Risks of Spruce Wood Dust in the Work Environment

Abstract

1. Introduction

1.1. Risks of Wood Dust in Terms of Explosions and Fires

1.2. Occupational Health Risks of Wood Dust

- Microscopic analysis of wood dust particles after sanding and measurement of dust particle dimensions.

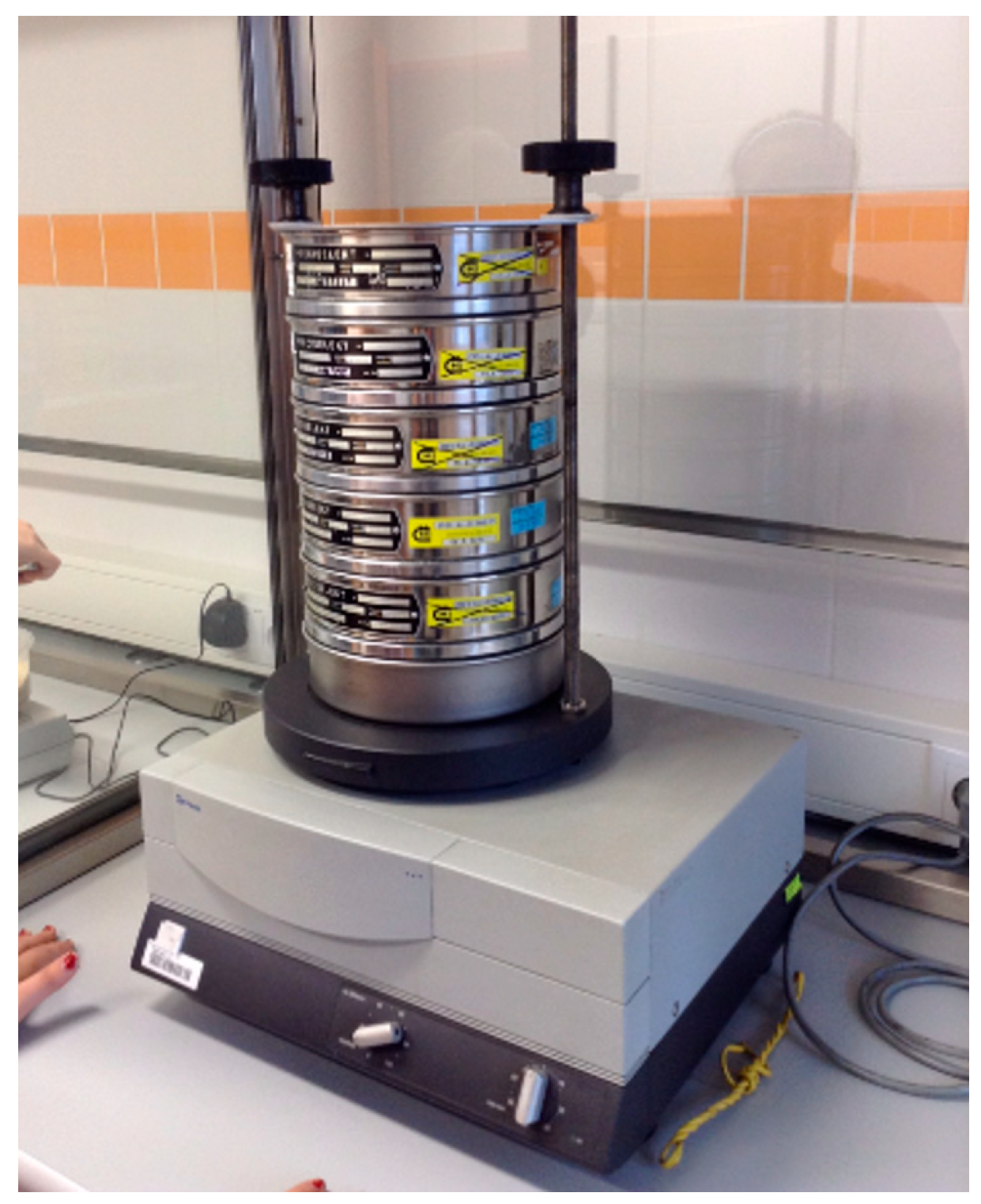

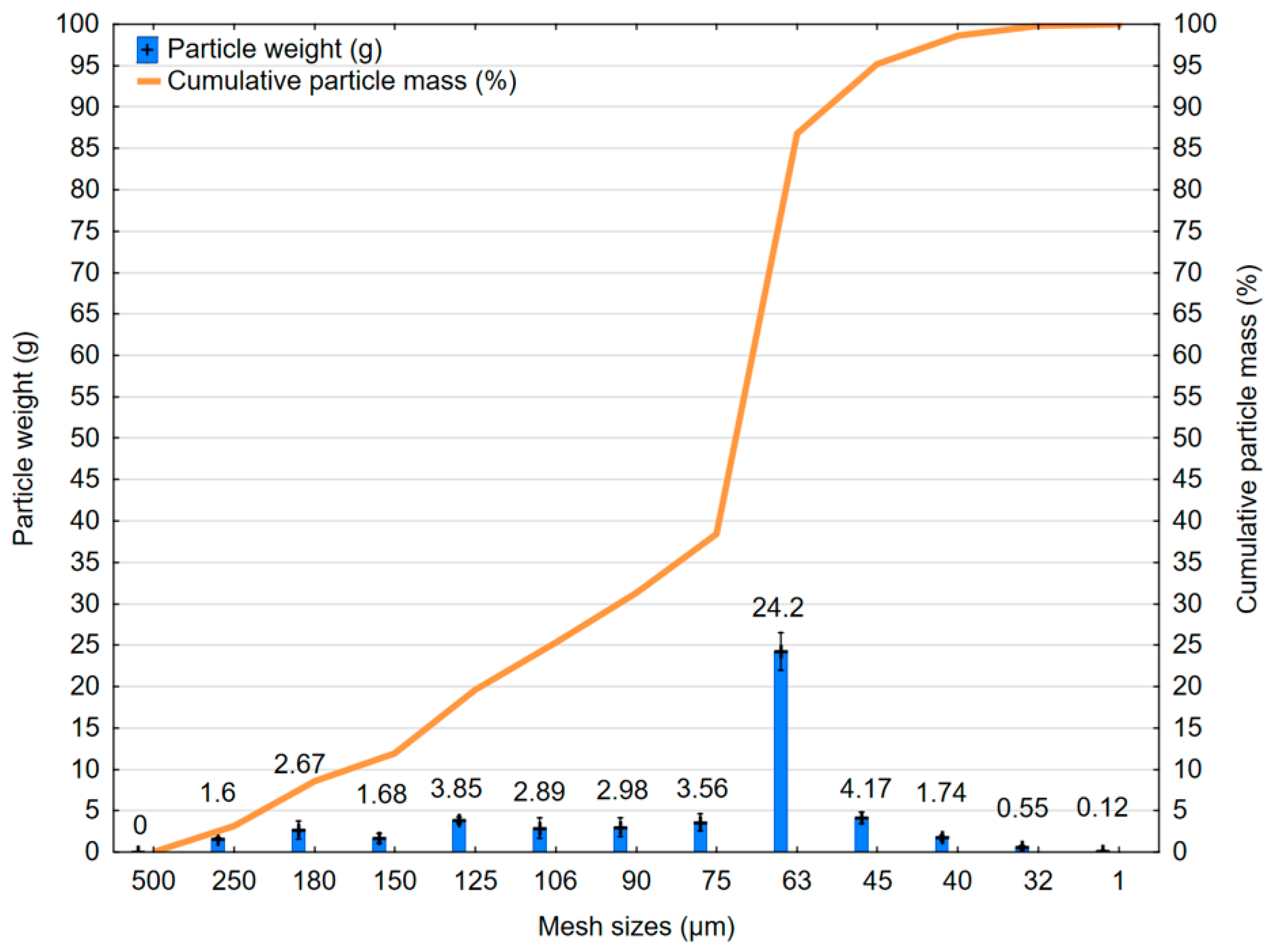

- Sieve analysis of dust particles.

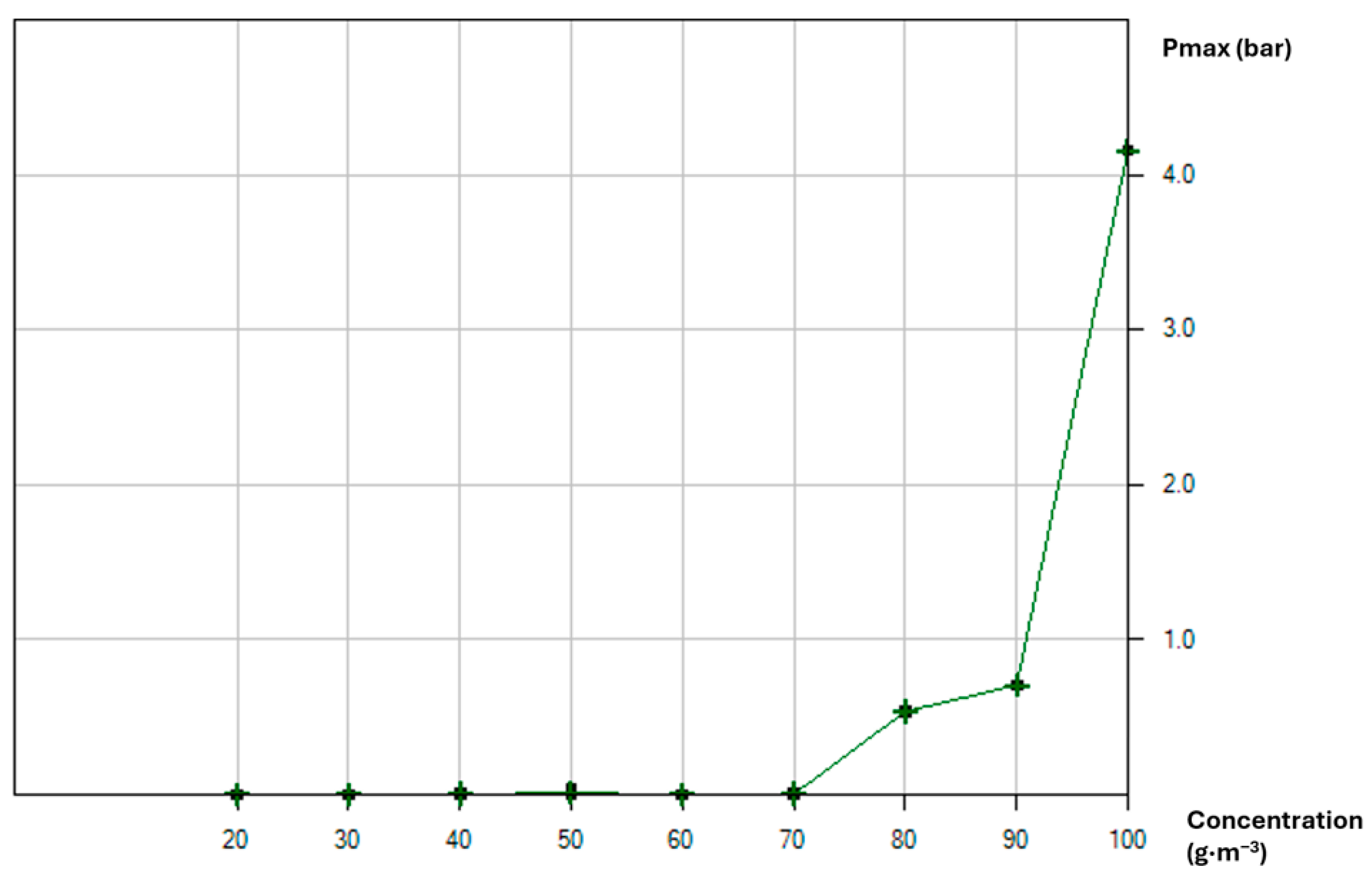

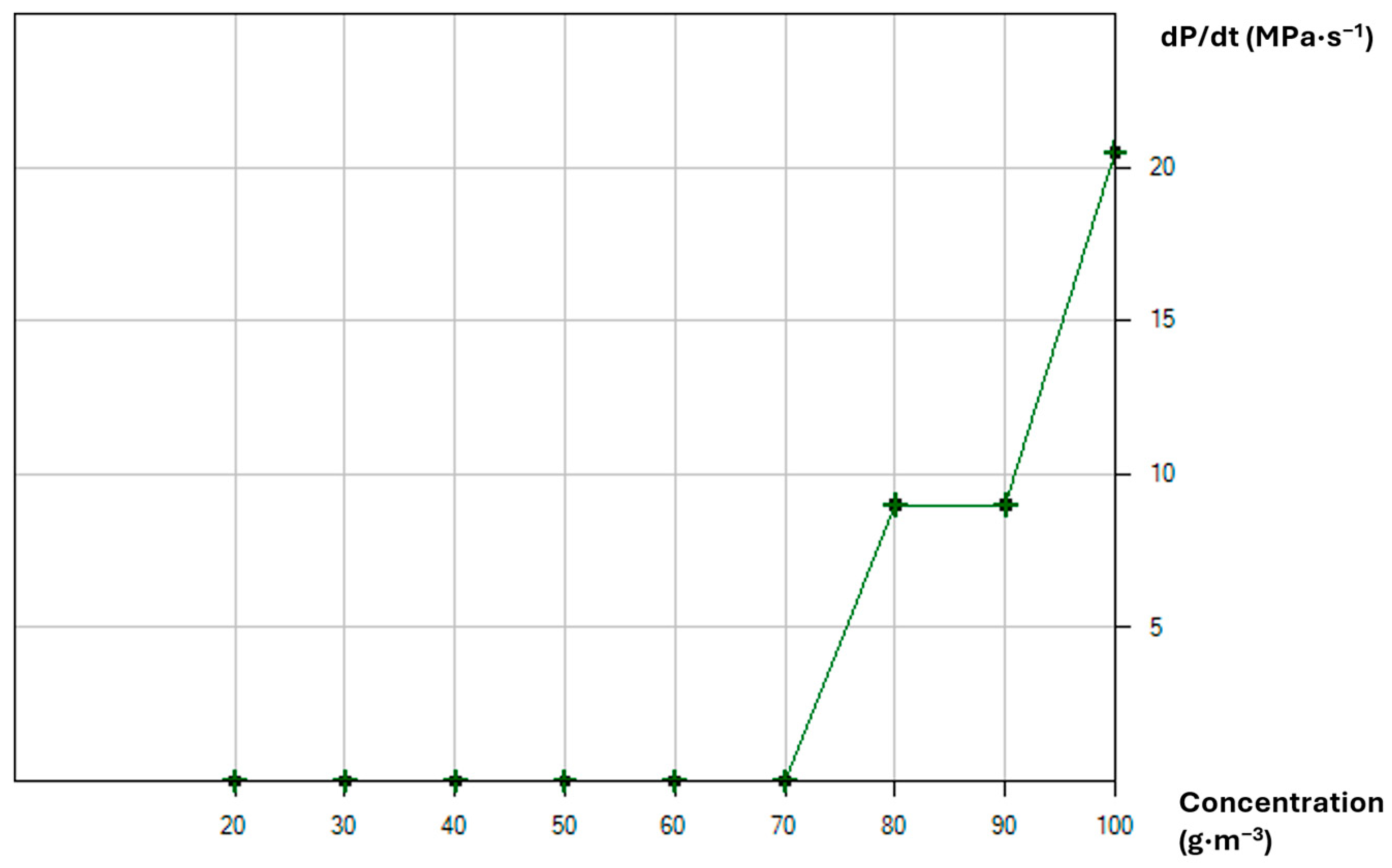

- Explosion parameters of dust in an autoclave.

2. Materials and Methods

2.1. Wood Dust Material

2.2. Determination of Wood Dust Moisture Content, Microscopic Analysis, and Sieve Analysis

2.3. Maximum Explosion Parameters of Wood Dust

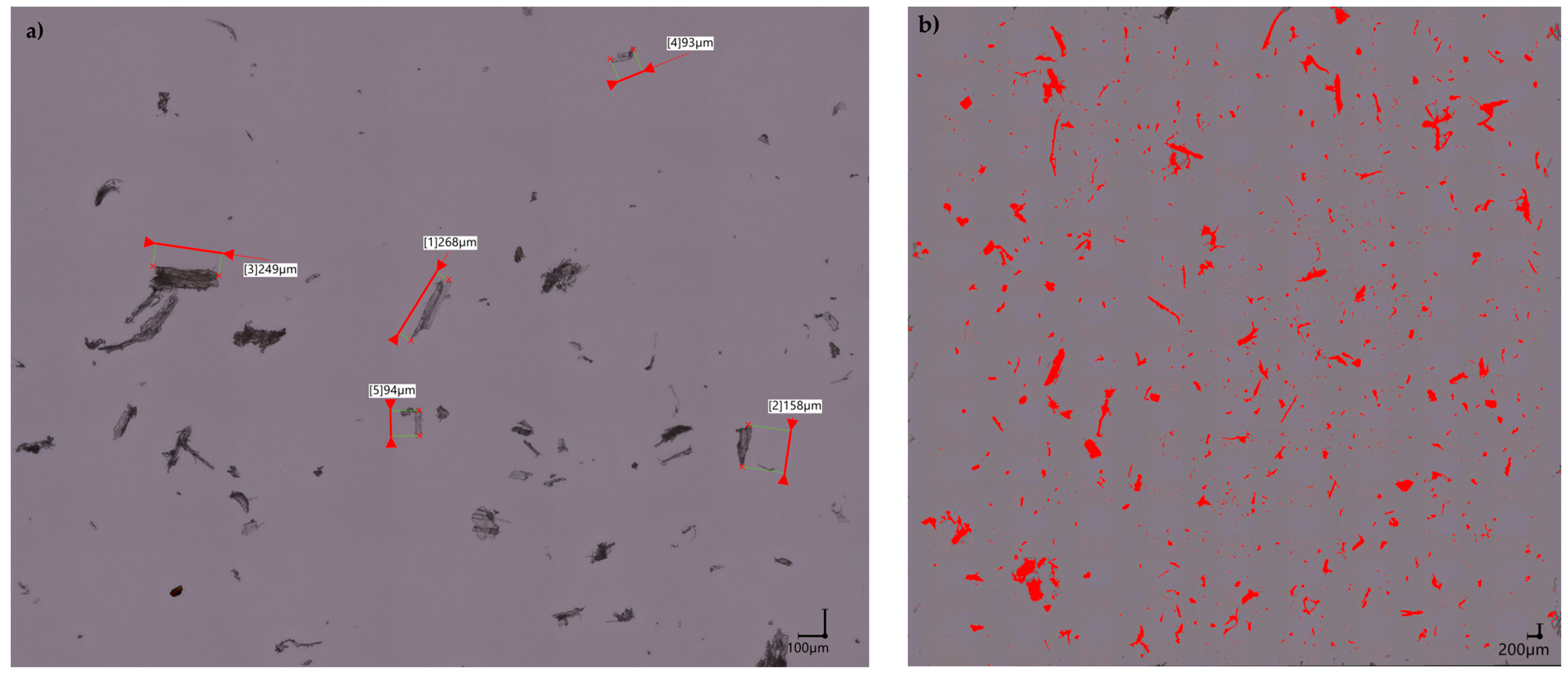

2.4. Statistical Evaluation of Wood Dust from Sanding

3. Results

3.1. Spruce Wood Dust Moisture Content

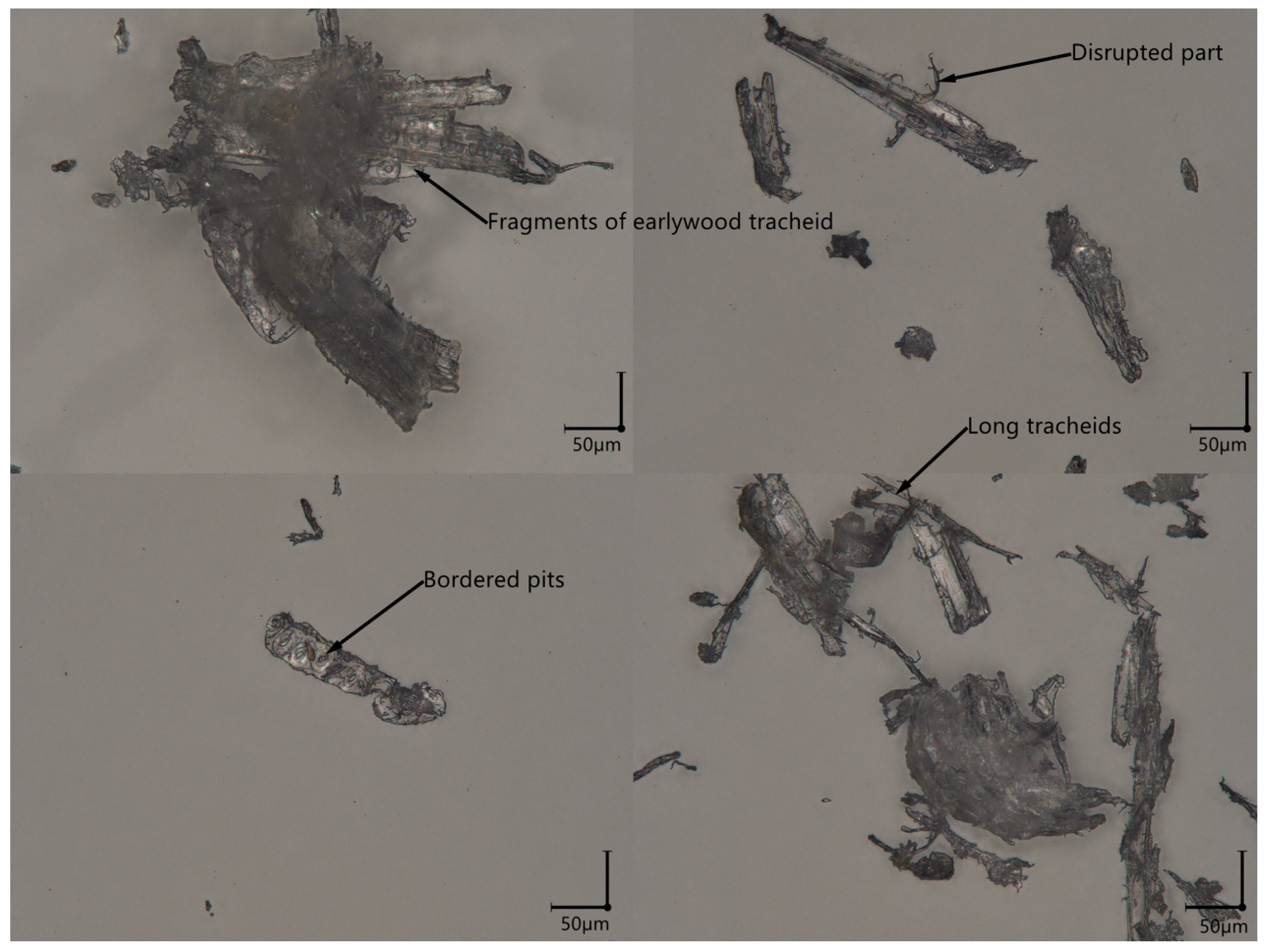

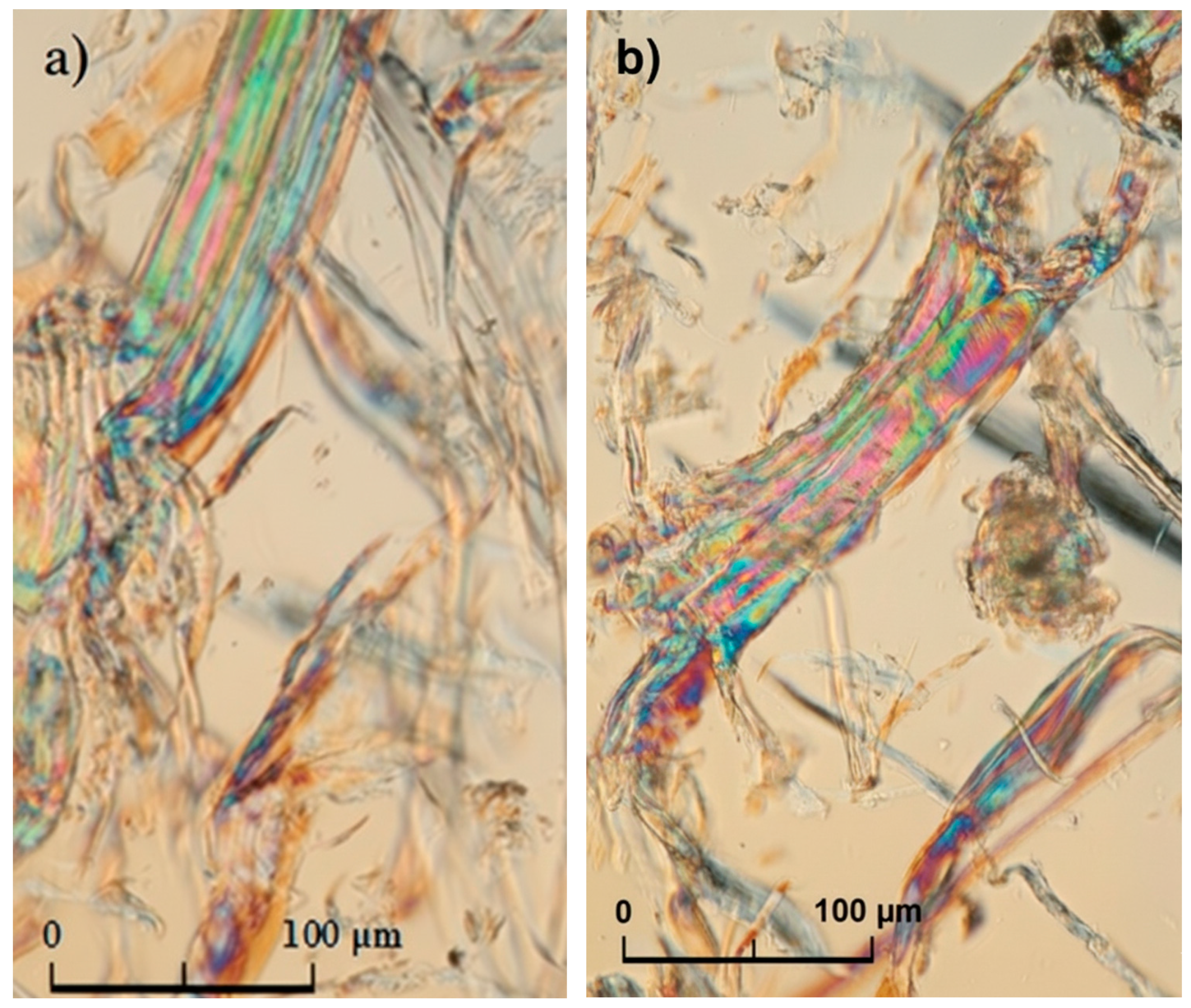

3.2. Microscopic Analysis of Wood Dust

3.3. Statistical Evaluation of Sieve Analysis of Spruce Wood Dust

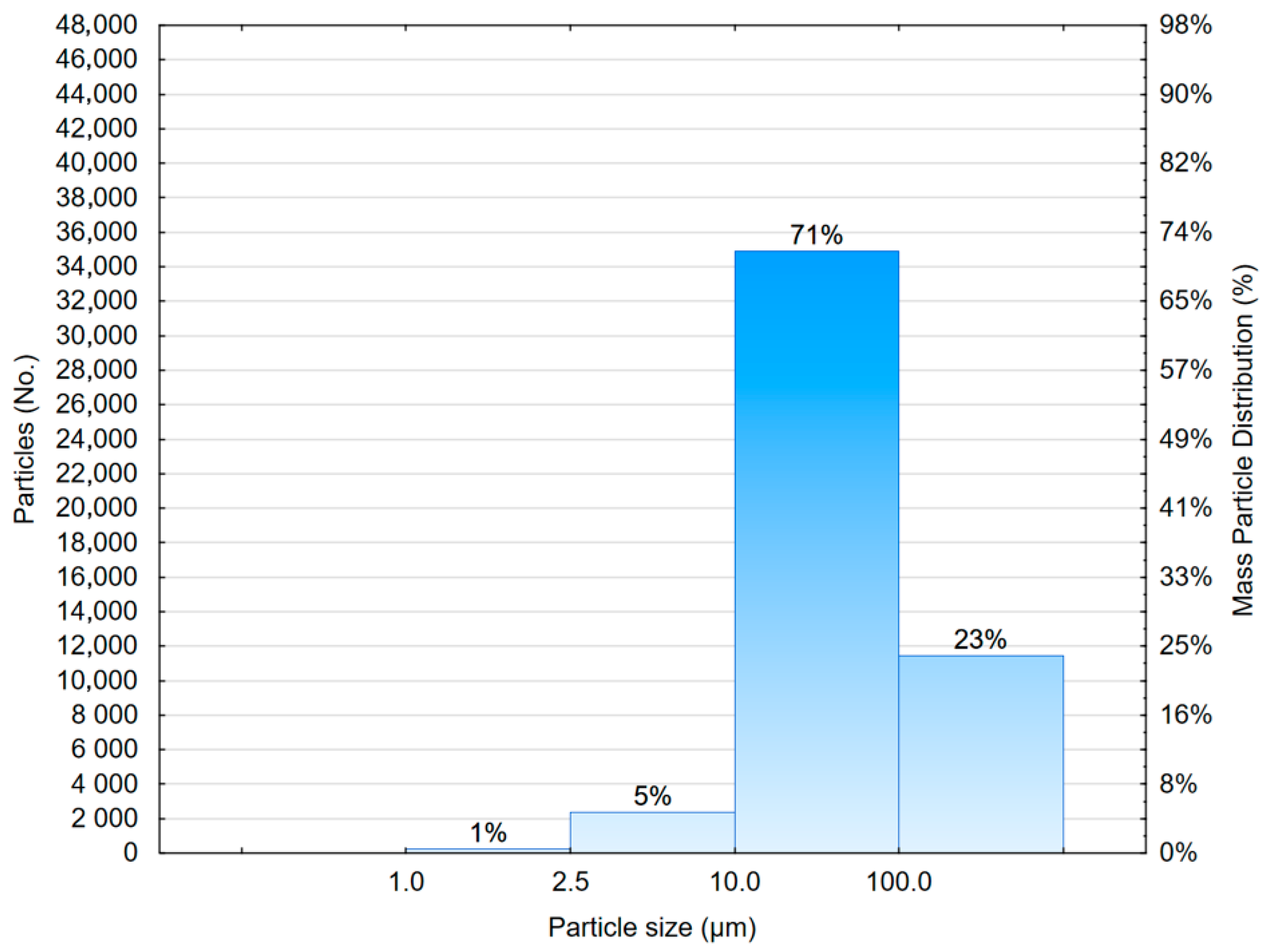

3.4. Fine Dust Particle Analysis

3.5. Lower Explosion Limit (LEL) of Spruce Wood Dust Depending on Concentration

3.6. Lower Explosion Limit (LEL) of Spruce Wood Dust Depending on Particle Size

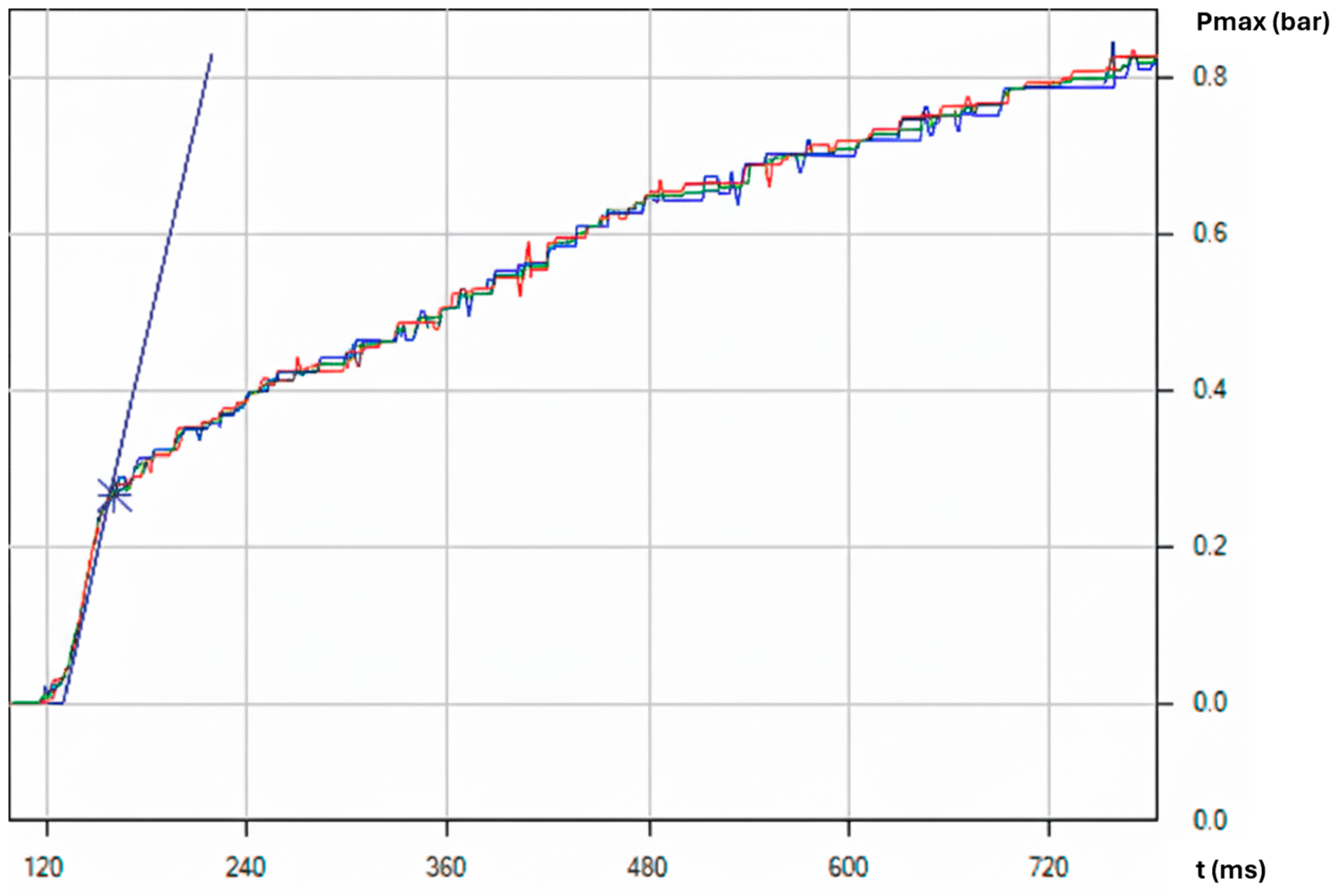

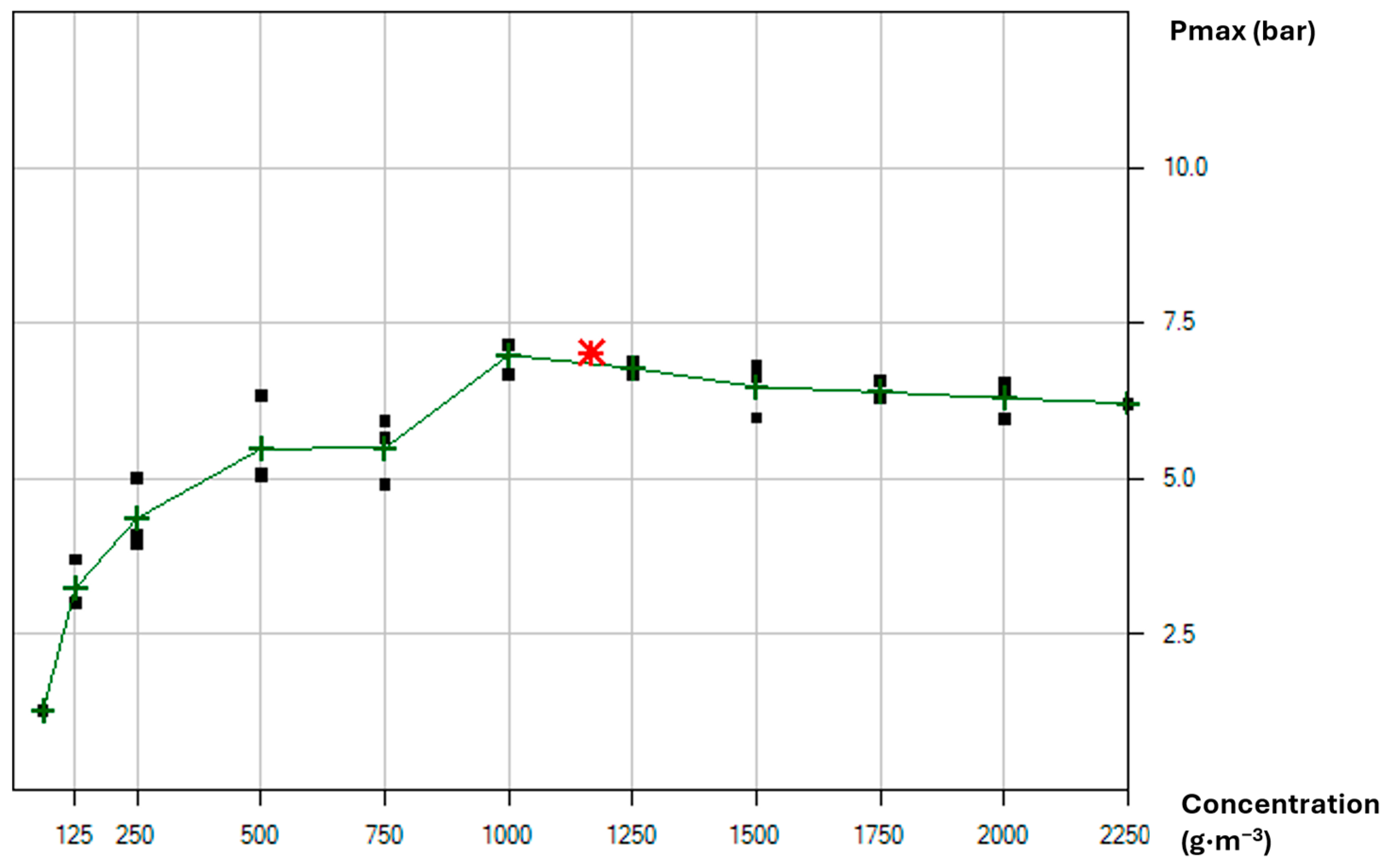

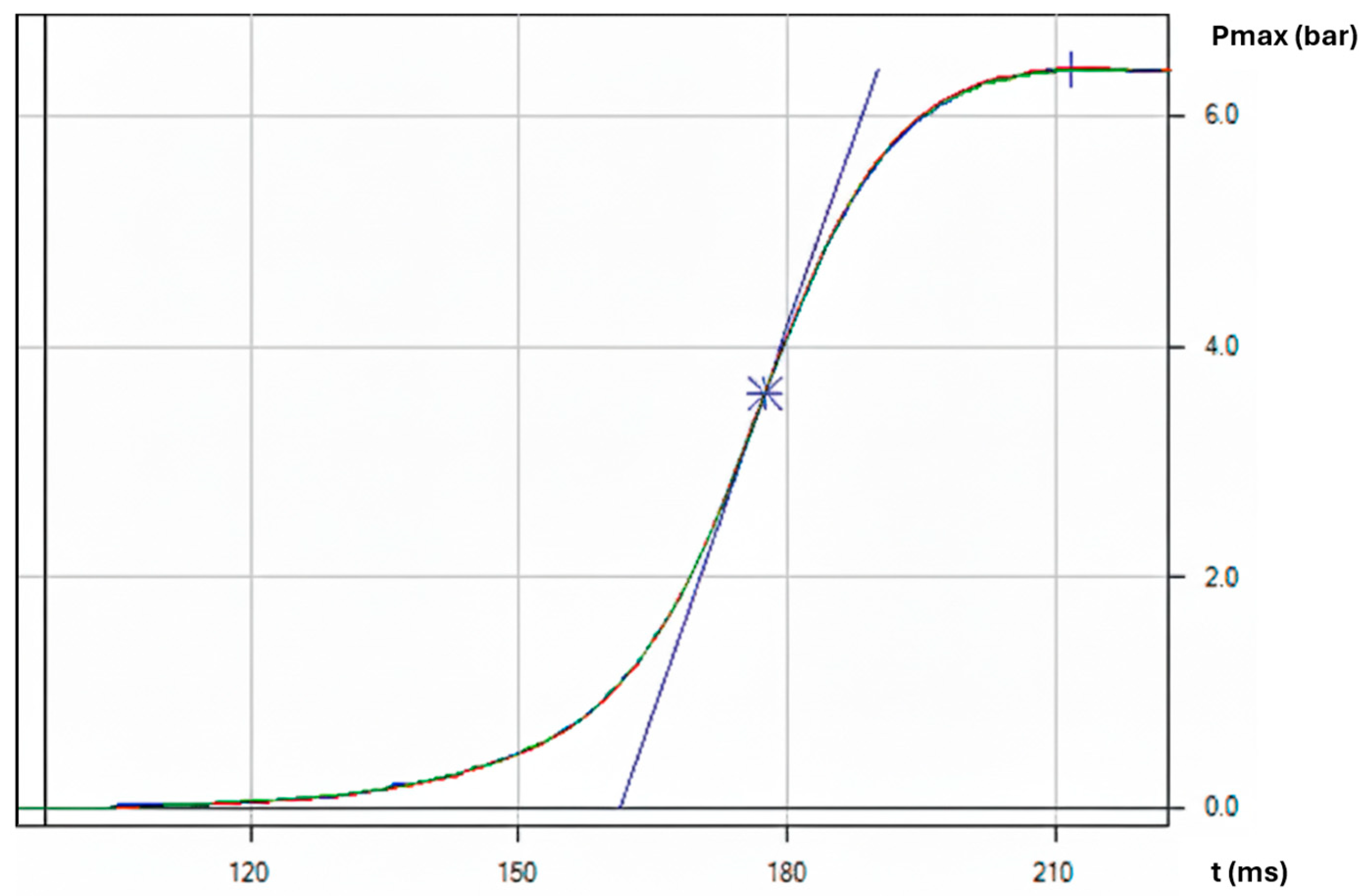

3.7. Explosion Pressure and Pressure Increase Rate of Spruce Wood Dust Depending on Concentration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Warguła, Ł.; Wilczyński, D.; Wieczorek, B.; Palander, T.; Gierz, L.; Nati, C.; Sydor, M. Characterizing Sawdust Fractional Composition from Oak Parquet Woodworking for Briquette and Pellet Production. Adv. Sci. Technol. Res. J. 2023, 17, 236–247. [Google Scholar] [CrossRef]

- Tong, R.; Cheng, M.; Zhang, L.; Liu, M.; Yang, X.; Li, X.; Yin, W. The construction dust-induced occupational health risk using Monte-Carlo simulation. J. Clean. Prod. 2018, 184, 598–608. [Google Scholar] [CrossRef]

- Çakiroğlu, E.O. Prediction of dust emissions during CNC milling of spruce and pine with machine learning. Eur. J. Wood Prod. 2025, 83, 173. [Google Scholar] [CrossRef]

- Pędzik, M.; Júda, M.; Kminiak, R.; Czerniejewska-Wolska, H.; Rogozinski, T. The Effect of Average Chip Thickness on The Potentially Respirable Dust from CNC Finish Milling of Wood-Based Materials. Drew. Pr. Nauk. Doniesienia Komun. = Wood Res. Pap. Rep. Announc. 2024; in press. [Google Scholar] [CrossRef]

- Chuchala, D.; Rogoziński, T.; Orlowski, K.A.; Pędzik, M.; Hanincová, L.; Eggertsson, O. Granulometric characterization of Arctic driftwood sawdust from frame sawing process. Ind. Crops Prod. 2024, 213, 118448. [Google Scholar] [CrossRef]

- Simon, C.; Donnot, A.; Méausoone, P.-J. Indoor wood dust analysis during machining with an original experimental device. Eur. J. Wood Prod. 2022, 80, 465–475. [Google Scholar] [CrossRef]

- Koleda, P.; Koleda, P.; Hrčková, M.; Júda, M.; Hortobágyi, Á. Experimental Granulometric Characterization of Wood Particles from CNC Machining of Chipboard. Appl. Sci. 2023, 13, 5484. [Google Scholar] [CrossRef]

- Çakıroğlu, E.O.; Demirarslan, K.O.; Taşdemir, T. Characterization of wood dust emission according to some wood species in 3D machining applied with CNC machine. Eur. J. Wood Prod. 2025, 83, 59. [Google Scholar] [CrossRef]

- Warguła, Ł.; Wieczorek, B.; Krystofiak, T.; Sydor, M. Impact of surface finishing technology on slip resistance of oak lacquer wood floorboards with distinct gloss levels. Wood Mater. Sci. Eng. 2024, 19, 1163–1172. [Google Scholar] [CrossRef]

- Majka, J.; Sydor, M.; Warguła, Ł.; Wieczorek, B. Anti-slip properties of thermally modified hardwoods. Eur. J. Wood Wood Prod. 2024, 83, 14. [Google Scholar] [CrossRef]

- Sydor, M.; Mirski, R.; Stuper-Szablewska, K.; Rogoziński, T. Efficiency of Machine Sanding of Wood. Appl. Sci. 2021, 11, 2860. [Google Scholar] [CrossRef]

- Pędzik, M.; Stuper-Szablewska, K.; Sydor, M.; Rogoziński, T. Influence of Grit Size and Wood Species on the Granularity of Dust Particles during Sanding. Appl. Sci. 2020, 10, 8165. [Google Scholar] [CrossRef]

- Hanincová, L.; Pędzik, M.; Majka, J.; Sydor, M.; Rogoziński, T. Influence of thermal modification and sanding parameters on finest particle content in pinewood dust. Wood Mater. Sci. Eng. 2024, 19, 887–895. [Google Scholar] [CrossRef]

- Ratnasingam, J.; Scholz, F.; Natthondan, V.; Graham, M. Dust-generation characteristics of hardwoods during sanding processes. Eur. J. Wood Prod. 2011, 69, 127–131. [Google Scholar] [CrossRef]

- Yuan, N.; Zhang, J.; Lu, J.; Liu, H.; Sun, P. Analysis of Inhalable Dust Produced in Manufacturing of Wooden Furniture. BioResources 2014, 9, 7257–7266. [Google Scholar] [CrossRef]

- Pędzik, M.; Rogoziński, T.; Majka, J.; Stuper-Szablewska, K.; Antov, P.; Kristak, L.; Kminiak, R.; Kučerka, M. Fine Dust Creation during Hardwood Machine Sanding. Appl. Sci. 2021, 11, 6602. [Google Scholar] [CrossRef]

- Marková, I.; Hroncová, E.; Tomaškin, J.; Tureková, I. Thermal Analysis of Granulometry Selected Wood Dust Particles. BioResources 2018, 13, 8041–8060. [Google Scholar] [CrossRef]

- Callé, S.; Klaba, L.; Thomas, D.; Perrin, L.; Dufaud, O. Influence of the size distribution and concentration on wood dust explosion: Experiments and reaction modelling. Powder Technol. 2005, 157, 144–148. [Google Scholar] [CrossRef]

- Santamaría-Herrera, A.; Hoyuelos, F.J.; Casado-Marcos, C. Characterization of the explosiveness of wood dust. Process Saf. Environ. Prot. 2023, 169, 252–259. [Google Scholar] [CrossRef]

- Welling, I.; Lehtimäki, M.; Rautio, S.; Lähde, T.; Enbom, S.; Hynynen, P.; Hämeri, K. Wood Dust Particle and Mass Concentrations and Filtration Efficiency in Sanding of Wood Materials. J. Occup. Environ. Hyg. 2008, 6, 90–98. [Google Scholar] [CrossRef]

- Eckhoff, R.K. Current status and expected future trends in dust explosion research. J. Loss Prev. Process Ind. 2005, 18, 225–237. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kaczmarzyk, P.; Anna, D. The Assessment of Fire Risk of Non-road Mobile Wood Chopping Machines. J. Res. Appl. Agric. Eng. 2019, 64, 58–64. [Google Scholar]

- Przybysz, J.; Celiński, M.; Kozikowski, P.; Mizera, K.; Borucka, M.; Gajek, A. Flammability and explosion characteristics of hardwood dust. J. Fire Sci. 2023, 41, 89–101. [Google Scholar] [CrossRef]

- Krentowski, J. Disaster of an industrial hall caused by an explosion of wood dust and fire. Eng. Fail. Anal. 2015, 56, 403–411. [Google Scholar] [CrossRef]

- Proto, A.R.; Zimbalatti, G.; Negri, M. The Measurement and Distribution of Wood Dust. J Agric. Eng. 2010, 41, 25. [Google Scholar] [CrossRef]

- Guo, L.; Xiao, Q.; Zhu, N.; Wang, Y.; Xu, C. Comparative studies on the explosion severity of different wood dusts from fiberboard production. BioRes 2019, 14, 3182–3199. [Google Scholar] [CrossRef]

- Eckhoff, R.K. Explosion Hazards in the Process Industries; Gulf Professional Publishing: Houston, TX, USA, 2016; ISBN 978-0-12-803273-2. [Google Scholar]

- Eckhoff, R.K.; Li, G. Industrial Dust Explosions. A Brief Review. Appl. Sci. 2021, 11, 1669. [Google Scholar] [CrossRef]

- Pérez-Peña, N.; Valenzuel, L.; Diaz-vaz, J.E.; Ananías, R.A. Prediction of equilibrium moisture content in wood in relation to the specific gravity of the cell wall and environmental variables. Maderas. Cienc. Tecnol. 2011, 13, 253–266. [Google Scholar] [CrossRef]

- Dudarski, G.; Kowal, M.; Czestochowski, C. Dust explosion hazard in wood processing. Ann. Wars. Univ. Life Sci.—SGGW. For. Wood Technol. 2015, 90, 61–65. [Google Scholar]

- Zhou, X.; Li, X.; Cui, Z.; Wu, L.; Zhou, H.; Lu, X. Combustible wood dust explosions and impacts on environments and health—A review. Environ. Res. 2023, 216, 114658. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Z.; Sun, K.; He, C.; Yuan, C. Ignition characteristics of mixtures of micro-sized wood dusts and centimeter-sized flakes and fibers initiated by deposit fires. J. Loss Prev. Process Ind. 2025, 94, 105575. [Google Scholar] [CrossRef]

- Chang, S.-C.; Cheng, Y.-C.; Zhang, X.-H.; Shu, C.-M. Effects of moisture content on explosion characteristics of incense dust in incense factory. J Therm. Anal. Calorim. 2022, 147, 2885–2892. [Google Scholar] [CrossRef]

- Shamssain, M.H. Pulmonary function and symptoms in workers exposed to wood dust. Thorax 1992, 47, 84–87. [Google Scholar] [CrossRef]

- Rekhadevi, P.V.; Mahboob, M.; Rahman, M.F.; Grover, P. Genetic damage in wood dust-exposed workers. Mutagenesis 2009, 24, 59–65. [Google Scholar] [CrossRef]

- Pérez-Escuredo, J.; Martínez, J.G.; Vivanco, B.; Marcos, C.Á.; Suárez, C.; Llorente, J.L.; Hermsen, M.A. Wood dust-related mutational profile of TP53 in intestinal-type sinonasal adenocarcinoma. Hum. Pathol. 2012, 43, 1894–1901. [Google Scholar] [CrossRef] [PubMed]

- Löfstedt, H.; Hagström, K.; Bryngelsson, I.-L.; Holmström, M.; Rask-Andersen, A. Respiratory symptoms and lung function in relation to wood dust and monoterpene exposure in the wood pellet industry. Upsala J. Med. Sci. 2017, 122, 78–84. [Google Scholar] [CrossRef] [PubMed]

- Kargar-Shouroki, F.; Dehghan Banadkuki, M.R.; Jambarsang, S.; Emami, A. The association between wood dust exposure and respiratory disorders and oxidative stress among furniture workers. Wien. Klin. Wochenschr. 2022, 134, 529–537. [Google Scholar] [CrossRef]

- Dalin, H.U.; Yiming, L.I.U.; Dongsheng, T. Relation between environmental pollution caused by free SiO2 dust and lipid peroxidation in erythrocyte membrane in human. Chin. J. Public Health 2005, 21, 1273–1274. [Google Scholar]

- Riva, D.R.; Magalhães, C.B.; Lopes, A.A.; Lanças, T.; Mauad, T.; Malm, O.; Valença, S.S.; Saldiva, P.H.; Faffe, D.S.; Zin, W.A. Low dose of fine particulate matter (PM2.5) can induce acute oxidative stress, inflammation and pulmonary impairment in healthy mice. Inhal. Toxicol. 2011, 23, 257–267. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.-L.; Gao, W.; Li, Y.; Wang, Y.-F. Concentration-dependent effects of PM2.5 mass on expressions of adhesion molecules and inflammatory cytokines in nasal mucosa of rats with allergic rhinitis. Eur. Arch. Otorhinolaryngol. 2017, 274, 3221–3229. [Google Scholar] [CrossRef]

- Tobin, E. Occupational Exposure to Wood Dust and Respiratory Health Status of Sawmill Workers in South-South Nigeria. J. Pollut. Eff. Control 2015, 4, 1000154. [Google Scholar] [CrossRef]

- Scheeper, B. Wood-dust exposure during wood-working processes. Ann. Occup. Hyg. 1995, 39, 141–154. [Google Scholar] [CrossRef]

- Ojima, J. Generation rate and particle size distribution of wood dust by handheld sanding operation. J. Occup. Health 2016, 58, 640–643. [Google Scholar] [CrossRef]

- Salthammer, T.; Gu, J.; Gunschera, J.; Schieweck, A. Release of chemical compounds and particulate matter. In Springer Handbook of Wood Science and Technology; Springer: Berlin/Heidelberg, Germany, 2023; pp. 1949–1974. [Google Scholar] [CrossRef]

- Thorpe, A.; Brown, R.C. Factors Influencing the Production of Dust During the Hand Sanding of Wood. Am. Ind. Hyg. Assoc. J. 1995, 56, 236–242. [Google Scholar] [CrossRef]

- ISO 1666:1996; Starch—Determination of Moisture Content—Oven-Drying Method. ISO: Geneva, Switzerland, 1996.

- EN 14034-2+A1; Determination of Explosion Characteristics of Dust Clouds. Part 2: Determination of the Maximum rate of Explosion Pressure rise (dp/dt)max of Dust Clouds. European Committee for Standardization: Brussels, Belgium, 2010.

- Tureková, I.; Marková, I. Ignition of Deposited Wood Dust Layer by Selected Sources. Appl. Sci. 2020, 10, 5779. [Google Scholar] [CrossRef]

- Stasiak, M.; Molenda, M.; Bańda, M.; Gondek, E. Mechanical properties of sawdust and woodchips. Fuel 2015, 159, 900–908. [Google Scholar] [CrossRef]

- Očkajová, A.; Beljakova, A.; Siklienka, M. Morphology of dust particles from the sanding process ofthe chosen tree species. Wood Res. 2010, 55, 89–98. [Google Scholar]

- Očkajová, A.; Kučerka, M.; Kminiak, R.; Banski, A. Sustainable Manufacturing Process in the Context of Wood Processing by Sanding. Coatings 2021, 11, 1463. [Google Scholar] [CrossRef]

- Mazzoli, A.; Favoni, O. Particle size, size distribution and morphological evaluation of airborne dust particles of diverse woods by Scanning Electron Microscopy and image processing program. Powder Technol. 2012, 225, 65–71. [Google Scholar] [CrossRef]

- Ding, T.; Zhao, J.; Zhu, N.; Wang, C. A comparative study of morphological characteristics of medium-density fiberboard dust by sieve and image analyses. J. Wood Sci. 2020, 66, 55. [Google Scholar] [CrossRef]

- Očkajová, A.; Beljaková, A.; Luptáková, J. Selected properties of spruce dust generated from sanding operations. Wood Ind./Drv. Ind. 2008, 59, 3–10. [Google Scholar]

- Sydor, M.; Majka, J.; Hanincová, L.; Kučerka, M.; Kminiak, R.; Kristak, L.; Pędzik, M.; Očkajová, A.; Rogoziński, T. Fine dust after sanding untreated and thermally modified spruce, oak, and meranti wood. Eur. J. Wood Prod. 2023, 81, 1455–1464. [Google Scholar] [CrossRef]

- He, Z.; Yang, H.-T.; Chen, Z.-J.; Ma, H.-H.; Zhang, X.-L.; Wang, L.-Q.; Shen, Z.-W. Explosion Characteristics of Layered Wood Dust with High Pressure Oxygen. Energy Sci. Eng. 2025, 13, 4944–4954. [Google Scholar] [CrossRef]

- Očkajová, A.; Kučerka, M.; Krišťák, L.; Igaz, R. Granulometric Analysis of Sanding Dust from Selected Wood Species. BioResources 2018, 13, 7481–7495. [Google Scholar] [CrossRef]

- Hlaskova, L.; Rogozinski, T.; Dolny, S.; Kopecky, Z.; Jedinak, M. Content of respirable and inhalable fractions in dust created while sawing beech wood and its modifications. Drew. Pr. Nauk. Doniesienia Komun. 2015, 58, 135–146. [Google Scholar] [CrossRef]

- Beljo-Lučić, R.; Čavlović, A.; Antonović, A.; Vujasinović, E.; Šimičić, I. Properties of chipped wood generated during mechanical wood processing. Drv. Ind. 2005, 56, 11–19. [Google Scholar]

- ISO 17225-1:2020; Solid Biofuels—Fuel Specifications and Classes—Part 1: General Requirements. ISO: Geneva, Switzerland, 2020.

- Sisler, J.D.; Mandler, W.K.; Shaffer, J.; Lee, T.; McKinney, W.G.; Battelli, L.A.; Orandle, M.S.; Thomas, T.A.; Castranova, V.C.; Qi, C.; et al. Toxicological assessment of dust from sanding micronized copper-treated lumber in vivo. J. Hazard. Mater. 2019, 373, 630–639. [Google Scholar] [CrossRef]

- Dado, M.; Lamperová, A.; Kotek, L.; Hnilica, R. An Evaluation of On-Tool System for Sanding Dust Collection: Pilot Study. Manag. Syst. Prod. Eng. 2020, 28, 184–188. [Google Scholar] [CrossRef]

- Vandličková, M.; Marková, I.; Makovická-Osvaldová, L.; Gašpercová, S.; Svetlík, J. Evaluation of African padauk (Pterocarpus soyauxii) explosion dust. BioRes 2019, 15, 401–414. [Google Scholar] [CrossRef]

- Kuracina, R.; Szabová, Z.; Balog, K. Study of Selected Fire Characteristics of Beech Wood Depending on Particle Size. In Wood & Fire Safety, Proceedings of the 9th International Conference on Wood & Fire Safety 2020, Strbske Pleso, Slovakia, 14 March 2020; Makovicka Osvaldova, L., Markert, F., Zelinka, S.L., Eds.; Springer International Publishing: Cham, Switzerland, 2020; pp. 16–21. [Google Scholar]

- Pang, Z.; Zhu, N.; Cui, Y.; Li, W.; Xu, C. Experimental investigation on explosion flame propagation of wood dust in a semi-closed tube. J. Loss Prev. Process Ind. 2020, 63, 104028. [Google Scholar] [CrossRef]

- Martinka, J.; Rantuch, P.; Balog, K. Assessment of the impact of spruce wood particle size and water content on the ignition temperature of dust clouds. Cellul. Chem. Technol. 2015, 49, 549–558. [Google Scholar]

- Kminiak, R.; Kučerka, M.; Kristak, L.; Reh, R.; Antov, P.; Očkajová, A.; Rogoziński, T.; Pędzik, M. Granulometric Characterization of Wood Dust Emission from CNC Machining of Natural Wood and Medium Density Fiberboard. Forests 2021, 12, 1039. [Google Scholar] [CrossRef]

- Saejiw, N.; Chaiear, N.; Sadhra, S. Exposure to Wood Dust and Its Particle Size Distribution in a Rubberwood Sawmill in Thailand. J. Occup. Environ. Hyg. 2009, 6, 483–490. [Google Scholar] [CrossRef]

- Zhang, X.; Kang, J.; Chen, H.; Yao, M.; Wang, J. PM2.5 Meets Blood: In vivo Damages and Immune Defense. Aerosol Air Qual. Res. 2018, 18, 456–470. [Google Scholar] [CrossRef]

- Thangavel, P.; Park, D.; Lee, Y.-C. Recent Insights into Particulate Matter (PM2.5)-Mediated Toxicity in Humans: An Overview. Int. J. Environ. Res. Public Health 2022, 19, 7511. [Google Scholar] [CrossRef]

- Castells, B.; Varela, A.; Castillo-Ruiz, F.J.; Calvo, L.F.; Medic, L.; Tascón, A. Ignition and explosion characteristics of olive-derived biomasses. Powder Technol. 2023, 420, 118386. [Google Scholar] [CrossRef]

- Przybysz, J.; Celiński, M.; Mizera, K.; Gloc, M.; Borucka, M.; Gajek, A. Flammability and explosion characteristics of softwood dust. J. Therm. Anal. Calorim. 2023, 148, 10727–10733. [Google Scholar] [CrossRef]

- Mráčková, E.; Milanko, V.; Gavanski, D.; Simedić, B. Rozbor vybraných dezintegrovaných vzoriek dreva z pohľadu výbušnosti a zdravotného rizika. Delta 2013, 7, 16–22. [Google Scholar]

- Kim, Y.S.; Lee, M.C.; Rie, D.H. Explosion characteristics of combustible wood dust in confined system: Analysis using oxygen consumption energy. J. Mech. Sci. Technol. 2016, 30, 5771–5779. [Google Scholar] [CrossRef]

- Huéscar Medina, C.; Phylaktou, H.N.; Andrews, G.E.; Gibbs, B.M. Explosion characteristics of pulverised torrefied and raw Norway spruce (Picea abies) and Southern pine (Pinus palustris) in comparison to bituminous coal. Biomass Bioenergy 2015, 79, 116–127. [Google Scholar] [CrossRef]

- Damec, J. Protivýbuchová Prevence, 1st ed.; Edice SBPI Spektrum 8: Ostrava, Czech Republic, 2005; ISBN 80-86111-21-0. [Google Scholar]

- Kuracina, R.; Zuzana, S.; Cekan, P. Determination of the Maximum Explosion Pressure and the Maximum Rate of Pressure Rise During Explosion of Wood Dust Clouds. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2015, 23, 48–56. [Google Scholar] [CrossRef]

- Bartknecht, W. Explosionsschutz: Grundlagen und Anwendung; Springer: Berlin/Heidelberg, Germany, 2011; ISBN 978-3-642-77516-1. [Google Scholar]

| Dust Particle | ||||

|---|---|---|---|---|

| Average (μm) | Minimum (μm) | Maximum (μm) | Standard Deviation (μm) | |

| Max. dimension | 73.21 | 2.38 | 499.71 | 73.52 |

| Min. dimension | 37.98 | 1.69 | 403.30 | 35.83 |

| dEC | 0.86 | 0.05 | 6.28 | 0.56 |

| Aspect ratio (elongation) | 0.41 | 0.04 | 0.92 | 0.18 |

| Mesh Sizes (μm) * | |||||

|---|---|---|---|---|---|

| <32 | 32–40 | 40–45 | 45–63 | 63–500 | |

| LEL (g·m−3) | 34.00 (±8.49) a | 35.00 (±7.07) ab | 40.00 (±1.00) b | 55.00 (±7.07) b | 70.00 (±14.14) b |

| Class ** | 1 | 1 | 1 | 2 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mračková, E.; Kminiak, R.; Adamčík, L. Risks of Spruce Wood Dust in the Work Environment. Forests 2025, 16, 1771. https://doi.org/10.3390/f16121771

Mračková E, Kminiak R, Adamčík L. Risks of Spruce Wood Dust in the Work Environment. Forests. 2025; 16(12):1771. https://doi.org/10.3390/f16121771

Chicago/Turabian StyleMračková, Eva, Richard Kminiak, and Lukáš Adamčík. 2025. "Risks of Spruce Wood Dust in the Work Environment" Forests 16, no. 12: 1771. https://doi.org/10.3390/f16121771

APA StyleMračková, E., Kminiak, R., & Adamčík, L. (2025). Risks of Spruce Wood Dust in the Work Environment. Forests, 16(12), 1771. https://doi.org/10.3390/f16121771