1. Introduction

While the conservation of stable forest ecosystems throughout changes in climatic conditions has become the primary directive for silvicultural strategies, the demand for renewable building materials is rising. Plywood and laminated veneer lumber are homogenized products, but still, a question for quality predictions arises: How are the factors of the thinning system, rotation age, and site quality potentially influencing the product quality of these engineered wood products? The effects of these silvicultural parameters could also be expressed by the anatomical characteristics of trees, like height and diameter, or different features of the crown, like its base height or radius. If mechanical board properties could be modeled depending on these factors with sufficient accuracy, an on-site non-destructive quality evaluation would be feasible to allocate timber lots efficiently to producers of different products.

Therefore, we have examined the mechanical properties of veneer boards, both plywood and laminated veneer lumber, produced from Norway spruce (Picea abies (L.) Karst.; PCAB) and Douglas fir (Pseudotsuga menziesii (M.) Franco; PSMN) logs of different origin. A change toward a focus on single trees in thinning regimes, prevalent as thinning from above, with selective measures in the co-dominant tree layer, has become predominant in Germany in recent decades, accompanied by concerns for accelerated growth with stronger knots and wider growth rings. Previously, a more uniform treatment of stands with the removal of subdominant and subordinate trees, thinning from below, led to denser, one-layered structures.

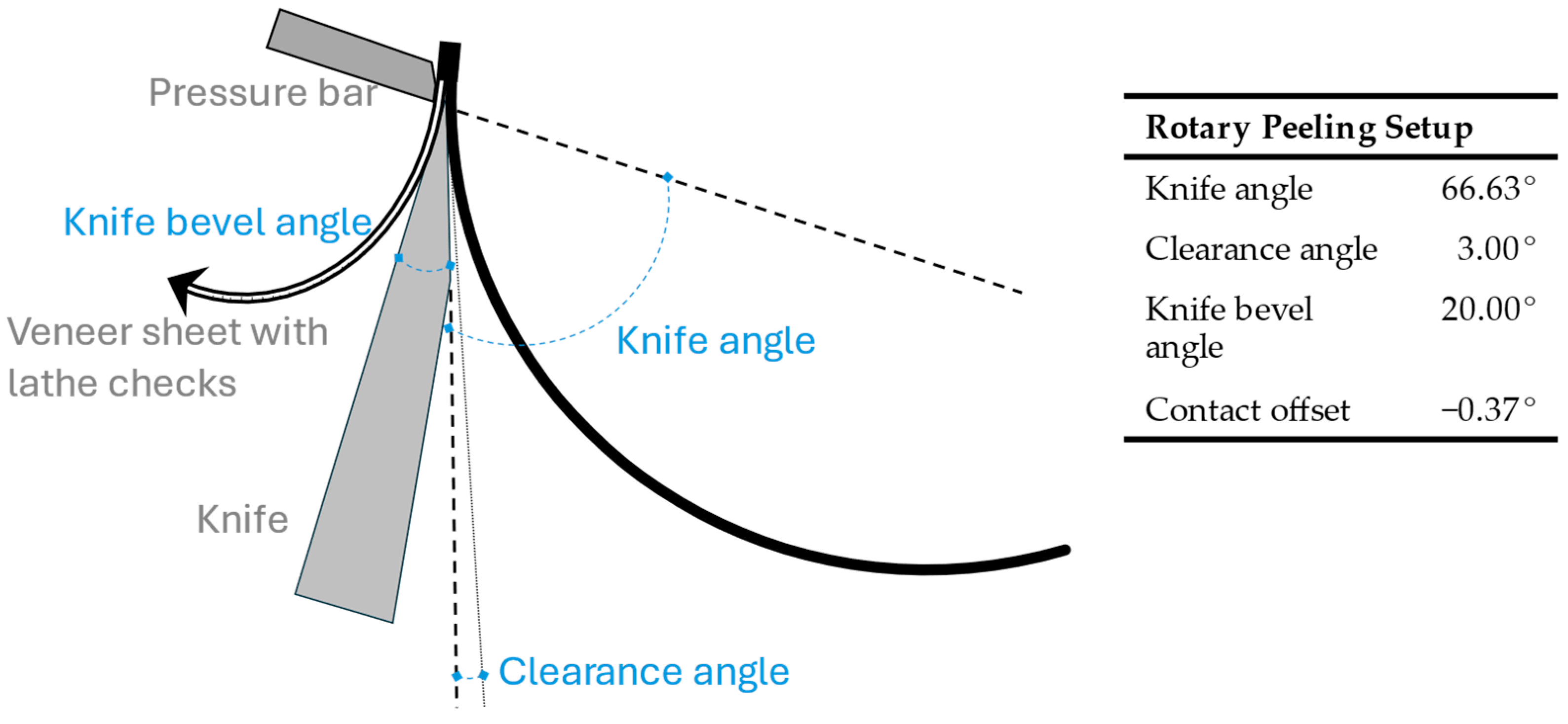

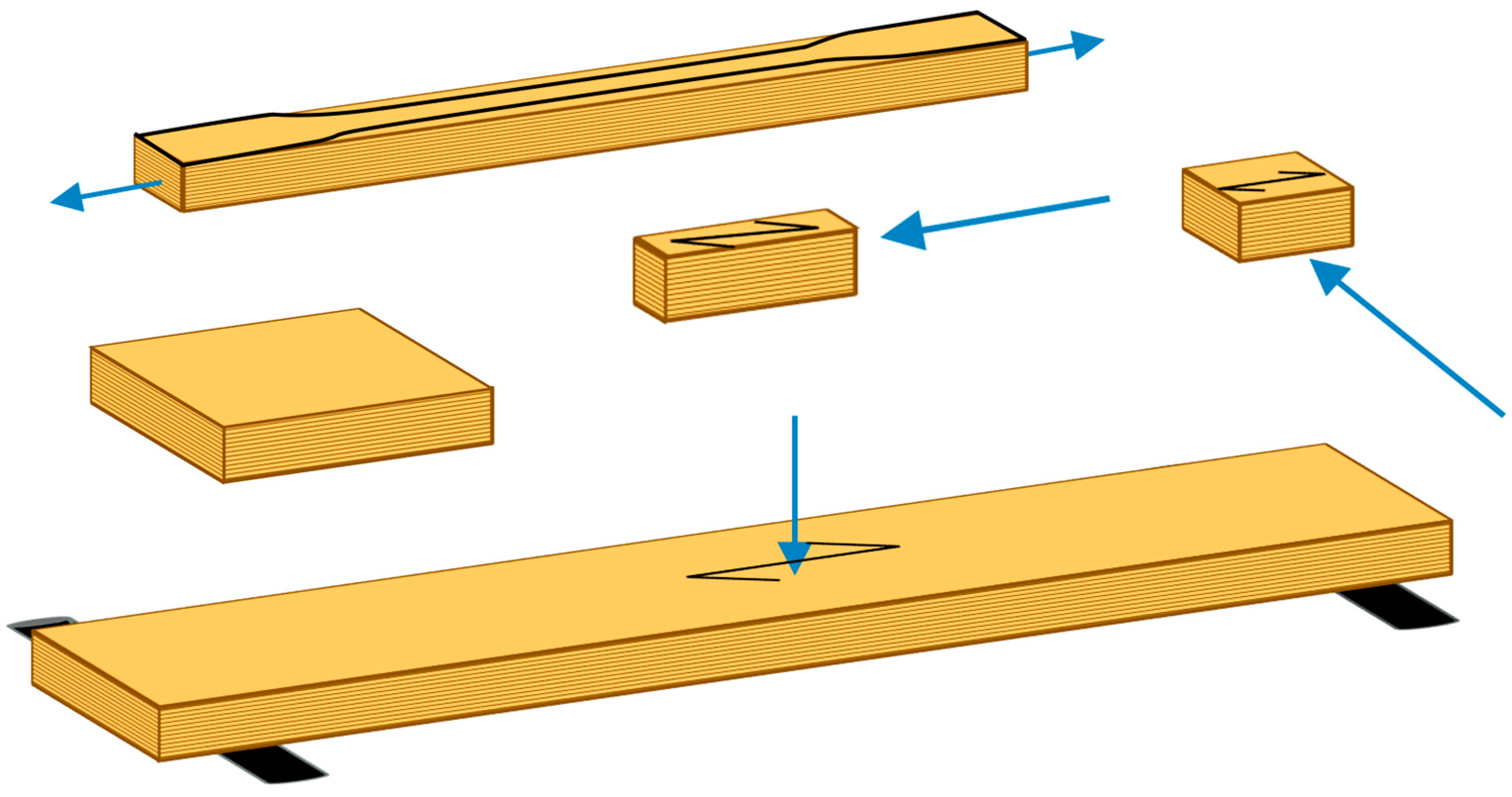

Laminated veneer products can be produced by rotary-peeling logs that have been pre-treated with heat and moisture to soften the wood material, depending on the grain orientation of plies, cross-directional and dimensional stable plywood, or unidirectional laminated veneer lumber, in reference to their substitute application as load-bearing beams. Hybrid products, with different layer build-up, have been researched to adjust the physical properties for both ply orientation and wood species combination [

1,

2,

3]. The advantage of veneer products lies in their high resource efficiency, which is paid for by the higher use of adhesive. The adhesive consumption has been addressed by efforts toward an ever-increasing veneer thickness, with a standard range of 1.5 to 3.5 mm being effectively raised to up to 7 mm [

4], with a certain effect in that regard [

5]. The resource efficiency applies to logs of very large dimensions that would require elaborate band-saw equipment in sawmills but that can be rotary-peeled with far less waste material [

6], as well as thin logs, especially with the use of spindleless rotary cutting machines [

7], or for low-quality wood [

3,

6] with the redistribution of wood defects reaching higher strengths than equal cross-sections of sawed timber. The quality assessment of veneers is mainly concerned with knots [

8,

9], surface roughness [

10,

11], and lathe cracks [

8,

12,

13,

14]. A comprehensive study on the general mechanical properties of LVL in the three primary directions has been carried out by Romero and Odenbreit [

15]. As an alternative to the costly setup of endless-LVL assembly lines, Gilbert et al. [

16] examined finger-jointed LVL from batch presses, finding a performance within 99% of the regular cross-section without joints.

Schönfelder et al. [

17] and Kask et al. [

18] investigated the effect of growth conditions and silvicultural practices on wood density for clean wood samples of Scots pine (

Pinus sylvestris L.). Higher wood densities were observed on poorer sites [

18] and lower variation of wood density along the log radius for slow-growing trees from the shelterwood practice [

17]. Shupe et al. [

19] were able to examine Loblolly pine (

Pinus taeda L.) plywood sourced from even-aged stands with different basal areas, finding an advantage in flexural stiffness in material from densely growing sites. Similarly, Huang et al. [

20] observed an advantage in mechanical properties for stands of

Larix olgensis (H.) with high density. Twenty-year-old and forty-year-old Southern pine from plantations was processed to LVL by Biblis [

21], who found a distinct advantage of using veneer from older stands. Differences in the mechanical properties of the sapwood and heartwood of softwoods also have to be considered but are detectable by the state-of-the-art optical grading of knots and the acoustic measurement of wood density. For French Douglas fir, significantly better performances in flexural behavior were measured for sapwood [

22], with heartwood performing 16% worse in flatwise bending and 20% worse in edgewise bending. Viguier et al. [

23] compared LVL from equally dimensioned beech logs from high wood and coppice and found significantly better flexural behavior in high-wood material but missing differences in wood density. The stiffness properties of roughly 50-year-old Douglas fir veneers have been compared to the acoustic velocity within trees by Lowell et al. [

24], finding a negative correlation of tree diameter and taper with veneer stiffness. Different non-destructive evaluation methods were tested in an extensive trial by Schimleck et al. [

25], examining NIR spectroscopy, computer tomography, Pilodyn, Resistograph, and acoustic velocity. These state-of-the-art methods all measure expressions of the tree wood density, while this study takes a more conservative approach by evaluating the anatomical appearance of trees and thereby indirectly deducing the wood properties; however, using laser scan data is a less researched approach.

4. Discussion

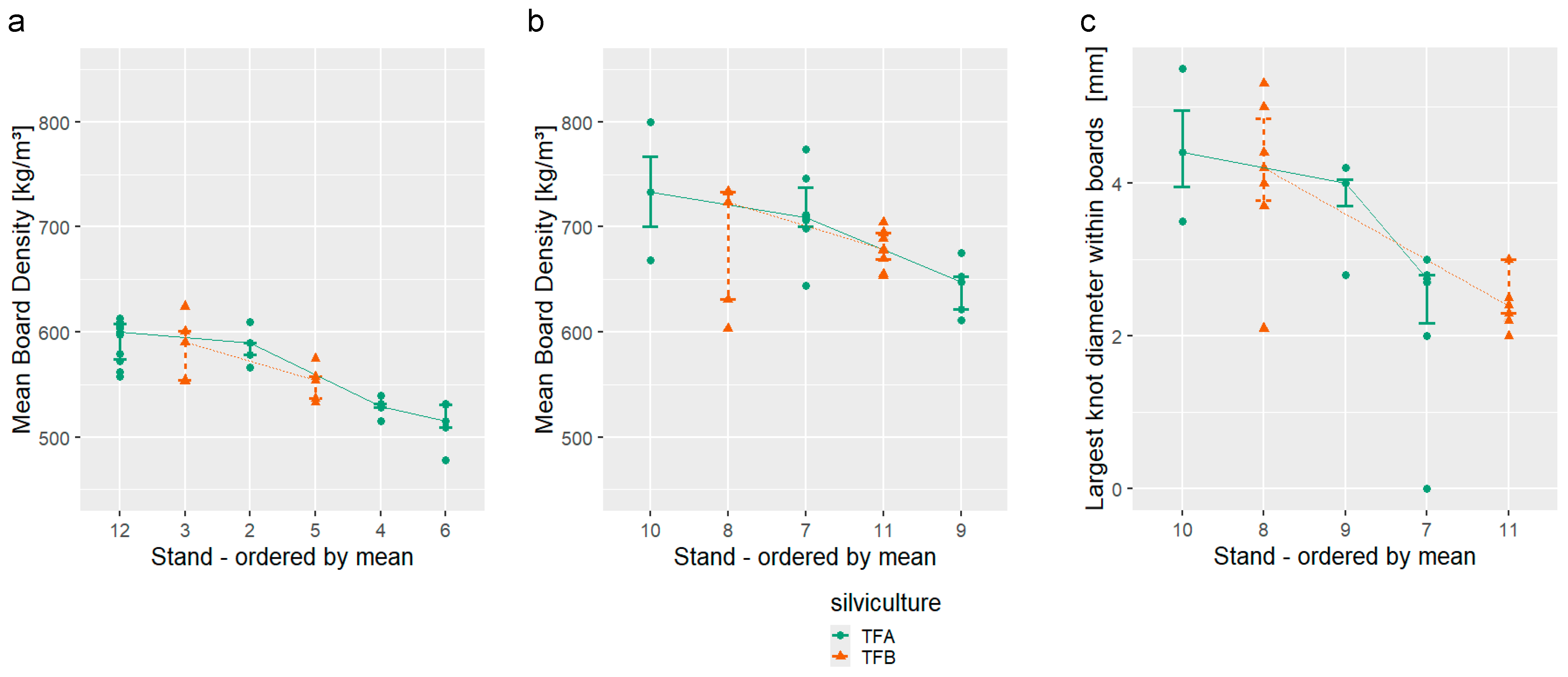

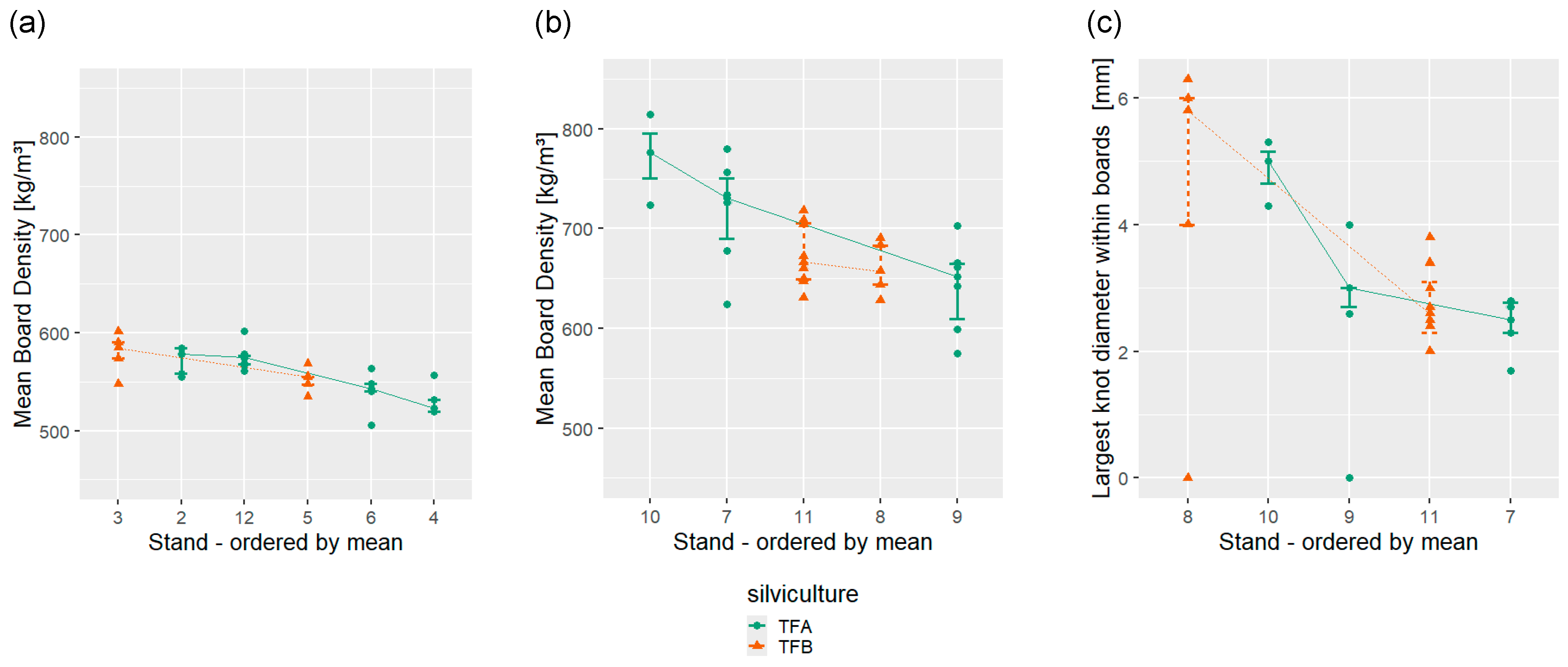

The site characteristics (

Table A1) suggest a certain rank order of wood density based on the water supply, the age and corresponding annual growth, and the presumed thinning intensity. A trend that was observed to be accurate for sawn timber [

27,

28]. With the press configuration set to achieve a defined thickness, the remaining variables to determine the final board density were the wood density itself and deviations in veneer thickness. Uneven veneers would experience a stronger springback during the relaxation phase, widening the press gap to 11.5 mm over the course of 20 s, and holding at that gap for 5 s before opening. When plywood and LVL within each species are compared, the mean densities of boards from one stand are similar, regardless of the product. This indicates that the deviations in veneer thickness were consistent for the treatment and peeling process of logs from each stand. Without changes to knife angle and gap, this suggests that logs with less diameter or density tend to yield thicker veneer or higher variance of sheet thickness. For PSMN, the σ of density is higher within the younger stand group, while this trend was undetermined for PCAB. The deductions regarding the material quality from different stands are mainly unaffected by this observation. Although the consequences of wood density are distorted during the production process, the factor of knot sizes for PSMN and the mechanical performance during tests correspond to stands with a younger age or with better water supply, exhibiting faster growth, which results in thicker knots compared to stands of a similar age (see

Table A8).

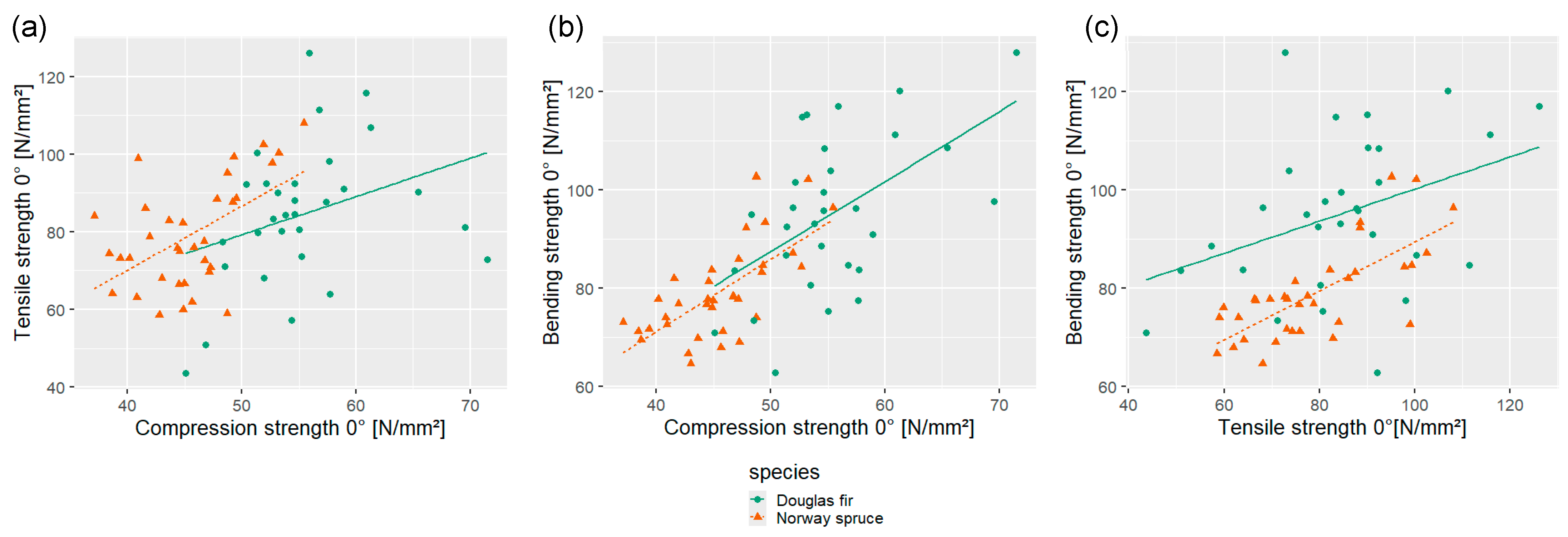

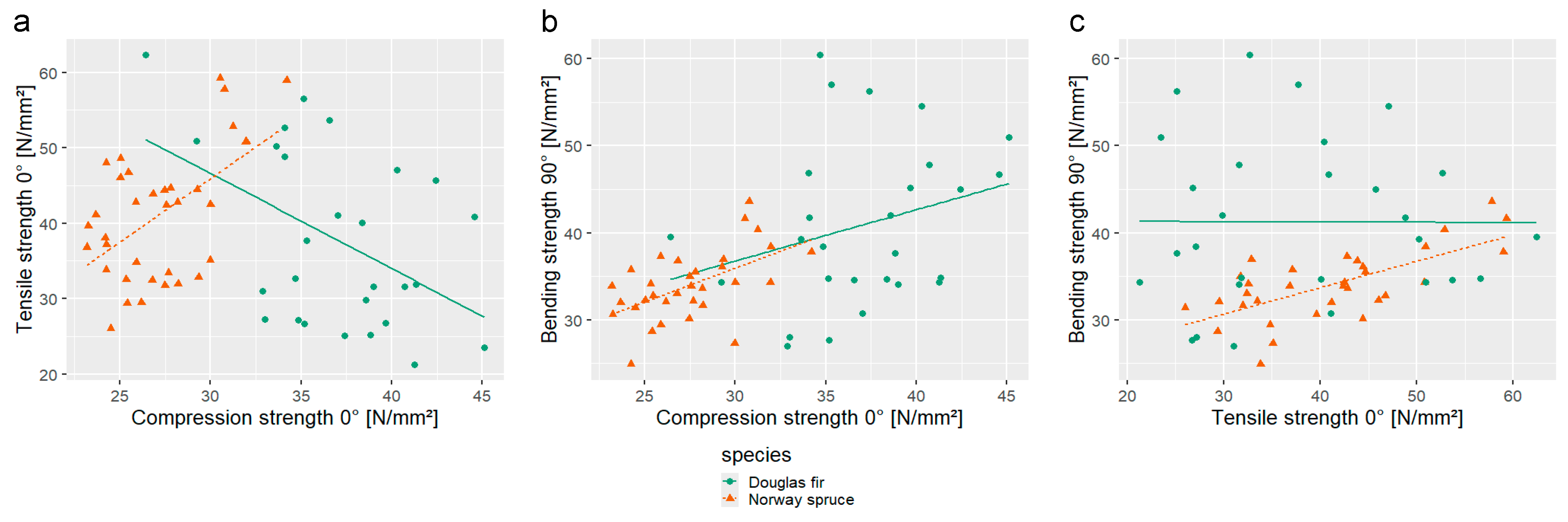

When evaluating the general mechanical properties of both species and products, the homogenized characteristics of plywood are recognizable, achieving a lower variance within species, when compared to the LVL boards. The high variance of PSMN products negatively influenced the deductions regarding the initial research hypothesis. For PCAB LVL and plywood, the highly significant models, based on thinning type, water supply, and age, adequately describe the product quality for the examined properties of bending strength, bending stiffness, and tensile and compression strength. The effect of the applied thinning system did not reach sufficient estimator coefficients to achieve p-values below 0.05. The flexural properties of LVL are the only exception for both PCAB and PSMN, with a slight significance between thinning type and test result. In conclusion, when the silvicultural framework is considered, the applied thinning system was negligible. Extended to the specifications of both systems, this implies that the intensity of thinning and resulting stand structure did not significantly influence the product quality.

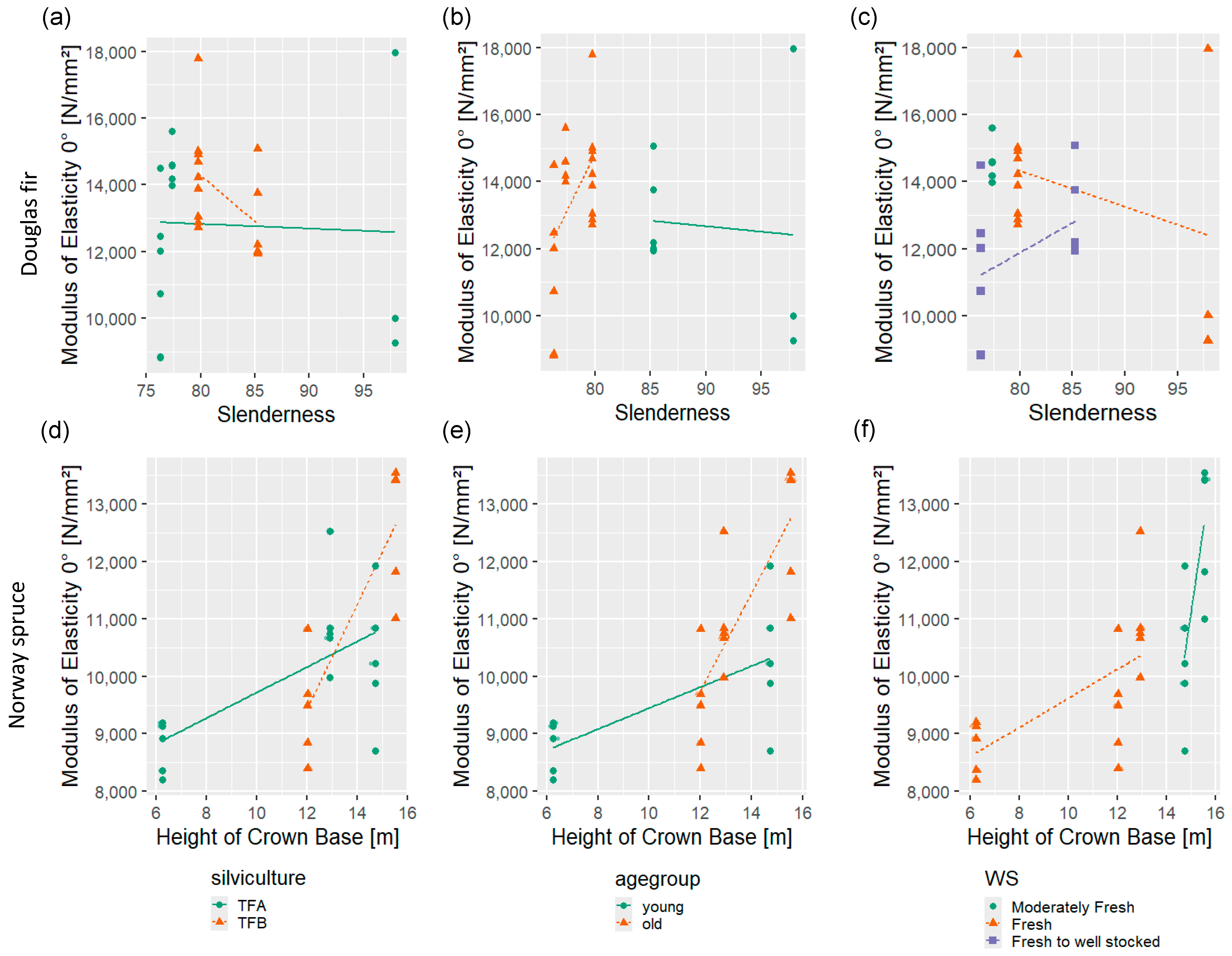

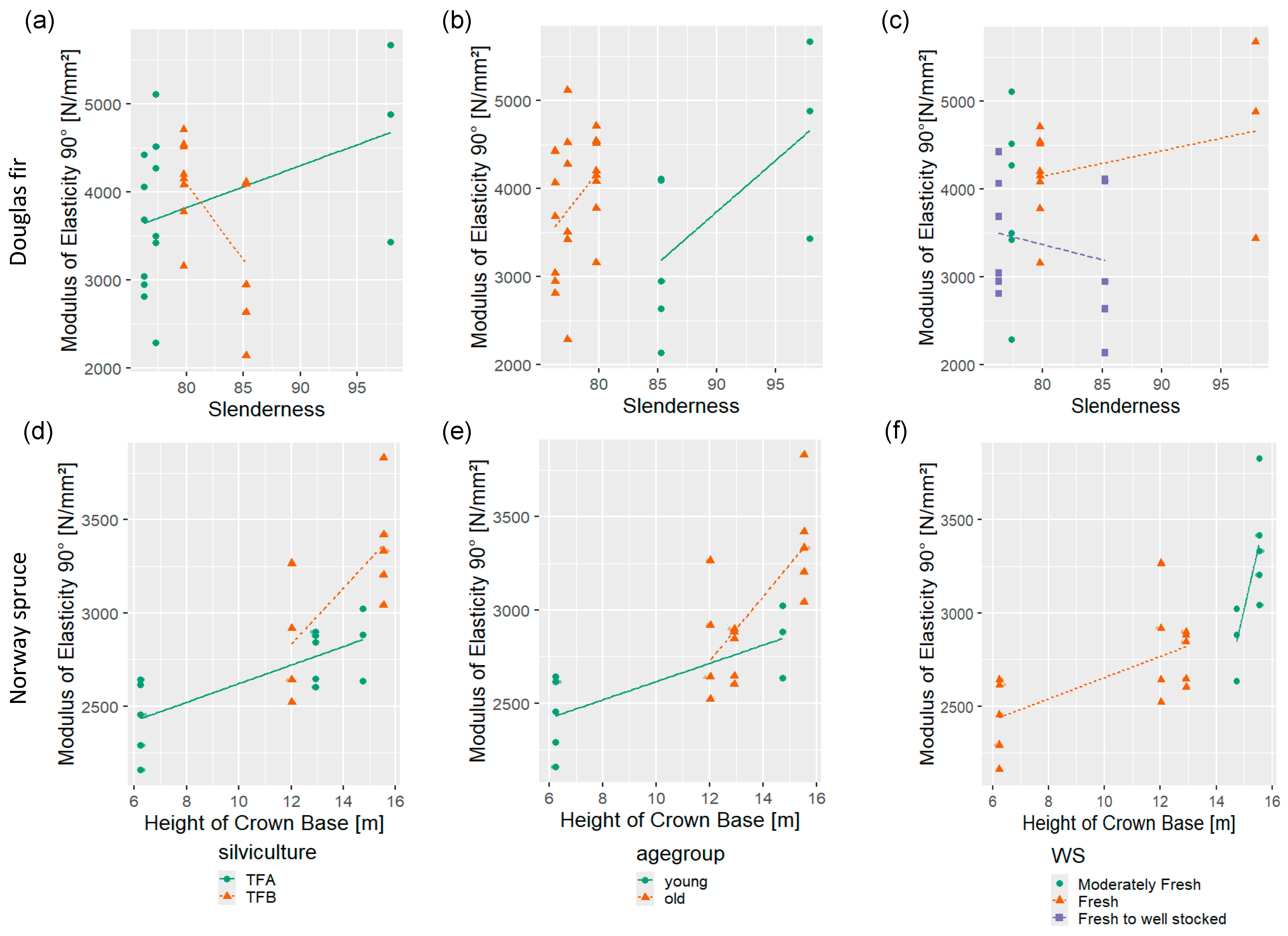

The prediction of LVL and plywood properties, based on the tree characteristics within a stand, was possible for the examined PCAB stands. The CODs between 0.50 and 0.59, with slenderness and CB as independent variables for tensile and bending properties of LVL, indicate promising accuracy. The model selection process of plywood made it necessary to include a factor of the higher-level data. For PCAB, the thinning type performed best in model comparisons and showed, in contrast to the effect in combination with age and WS, that TFB tends to result in higher mechanical board properties. The high CODs for PCAB plywood properties could have been caused by the higher grade of isotropy within boards and a lower variance compared to LVL. The high CODs for crown parameters arguably could be facilitated by the use of stand means, with values for crown factors taking on categorical properties; this was, however, controlled for with tests for variation inflation of included factors resulting in the concise models as presented. The number of logs would not be appropriate for linear mixed models, and verifications for the PSMN data did not increase model quality in an evaluation by tree.

For PSMN, the high σ resulted in low model quality. Although the general performance of PSMN products was superior to that of PCAB in regard to compression strength and bending properties, the assignment of mechanically relevant effects to stand and tree characteristics was inconclusive. Significant model determination was only reached in a few instances. Where models reached significance or near-significance, with p-values below 0.1, water supply or age group were the determining factors but never simultaneous. The higher variance of PSMN and thus the model failure can be explained by the wood anatomy of PSMN. The variance difference between PSMN and PCAB is already caused on the board level. The significantly larger growth rings of PSMN resulted in larger sections of pure latewood and early wood within sheets. Even without discussing the variance distinction between core- and sapwood, when layered randomly, it is possible to achieve board sections of higher and lower mechanical properties. With a seven-layered setup, the homogenization might have been insufficient. Wider growth rings led to more pronounced extremes of density across boards, which in turn increased the within-board variance for all mechanical properties. An indication of this may be found in the lower correlation of bending strength and elasticity of PSMN. Higher latewood content, with a higher density, could still result in a more brittle specimen due to higher lignin content, i.e., a high module of elasticity but lower bending strength due to impaired tensile properties.

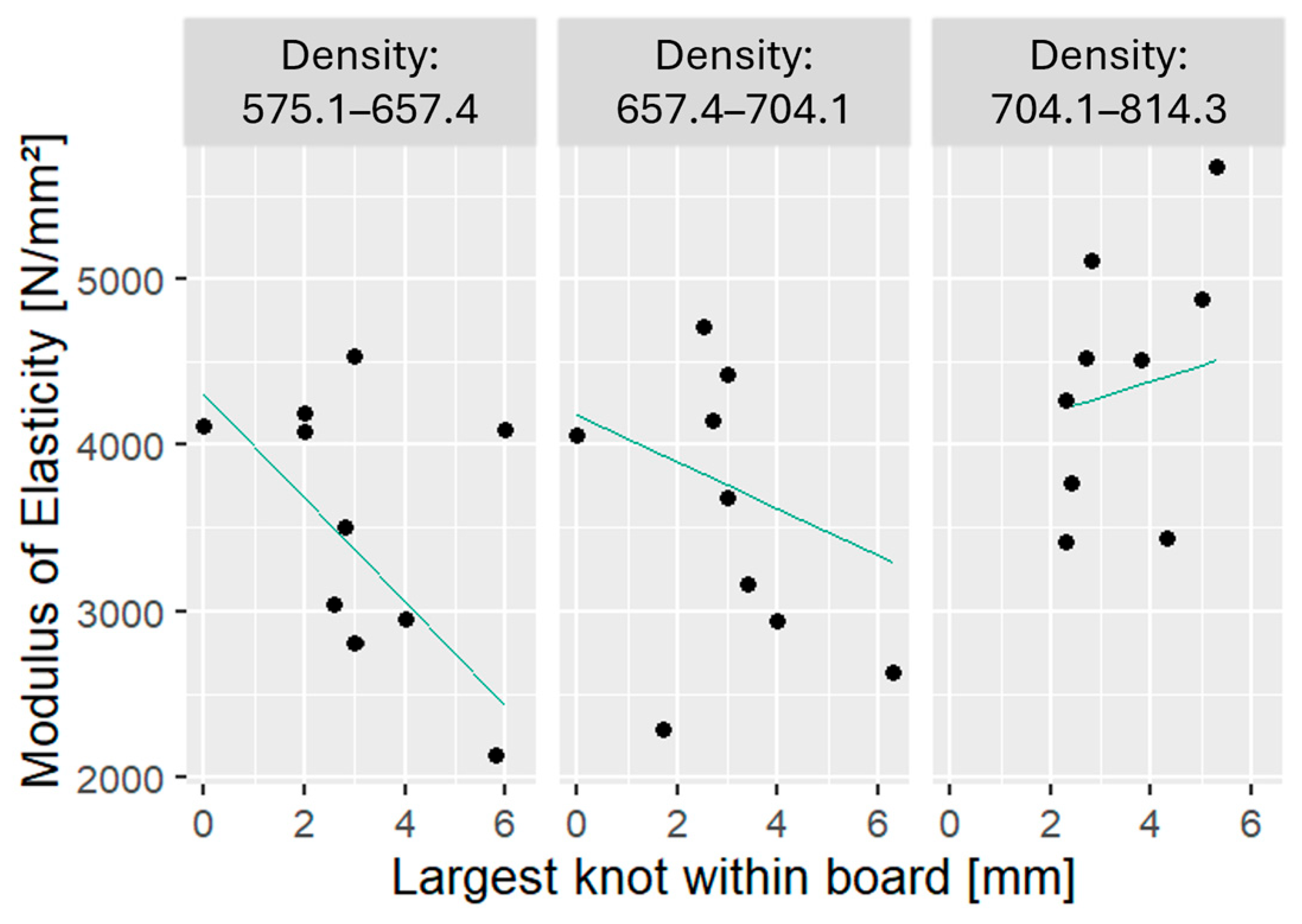

The examined sample size was appropriate to give indications on the predictability of veneer product quality, and an on-site pre-grading of PCAB seems promising. The model quality of PSMN board properties was insufficient. Considering the maximum knot sizes within boards and the density of boards as predictors, CODs of 0.44 are reached for bending stiffness (Em,0) of LVL and 0.41 (Em,90) for plywood. This should only be used as an approximation, as a plant-grading process would employ the sheet density for veneer grading, and we discovered disparities between board density, suggested wood density, and test performance in our data, as discussed previously.

Generalizing the results for softwood veneer products, higher rotation ages and lower water supply are noticeably beneficial for mechanical performance. The effect of the applied silvicultural thinning system only reached slight significance for LVL performance, with more evidence within PCAB than in PSMN boards. The significance was less pronounced for plywood boards, although for PCAB, the thinning system was a suitable second factor in combination with CB, while PSMN plywood showed no evidence for a significance of thinning type. The overall suggestion of the models in regard to species amounts to the suggestion that PCAB is more prone to the influence of active management measures, while PSMN seems less responsive. The reaction of different tree species to environmental changes is known to differ. The best example for PCAB and PSMN is a difference in resistance and resilience to drought. PCAB has lower resistance, while PSMN was observed to have lower resilience, expressed by a growth rate decline and the recovery of growth rate after drought years [

41,

42]. Similar behavior could be suspected for crown development and growth after thinning. Should PSMN, despite generally higher growth rates than spruce, show a slower rate of adaptation in regard to changes in available crown space and resulting potential additional growth, i.e., low plasticity of growth behavior, earliest stand development determines the growth characteristics, and the differences in specific intervention strategy, i.e., thinning type, are without effect. The research by Dušek and Novák [

43] seems to imply such a connection for early and delayed thinnings of PSMN. The homogenization in processed wood products, like LVL and plywood, further obscure these causations.

Due to the scope, limited by the processability at the technical laboratory-scale level, and to keep the LVL comparable to plywood, the deductions of this work should be taken as indicators. However, they exemplify the potential for additional research on the non-destructive evaluation for PCAB and for a focus on the site quality and stand age for PSMN at a higher sample size to account for the high observed variance. Further research should be carried out on beam-sized samples of LVL for a better comparability of industry-scale specimens. A qualitative analysis of strength classes would be possible for plywood, while for LVL, there are no defined classifications, but strength classes of glue-laminated timber could pose an adequate substitute.