Study on the Synergistic Effect of Plant Dyes and Mordants on the Dyeing and Anti-Mold Effect of Moso Bamboo

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Experimental Methods

2.2.1. Preparation of Dye Solution

2.2.2. Dyeing and Color Measurement of Bamboo Wood

Dyeing Treatment of Bamboo Wood

Color Measurements

2.2.3. Mold Inhibition of Plant Dyes and Mordants

Mold Inhibition by Plant Dyes

Mold Inhibition of Metal Mordants

2.2.4. Experiment on the Joint Effect of Dyeing and Mold Prevention

Dyeing and Color-Fixing Treatment of Bamboo Wood

Absorbance Photometric Measurement of Dyeing and Color Fixation Rates

Impregnated Bamboo Wood

Determination of the Mold Resistance of Impregnated Bamboo Wood

2.2.5. Analysis of Dyeing Anti-Mold Effect

Fourier-Transform Infrared Spectroscopy Analysis

Scanning Electron Microscope Observation

Determination of Copper Content and Its Effect on the Color of Bamboo Wood

3. Results and Analysis

3.1. Surface Color Values of Dyed Bamboo Wood

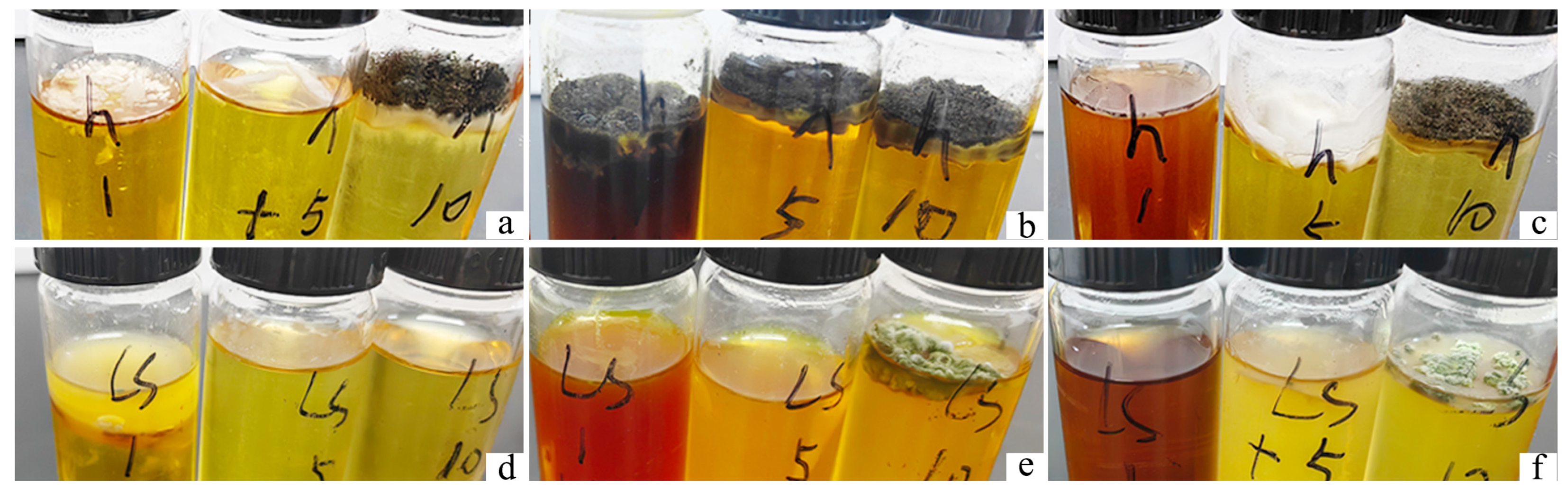

3.2. Results of Mold Inhibition of Plant Dyes

3.3. Results of Mold Inhibition of Metal Mordants

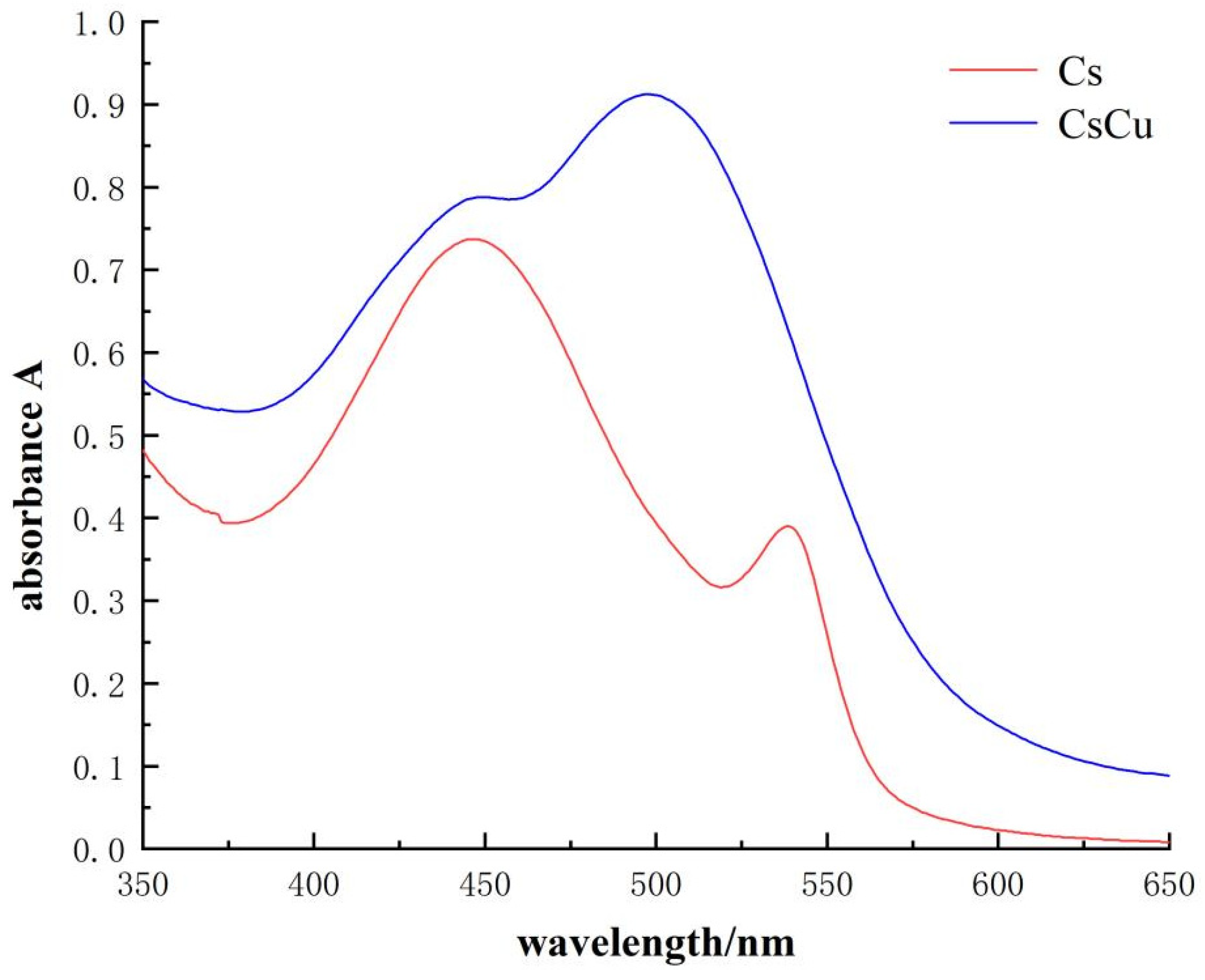

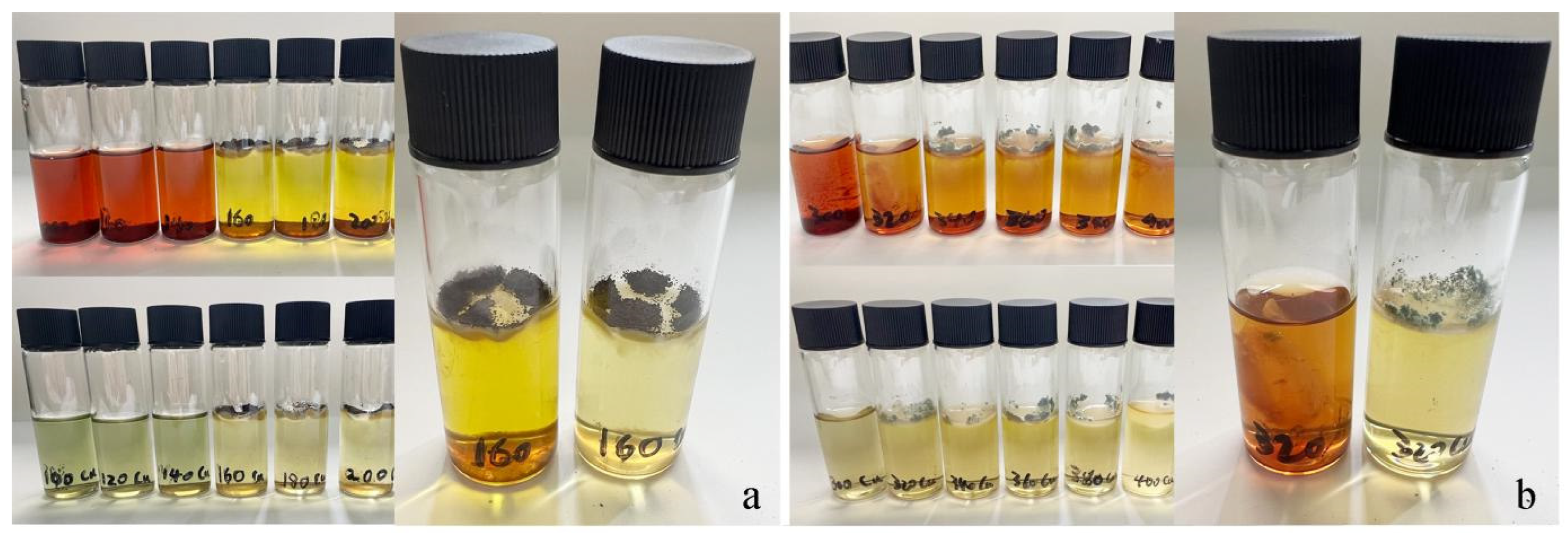

3.4. Dyeing and Color Fixation Rates Under Combined Effects

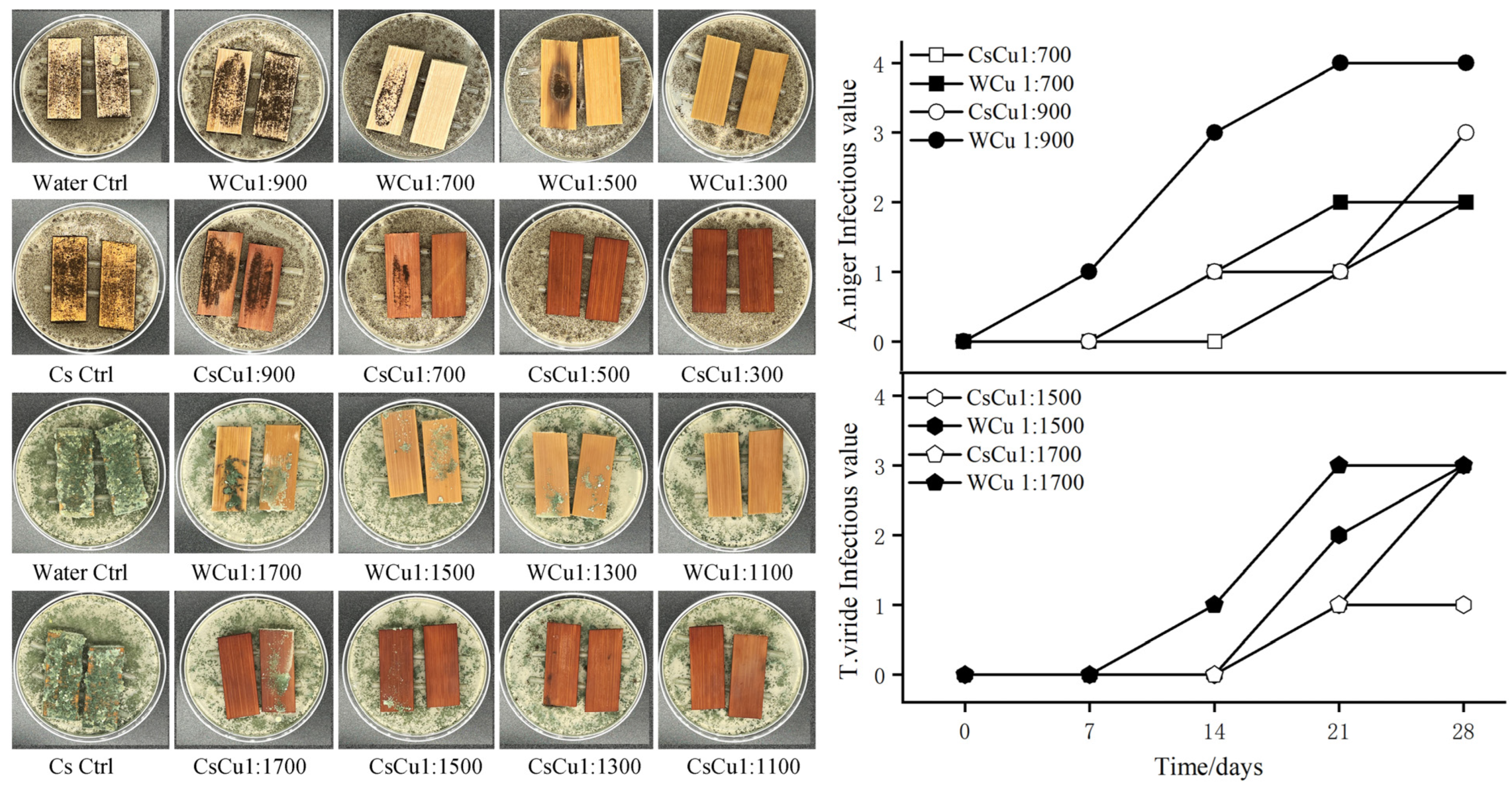

3.5. Mold Inhibition of Impregnated Bamboo Under Combined Effect

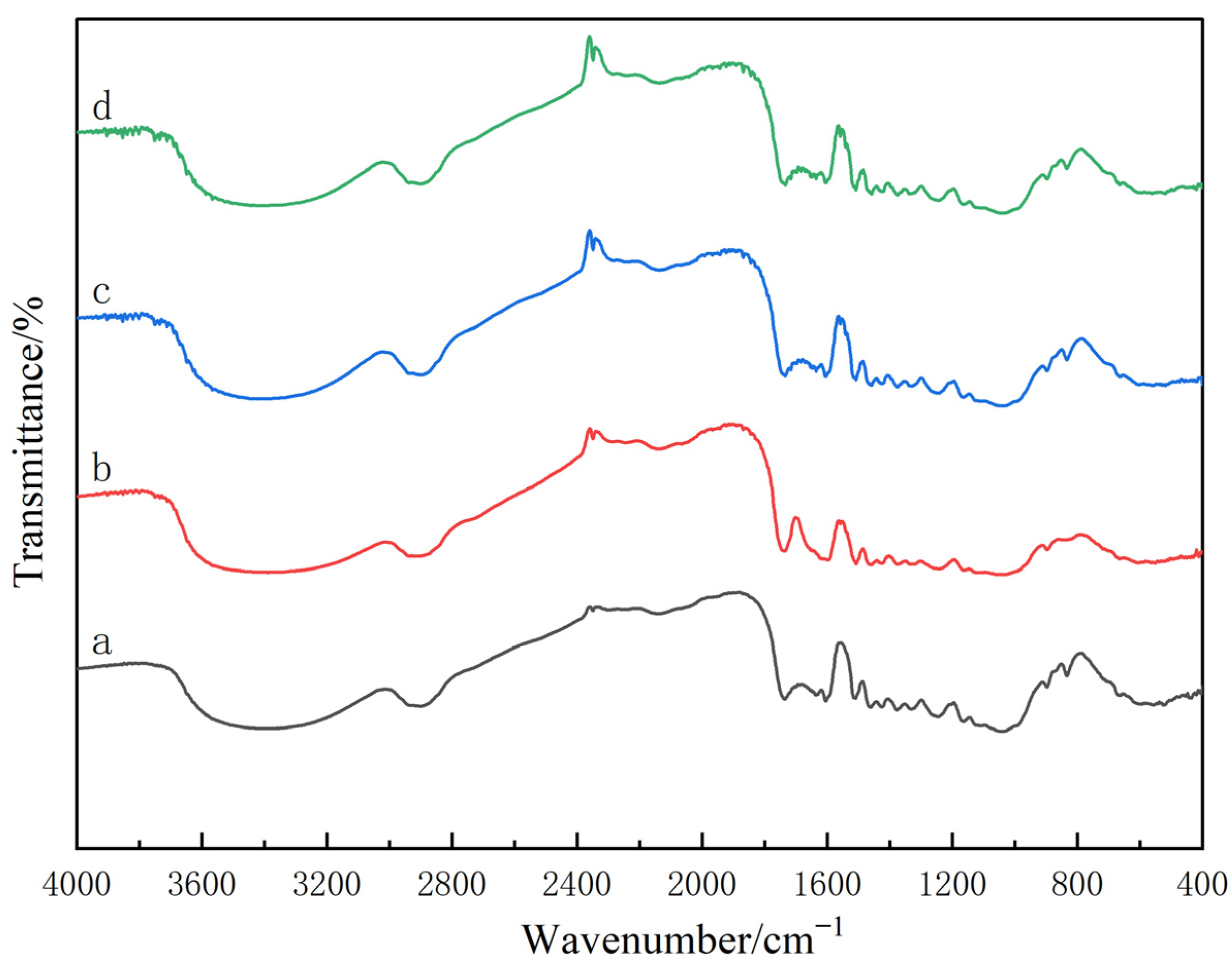

3.6. Fourier-Transform (FTIR) Analysis of Bamboo

3.7. SEM Analysis of Bamboo

3.8. Results of the Determination of Copper Content and Its Effect on the Color of Bamboo Wood

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dulo, B.; Phan, K.; Githaiga, J.; Raes, K.; Meester, S.D. Natural Quinone Dyes: A Review on Structure, Extraction Techniques, Analysis and Application Potential. Waste Biomass Valorization 2021, 12, 6339–6374. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, Y.; Yu, Z.; Zhang, Y. Study on infection behavior and characteristics of poplar wood dyed by Lasiodiplodia theobromae. Eur. J. Wood Wood Prod. 2022, 80, 1151–1163. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, Y.; Yu, Z.; Qi, C.; Tang, R.; Zhao, B.; Wang, H.; Han, Y. Microbial dyes: Dyeing of Poplar Veneer with Melanin Secreted by Lasiodiplodia Theobromae Isolated from Wood. Appl. Microbiol. Biotechnol. 2020, 104, 3367–3377. [Google Scholar] [CrossRef]

- Wu, M.; Song, T.; Pang, T.; Zhuang, P.; Niu, J.; Li, Y.; Sun, J. Characterization of the Red Dye from Arthrinium phaeospermum and Its Application in Wood Dyeing. J. Basic Microbiol. 2025. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Liu, S.; Bai, H.; Huang, Y.; Yu, Y.; Yu, W. Effect of tannic/gallic acid-iron dyeing treatment on surface color and light fastness of bamboo veneer. Heliyon 2024, 10, e24082. [Google Scholar] [CrossRef]

- Erkmen, O.; Ozcan, M. Antimicrobial effects of essential oils on growth of bacteria, yeasts and molds. J. Essent. Oil Bear. Plants 2004, 7, 279–287. [Google Scholar] [CrossRef]

- Rossi, T.; Silva, P.M.S.; De Moura, L.F.; Araújo, M.C.; Brito, J.O.; Freeman, H.S. Waste from eucalyptus wood steaming as a natural dye source for textile fibers. J. Clean. Prod. 2017, 143, 303–310. [Google Scholar] [CrossRef]

- Wang, X.; Guo, Z. Study on dyeing process of bamboo pulp fibers with onion peel pigments. Wool Text. J. 2018, 46, 46–49. [Google Scholar]

- Yan, X.; Zhou, Y. Mimicking the champagne colour of commercial satin silk integrating the extract from Eupatorium adenophorum with metal ions—An Economic Solution to Tackle with Invasive Plants. Sustain. Mater. Technol. 2025, 43, e01292. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, Y.; Fu, Y.; Sun, J. Dyeing process and mechanism of eucalyptusveneer with Dalbergia bariensis heartwood pigment as dye. J. Beijing For. Univ. 2020, 42, 151–159. [Google Scholar]

- Qin, C.; Chen, D.; Tang, R.; Huang, Y.; Wang, X.; Chen, G. Studies on silk fabric dyed with a hemicyanine dye. Color. Technol. 2010, 126, 303–307. [Google Scholar] [CrossRef]

- Zhou, P.; Li, X.; Zhou, J.; Wang, Y.; Lu, Y.; Jiang, Z. Microcapsules loaded with essential oil: Enhancing the Hydrophobic and Antifungal Properties of Wood-Based Panels. Ind. Crops Prod. 2025, 225, 120471. [Google Scholar] [CrossRef]

- Ferdes, M.; Al Juhaimi, F.; Özcan, M.M.; Ghafoor, K. Inhibitory effect of some plant essential oils on growth of Aspergillus niger, Aspergillus oryzae, Mucor pusillus and Fusarium oxysporum. S. Afr. J. Bot. 2017, 113, 457–460. [Google Scholar] [CrossRef]

- Salem, M.Z.; Zidan, Y.E.; El Hadidi, N.M.N.; Mansour, M.M.A.; Elgat, W.A.A.A. Evaluation of usage of three natural extracts applied to three commercial wood species against five common molds. Int. Biodeterior. Biodegrad. 2016, 110, 206–226. [Google Scholar] [CrossRef]

- Song, J.; Chen, Y.; Wang, J. Low-temperature preparation of ZnO on bamboo surface and its anti-mold performance. J. For. Eng. 2017, 2, 19–23. [Google Scholar]

- Tadtong, S.; Puengseangdee, C.; Prasertthanawut, S.; Hongratanaworakit, T. Antimicrobial Constituents and Effects of Blended Eucalyptus, Rosemary, Patchouli, Pine, and Cajuput Essential Oils. Nat. Prod. Commun. 2016, 11, 267–270. [Google Scholar] [CrossRef] [PubMed]

- Saglam, C.; Mzcan, M.; Boyraz, N. Fungal Inhibition by Some Spice Essential Oils. J. Essent. Oil Bear. Plants 2009, 12, 742–750. [Google Scholar] [CrossRef]

- Salah, I.; Parkin, I.P.; Allan, E. Copper as an antimicrobial agent: Recent Advances. RSC Adv. 2011, 11, 18179–18186. [Google Scholar] [CrossRef]

- Vincent, M.; Hartemann, P.; Engels-Deutsch, M. Antimicrobial applications of copper. Int. J. Hyg. Environ. Health 2016, 219, 585–591. [Google Scholar] [CrossRef]

- Dai, X.; Qi, Y.; Luo, H.; He, Z.; Wei, L.; Dong, X.; Ma, X.; Yang, D.Q.; Li, Y. Leachability and Anti-Mold Efficiency of Nanosilver on Poplar Wood Surface. Polymers 2022, 14, 884. [Google Scholar] [CrossRef]

- Ermini, M.L.; Voliani, V. Antimicrobial Nano-Agents: The Copper Age. ACS Nano 2021, 15, 6008–6029. [Google Scholar] [CrossRef] [PubMed]

- Sun, F.; Yu, Y.; Jiang, Z.; Ren, H.; Wang, G.; Liu, X. Nano-TiO2 modification of bamboo and its antibacterial and anti-mold performance. Spectrosc. Spectr. Anal. 2010, 30, 1056–1060. [Google Scholar]

- Bao, Q.; Yang, F.; Zhang, S.; Zhu, J.; Du, C.; Ran, Y.; Tao, P.; Ding, J.; Wang, X.; Yin, W. Selective impact of lignin and hemicelluloses macromolecules in bamboo cell walls by mildew. Int. J. Biol. Macromol. 2025, 306, 141495. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Wu, Y.; Yang, J.; Zhu, X.; Sun, F.; Li, L.; Shen, Z.; Pang, Y.; Wu, Q.; Chen, H. Gentle fabrication of colorful superhydrophobic bamboo based on metal-organic framework. J. Colloid Interface Sci. 2021, 593, 41–50. [Google Scholar] [CrossRef]

- Manian, A.P.; Paul, R.; Bechtold, T. Metal mordanting in dyeing with natural colorants. Color. Technol. 2016, 132, 107–113. [Google Scholar] [CrossRef]

- Lin, L.; Cao, J.; Zhang, J.; Cui, Q.; Liu, Y. Enhanced Anti-Mold Property and Mechanism Description of Ag/TiO2 Wood-Based Nanocomposites Formation by Ultrasound- and Vacuum-Impregnation. Nanomaterials 2020, 10, 682. [Google Scholar] [CrossRef]

- Amesimeku, J.; Fan, L.; Jakpa, W.; Wang, C. Dyeing properties of meta-aramid fabric dyed with basic dye using ultrasonicmicrowave irradiation, Journal of Cleaner Production. J. Clean. Prod. 2021, 285, 124844. [Google Scholar] [CrossRef]

- Amaral, L.M.D.; de Mello Innocentini, M.D.; Kadivar, M.; Savastano, H. An exploratory study on bamboo permeability for the evaluation of treatability with chemical solutions. Mater. Today Commun. 2024, 40, 109719. [Google Scholar] [CrossRef]

- Gu, W.; Zhang, W.; Tao, H.; Bao, M.; Li, Y.; Lin, F.; Zheng, Y.; Zhao, S. Effect of Hydrothermal Treatment on the Mechanical and Microscopic Properties of Moso Bamboo. Forests 2024, 15, 281. [Google Scholar] [CrossRef]

- Al’Afifah, J.A.; Sumardi, I.; Darwis, A.; Melani, L.; Suhaya, Y. Evaluation of Staining Betung Bamboo (Dendrocalamus Asper) Using Natural and Synthetic Dyes with and without the Addition of Preservatives. IOP Conf. Ser. Earth Environ. Sci. 2024, 1309, 012002. [Google Scholar] [CrossRef]

- Nguyen, N.; Ozarska, B.; Fergusson, M.; Vinden, P. Comparison of two dye uptake measurement methods for dyed wood veneer assessment. Eur. J. Wood Wood Prod. 2018, 76, 1757–1759. [Google Scholar] [CrossRef]

- GB/T 18261-2013; Chinese National Standard. Effectiveness of Anti-fungal Agent for the Prevention and Control of Mold and Discoloration Bacteria on Wood. Chinese Standards: Beijing, China, 2013.

- Cui, H.; Cai, R.; Hua, Z.; Tang, Y. Plant colorants for natural hair coloration: Dyeing Optimization and Photostability Assessment. Sustain. Chem. Pharm. 2023, 36, 101285. [Google Scholar] [CrossRef]

- Fei, B.; Liu, R.; Liu, X.; Chen, X.; Zhang, S. Research progress on bamboo pore structure and characterization methods. J. For. Eng. 2019, 4, 13–18. [Google Scholar]

- Bao, Y.; Wu, Z.; Wang, S.; Zhong, Z. Comparative study on pore structure characteristics of activated carbon prepared from different bamboos. Bamboo Res. J. 2010, 29, 32–35. [Google Scholar]

- Liu, R.; Chen, M.; Liu, X.; Fei, B. Study on pore characteristics of bamboo cell wall by resin casting method. For. Sci. 2019, 55, 196–202. [Google Scholar]

- Sepahi, S.; Barani, H.; Khazaee, F. Transforming parasitic weeds into sustainable natural dyes: A Study of Wool Dyeing with Orobanche Plant extract. Clean. Eng. Technol. 2025, 26, 100932. [Google Scholar] [CrossRef]

- Shen, L.; Li, C. Current status and trend of wood dyeing technology development under the perspective of sustainability. World For. Res. 2024, 37, 49–54. [Google Scholar]

- Taherirad, F.; Maleki, H.; Barani, H.; Khashei-Siuki, A.; Khazaei, F. Optimizing dyeing parameters for sustainable wool dyeing using quinoa plant components with antibacterial properties. Clean. Eng. Technol. 2024, 21, 100780. [Google Scholar] [CrossRef]

| NBS Unit | Level of Chromatic Aberration |

|---|---|

| 0–0.5 | Minute color difference (imperceptible) |

| 0.5–1.5 | Small color difference (barely perceptible) |

| 1.5–3 | Perceivable change (noticeable in controlled light) |

| 3–6 | Marked change (distinctly visible) |

| >6 | Extremely marked change (different color) |

| Infectious Value | Specimen Infected Area |

|---|---|

| 0 | No mycelium or mold on the surface |

| 1 | Infected area < 1/4 of the surface |

| 2 | Infected area < 1/4–1/2 of the surface |

| 3 | Infected area < 1/2–3/4 of the surface |

| 4 | Infected area > 3/4 of the surface |

| Sample | L2* | a2* | b2* | ΔL* | Δa* | Δb* | ΔE* | Trial Color |

|---|---|---|---|---|---|---|---|---|

| Boil | 80.83 | 6.92 | 28.32 | 2.50 | 1.17 | 5.12 | 5.81 |  |

| Cs | 59.83 | 21.48 | 47.63 | −20.45 | 14.72 | 19.22 | 31.69 |  |

| CsAl | 55.92 | 38.70 | 30.82 | −23.92 | 31.93 | 3.00 | 40.01 |  |

| CsCu | 45.58 | 31.83 | 19.60 | −35.22 | 25.05 | −8.67 | 44.08 |  |

| CsFe | 34.93 | 8.68 | 4.23 | −45.02 | 1.82 | −22.58 | 50.40 |  |

| Ct | 67.88 | 20.73 | 40.20 | −11.96 | 13.74 | 11.63 | 21.61 |  |

| CtAl | 70.38 | 14.73 | 36.35 | −11.17 | 7.82 | 7.88 | 15.75 |  |

| CtCu | 67.27 | 14.65 | 36.47 | −13.83 | 7.33 | 8.20 | 17.67 |  |

| CtFe | 57.47 | 10.55 | 27.25 | −21.87 | 3.68 | −1.07 | 22.20 |  |

| Rc | 57.30 | 27.65 | 32.10 | −24.28 | 20.93 | 3.88 | 32.29 |  |

| RcAl | 64.87 | 20.80 | 36.65 | −16.97 | 14.03 | 8.33 | 23.54 |  |

| RcCu | 69.12 | 10.45 | 35.65 | −11.72 | 3.33 | 7.43 | 14.27 |  |

| RcFe | 59.27 | 10.10 | 30.58 | −21.62 | 3.23 | 2.32 | 21.98 |  |

| Sample | λmax | A0n0 | A1n1 | A2n2 | E/% | F/% |

|---|---|---|---|---|---|---|

| Cs | 446 | 0.737 | 0.666 | 0.714 | 9.63 | 3.12 |

| CsCu | 498 | 0.913 | 0.816 | 0.829 | 10.62 | 9.20 |

| Mold | Sample | Area Infected (CsCu, Days) | Infectious Value | Resistance/% | Area Infected (WCu, Days) | Infectious Value | Resistance/% | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 14 | 21 | 28 | 14 | 21 | 28 | ||||||

| A. niger | ctrl | 9/10 | 1 | 1 | 4 | - | 1 | 1 | 1 | 4 | - |

| 300 | 0 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 0 | 100 | |

| 500 | 0 | 0 | 1/30 | 1 | 75 | 0 | 1/4 | 1/3 | 2 | 50 | |

| 700 | 0 | ¹⁄₆ | 1/4 | 2 | 50 | 1/40 | 1/4 | 1/3 | 2 | 50 | |

| 900 | 1/30 | ¹⁄₆ | ⅔ | 3 | 25 | 1/2 | 5/6 | 9/10 | 4 | 0 | |

| T. viride | ctrl | 1 | 1 | 1 | 4 | - | 1 | 1 | 1 | 4 | - |

| 1100 | 0 | 0 | 0 | 0 | 100 | 0 | 0 | 0 | 0 | 100 | |

| 1300 | 0 | 0 | 1/30 | 1 | 75 | 0 | 1/5 | 1/4 | 1 | 75 | |

| 1500 | 0 | 1/10 | 1/8 | 1 | 75 | 0 | 1/4 | 1/3 | 3 | 25 | |

| 1700 | 0 | 1/4 | 1/3 | 3 | 25 | 1/30 | 1/3 | 2/3 | 3 | 25 | |

| Sample | Sampling Mass/g | Instrument Readings | Unit | Conversion Content | Unit | Mass Fraction % |

|---|---|---|---|---|---|---|

| CsCu1:300 | 0.1966 | 2.5861 | mg/L | 3288.5 | mg/kg | 0.3288 |

| WCu1:300 | 0.2012 | 2.7929 | mg/L | 3470.4 | mg/kg | 0.3470 |

| CsCu1:1100 | 0.2009 | 1.1434 | mg/L | 1422.9 | mg/kg | 0.1423 |

| WCu1:1100 | 0.2019 | 1.1945 | mg/L | 1479.1 | mg/kg | 0.1479 |

| Sample | L* | a* | b* | Trial Color | Test Piece | L* | a* | b* | Trial Color |

|---|---|---|---|---|---|---|---|---|---|

| CsCu1:300 | 39.7 | 26.4 | 19.2 |  | CsCu1:1100 | 39.4 | 27.4 | 18.2 |  |

| CsCu1:500 | 45.1 | 27.2 | 23.1 |  | CsCu1:1300 | 43.6 | 28.7 | 22 |  |

| CsCu1:700 | 41.8 | 27.5 | 20.5 |  | CsCu1:1500 | 42.5 | 27.9 | 19.5 |  |

| CsCu1:900 | 40.5 | 27.9 | 20.2 |  | CsCu1:1700 | 45.8 | 28.2 | 23.2 |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Xiong, J.; Zheng, L.; Han, Y.; Sun, S.; Peng, Y.; Xu, K.; Chen, T. Study on the Synergistic Effect of Plant Dyes and Mordants on the Dyeing and Anti-Mold Effect of Moso Bamboo. Forests 2025, 16, 755. https://doi.org/10.3390/f16050755

Li S, Xiong J, Zheng L, Han Y, Sun S, Peng Y, Xu K, Chen T. Study on the Synergistic Effect of Plant Dyes and Mordants on the Dyeing and Anti-Mold Effect of Moso Bamboo. Forests. 2025; 16(5):755. https://doi.org/10.3390/f16050755

Chicago/Turabian StyleLi, Shan, Jianwen Xiong, Lilang Zheng, Yuxing Han, Song Sun, Yuxiang Peng, Kaimeng Xu, and Taian Chen. 2025. "Study on the Synergistic Effect of Plant Dyes and Mordants on the Dyeing and Anti-Mold Effect of Moso Bamboo" Forests 16, no. 5: 755. https://doi.org/10.3390/f16050755

APA StyleLi, S., Xiong, J., Zheng, L., Han, Y., Sun, S., Peng, Y., Xu, K., & Chen, T. (2025). Study on the Synergistic Effect of Plant Dyes and Mordants on the Dyeing and Anti-Mold Effect of Moso Bamboo. Forests, 16(5), 755. https://doi.org/10.3390/f16050755