Abstract

This study investigates the color variations of Turkey oak (Quercus cerris L.) wood originating from different regions in Hungary and different growing site types. Samples were collected from pure and mixed stands under both good and poor growing conditions across several regions. Color parameters were monitored and presented using the CIE L*a*b* color measurement system. Significant differences were detected between sapwood and heartwood, with sapwood being lighter and more yellowish. Growing site type had a marked effect on color parameters, especially on lightness (L*), confirming the influence of site quality and stand composition. Within-tree color homogeneity was generally high, although mixed stands under poor conditions exhibited greater variation, up to 17.6%. Pure stands produced more uniform color, indicating their higher suitability for industrial uses requiring visual consistency. These results contribute to our understanding of Turkey oak’s esthetic and material properties, and support its broader utilization in furniture and interior applications.

1. Introduction

Turkey oak (Quercus cerris L.) trees are becoming increasingly common in Hungary, the region, and throughout Europe [1,2]. It is therefore important to find suitable uses for them. In this way, in the distant future, when they are expected to play a much more dominant role among industrial wood species due to anticipated wood shortages, we will be able to use Turkish oak wood appropriately. In addition, it is necessary to have the right trees and logs available for industrial purposes available. Forecasts for the future indicate that, in a century, Turkey oak will no longer be the dominant tree species [3], but until then, large quantities will be available, especially during periods of expected mass dieback. Hungary currently has 218,518 hectares of Turkey oak forest, which accounts for 11.6% of the total forest area. This equates to 52,135,529 m3 of standing Turkey oak tree, 12.6% of the total stock [4]. As is evident, Hungary, like many European countries, has a large amount of Turkey oak forest, but only a small proportion of this is used for industrial purposes. The color of wood and the possible color variations of wood are extremely important factors for its use, especially in furniture manufacturing and interior design. Color is the most evident esthetic feature of wooden constructions [5]. Wood color and its modification have been intensively studied since computer-aided colorimeters became available [6,7,8,9].

Chromophore molecules with double-bound chemical systems are responsible for the visible colors of wood. Compounds such as flavonoids and tannins, which influence wood coloration, vary with growing conditions and site chemistry. Chromophores have special absorption bands in the visible region. Wood polyoses do not absorb visible light. Lignin absorbs light below 400 nm wavelength [10,11,12,13] and has a pale yellow color. In general, this yellow color is typical for sapwood of almost all wood species. As sapwood turns into heartwood, extractives are deposited in the cell walls and on the vessel walls [14,15,16]. These constituents make significant contributions to the properties of wood such as color, odor, and decay resistance [17,18,19].

Wood colors differ widely among species, as well as within a tree [20]. The color variation between trees from the same species is generated by several factors such as tree age, soil composition, tree growth, and the location of boards inside the tree [21,22]. Environmental conditions and genetics determine the color of wood, although environmental conditions are more relevant [23].

Eight black walnut trees each were harvested from three sites in the state of Missouri to investigate their color variations [24]. The X, Y, and Z tristimulus values were determined and compared. Percentage luminance (brightness or lightness) was derived directly from the Y tristimulus value. It was found that variability in luminance (i.e., darkness or lightness) was the primary cause of heartwood color variability.

There is very little research dedicated to the problem of color variations among one specific species harvested in different forests or regions. In a recent study [25], 89 samples were taken from heartwood of seven oak species, and their color variations were detected using objective color measurement. The differences were mainly observed in terms of their lightness (L*) and yellowness (b*). Moya and Calvo-Alvarado [26] studied the relationship between the physical environmental factors and color parameters of Tectona grandis wood grown in 22 forest plots in Costa Rica. These plots were grouped into five cluster sites. It was found that heartwood produced in dry climates with deeper and fertile sites had the most yellowish-brown color.

The heartwood color of Juglans mandshurica var. sachalinensis was studied, and the results show that, among the soil properties, it was not soil nitrogen, but rather soil magnesium contents alone that had a significant influence on the redness and yellowness of heartwood [27]. Higher soil magnesium contents resulted in the decreased redness and increased yellowness of heartwood.

This study focuses on color and grain as esthetically important properties among the many characteristics of wood. The aim was, therefore, to examine whether different types of growing sites cause color differences in the wood of Turkey oak trees. In addition, the color homogeneity of individual trees was examined, as well as the color characteristics of sapwood and heartwood. This will contribute to understanding which type of growing site is most suitable for producing high-quality, or at least better-quality, Turkey oak wood. This will promote its wider use in industry and provide foresters with information on how to cultivate more valuable stands.

2. Materials and Methods

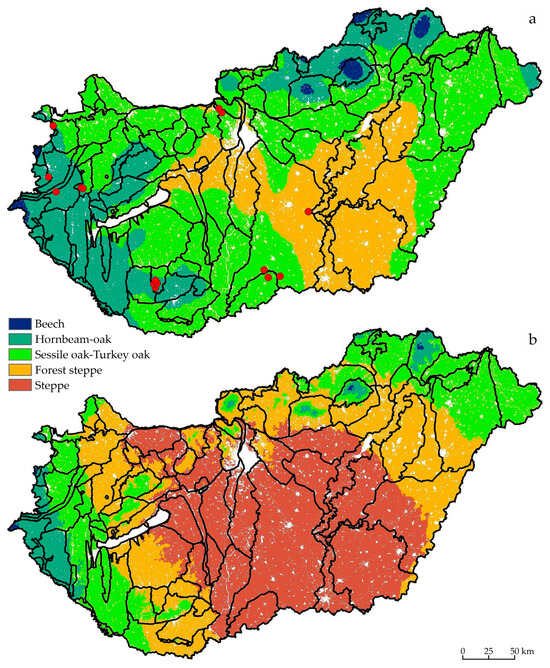

For the tests, only Turkey oak logs (Quercus cerris L.) were used, collected from different growing sites in various regions of Hungary (Figure 1). The climate zones in which the sample trees grew are also shown in Figure 1a. Figure 1b shows the climate zones expected in the future based on one of the current forecasts. This proves that a large amount of raw material can be expected in the timber industry in the future, either because Turkey oak will become the dominant tree species or because it will be available in large quantities in certain periods and areas due to mass forest dieback. Turkey oak typically prefers an oak forest climate, but it can also be found, to some extent, in beech forests, meaning that it currently has significant potential for spread, as shown in Figure 1a. Regions where Turkey oak occurs in significant proportions, or where it can be expected to spread more significantly in the near future, were studied. In each region, the following four site types (forests or forest-sections) were targeted:

Figure 1.

Map (a) shows the 69 major forest areas of Hungary, with color coding indicating the climate zones prevailing between 1981 and 2010. Red dots indicate the sampling sites from which the Turkey oak (Quercus cerris L.) samples were taken; the coordinates of the sampling sites can be found in Table 1 (image based on Illés et al. [28]). Map (b) shows the climate forecast for the period 2041–2070 using the same color coding as subfigure (a) [28].

- Poor growing conditions, mixed-species forest;

- Poor growing conditions, pure-species forest;

- Good growing conditions, mixed-species forest;

- Good growing conditions, pure-species forest.

The quality of the growing site was classified based on soil layers, soil water management, precipitation, slope and sun exposure, etc., with the help of official regional data and the experiences of local forestry colleagues. In mixed stands, the proportion of the main tree species was a maximum of 80%. Table 1 lists the available samples and some of their properties used in this study. For sampling, tree characteristics of the forest area were sought. The health condition, diameter, height, branch structure, etc., of the trees were taken into account. It was important that the trees had a significant amount of heartwood, so young trees were not selected. Logs were taken from the lower section of the trunk. For larger diameters, 150 cm above the stump was sufficient because the right amount of sawn timber for the planned tests was able to be obtained, while for small diameters, the samples had to be longer to obtain a similar amount of wood.

Table 1.

Growing location data for the samples used in this study.

After delivery, the logs were sawn and kiln-dried to 12% moisture content using the appropriate drying schedule set by the manufacturer for the wood species [29]. They were placed in closed storage, and, later, the middle planks selected for color measurement were planed; no other preparations were made. The color measurement was performed at the same moisture content because the planks were stored in a closed storage room for at least six months prior to use. The moisture content settled at around 10% at the time of specimen preparation and measurement. First, the wide planks were sawn in half along the grain to fit on the planing machine. Planing was carried out under identical conditions to ensure that the surfaces of the different planks were uniform and that the results could be compared. The tests were performed within three days of planing to avoid color changes caused by oxidation. On each middle plank—or, in the case of large logs, on each half-plank—all parts of the tree, from heartwood to bark, appeared, and color measurement was performed on the radial sections. All samples contained a significant proportion of heartwood; young trees were not used in the measurements. Therefore, due to the age of the samples, parts that have been transformed into heartwood can always be found. Extractives, tyloses, and other extraneous materials are in the cells, causing different colors compared to sapwood, and the results of heartwoods are comparable [30]. Mature wood and juvenile wood cannot be distinguished from each other with the naked eye, so they were treated together as heartwood in the color measurements. The pith and the parts directly adjacent to the pith were not measured. On average, 23 measurements were taken on heartwood and 28 measurements on sapwood for each plank using a Konica-Minolta 2600d colorimeter (Konica Minolta Inc., Tokyo, Japan). The Commission Internationale de l’Éclairage (CIE) value of L* ranges from black (0) to white (100), the value of the a* axis is – for green and + for red color components, and the value of the b* axis is – for blue and + for yellow color components [17]. The color of wood is usually found in the positive part of the three axes. Accordingly, the values CIE L* (Lightness), a* (Redness), and b* (Yellowness) will be referred to as CIE values hereafter.

The color space data were calculated based on the D65 illuminant and 10° standard observer with a test window diameter of 8 mm. This test window diameter was sufficient to examine at least two, but potentially up to five, growth rings for each measurement, based on the typical annual ring width of the Turkey oak. This provided much more reliable results compared to examining only one annual ring or a latewood using a smaller diameter test window. Based on the L*, a*, b* color coordinates, the calculated color difference (∆E*) is an important value in terms of the perceptibility of differences visible to the naked eye, as it determines the distance between two color points in the coordinate system (Equation (1), Brainard 2003 [31]). ∆E* indicates the color difference to the naked eye by exact numbers (Table 2):

where ∆L = (L*2 − L*1), ∆a = (a*2 − a*1), and ∆b = (b*2 − b*1) are the compared color differences.

Table 2.

The correlation between visual perception by naked eye and ∆E* [32].

Prior to statistical analysis, misleading results from the dataset were removed that could have been caused by measurement errors, such as specimens that showed discoloration of sapwood. Thus, a total of 1502 sapwood and 1389 heartwood measurement points were subjected to statistical analysis and evaluation, each with three coordinates that had to be treated separately. One-way ANOVA Fisher-LSD test at a significance level of 0.05 was performed using TIBCO Statistica version 14.0.1.25 (TIBCO Software Inc., Palo Alto, CA, USA) software.

3. Results and Discussion

3.1. Comparison of Sapwood and Heartwood

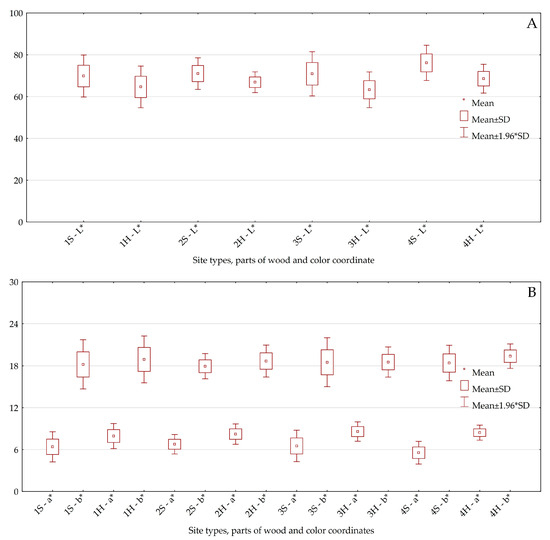

The color of the Turkey oak sapwood, like that of many other wood species, is lighter than heartwood, which has been confirmed by all tests, showing significant differences in lightness, as evidenced by ANOVA tests (Figure 2).

Figure 2.

The results of the three-color coordinate measurements of the samples, sorted by site properties. The values of the coordinate points are shown on the Y axis and have no units of measurement. The abbreviations on the X axis are structured as follows: the serial number indicates the site types according to Table 1 (Nr. 1: Poor growing conditions, mixed stand; Nr. 2: Poor growing conditions, pure stand; Nr. 3: Good growing conditions, mixed stand; Nr. 4: Good growing conditions, pure stand); the second character indicates sapwood (S) or heartwood (H); after the hyphen, the color coordinate can be read as follows: (A) L*; (B) a* and b*. SD—standard deviation.

There are relatively smaller differences (in percentage) in yellowness than in redness. Sapwood is visually more yellowish-white in color than heartwood because of the considerably lower redness value. The average a* value of sapwood is higher by 28.8% than that of heartwood. The visible color difference between earlywood and latewood Turkey oak, as well as its characteristic slightly striped appearance, can significantly influence the results of color measurement by increasing the standard deviation (SD). Thus, the highest variance of 17.6% in the a* value can be considered low (sapwood in good growing conditions, mixed stand). The average of b* values for sapwood and heartwood are very similar, with a difference of 3.0%, and this is only minimally influenced by the growing site. The variances of b* are very low, below 10% in all samples according to this sorting method.

3.2. Differences Between Growing Sites Countrywide

The selection of growing sites and the categorization of good and poor growing sites were successful, based on the results of the ANOVA analysis. As shown in Figure 2, the growing site types were categorized and numbered (1: Poor growing conditions, mixed-species forest; 2: Poor growing conditions, pure-species forest; 3: Good growing conditions, mixed-species forest; 4: Good growing conditions, pure-species forest). Sapwood (S) and heartwood (H) were evaluated separately in the statistical analysis. Similarities in color components between different growing sites were sought. For L*, there was a similarity in only one case, between 2S and 3S, while in all other cases there were no significant similarities, with the highest probability of 0.23%. Since L* has the most significant value among the color components, it alone can predict the success of the classification of the growing sites with a high degree of certainty. This is confirmed by the analysis of the a* color component. There were weak similarities between 1S and 3S (13.4% probability) and 3H and 4H (6.4% probability). In all other cases, the coordinates of the habitat types were clearly different. For b*, seven matches could be found, including some with low and some with high probabilities. However, none of them matched the similarity found for L*, i.e., they did not strengthen the probability observed for robust L*. Furthermore, the color matches for sapwoods are much more likely due to its significantly lighter, paler color (Figure 3).

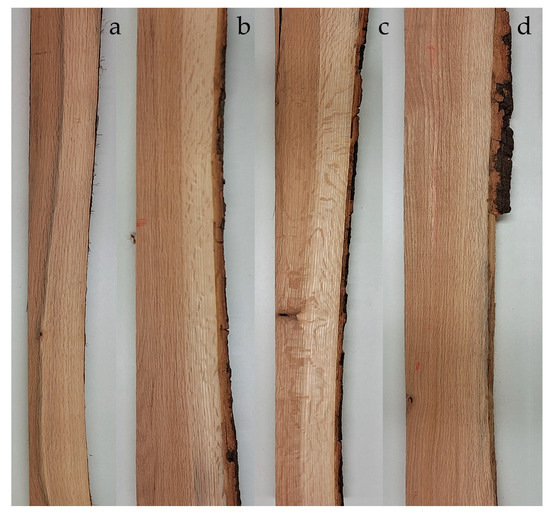

Figure 3.

Images of typical test specimens after the color measurement (dried, planed middle planks). All of them originate from different types of growing sites in Kiskunság: (a) poor growing conditions, mixed stand; (b) poor growing conditions, pure stand; (c) good growing conditions, mixed stand; (d) good growing conditions, pure stand.

3.3. Differences Between Growing Sites Regionally

If the same study is conducted at the regional level rather than at the country level, a more refined view of the types of growing sites will be obtained. Samples were selected from a total of five regions in the country, but in one of them, only one type of growing site was found, so it was not possible to perform this analysis there. In another region (Pilis-Buda Hills), only wood from two types of growing sites were able to be obtained.

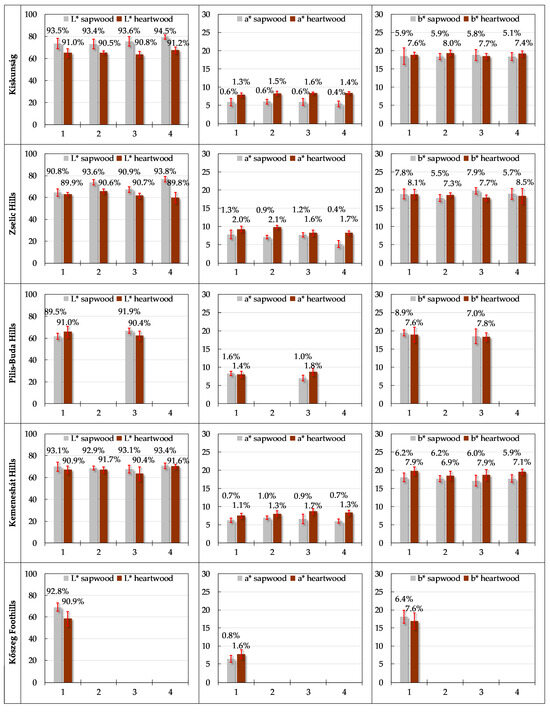

In general, it can be said that differences in the color coordinates of Turkey oak wood indicate the influence of the growing environment. In the regions Kiskunság and Zselic Hills, the L* and a* coordinates of the four growing areas showed little similarity, and the analysis of b* reveals numerous similarities (altogether, 13 similarities in the 2 sides, that is, 7.7% of all possibilities). In contrast, in the region Kemeneshát Hills, the opposite was true: a* and b* contained very few similarities (altogether, 4 pieces, that is, 4.8% of all possibilities). For sapwood, the chance of similarities is greater due to its lighter, fundamentally more homogeneous color, as mentioned earlier. Surprisingly, in several cases, similarities between sapwood and heartwood were found. This is because the data can only be compared for a single color coordinate at a time, while the differences visible to the eye are caused by the combined effect of all three coordinates. Even if the yellow color component (b*) is the same, as an example, the two colors can differ greatly from each other due to the effect of the other two coordinates. For this reason, it is advisable to focus mainly on heartwood, as the industrial use of sapwood is typically negligible anyway. L* has the most significant effect among the color coordinates, as shown in Figure 4, presenting the means and standard deviations of the examined regions, sites, and wood parts. Therefore, the analysis of L* is primary.

Figure 4.

Averages of sapwood and heartwood color coordinates of the different site types in each studied region, marked on the left. Standard deviation is indicated by the red line, while the percentages above the columns show the average contribution ratio of the given color coordinate to ΔE*, i.e., the ratio responsible for causing the color difference. The numbers on the horizontal axes indicate the site types: 1—Good growing conditions, mixed-species; 2—Good growing conditions, pure-species; 3—Poor growing conditions, mixed-species; 4—Poor growing conditions, pure-species.

Among the four site types in the four regions, a total of three matches in the L* values were found, examined by growing area. One of these matches has a low probability (6.5%), so it can be concluded that, out of a total of thirty-three possible matches, two or three is a low number. Such a small amount can be attributed to chance, given such a large sample size and measurement data series. The averages and standard deviations shown in Figure 4, for example, were calculated based on 427 sapwood and 384 heartwood color measurements on specimens from the Kiskunság region. Thus, examined by region, the colors of the specimens differ depending on the site type. The growing location influences the color detected by the colorimeter, even if it appears similar to the naked eye. The quality of the growing site has a significant impact on the growth of Turkey oak trees [33], and can therefore influence their characteristics, such as wood color.

There were only three cases where similarities were found between the same site types for all three color coordinates, and only one of these was between heartwoods. The poor growing conditions—mixed-species and the poor growing conditions—pure-species growing site types at Zselic region produced a weak but statistically significant match, with 6.5% probability. This may be due to the fact that the Zselic sampling sites were located very close to each other, which may have contributed to the color match.

3.4. Comparison of Several Trees at One Growing Site

Statistical comparison of samples from a single growing site, for example, three boards each from logs nr. 02 and 03, which originate from a poor growing site of Kiskunság, yielded very varied results for both sapwood and heartwood. A comparative analysis of the measurement results of individual specimens better highlights the color variation of the wood of a given plank or log. This applies to all three CIE coordinates. It also applies to the comparison results of the middle planks of two logs and two middle planks from the same log. It is interesting to note that even the middle planks from the same log showed statistically significant differences in at least one color coordinate, and it was very rare for all three coordinates to be statistically identical. Of course, the color point in the L*a*b* coordinate system is influenced by all three coordinates, so it is possible that color points that differ significantly in at least one coordinate are very close to each other. However, this can only be verified by calculating each color point, which is an impossible task with such a large amount of data. To simplify this, the ∆E* value was calculated using sample averages, which allowed us to determine, based on Mokrzycki and Tatol [32], whether the difference between the average colors of the two planks is detectable to the naked eye (Table 2). In general, it can be said that, in the case of heartwoods, there are greater color differences between the middle planks of two trees growing in the same location (Figure 5).

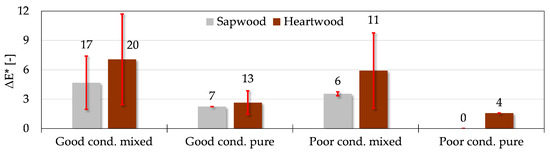

Figure 5.

Average color differences characteristic of the four forest types, comparing individual trees at a single growing site separately for sapwood and heartwood. The standard deviation is indicated by the red line, while the numbers above the columns show the number of specimens used for the analysis. Abbreviations: Good cond. mixed—Good growing conditions, mixed-species; Good cond. pure—Good growing conditions, pure-species; Poor cond. mixed—Poor growing conditions, mixed-species; Poor cond. pure—Poor growing conditions, pure-species.

It can be concluded that the variations are extremely high in several places. For example, for both sapwood and heartwood from the good growing conditions—mixed-species site, there were specimen pairs where no color difference could be detected with the naked eye (e.g., sapwood of logs nr. 04 and 05 from the Kőszeg Foothills). However, significant differences were also visible in specimens delivered from sites with the same classification (e.g., sapwood of logs nr. 04 and 06 from the Kemeneshát Hills). The specimens used had to be free of disease. Sapwood from the poor growing conditions—pure-species site was, therefore, not included in the analysis due to the discoloration caused by fungus. Based on the average ∆E* values in the diagram in Figure 5, the colors of Turkey oak trees growing in the same area often differ greatly from one another, as is visible to the naked eye. There are distinct or significant color differences in the two mixed-species forest types, while the differences are barely noticeable in the pure-species forest types. This is probably due to the mixed stand and the effects of forestry management. If young Turkey oak trees are cut back to favor other tree species, they will produce more extractives due to the need for defense, which causes discoloration.

3.5. Color Variegation Within a Single Piece of Sawnwood

However, the variegation of samples can primarily be examined on a plank-by-plank basis. The standard deviation of color components best expresses the extent of variation within one sawnwood. Of course, sapwood and heartwood must be treated separately. According to the above-mentioned criteria, the variances for all specimens were calculated included in the study. In general, it can be said that the variegation of the Turkey oak planks is slight: each specimen has a relatively homogeneous color (Figure 3).

Where L* had a high SD, all color coordinates had high SD. The high SD of b* occurred exclusively in conjunction with the high SD of a*. However, in many cases, a* showed a high SD on its own. It should be noted that, considering the aforementioned basic color variability of wood, the SDs cannot be considered high, as the highest value was 24.2%. It is only significant in comparison to the averages, as values are generally below 10%, with the majority below 5%. This proves that the color measurements were performed consistently and accurately, and that variegation is not typical of Turkey oak in general. However, it can be concluded that the poor growing site—pure stand proved to be almost perfect, with a single a* variance of 15.4%. Even in the good growing site—pure stand, higher variegation was only present in sapwood, exclusively due to a*, but here were below 20% the variances in all cases. In other words, pure-species Turkey oak stands produce wood with a more uniform color. However, mixed stands, especially those grown in poor conditions, showed significantly greater color variations. In this category, the higher SD of L* and b* was also not a major factor. However, a* had a variance of over 10% in 26.3% of sapwood specimens and 23.8% of heartwood specimens. This is probably due to the worse growing conditions, as the trees may have been affected by several factors, causing them to deposit more extractives in certain annual rings as a defense mechanism. Coexistence with other tree species, especially sessile oak, may have had a similar effect. Forestry practices can also play a role in this, because Turkey oak trees, which grow rapidly at first, are often cut back severely at a few years of age to give preference to more valuable sessile oak trees. This certainly causes serious trauma for the Turkey oak trees, which will have an impact in the future: less sunlight results in weaker growth, infections entering through injuries, more knots due to low-growing new branches, shorter clear trunk sections, and, of course, color variation, among other things.

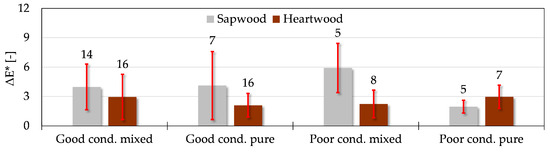

Another study on the same issue was also conducted: the variegation of individual sawnwoods. Those logs could be used in the analysis, where the color of several sawn timbers was measured. This made it possible to compare the average color of different sawn timbers from the same tree (Figure 6).

Figure 6.

Average color differences characteristic of the four forest types, based on a comparison of color measurements of planks extracted from the same tree separately for sapwood and heartwood. Standard deviation is indicated by the red line, while the numbers above the columns show the number of specimens used for the analysis. Abbreviations: Good cond. mixed—Good growing conditions, mixed-species; Good cond. pure—Good growing conditions, pure-species; Poor cond. mixed—Poor growing conditions, mixed-species; Poor cond. pure—Poor growing conditions, pure-species.

The standard deviations are very large in all cases, indicating a high degree of variation in color differences. From almost zero difference between the colors of two pieces of timber from the same tree to differences that are clearly visible to the naked eye from far, everything can be found in all of the forest types and wood sections examined. It is also true that, looking at the averages, the poor growing conditions—mixed-species forest-type stands out from the results, but apart from that, large color differences within a single tree are not typical. Taking into account naked-eye perception based on ∆E*, in all heartwoods from the four forest types, noticeable color differences can be seen within a tree, but are not distinct. Sapwood is much more varied, with differences ranging from barely noticeable to large.

A solution could be to use mild steaming to reduce the color differences between sapwood and heartwood. After steaming, sapwood could be used on visible surfaces, similarly to heartwood [34,35,36,37,38]. Steaming would also reduce the stresses that are inherent in the material [39]. Another modification that can bring positive changes is treatment with acetic anhydride. This makes the wood lighter and duller in color and improves its weather resistance with excellent efficiency [40,41]. The question is how successfully such a darker wood can be incorporated into future design trends to broaden the usability of Turkey oak. Knowledge about the color variability of Turkey oak wood has significant value for the wood industry, as color and color uniformity are among the most important esthetic and quality characteristics during wood processing. Accurate information on the color coordinates and tonal differences between heartwood and sapwood enables a more deliberate selection of logs and sorting according to their intended use—for example, in furniture manufacturing, parquet, or veneer production. The color differences resulting from variations in site conditions and stand composition can also serve as a basis for distinguishing regional wood and for building product identity or branding. Furthermore, understanding the degree of color heterogeneity supports the optimization of surface treatment technologies, since procedures required to achieve color uniformity (e.g., staining, coloring) can be designed more precisely. Overall, such studies contribute to the value-added utilization of Turkey oak, strengthen its market position, and promote the high-quality use of domestic wood resources.

Before drawing a final conclusion regarding color differences, it should be noted that the color of wood is largely determined by its extractive content [5,42]. It is not the quantity of extractives, but rather their quality and the types of chemical components that serve as the main determining factors.

Significant differences exist in the extractive content between Turkey oak and other oak species, both in heartwood and sapwood. It was found that Turkey oak sapwood contained high amounts of soluble extractives (5.34% in cold water, 7.77% in hot water, and 21.60% in 1% NaOH), with values close to those obtained for sessile oak heartwood. In contrast, Turkey oak heartwood contained considerably fewer soluble extractives (2.95% in cold water, 4.25% in hot water, and 17.07% in 1% NaOH) than sapwood [42].

The fact that heartwood contains fewer extractives than sapwood appears to contradict the observation that heartwood is darker than sapwood, as confirmed by both visual inspection and objective color measurements. From another perspective, in most oak species, heartwood contains more extractives than sapwood [43,44,45], and, accordingly, heartwood is typically darker than sapwood. These findings indicate that only a portion of the extractives contribute to color formation, as was evidenced by Hofmann et al. [46].

It would be a valuable task for wood chemists to determine the extent to which individual chemical compounds within the extractives contribute to wood coloration. Current scientific knowledge in this area is still highly incomplete.

4. Conclusions

This study investigates the color characteristics and variability of Turkey oak (Quercus cerris L.) wood from different growing site types in Hungary, with the goal of understanding how site quality and stand composition influence its esthetic properties. Turkey oak is an increasingly important species in Europe, mainly in Central Europe, and knowledge of its color behavior supports its broader industrial utilization.

Wood samples were collected from four site types—poor/good growing conditions and pure/mixed stands—distributed across five regions in Hungary. After kiln drying and planing, 1502 sapwood and 1389 heartwood measurement points were analyzed using a Konica-Minolta CM-2600d colorimeter in the CIE L*a*b* color space (D65 illuminant, 10° observer). Using statistical analysis, significant differences between site types and wood sections were determined.

The results show that sapwood was substantially lighter and more yellowish than heartwood, with a 28.8% higher average a* value of sapwood, while site conditions significantly influenced lightness, confirming that environmental factors strongly affect color formation.

Of the four location types in the regions, a total of three similarities were found in the L* values based on the analysis of the growing sites. In total, 3 of the 33 possible matches are a low number, meaning that the results of the growing sites can be considered different and that the characteristics of the growing sites have an impact on wood color.

Color variability within individual trees was generally low, with most standard deviations below 10%, although pure stands under good conditions showed higher variability (below 20% in a*). Pure stands produced wood with more uniform color, making them preferable for industrial applications requiring visual consistency.

The results quantitatively demonstrate that growing conditions and stand composition significantly affect the visual appearance of Turkey oak wood primarily through its chemical composition, especially its extractable substances. The results provide a foundation for improved material selection and processing strategies in the wood industry.

Author Contributions

Conceptualization, M.B., R.N. and L.T.; Methodology, M.B., R.N. and L.T.; Validation, M.B. and L.T.; Formal Analysis, M.B. and L.T.; Investigation, L.T.; Resources, M.B. and R.N.; Writing—Original Draft Preparation, M.B. and L.T.; Writing—Review and Editing, M.B., R.N. and L.T.; Visualization, M.B.; Supervision, M.B.; Project Administration, M.B. and R.N.; Funding Acquisition, R.N. All authors have read and agreed to the published version of the manuscript.

Funding

The publication was made in frame of the project TKP2021-NKTA-43, which has been implemented with the support provided by the Ministry of Culture and Innovation of Hungary from the National Research, Development and Innovation Fund, financed under the TKP2021-NKTA funding scheme.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

We would like to take this opportunity to thank all of our forestry colleagues, both their managers and employees, who helped us select and procure our raw materials, as follows: KEFAG Kiskunsági Erdészeti és Faipari Ltd.: Ferenc Sulyok; Dániel Andrési; Mecsekerdő Ltd.: István Ripszám; Endre Burián; Gábor Drávavölgyi; Tamás Lázár; Pilisi Parkerdő Ltd.: Gábor Reinitz; Zoltán Némedy; Gábor Szenthe; Szombathelyi Erdészeti Ltd.: József Bugán; Csaba Gángó; András Németh; Bence Szalay; TAEG Tanulmányi Erdőgazdaság Ltd.: Gyula Sándor; Ádám Folcz; Márk Preisinger. Unfortunately, we are unable to list all the forestry colleagues who have provided valuable assistance. However, we would like to acknowledge the invaluable contributions to log processing, the organized storage of sawn timber, and specimen preparation of Imre Horváth.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Govina, J.K.; Németh, R.; Bak, M.; Báder, M. Effect of Variable Growth Conditions on Selected Anatomical Properties of Hungarian Turkey Oak Wood. Bull. Transilv. Univ. Brasov Ser. II For. Wood Ind. Agric. Food Eng. 2023, 16, 83–98. [Google Scholar] [CrossRef]

- Csépányi, P.; Csór, A. Economic Assessment of European Beech and Turkey Oak Stands with Close-to-Nature Forest Management. Acta Silv. Lignaria Hung. 2017, 13, 9–24. [Google Scholar] [CrossRef][Green Version]

- Illés, G.; Móricz, N. Hazai Fafajok Klímaanalóg Területeinek Vizsgálata a Klímaváltozás Tükrében. Erd. Közlemények 2022, 12, 91–112. [Google Scholar] [CrossRef]

- Ministry of Agriculture. Summary Data on Hungary’s Forests 2023 (Magyarország Erdeinek Összefoglaló Adatai 2023); Agrárminisztérium, Hungary: Budapest, Hungary, 2024; 2p.

- Musat, E.-C.; Salca, E.-A.; Dinulica, F.; Ciobanu, V.D.; Dumitrascu, A.-E. Evaluation of Color Variability of Oak Veneers for Sorting. BioResources 2016, 11, 573–584. [Google Scholar] [CrossRef]

- Chang, S.-T.; Wang, S.-Y.; Cheng, S.-S. Red Color Enhancement of Sugi (Cryptomeria japonica D. Don) Heartwood by Light Irradiation. J. Wood Sci. 1999, 45, 271–273. [Google Scholar] [CrossRef]

- Mitsui, K.; Takada, H.; Sugiyama, M.; Hasegawa, R. Changes in the Properties of Light-Irradiated Wood with Heat Treatment. Part 1. Effect of Treatment Conditions on the Change in Color. Holzforschung 2001, 55, 601–605. [Google Scholar] [CrossRef]

- Yazaki, Y. Wood Colors and Their Coloring Matters: A Review. Nat. Prod. Commun. 2015, 10, 1934578X1501000332. [Google Scholar] [CrossRef]

- Dzurenda, L. Natural Variability of the Color of Beech Wood in the Color Space CIE L*a*b*. Forests 2023, 14, 1103. [Google Scholar] [CrossRef]

- Belov, N.P.; Sherstobitova, A.S.; Yaskov, A.D. Diffuse Reflection of Light by Cellulose Pulp and Optical Absorption of Aqueous Residual Lignin Solutions. J. Appl. Spectrosc. 2011, 78, 138–140. [Google Scholar] [CrossRef]

- Afrin, T.; Tsuzuki, T.; Wang, X. UV Absorption Property of Bamboo. J. Text. Inst. 2012, 103, 394–399. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, L.; Gao, J.; Guo, H.; Chen, Y.; Cheng, Q.; Via, B.K. Surface Photo-Discoloration and Degradation of Dyed Wood Veneer Exposed to Different Wavelengths of Artificial Light. Appl. Surf. Sci. 2015, 331, 353–361. [Google Scholar] [CrossRef]

- Lee, S.C.; Tran, T.M.T.; Choi, J.W.; Won, K. Lignin for White Natural Sunscreens. Int. J. Biol. Macromol. 2019, 122, 549–554. [Google Scholar] [CrossRef]

- Koch, G.; Kleist, G. Application of Scanning UV Microspectrophotometry to Localise Lignins and Phenolic Extractives in Plant Cell Walls. Holzforschung 2001, 55, 563–567. [Google Scholar] [CrossRef]

- Kleist, G.; Bauch, J. Cellular UV Microspectrophotometric Investigation of Sapelli Heartwood (Entandrophragma cylindricum Sprague) from Natural Provenances in Africa. Holzforschung 2001, 55, 117–122. [Google Scholar] [CrossRef]

- Koch, G.; Richter, H.-G.; Schmitt, U. Topochemical Investigation on Phenolic Deposits in the Vessels of Afzelia (Afzelia spp.) and Merbau (Intsia spp.) Heartwood. Holzforschung 2006, 60, 583–588. [Google Scholar] [CrossRef]

- Tolvaj, L. Measurement and Data Evaluation of Wood Colour and Gloss. In Optical Properties of Wood; Smart Sensors, Measurement and Instrumentation; Springer Nature Switzerland: Cham, Switzerland, 2024; Volume 45, pp. 51–90. ISBN 978-3-031-46905-3. [Google Scholar]

- Hofmann, T.; Seidu, H.; Kipkoror, K. Polyphenol Content of Underutilized Wood Species from Hungary. In Proceedings of the 11th Hardwood Conference Proceedings, Sopron, Hungary, 30–31 May 2024; Németh, R., Hansmann, C., Militz, H., Bak, M., Báder, M., Eds.; University of Sopron Press: Sopron, Hungary, 2024; pp. 136–140, ISBN 978-963-334-518-4. [Google Scholar] [CrossRef]

- Hofmann, T.; Albert, L.; Rétfalvi, T.; Fehér, S. HPTLC Investigation of a Ring-like Discoloration of Pedunculate Oak (Quercus robur L.) Heartwood. J. Planar Chromatogr.—Mod. TLC 2010, 23, 315–319. [Google Scholar] [CrossRef]

- Nishino, Y.; Janin, G.; Chanson, B.; Détienne, P.; Gril, J.; Thibaut, B. Colorimetry of Wood Specimens from French Guiana. J. Wood Sci. 1998, 44, 3–8. [Google Scholar] [CrossRef]

- Liu, S.; Loup, C.; Gril, J.; Dumonceaud, O.; Thibaut, A.; Thibaut, B. Studies on European Beech (Fagus sylvatica L.). Part 1: Variations of Wood Colour Parameters. Ann. For. Sci. 2005, 62, 625–632. [Google Scholar] [CrossRef][Green Version]

- Klumpers, J.; Janin, G.; Becker, M.; Lévy, G. The Influences of Age, Extractive Content and Soil Water on Wood Color in Oak: The Possible Genetic Determination of Wood Color. Ann. Sci. For. 1993, 50, 403s–409s. [Google Scholar] [CrossRef]

- Mosedale, J.; Charrier, B.; Janin, G. Genetic Control of Wood Colour, Density and Heartwood Ellagitannin Concentration in European Oak (Quercus petraea and Q. robur). Forestry 1996, 69, 111–124. [Google Scholar] [CrossRef]

- Phelps, E.; Garrett, H.; Cox, G. Growth-Quality Evaluation of Black Walnut Wood. Part II—Color Analyses of Veneer Produced on Different Sites. Wood Fiber Sci. 1983, 15, 177–185. [Google Scholar]

- Hălălișan, A.-F.; Dinulică, F.; Gurean, D.M.; Codrean, C.; Neykov, N.; Antov, P.; Bardarov, N. Wood Colour Variations of Quercus Species in Romania. Forests 2023, 14, 230. [Google Scholar] [CrossRef]

- Moya, R.; Calvo-Alvarado, J. Variation of Wood Color Parameters of Tectona Grandis and Its Relationship with Physical Environmental Factors. Ann. For. Sci. 2012, 69, 947–959. [Google Scholar] [CrossRef]

- Makoto, K.; Susloparova, E.; Tsuyama, I.; Shimase, T.; Nakaba, S.; Takahashi, N.; Yoshida, T. Influence of Soil Properties on the Heartwood Colour of Juglans mandshurica var. sachalinensis in a Cool Temperate Forest. J. Wood Sci. 2021, 67, 49. [Google Scholar] [CrossRef]

- Illés, G.; Fonyó, T.; Borovics, A. SiteViewer a Decision Support Tool for Forest Management. Hung. Agric. Res. Environ. Manag. Land Use Biodivers. 2024, 34, 11–14. [Google Scholar]

- Deaconu, I.; Campean, M. Survey Concerning the Challenges of Industrial Drying of Quercus Lumber. Ligno 2022, 18, 36–44. [Google Scholar]

- Butterfield, B.G.; Meylan, B.A.; Peszlen, I.M. A Fatest Háromdimenziós Szerkezete: Three-Dimensional Structure of Wood: Hungarian Edition; Faipari Tudományos Alapítvány: Budapest, Hungary, 1997; ISBN 978-963-04-8812-9. [Google Scholar]

- Brainard, D.H. Color Appearance and Color Difference Specification. In The Science of Color; Elsevier Ltd.: Amsterdam, The Netherlands, 2003; pp. 192–213. ISBN 0-444-5/2-519. [Google Scholar]

- Mokrzycki, W.; Tatol, M. Color Difference ΔE: A Survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- Istrefi, E.; Toromani, E.; Çollaku, N. Allometric Relationships for Estimation of Above-Ground Biomass in Young Turkey Oak (Quercus cerris L.) Stands in Albania. Acta Silv. Lignaria Hung. 2018, 14, 65–81. [Google Scholar] [CrossRef]

- Tolvaj, L.; Molnár, S. Colour Homogenisation of Hardwood Species by Steaming. Acta Silv. Lignaria Hung. 2006, 2, 105–112. [Google Scholar] [CrossRef]

- Ferrari, S.; Allegretti, O.; Cuccui, I.; Moretti, N.; Marra, M.; Todaro, L. A Revaluation of Turkey Oak Wood (Quercus cerris L.) through Combined Steaming and Thermo-Vacuum Treatments. BioResources 2013, 8, 5051–5066. [Google Scholar] [CrossRef]

- Tolvaj, L. Applications of Colour Measurement in Wood Research. In Optical Properties of Wood; Smart Sensors, Measurement and Instrumentation; Springer Nature Switzerland: Cham, Switzerland, 2024; Volume 45, pp. 91–156. ISBN 978-3-031-46905-3. [Google Scholar]

- Todaro, L.; Zanuttini, R.; Scopa, A.; Moretti, N. Influence of Combined Hydro-Thermal Treatments on Selected Properties of Turkey Oak (Quercus cerris L.) Wood. Wood Sci. Technol. 2012, 46, 563–578. [Google Scholar] [CrossRef]

- Todaro, L.; Zuccaro, L.; Marra, M.; Basso, B.; Scopa, A. Steaming Effects on Selected Wood Properties of Turkey Oak by Spectral Analysis. Wood Sci. Technol. 2012, 46, 89–100. [Google Scholar] [CrossRef]

- Timar, M.; Varodi, A.; Hacibektasoglu, M.; Campean, M. Color and FTIR Analysis of Chemical Changes in Beech Wood (Fagus sylvatica L.) after Light Steaming and Heat Treatment in Two Different Environments. BioResources 2016, 11, 8325–8343. [Google Scholar] [CrossRef]

- Fodor, F.; Bak, M. Studying the Wettability and Bonding Properties of Acetylated Hornbeam Wood Using PVAc and PUR Adhesives. Materials 2023, 16, 2046. [Google Scholar] [CrossRef]

- Fodor, F.; Hofmann, T. Chemical Composition and FTIR Analysis of Acetylated Turkey Oak and Pannonia Poplar Wood. Forests 2024, 15, 207. [Google Scholar] [CrossRef]

- Deaconu, I.; Porojan, M.; Timar, M.C.; Bedelean, B.; Campean, M. Comparative Research on the Structure, Chemistry, and Physical Properties of Turkey Oak and Sessile Oak Wood. BioResources 2023, 18, 5724–5749. [Google Scholar] [CrossRef]

- Sousa, V.; Cardoso, S.; Pereira, H. Characterization of the Chemical Composition of Quercus faginea Wood. In Proceedings of the 6th National Forestry Congress—The Forest in a Globalized World, Ponta Delgada, Portugal, 6–9 October 2009; Portuguese Society of Forest Sciences: Ponta Delgada, Portugal, 2009; pp. 563–571. [Google Scholar]

- Miranda, I.; Sousa, V.; Ferreira, J.; Pereira, H. Chemical Characterization and Extractives Composition of Heartwood and Sapwood from Quercus faginea. PLoS ONE 2017, 12, e0179268. [Google Scholar] [CrossRef] [PubMed]

- Bajraktari, A.; Nunes, L.; Knapic, S.; Pimenta, R.; Pinto, T.; Duarte, S.; Miranda, I.; Pereira, H. Chemical Characterization, Hardness and Termite Resistance of Quercus cerris Heartwood from Kosovo. Maderas Cienc. Tecnol. 2018, 20, 305–314. [Google Scholar] [CrossRef]

- Hofmann, T.; Visi-Rajczi, E.; Albert, L. Role of Extractable and Non-Extractable Polyphenols in the Formation of Beech (Fagus sylvatica L.) Red Heartwood Chromophores. Forests 2025, 16, 1557. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).