlsQTPZCMvsp6ZYDBx9TpkSy2wDAnVdbGDnBGHJXDkG9dMvyMkVTXL3TfxSOBweEtyZqKhwnHrWvpkenPGkk=&uniplatform=NZKPT (accessed on 1 July 2025). (In Chinese).

- Gao, Y. Study on the Trade Scale and Influencing Factors of China’s Import of Russian Wood Forest Products. Master’s Thesis, Northeast Forestry University, Harbin, China, 2022. [Google Scholar]

- Narins, T.P. Dynamics of the Russia–China Forest Products Trade. Growth Chang. 2015, 46, 688–703. [Google Scholar] [CrossRef]

- Bernard, M.S. The Concept of Resilience Revisited. Disasters 2006, 30, 433–450. [Google Scholar]

- Taylor, I.W.; Hossain, N.U.I. A System Dynamics Model of Organizational Resilience. INCOSE Int. Symp. 2024, 34, 1184–1195. [Google Scholar] [CrossRef]

- Yu, Z.; Li, Z.; Ma, L. Strategies for the Resilience of Power—Coal Supply Chains in Low—Carbon Energy Transition: A System Dynamics Model and Scenario Analysis of China up to 2060. Sustainability 2023, 15, 7154. [Google Scholar] [CrossRef]

- Mcalister, M.M.; Murali, P.S.; Zhang, Q.; Wells, E.C.; Mohebbi, S. Improving and Quantifying Organizational Resilience for Sustainable Management of Critical Infrastructures: A Multi—Level System Dynamics Approach. Int. J. Disaster Risk Reduct. 2024, 115, 105079. [Google Scholar] [CrossRef]

- Guo, N.; Wu, F.; Sun, D.; Shi, C.; Gao, X. Mechanisms of Resilience in Cities at Different Development Phases: A System Dynamics Approach. Urban Clim. 2024, 53, 101793. [Google Scholar] [CrossRef]

- Li, W.; Jiang, R.; Wu, H.; Xie, J.; Zhao, Y.; Song, Y.; Li, F. A System Dynamics Model of Urban Rainstorm and Flood Resilience to Achieve the Sustainable Development Goals. Sustain. Cities Soc. 2023, 96, 104265. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, T. Urban Resilience under the COVID-19 Pandemic: A Quantitative Assessment Framework Based on System Dynamics. Cities 2023, 136, 104265. [Google Scholar] [CrossRef]

- Götz, P.; Auping, W.L.; Krapels, S.H. Contributing to Health System Resilience during Pandemics via Purchasing and Supply Strategies: An Exploratory System Dynamics Approach. BMC Health Serv. Res. 2024, 24, 130. [Google Scholar] [CrossRef] [PubMed]

- Caetano, H.O.; Desuó, L.; Fogliatto, M.S.; Maciel, C.D. Resilience assessment of critical infrastructures using dynamic Bayesian networks and evidence propagation. Reliab. Eng. Syst. Saf. 2024, 241, 109691. [Google Scholar] [CrossRef]

- Tang, J.; Heinimann, H.; Han, K.; Luo, H.; Zhong, B. Evaluating Resilience in Urban Transportation Systems for Sustainability: A Systems—Based Bayesian Network Model. Transp. Res. C Emerg. Technol. 2020, 121, 102840. [Google Scholar] [CrossRef]

- Jomthanachai, S.; Wong, W.; Lim, C. A Coherent Data Envelopment Analysis to Evaluate the Efficiency of Sustainable Supply Chains. IEEE Trans. Eng. Manag. 2023, 70, 294–311. [Google Scholar] [CrossRef]

- Wang, S.L.; Chen, C.; Zhang, J.H.; Luan, S.Y. Resilience Analysis of Interconnected Public Transportation Systems Based on Complex Networks. Complex Syst. Complex. Sci. 2022, 19, 47–54. (In Chinese) [Google Scholar] [CrossRef]

- Miao, C.; Na, M.; Chen, H.; Ding, M. Urban Resilience Evaluation Based on Entropy—TOPSIS Model: A Case Study of County—Level Cities in Ningxia, Northwest China. Int. J. Environ. Sci. Technol. 2024, 22, 4187–4202. [Google Scholar] [CrossRef]

- Wang, Y. Comprehensive Evaluation of Community Public—Health—Safety Resilience Based on Entropy—TOPSIS Method. MEDS Public Health Prev. Med. 2022, 2, 1–15. [Google Scholar]

- Wang, Y.; Peng, D.; Bo, T.; Zhao, X.; Bo, J. A Comprehensive Evaluation Method for Assessing the Seismic Resilience of Building Sites Based on the TOPSIS Model and the Entropy Method. Buildings 2024, 14, 3667. [Google Scholar] [CrossRef]

- Zhang, Y.; Tian, R.; Peng, L.; Yu, X.; Wang, Y. Fire Safety Resilience Assessment of Residential Self—Built Houses According to the TOPSIS Method. Sustainability 2023, 15, 12417. [Google Scholar] [CrossRef]

- He, Y.Q.; Ou, Y.; Meng, J.Q. Study on the Measurement of China’s Regional Supply Chain Resilience and Its Spatial—Temporal Differentiation Characteristics. Soft Sci. 2025, 1–17. (In Chinese) [Google Scholar]

- Lin, J.C.; Chan, W.H.; Wu, M.S. A bibliometric analysis of timber supply chain research. J. For. Res. 2025, 30, 11–21. [Google Scholar] [CrossRef]

- Veronika, A.; Peter, R. Wood Supply Chain Risks and Risk Mitigation Strategies: A Systematic Review Focusing on the Northern Hemisphere. Biomass Bioenergy 2021, 148, 106059. [Google Scholar]

- Mao, X.Y.; Chen, Y.; Qu, X.Y.; Liang, Y.Y. Research Progress on International Timber Source Tracing Technology. World For. Res. 2024, 37, 31–36. (In Chinese) [Google Scholar] [CrossRef]

- Han, Y.K.; Ma, C.L.; Li, C.P.; Shao, X.R. Study on the Optimization of Sustainable Supply Chain for Timber Processing Enterprises in Heilongjiang Province. For. Eng. 2021, 37, 137–144. (In Chinese) [Google Scholar] [CrossRef]

- Ming, Z.X. In—Depth Exploration of the Development Path of Guangxi Furniture Supply Chain. China For. Ind. 2022, 80–83. (In Chinese) [Google Scholar]

- Lin, Q.P.; Cai, Y.; Zhang, N. A Comparative Study of Supply Chain Resilience Research at Home and Abroad Based on CiteSpace. Logist. Res. 2025, 36–43. (In Chinese) [Google Scholar]

- Zhu, L.; Chen, J.Y.; Yuan, J.F. Study on Key Influencing Factors of Prefabricated Building Supply Chain Resilience Based on ISM. J. Civ. Eng. Manag. 2020, 37, 108–114. (In Chinese) [Google Scholar] [CrossRef]

- Singh, R.K.; Modgil, S.; Acharya, P. Assessment of Supply Chain Flexibility Using System Dynamics Modeling. Glob. J. Flex. Syst. Manag. 2019, 20, 39–63. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Z. Simulation analysis of supply chain resilience of prefabricated building projects based on system dynamics. Buildings 2023, 13, 2629. [Google Scholar] [CrossRef]

- Spiegler, V.L.M.; Naim, M.M.; Wikner, J. A control engineering approach to the assessment of supply chain resilience. Int. J. Prod. Res. 2012, 50, 6162–6187. [Google Scholar] [CrossRef]

- Rebs, T.; Brandenburg, M.; Seuring, S. System Dynamics Modeling for Sustainable Supply Chain Management: A Literature Review and Systems Thinking Approach. J. Clean. Prod. 2019, 208, 1265–1280. [Google Scholar] [CrossRef]

- Kuse, H.; Endo, A.; Iwao, E. Logistics Facility, Road Network and District Planning: Establishing Comprehensive Planning for City Logistics. Procedia Soc. Behav. Sci. 2010, 2, 6251–6263. [Google Scholar] [CrossRef]

- Zhang, M.; Sun, M.; Bi, D.; Liu, T. Green Logistics Development Decision—Making: Factor Identification and Hierarchical Framework Construction. IEEE Access 2020, 8, 127897–127912. [Google Scholar] [CrossRef]

- Verschuur, J.; Koks, E.E.; Hall, J.W. Port disruptions due to natural disasters: Insights into port and logistics resilience. Transp. Res. D Transp. Environ. 2020, 85, 102393. [Google Scholar] [CrossRef]

- Styrman, M.; Wibe, S. Wood Resources and Availability as Determinants of the Supply of Timber. Can. J. For. Res. 1986, 16, 256–259. [Google Scholar] [CrossRef]

- Garrido-Vega, P.; Jimenez, C.H.O.; de Los Ríos, J.L.D.P.; Morita, M. Implementation of Technology and Production Strategy Practices: Relationship Levels in Different Industries. Int. J. Prod. Econ. 2015, 161, 201–216. [Google Scholar] [CrossRef]

- Simeone, J. Timber Export Taxes and Trade Between Russia and China: Development of the Forestry Sector in the Russian Far East. For. Chron. 2012, 88, 585–592. [Google Scholar] [CrossRef]

- Wei, H.; Dong, M. Import—Export Freight Organization and Optimization in the Dry—Port—Based Cross—Border Logistics Network under the Belt and Road Initiative. Comput. Ind. Eng. 2019, 130, 472–484. [Google Scholar] [CrossRef]

- Oliinyk, O.; Grytsyshen, D.; Romanchenko, Y.; Tokarchuk, O.; Sedliakivska, K. Financial Consequences of Geopolitical Turmoil and Trade Restrictions. Afr. J. Appl. Res. 2025, 11, 439–455. [Google Scholar] [CrossRef]

- Ma, C.; Zhang, L.; Gao, X.; Liu, C. Modelling and Evaluating Wood Supply Chain Resilience Factors Based on System Dynamics. Sci. Rep. 2025, 15, 16207. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Chen, S.; Zheng, Y.; Chai, S.; Nie, R. Resilience Assessment of China’s Natural Gas System Under Supply Shortages: A System Dynamics Approach. Energy 2022, 247, 123380. [Google Scholar] [CrossRef]

- Li, Z.; Luo, Z.; Wang, Y.; Fan, G.; Zhang, J. Suitability Evaluation System for the Shallow Geothermal Energy Implementation in Region by Entropy Weight Method and TOPSIS Method. Renew. Energy 2022, 184, 564–576. [Google Scholar] [CrossRef]

- Cabello-Solorzano, K.; Ortigosa de Araujo, I.; Peña, M.; Correia, L.; Tallón-Ballesteros, A.J. The Impact of Data Normalization on the Accuracy of Machine Learning Algorithms: A Comparative Analysis. In Proceedings of the 18th International Conference on Soft Computing Models in Industrial and Environmental Applications, Salamanca, Spain, 20–22 September 2023; pp. 344–353. [Google Scholar]

- Shirali, G.A.; Rashnoudi, P.; Salehi, V.; Ghanbari, S. A hierarchical assessment of resilience engineering indicators in petrochemical industries using AHP and TOPSIS. Hum. Factors Ergon. Manuf. Serv. Ind. 2023, 33, 3–26. [Google Scholar] [CrossRef]

- Yan, Y. The Transportation Cooperation Between Northeast China and the Russian Far East Under the Russia—Ukraine War. J. World Econ. 2024, 3, 64–73. [Google Scholar] [CrossRef]

- Ellinger, A.E.; Ketchen, D.J.; Hult, G.T.M.; Elmadağ, A.B.; Richey, R.G. Market Orientation, Employee Development Practices, and Performance in Logistics Service Provider Firms. Ind. Mark. Manag. 2007, 37, 353–366. [Google Scholar] [CrossRef]

- Wang, X.; Lu, Y. Optimization of Grain Import Market Layout in the Context of Food Security: A Study of Soybean in China. Front. Sustain. Food Syst. 2025, 9, 1549463. [Google Scholar] [CrossRef]

- Rodrik, D. What Do Trade Agreements Really Do? J. Econ. Perspect. 2018, 32, 73–90. [Google Scholar] [CrossRef]

| Capability Dimension | Definition | Representative Indicators | Data Description |

|---|---|---|---|

| Russian Logistics and Transportation Capability | Stability and efficiency of timber resource supply and cross-border transportation. | Russian logistics freight volume (million tons) | Freight volume reflects the carrying capacity of the logistics network and resource transportation efficiency; a stronger carrying capacity indicates greater logistics resilience. |

| Russian Primary Wood Processing Capability | Production capacity and technical level of Russian primary wood processing. | Russian wood processing output (thousand cubic meters) | Reflects the efficiency of raw material conversion and technical stability; stable output with high added value indicates strong risk resistance in the processing link, as it ensures a consistent supply of intermediate products despite external shocks. |

| Sino-Russian Timber Import-Export Capability | Policy adaptability and cross-border coordination efficiency in Sino-Russian timber trade. | Sino-Russian timber import-export volume (ten million yuan) | Import–export volume is significantly influenced by factors such as production volume, tariff policies, customs clearance efficiency, and bilateral trade agreements. Stable growth or low volatility in this indicator reflects strong resilience in the import–export link, indicating the system’s ability to maintain trade flows amid policy or market fluctuations. |

| Heilongjiang (China) Furniture Sales Capability | Terminal market demand response and value realization capability. | Heilongjiang furniture sales revenue (ten million yuan) | Sales revenue reflects how furniture output responds to market fluctuations (e.g., real estate cycles, consumer upgrading) and supply chain changes. It captures the ability to balance production with consumer needs and maintain value realization in the supply chain’s terminal link. |

| Year | Statistical Classification | RLTC | RTS | RPPC | SRTIEC | HWFIOC | HWFISC |

|---|---|---|---|---|---|---|---|

| 2017 | Actual Value | 8072.60 | 828.00 | 252 | 949.256 | 595.52 | 455.776 |

| Predicted Value | 8072.60 | 828.00 | 252 | 949.256 | 595.5203 | 455.7761 | |

| Error Rate | 0.00% | 0.00% | 0.00% | 0.00% | 0.00% | 0.00% | |

| 2018 | Actual Value | 8198.85 | 825.39 | 280.407 | 870.435 | 388.728 | 277.866 |

| Predicted Value | 8265.30 | 828.00 | 285 | 851.163 | 409.6494 | 308.3466 | |

| Error Rate | −0.80% | −0.32% | −1.61% | 2.26% | −5.11% | −9.89% | |

| 2019 | Actual Value | 8255.09 | 825.05 | 288.391 | 671.999 | 220.737 | 171.288 |

| Predicted Value | 8425.80 | 826.00 | 300 | 624.662 | 223.7785 | 160.9171 | |

| Error Rate | −2.03% | −0.12% | −3.87% | 7.58% | −1.36% | 6.44% | |

| 2020 | Actual Value | 8306.71 | 825.51 | 291.32 | 556.054 | 209.929 | 100.904 |

| Predicted Value | 7959.60 | 825.00 | 293 | 521.936 | 226.2149 | 92.867 | |

| Error Rate | 4.36% | 0.06% | −0.57% | 6.54% | −7.20% | 8.65% | |

| 2021 | Actual Value | 8276.89 | 826.20 | 294.247 | 488.968 | 233.993 | 80.528 |

| Predicted Value | 8262.50 | 824.00 | 323 | 534.697 | 248.5548 | 77.166 | |

| Error Rate | 0.17% | 0.27% | −8.90% | −8.55% | −5.86% | 4.36% | |

| 2022 | Actual Value | 8319.08 | 827.04 | 318.82 | 190.581 | 219.695 | 76.108 |

| Predicted Value | 8779.40 | 825.00 | 298 | 181.406 | 236.4683 | 83.018 | |

| Error Rate | −5.24% | 0.25% | 6.99% | 5.06% | −7.09% | −8.32% |

| Strategy | Synergistic Development (%) | Logistics—Focused Development (%) | Production—Focused Development (%) | Trade—Focused Development (%) | Sales—Focused Development (%) |

|---|---|---|---|---|---|

| Russian Logistics Capacity Growth | 50 | 80 | 40 | 40 | 40 |

| Russian Timber Primary Processing Capacity Enhancement | 50 | 40 | 80 | 40 | 40 |

| Sino—Russian Timber Import—Expo Capacity Growth | 50 | 40 | 40 | 80 | 40 |

| Heilongjiang Furniture Sales Capacity Growth | 50 | 40 | 40 | 40 | 80 |

| Capability Dimension | Information Entropy (e) | Information Utility (d) | Weight (%) |

|---|---|---|---|

| Russian logistics and transportation capability | 0.8 | 0.2 | 23.2 |

| Russian Far East primary processing capability | 0.88 | 0.12 | 14.18 |

| Sino-Russian timber import-export capability | 0.87 | 0.13 | 15.61 |

| Heilongjiang furniture sales capability | 0.6 | 0.4 | 47.01 |

| Year | Logistics Capacity (Million Tons) | Primary Processing Capacity (Thousand Cubic Meters) | Timber Import-Export Capacity (CNY 10 Million) | Sales Capacity (CNY 10 Million) |

|---|---|---|---|---|

| 2017 | 8072.60 | 252 | 949.256 | 455.776 |

| 2018 | 8198.85 | 280.407 | 870.435 | 277.866 |

| 2019 | 8255.09 | 288.391 | 671.999 | 171.288 |

| 2020 | 8306.71 | 291.32 | 556.054 | 100.904 |

| 2021 | 8276.89 | 294.247 | 488.968 | 80.528 |

| 2022 | 8319.08 | 318.82 | 190.581 | 76.108 |

| 2023 | 8365.60 | 317.844 | 196.456 | 75.573 |

| 2024 | 8413.66 | 321.268 | 205.891 | 68.835 |

| 2025 | 8462.28 | 325.993 | 320.174 | 64.852 |

| 2026 | 8511.05 | 331.099 | 426.315 | 68.404 |

| 2027 | 8559.93 | 336.331 | 508.634 | 77.009 |

| 2028 | 8608.85 | 341.608 | 573.355 | 84.348 |

| 2029 | 8657.78 | 346.909 | 625.059 | 91.585 |

| 2030 | 8706.66 | 352.223 | 667.126 | 98.639 |

| 2031 | 8755.58 | 357.558 | 702.07 | 106.51 |

| 2032 | 8804.51 | 362.911 | 731.75 | 115.111 |

| 2033 | 8853.45 | 368.282 | 757.541 | 120.795 |

| Scenario Type | Resistance (Minimum Value, Decline Rate) | Recovery Capacity (Annual Rate) |

|---|---|---|

| Baseline Scenario | 0.1549 (76.9%) | 0.0203 |

| Synergistic Development | 0.2739 (59.2%) | 0.0332 |

| Logistics-Focused Development | 0.2754 (58.9%) | 0.0294 |

| Production-Focused Development | 0.2714 (59.5%) | 0.0365 |

| Import/Export-Focused | 0.2664 (60.3%) | 0.0389 |

| Sales-Focused Development | 0.2732 (59.3%) | 0.0458 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, C.; Liu, C.; Feng, J.; Zhang, L. A System Dynamics Approach to Resilience Analysis in the Sino-Russian Timber Supply Chain. Forests 2025, 16, 1106. https://doi.org/10.3390/f16071106

Ma C, Liu C, Feng J, Zhang L. A System Dynamics Approach to Resilience Analysis in the Sino-Russian Timber Supply Chain. Forests. 2025; 16(7):1106. https://doi.org/10.3390/f16071106

Chicago/Turabian StyleMa, Chenglin, Changjiang Liu, Jiajia Feng, and Lin Zhang. 2025. "A System Dynamics Approach to Resilience Analysis in the Sino-Russian Timber Supply Chain" Forests 16, no. 7: 1106. https://doi.org/10.3390/f16071106

APA StyleMa, C., Liu, C., Feng, J., & Zhang, L. (2025). A System Dynamics Approach to Resilience Analysis in the Sino-Russian Timber Supply Chain. Forests, 16(7), 1106. https://doi.org/10.3390/f16071106