A Comparative Study on the Effects of Heat Treatment on the Properties of Rubberwood Veneer

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Heat-Treated Veneer

2.2.2. Fourier-Transform (FTIR) Analysis

2.2.3. X-Ray Diffraction Spectroscopy (XRD) Analysis

2.2.4. Measurement of Tensile Strength Along the Grain Direction

2.2.5. Color Measurements

2.2.6. Dynamic Vapor Sorption (DVS) Measurement

2.2.7. Thermogravimetric (TG) Analysis

2.2.8. Scanning Electron Microscopy (SEM) Observation

3. Results

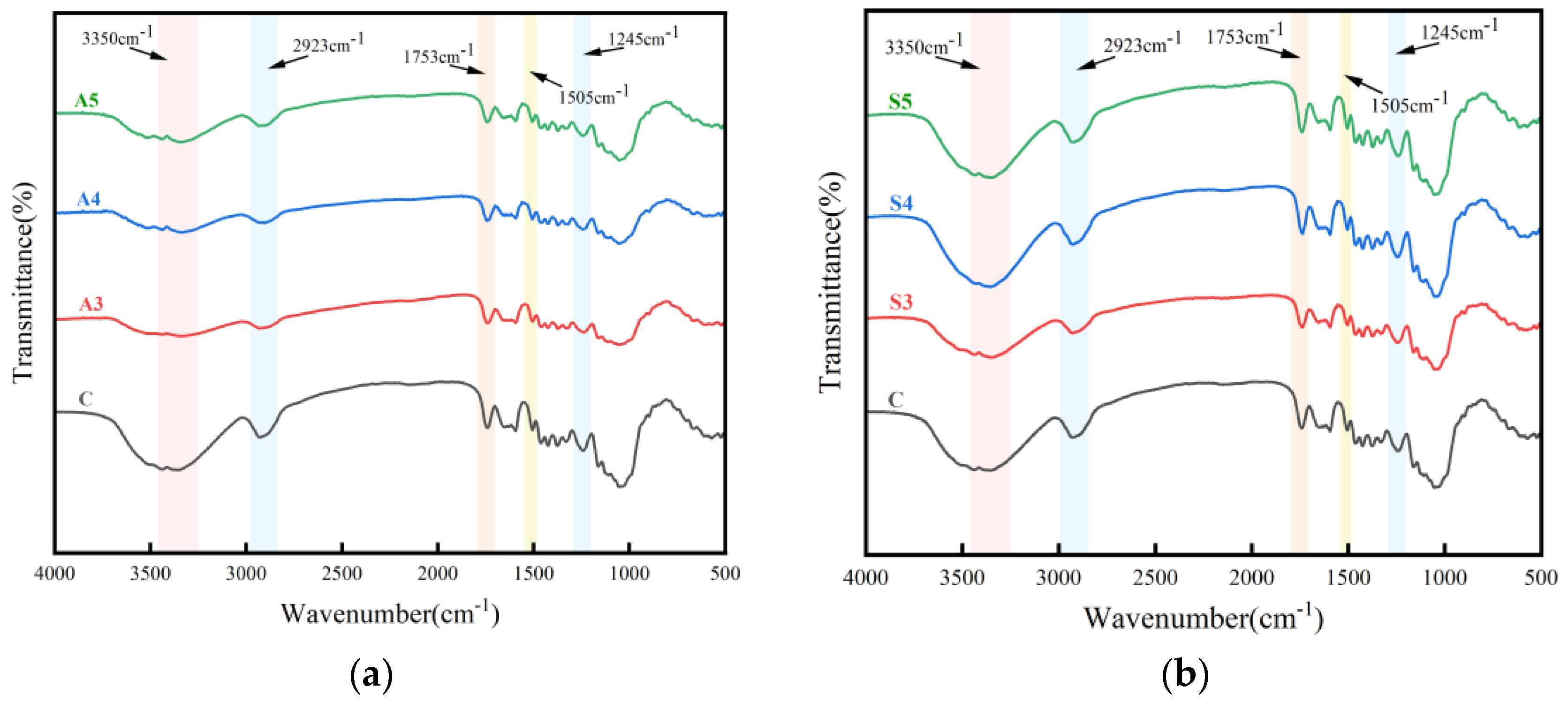

3.1. FTIR Analysis

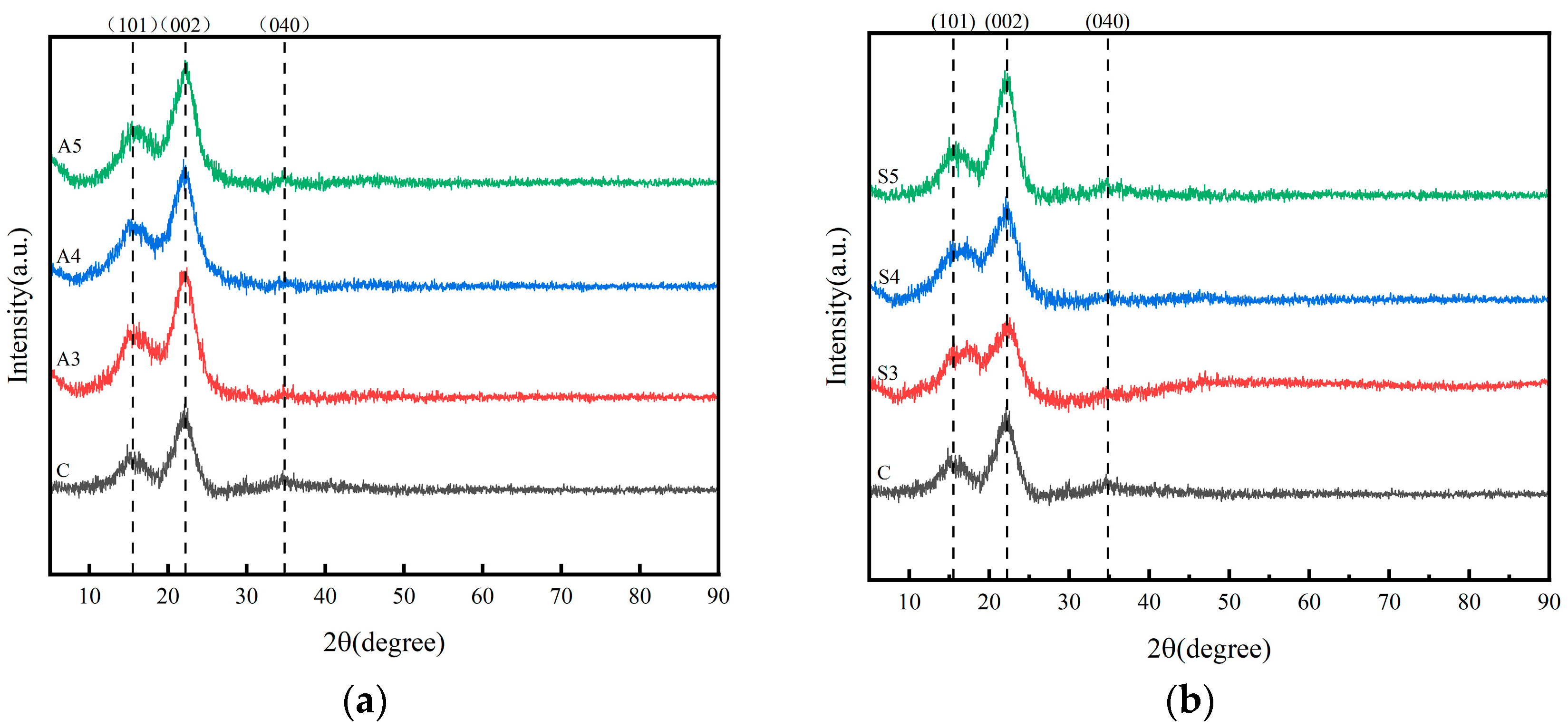

3.2. XRD Analysis

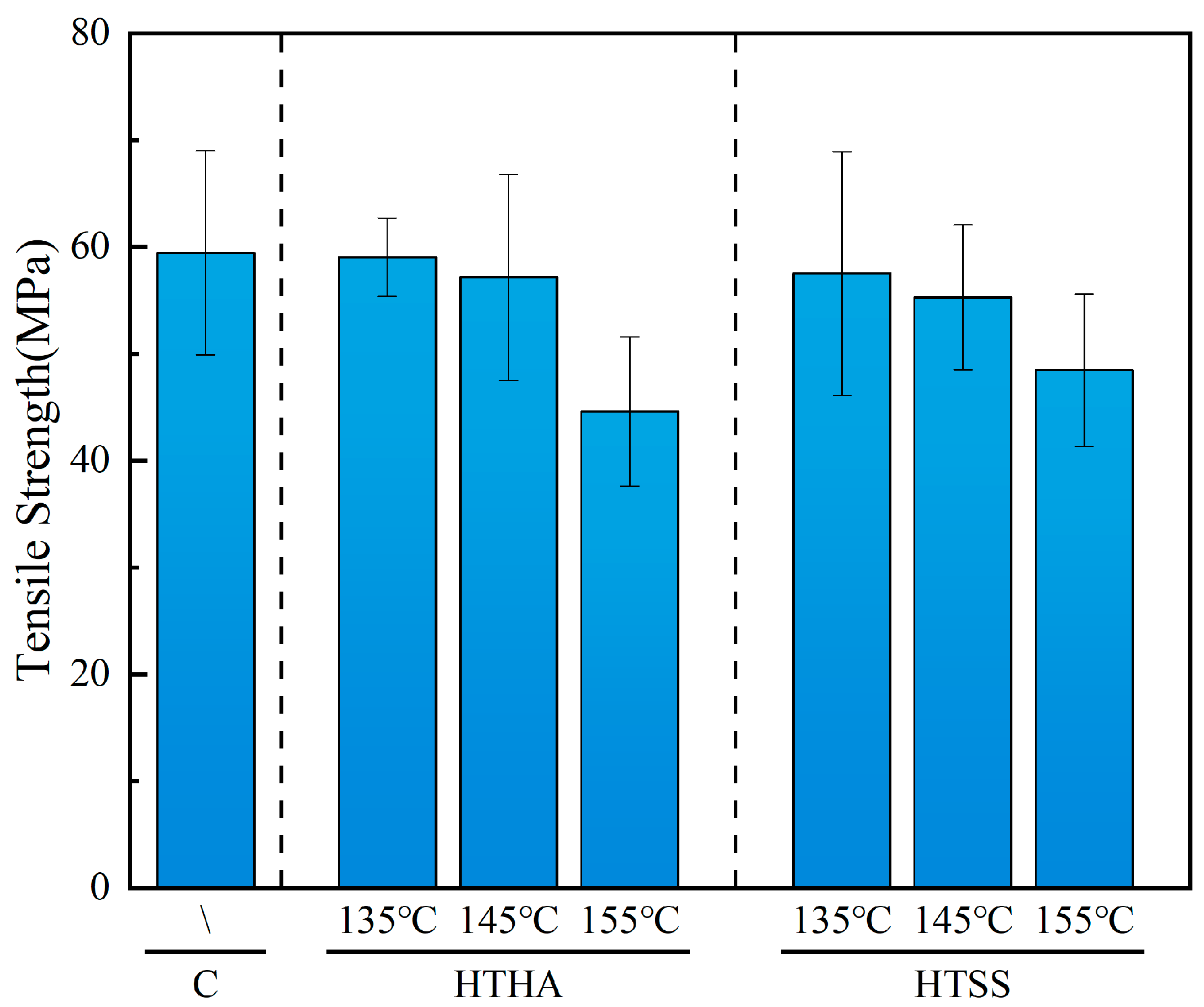

3.3. Tensile Strength Along the Grain Direction Analysis

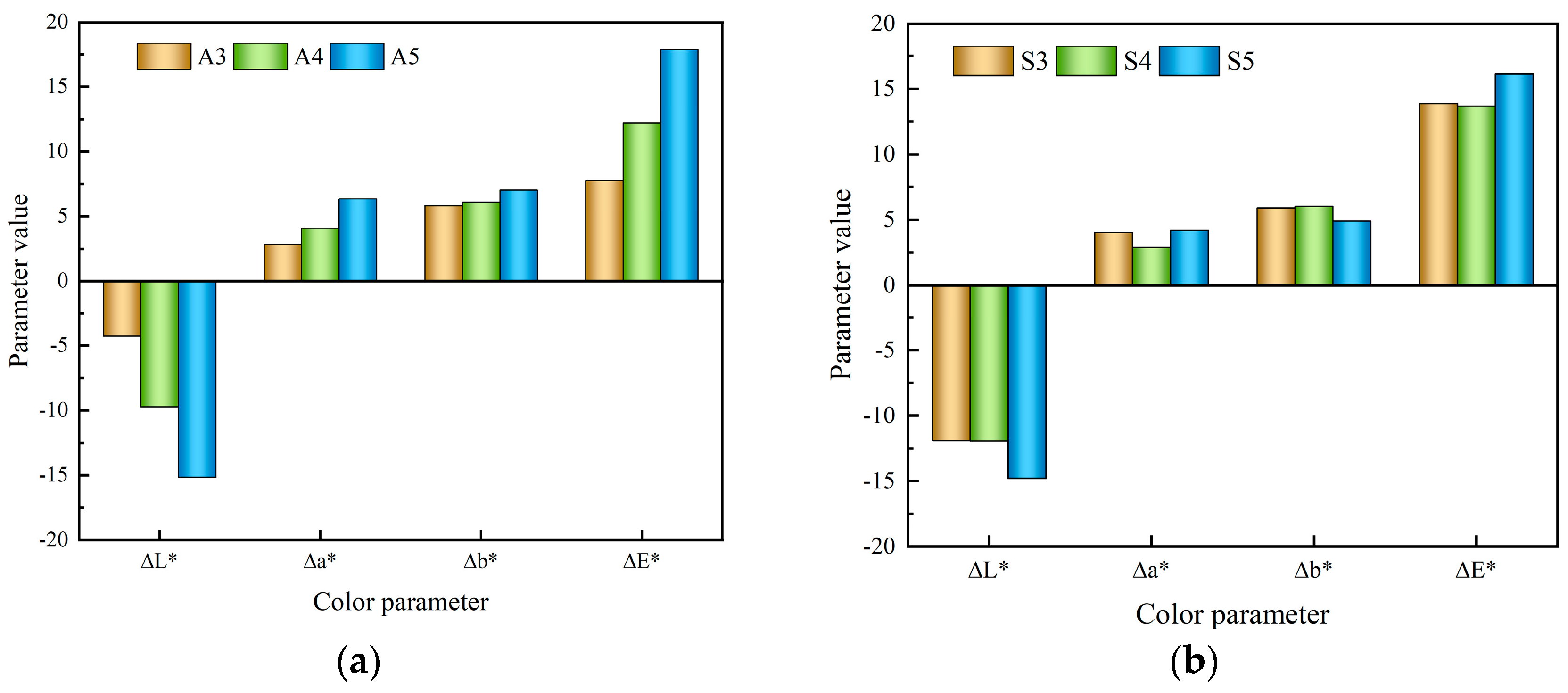

3.4. Color Analysis

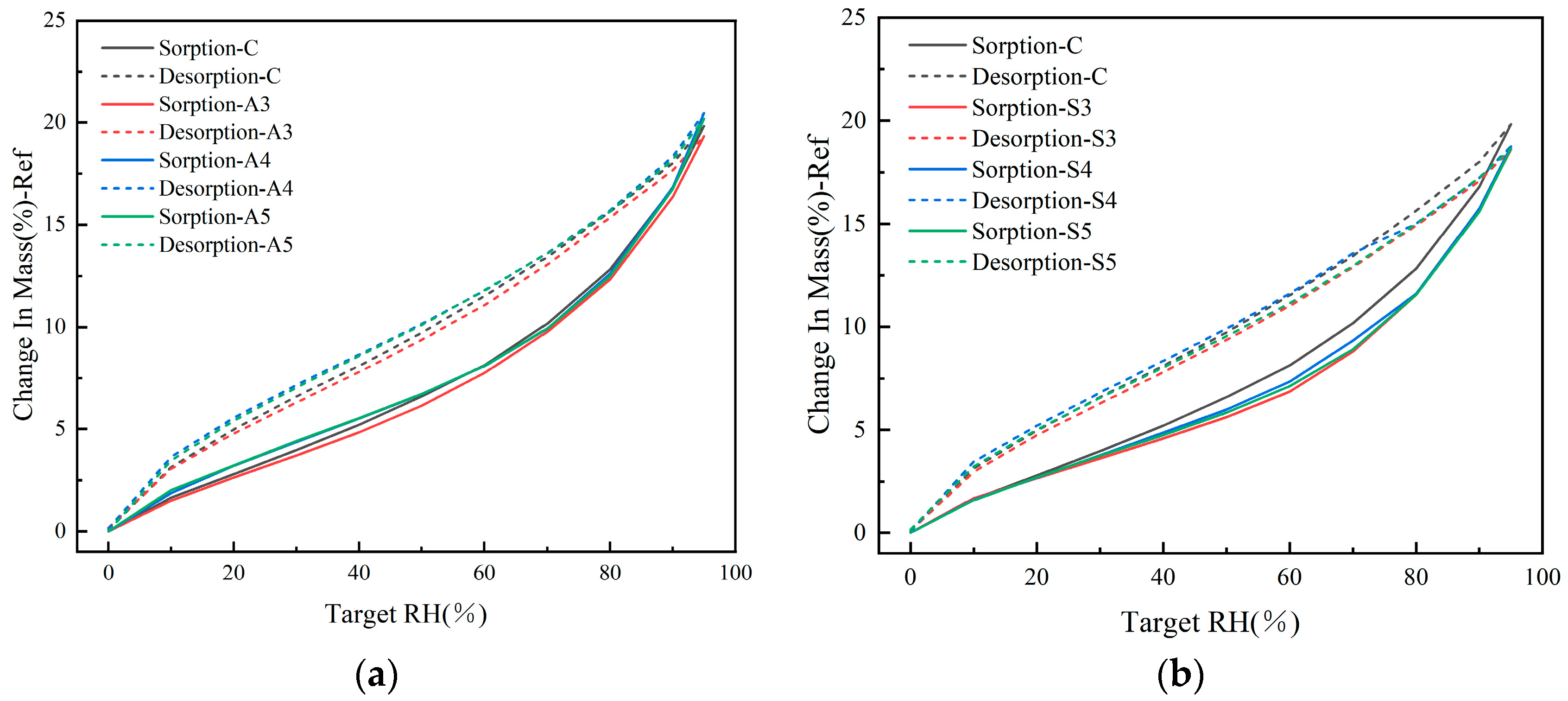

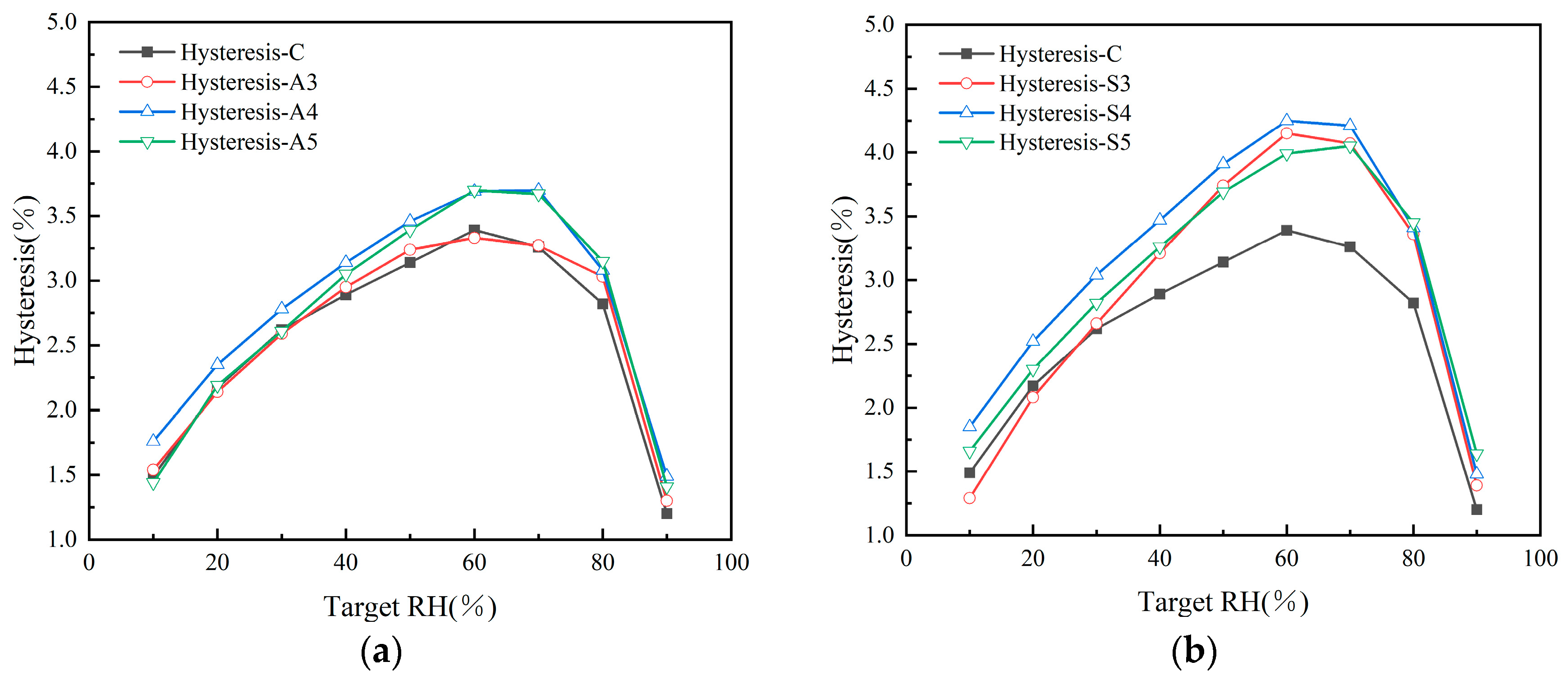

3.5. DVS Analysis

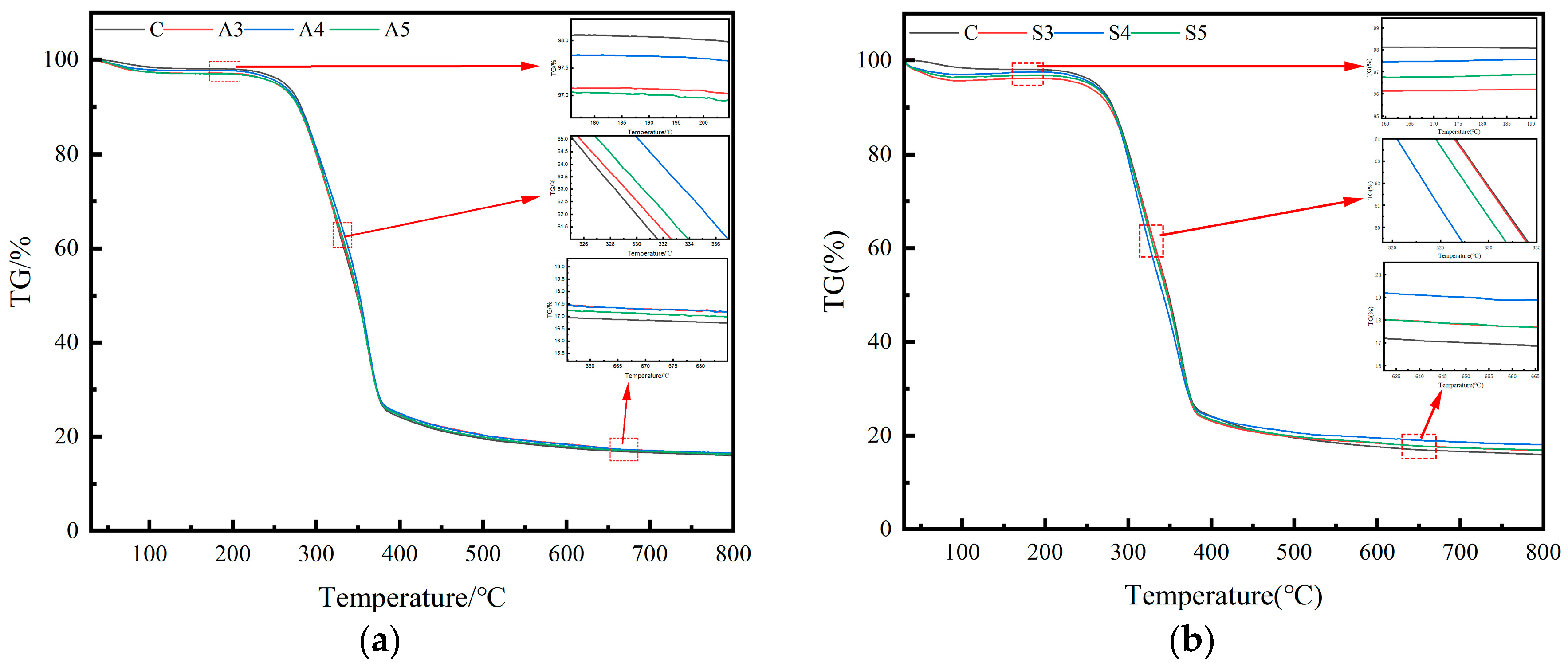

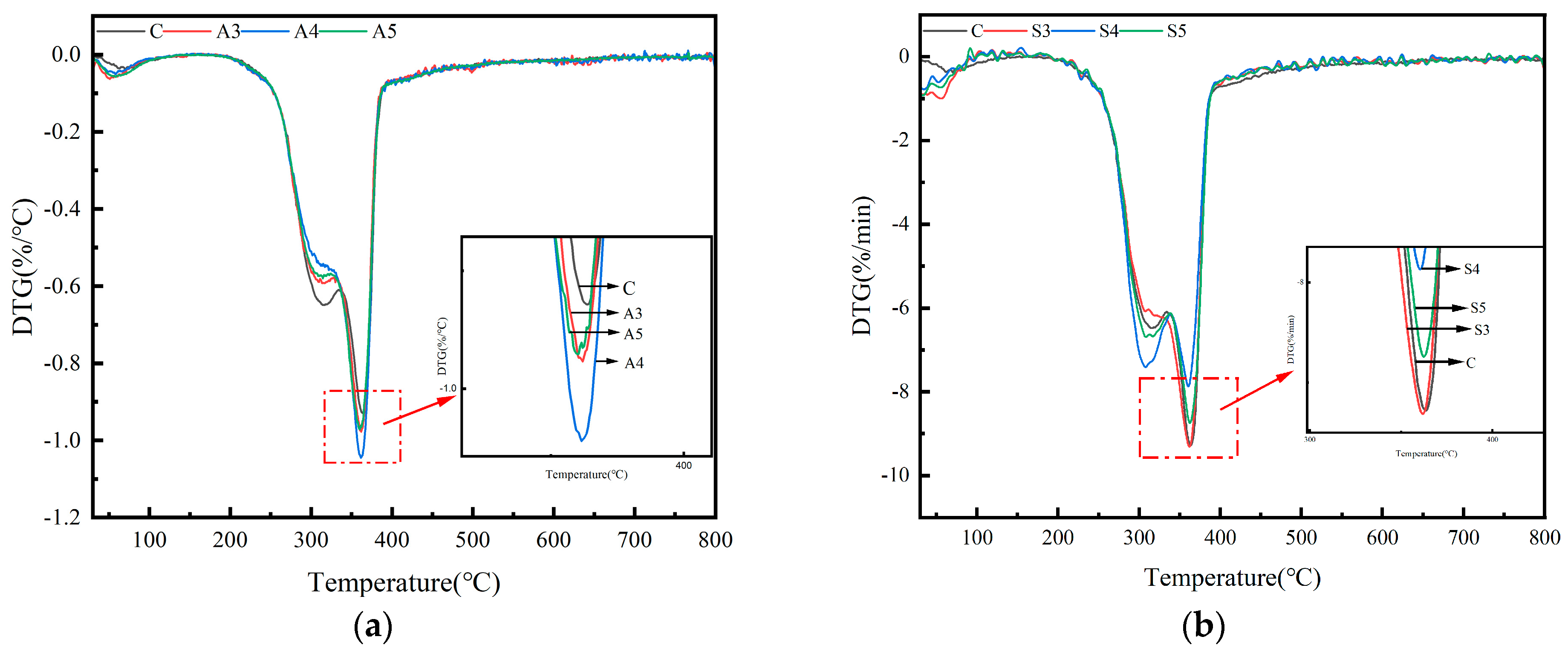

3.6. TG Analysis

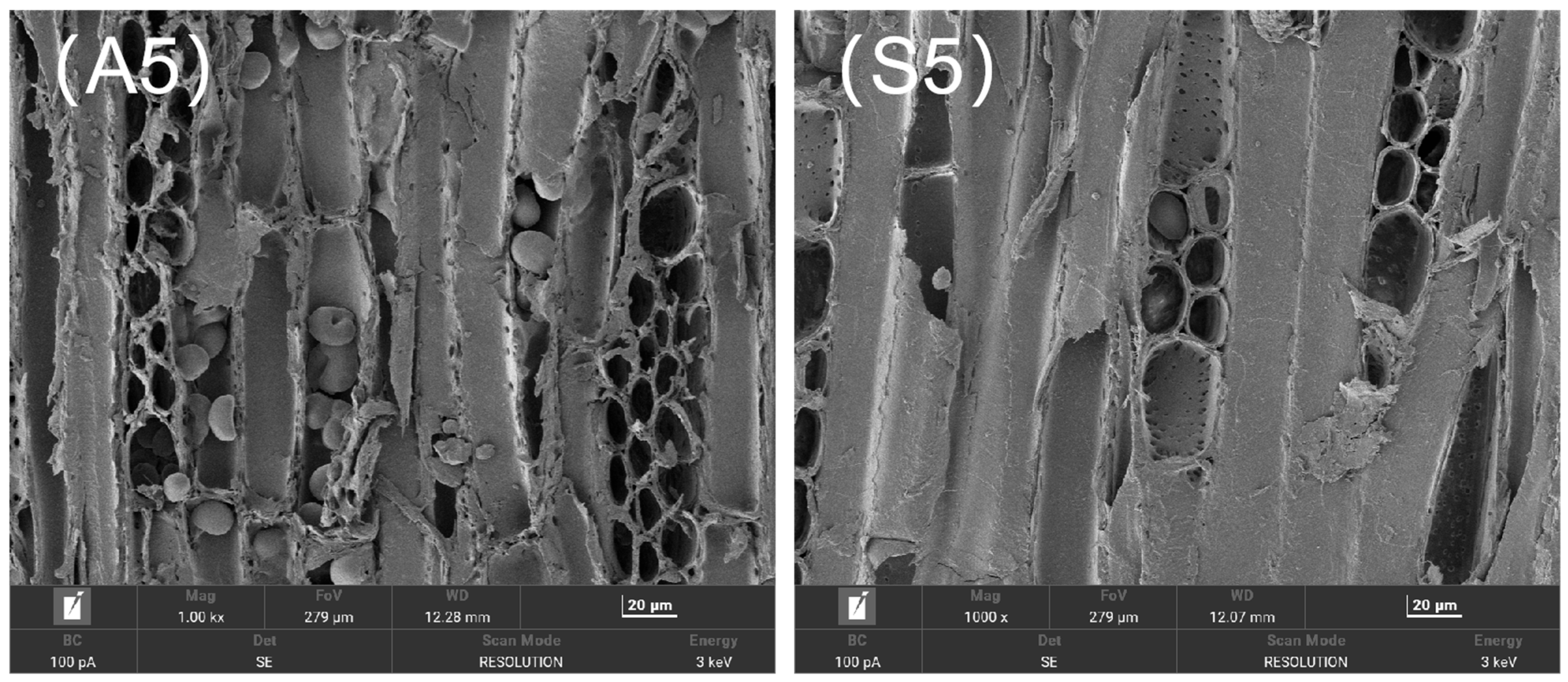

3.7. SEM Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.; Tu, D.; Chen, C.; Zhou, Q. Prediction of the mechanical properties of thermally-modified rubber wood on the basic of its surface characteristic. Wood Res. 2019, 64, 25–34. [Google Scholar]

- Patcharawijit, A.; Choodum, N.; Yamsaengsung, R. Effects of superheated steam treatment on moisture adsorption and mechanical properties of pre-dried rubberwood. Dry. Technol. 2019, 37, 1647–1655. [Google Scholar] [CrossRef]

- Yin, T.; Han, Z.; Li, J.; Xu, P.; Su, G. Experimental Study on Mechanical Properties of Hainan Rubberwood. Build. Constr. 2025, 47, 76–80. [Google Scholar]

- Gao, Y.; Xu, K.; Zhan, T.; Jiang, J.; Jiang, J.; Zhao, L.; Lu, J. Review on the Effects and Mechanism of Heat Treatment on Moisture Absorption of Wood. Mater. Rev. 2022, 36, 212–219. [Google Scholar]

- Lin, X.; Wang, L.; Xu, M. Effects of Polyethylene Glycol Combined with Heat Modification on the Properties of Rubberwood. J. Northeast. For. Univ. 2021, 49, 106–110+116. [Google Scholar]

- Fang, C.; Mariotti, N.; Cloutier, A.; Koubaa, A.; Blanchet, P. Densification of wood veneers by compression combined with heat and steam. Eur. J. Wood Wood Prod. 2012, 70, 155. [Google Scholar] [CrossRef]

- Ferreira, B.S.; Arroyo, F.N.; Kondo, M.Y.; Lahr, F.A.R.; Christoforo, A.L.; Campos, C.I.D. Physical and mechanical properties of plywood produced with thermally treated Pinus taeda veneers. Forests 2022, 13, 1398. [Google Scholar] [CrossRef]

- Song, W.; Wei, W.; Ren, C.; Zhang, S. Effect of heat treatment or alkali treatment of veneers on the mechanical properties of eucalyptus veneer/polyethylene film plywood composites. BioResources 2017, 12, 8683–8703. [Google Scholar] [CrossRef]

- Chen, Z.; White, M.; Mack, R.; Rider, D.; Reddy, V.; O’Neill, S. International Supply Chain Handling Practices and the Quality of Heat-treated, White Oak Veneer Logs. BioResources 2023, 18, 3802. [Google Scholar] [CrossRef]

- Altgen, M.; Awais, M.; Altgen, D.; Kyyrö, S.; Seppäläinen, H.; Rautkari, L. Micro-tensile behavior of Scots pine sapwood after heat treatments in superheated steam or pressurized hot water. J. Mater. Sci. 2020, 55, 12621–12635. [Google Scholar] [CrossRef]

- Salca, E.A.; Kobori, H.; Inagaki, T.; Kojima, Y.; Suzuki, S. Effect of heat treatment on colour changes of black alder and beech veneers. J. Wood Sci. 2016, 62, 297–304. [Google Scholar] [CrossRef]

- Jiang, H.; Lu, Q.; Li, G.; Li, M.; Li, J. Effect of heat treatment on the surface color of rubber wood (Hevea brasiliensis). Wood Res. 2020, 65, 633–644. [Google Scholar] [CrossRef]

- Chotikhun, A.; Kittijaruwattana, J.; Salca, E.A.; Hiziroglu, S. Selected physical and mechanical properties of microwave heat treated rubberwood (Hevea brasiliensis). Appl. Sci. 2020, 10, 6273. [Google Scholar] [CrossRef]

- Chotikhun, A.; Kittijaruwattana, J.; Lee, S.H.; Salca, E.A.; Arsyad, W.O.M.; Hadi, Y.S.; Neimsuwan, T.; Hiziroglu, S. Characterization of plywood made from heat-treated rubberwood veneers bonded with melamine urea formaldehyde resin. J. Wood Sci. 2023, 69, 23. [Google Scholar]

- Segal, L.; Creely, J.J.; Martin, A.E., Jr.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Jiang, J.; Li, J.; Zhang, J.; Wang, B.; Zhan, J. Effects of Oil-Wax Heat Treatment on Physical Properties and Dimensional Stability of Wood. For. Eng. 2024, 40, 106–113. [Google Scholar]

- Kamperidou, V. Chemical and structural characterization of poplar and black pine wood exposed to short thermal modification. Drv. Ind. 2021, 72, 155–167. [Google Scholar] [CrossRef]

- Özgenç, Ö.; Durmaz, S.; Boyaci, I.H.; Eksi-Kocak, H. Determination of chemical changes in heat-treated wood using ATR-FTIR and FT Raman spectrometry. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2017, 171, 395–400. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Luo, C.; Wang, X.; Mu, J. Effects of high-temperature heat treatment on the vibration performance and chemical composition of Norway spruce and Paulownia wood. China For. Ind. 2023, 60, 14–20. [Google Scholar]

- Ren, A.; Zhao, Y.; Wang, X.; Xu, Z.; Yu, C.; Pan, B. Effects of high-temperature heat treatment on the physical and mechanical properties of Metasequoia glyptostroboides wood. J. For. Eng. 2024, 9, 25–33. [Google Scholar]

- Rautkari, L.; Hill, C.A.S.; Curling, S.; Jalaludin, Z.; Ormondroyd, G. What is the role of the accessibility of wood hydroxyl groups in controlling moisture content? J. Mater. Sci. 2013, 48, 6352–6356. [Google Scholar] [CrossRef]

- Yin, Y.; Berglund, L.; Salmén, L. Effect of steam treatment on the properties of wood cell walls. Biomacromolecules 2011, 12, 194–202. [Google Scholar] [CrossRef] [PubMed]

- Ganne-Chédeville, C.; Jääskeläinen, A.S.; Froidevaux, J.; Hughes, M.; Navi, P. Natural and artificial ageing of spruce wood as observed by FTIR-ATR and UVRR spectroscopy. Holzforschung 2012, 66, 163–170. [Google Scholar] [CrossRef]

- Rinaldi, R.; Schüth, F. Acid hydrolysis of cellulose as the entry point into biorefinery schemes. ChemSusChem Chem. Sustain. Energy Mater. 2009, 2, 1096–1107. [Google Scholar] [CrossRef] [PubMed]

- Wada, M.; Chanzy, H.; Nishiyama, Y.; Langan, P. Cellulose IIII crystal structure and hydrogen bonding by synchrotron X-ray and neutron fiber diffraction. Macromolecules 2004, 37, 8548–8555. [Google Scholar] [CrossRef]

- Maki-Arvela, P.; Salmi, T.; Holmbom, B.; Willför, S.; Murzin, D.Y. Synthesis of sugars by hydrolysis of hemicelluloses-a review. Chem. Rev. 2011, 111, 5638–5666. [Google Scholar] [CrossRef]

- Fan, W.; Tu, D.; Peng, C.; Han, Y.; Cai, J. Mechanism of the influence of heat treatment on the mechanical properties of Populus tomentosa wood. J. Northeast. For. Univ. 2015, 43, 88–91. [Google Scholar]

- Endo, K.; Obataya, E.; Zeniya, N.; Matsuo, M. Effects of heating humidity on the physical properties of hydrothermally treated spruce wood. Wood Sci. Technol. 2016, 50, 1161–1179. [Google Scholar] [CrossRef]

- Wu, Z.; Deng, X.; Li, L.; Xi, X.; Tian, M.; Yu, L.; Zhang, B. Effects of heat treatment on interfacial properties of Pinus Massoniana wood. Coatings 2021, 11, 543. [Google Scholar] [CrossRef]

- Lu, J.; Ding, T.; Shi, J.B.; Du, J.J. Effects of heating rate during heat treatment on the microstructure and physical-mechanical properties of oak wood. J. For. Eng. 2023, 8, 76–83. [Google Scholar]

- Poncsák, S.; Kocaefe, D.; Bouazara, M.; Pichette, A. Effect of high temperature treatment on the mechanical properties of birch (Betula papyrifera). Wood Sci. Technol. 2006, 40, 647–663. [Google Scholar] [CrossRef]

- Cai, J.B.; Li, T.; Zhang, B.L.; Xu, W. Research on the Effects of High Temperature Heat Treatment on the Physical and Mechanical Properties of Larch Boards. For. Prod. Ind. 2009, 36, 31–34. [Google Scholar]

- Li, T.; Gu, L.B. Effects of 185℃ High Temperature Heat Treatment on the Mechanical Properties of Fraxinus mandshurica Wood. Sci. Silvae Sin. 2009, 45, 92–97. [Google Scholar]

- Kamperidou, V.; Barboutis, I.; Vasileiou, V. Response of colour and hygroscopic properties of Scots pine wood to thermal treatment. J. For. Res. 2013, 24, 571–575. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Z.; Zhao, L.; Lyu, J. Effect of Heat Treatment on Hygroscopicity of Chinese Fir (Cunninghamia lanceolata [Lamb.] Hook.) Wood. Forests 2024, 15, 630. [Google Scholar] [CrossRef]

- Yin, F.; Du, Y.; Li, Z.; Jiang, J. Water vapor sorption characteristics and hysteresis of earlywood and latewood within the same growth ring of Catalpa bungei. Wood Sci. Technol. 2023, 57, 507–521. [Google Scholar] [CrossRef]

- Hou, S.; Wang, J.; Yin, F.; Qi, C.; Mu, J. Moisture sorption isotherms and hysteresis of cellulose, hemicelluloses and lignin isolated from birch wood and their effects on wood hygroscopicity. Wood Sci. Technol. 2022, 56, 1087–1102. [Google Scholar] [CrossRef]

- Cerc Korošec, R.; Žener, B.; Čelan Korošin, N.; Humar, M.; Kržišnik, D.; Rep, G.; Lavrenčič Štangar, U. Searching for Optimal Measurement Parameters by Thermogravimetry for Determining the Degree of Modification of Thermally Modified Wood. Forests 2023, 15, 8. [Google Scholar] [CrossRef]

- Kačíková, D.; Eštoková, A.; Gaff, M.; Kmeťová, E.; Kúdela, J.; Kačík, F. Thermal analysis of thermally treated spruce wood after its accelerated aging. J. Therm. Anal. Calorim. 2025, 150, 3283–3295. [Google Scholar] [CrossRef]

- Magdziarz, A.; Wilk, M.; Straka, R. Combustion process of torrefied wood biomass: A kinetic study. J. Therm. Anal. Calorim. 2017, 127, 1339–1349. [Google Scholar] [CrossRef]

- Hong, H.; Guan, M.J.; Tian, H.Y. Thermogravimetric Analysis of Heat-Treated Khaya senegalensis Wood. J. For. Sci. Technol. Dev. 2015, 29, 73–76. [Google Scholar]

- Zhang, J.; Qi, C.S.; Mu, J. Effects of Heat Treatment Temperature and Time on Mass Loss and Static Bending Strength of Chinese Fir. J. Beijing For. Univ. 2020, 42, 137–144. [Google Scholar]

- Teoh, Y.P.; Don, M.M.; Ujang, S. Assessment of the properties, utilization, and preservation of rubberwood (Hevea brasiliensis): A case study in Malaysia. J. Wood Sci. 2011, 57, 255–266. [Google Scholar] [CrossRef]

- Patcharawijit, A.; Yamsaengsung, R.; Choodum, N. Superheated steam treatment of rubberwood to enhance its mechanical, physiochemical, and biological properties. Wood Mater. Sci. Eng. 2020, 15, 261–268. [Google Scholar] [CrossRef]

| Wavenumber/cm−1 | Functional Group |

|---|---|

| 3350 | -OH |

| 2923 | -CH3 or -CH2 |

| 1753 | C=O |

| 1505 | Aromatic ring C=C |

| 1245 | Lignin S and G units and -OH |

| Sample | CrI/% | Standard Deviation | 2θ/° |

|---|---|---|---|

| C | 65.46 | 0.158 | 22.12 |

| A3 | 65.97 | 0.233 | 22.08 |

| A4 | 66.65 | 0.290 | 22.00 |

| A5 | 66.83 | 0.245 | 22.06 |

| S3 | 66.26 | 0.157 | 22.14 |

| S4 | 66.79 | 0.244 | 22.28 |

| S5 | 66.95 | 0.209 | 21.88 |

| Sample | Tensile Strength/MPa | Standard Seviation |

|---|---|---|

| C | 59.44 | 9.54 |

| A3 | 59.03 | 3.667 |

| A4 | 57.14 | 9.627 |

| A5 | 44.59 | 6.987 |

| S3 | 57.51 | 11.40 |

| S4 | 55.28 | 6.79 |

| S5 | 48.46 | 7.12 |

| Sample | ∆L* | ∆a* | ∆b* | ∆E* | Standard Deviation |

|---|---|---|---|---|---|

| A3 | −4.26 | 2.84 | 5.82 | 7.75 | 0.053 |

| A4 | −9.72 | 4.09 | 6.10 | 12.18 | 0.088 |

| A5 | −15.15 | 6.35 | 7.02 | 17.86 | 0.103 |

| S3 | −11.91 | 4.03 | 5.89 | 13.88 | 0.064 |

| S4 | −11.95 | 2.89 | 6.02 | 13.69 | 0.067 |

| S5 | −14.80 | 4.18 | 4.89 | 16.13 | 0.095 |

| Sample | Phase 1 | Phase 2 | Phase 3 | ||||

|---|---|---|---|---|---|---|---|

| MLP/% | MLR/%/°C | Peak Temp/°C | MLP/% | MLR/%/°C | Peak Temp/°C | MRP/% | |

| C | 1.89 | 0.35 | 67.6 | 82.16 | 9.19 | 363.5 | 15.95 |

| A3 | 2.89 | 0.57 | 54 | 80.67 | 9.45 | 360.0 | 16.45 |

| A4 | 2.30 | 0.49 | 58.6 | 81.27 | 10.38 | 362.5 | 16.44 |

| A5 | 2.90 | 0.56 | 62.4 | 80.81 | 9.52 | 359.1 | 16.28 |

| S3 | 4.18 | 1.00 | 56.24 | 79.04 | 9.31 | 361.3 | 16.77 |

| S4 | 2.63 | 0.78 | 34.92 | 79.26 | 7.87 | 359.9 | 17.10 |

| S5 | 3.52 | 0.91 | 34.74 | 79.55 | 8.74 | 362.3 | 16.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Sun, H.; You, Z.; He, Z.; Zeng, S.; Han, Y.; Chen, T. A Comparative Study on the Effects of Heat Treatment on the Properties of Rubberwood Veneer. Forests 2025, 16, 1010. https://doi.org/10.3390/f16061010

Wu Y, Sun H, You Z, He Z, Zeng S, Han Y, Chen T. A Comparative Study on the Effects of Heat Treatment on the Properties of Rubberwood Veneer. Forests. 2025; 16(6):1010. https://doi.org/10.3390/f16061010

Chicago/Turabian StyleWu, Yayun, He Sun, Zi You, Zhiwei He, Shiqi Zeng, Yuxing Han, and Taian Chen. 2025. "A Comparative Study on the Effects of Heat Treatment on the Properties of Rubberwood Veneer" Forests 16, no. 6: 1010. https://doi.org/10.3390/f16061010

APA StyleWu, Y., Sun, H., You, Z., He, Z., Zeng, S., Han, Y., & Chen, T. (2025). A Comparative Study on the Effects of Heat Treatment on the Properties of Rubberwood Veneer. Forests, 16(6), 1010. https://doi.org/10.3390/f16061010