On the Rheological Behavior of Pine (Pinus sylvestris L.) Shavings and the Briquettes Obtained from Them

Abstract

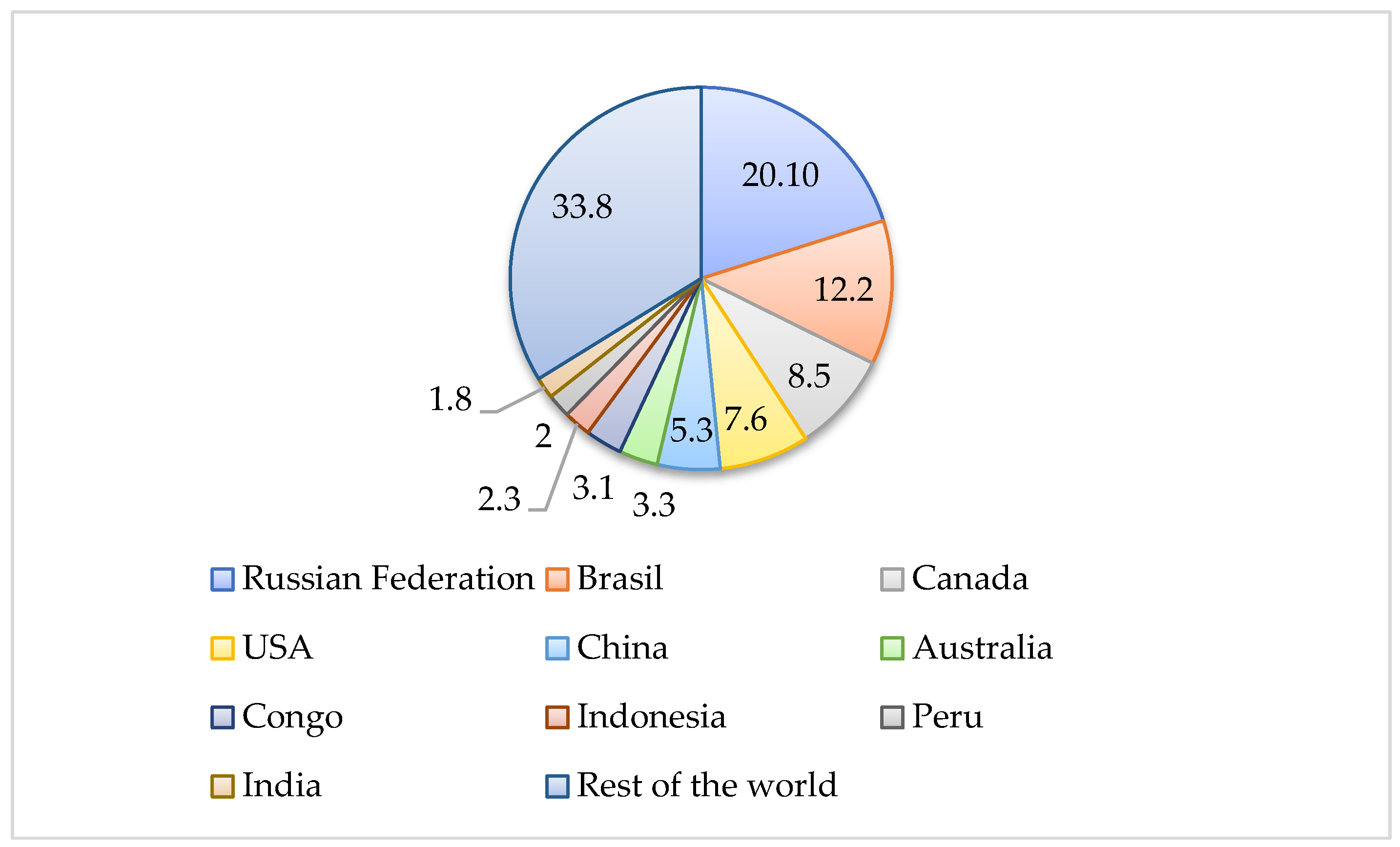

1. Introduction

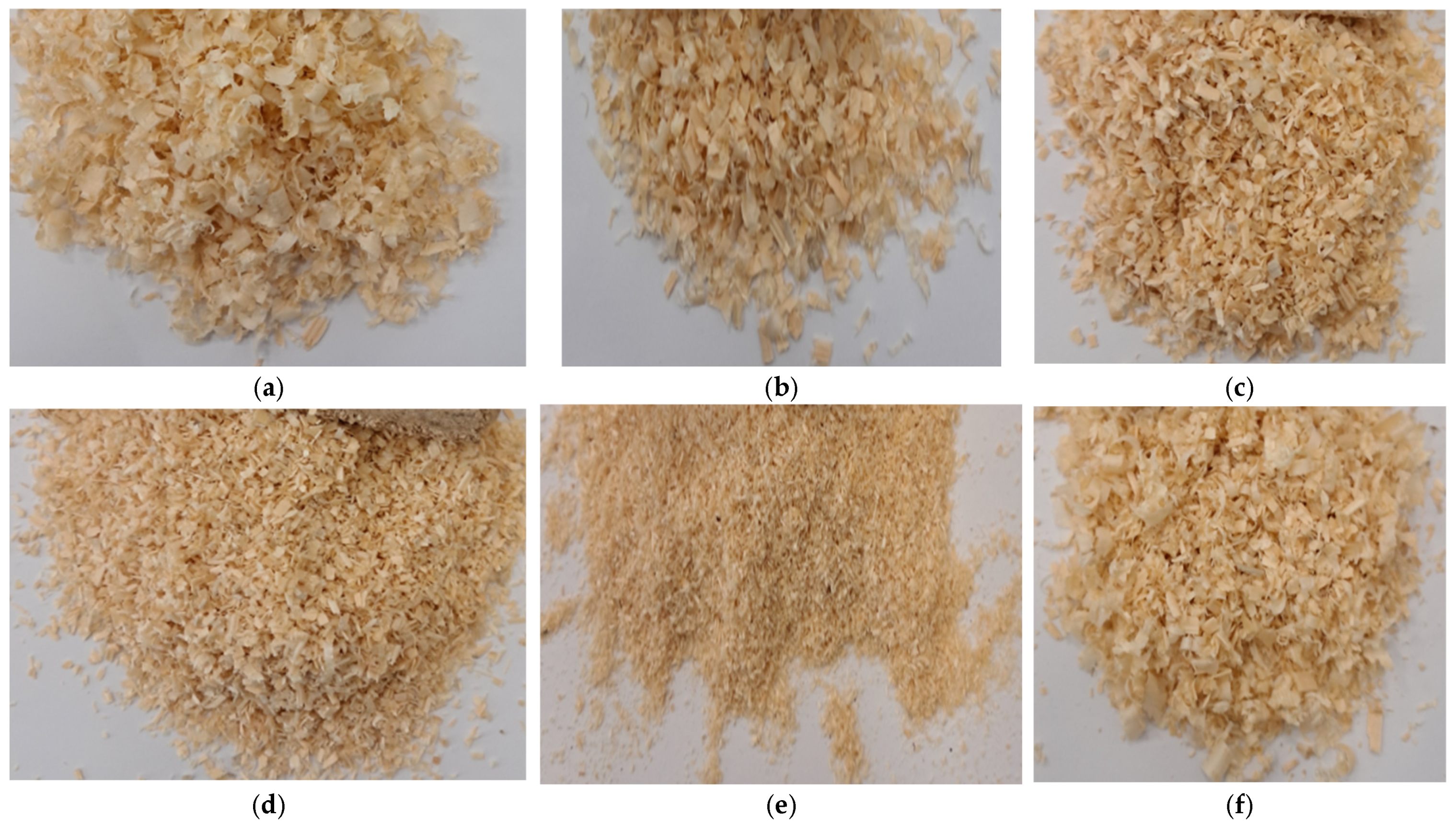

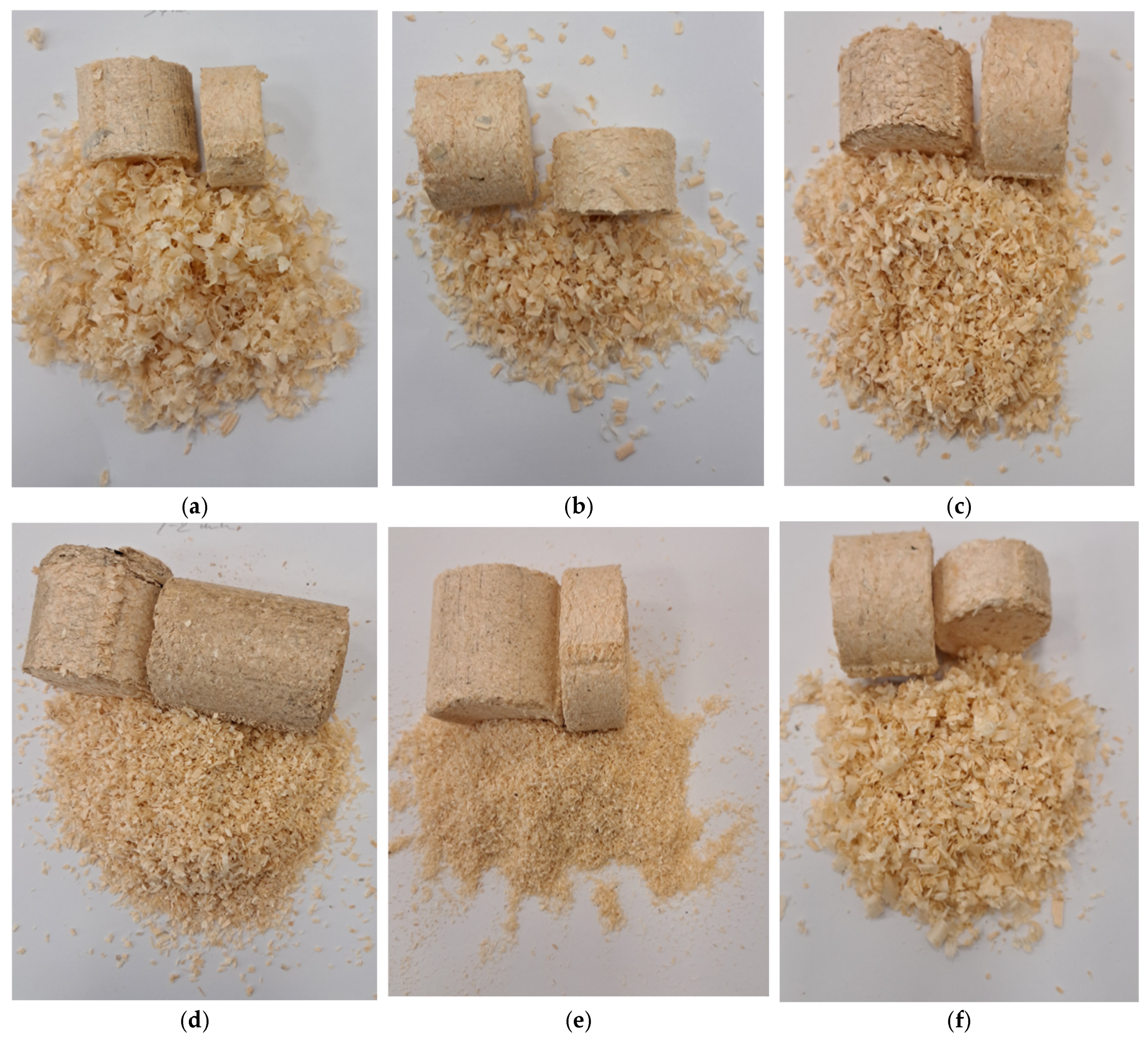

2. Materials and Methods

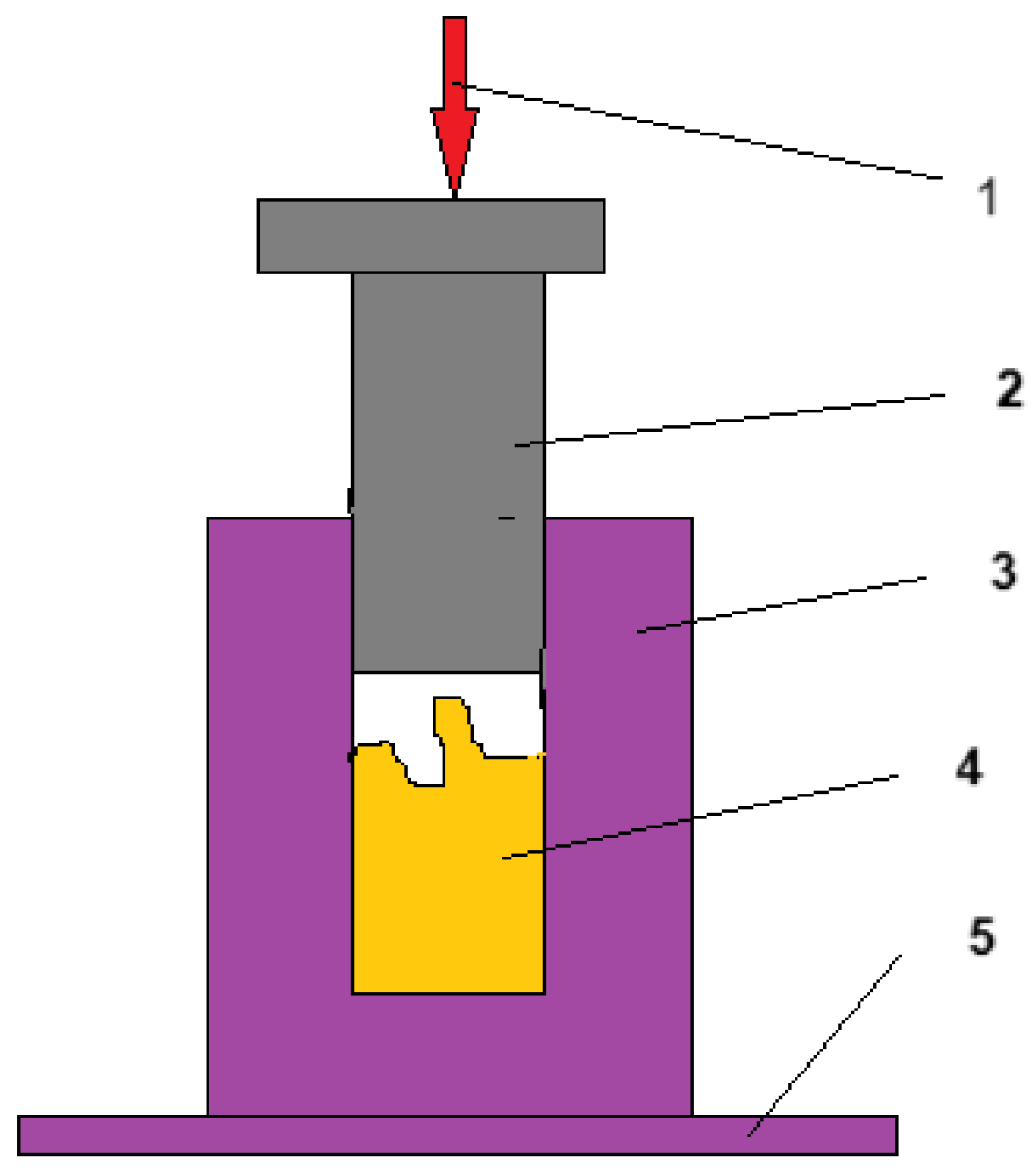

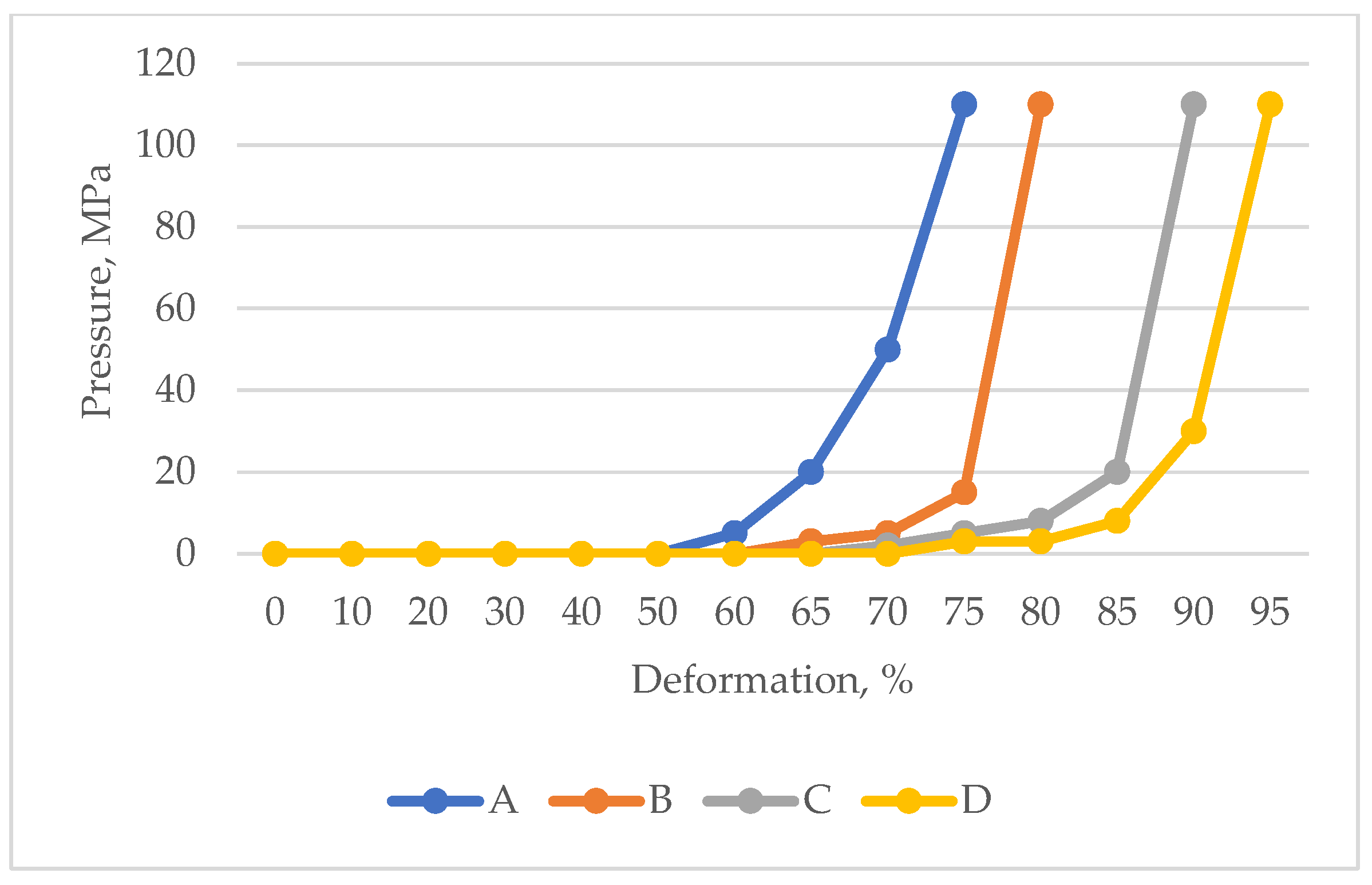

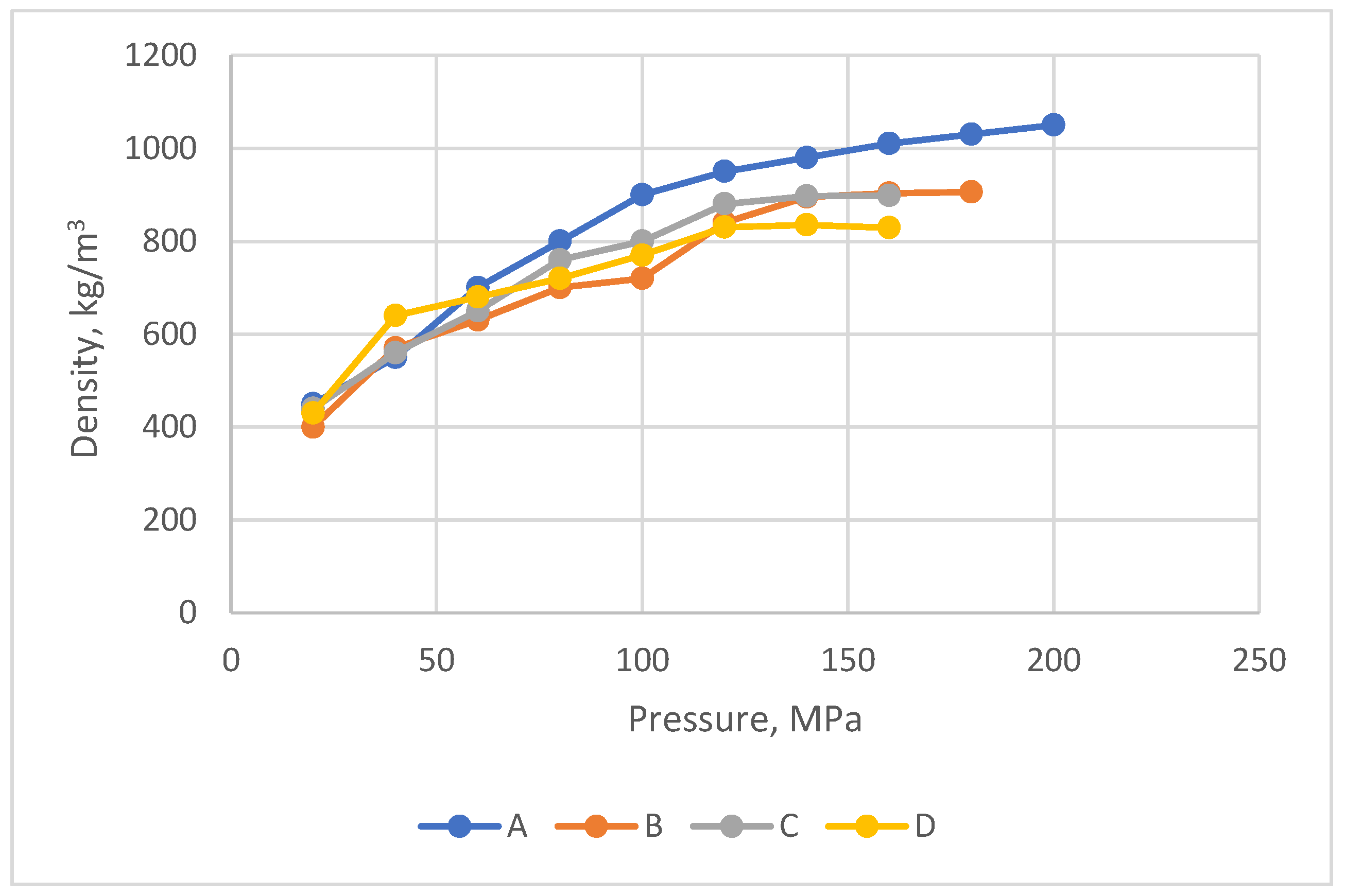

2.1. Rheological Behavior of Shredded Pine During Uniaxial Pressing

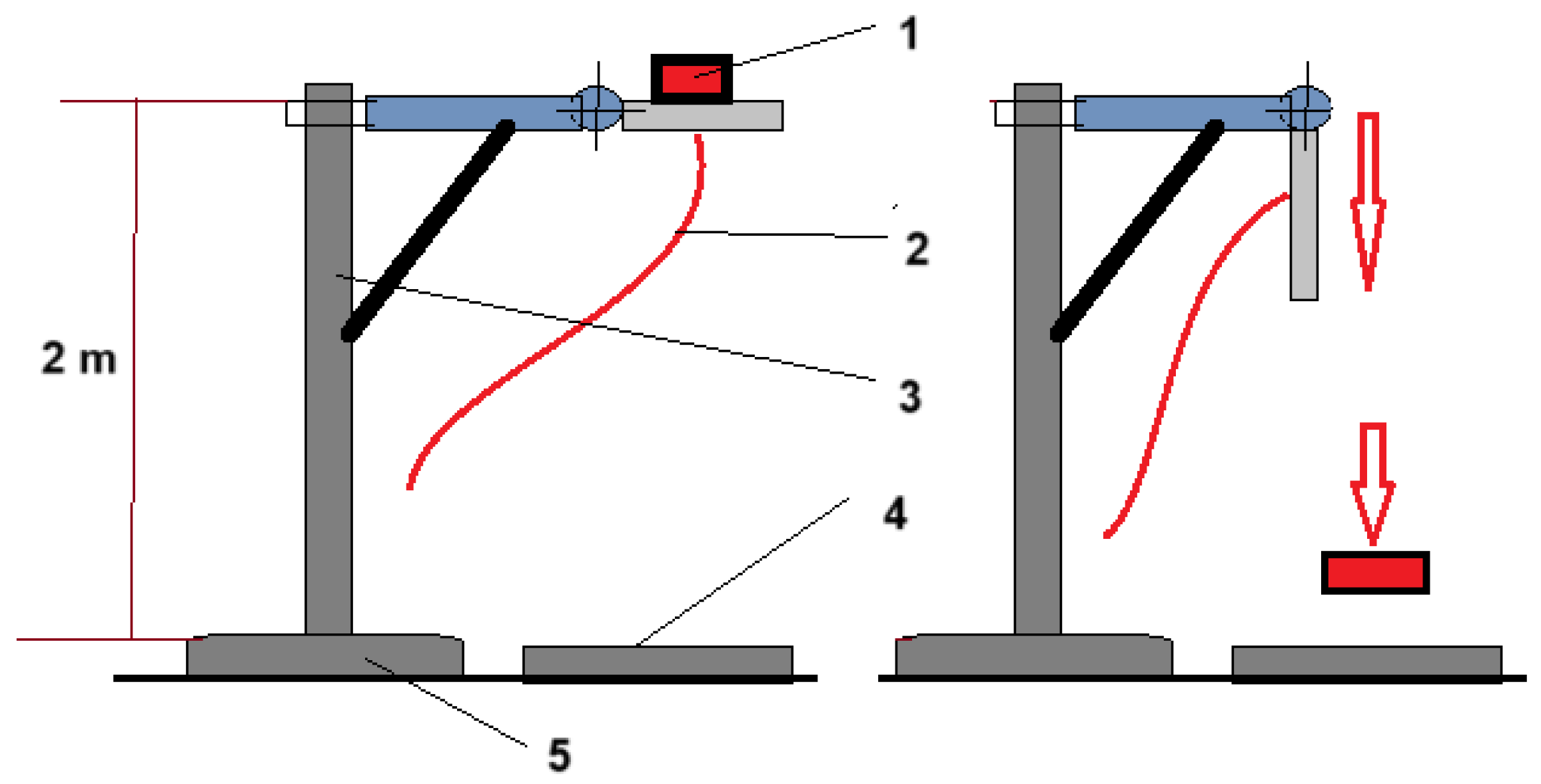

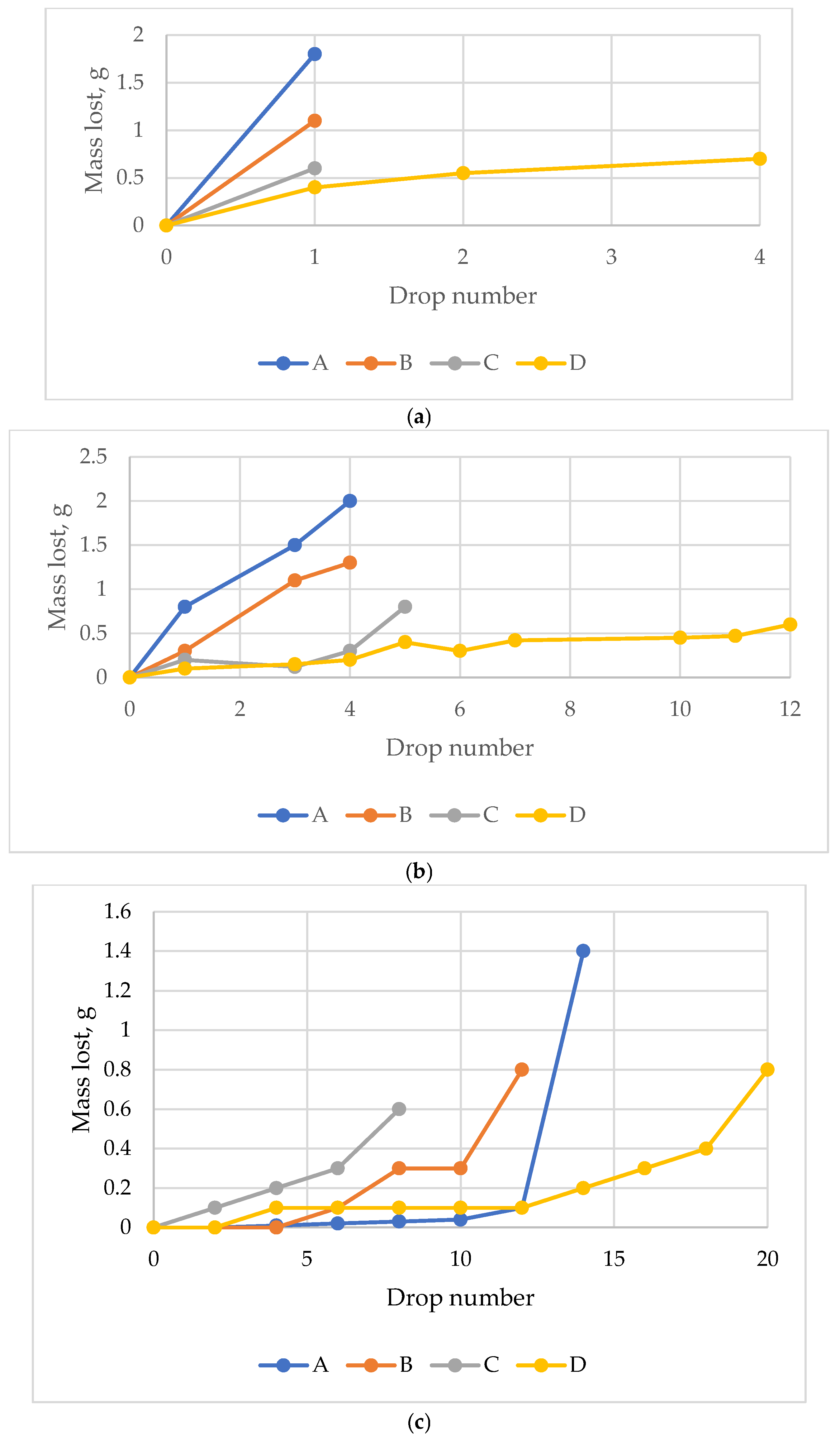

2.2. Methodology for Briquettes

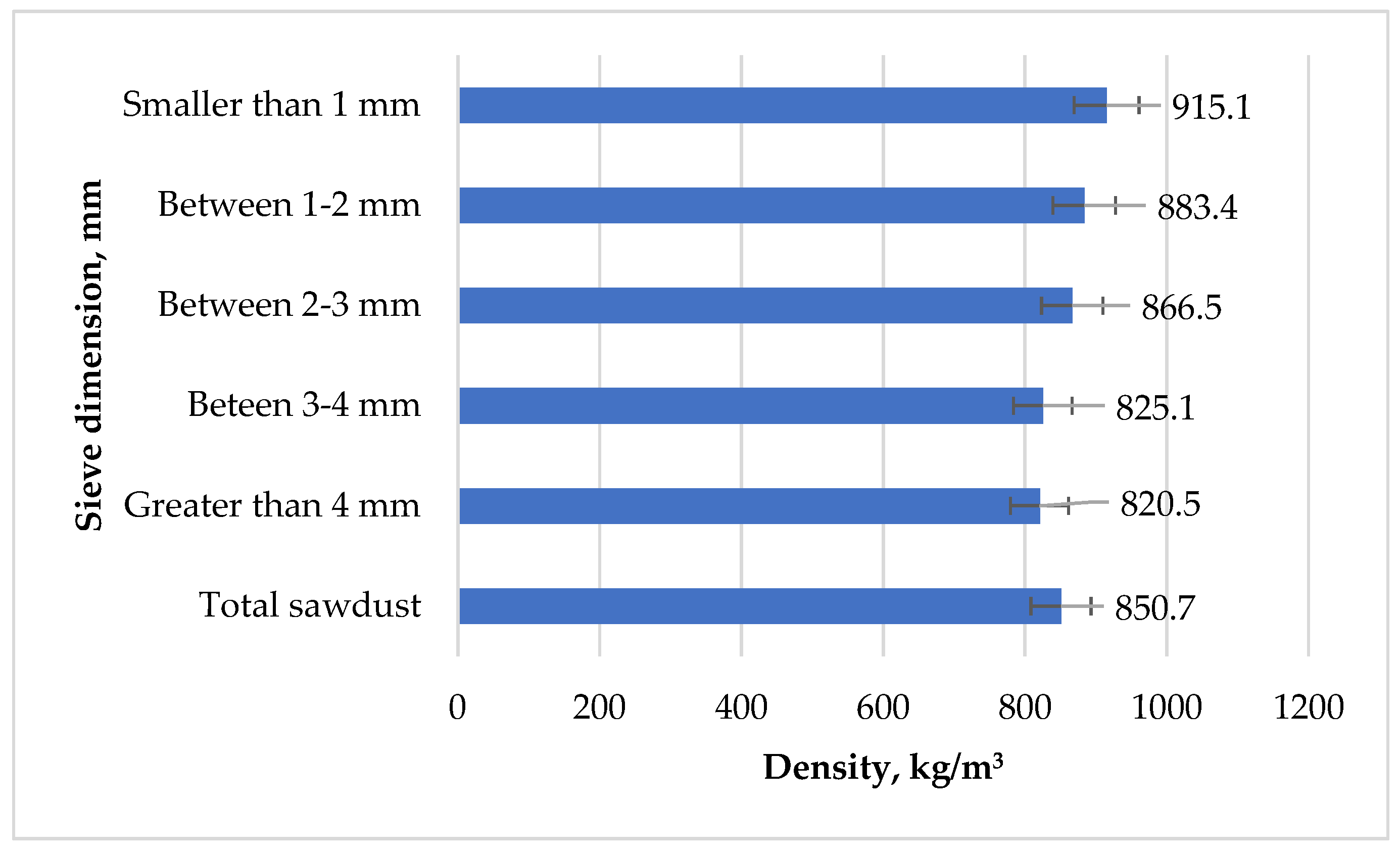

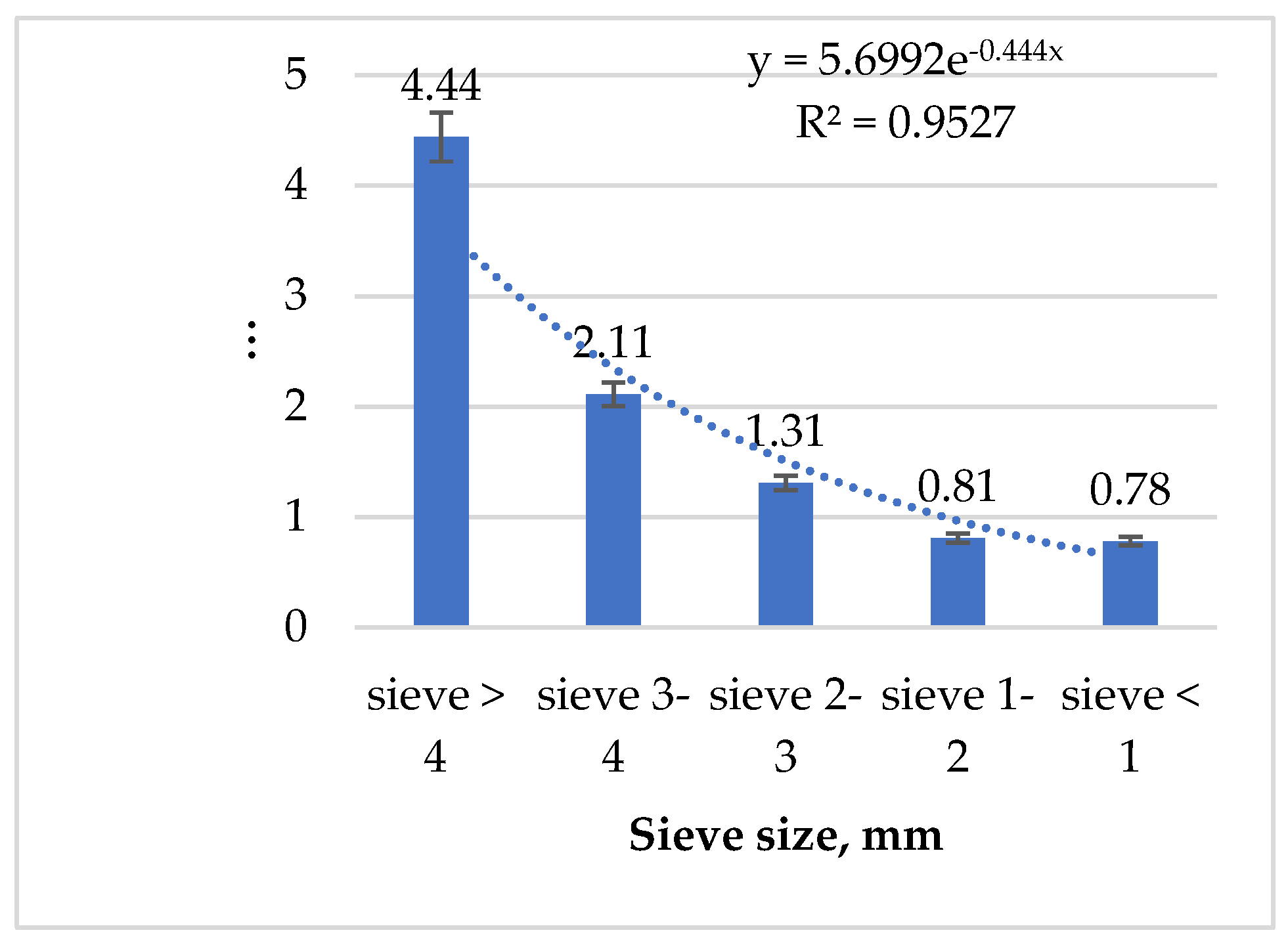

| Particle Size | Mass, g | Height, cm | Pressing Height, cm | Bulk Density, g/cm | Compacted Density, g/cm3 | Relative Density g/cm3 |

|---|---|---|---|---|---|---|

| A: d < 1 mm | 3.122 | 4.9 | 0.6 | 0.131 | 1.060 | 0.693 |

| B: 1 < d < 2 mm | 3.195 | 5.3 | 0.7 | 0.123 | 0.930 | 0.608 |

| C: 2 < d < 3 mm | 3.382 | 5.7 | 0.8 | 0.121 | 0.862 | 0.563 |

| D: d > 4 mm | 3.358 | 6.7 | 0.8 | 0.103 | 0.855 | 0.559 |

3. Results

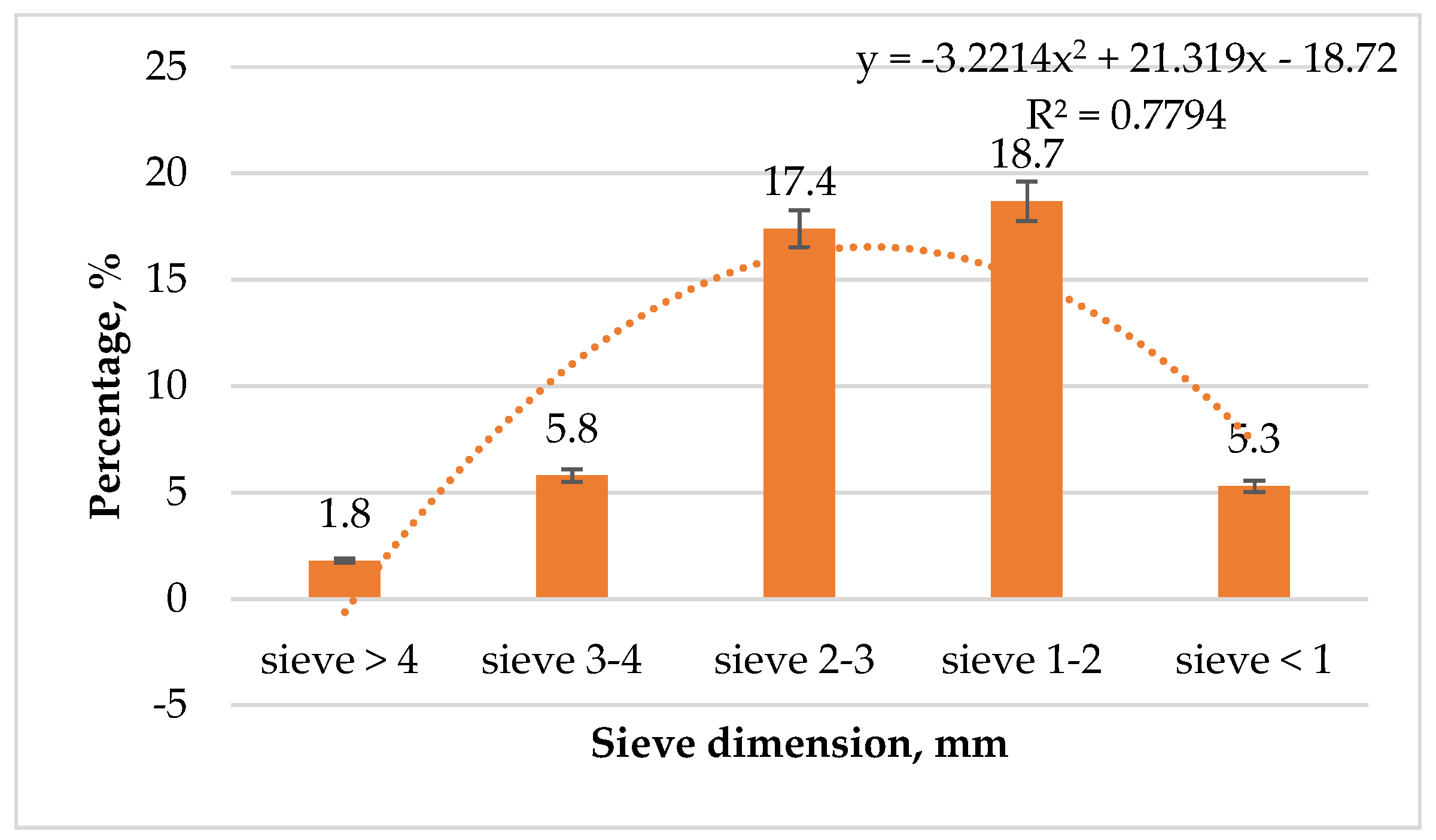

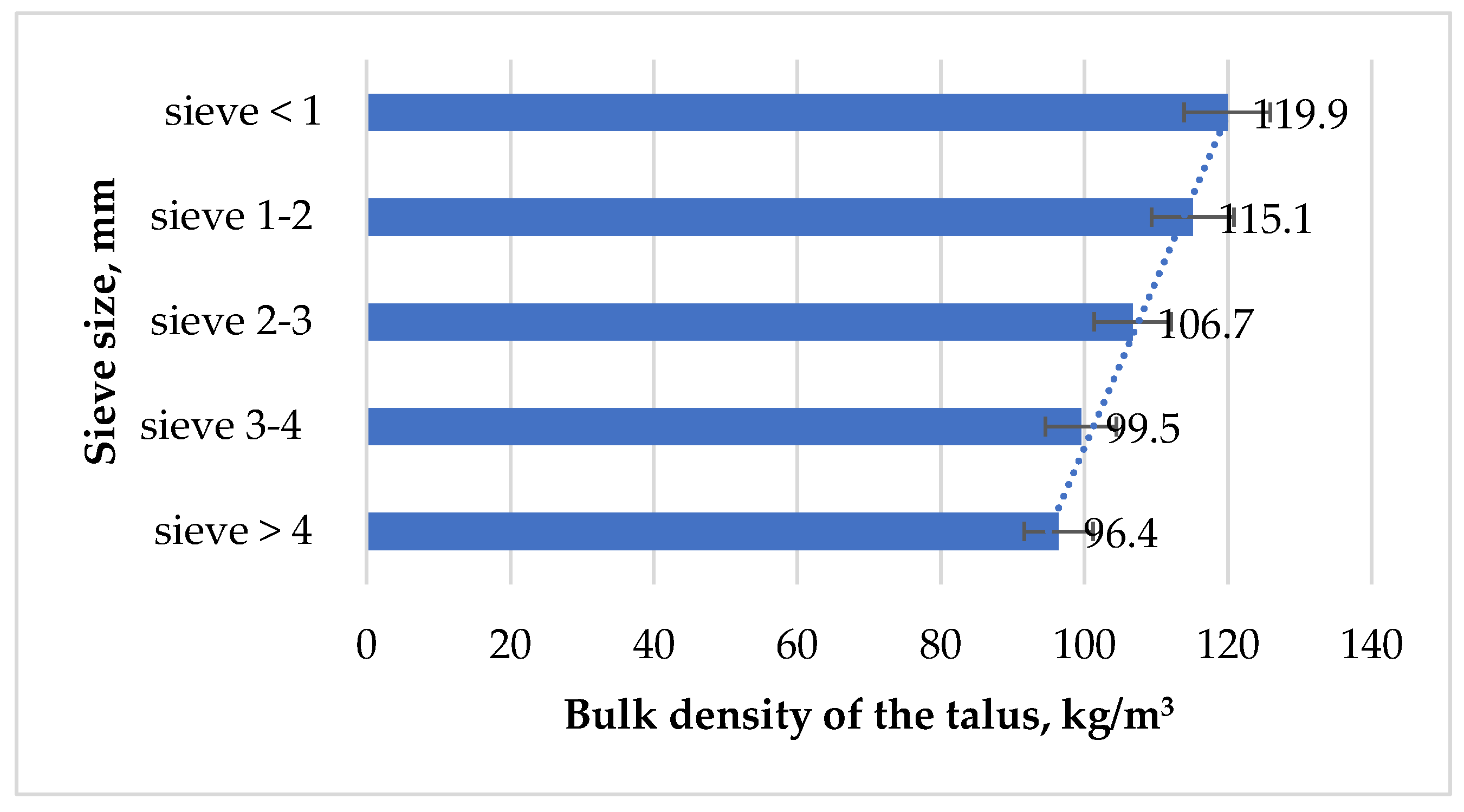

3.1. Results Regarding Agglomerate Compaction

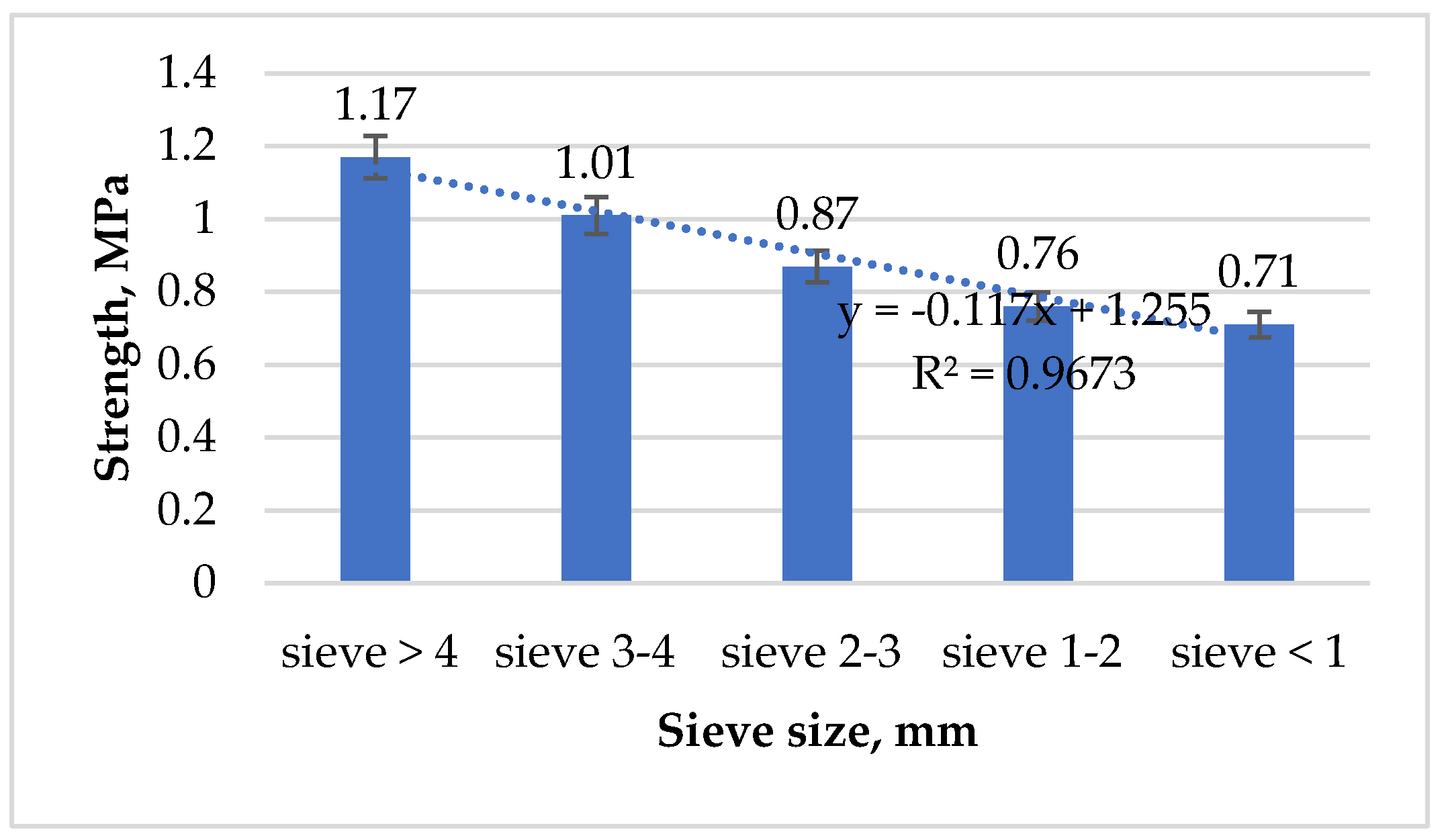

3.2. Results Regarding Wood Briquettes

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Griu, T. Evaluation of the Calorific Value of Woody Biomas. Ph.D. Thesis, Universitatea Transilvania din Brasov, Brasov, Romania, 2014. (In Romanian). [Google Scholar]

- Krajnic, N. Wood Fuel Handbook; Food and Agriculture Organization (FAO) of the United Nations: Pristina, Kosovo, 2015. [Google Scholar]

- Prasertsan, S.; Sajakulnukit, B. Biomass and Bioenergy in Thailand: Potential, Opportunity and Barriers. Renew. Energ. 2006, 31, 599–610. [Google Scholar] [CrossRef]

- Demirbas, A. Biomass Resource Facilities and Biomass Conversion Processing for Fuels and Chemicals. Energ. Convers. Manag. 2001, 42, 1357–1378. [Google Scholar] [CrossRef]

- Demirbas, A.; Demirbas, A.S. Briquetting Properties of Biomass Waste Materials. Energ. Source Part A 2004, 26, 83–91. [Google Scholar] [CrossRef]

- Spirchez, C.; Lunguesa, A.; Matei, M. Particularities of hollow-core briquettes obtained out of spruce and oak wooden waste. Maderas Cienc. Tecnol. 2018, 20, 139–152. [Google Scholar] [CrossRef]

- Ramírez-Ramírez, M.A.; Carrillo-Parra, A.; Ruíz-Aquino, F.; Pintor-Ibarra, L.F.; González-Ortega, N.; Orihuela-Equihua, R.; Carrillo-Ávila, N.; Luján-Álvarez, C.; Rutiaga-Quinones, J.G. Valorization of briquettes fuel using Pinus spp. sawdust from five regions of Mexico. BioResources 2021, 16, 2249–2263. [Google Scholar] [CrossRef]

- Borowsky, G. Possibilities of Utilisation of Energy Briquettes. Electr. Enginering Res. Rep. 2011, 1, 48–51. Available online: http://eeeic.org/proc/papers/74.pdf (accessed on 2 December 2024).

- Marreiro, H.M.P.; Peruchi, R.S.; Lopes, R.M.B.P.; Andersen, S.L.F.; Eliziário, S.A.; Junior, P.R. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies 2021, 14, 8320. [Google Scholar] [CrossRef]

- Lundborg, A. A Sustainable Forest Fuel System in Sweden. Biomass Bioenerg. 1998, 15, 399–406. [Google Scholar] [CrossRef]

- Lakó, J.; Hancsók, J.; Yuzhakova, T.; Marton, G.; Utasi, A.; Rédey, A. Biomass—A Source of Chemicals and Energy for Sustainable Development. Environ. Eng. Manag. J. 2008, 7, 499–509. Available online: http://www.eemj.icpm.tuiasi.ro/pdfs/vol7/no5/2_Lako_J.pdf (accessed on 7 December 2024). [CrossRef]

- FAO. FAO: State of the World’s Forests 2024. Available online: https://www.donorplatform.org/post/fao-state-of-the-worlds-forests-2024/ (accessed on 9 December 2024).

- Šturc, M. Eurostat, Statistics in Focus 44/2012. Environment and Energy. Available online: https://ec.europa.eu/eurostat/web/products-statistics-in-focus/-/ks-sf-12-044 (accessed on 12 December 2024).

- European Commission (EC). Energy for the Future: Renewable Sources of Energy. White Paper for a Community Strategy and Action Plan, COM (97)599 Final (26/11/1997). Available online: http://ec.europa.eu/energy/library/599fi_en.pdf (accessed on 17 November 2024).

- Plepys, A.; Boutin, J.-P.; Gervasoni, G.; Hlep, R.; Seyboth, K.; Lamers, P.; Ratton, M.; McCormick, K.; Mundaca, L. Alternative Energy Sources in Transition Countries. The Case of Bio-energy in Ukraine. Environ. Eng. Manag. J. 2007, 6, 3–11. Available online: http://www.eemj.icpm.tuiasi.ro/pdfs/vol6/no1/2_Jean-Philippe%20Boutin.pdf (accessed on 16 December 2024). [CrossRef]

- Kim, S.; Dale, B.E. Cumulative Energy and Global Warming Impact from the Production of Biomass for Biobased Products. J. Ind. Ecol. 2003, 7, 147–162. Available online: http://arrahman29.files.wordpress.com/2008/02/lca-use.pdf (accessed on 2 May 2012). [CrossRef]

- Junginger, M.; Bolkesjø, T.; Bradley, D.; Dolzan, P.; Faaij, A.; Heinimö, J.; Hektor, B.; Leistad, Ø.; Ling, E.; Perry, M.; et al. Developments in International Bioenergy Trade. Biomass Bioenergy 2008, 32, 717–729. [Google Scholar] [CrossRef]

- Verma, V.K.; Bram, S.; de Ruyck, J. Small Scale Biomass Systems: Standards, Quality Labeling and Market Driving Factors—An EU Outlook. Biomass Bioenergy 2009, 33, 1393–1402. [Google Scholar] [CrossRef]

- Roser, D.; Asikainen, A. Sustainable Use for Forest Biomass for Energy; Springer Series in Wood Science; Springer: Berlin/Heidelberg, Germany, 2006. [Google Scholar]

- Okello, C.; Pindozzi, S.; Faugno, S.; Boccia, L. Bioenergy potential of agricultural and forest residues in Uganda. Biomass Bioenergy 2013, 56, 515–525. [Google Scholar] [CrossRef]

- Aebiom (European Biomass Association). Wood Fuels Handbook. Available online: https://www.lemvigbiogas.com/BiogasHandbook.pdf (accessed on 18 December 2024).

- Kostanaki, E.; Vamvuka, D. A comparative reactivity and kinetic study on the combustion of coal-biomass char blends. Fuel 2006, 85, 1186–1193. [Google Scholar] [CrossRef]

- Petrovici, V.; Popa, N. Chemistry and Chemical Wood Processing; Lux Libris Print House: Brasov, Romania, 1997. (In Romanian) [Google Scholar]

- DIN 51731 [1996]; Testing of Solid Fuels—Compressed and Untreated Wood—Requirements and Testing. German Institute for Standardization: Berlin, Germany, 1996.

- EN ISO 17225-1: 2014 [2014]; Solid Biofuels—Fuel Specifications and Classes—Part 1: General Requirements. European Committee of Standardization: Brussels, Belgium, 2014.

- Equilabo, Catalogue 1200. Parr. Oxygen Bomb Calorimeters and Accessories. Available online: https://www.parrinst.com/products/oxygen-bomb-calorimeters/ (accessed on 8 July 2012).

- EN 14774-1:2009; Solid Biofuels-Determination of Moisture Content-Oven Dry Method-Part 1: Total Moisture-Reference Method. European Committee of Standardization: Brussels, Belgium, 2009.

- Hahn, B. Existing Guidelines and Quality Assurance for Fuel Pellets. Pellets for Europe 2004, Umbera. Available online: http://www.pelletcentre.info/resources/1020.pdf (accessed on 18 December 2024).

- ÖNORM M 7135 [2000]; Pellets and Briquettes—Requirements and Test Conditions. Austria Standards Institute: Vienna, Austria; European Committee of Standardization: Brussels, Belgium, 2000.

- Gocławski, J.; Korzeniewska, E.; Sekulska-Nalewajko, J.; Kiełbasa, P.; Dróżdż, T. Method of Biomass Discrimination for Fast Assessment of Calorific Value. Energies 2022, 15, 2514. [Google Scholar] [CrossRef]

- DIN 51900-1; Determining the Gross Calorific Value of Solid and Liquid Fuels Using the Bomb Calorimeter and Calculation of Net Calorific Value. Part 1: General Information. German National Standard: Berlin, Germany, 2000.

- Nurek, T.; Gendek, A.; Dąbrowska, M. Influence of the Die Height on the Density of the Briquette Produced from Shredded Logging Residues. Materials 2021, 14, 3698. [Google Scholar] [CrossRef]

- ISO 1928:2009; Solid Mineral Fuels. Determining the Gross Calorific Power by Calorimeter Bomb and Calculus of Net Calorific Power. International Organization for Standardization: Geneva, Switzerland, 2009.

- ASTM E1755-01; Standard Method for the Determination of Ash in Biomass. American Society for Testing and Materials, International: Philadelphia, PA, USA, 2000.

- Kers, J.; Kulu, P.; Aruniit, A.; Laurmaa, V.; Križan, P.; Šooš, L.; Kask, Ü. Determination of physical, mechanical and burning characteristics of polymeric waste material briquettes. Est. J. Eng. 2013, 19, 307–316. Available online: http://www.kirj.ee/18098/?tpl=1061&c_tpl=1064 (accessed on 18 December 2024). [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass. Bioenerg. 2011, 35, 910–918. [Google Scholar] [CrossRef]

- Mitchual, S.J.; Frimpong-Mensah, K.; Darkwa, N.A. Effect of Species, Particle Size and Compacting Pressure on Relaxed Density and Compressive Strength of Fuel Briquettes. Int. J. Energy Environ. Eng. 2013, 4, 30. [Google Scholar] [CrossRef]

- Sola, O.C.; Atis, C.D. The Effects of Pyrite Ash on the Compressive Strength Properties of Briquettes. KSCE J. Civ. Eng. 2012, 16, 1225–1229. [Google Scholar] [CrossRef]

- Plištil, D.; Brožek, M.; Malaták, J.; Roy, A.; Hutla, P. Mechanical Characteristics of Standard Fuel Briquettes on Biomass Basis. Res. Agric. Eng. 2005, 51, 66–72. Available online: http://agriculturejournals.cz/publicFiles/57241.pdf (accessed on 18 December 2024). [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass. Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Rahman, A.N.E.; Masood, M.A.; Prasad, C.S.N.; Venkatesham, M. Influence of Size and Shape on the Strength of Briquettes. Fuel Process Technol. 1989, 23, 185–195. [Google Scholar] [CrossRef]

- Tabarés, J.L.M.; Ortiz, L.; Granada, E.; Viar, F.P. Feasibility Study of Energy Use for Densificated Lignocellulosic Material (briquettes). Fuel 2000, 79, 1229–1237. [Google Scholar] [CrossRef]

- Mikheev, M.V.; Komina, A.V.; Gorbacheva, G.A.; Kalinina, A.A.; Bolotskaya, A.V.; Sanaev, V.G.; Stolin, A.M. Study of disintegrated pine wood rheological behavior under uni-axial compressing]. Lesn. Vestn. For. Bull. 2024, 28, 116–126. [Google Scholar]

| Number Sample | Mass (g) | Diameter (mm) | Length (mm) | Density (kg/m3) |

|---|---|---|---|---|

| 1. | 22.1 | 41.66 | 19.6 | 827.61 |

| 2. | 22.9 | 40.92 | 19.4 | 858.81 |

| 3. | 30.9 | 40.89 | 28.93 | 813.77 |

| 4. | 27.1 | 40.87 | 25.62 | 806.69 |

| 5. | 22.4 | 40.54 | 20.35 | 853.19 |

| 6. | 30.9 | 40.85 | 27.83 | 847.61 |

| 7. | 35.5 | 41.81 | 31.67 | 816.86 |

| 8. | 31.1 | 41.27 | 29.33 | 793.06 |

| 9. | 50 | 41.51 | 42.46 | 870.59 |

| 10. | 36.9 | 41.69 | 34.81 | 776.94 |

| 11. | 31.4 | 40.66 | 32.6 | 742.17 |

| 12. | 21.8 | 41.25 | 19.78 | 825.11 |

| 13. | 33.1 | 41.15 | 29.7 | 838.42 |

| 14. | 25.9 | 41.23 | 22.04 | 880.62 |

| Mean | 30.14 | 41.16 | 27.43 | 822.84 |

| Std.dev. | 4.86 | |||

| Coeff. of variation | 0.006 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spirchez, C.; Lunguleasa, A.; Șova, D.; Gorbacheva, G. On the Rheological Behavior of Pine (Pinus sylvestris L.) Shavings and the Briquettes Obtained from Them. Forests 2025, 16, 267. https://doi.org/10.3390/f16020267

Spirchez C, Lunguleasa A, Șova D, Gorbacheva G. On the Rheological Behavior of Pine (Pinus sylvestris L.) Shavings and the Briquettes Obtained from Them. Forests. 2025; 16(2):267. https://doi.org/10.3390/f16020267

Chicago/Turabian StyleSpirchez, Cosmin, Aurel Lunguleasa, Daniela Șova, and Galina Gorbacheva. 2025. "On the Rheological Behavior of Pine (Pinus sylvestris L.) Shavings and the Briquettes Obtained from Them" Forests 16, no. 2: 267. https://doi.org/10.3390/f16020267

APA StyleSpirchez, C., Lunguleasa, A., Șova, D., & Gorbacheva, G. (2025). On the Rheological Behavior of Pine (Pinus sylvestris L.) Shavings and the Briquettes Obtained from Them. Forests, 16(2), 267. https://doi.org/10.3390/f16020267