1. Introduction

The Brazilian forestry sector encompasses 9.94 million hectares of planted forests, with 76% allocated to eucalyptus plantations, predominantly for pulp and paper production. In 2022, the sector contributed 6.3% to Brazil’s Gross Domestic Product (GDP), underscoring its significant economic impact. The industry generated revenue of USD 50.4 billion (around BRL 260 billion) and produced 25 million tons of pulp, highlighting its critical role in the national economy [

1].

On a global scale, Brazil is a leading producer and exporter of pulp, occupying a pivotal role in the international market. Brazilian eucalyptus plantations cater not only to the domestic demands but also supply raw materials to numerous global markets. The sector’s growth in plantation area and production efficiency is vital to addressing the increasing global demand for forest products and advancing environmental sustainability. Furthermore, ongoing technological innovations and the implementation of best practices have enhanced productivity and sustainability, solidifying Brazil’s status as a global leader in the forestry industry, particularly in the realms of harvesting, loading, and transportation technologies [

2].

Such an approach not only ensures high productivity but also optimizes operational procedures [

3,

4]. Detailed planning of logistics, particularly truck loading, is essential for minimizing operational and production costs, as well as ensuring a continuous supply of timber to the processing facility without compromising the integrity of the field machinery fleet [

5]. Effective logistical coordination and precise management of operations contribute to the overall efficiency and sustainability in forestry activities, promoting better resource utilization and enhanced operational cost-efficiency. In this context, inefficient forest loading can lead to high costs in forest transportation, significantly affecting the final cost of pulp and the subsequent supply to the factory.

The fully mechanized cut-to-length (CTL) harvesting system has become widely adopted in several industrialized European countries, such as Sweden, Ireland, and Finland, where forest conditions and stand structures are favorable [

6]. In Brazil, the CTL system is widely employed in forestry operations aimed at pulp production. In this method, logs up to six meters in length are produced [

7]. After cutting, processing, and extraction, woodpiles are formed at the roadside. The stage connecting harvesting to transportation is loading, where, after a drying period generally ranging from 60 to 90 days, the woodpiles are transferred to the trailers and/or semi-trailers of trucks using a machine known as a log loader. Following loading, the wood is carried to the processing facility or intermediate yards.

Loading is often considered a critical point in the forest harvesting system, as it functions as the link between primary transport (from the extraction site to the roadside) and secondary transport (from the roadside to processing mills or central yards). Any delay in this process can negatively impact other components, such as extraction machinery and trucks, especially in hot decking operations, or lead to excessive log accumulation in cold decking systems, further reducing the overall harvesting efficiency [

8]. According to Ghotb et al. [

9], the synchronization of trucks during operation and the quality of wood stacking in the trucks significantly influence transportation costs. Efficient loading and proper planning are crucial for minimizing operational costs and ensuring the integrity of forest products during transportation. Enhancements in loading techniques and the optimization of logistical operations are essential for improving profitability and sustainability in the sector.

The productivity of the log loader is influenced by various factors, including the increase in volume per tree, reduction in machinery travel distances, loading speed and efficiency, woodpile organization, human–machine interaction factors [

10], and technical variations according to the standards adopted by each forestry company [

11]. Key productive aspects of the forest and soil, such as planting spacing, average volume per tree, terrain slope, number of logs, load volume, and operator experience, play crucial roles in operational efficiency [

12]. Negative factors affecting the productivity of these machines are related to terrain steepness and travel distances, while useful load volume and machine capacity have a positive influence [

13,

14].

The efficiency of the loading process directly impacts truck fleet sizing, tire and fuel costs, waiting times, load quantities, overweight fines, and tolls during transportation to the processing facility or intermediate yards [

15,

16].

Wood loading plays a crucial role in determining operational costs and supply chain efficiency in forestry [

17]. The method and speed of loading wood onto trucks directly affect the amount of cargo transported per trip and transportation safety. Poorly organized loading can lead to wasted space, increasing the cost per ton and extending the total operation time, which negatively impacts productivity [

18]. Therefore, implementing effective strategies to enhance loading terminals, focusing on optimizing truck space and reducing operation time, is essential for lowering costs and improving the profitability of forestry transportation.

In this context, it is the responsibility of organizations to pursue more sustainable forestry practices [

19]. Systematic management of the loading process and analysis of the associated logistics costs are crucial for understanding the factors influencing this operation, which represents a significant portion of the total cost of wood delivered to the mill [

9,

16,

18]. Given the ongoing importance of wood to processing facilities, harvesting and transportation emerge as essential and costly activities, subject to variables that directly affect machine productivity and operational costs [

20].

Thus, detailed analysis is critical for developing planning tools that ensure a continuous and efficient flow of wood to consumer units at competitive costs. In this sense, this study aims to optimize the operational cycle of the log loader based on productivity prediction models (i), operational cycle assessment (ii), and the loading costs of tri-train trucks (iii).

2. Materials and Methods

2.1. Study Area

The data were collected from areas managed by a forestry company located in northeastern Brazil, specifically in the state of Bahia, between the geographical coordinates of 39°34′31″ to 40°34′48″ west longitude and 16°22′22″ to 17°22′00″ south latitude. The region is characterized by predominantly flat terrain, with an average altitude of 190 m. According to Köppen’s climate classification, the area experiences a tropical rainforest climate (Af), with an average annual temperature of 23 °C and an average precipitation of 1256 mm [

21].

The study areas consist entirely of eucalyptus plantations using hybrid clones under first rotation and coppice systems, both with a six-year harvest cycle. Planting spacing ranges from 4.0 × 3.0 m to 5.0 × 2.4 m, with mechanized harvesting operations restricted to slopes of up to 25°. The harvesting is fully mechanized, operating seven days a week in three eight-hour shifts, utilizing the cut-to-length system. According to Noordermeer et al. [

22], in this system, trees are felled and processed directly in the field into small logs less than six meters in length, which are then transported to the roadside or intermediate yards.

This approach is used to optimize the operational efficiency and ensure a continuous flow of raw material to processing units, taking into account the specific terrain, climate, and cultivation regimes present in the region.

2.2. Technical Characteristics of the Log Loader and Sampling

In this study, tracked log loaders from the caterpillar brand, model 320, manufactured by Caterpillar Inc. (Irving, TX, USA), were used for wood loading, as shown in

Table 1 and

Figure 1.

To establish the conditions for analyzing the operation, the minimum number of work cycles required to ensure a sampling error of no more than 5%, thereby providing a 95% confidence level, was determined using the methodology proposed by Barnes [

23]. This methodology is detailed in Equation (1).

where

is the minimum number of required cycles;

is the t value for the desired probability level and (

n − 1) degrees of freedom;

is the coefficient of variation (%);

is the admissible sampling error at 95% probability.

A total of five log loaders have been evaluated for each class of average volume per tree (AVT), ensuring coverage of a wide range of operating conditions. The machines operated continuously over a 24 h period, divided into three 8 h shifts. A different operator, totaling 15 operators across all AVT classes, conducted each shift. The operators were between 27 and 38 years old and had comparable levels of experience and productivity, which helped reduce variability due to human performance. This structure ensured consistent data collection and enhanced the reliability of the productivity analysis under varying machine-operating scenarios.

The loading activity of the tri-trains trucks was assessed by considering the elements of the operational cycle and the varying values of the average volume per tree (AVT).

Table 2 outlines the different investigation scenarios conducted for both activities.

2.3. Study of Productivity Capacity

As previously detailed in the methodological framework, the analyzed machines operated under similar topographic conditions and were handled by operators with comparable productivity levels. The multi-moment method was used with 15 s intervals per observation. Productivity was measured as the volume of wood effectively handled by the log loader during the truck loading operations, expressed in cubic meters per productive machine hour (m3·h−1). This metric was derived by combining accurate time study data with certified volumetric load measurements.

The volume of wood loaded was quantified based on the actual loads transported by triple road train trucks. Each truck was weighed upon arrival at the company’s industrial yard using certified truck scales. Additionally, the volume of each load was estimated using the Pivotex® system—an automated measurement tool widely adopted in the Brazilian forestry sector to determine transported wood volume based on log density and load geometry.

To determine the time spent in each phase of the wood loading activity, a time and motion study was conducted during the work shifts of each machine, using the continuous-time sampling method, which allows for precise recording of the time allocated to each stage of the operational cycle [

24]. The data collected were then compared in the statistical analysis to assess significant differences between the various phases of the process and operational conditions.

For the evaluation of the log loader, the operational cycle was divided into the following phases:

- (1)

Crane movement, which includes the actions of lifting, positioning, and placing logs. Each of these movements is crucial for optimizing the loading process, and a detailed analysis of each action will help improve the efficiency of the crane operation;

- (2)

Organization of fallen wood on the ground, referring to the process of sorting and arranging the logs or tree sections that have fallen, preparing them for the crane to lift. This step ensures that the logs are positioned in a way that allows for efficient handling by the crane;

- (3)

Organization of wood in the pile, which involves stacking or arranging the logs in a pile after they are lifted. This phase is important for optimizing the subsequent loading process, ensuring the logs are easy to handle and stable;

- (4)

Adjustment of logs on the truck, which is the process of repositioning the logs on the truck to ensure proper load distribution and stability. This step is essential to prevent load shifts during transport and ensure safety;

- (5)

Machine displacement, referring to the movement of the log loader within the landing area to reposition the machine for different tasks. This phase involves maneuvering the machine to different locations for optimal loading efficiency;

- (6)

Displacement of the tri-train truck, which involves the movement of the truck both within the landing area and when transporting logs to the next stage. This phase includes navigating the truck and ensuring that logs are efficiently loaded and delivered;

- (7)

Idle time (personal breaks), which includes periods when the machine or operators are not active, either due to breaks, delays, or waiting for materials. This phase is important for understanding the overall efficiency of the operation and identifying any potential areas for improvement.

The activities involving the log loader were documented using video recordings from cameras installed both internally and externally on the machines. This methodology minimized interference with operator productivity, as no evaluators were present in the field. Additionally, it allowed for precise identification of operational activities, contributing to a reduction in the time required for data collection.

2.4. Financial and Operational Cost Analysis

The economic analysis focused on accurately determining all operational and production costs associated with the log loader. As part of the financial evaluation, the economic analysis focused on accurately determining all operational and production costs associated with the log loader. To this end, a representative machine was selected, and a comprehensive assessment of its financial parameters was carried out. These data were then extrapolated using the adjusted productivity models described in the previous sections, ensuring consistency with the operational scenarios analyzed.

The estimated operating cost for forest wood loading activities was conducted based on the guidelines established by the American Society of Agricultural and Biological Engineers (ASABE) [

25], specifically following the ASABE D497.7—Agricultural Machinery Management Data standard. This methodology provides a structured and widely accepted approach for calculating both fixed and variable machinery costs, including depreciation, interest, insurance, fuel, maintenance, and labor.

To ensure contextual accuracy, all of the economic parameters were adapted to Brazilian conditions. The exchange rate of BRL 5.1186 per USD, recorded on 14 April 2024, was used to convert international references where necessary.

In accordance with the ASABE framework, all cost components relevant to forest wood loading operations were identified. These included personnel costs, equipment and material costs, maintenance and repair, fuel and lubricants, and transportation expenses. The aggregated values of these components were used to determine the total operational costs, as expressed in Equation (2).

where

is the total operational costs (USD·PMH);

is the fixed costs (USD·PMH);

is the variable costs (USD·PMH).

Production costs were calculated based on the volume, expressed in dollars per cubic meter harvested (USD·m

−3) for each type of machine (Equation (3)).

where

is the production cost of the machines (USD·m

−3);

is the total operational cost of the machinery (USD·PMH);

is the productivity of the evaluated machines (m

3·PMH).

This cost was determined by the ratio between the operational cost and the effective productivity of the machines, considering the scenarios of the average volume per tree (AVT) described in this study. This allowed for the identification of the equipment most sensitive to changes in the AVT.

The fixed costs analyzed included depreciation, interest, insurance, taxes (Equations (4) and (5)), storage (Equation (6)), and administrative fees (Equation (7)).

where

is the acquisition cost (log loader USD 129,211.42);

is the residual value of the machine (

);

is the interest, insurance, and taxes;

is the annual average investment;

is the interest rate (12%);

is the productive machine hours (4045.86 PMH);

is the useful life (5 years);

is the storage facility;

is the storage facility factor (0.75%);

is the administrative fees;

is the administrative factor (4%).

The variable operating costs include fuel (Equation (8)), lubricants (8.0% of the fuel cost), hydraulic oil (16.0% of the fuel cost), tracks (Equation (9)), maintenance and repairs (Equation (10)), labor (Equation (11)), labor transportation (Equation (12)), and machinery transportation (Equation (13)).

where

represents the final fuel cost;

is the fuel price (USD 1.32 L

−1);

is the fuel consumption (20.5 L h

−1);

is the cost of tracks;

is the number of tracks;

is the price per track (USD 8010);

is the service life of the track (12,500 h);

is the cost of maintenance and repairs;

is the repair factor 1 (0.005);

is the repair factor 2 (2);

refers to the accumulated hours of use up to the start of the evaluation (2113.82 h);

is the labor cost;

is the operator’s monthly wage (USD 910.22);

is the labor rate (3.0);

is the number of operators (3);

is the number of months (12);

is the labor transportation cost;

is the average daily distance traveled to transport workers to the sites (220 km day

−1);

is the cost per kilometer (USD 1.62 km

−1);

is the number of working days in a year (365);

is the number of workers per transport vehicle (18);

is machinery transportation;

is the machinery transportation index (75%);

is the labor transportation cost.

2.5. Statistical Analyses

For regression analysis, statistical correlation, mean tests, analysis of the residuals, descriptive statistical inferences, and result presentation, the software “GraphPad Prism 8” (GraphPad Software Inc., San Diego, CA, USA), “Statistical 7.0” (StatSoft Inc., Tulsa, OK, USA), and “SPSS 11.0” (SPSS Inc., Chicago, IL, USA) were utilized. Statistical analysis of the equations was based on selecting productivity equations with the highest coefficient of determination (R2), followed by the lowest number of variables. To compare the mean times of the log loader’s operational cycles, ANOVA (Analysis of Variance) and the Student–Newman–Keuls test were applied for multiple comparisons and significance at the 5% level.

The data used in the predictive models exhibited a normal distribution, as confirmed by the Shapiro–Wilk [

26] and Kolmogorov–Smirnov [

27] tests, thereby ensuring the validity of the parametric analyses. Linear correlation analyses were conducted with the productivity data (m

3·h

−1) of the log loader. These analyses were verified using Pearson’s statistical test at a 1% significance level. Subsequently, the results were compiled along with the regression models, and graphs for each scenario were created using the “GraphPad Prism 8” software.

The adjusted models, as described by Burnham and Anderson [

28], were compared using the Akaike Information Criterion (AIC) to determine which model best describes the productivity of the forestry machines. To assess dependency, the stepwise regression method was applied at the 5% significance level [

29]. Variables that did not show statistically significant influence were excluded from the models.

3. Results

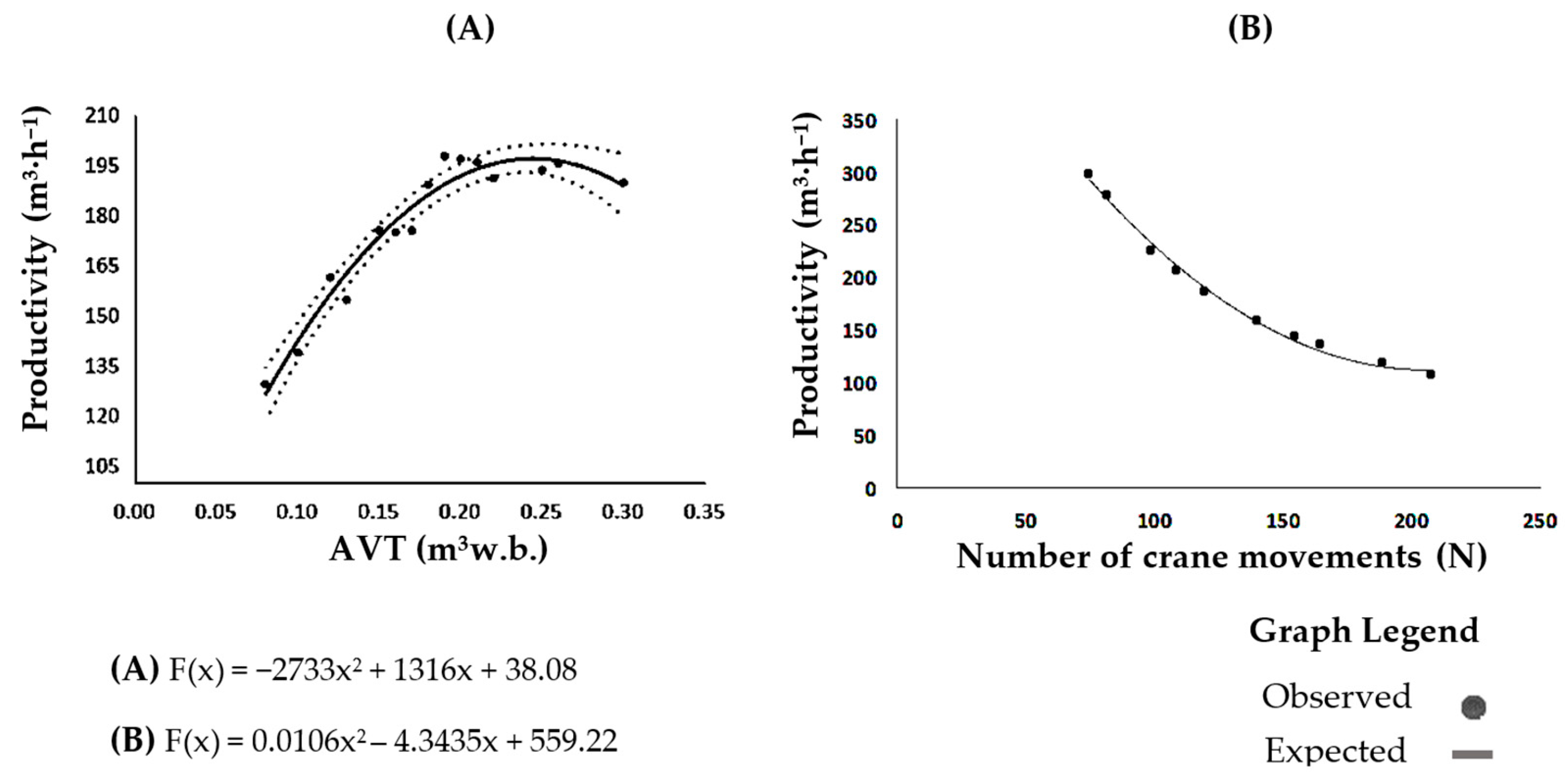

The productivity curve of the log loader was calculated based on the average volume per tree (AVT) and the number of movements recorded in the time study (

Figure 2). Notables are the high coefficients of determination (R

2) and the strong statistical correlations (r).

Descriptive statistics and linear correlation analyses of the tested variables are presented in

Table 3.

The mean and median productivity values (m

3·PMH) are closely aligned, suggesting a distribution that is approximately symmetrical around the mean. To validate this, we conducted normality tests, including the Shapiro–Wilk and Kolmogorov–Smirnov tests, both of which confirmed that the data adhere to a normal distribution. Furthermore, the visual inspection of the models presented in

Figure 2 further supports the assumption of a symmetric distribution.

Moreover, the high coefficient of determination (R2) for the log loader in relation to the average volume per tree (AVT) (A) and the number of crane movements (B) indicates a robust fit between the statistical models and the observed data. The strong positive linear correlation coefficients (r) observed in these models demonstrate not only excellent predictive accuracy but also a clear, direct relationship between the variables and the productivity of the machines.

The residual analysis of Models A and B confirms the statistical adequacy of the regression functions applied to estimate forest machine productivity (m3·h−1). Model A, with a Root Mean Square Error (RMSE) of 9.85 m3·h−1, corresponds to approximately 6.88% of the total range of observed productivity values (ranging from 98.79 to 241.99 m3·h−1), which reflects an acceptable level of predictive accuracy. In contrast, Model B presented a substantially lower RMSE of 4.81 m3·h−1, equivalent to about 2.4% to 2.7% of the range, indicating a more precise fit. This reduction in error suggests that Model B performs better, particularly at the lower and upper extremes of the explanatory variable, where Model A exhibited greater deviations.

Additionally, the residual distribution for both models shows no apparent systematic patterns and appears randomly scattered around zero, indicating that the models adequately capture the structural behavior of the data. The symmetric distribution of residuals further suggests the absence of bias in the predictions, with no consistent overestimation or underestimation. The assumption of homoscedasticity is also known, as the variance of residuals remains relatively stable across the range of inputs. Collectively, these findings support the statistical robustness and practical reliability of both models—especially Model B—for predicting productivity and informing decision-making in mechanized forest harvesting operations.

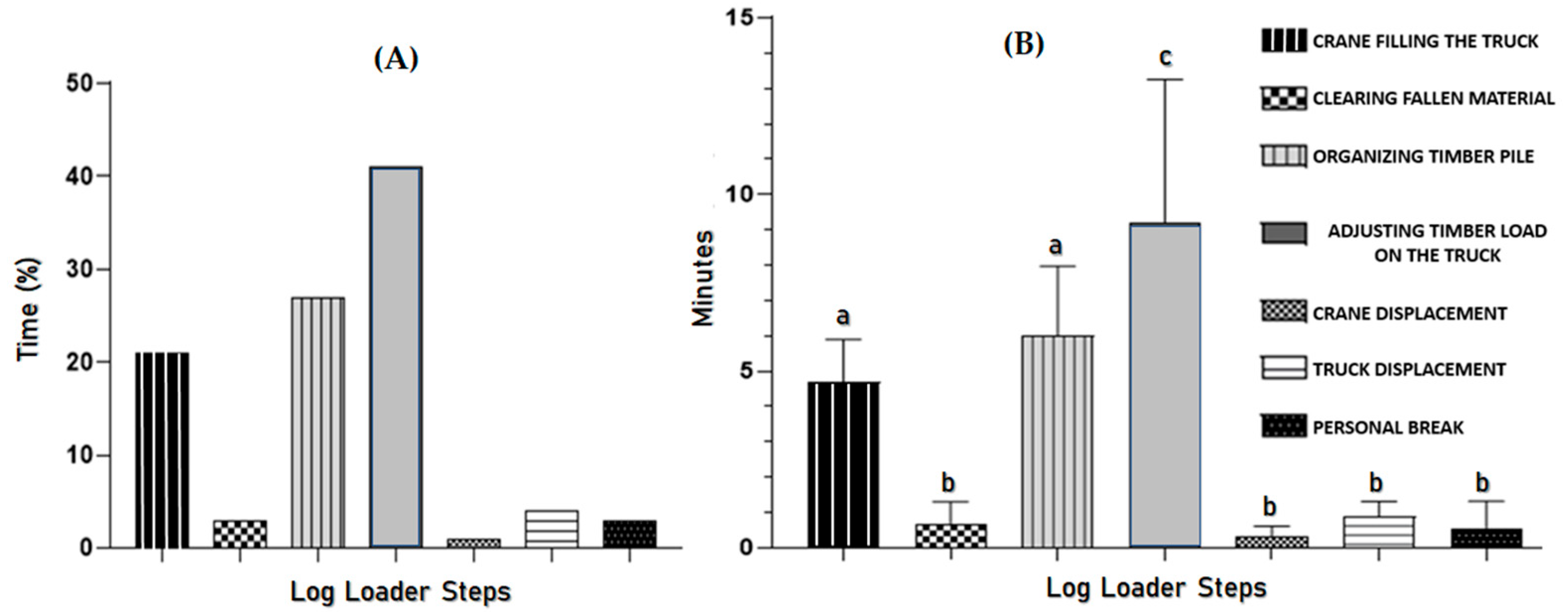

The study of productivity capacity based on the operational cycles of the log loader is presented in

Figure 3.

In the log loader operation, the stage of adjusting the wood on the timber stanchion semi-trailer platform was the phase with the highest time demand, accounting for 42% of the operational cycle. This step was statistically different from the other phases of the operational cycle. When adding the time spent on adjusting the wood in the truck to the time spent on organizing the pile, it reached 68% of the total cycle time. Therefore, the importance of the final extraction stage with the forwarder is underscored, as a well-organized woodpile during forwarder unloading will enhance the performance of the log loader by reducing the time spent on organizing the woodpile.

In the present study, the log loader demonstrated an average productivity of 185.51 m3·h−1, with a standard deviation of 62.70 m3·h−1. It has also been observed that during the operational cycle, operators tend to spend more time organizing the wood inside and outside the tri-train truck rather than actually loading the cargo box, highlighting the need to optimize this stage through focused training and work standardization.

The economic analysis of the log loader revealed an annual total cost of USD 507,570.66 and a total cost over its useful life of USD 2,537,853.30. Based on these results, cost projections associated with operational variables and forest productivity were estimated and are presented in

Table 4 and

Table 5.

The study conducted with the log loader was carried out in forest plantations with varying productivity levels, and the results indicate a reduction in costs as the average volume per tree (AVT) increases, with a tendency for cost stabilization in forests with a higher AVT. In this context, working in forests with a higher AVT led to a cost reduction of up to 44%. Loading logs with larger diameters is likely associated with reduced work for the grapple, as it decreases the time required for pile organization and wood adjustment on truck trailers. This finding is supported by the operational cycle study.

On the other hand, the analysis of cost variation with the number of log loader movements revealed that costs have an inverse relationship with the number of movements. When the machinery performs fewer movements, the calculated cost was 0.19 USD/m3. However, if the machine spends more time performing tasks such as organizing wood within the truck’s cargo box or adjusting the woodpile, the costs can reach up to 0.76 USD/m3, representing an increase of up to 154% in loading costs.

4. Discussion

When comparing the productivity of the log loader across forests with different average volume per tree (AVT) values (

Figure 2A), an increase of up to 50.85% is observed as the AVT increases. The analysis was based on AVT classes ranging from 0.07 to 0.30 m

3/tree. However, this upward trend does not persist beyond certain thresholds. The fitted model shows a tendency toward productivity decline in AVT classes above 0.25 m

3/tree. Since the model was calibrated using data up to 0.30 m

3/tree, this reduction was confirmed within that range (RMSE = 9.85, R

2 = 0.95, r = 0.90). Further studies are recommended to assess whether this pattern reflects a productivity plateau or a more significant decrease beyond the observed interval.

This behavior is mainly attributed to an increasing operational complexity in wood organization during the piling and truck loading stages in areas with a higher AVT. Proper log arrangement inside the truck is essential to avoid overloading or underloading, thus ensuring transport efficiency. Given that transport costs are generally much higher than in-field loading costs, the optimization of truck loading becomes a key factor in sustaining operational performance.

In this context, the logistical planning of timber transportation must rigorously consider appropriate loading conditions, given the high volume of supply and demand in contrast with the limited payload capacity of trucks, which necessitates a substantial number of trips to meet operational requirements [

30]. In some countries with a well-established forestry sector, such as Chile, the delivery of logs to sawmills may account for more than 45% of the total operational costs [

31]. Thus, implementing transport optimization strategies is essential to ensure cost-effectiveness and maintain the competitiveness of the forestry value chain [

32].

One such strategy involves the synchronization of trucks and loaders, which has been identified as an effective approach in reducing idle time during loading operations, thereby enhancing resource efficiency and overall system productivity [

30]. Moreover, the moisture content in wood plays a critical role in transportation costs, as a higher water content increases the total load weight, leading to elevated fuel consumption and greater mechanical wear on transport equipment [

33].

Supporting these findings, previous research has emphasized that the productivity of loading and unloading operations is influenced by a combination of factors, including the terrain slope, precipitation intensity, type of equipment used, and the level of operator training [

34].

The model of the log loader concerning crane movements indicates an increase of up to 177.33% in machinery productivity with a reduction in crane movements. This finding warrants further investigation into the operational cycle, as efficient operation of the log loader does not necessarily translate to optimal loading of the tri-train truck. Nonetheless, it underscores the need to optimize this operation to establish an ideal working range. According to Arcego et al. [

12], increasing the log length from 2.40 m to 7.00 m improves the loading and unloading performance due to a positive impact on system efficiency, particularly in crane operations.

When analyzing the descriptive statistics and linear correlation of the variables, the coefficients of determination found exceed those reported by Masioli et al. [

11], who investigated the performance of the log loader under similar conditions. The author also highlighted the significant time required for adjusting the wood in the loading area of transport vehicles. This factor is directly linked to the quality of the loading process and can lead to high transportation costs if not properly managed. According to Ghaffariyan [

8] and Belisario et al. [

35], increasing the log length can enhance loading and transportation efficiency; however, this outcome depends on the final use of the product in the manufacturing facility.

Regarding the coefficients of variation (CV), the log loader exhibited moderate variability in relation to the average volume per tree (AVT) (A). In contrast, its productivity showed high variability in low-productivity forests as a function of the crane movements (B). This indicates a need for optimization and standardization of the machine’s operations, particularly following time and motion studies [

36,

37]. These statistical approaches provide deeper insights into the variations in the operational cycle times, costs, and productivity of forestry equipment, aiding in informed decision-making and the optimization of loading processes [

2,

30,

38].

Although the initial investment required to acquire larger machinery is higher, these machines are expected to offer superior productivity and a lower unit cost per cubic meter. Studies, such as those by Lindroos [

39] and Gülci and Erdaş [

40], discuss how the loading and unloading stages consume a large portion of the operational time. It is also important to note that the shape and positioning of wood stacks at the edges of the stand can impact both the operational cycle times and the efficiency of the loading crane.

Comparison of log loader operating cycles indicates that an increase in the number of log loader movements results in a decrease in machine productivity (m3 h−1). The log loader’s stages of personal breaks, truck movement, crane movement, and debris cleanup were not statistically different.

The study observed that with an increase in the number of repetitions of the operational cycle, the time spent on the crane filling the truck tends to decrease proportionally, as the machine spends more time performing tasks related to organizing the woodpile outside the truck and adjusting the wood inside the truck. This highlights the need to optimize this stage, as the proper adjustment of wood in the truck’s cargo box is essential to avoid underestimating the transport capacity to the manufacturing unit due to excess empty spaces in the wood stacking [

41].

In this context, the loading activity takes place on forest roads, which present unfavorable conditions compared to the yard at the processing facility [

42,

43]. Moreover, it is important to highlight that loading and timber transportation are complementary processes with interconnected costs, as they occur concurrently on forest roads [

44,

45].

The average productivity of the log loader obtained in this study (185.51 m

3·h

−1) is substantially higher than that documented by Simões et al. [

46], who reported an average operational productivity of 94.75 m

3 h

−1. The significant variability of these data can be assigned mainly to the level of training and experience of the operators. Thus, the importance of human factors in operational efficiency is highlighted, suggesting that continuous improvement in operator skills can lead to significant productivity gains [

4,

7,

10,

47,

48].

Analyzing operational cycle times, the time and motion study demonstrates that the most time-consuming part of the timber loading operation is moving the load onto the truck [

18]. However, it is crucial to note that faster work by the log loader does not necessarily result in proper loading. Inadequate stacking of the logs can lead to underutilized space within the truck bed, with excessive empty areas between or around the logs. This results in reduced payload efficiency and an increased number of trips required to transport the same volume of timber [

41]. Such inefficiencies highlight the importance of investing in operator training and process standardization. With proper preparation, the task can be performed more efficiently and with fewer movements, ultimately optimizing loading performance and reducing transportation costs [

49,

50].

To maximize the economic efficiency of the loading phase, this study recommends prioritizing the use of logs with greater length and diameter. Additionally, standardizing operations through proper alignment of wood stacks along forest roads and establishing a single direction of movement for tri-train trucks are essential. It is also crucial to enhance the training of log loader operators, which will not only reduce productivity fluctuations but also ensure efficient loading, lower average operating costs, and minimize the risk of accidents [

51].

Additionally, it is important to consider that beyond the Average Individual Volume (AVT) and the number of movements required to perform the loading activity, various other factors influence the machine’s individual productivity, subsequently impacting the loading costs. These factors include operator experience, log size, forest density, species composition, forest management, forest rotation, topography, machine capacity, soil type, and climatic conditions [

19,

30,

52,

53,

54,

55]. Therefore, future studies should delve deeper into these aspects, as loading remains an underexplored area in the scientific literature when compared to forest harvesting and transportation.

5. Conclusions

This study indicates that predictive models for the log loader in loading tri-train trucks adequately explain productivity (m3·h−1). The economic analysis revealed that production costs are inversely proportional to the number of movements made by the log loader. In operations with fewer movements, the calculated cost is lower, whereas a higher number of movements results in significantly higher costs. These findings are consistent with the existing literature, which identifies load movement as a critical stage in wood loading operations.

The study demonstrates that the productivity of the machinery (m3·h−1) is directly proportional to forest productivity. Therefore, it is desirable for forestry companies to promote plantations with higher average volume per tree (AVT) classes. The results showed that log loader productivity increases with higher AVT values, although a trend toward cost stabilization is observed in stands with a high AVT. This indicates that, despite the potential for increased production costs, forests with a high AVT allow for greater operational efficiency, which contributes to keeping these costs more predictable and manageable. The study also highlighted that reducing crane movements is directly associated with lower loading costs, emphasizing the need for operational optimization and operator training to minimize such movements.

The productive capacity of the log loader revealed that 68% of the operational cycle is spent on wood adjustment and pile organization. The study provided significant insights into the efficiency and costs associated with using the log loader in forestry operations, revealing that factors such as the trunk size, forest density, soil type, and climatic conditions also play crucial roles in productivity and cost variability. Future studies should delve deeper into these factors to further understand their impact on forest operations and enhance the optimization of loading processes.