Abstract

Simulator training offers a safe and cost-effective approach to providing new operators opportunities to become familiar with operating modern machinery. However, in Korea, the current programs are insufficient in training skilled operators capable of handling advanced forestry machinery. Consequently, these programs fall short of developing the required technical expertise, leading to difficulties in workforce employment. We compared the performance of simulator-trained participants with that of machine-trained participants by testing operators on real equipment and assessing their stress levels. Participants were categorized as those with and without excavator certificates. Within each category, participants were further divided into those receiving training via simulators or those who were trained using actual equipment. Although we detected no significant differences in the overall performance of simulator- and machine-trained participants, compared with real machine training, simulator training promoted better performance, lower levels of frustration, and a reduced mental workload due to the safer and more controlled virtual environment. These findings can be used to develop more effective training programs by incorporating simulator-based modules that enhance skill acquisition whilst reducing risks. They can also inform policy decisions to improve workforce training in industries dependent on the operation of advanced machinery, thereby ensuring that operators achieve higher levels of competence and safety.

1. Introduction

In South Korea (hereafter, Korea), approximately 70% of the total forested area is classified as steep terrain, with slopes of up to 100% in some locations [1]. Given the associated challenges of managing such forests, the Korean Forest Service has been working actively since the 1990s to expand the application of mechanized forestry practices supported by government policies to enhance the use of machinery in forestry [2]. To meet the demands of such challenging topographies, specialized machinery and techniques have been developed and are currently being utilized. The primary operation systems used in Korea include motor–manual felling combined with the use of small-shovel machines for the cut-to-length method, the use of tower yarders for longer tree lengths, and whole-tree operations on steep slopes [2]. However, although these systems remain standard, their use is physically demanding and pose significant risks to the safety of workers. In particular, cable logging is inherently more complex and expensive than ground-based harvesting methods [3,4].

By replicating real-world scenarios in a virtual environment and enhancing learning experiences by improving valuable skill sets, simulator technology provides an effective solution for workplace training and development [5,6,7]. For example, driving simulators offer on-demand training solutions that allow learners virtually immersive hands-on practice whenever required [8] and provide a cost-effective and entirely safe alternative for both the operator and the environment, whilst delivering practical guidance for completing essential tasks more efficiently than traditional machine-based training methods [9,10]. In addition, simulators can analytically measure vehicle dynamics and evaluate whether users respond appropriately to simulated situations, thereby providing a data-driven approach to training [11]. Consequently, simulator training would be particularly beneficial to the operators of forestry equipment, given the necessity for these workers to operate complex machinery in challenging environments [6,12]. However, simulated training has certain limitations, among which are limited instructor feedback, rigid learning plans, and challenges in skill transfer to real-world situations, owing to differences between the simulated and actual work environments [9,10]. Such limitations can accordingly hinder the practical applicability of simulator training during logging operations. Furthermore, there has to date been limited research assessing the efficacy of simulator training for forestry machine operators and the degree to which the skills acquired using simulators translate to real-world performance. Addressing these gaps is thus considered essential for optimizing simulator use in forestry training.

An alternative technology for forest harvesting is the ground-based harvesting system, which offers notable advantages with respect to improved safety and productivity whilst minimizing manual labor as mechanization continues to advance [13,14]. In recent years, winch-assisted or tethered timber harvesting systems have been rapidly adopted, particularly for use on steep terrains in regions such as North America and New Zealand [15]. These systems are designed to replace hazardous manual tree felling in cable yarding areas, thereby enabling safer and more efficient operations [16,17]. Furthermore, they facilitate cost-effective ground-based harvesting on slopes that were previously dependent on cable logging [18]. These systems can accordingly be utilized to enable safe and efficient mechanical harvesting in areas with steep terrains. Moreover, although ground-based systems offer operational advantages, they also pose environmental risks such as soil disturbance and erosion, which can be mitigated through the adoption of new technologies [19]. Although the safety and productivity benefits of mechanized harvesting are widely acknowledged, logging contractors in Korea continue to face two major challenges: a shortage of trained operators and the high capital investment required to operate advanced machinery [1]. To address these issues, the three forest training centers operated by the Korea Forestry Promotion Institute offer both theoretical and practical programs for forestry professionals and interested individuals. These programs, which are conducted in accordance with the Forestry and Mountain Villages Development Promotion Act, are of at least 3 weeks’ duration and cover machine operation, maintenance, and preparation for the national forestry technician certification exam. However, despite these efforts, recent surveys of logging business owners indicate that, in addition to a shrinking workforce, securing skilled operators remains a major challenge for sustaining successful operations [1]. Similarly, the findings from trainee surveys indicate that the current programs fall short in terms of equipping professional operators with advanced forestry machinery skills [20,21]. This deficiency thus provides evidence to indicate that the existing approaches to training do not adequately provide the technical expertise required in real-world logging environments. Consequently, without an improved training system and a well-prepared workforce, maintaining the long-term viability of Korea’s forest products industry will become increasingly difficult.

As an approach for addressing this problem, in this study, we investigated the potential application of simulator technology in enhancing workplace training, based on the development of virtual environments that replicate real-world scenarios. This approach is designed to enhance the learning experience and enable trainees to develop essential skills more effectively. Given the limited number of participants, the short training duration, and the sole use of flat terrain conditions, we framed this research as a preliminary study intended to explore the baseline feasibility of simulator-based training. Our primary objective in this study was to evaluate the potential utility of simulator-based training for operators of advanced forestry machinery, with an initial focus on flat terrain. Specifically, through a comparison with traditional machine training methods, we sought to assess how simulator training influences skill acquisition, operational proficiency, and the associated workload and stress. By addressing both skill development and psychological factors, we undertook a comprehensive evaluation of simulator training as a viable solution to enhance the workforce capabilities in the forestry sector.

2. Materials and Methods

2.1. Training Program

The study was completed during the summer of 2023 at the Korea Forest Science High School training site, Bongwha-gun, Gyeongsangbuk-do. Simulator training took place in a classroom at the high school. The 1-week course comprised 5 days of real equipment and simulator exercises, during which we trained a total of twelve 18-year-old male high school students majoring in forestry who had no prior experience of operating logging equipment. This group of students, selected by the school authorities, included six participants holding an excavator license, whereas the remaining six did not. The students in each of these two sub-groups were further categorized into those who were trained using actual equipment (3 participants) and those who trained using a simulator (3 participants). For safety purposes, participants using actual equipment were assisted by an experienced operator when in the cab of a forwarder.

The forwarder used in this study was a PONSSE Buffalo (Figure 1), a versatile and reliable forwarder model produced by the Finnish company Ponsse, which designs and manufactures advanced harvesters and forwarders. The same company also developed the simulator used in this study, which is designed to enhance training and produce more experienced operators, thereby making the process more economical, effective, and safe [22]. The simulator we used was a PONSSE basic simulator (PONSSE, Vieremä, Finaland; Figure 2). This technology includes a Scorpion harvester and Buffalo forwarder, as well as a standard basic Sim Trainer training management system. This simulator is equipped with forwarder joysticks, which are similar to those used in the actual machines.

Figure 1.

Testing site for an actual forwarder machine (a) and the simulator (b).

Figure 2.

PONSSE basic simulator (photo by PONSSE, 2024).

Training using both the actual equipment and a simulated forwarder was provided to the 12 participants over the course of 4 days, totaling 8 h of training (2 h per day) for each (Table 1). The training components followed those pre-programmed into the PONSSE simulator and were replicated at the training site for the machine training group. Only a single machine or simulator was available for each training session, so all participants rotated between practicing using the machine or the simulator. Each participant was able to achieve between one and five rotations (loading and unloading operations) in the 2 h allotted for each training module.

Table 1.

A sample schedule for the participants in the study.

2.2. Evaluation of Operator Performance

Participants in the machine-trained group performed a test task on a real forwarder both before the start of training and at the end of each day of training. In contrast, those in the simulator-trained group completed a test task on a real forwarder prior to training and after having completed 4 days of training to minimize the influence of operating real equipment on their learning curve. Furthermore, after each 2 h simulator training session, students were required to complete a standardized assessment task adapted from the PONSSE Sim Trainer training. To contextualize the difficulty level of the assigned test task, a baseline completion time was obtained from the only three individuals in Korea with prior forwarder operation experience. The average completion time of 3.8 min was used as a reference for evaluating the participants’ relative learning progress. To assess machine operation skills and task performance, the participants were presented with a scenario in which they loaded six logs and neatly stacked the transported logs next to the road to complete the task. As the simulator was insufficient with respect to evaluating the time spent driving (beginning when the six logs were loaded and ending when the forwarder reached the landing), we excluded this part when assessing the learning effect. The trainer was instructed to avoid providing the participants with tips or information that could help improve their performance during the testing sessions.

A time-and-motion study was conducted to assess each loading and unloading element. Lopes et al. [23] noted that trainees experienced more difficulty in completing log loading and unloading tasks, as they were unable to gain a clear view when using a simulator device. Accordingly, for the purposes of the present study, we defined loading as commencing when the operator moved the grapple loader to load a pile of logs and ending when the logs were placed in a bunk. Unloading commenced after the forwarder reached the landing and ended when all the logs were unloaded onto a pile or truck. Forwarder activities were recorded via a digital camera mounted on the cabin. This technology facilitated an accurate assessment of the time taken to complete each work element in the assessment task. Prior to analysis, each delay and machine activation and deactivation was identified and isolated from the data.

2.3. Evaluation of Operator’s Workload

After completing each skill test, participants were requested to complete a confidence, anxiety, and workload survey [the National Aeronautics and Space Administration (NASA) Task Load Index (TLX)], which was initially developed for use in the aviation industry by NASA’s Human Performance Research Group and is the most widely applied tool for assessing procedural workloads after completing a task [24,25]. The frequent use of this method can be attributed to its practical advantages (i.e., its readiness of implementation and non-intrusiveness) and the continuous data it provides, which contribute to the assessment of an operator’s mental load [26]. Moreover, the NASA-TLX is a multidimensional tool designed to assess workload scores across six dimensions; three measure (mental, physical, and temporal) demands and three (performance, effort, and frustration) assess task responses. We therefore used the NASA-TLX questionnaire to analyze the mental workload of participants and evaluate differences based on the training methods.

2.4. Statistical Analysis

For statistical analyses, we used R statistics software version 4.3.1. Prior to performing comparative tests, we prepared the dataset by performing the necessary preprocessing steps, including checks for normality using the Shapiro–Wilk test and for the homogeneity of variances using Levene’s test, to ensure data integrity and suitability for analysis. Using the t-test function in R, we assessed the significance of the differences between the mean values obtained for the groups under study, namely, the differences in the task performance ability of participants with and without an excavator certification prior to training and differences in the performance, levels of confidence, anxiety, and mental workload of simulator- and machine-trained students after completing the training. A significance level of 0.05 was applied for all statistical tests. This comprehensive analysis thus provided valuable insights into the effects of the respective training methods.

3. Results

3.1. Comparison of Operators’ Performance

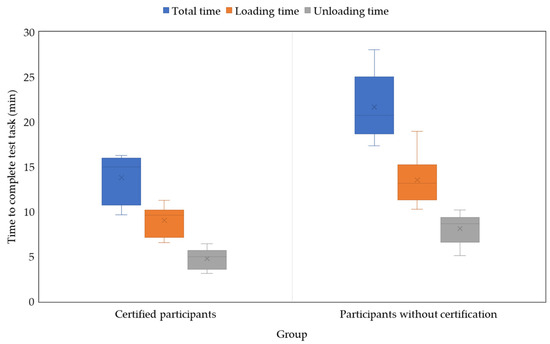

Prior to training, the average task completion time for participants who held an excavator license was 13.8 min (13 min 47 s, SD = 1.12 min), whereas those without a license took 21.7 min on average (21 min 39 s, SD = 1.56 min) (Figure 3), a difference which was statistically significant (p = 0.002). This difference was also evident when the tasks were divided into loading and unloading operations (p < 0.001).

Figure 3.

Within-group variation for certified and non-certified participants in performance when using forwarder, averaged across all testing sessions.

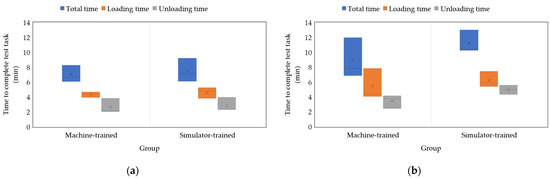

Having completed a total of 8 h of training, an analysis of the trainees’ performance revealed that when targeting certified participants, there was no significant difference in the overall performance between the simulator and machine training groups (p > 0.05; Figure 4a), with the simulator-trained group averaging 7.5 min (7 min 28 s, SD = 0.91 min) and the machine-trained group averaging 7.0 min (7 min 1 s, SD = 0.64 min. This lack of a significant difference between the groups applied to both the loading and unloading operations (p > 0.05). Thus, simulator-based training enabled participants to achieve comparable task performance to that of those who had undergone machine-based training.

Figure 4.

Within-group variation in performance for certified (a) and non-certified (b) groups trained on forwarder, averaged across all testing sessions.

Similarly, for those without certification, we detected no significant differences in the performance of participants undertaking training using the two methods (p > 0.05; Figure 4b), with the simulator-trained individuals averaging 11.2 min (11 min 13 s, SD = 0.89 min) and those undertaking machine training averaging 8.9 m (8 min 53 s, SD = 1.56). Consistently, no significant differences were found between the training methods in either the loading or unloading tasks (p > 0.05), suggesting that simulator training did not negatively impact the task performance.

Upon the completion of training on the actual equipment, the performance of certified participants was similar to that of those without certification (p > 0.05). In contrast, the simulator training results revealed a significant difference in the performance of the participants in the two groups (p = 0.041). These results suggest that while machine-based training helped to equalize the performance of certified and non-certified participants, simulator-based training may require additional adjustments to fully bridge initial skill gaps.

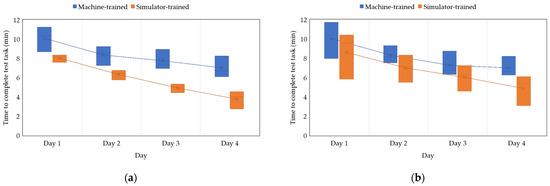

In terms of proficiency, for both machine- and simulator-trained participants, we detected a reduction in the time required to complete the test task over the course of the training period (Figure 5). Although the simulator-trained group exhibited a trend toward more rapid improvement during the training sessions, this should not be interpreted as demonstrating superior training efficacy, given that each group was evaluated within the same type of environment in which they trained. That is, the machine-trained group was evaluated using a machine and the simulator-trained group using a simulator. In addition, we detected a general reduction in the within-group variance over time, which indicates that participants’ performances became more consistent as training progressed. Furthermore, we observed no extreme outliers in any of the test sessions, thereby indicating a relatively uniform training effect among the assessed participants.

Figure 5.

Within-group variation in performance in each testing session for certified (a) and non-certified (b) participants.

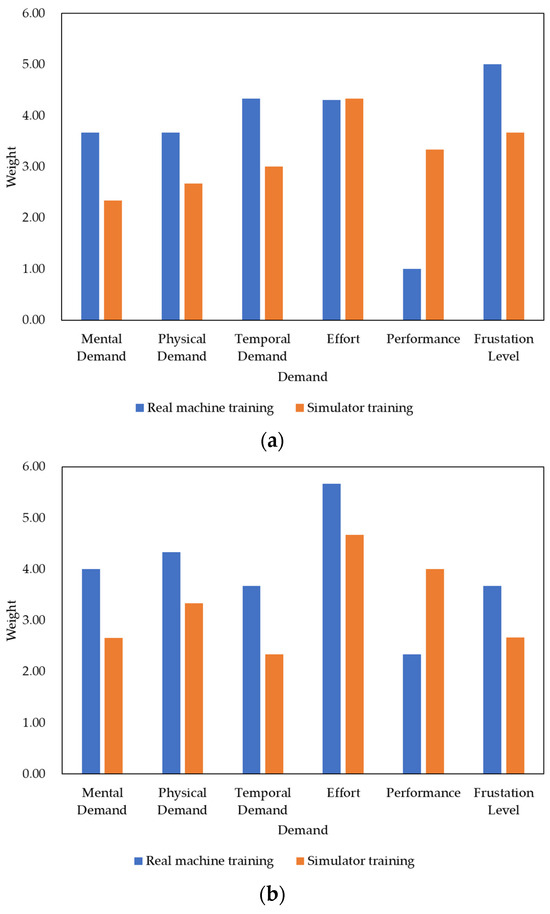

3.2. Perceived Levels of Confidence, Anxiety, and Mental Workload

Regardless of whether they were certified, we detected no significant differences between the machine- and simulator-trained individuals with respect to their levels of confidence (p > 0.05; Figure 6). However, compared with participants who underwent simulator training, trainees who were trained on real machines tended to be characterized by a lower degree of confidence on average, which may be attributed to the higher physical demands and perceived operational risks associated with machine handling. Compared with those receiving real machine training, the participants trained using the simulator obtained higher performance scores (p > 0.05), thereby providing evidence that the latter individuals felt more comfortable in a virtual setting in which they had better control and had to contend with fewer risks. Participants’ levels of frustration, which can reflect anxiety, were generally higher during real machine training than during simulator training, indicating that real equipment operation may impose greater psychological stress compared to simulator-based exercises. In contrast, the participants felt less frustrated during the simulator training, presumably reflecting the fact that the virtual environment reduced the pressure and provided a more controlled learning experience. Consistently, our evaluation of the mental workload based on the mental, temporal, and effort demands revealed that most participants experienced greater cognitive strain during machine training, particularly due to the effort required and time constraints, which were likely due to the need for precise control and rapid decision-making in real-world operations.

Figure 6.

Average weights of the workload measures for the machine and simulator training groups for certified (a) and non-certified (b) participants based on the NASA-TLX survey (n = 3). The survey presented pairs of factors and asked operators to select the more important one. The number of times each factor was selected determined its weight.

4. Discussion

Forest machine operations can achieve high productivity levels, and skilled operators are essential to maximize the return on the investment in the machinery [27,28]. However, a significant proportion of accidents occur among unskilled workers (i.e., those with less than one year of experience), including seasonal employees, young workers, and those newly entering the profession [29,30]. Operators’ performance is influenced by both their inherent aptitude and the skills acquired through training [9,31]. As a result, the competence requirements for forestry machine operators are high. Despite this, formal training systems for future operators remain underdeveloped or inconsistently implemented in many countries, particularly in Europe, the United States, and Korea. This reflects regional differences in mechanization levels. In Europe and the United States, fully mechanized operations are common, with a large number of harvesters and forwarders in use [14,32]. In contrast, Korea has adopted such systems to a much lesser extent, due to steep terrain, fragmented forest ownership, and a reliance on manual labor. These differences highlight the need for Korea-specific training methods, such as simulator-based instruction, which offers a safer and more accessible alternative to field-based training. To address the lack of structured training and the high competence requirements discussed above, simulator-based training has emerged as a promising approach in forestry education and operator skill development.

Simulator training benefits new and experienced drivers alike by enabling them to experience complex situations in a safe and controlled environment [11]. Moreover, individual simulator training can complement traditional training practices and address their weaknesses [7]. Previous studies evaluating the skills of forwarder operators involved 6 to 26 participants who trained on a simulator and machine for 26–40 h [9,23]. These studies found that heavy equipment simulators were effective training tools for all the assessed durations. For example, Polowy and Rutkowski [10] observed 11 trainees who received 15 h of training on a harvester simulator only. Similarly, So et al. [33] conducted simulator and real excavator training with eight participants over 10 h. In this study, after 8 h of training, participants (n = 12) in both the simulator and machine groups achieved comparable proficiency levels, suggesting that simulator training can effectively supplement traditional methods, particularly in the initial stages of skill acquisition. However, the learning curve was not conclusively determined, indicating the need for further research to assess when skill acquisition plateaus.

Despite the positive findings, this study is constrained by several limitations. First, the small sample size of twelve participants reduced the statistical power and generalizability of the findings, potentially leading to an underestimation or overestimation of the training effects. Additionally, the training duration was limited to 8 h, focusing solely on flat terrain. Given the prevalence of steep slopes in South Korea, future studies should extend the training periods and include diverse terrain simulations to comprehensively assess the transferability of skills acquired through simulator-based training.

Burk et al. [9] failed to detect any significant differences in the NASA-TLX weight scores obtained for simulator and machine training groups. However, operators trained on a machine had slightly higher weights for mental, physical, temporal, and frustration demands and lower weights for effort demands than those trained on a simulator, which aligns with our findings that machine-trained participants experienced higher overall demands, thereby potentially contributing to increased psychological stress during training. Nevertheless, despite the differing demands, operators’ performance appears to be influenced to a greater extent by their intrinsic motivation and effort than by the type of training, thereby possibly explaining the similar performance outcomes of the two groups [9]. In this regard, the Yerkes–Dodson law states that the stress associated with higher demands in machine training can enhance performance by increasing a trainee’s motivation and focus to an optimal level [34]. This could account for our findings that the performance of the machine- and simulator-trained participants did not differ significantly, despite differing reported levels of demands.

On the basis of our findings in this study, we can thus state that the learning outcomes for the assigned test tasks improved as a consequence of both simulator and machine training. The participants’ performance improved to a level closely approaching the baseline completion time of 3.8 min established by experienced operators, indicating substantial learning progress. However, it remains uncertain whether an 8 h training period is sufficient to fully prepare operators for the complexities of real-world forestry operations, particularly those involving steep terrain.

In this regard, Lopes et al. [23] and Burk et al. [9] are of the opinion that less than 30 h of training for each of the loading and unloading exercises would be insufficient for trainees to meet satisfactory operator performance standards. This lack of preparedness arises from the fact that training tasks are intentionally designed to be straightforward and, consequently, excelling in these tasks does not necessarily equate to having a full understanding of the complex challenges faced in a real operational environment.

Accordingly, future research should aim to extend the training and evaluation periods to gain a more complete insight into the efficacy of simulator-based training for novice operators in comprehensive programs. Moreover, it would be valuable to investigate the transformation of expert excavator operators in their 50s and 60s, who have had long careers and vast experience in the forestry industry, to advanced machine operators, given that this aspect was not addressed in the present study. Thus, further research is needed to facilitate their transition and efficacy and to gain a better understanding of the contribution of simulator training across the forestry sector.

Nevertheless, it is important to acknowledge that the relatively small sample size in this study may have limited the statistical power to detect significant differences between the groups. As a preliminary investigation, these findings should therefore be interpreted with caution. Future studies with larger sample sizes are necessary to validate and extend the current results, thereby providing a more robust and generalizable evaluation of simulator-based training’s efficacy in the forestry sector. Additionally, if resources permit, further studies should take into consideration the value of assessing larger sample sizes (more than 10 participants), which would contribute to facilitating a more robust evaluation of the efficacy of simulator training.

5. Conclusions

In this study, we evaluated the efficacy of simulator-based training compared with traditional machine training for novice forestry equipment operators. Our findings indicated that after a total of 8 h of training, the participants (n = 12) in the two groups showed similar levels of proficiency, suggesting that simulators can effectively facilitate skill acquisition to a degree comparable to that of conventional methods. In terms of operational proficiency, the simulator-trained participants achieved outcomes equivalent to those of the machine-trained participants, indicating that simulators may adequately prepare operators for basic machine handling tasks. Moreover, simulator training was found to enhance trainees’ confidence and reduce stress, which can be attributed to the safe and controlled environment provided by the virtual platform. Taken together, these results suggest that simulator training offers an efficient and psychologically supportive entry-level learning method, while avoiding the physical risks associated with real equipment operation. Nonetheless, the limited training duration and small sample size (n = 12) restrict the generalizability of these findings. To avoid drawing misleading conclusions based on these constraints, we adopted a conservative analytical approach and deliberately refrained from adjusting our interpretations based on test outcomes that may have been affected by individual variability. Given these limitations, future research should accordingly focus on evaluating the effects of extending the training period and thereby gain a more in-depth understanding of the long-term efficacy of simulator-based training. In addition, assessments based on larger sample sizes would contribute to a more robust evaluation of the potential role of simulator training in the forestry sector.

Author Contributions

Conceptualization, E.L. and H.M.; methodology, E.L., H.M., H.L. and S.P.; validation, E.L., H.M., H.L. and S.P.; formal analysis, E.L., H.M., H.L. and S.P.; investigation, E.L., H.M., H.L. and S.P.; resources, E.L., H.M., H.L. and S.P.; data curation, E.L., H.M., H.L. and S.P.; writing—original draft preparation, E.L.; writing—review and editing, E.L., H.M., H.L. and S.P.; visualization, E.L., H.M., H.L. and S.P.; supervision, H.M.; project administration, E.L. and H.M.; funding acquisition, H.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Korea Forest Service (grant number FO0200-2024-01-2024).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

This study would not have been possible without the generous support and contributions of our partnering organizations and educational institutions. Our partners include the Yurah Corporation in Seoul and the Korea Forest Science High School in Bongwha-gun, Gyeongsangbuk-do. We extend our heartfelt gratitude to everyone who participated in this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Korea Forest Service. Available online: https://www.forest.go.kr/kfsweb/kfs/idx/Index.do (accessed on 6 January 2015).

- Lee, E.; Choi, Y.; Cho, M.; Cho, K.; Oh, J.; Han, S.; Im, S. A literature review on cable extraction practices of South Korea: 1990–2020. Forests 2021, 12, 908. [Google Scholar] [CrossRef]

- Visser, R.; Harrill, H. Cable yarding in North America and New Zealand: A review of developments and practices. Croat. J. Eng. 2017, 38, 209–217. [Google Scholar]

- Eber, G.; Visser, R.; Leitner, S.; Harrill, H.; Spinelli, R.; Picchio, R.; Varch, T.; Stampfer, K. Advance in cable yarding: A review of recent developents in carriers for mobile skyline cable yarding. Curr. For. Rep. 2025, 11, 14. [Google Scholar] [CrossRef]

- Rolfe, J.M.; Caro, P.W. Determining the training effectiveness of flight simulators: Some basic issues and practical developments. Appl. Ergon. 1982, 13, 243–250. [Google Scholar] [CrossRef] [PubMed]

- Burk, E.; Han, H.-S.; Smidt, M.; Fox, B. Incorporating simulators into a training curriculum for forestry equipment operators: A literature review. Croat. J. Eng. 2024, 45, 199–215. [Google Scholar] [CrossRef]

- Marcano, L.; Komulainen, T.M.; Haugen, F.A. Implementation of performance indicators for automatic assessment. Comput. Aid. Chem. Eng. 2017, 40, 2971–2976. [Google Scholar] [CrossRef]

- Sanchez, D.R.; Rueda, A.; Kawasaki, K.; Van Lysebetten, S.; Diaz, D. Reviewing simulation technology: Implications for workplace Training. Multimodal Technol. Interact. 2023, 7, 50. [Google Scholar] [CrossRef]

- Burk, E.; Han, H.-S.; Smidt, M.; Fox, B. Effectiveness of simulator training compared to machine training for equipment operators in the logging industry. Int. J. Eng. 2023, 34, 373–384. [Google Scholar] [CrossRef]

- Polowy, K.; Rutkowski, D. Learning curves of harvester operators in a simulator environment. Forests 2024, 15, 1277. [Google Scholar] [CrossRef]

- Alonso, F.; Faus, M.; Riera, J.V.; Fernandez-Marin, M.; Useche, S.A. Effectiveness of driving simulators for drivers’ training: A systematic review. Appl. Sci. 2023, 13, 5266. [Google Scholar] [CrossRef]

- Ovaskainen, H. Comparison of harvester work in forest and simulator environments. Silva Fenn. 2005, 39, 89–101. [Google Scholar] [CrossRef]

- Visser, R.; Stampfer, K. Expanding ground-based harvesting onto steep terrain: A review. Croat. J. Eng. 2015, 36, 321–331. [Google Scholar]

- Bacescu, N.M.; Cadei, A.; Moskalik, T.; Wiśniewski, M.; Talbot, B.; Grigolato, S. Efficiency assessment of fully mechanized harvesting system through the use of fleet management system. Sustainability 2022, 14, 16751. [Google Scholar] [CrossRef]

- Holzfeind, T.; Visser, R.; Chung, W.; Holzleitner, F.; Erber, G. Development and benefits of winch-assist harvesting. Curr. For. Rep. 2020, 6, 201–209. [Google Scholar] [CrossRef]

- Chung, W.; Morrissette, B.; Green, P.; Garrelts, B.; Leshchinsky, B.; Belart, F.; Sessions, J.; Wimer, J.; Garland, J. Effects of pre-bunching trees with a tethered Feller-Buncher on cable logging productivity and costs: A case study in Southern Oregon. Forest Sci. 2022, 68, 325–333. [Google Scholar] [CrossRef]

- Visser, R.M.; Spinelli, R. Benefits and limitations of winch-assist technology for skidding operations. Forests 2023, 14, 296. [Google Scholar] [CrossRef]

- Belart, F.; Leshchinsky, B.; Sessions, J.; Chung, W.; Green, P.; Wimer, J.; Morrissette, B. Sliding stability of cable-assisted tracked equipment on steep slopes. For. Sci. 2019, 65, 304–311. [Google Scholar] [CrossRef]

- Latterini, F.; Spinelli, R.; Venanzi, R.; Picchio, R. Focus on ground-based extraction systems: Is skidding really more impactful than forwarding? For. Ecol. Manag. 2024, 551, 121514. [Google Scholar] [CrossRef]

- Kim, J.-H.; Mun, H.-S.; Han, S.-Y.; Park, S.-J. An analysis on the situation of forestry mechanization in the production and supply of timber. J. Korean For. Soc. 2015, 104, 607–614. [Google Scholar] [CrossRef]

- National Institute of Forest Science. A Study on Improving the Training System for Professional Technicians and the Efficient Operation of Distributed Forestry Machinery; Report 23-24; National Institute of Forest Science: Seoul, Republic of Korea, 2024; ISSN 11-1400377-001524-01. [Google Scholar]

- PONSSE Simulators; PONSSE: Vieremä, Finland, 2024; pp. 1–8.

- Lopes, E.D.S.; Oliveira, D.D.; Da Silva, P.C.; Chiqueto, A.L. Evaluation of operator’s performance training with forwarder simulator. Cien. Florest. 2010, 20, 179–189. [Google Scholar]

- Said, S.; Gozdzik, M.; Roche, T.R.; Braun, J.; Rössler, J.; Kaserer, A.; Spahn, D.R.; Nöthiger, C.B.; Tscholl, D.W. Validation of the raw National Aeronautics and Space Administration Task Load Index (NASA-TLX) questionnaire to assess perceived workload in patient monitoring tasks: Pooled analysis study using mixed models. J. Med. Internet Res. 2020, 22, e19472. [Google Scholar] [CrossRef] [PubMed]

- De la Torre, G.G.; Ramallo, M.A.; Cervantes, E. Workload perception in drone flight training simulators. Comput. Hum. Behav. 2016, 64, 449–454. [Google Scholar] [CrossRef]

- Hart, S.G.; Staveland, L.E. Development of NASA-TLX (Task Load Index): Results of empirical and Theoretical Research. In Human Mental Workload; Elsevier: Amsterdam, The Netherlands, 1988; pp. 139–183. [Google Scholar] [CrossRef]

- Kirk, P.; Byers, J.; Parker, R.; Sullman, M. Mechanisation developments within the New Zealand Forest Industry: The human factors. Int. J. Eng. 1997, 8, 75–80. [Google Scholar]

- Purfürst, F.T. Learning curves of harvester operators. Croat. J. For. Eng. 2010, 30, 89–97. [Google Scholar]

- Milburn, J.S. Injuries on Mechanized Logging Operations in the Southeastern United States. Master’s Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 1998. [Google Scholar]

- FAO, ILO, United Nations. Occupational Safety and health In the Future of Forestry Work; Forestry Working Paper, No. 37; FAO, ILO, United Nations: Rome, Italy, 2023; p. 2. [Google Scholar]

- Rutkowska, A.; Adamowicz, K. Educational Aspects of the Profession of ‘Forest Machinery Operator’ in View of Survey Results. For. Res. Pap. 2019, 79, 199–206. [Google Scholar] [CrossRef]

- Green, P.Q.; Chung, W.; Leshchinsky, B.; Belart, F.; Sessions, J.; Fizgerald, S.A.; Wimer, J.A.; Cushing, T.; Garland, J.J. Insight into the productivity, cost and soil impacts of cable-assisted harvester-forwarder thinning in Western Oregon. For. Sci. 2020, 66, 82–96. [Google Scholar] [CrossRef]

- So, J.C.Y.; Macrowski, L.M.; Dunston, P.S.; Proctor, R.W.; Goodney, J.E. Transfer of operator training from simulated to real hydraulic excavators. In Proceedings of the 2016 Construction Research Congress, San Juan, PR, USA, 31 May–2 June 2016. [Google Scholar] [CrossRef]

- Yerkes, R.M.; Dodson, J.D. The Relation of Strength of Stimulus to Rapidity of Habit Formation. J. Comp. Neurol. 1908, 18, 459–482. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).