A Preliminary Model for Forestry Machinery Chain Selection and Calculation of Operating Costs for Wood Recovery †

Abstract

1. Introduction

2. Materials and Methods

- M1—machinery chain selection;

- M2—machinery chain organization;

- M3—operating cost calculation.

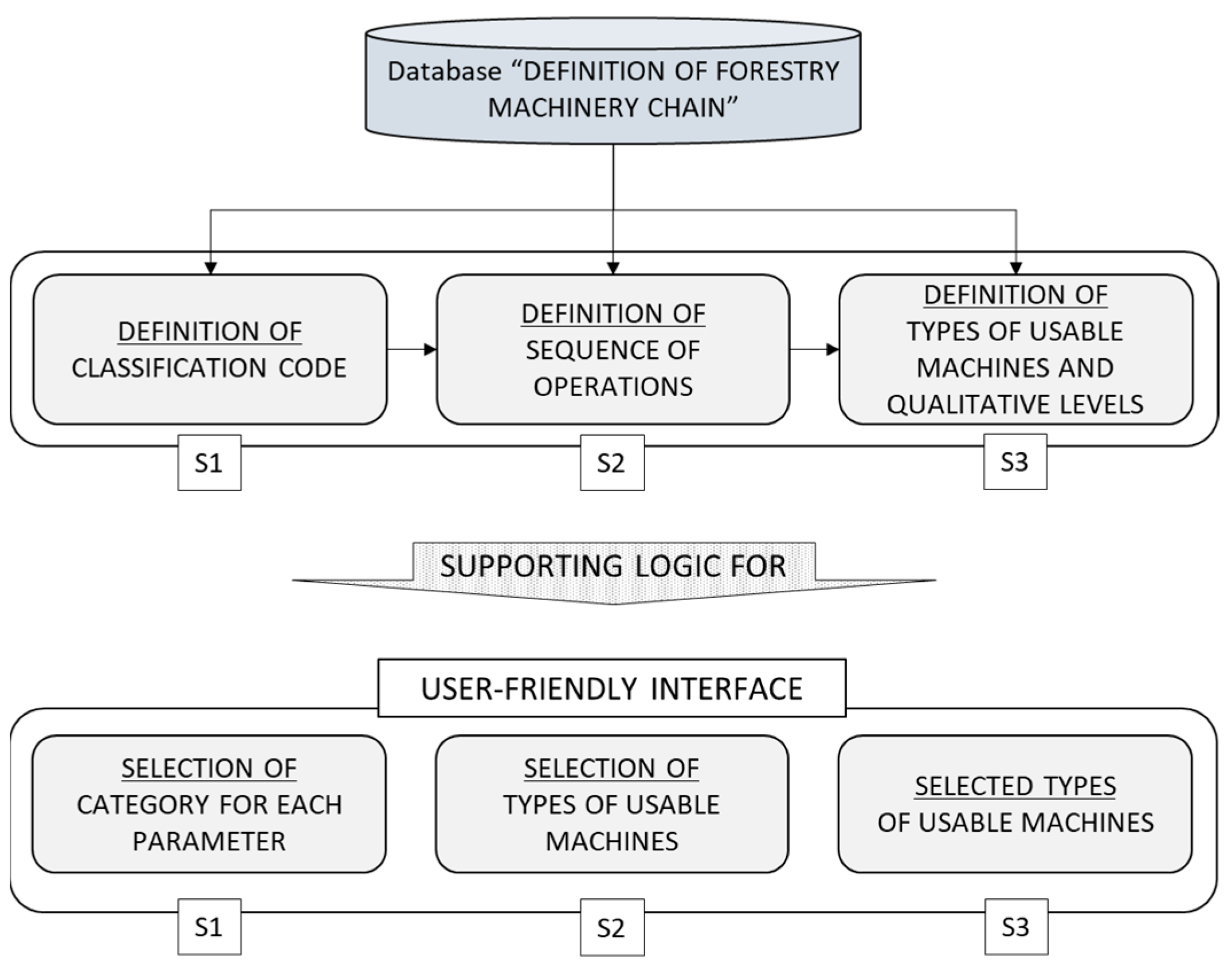

2.1. M1—Machinery Chain Selection

- Step 1—definition of classification code;

- Step 2—definition of sequence of operations;

- Step 3—definition of types of usable machines and qualitative levels.

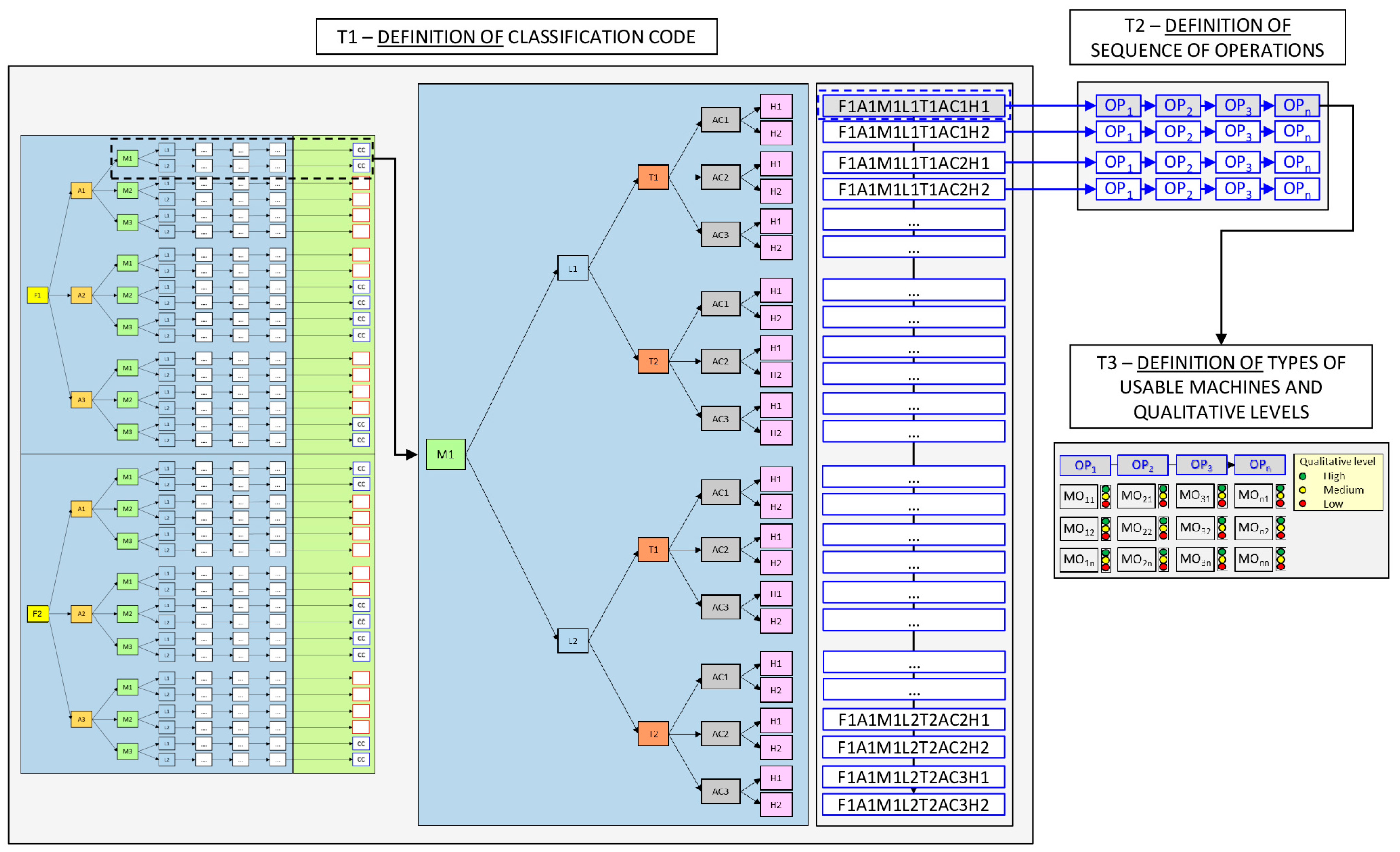

2.1.1. Database “Definition of Forestry Machinery Chain”

Step 1—Definition of the Classification Code

- Characteristics of the forest;

- Characteristics of the production system;

- Site-specific operating conditions.

- Wood assortment;

- Harvesting method;

- Degree of mechanization;

- Forest road transitability class;

- Forest accessibility class;

- Harvested mass (t∙ha−1 DM).

Step 2—Definition of Sequence of Operations

Step 3—Definition of Types of Usable Machines and Qualitative Levels

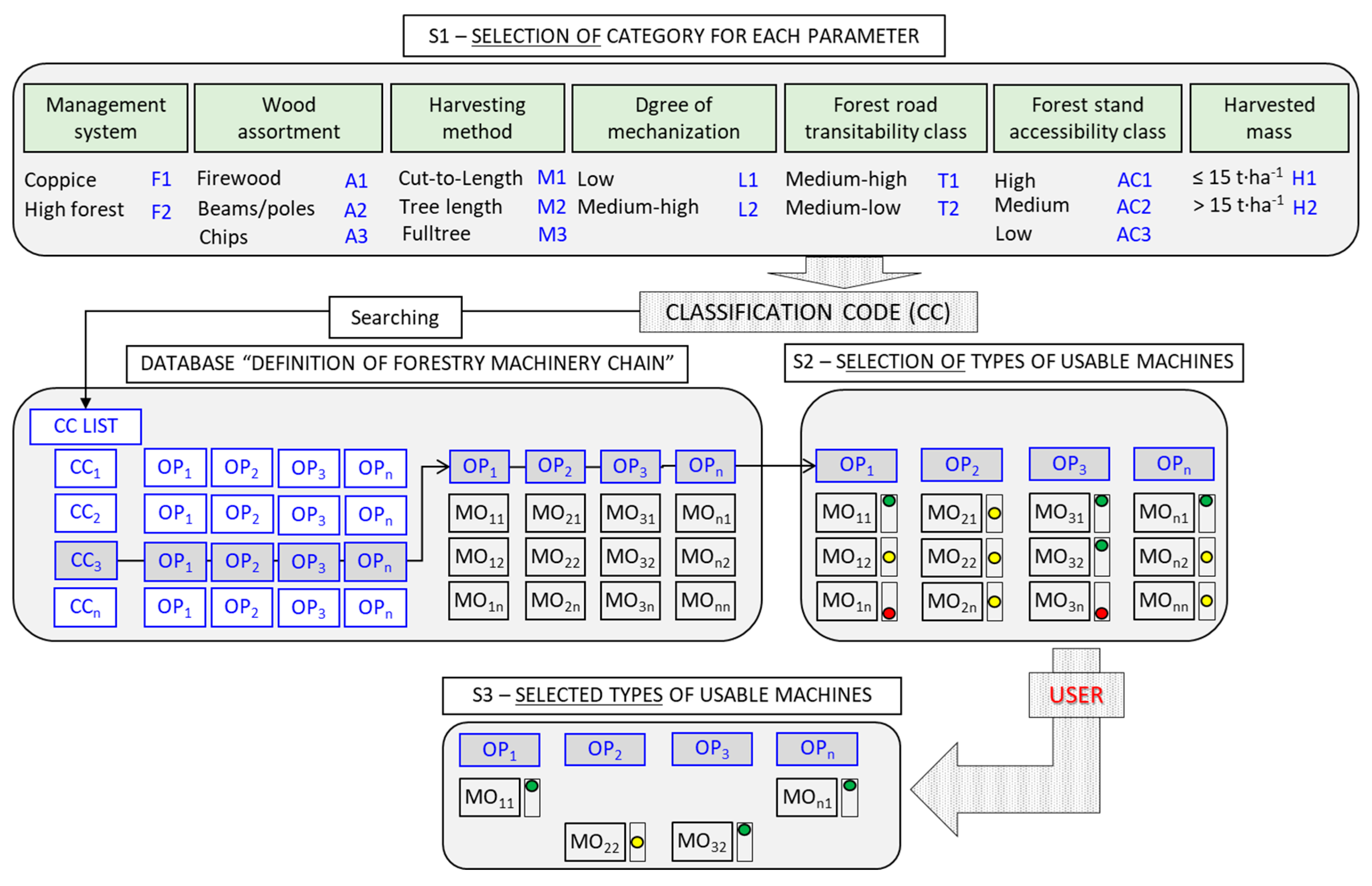

2.1.2. User-Friendly Interface

- Step 1—selection of category for each parameter;

- Step 2—selection of types of usable machines and qualitative levels;

- Step 3—selected types of usable machines.

Step 1—Selection of Category for Each Parameter

Step 2—Selection of Types of Usable Machines and Qualitative Levels

Step 3—Selected Types of Usable Machines

2.2. M2—Machinery Chain Organization

- Cut area (ha);

- Wood species;

- Harvested wood volume yield (m3·ha−1).

- Useful time (days);

- Number of working hours per employee per shift (h·employee−1·shift−1);

- Number of shifts per day (shifts·day−1);

- Number of employees (1 machine/implement).

- Distance (m);

- Operator speed (m·s−1);

- Rope winding speed (m·s−1);

- Extraction distance (m);

- Machine speed (km·h−1), forward (loaded) and backward (unloaded);

- Extracted wood volume per cycle (m3·cycle−1);

- Required working time (1 machine/implement; h).

- Distance (km);

- Machine speed (km·h−1), forward (loaded) and backward (unloaded);

- Loaded wood volume per cycle (m3·cycle−1);

- Volumetric filling coefficient (ratio between the volume occupied by the wood material and the useful loading volume of the implement used for long-distance transport; dimensionless);

- Required working time (1 machine/implement; h).

- Useful time per employee (h·employee−1);

- Required working times (1 machine/implement; h);

- No. of required machines and/or implements (−);

- Productivity (total, related to “n” machines and/or implements; t·h−1 DM);

- No. of employees (total, related to “n” machines and/or implements; −);

- Required working time (total, related to “n” machines and/or implements working simultaneously; h).

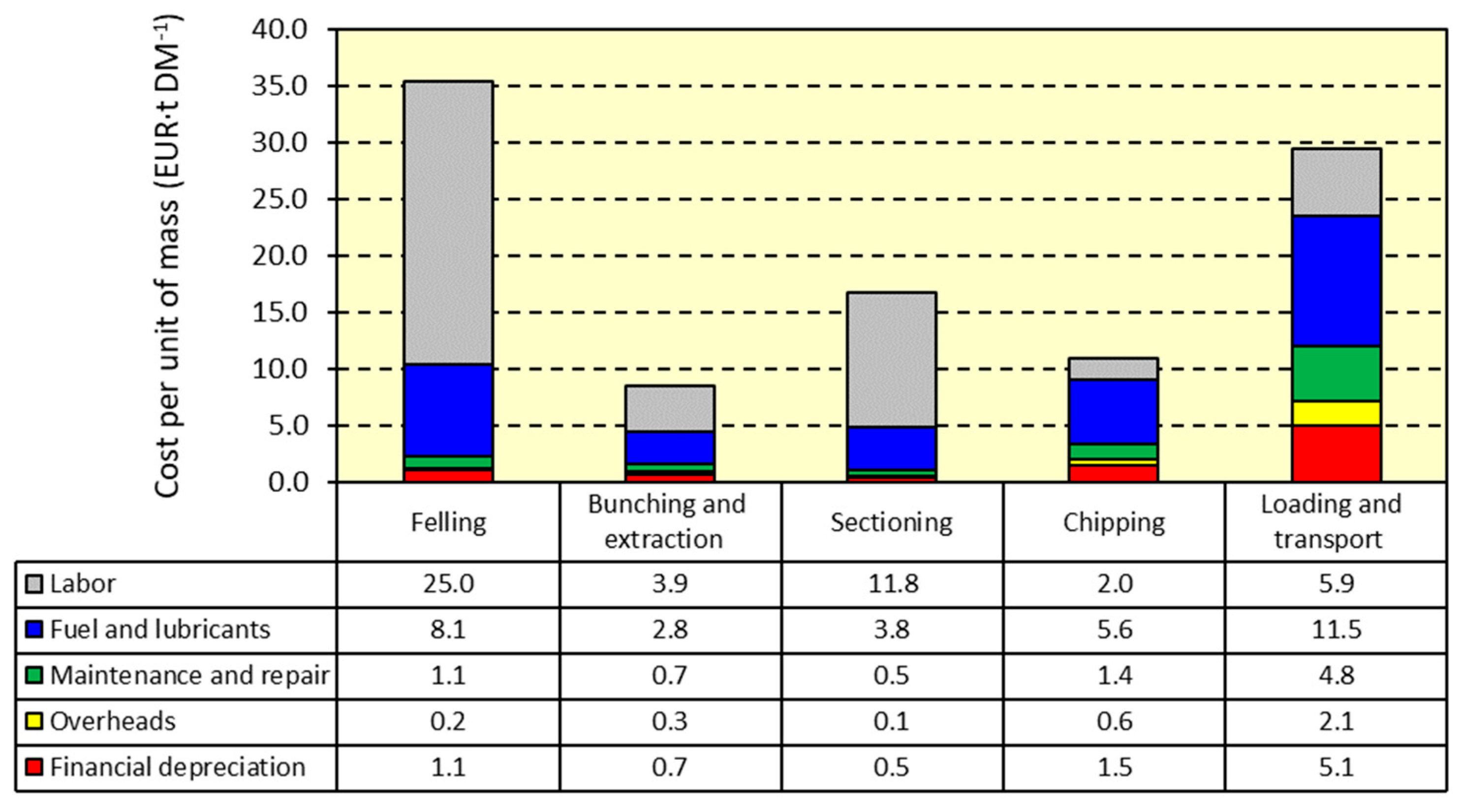

2.3. M3—Operating Costs

3. Case Study and Results

3.1. Machinery Chain Selection

3.2. Machinery-Chain Organization

3.3. Operating Costs

4. Discussion

4.1. Selecting Algorithm for Machinery-Chain Selection: Strengths and Weaknesses and Future Development

4.2. Case Study: Machinery-Chain Organization, Working Times, and Productivity

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nutto, L.; Malinovski, J.R.; Pereira Castro, G.; Malinovski, R.A. Harvesting Process. In Tropical Forestry Handbook, 2nd ed.; Pancel, L., Köhl, M., Eds.; Springer-Verlag: Berlin/Heidelberg, Germany, 2016; pp. 2363–2394. ISBN 978-3-642-54600-6. [Google Scholar]

- Pereira Castro, G.; Nutto, L.; Malinovski, J.R.; Malinovski, R.A. Harvesting Systems. In Tropical Forestry Handbook, 2nd ed.; Pancel, L., Köhl, M., Eds.; Springer-Verlag: Berlin/Heidelberg, Germany, 2016; pp. 2445–2485. ISBN 978-3-642-54600-6. [Google Scholar]

- Pucher, C.; Eberhard, B.; Bronisz, K.; Zasada, M.; Prinz, R.; Routa, J. Knowledge and Technologies for Effective Wood Procurement. Deliverable 2.3—Report on Ensuring Continued Forest Resource Production in the Long Term. Available online: https://www.tech4effect.eu/wp-content/uploads/2020/03/d23-report-on-ensuring-continued-forest-resource-production-in-the-long-run-final.pdf (accessed on 29 September 2023).

- Kühmaier, M.; Stampfer, K. Development of a multi-attribute spatial decision support system in selecting timber harvesting systems. Croat. J. For. Eng. 2010, 31, 75–88. [Google Scholar]

- Stampfer, K.; Steinmueller, T.H. Harvester und Seilgeraet in Steilgelaende. Eigenverlag des Instituts fuer Forsttechnik; Univesitaet fuer Bodenkultur: Wien, Austria, 2004; p. 25. [Google Scholar]

- Zambelli, P.; Lora, C.; Spinelli, R.; Tattoni, C.; Vitti, A.; Zatelli, P.; Ciolli, M. A GIS decision support system for regional forest management to assess biomass availability for renewable energy production. Environ. Model. Softw. 2012, 38, 203–213. [Google Scholar] [CrossRef]

- Langin, D.; Ackerman, P.A.; Krieg, B.; Immelmann, A.; Potgieter, C.; van Rooyen, J.; Upfold, S. South African Ground Based Harvesting Handbook; Forest Engineering Southern Africa and Institute for Commercial Forestry Research: Scottsville, South Africa, 2010; pp. 1–182. ISBN 978-0-620-49065-8. [Google Scholar]

- Mokhirev, A. The method of selection of forest machines under the climatic conditions. For. Eng. J. 2017, 6, 208–215. [Google Scholar] [CrossRef]

- FAO. Forest Harvesting Case-Study 16. Forest Harvesting Practice in Timber Concessions in Suriname; Forest Products Division; FAO: Rome, Italy, 2001; Available online: http://www.fao.org/3/Y2698E/Y2698E00.htm (accessed on 15 March 2021).

- Latterini, F.; Stefanoni, W.; Venanzi, R.; Tocci, D.; Picchio, R. GIS-AHPApproach in Forest Logging Planning to Apply Sustainable Forest Operations. Forests 2022, 13, 484. [Google Scholar] [CrossRef]

- Marčeta, D.; Petković, V.; Ljubojević, D.; Potočnik, I. Harvesting System Suitability as Decision Support in Selection Cutting Forest Management in Northwest Bosnia and Herzegovina. Croat. J. For. Eng. 2020, 41, 251_265. [Google Scholar] [CrossRef]

- Lüthy, D. Entwicklung Eines Spatial Decision Support-Systems (Sdss) Für Die Holzernteplanung in Steilen Geländeverhältnissen (Development of a Spatial Sdss for Timber Harvesting in Steep Terrain); Vdf, Hochschul-Verl. an der ETH: Zürich, Switzerland, 1998; p. 260. ISBN 3-7281-2654-3. [Google Scholar]

- Yoshioka, T.; Sakai, H. Amount and availability of forest biomass as an energy resource in a mountainous region in Japan: A GIS-based analysis. Croat. J. For. Eng. 2005, 26, 59–68. [Google Scholar]

- Shadbahr, J.; Bensebaa, F.; Ebadian, M. Impact of forest harvest intensity and transportation distance on biomass delivered costs within sustainable forest management-A case study in southeastern Canada. J. Environ. Manag. 2021, 284, 112073. [Google Scholar] [CrossRef]

- Picchio, R.; Latterini, F.; Mederski, P.S.; Tocci, D.; Venanzi, R.; Stefanoni, W.; Pari, L. Applications of GIS-Based Software to Improve the Sustainability of a Forwarding Operation in Central Italy. Sustainability 2020, 12, 5716. [Google Scholar] [CrossRef]

- Picchio, R.; Pignatti, G.; Marchi, E.; Latterini, F.; Benanchi, M.; Foderi, C.; Venanzi, R.; Verani, S. The Application of Two Approaches Using GIS Technology Implementation in Forest Road Network Planning in an Italian Mountain Setting. Forests 2018, 9, 277. [Google Scholar] [CrossRef]

- Synek, M.; Klimánek, M. Proposal of using GIS for multi-criteria evaluation of environmentally friendly use of skidding technologies in forestry. J. For. Sci. 2014, 60, 51–60. [Google Scholar] [CrossRef]

- Grigolato, S.; Mologni, O.; Cavalli, R. GIS applications in forest operations and road network planning: An overview over the last two decades. Croat. J. For. Eng. 2017, 38, 175–186. [Google Scholar]

- Ackerman, P.; Belbo, H.; Eliasson, L.; de Jong, A.; Lazdins, A.; Lyons, J. The COST model for calculation of forest operations costs. Int. J. For. Eng. 2014, 25, 75–81. [Google Scholar] [CrossRef]

- Holm, S.; Frutig, F.; Lemm, R.; Thees, O.; Schweier, J. HeProMo: A decision support tool to estimate wood harvesting productivities. PLoS ONE 2020, 15, e0244289. [Google Scholar] [CrossRef]

- Lan, Z. A Cost Model for Forest Machine Operation in Wood Cutting and Extraction. Report of the Project “Development of a Protocol for Ecoefficient Wood Harvesting on Sensitive Sites—ECOWOOD”; University of Helsinki: Helsinki, Finland, 2001; p. 15. Available online: https://helda.helsinki.fi/bitstream/handle/1975/8036/LAN2001.pdf?sequence=3&isAllowed=y (accessed on 13 December 2023).

- Triplat, M.; Krajnc, N. Assessment of Costs in Harvesting Systems Using WoodChainManager Web-based Tool. Croat. J. For. Eng. 2020, 41, 49–57. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N.; Hartsough, B. Integrated harvesting of roundwood and biomass from the group-cuts in Alpine forests. Ital. J. For. Mt. Environ. 2006, 61, 303–316. [Google Scholar] [CrossRef]

- Lombardy Region. Directive Related to the Local Road Service to the Agro-Silvo Pastoral Activity. 2008, p. 40. Available online: https://www.regione.lombardia.it/wps/wcm/connect/661566fe-8da7-437c-82f6-518be7143599/Direttiva+strade+asp_2003.pdf?MOD=AJPERES&CACHEID=ROOTWORKSPACE-661566fe-8da7-437c-82f6-518be7143599-lLSBYAD (accessed on 30 November 2023).

- Nonini, L.; Fiala, M. Harvesting of wood for energy generation: A quantitative stand-level analysis in an Italian mountainous district. Scand. J. For. Res. 2021, 36, 474–490. [Google Scholar] [CrossRef]

- Nonini, L.; Schillaci, C.; Fiala, M. Assessing logging residues availability for energy production by using forest management plans data and geographic information system (GIS). Eur. J. For. Res. 2022, 141, 959–977. [Google Scholar] [CrossRef]

- Hippoliti, G.; Piegai, F. Techniques and Harvesting Systems: The Collection of Wood; Compagnia delle Foreste: Arezzo, Italy, 2000; p. 157. [Google Scholar]

- Marchi, E.; Piegai, F.; Neri, F. The Design, the Construction and the Maintenance of Forest Works and Related Works; Regione Toscana, Giunta Regionale Direzione Generale Competitività del sistema regionale e sviluppo delle competenze Area di coordinamento Politiche per lo Sviluppo Rurale Settore Forestazione, promozione dell’innovazione e interventi comunitari per l’agroambiente: Firenze, Italy, 2013. [Google Scholar]

- Reboul, C. Temps des travaux et jours disponibles en agriculture. Econ. Rural. 1964, 61, 50–80. [Google Scholar] [CrossRef]

- Federici, S.; Vitullo, M.; Tulipano, S.; De Lauretis, R.; Seufert, G. An approach to estimate carbon stocks change in forest carbon pools under the UNFCCC: The Italian case. iFor. Biogeosci. For. 2008, 1, 86–95. [Google Scholar] [CrossRef]

- Fiala, M. Energy from Biomass. Production and Utilization. With Practical Examples; Maggioli, Ed.; Impresa Agricola: Bologna, Italy, 2012; p. 437. ISBN 978-88-387-7090-5. [Google Scholar]

- Carbone, F. Machinery costs, operational costs and forestry management costs. Ital. J. For. Mt. Environ. 2008, 63, 333–350. [Google Scholar]

- Lazzari, M.; Mazzetto, F. Handbook of Agricultural Mechanics and Mechanization; REDA Edizioni: Torino, Italy, 2005; p. 222. [Google Scholar]

- Brinker, R.W.; Kinard, J.; Rummer, B.; Landford, B. Machine Rates for Selected Harvesting Machines. Circular 296; Alabama’s Agricultural Experiment Station, Auburn University: Montgomery, AL, USA, 2002; p. 32. Available online: https://www.srs.fs.usda.gov/pubs/ja/ja_rummer020.pdf (accessed on 22 February 2024).

- Blanc, S. Analysis and evaluations of labor and machines in the agro-forestry sector. In Quaderni del Dipartimento di Economia e Ingegneria Agraria, Forestale e Ambientale; University of Torino: Turin, Italy, 2010; p. 98. ISBN 978-88-88854-41-0. [Google Scholar]

- Dietz, P.; Knigge, W.; Löffler, H. Walderschließung; Verlag Paul Parey (VPP): Hamburg, Germany, 1984. [Google Scholar]

- Diaz-Balteiro, L.; Romero, C. Making forestry decisions with multiple criteria: A review and an assessment. For. Ecol. Manag. 2008, 255, 3222–3241. [Google Scholar] [CrossRef]

- Cambi, M.; Grigolato, S.; Neri, F.; Picchio, R.; Marchi, E. Effects of forwarder operation on soil physical characteristics: A case study in the Italian alps. Croat. J. For. Eng. 2016, 37, 233–239. [Google Scholar]

- Heinimann, H.R. A computer model to differentiate skidder and cable-yarder based road network concepts on steep slopes. J. For. Res. 1997, 3, 1–9. [Google Scholar] [CrossRef]

- Keenan, R.J.; Kimmins, P.J. The ecological effects of clear-cutting. Environ. Rev. 1993, 1, 121–144. [Google Scholar] [CrossRef]

- Jurgensen, M.F.; Harvey, A.E.; Graham, R.T.; Page-Dumroese, D.S.; Tonn, J.R.; Larsen, M.J.; Jain, T.B. Impacts of timber harvesting on soil organic matter, nitrogen, productivity, and health of inland northwest forests. For. Sci. 1997, 43, 234–251. [Google Scholar] [CrossRef]

- Marčeta, D. Comparison of Technologies of Wood Biomass Utilization in Beech Stands. Ph.D. Thesis, University of Ljubljana, Biotechnical Faculty, Ljubljana, Slovenia, 2015; pp. 1–157. [Google Scholar]

- Visser, R.; Stampfer, K. Expanding Ground-based Harvesting onto Steep Terrain: A Review. Croat. J. For. Eng. 2015, 36, 321–331. [Google Scholar]

- Visser, R. Cable-Assist in Forest Harvesting: Developments and Operating Limits. (prezentacja) DEMO—Vancouver—19–21 Sept 2016. 2016. Available online: https://www.cif-ifc.org/ (accessed on 20 March 2018).

- Maleki, K.; Lafleur, B.; Leduc, A.; Bergeron, Y. Modelling the influence of different harvesting methods on forest dynamics in the boreal mixedwoods of western Quebec, Canada. For. Ecol. Manag. 2021, 479, 118545. [Google Scholar] [CrossRef]

- Bont, L.G.; Fraefel, M.; Frutig, F.; Holm, S.; Ginzler, C.; Fischer, C. Improving forest management by implementing best suitable timber harvesting methods. J. Environ. Manag. 2022, 302, 114099. [Google Scholar] [CrossRef]

- Unrau, A.; Becker, G.; Spinelli, R.; Lazdina, D.; Magagnotti, N.; Nicolescu, V.N.; Buckley, P.; Bartlett, D.; Kofman, P.D. (Eds.) Coppice Forests in Europe; Albert Ludwig University of Freiburg: Freiburg im Breisgau, Germany, 2018; p. 392. Available online: https://www.eurocoppice.uni-freiburg.de/intern/coppiceineurope-volume/coppice-forests-in-europe-2018-09-10-final-small.pdf (accessed on 29 September 2023).

- Spinelli, R.; Cacot, E.; Mihelic, M.; Nestorovski, L.; Mederski, P.; Tolosana, E. Techniques and productivity of coppice harvesting operations in Europe: A meta-analysis of available data. Ann. For. Sci. 2016, 73, 1125–1139. [Google Scholar] [CrossRef]

- Spinelli, R.; Magagnotti, N. Wood Extraction with Farm Tractor and Sulky: Estimating Productivity, Cost and Energy Consumption. Small-Scale For. 2012, 11, 73–85. [Google Scholar] [CrossRef]

- Björheden, R.; Apel, K.; Shiba, M.; Thompson, M.A. IUFRO Forest Work Study Nomenclature 1995; Department of Operational Efficiency, Swedish University of Agricultural Science: Garpenberg, Sweden, 1995; p. 22. [Google Scholar]

- Cataldo, M.F.; Proto, A.R.; Macrì, G.; Zimbalatti, G. Evaluation of different wood harvesting systems in typical Mediterranean small-scale forests: A Southern Italian case study. Ann. Silvic. Res. 2020, 45, 1–11. [Google Scholar] [CrossRef]

- Pignatti, G.; Verani, S.; Sperandio, G. Production of firewood from short rotation eucalyptus coppices: Productivity and costs. L’Italia For. Mont. 2019, 74, 217–226. [Google Scholar] [CrossRef]

- Verani, S.; Sperandio, G.; Civitarese, V.; Spinelli, R. Harvesting mechanization in plantations for wood production: Working productivity and costs. For. J. Silvic. For. Ecol. 2017, 14, 36–45. [Google Scholar] [CrossRef]

- Picchio, R.; Venanzi, R.; Di Marzio, N.; Tocci, D.; Tavankar, F. A Comparative Analysis of Two Cable Yarder Technologies Performing Thinning Operations on a 33 Year Old Pine Plantation: A Potential Source of Wood for Energy. Energies 2020, 13, 5376. [Google Scholar] [CrossRef]

| TC | Types of Machines | Max Load lmax (t) | Min Width wmin (m) | Prevailing Slope sp (%) a | Max Slope smax (%) | Min Turning Radius tr (m) |

|---|---|---|---|---|---|---|

| I | Truck | 25 | 3.5 | ≤10 | 12 (16) b | 9 |

| II | Tractors and trailers | 20 | 2.5 | ≤12 | 14 (20) | 8 |

| III | Small tractors | 10 | 2.0 | ≤14 | 16 (25) | 6 |

| IV | Small vehicles | 4 | 1.8 | >14 | >16 (>25) | <6 |

|

| Limiting Factor | Technical Parameter | ||||

|---|---|---|---|---|---|

| No. | Name | No. | Name | Category | Sub-Code |

| 1 | Characteristics of the forest | 1 | Management system | Coppice | F1 |

| High forest | F2 | ||||

| 2 | Characteristics of the production system | 2 | Wood assortment | Firewood | A1 |

| Beams/poles | A2 | ||||

| Chips | A3 | ||||

| 3 | Harvesting method | Cut-to-length | M1 | ||

| Tree length | M2 | ||||

| Fulltree | M3 | ||||

| 4 | Degree of mechanization | Low | L1 | ||

| Medium–high | L2 | ||||

| 3 | Site-specific operating conditions | 5 | Forest road transitability class | Medium–high | T1 |

| Medium–low | T2 | ||||

| 6 | Forest area accessibility class | Maximum (AC I) | AC1 | ||

| Medium–high (AC II) | AC2 | ||||

| Low (AC III) | AC3 | ||||

| 7 | Harvested mass | ≤15 t∙ha−1 DM | H1 | ||

| >15 t∙ha−1 DM | H2 | ||||

| OP | Harvesting Method | ||

|---|---|---|---|

| Cut-to-Length | Tree Length | Fulltree | |

| Felling | First | First | First |

| Delimbing | Second | Second | Fourth |

| Sectioning | Third | Fifth | Fifth |

| Bunching | Fourth | Third | Second |

| Extraction | Fifth | Fourth | Third |

| Chipping | - | - | Sixth |

| Loading and long-distance transport | Sixth | Sixth | Seventh |

| Machine Types | |||||

|---|---|---|---|---|---|

| N. | Type | N. | Type | N. | Type |

| 1 | Chainsaw | 8 | Cable crane mds a | 17 | Tractor with cages |

| 2 | Feller buncher | 9 | Grapple skidder | 18 | Grapple tractor |

| 3 | Feller skidder | 10 | Skidder with winch | 19 | Tractor with dumper |

| 4 | Harvester 4-wheel drive | 11 | Traditional cable crane | 20 | Forwarder |

| 5 | Crawler harvester | 12 | Forvester | 21 | Lorry |

| 6 | Processor | 15 | Helicopter | 22 | Chipper |

| 7 | Tractor with winch | 16 | Tractor with trailer | 23 | Road train |

| Technical Parameter | Category |

|---|---|

| Management system | Coppice |

| Wood assortment | Chips |

| Harvesting method | Fulltree |

| Degree of mechanization | Medium–high |

| Forest road transitability class | Medium–high |

| Area accessibility class a | High |

| Harvested mass (t∙ha−1 DM) | ≤15.0 |

| Operation | Types of Usable Machines | Selected Types of Usable Machine | Machine Models | |

|---|---|---|---|---|

| N. | Name | |||

| 1 | Felling | Chainsaw, harvester 4WD, crawler harvester, feller buncher, feller skidder, forvester | Chainsaw | Stihl MS 660 |

| 2 | Bunching and extraction | Grapple tractor, tractor with winch, grapple skidder, skidder with winch, forvester, forwarder, cable crane with mobile drive station, traditional cable crane | Tractor with winch | TR: Case IH Puma 145; winch: Krpan 4.5 E |

| 3 | Sectioning | Chainsaw, processor | Chainsaw | Stihl MS 660 |

| 4 | Chipping | Chipper | Tractor + chipper | TR: John Deere 8270 R; chipper: Gandini 40–60 TTS |

| 5 | Loading and long-distance transport | Tractor with trailer, lorry, road train | Tractor with trailer | TR: Massey Ferguson 7626; trailer: Bossini R2A2005D |

| Input Data | Unit of Measure | Value |

| Bunching distance | m | 100.0 |

| Employee speed | m·s−1 | 1.0 |

| Speed of rope winding on the winch a | m·s−1 | 1.3 |

| Extraction distance | m | 250.0 |

| Forward speed (loaded) | m·s−1 | 1.5 |

| Return speed (unloaded) | m·s−1 | 2.0 |

| Extracted wood volume per cycle b | m3·cycle−1 | 2.0 |

| Output Data | Unit of Measure | Value |

| No. of cycle | - | 50 |

| Time for rope winding on the winch | s | 80 |

| Time for transfer (travel loaded) | s | 167 |

| Time of effective work (EF; rope winding + travel loaded) | h | 3.4 |

| Additional time (AT) | ||

| Machine/implement arrangement on field | s | 900 |

| Time of transfer (travel unloaded) | s | 6250 |

| On-field maintenance c | s | 123 |

| Delays (avoidable and unavoidable) d | s | 0 |

| Employee rest | s | 0 |

| Other times not included in the previous ones e | s | 9250 |

| Required time (EF + AT; 1 machine) | h | 8.0 |

| Productivity (1 machine) | t·h−1 DM | 7.6 |

| Input data | ||

| Transport distance | km | 10.0 |

| Forward speed (loaded) | km·h−1 | 25.0 |

| Return speed (unloaded) | km·h−1 | 35.0 |

| Loaded wood volume per cycle | m3 | 16.0 |

| Volumetric filling coefficient | % | 100 |

| Output data | ||

| No. of cycle | - | 19 |

| Time of effective work (EF; travel loaded) | h | 7.6 |

| Additional time (AT) | ||

| Machine/implement arrangement on field | s | 0.0 |

| Time of transfer (travel unloaded) | s | 19,481 |

| On-field maintenance a | s | 273 |

| Delays (avoidable and unavoidable) b | s | 0 |

| Employee rest | s | 0 |

| Other times not included in the previous ones c | s | 35,618 |

| Required time (1 machine; EF + AT) | h | 23.0 |

| Productivity (1 machine) | t·h−1 DM | 2.7 |

| Data | Unit | OPs and Machines | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Chainsaw | Tractor with Winch | Chainsaw | Tractor with Chipper | Tractor with Trailer | ||

| Useful time | Days | 5.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| No. of working hours per employee per shift | h·employee−1·shift−1 | 8.0 | 8.0 | 8.0 | 8.0 | 8.0 |

| No. of shifts per day | Shifts·day−1 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Useful time per employee | h·employee−1 | 40.0 | 8.0 | 8.0 | 8.0 | 8.0 |

| Productivity (1 machine/imp.) | t·h−1 DM | 0.6 | 7.6 | 1.2 | 7.6 | 2.7 |

| Required working time (1 machine/imp.) | h | 100.0 | 8.0 | 50.0 | 8.0 | 23.0 |

| No. of required machines/imp. | - | 3 | 1 | 6 | 1 | 3 |

| Productivity (total) | t·h−1 DM | 1.8 | 7.6 | 7.6 | 7.6 | 7.6 |

| No. of employees (1 machine/imp.) | - | 1 | 2 | 1 | 3 | 1 |

| No. of employees (total) | - | 3 | 2 | 6.0 | 3 | 3 |

| Required working time (total) | h | 33.3 | 8.0 | 8.0 | 8.0 | 8.0 |

| Data/Parameters | Machines | ||||||

|---|---|---|---|---|---|---|---|

| Chainsaw | TR | Winch | TR | Chipper | TR | Trailer | |

| Model | Stihl MS 660 | Case IH Puma 145 | Krpan 4.5 E | John Deere 8270R | Gandini 40–60 TTS | Massey Ferguson 7626 | Bossini R2A2005D |

| Max engine power (kW) | 5.2 | 117.6 | - | 201.6 | - | 183.6 | - |

| Purchase price (P; EUR) | 1200 | 46,500 | 3300 | 82,000 | 25,000 | 75,000 | 15,000 |

| Salvage value rate (EUR; % P) | 20.0% | 12.5% | 10% | 12.5% | 20.0% | 12.5% | 18.0% |

| Interest rate (EUR; % P) | 4.0% | 5.0% | 4.0% | 5.0% | 4.0% | 5.0% | 4.0% |

| Overhead rate (EUR; % P) | 4.0% | 4.0% | 4.0% | 4.0% | 4.0% | 4.0% | 4.0% |

| Employee wage (EUR∙h−1) | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 |

| Repair and maintenance rate (% D a) | 100% | 100% | 100% | 100% | 100% | 100% | 100% |

| Fuel price (EUR∙dm−3) | 1.5 | 1.5 | - | 1.5 | - | 1.5 | - |

| Lubricant price (EUR∙dm−3) | 4.0 | 4.0 | - | 4.0 | - | 4.0 | - |

| Service life (h) | 3175 | 12,000 | 6000 | 12,000 | 10,000 | 12,000 | 4000 |

| Economic life (y) | 3 | 12 | 8 | 12 | 10 | 12 | 12 |

| Annual use (h∙y−1) | 400 | 1000 | 250 | 1000 | 800 | 1000 | 250 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nonini, L.; Cavicchioli, D.; Fiala, M. A Preliminary Model for Forestry Machinery Chain Selection and Calculation of Operating Costs for Wood Recovery. Forests 2025, 16, 1069. https://doi.org/10.3390/f16071069

Nonini L, Cavicchioli D, Fiala M. A Preliminary Model for Forestry Machinery Chain Selection and Calculation of Operating Costs for Wood Recovery. Forests. 2025; 16(7):1069. https://doi.org/10.3390/f16071069

Chicago/Turabian StyleNonini, Luca, Daniele Cavicchioli, and Marco Fiala. 2025. "A Preliminary Model for Forestry Machinery Chain Selection and Calculation of Operating Costs for Wood Recovery" Forests 16, no. 7: 1069. https://doi.org/10.3390/f16071069

APA StyleNonini, L., Cavicchioli, D., & Fiala, M. (2025). A Preliminary Model for Forestry Machinery Chain Selection and Calculation of Operating Costs for Wood Recovery. Forests, 16(7), 1069. https://doi.org/10.3390/f16071069