Potential of Oil Palm Wood Thermally Modified via Hot Press Machine for Eco-Friendly Wall Insulation Applications

Abstract

1. Introduction

2. Materials and Methods

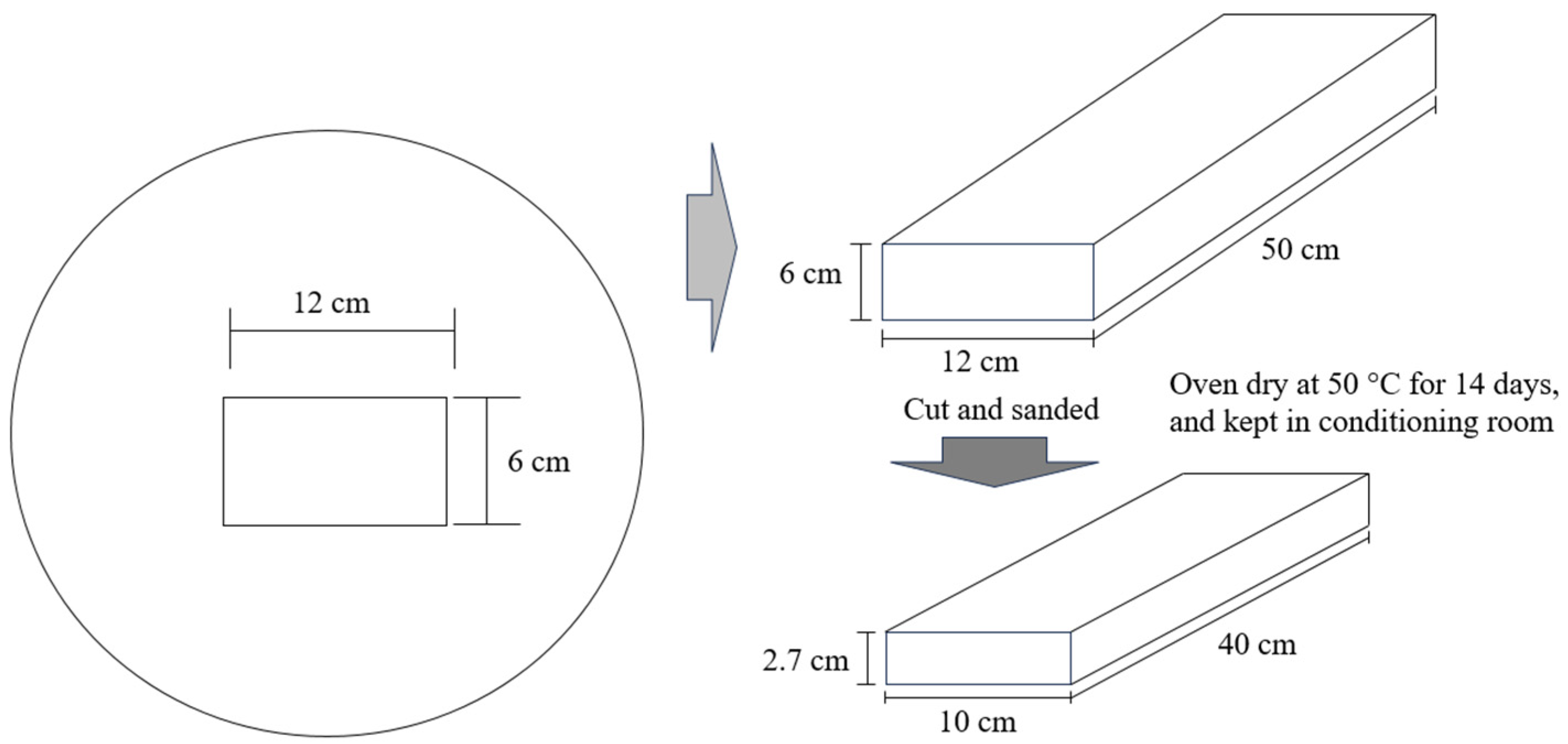

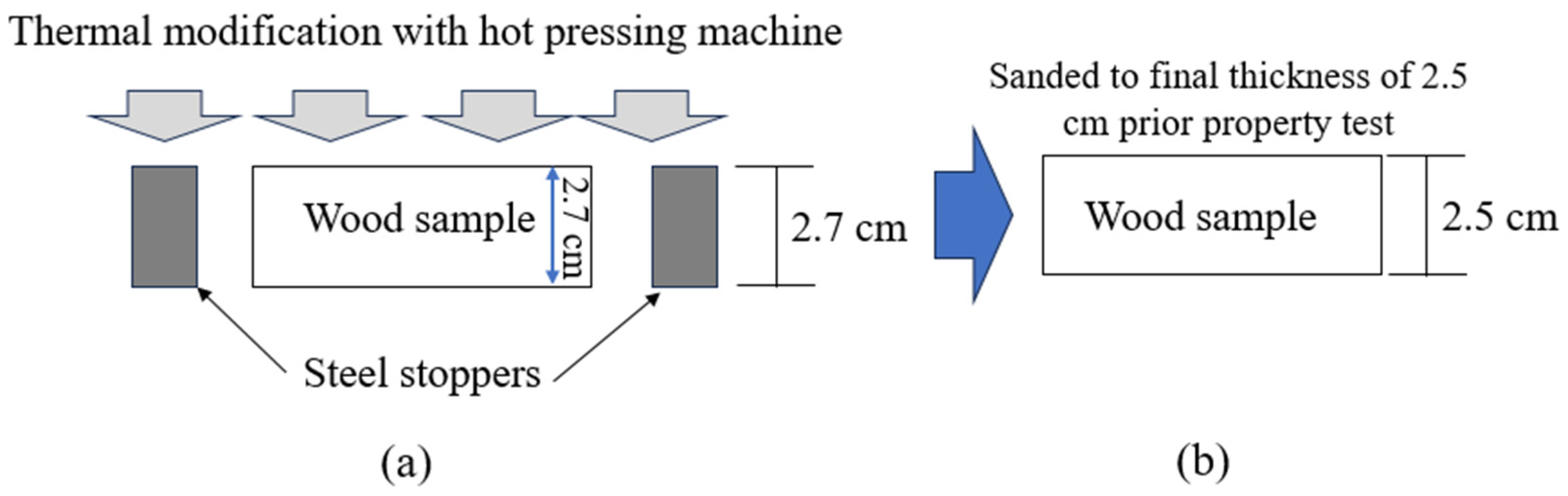

2.1. Preparation of TM Oil Palm Wood

2.2. Property Tests of TM Oil Palm Wood

- Mass Loss (ML)

- Density ()

- Dimensional Stability

- Thermal Conductivity (k)

- Sound-Absorption Property

- VOC Emissions

3. Results

3.1. Properties of Thermally Modified Oil Palm Wood

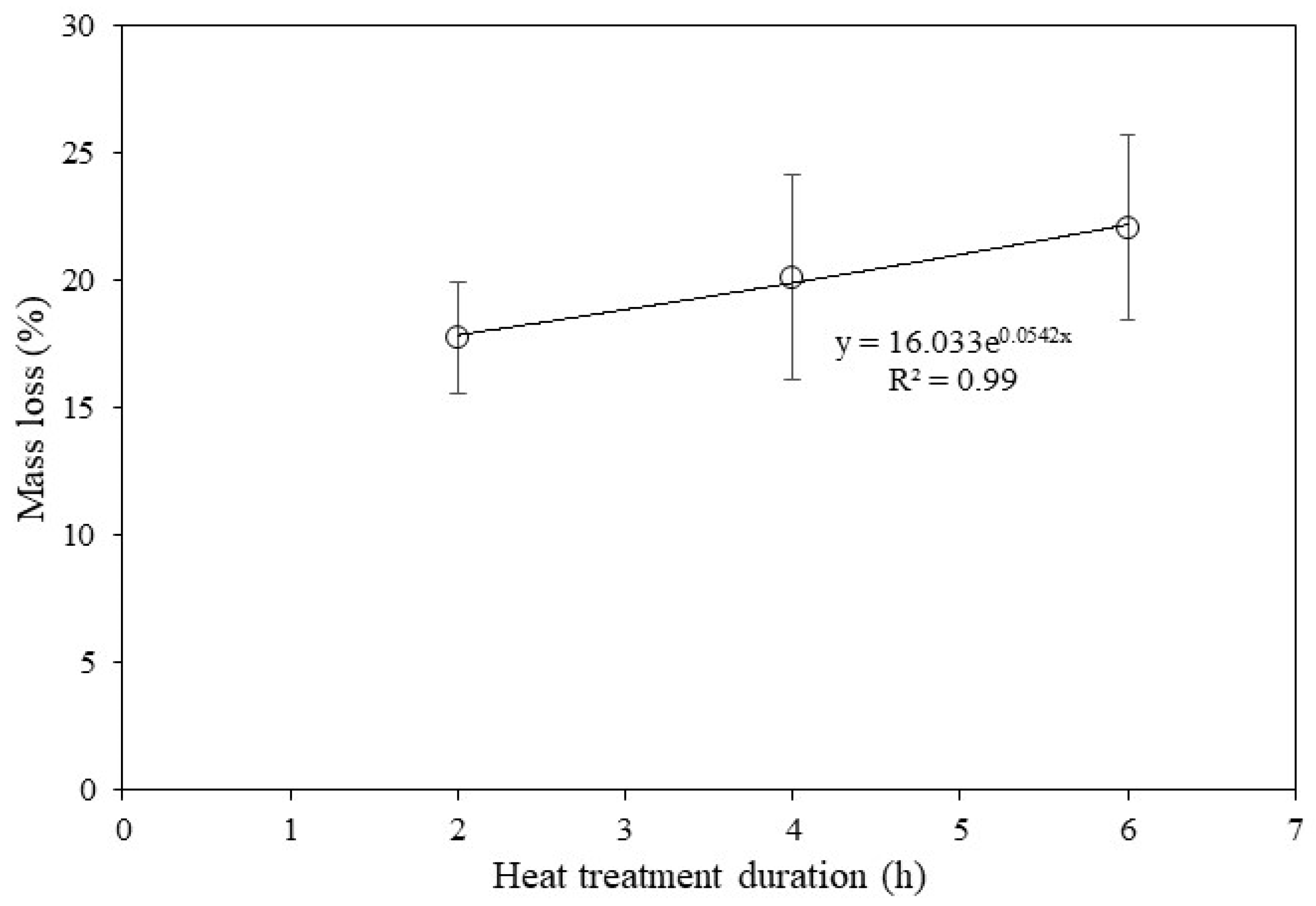

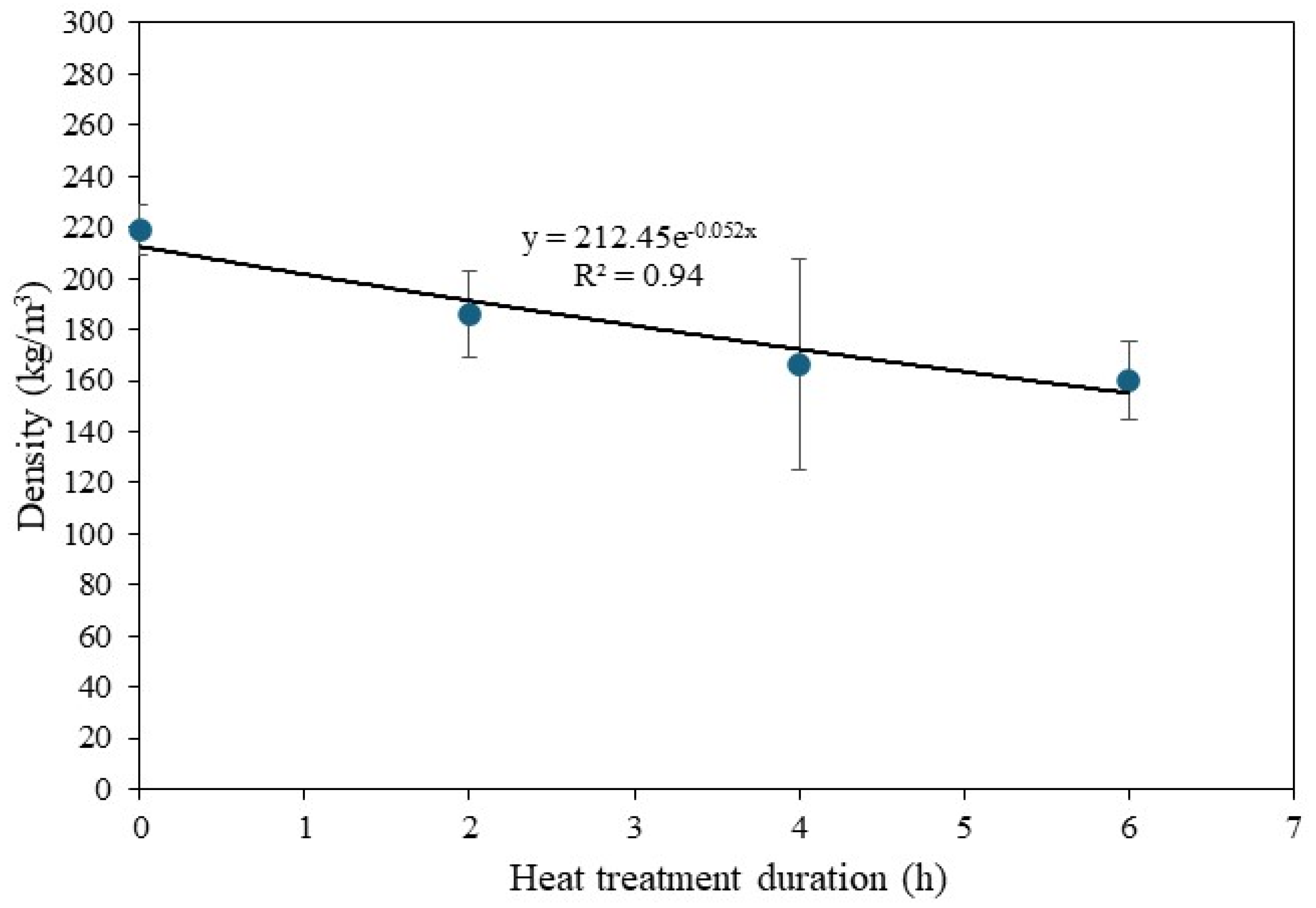

3.1.1. Mass Loss and Density

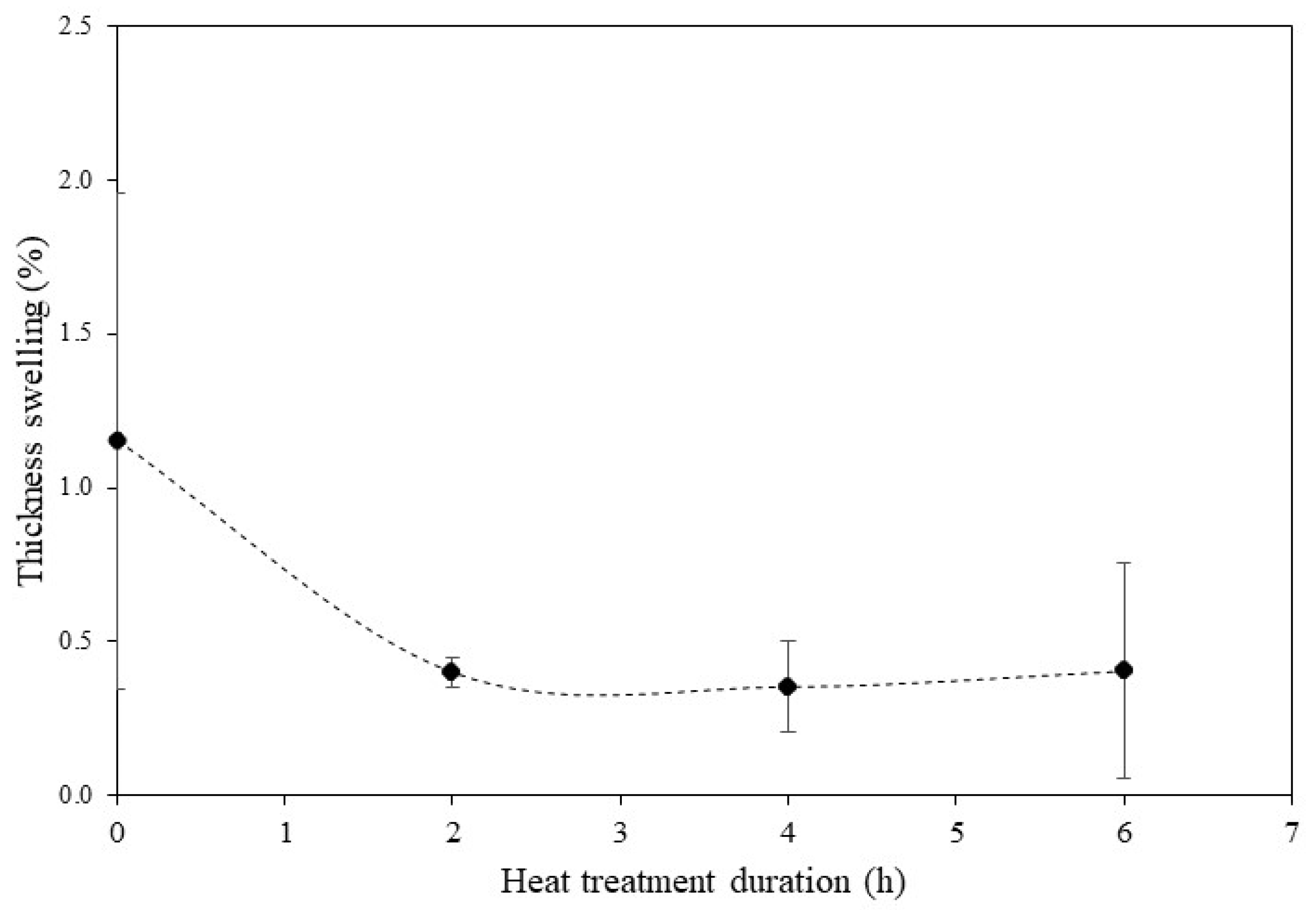

3.1.2. Dimensional Stability

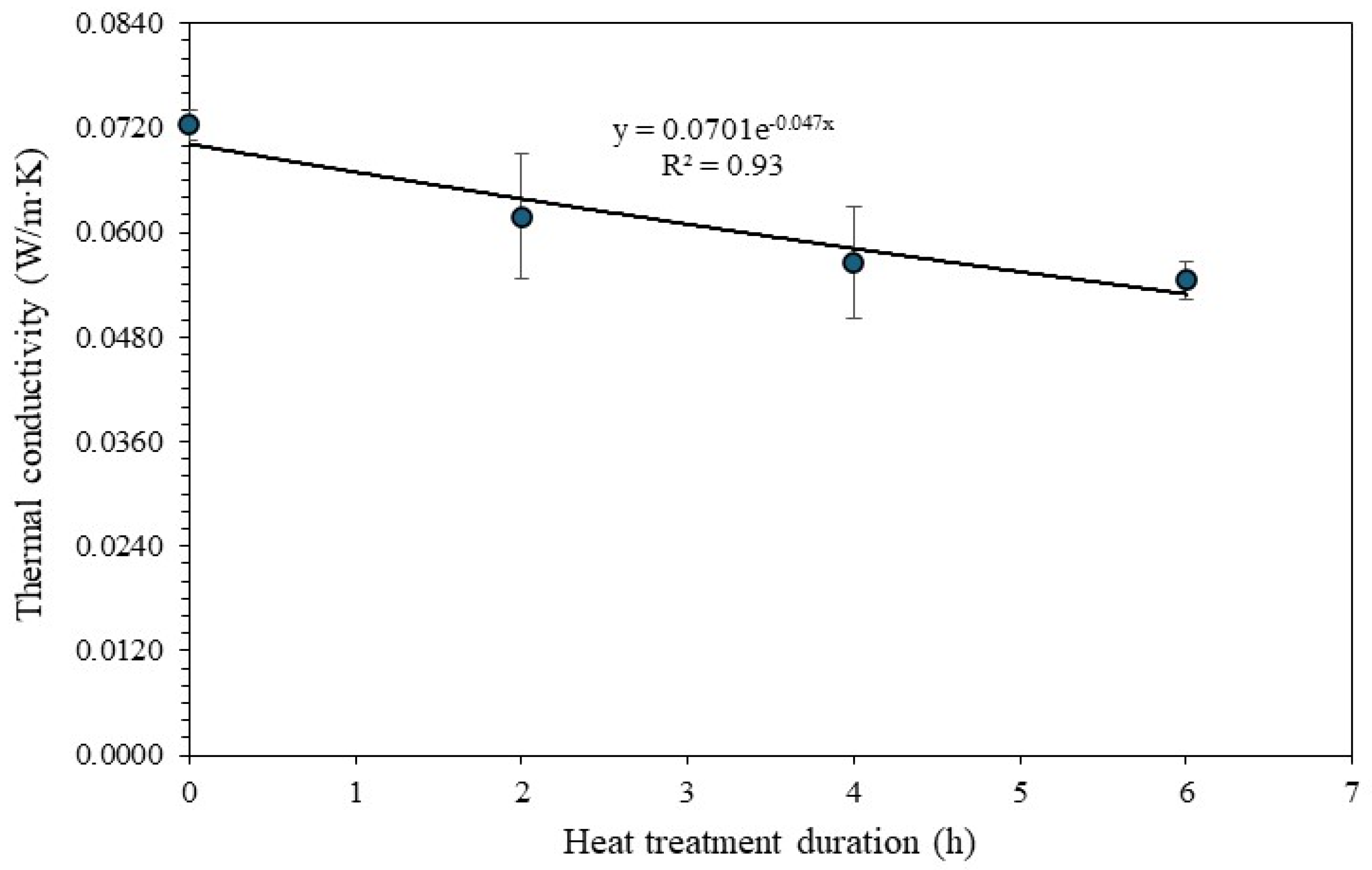

3.1.3. Thermal Conductivity

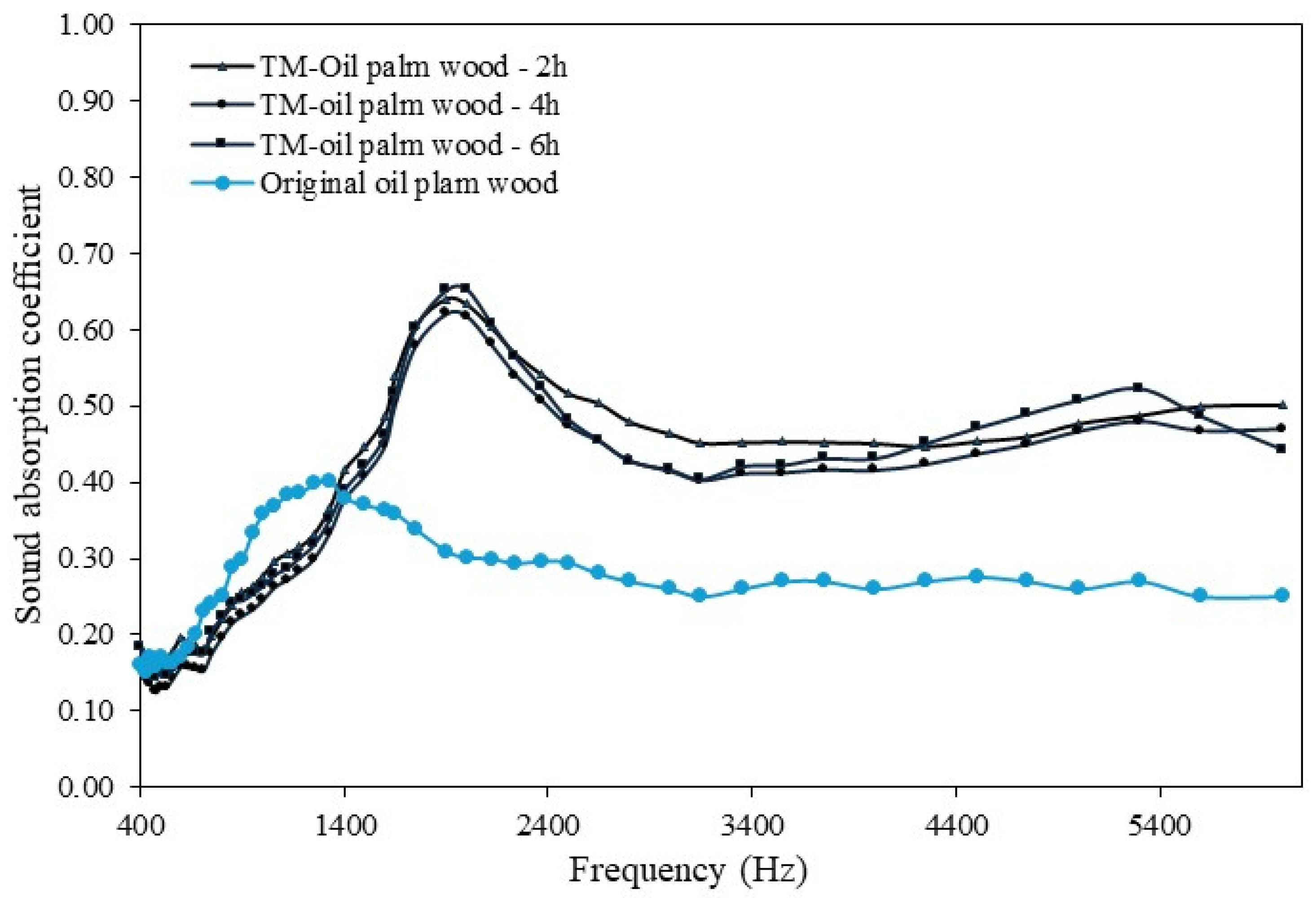

3.1.4. Sound-Absorption Coefficient

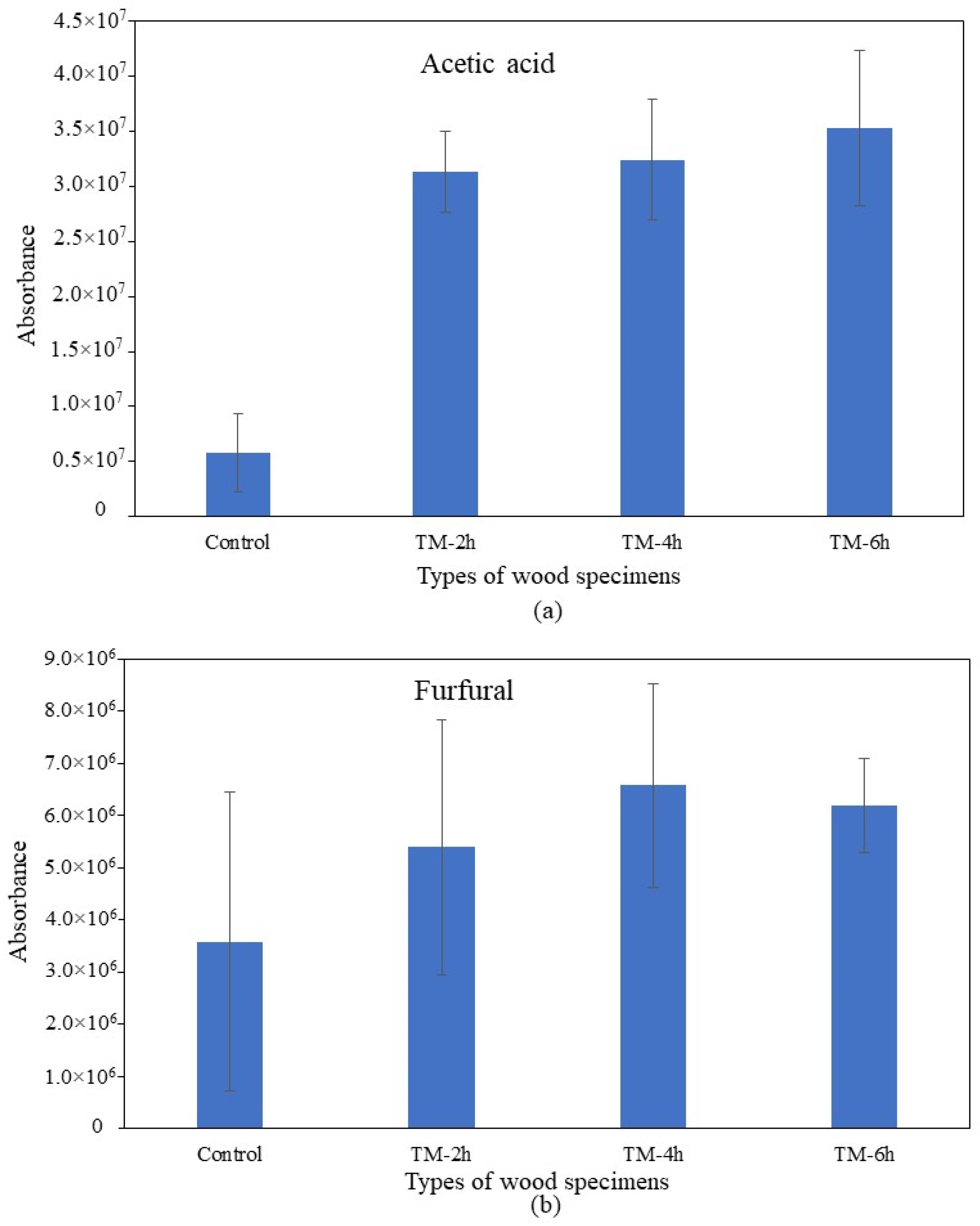

3.1.5. Volatile Organic Compound Emission

4. Conclusions

- The thermal modification (TM) of oil palm wood via a hot press machine improved dimensional stability and thermal and sound-insulation properties but triggered more volatile organic compound (VOC) emissions, suggesting that it should be reduced or prevented to avoid the impact on human health.

- Heat-treatment duration exponentially decreased density and thermal conductivity but increased mass loss due to the thermal degradation of wood substance. The sound-absorption coefficient, thickness swelling, and VOC emission appeared to be similar at all heat-treatment durations.

- Compared with the available natural materials developed for use as wall insulation, the TM oil palm wood showed superior insulation performance for all heat-treatment durations. Thus, it had potential for an insulation-efficient and dimensionally stable wall application.

- Regarding the benefit of the heat-treatment duration, the heat-treatment duration of 2 h is suggested to save energy consumption during the heat-treatment process while still achieving the same level of dimensional stability, sound absorption, and VOC emission performance as that of the long heat-treatment duration. However, if the thermal conductivity is the major performance criterion to achieve, a long heat-treatment duration is recommended.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vasconcelos, G.; Lourenço, P.B.; Mendonça, P.; Camões, A.; Mateus, R.; Bragança, L.; Brito, A.G.; Poletti, E. Proposal of an innovative solution for partition walls: Mechanical, thermal and acoustic validation. Constr. Build. Mater. 2013, 48, 961–979. [Google Scholar] [CrossRef]

- Roque, E.; Santos, P.; Pereira, A.C. Thermal and sound insulation of lightweight steel-framed façade walls. Sci. Technol. Built Environ. 2019, 25, 156–176. [Google Scholar] [CrossRef]

- Júnior, O.J.; Pinheiro, M.A.; Silva, J.R.; Pires, T.A.; Alencar, C.O. Sound insulation of gypsum block partitions: An analysis of single and double walls. J. Build. Eng. 2021, 39, 102253. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Sharma, S.; Verma, A.; Rangappa, S.M.; Siengchin, S. Mechanical, thermal, and acoustical studies on natural alternative material for partition walls: A novel experimental investigation. Polym. Compos. 2022, 43, 4711–4720. [Google Scholar] [CrossRef]

- Li, H.; Yang, M.; Zhang, J.S.; Salonvaara, M. Measurements and Modeling of VOC Emissions from a Large Wall Assembly of Typical Wood-Framed Residential Houses. ASHRAE Trans. 2005, 111, 210–217. [Google Scholar]

- Mateus, R.; Neiva, S.; Bragança, L.; Mendonça, P.; Macieira, M. Sustainability assessment of an innovative lightweight building technology for partition walls–comparison with conventional technologies. Build. Environ. 2013, 67, 147–159. [Google Scholar] [CrossRef]

- Zhou, X. Volatile Organic Compound Emissions in Building Materials; Woodhead Publishing Series in Civil and Structural Engineering, Advances in the Toxicity of Construction and Building Materials; Woodhead Publishing: Sawston, UK, 2022. [Google Scholar] [CrossRef]

- Yilmaz, F.; Becque, J.; Mojtabaei, S.M.; Hajirasouliha, I. Experimental investigation of the behaviour and capacity of sheathed cold-formed steel stud walls under inward flexural loading. Thin-Walled Struct. 2023, 192, 111048. [Google Scholar] [CrossRef]

- Afzal, Q.; Abbas, S.; Abbass, W.; Ahmed, A.; Azam, R.; Riaz, M.R. Characterization of sustainable interlocking burnt clay brick wall panels: An alternative to conventional bricks. Constr. Build. Mater. 2020, 231, 117190. [Google Scholar] [CrossRef]

- Ferreira, S.; Morais, M.; Costa, V.; Velosa, A.; Vela, G.; Teles, J.; Pereira, T. Modular sandwich panel system for non-loadbearing walls–Experimental mechanical, fire and acoustic testing. J. Build. Eng. 2023, 78, 107642. [Google Scholar] [CrossRef]

- Amran, Y.M.; El-Zeadani, M.; Lee, Y.H.; Lee, Y.Y.; Murali, G.; Feduik, R. Design innovation, efficiency and applications of structural insulated panels: A review. Structures 2020, 27, 1358–1379. [Google Scholar] [CrossRef]

- Brandner, R.; Flatscher, G.; Ringhofer, A.; Schickhofer, G.; Thiel, A. Cross laminated timber (CLT): Overview and development. Eur. J. Wood Wood Prod. 2016, 74, 331–351. [Google Scholar] [CrossRef]

- Ferreira, R.; Pereira, D.; Gago, A.; Proença, J. Experimental characterisation of cork agglomerate core sandwich panels for wall assemblies in buildings. J. Build. Eng. 2016, 5, 194–210. [Google Scholar] [CrossRef]

- Wang, M.; Dong, R.; Lu, Z.; Jia, W. Process parameter investigations on poplar wooden brick for indoor partition wall. For. Prod. J. 2020, 70, 317–325. [Google Scholar] [CrossRef]

- Bakar, E.S.; Sahri, M.H.; H’ng, P.S. Anatomical characteristics and utilization of oil palm wood. In The Formation of Wood in Tropical Forest Tress: A Challenge from the Perspective of Functional Wood Anatomy; Nobuchi, T., Sahri, M.H., Eds.; UPM Press: Serdang, Malysia, 2008. [Google Scholar]

- Singh, S.; Maiti, S.; Bisht, R.S.; Balam, N.B.; Solanki, R.; Chourasia, A.; Panigrahi, S.K. Performance behaviour of agro-waste based gypsum hollow blocks for partition walls. Sci. Rep. 2022, 12, 3204. [Google Scholar] [CrossRef] [PubMed]

- Kawasaki, T.; Kawai, S. Thermal insulation properties of wood-based sandwich panel for use as structural insulated walls and floors. J. Wood Sci. 2006, 52, 75–83. [Google Scholar] [CrossRef]

- Novais, R.M.; Senff, L.; Carvalheiras, J.; Seabr, M.P.; Pullar, R.C.; Labrincha, J.A. Sustainable and efficient cork-inorganic polymer composites: An innovative and eco-friendly approach to produce ultra-lightweight and low thermal conductivity materials. Cem. Concr. Compos. 2019, 97, 107–117. [Google Scholar] [CrossRef]

- Thongcharoen, N.; Khongtong, S.; Srivaro, S.; Wisadsatorn, S.; Chub-Uppakarn, T.; Chaowana, P. Development of structural insulated panels made from wood-composite boards and natural rubber foam. Polymers 2021, 13, 2497. [Google Scholar] [CrossRef]

- Srivaro, S.; Lim, H.; Li, M.; Altaner, C. Effect of pressing parameters on dimensional stability and bonding performance of thermally compressed coconut wood. Constr. Build. Mater. 2022, 357, 129359. [Google Scholar] [CrossRef]

- Hill, C.; Altgen, M.; Rautkari, L. Thermal modification of wood—A review: Chemical changes and hygroscopicity. J. Mater. Sci. 2021, 56, 6581–6614. [Google Scholar] [CrossRef]

- Masoumi, A.; Bond, B.H. Dimensional Stability and Equilibrium Moisture Content of Thermally Modified Hardwoods. BioResources 2024, 19, 1218. [Google Scholar] [CrossRef]

- Chung, H.; Park, Y.; Yang, S.Y.; Kim, H.; Han, Y.; Chang, Y.S.; Yeo, H. Effect of heat treatment temperature and time on sound absorption coefficient of Larix kaempferi wood. J. Wood Sci. 2017, 63, 575–579. [Google Scholar] [CrossRef]

- Czajkowski, Ł.; Olek, W.; Weres, J. Effects of heat treatment on thermal properties of European beech wood. Eur. Wood Wood Prod. 2020, 78, 425–431. [Google Scholar] [CrossRef]

- Pásztory, Z.; Horváth, N.; Börcsök, Z. Effect of heat treatment duration on the thermal conductivity of spruce and poplar wood. Eur. Wood Wood Prod. 2017, 75, 843–845. [Google Scholar] [CrossRef]

- Pohleven, J.; Burnard, M.D.; Kutnar, A. Volatile organic compounds emitted from untreated and thermally modified wood-a review. Wood Fiber Sci. 2019, 51, 231–254. [Google Scholar] [CrossRef]

- ISO 13061-3; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 3: Determination of Ultimate Strength in Static Bending. International Organization for Standardization: Geneva, Switzerland, 2014.

- ASTM E1050; Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System. ASTM Annual Book of Standards; ASTM International: West Conshohoken, PA, USA, 2019.

- Glass, S.V.; Zelinka, S.L. Moisture relations and physical properties of wood. In Wood Handbook: Wood as an Engineering Material; Ross, R.J., Ed.; Forest Product Laboratory: Madison, WI, USA, 2010. [Google Scholar]

- Jang, E.S.; Kang, C.W. Sound absorption characteristics of three species (binuang, balsa and paulownia) of low density hardwood. Holzforschung 2021, 75, 1115–1124. [Google Scholar] [CrossRef]

- Jang, E.S. Sound absorbing properties of selected green material—A review. Forests 2023, 14, 1366. [Google Scholar] [CrossRef]

- Čech, P. Comparison of VOC emissions from natural wood and heat-treated wood. Wood Industry 2018, 69, 297–309. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Srivaro, S.; Lim, H.; Cho, H.; Oh, J.-K.; Pasztory, Z.; Eadkhong, T. Potential of Oil Palm Wood Thermally Modified via Hot Press Machine for Eco-Friendly Wall Insulation Applications. Forests 2025, 16, 880. https://doi.org/10.3390/f16060880

Srivaro S, Lim H, Cho H, Oh J-K, Pasztory Z, Eadkhong T. Potential of Oil Palm Wood Thermally Modified via Hot Press Machine for Eco-Friendly Wall Insulation Applications. Forests. 2025; 16(6):880. https://doi.org/10.3390/f16060880

Chicago/Turabian StyleSrivaro, Suthon, Hyungsuk Lim, Heejin Cho, Jung-Kwon Oh, Zoltan Pasztory, and Thammarong Eadkhong. 2025. "Potential of Oil Palm Wood Thermally Modified via Hot Press Machine for Eco-Friendly Wall Insulation Applications" Forests 16, no. 6: 880. https://doi.org/10.3390/f16060880

APA StyleSrivaro, S., Lim, H., Cho, H., Oh, J.-K., Pasztory, Z., & Eadkhong, T. (2025). Potential of Oil Palm Wood Thermally Modified via Hot Press Machine for Eco-Friendly Wall Insulation Applications. Forests, 16(6), 880. https://doi.org/10.3390/f16060880