Evaluation of Discolourations of Wooden Shingles as a Function of Outdoor Exposure

Abstract

1. Introduction

- The foundation, nowadays made of reinforced concrete, supports the entire structure.

- The frame, generally made of oak wood, is composed of two or more support columns, topped by wooden beams and buttresses. Doors of different sizes can be arranged between the columns. Hand-carved when the wood is still fresh—and therefore easier to work—oak guarantees a long life and a pleasant aesthetic appearance to the structure. Oak wood shows significant swelling due to changes in environmental humidity, and the presence of numerous parenchymatous rays requires a very slow drying session. In case of forced drying, honeycomb-shaped cracks may form on the surface [13], compromising the beauty of the decoration and the performance of the material.

- The protective roof is made up of wooden trusses and covered with spruce or fir wooden shingles. The main function of the roof is the partial protection of the underlying structures, slowing down the degradation process due to rain, snow, hail, wind and solar radiation. In the design of wooden sheds, the material used as well as the shape and profile of the elements assume particular importance to prevent the infiltration and stagnation of water [14]. Shingles, used for centuries as a roofing material, give originality and a pleasant aesthetic appearance to the structures [15]. Made with natural and biodegradable materials such as wood, in Romania, they are still the result of the skill of local carpenters and artisans. Manually, by sawing or splitting the trunk in a radial direction, the shingles are interchangeable elements that can assume different shapes and sizes depending on the construction needs [15]. For the construction of a roof, the shingles overlap in a minimum of two and a maximum of four layers, depending on the inclination and slope of the roof pitches [14].

2. Materials and Methods

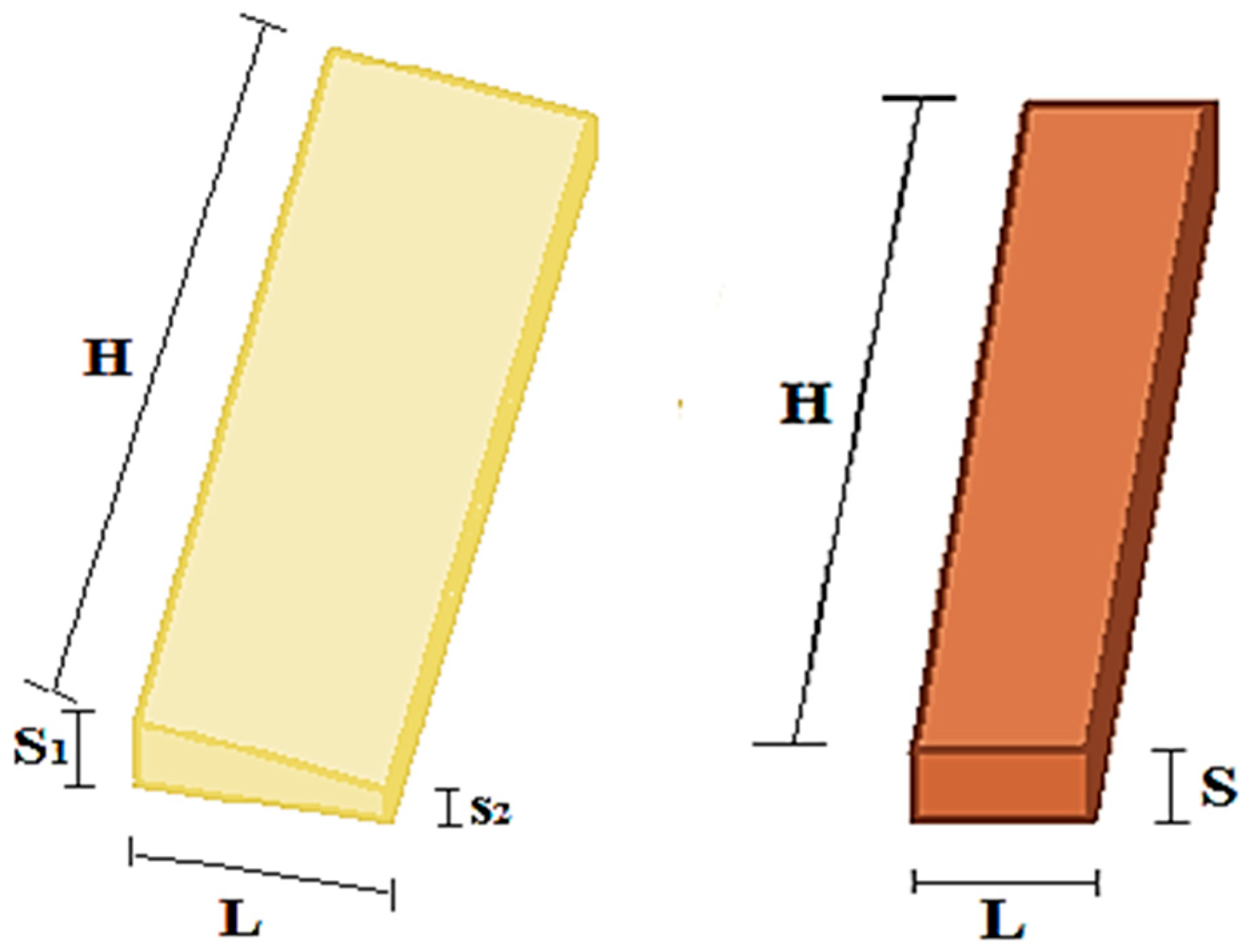

2.1. Materials

2.2. Outdoor Exposure of the Samples

2.3. Colour Measurement of the Samples

2.4. Determination of the Moisture Content of the Samples

3. Results

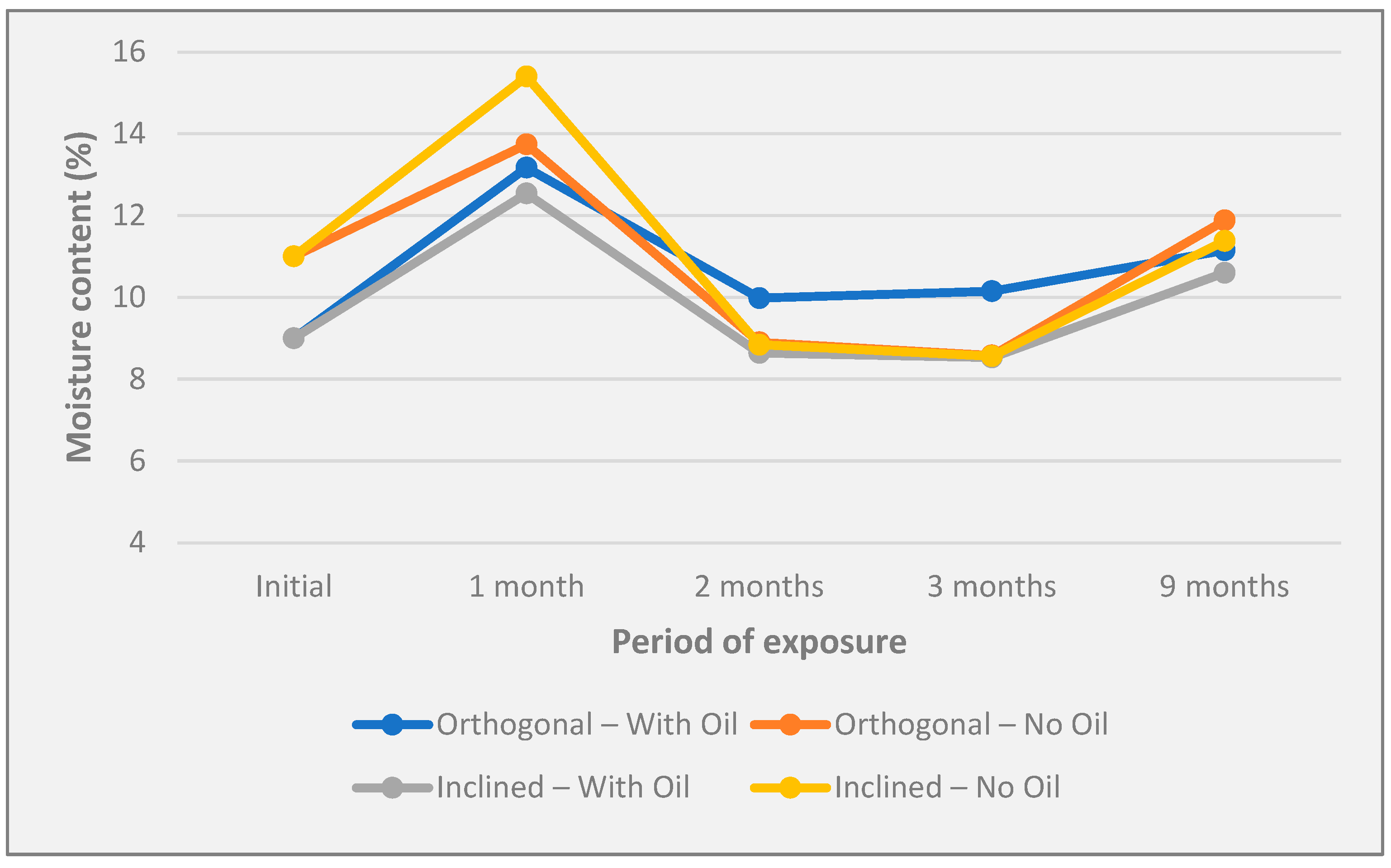

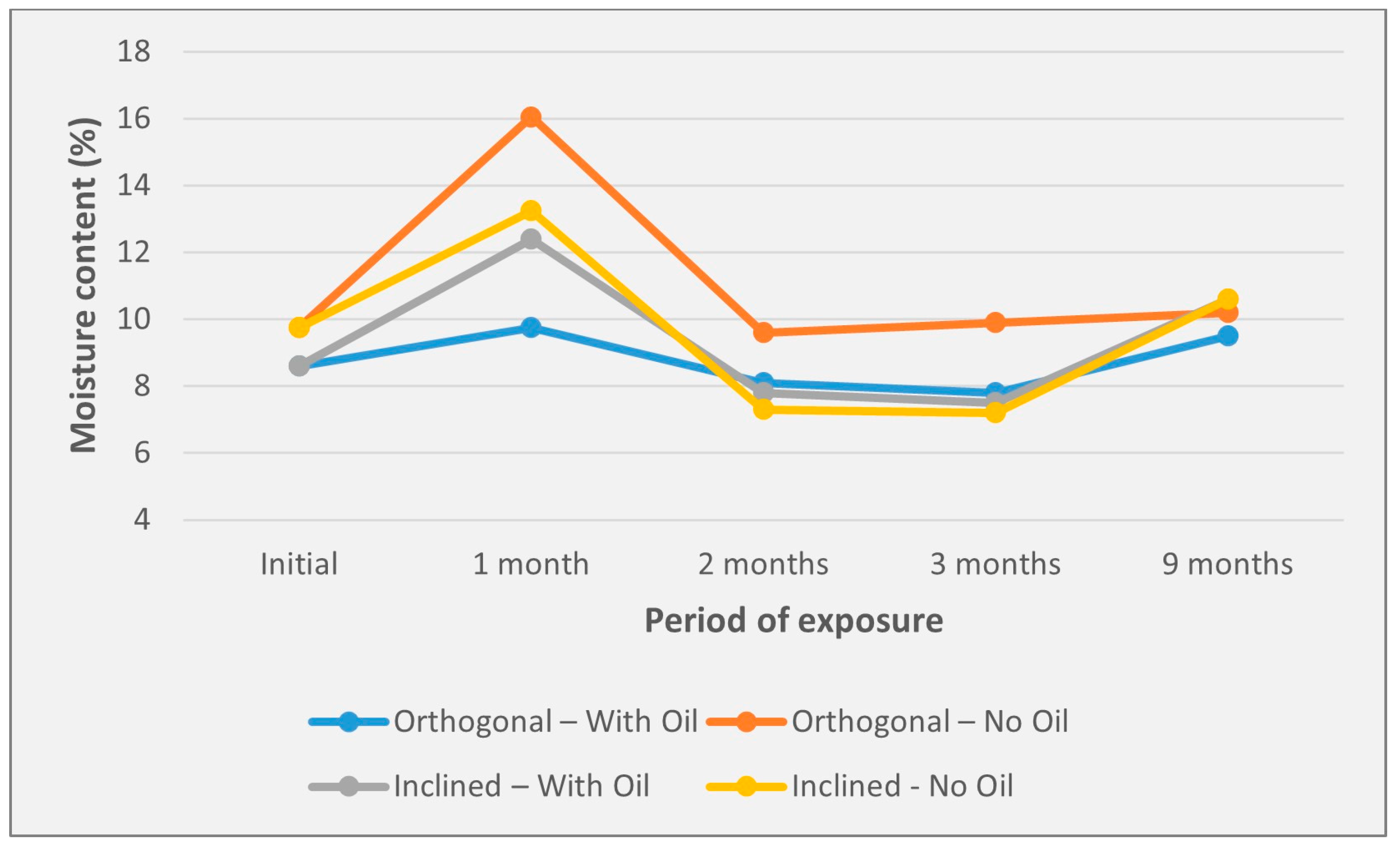

3.1. Evaluation of the Moisture Content of the Samples

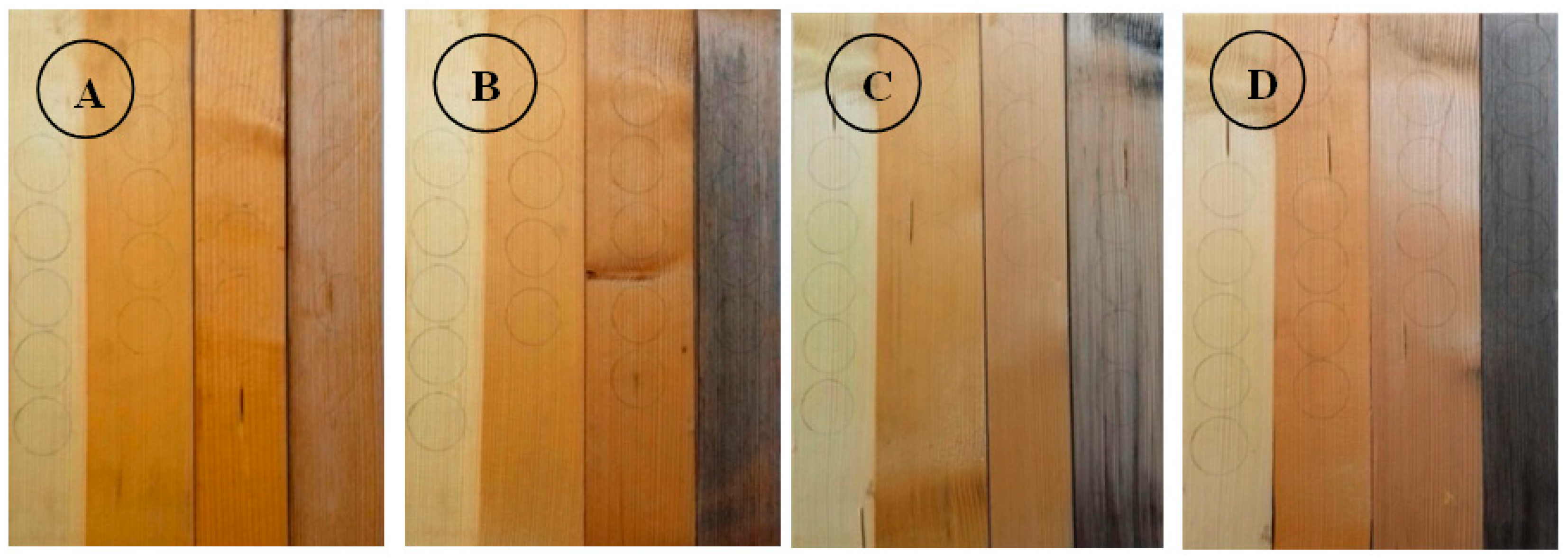

3.2. Visual Analysis of the Wood Surfaces of the Samples

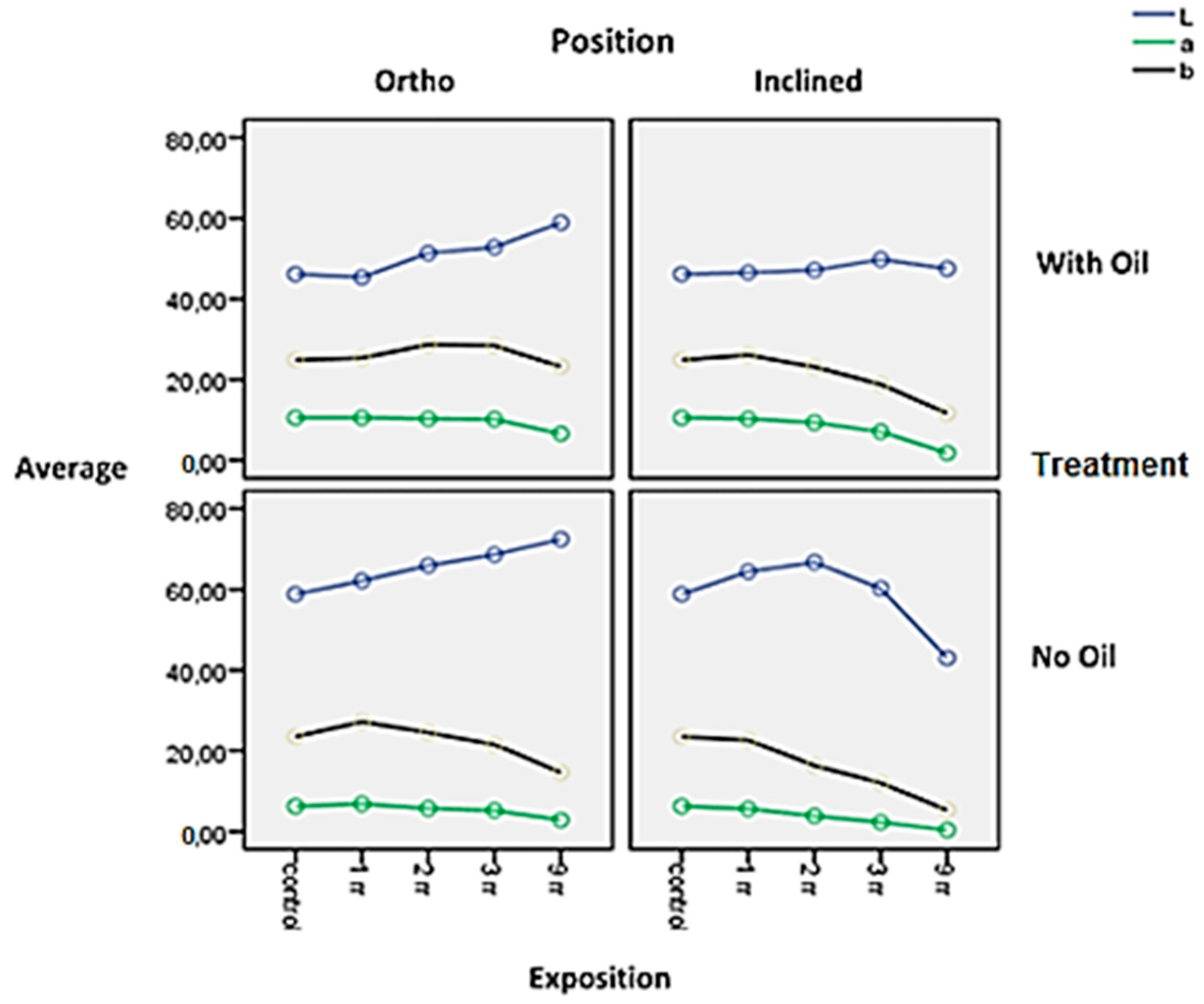

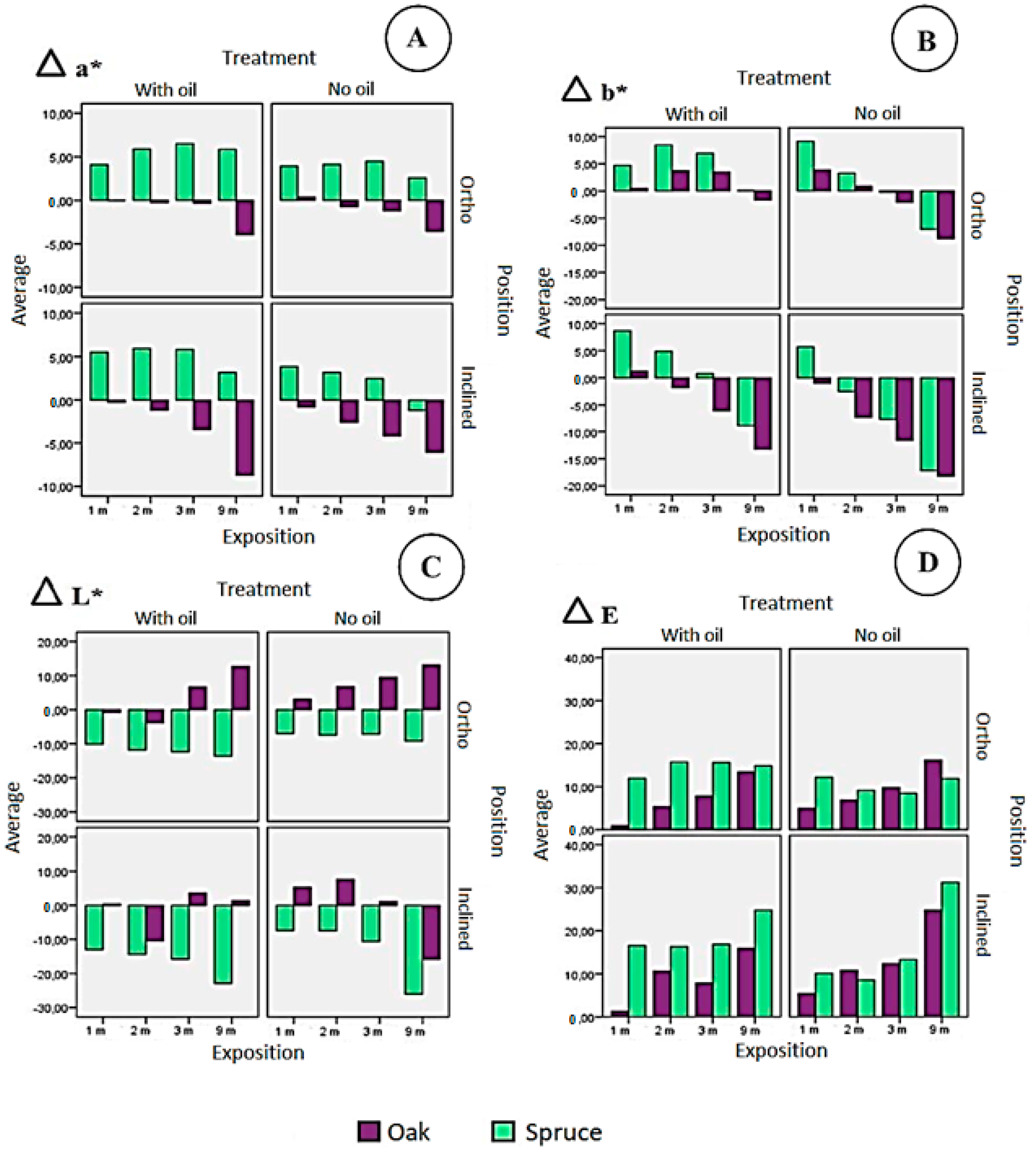

3.3. Evaluation of Colour Changes in the Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kranitz, K.; Sonderegger, W.; Bues, C.T.; Niemz, P. Effects of aging on wood: A literature review. Wood Sci. Technol. 2015, 50, 7–22. [Google Scholar] [CrossRef]

- Tolvaj, L. Monitoring of Wood Photodegradation by Colour Measurement. In Optical Properties of Wood. Smart Sensors, Measurement and Instrumentation; Springer: Cham, Switzerland, 2024; Volume 45. [Google Scholar] [CrossRef]

- Kropat, M.; Hubbe, M.A.; Laleicke, F. Natural, accelerated, and simulated weathering of wood: A review. BioResources 2020, 15, 9998–10062. [Google Scholar] [CrossRef]

- Topaloglu, E. Effects of natural aging on selected properties of wooden facade elements made of Scots pine and chestnut. Maderas. Cinecia Tecnol. 2023, 25, e1823. [Google Scholar] [CrossRef]

- Feist, W.C. Outdoor Wood Weathering and Protection. In Archaeological Wood: Properties, Chemistry, and Preservation; Advances in Chemistry Series, 225; Rowell, R.M.B., James, R., Eds.; American Chemical Society: Washington, DC, USA, 1990. [Google Scholar] [CrossRef]

- Rüther, P.; Jelle, B.P. Colour changes of wood and wood-based materials due to natural and artificial weathering. Wood Mater. Sci. Eng. 2013, 8, 13–25. [Google Scholar] [CrossRef]

- Williams, R.S. Weathering of Wood. In Handbook of Wood Chemistry and Wood Composites; Rowell, R.M., Ed.; Taylor and Francis CRC Press: Boca Raton, FL, USA, 2005. Available online: https://www.fpl.fs.usda.gov/documnts/pdf2005/fpl_2005_williams001.pdf (accessed on 1 February 2025).

- Müller, M.; Rätsch, M.; Schwanninger, M.; Steiner, M.; Zöbl, H. Yellowing and IR-changes of spruce wood as result of UV-irradiation. J. Photochem. Photobiol. B Biol. 2003, 69, 97–105. [Google Scholar] [CrossRef]

- Reinprecht, L. Wood Deterioration, Protection and Maintenance; John Wiley & Sons: Hoboken, NJ, USA, 2016; Available online: https://onlinelibrary.wiley.com/doi/book/10.1002/9781119106500 (accessed on 1 February 2025).

- Ozgenc, O.; Okan, O.T.; Yildiz, U.C.; Deniz, I. Wood surface protection against artificial weathering with vegetable seed oils. Bioresurces 2013, 8, 6242–6262. [Google Scholar] [CrossRef]

- Williams, R.S.; Knaebe, M.T.; Evans, J.W.; Feist, W.C. Erosion rates of wood during natural weathering: Part III. Effect of exposure angle on erosion rate. Wood Fiber Sci. 2001, 33, 50–57. [Google Scholar]

- Schnabel, T.; Zimmer, B.; Petutschnigg, A.J. On the modelling of colour changes of wood surfaces. Eur. J. Wood Prod. 2009, 67, 141–149. [Google Scholar] [CrossRef]

- Martinelli, C. Traditional Gates in Maramures. Study on the Weathering of Picea abies (L.) and Quercus petraea Liebl Wooden Surfaces. Master’s Dissertation, University of Basilicata, Potenza, Italy, 2018. (In Italian). [Google Scholar]

- Dwyer, J.; Bonura, T.; Nebelsick, A.; Williams, S.; Hunt, C.G. Installation, Care, and Maintenance of Wood Shake and Shingle Siding; General technical report FPL-GTR-202; U.S. Dept. of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2011; 13p.

- Vidholdova, Z. Colour changes of wooden shingles treated with pine tar after weathering. In Proceedings of the Book of Abstracts of COST FP1303 Meeting: Design—Application and Aesthetics of Biobased Building Materials, Sofia, Bulgaria, 28 February–1 March 2017. [Google Scholar]

- Timar, M.C.; Varodi, A.M.; Liu, X.Y. The Influence of Artificial Ageing on Selected Properties of Wood Surfaces Finished With Traditional Materials—An Assessment for Conservation Purposes. Bull. Transilv. Univ. Bras. Ser. II For. Wood Ind. Agric. Food Eng. 2020, 13, 82–94. [Google Scholar] [CrossRef]

- ISO 7724-2:1984; Paints and Varnishes—Colourimetry—Part 2: Colour Measurement. International Organization for Standardization (ISO): Geneva, Switzerland, 1984.

- IBM. SPSS Statistics, Version 23; IBM: Armonk, NY, USA, 2021. Available online: https://www.ibm.com/support/pages/downloading-ibm-spss-statistics-23 (accessed on 1 February 2025).

- Giordano, G. Tecnologia del Legno; (Technology of wood, vol.1); Unione Tipografico-Editrice Torinese: Turin, Italy, 1971; Volume 1. [Google Scholar]

- Slabejova, G.; Vidholdova, Z.; Kaloc, J. The Colour Changes of Pinewood After Weathering; Annals of Warsaw University of Life Sciences—SGGW, Forestry and Wood Technology; Warsaw University of Life Sciences: Warsaw, Poland, 2016; No. 96:125:129. [Google Scholar]

- Aydın, M.A.; Can, A.; Tomak, E.D.; Ermeydan, M.A. Weathering of wood under indoor and outdoor environmental conditions. Color. Technol. 2025. [Google Scholar] [CrossRef]

- Zahri, S.; Belloncle, C.; Charrier, F.; Pardon, P.; Quideau, S.; Charrier, B. UV light impact on ellagitannins and wood surface colour of European oak (Quercus petraea and Quercus robur). Appl. Surf. Sci. 2007, 253, 4985–4989. [Google Scholar] [CrossRef]

- Cirule, D.; Andersone, I.; Kuka, E.; Andersons, B. Recent Research on Linseed Oil Use in Wood Protection—A Review. Sci 2024, 6, 54. [Google Scholar] [CrossRef]

| Species | Dimensions, mm | Position | Total Number of Samples | Control Samples | Number of Samples per Treatment | Treatment | Exposure |

|---|---|---|---|---|---|---|---|

| Spruce | S1 = 18 | Orthogonal (90°) | 30 | 1 + 1 | 7 | With Oil | Control 1 month 2 months 3 months 9 months |

| S2 = 5 | 7 | No Oil | |||||

| H = 550 | Inclined (60°) | 7 | With Oil | ||||

| L = 70 | 7 | No Oil | |||||

| Oak | S = 25 | Orthogonal (90°) | 10 | 1 + 1 | 2 | With Oil | |

| H = 210 | 2 | No Oil | |||||

| L = 35 | Inclined (60°) | 2 | With Oil | ||||

| 2 | No Oil |

| Moisture content (%) of spruce samples | |||||

| Initial | 1 month | 2 months | 3 months | 9 months | |

| Orthogonal—With Oil | 9.00 | 13.17 | 9.98 | 10.15 | 11.15 |

| Orthogonal—No Oil | 11.00 | 13.74 | 8.90 | 8.58 | 11.88 |

| Inclined—With Oil | 9.00 | 12.54 | 8.64 | 8.53 | 10.60 |

| Inclined—No Oil | 11.00 | 15.40 | 8.84 | 8.56 | 11.38 |

| Moisture content (%) of oak samples | |||||

| Initial | 1 month | 2 months | 3 months | 9 months | |

| Orthogonal—With Oil | 8.6 | 9.75 | 8.10 | 7.80 | 9.50 |

| Orthogonal—No Oil | 9.75 | 16.05 | 9.60 | 9.90 | 10.20 |

| Inclined—With Oil | 8.6 | 12.40 | 7.8 | 7.50 | 10.60 |

| Inclined—No Oil | 9.75 | 13.25 | 7.30 | 7.20 | 10.60 |

| Exposure | Position | L* | a* | b* | L* | a* | b* |

|---|---|---|---|---|---|---|---|

| Spruce—with oil | Oak—with oil | ||||||

| Control | -- | 83.03 (0.63) * | 1.52 (0.19) | 25.63 (1.36) | 46.17 (0.94) | 10.55 (0.30) | 24.92 (0.89) |

| 1 month | Orthogonal | 72.88 (1.34) | 6.70 (0.27) | 36.32 (0.8) | 45.37 (2.69) | 10.55 (0.49) | 25.39 (1.91) |

| Inclined | 70.01 (1.41) | 7.02 (0.18) | 34.31 (1.11) | 46.52 (1.76) | 10.28 (0.57) | 26.14 (1.53) | |

| 2 months | Orthogonal | 71.18 (1.34) | 7.42 (0.26) | 34.12 (1.34) | 51.37 (0.48) | 10.29 (0.25) | 28.66 (0.65) |

| Inclined | 68.59 (1.71) | 7.44 (0.34) | 30.54 (1.82) | 35.74 (1.88) | 9.38 (0.37) | 23.12 (1.21) | |

| 3 months | Orthogonal | 70.68 (1.19) | 8.03 (0.26) | 32.59 (1.35) | 52.86 (0.6) | 10.21 (0.37) | 28.42 (0.74) |

| Inclined | 67.21 (2.03) | 7.32 (0.57) | 26.41 (2.75) | 49.79 (1.32) | 7.11 (0.29) | 18.84 (0.91) | |

| 9 months | Orthogonal | 70.21 (1.78) | 7.36 (0.49) | 24.47 (2.33) | 58.91 (0.65) | 6.61 (0.21) | 23.28 (0.91) |

| Inclined | 60.12 (6.27) | 4.69 (2.36) | 16.68 (6.26) | 47.54 (0.76) | 1.82 (0.35) | 11.67 (0.88) | |

| Spruce—no oil | Oak—no oil | ||||||

| Control | -- | 83.21 (2.69) | 2.29 (1.35) | 22.25 (1.64) | 59.82 (4.73) | 6.26 (0.33) | 23.50 (0.74) |

| 1 month | Orthogonal | 76.87 (1.34) | 6.23 (0.31) | 31.43 (0.69) | 62.20 (0.86) | 6.84 (0.37) | 27.48 (2.19) |

| Inclined | 75.82 (1.20) | 6.13 (0.23) | 28.00 (0.99) | 64.40 (1.81) | 5.63 (0.44) | 22.61 (0.66) | |

| 2 months | Orthogonal | 75.77 | 6.43 (0.24) | 25.52 (0.97) | 66.26 (0.93) | 4.88 (1.04) | 20.87 (4.45) |

| Inclined | 75.68 (1.01) | 5.46 (0.33) | 19.75 (1.14) | 66.71 (0.95) | 3.86 (1.25) | 16.33 (1.15) | |

| 3 months | Orthogonal | 76.06 (1.29) | 6.79 (0.23) | 22.03 (0.99) | 68.61 (1.16) | 5.23 (0.42) | 21.55 (1.44) |

| Inclined | 72.59 (2.77) | 4.78 (0.69) | 14.61 (1.56) | 60.22 (1.58) | 2.26 (0.24) | 12.00 (0.87) | |

| 9 months | Orthogonal | 74.00 (3.82) | 4.88 (0.91) | 15.21 (2.16) | 72.24 (1.53) | 2.90 (0.38) | 14.82 (1.11) |

| Inclined | 57.12 (3.01) | 1.11 (0.19) | 5.07 (0.68) | 43.01 (1.10) | 0.37 (0.03) | 5.29 (0.38) | |

| Source | Var. | Type III Sum of Squares | df | Mean Square | F | Sig. | Partial Eta Squared |

|---|---|---|---|---|---|---|---|

| Time | L | 9596.117 | 4 | 2399.029 | 179.766 | 0.000 | 0.619 |

| a | 1006.350 | 4 | 251.588 | 209.887 | 0.000 | 0.655 | |

| b | 17,034.416 | 4 | 4258.604 | 561.584 | 0.000 | 0.836 | |

| Treatment | L | 1561.471 | 1 | 1561.471 | 117.005 | 0.000 | 0.209 |

| a | 235.788 | 1 | 235.788 | 196.707 | 0.000 | 0.308 | |

| b | 7842.242 | 1 | 7842.242 | 1034.160 | 0.000 | 0.701 | |

| Inclination | L | 2015.189 | 1 | 2015.189 | 151.004 | 0.000 | 0.255 |

| a | 118.622 | 1 | 118.622 | 98.961 | 0.000 | 0.183 | |

| b | 2848.943 | 1 | 2848.943 | 375.691 | 0.000 | 0.459 |

| Source | Variable | Type III Sum of Squares | df | Mean Square | F | Sig. | Partial Eta Squared |

|---|---|---|---|---|---|---|---|

| Time | L | 1,153,730.996 | 4 | 288,432.749 | 1.444 | 0.226 | 0.058 |

| a | 340.201 | 4 | 85.050 | 92.831 | 0.000 | 0.800 | |

| b | 1518.805 | 4 | 379.701 | 37.266 | 0.000 | 0.616 | |

| Treatment | L | 102,083.397 | 1 | 102,083.397 | 0.511 | 0.476 | 0.005 |

| a | 465.415 | 1 | 465.415 | 507.994 | 0.000 | 0.845 | |

| b | 456.226 | 1 | 456.226 | 44.776 | 0.000 | 0.325 | |

| Inclination | L | 500,575.033 | 1 | 500,575.033 | 2.506 | 0.117 | 0.026 |

| a | 65.232 | 1 | 65.232 | 71.200 | 0.000 | 0.434 | |

| b | 661.556 | 1 | 661.556 | 64.928 | 0.000 | 0.411 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martinelli, C.; Salca, E.-A.M.; Dinulica, F. Evaluation of Discolourations of Wooden Shingles as a Function of Outdoor Exposure. Forests 2025, 16, 1638. https://doi.org/10.3390/f16111638

Martinelli C, Salca E-AM, Dinulica F. Evaluation of Discolourations of Wooden Shingles as a Function of Outdoor Exposure. Forests. 2025; 16(11):1638. https://doi.org/10.3390/f16111638

Chicago/Turabian StyleMartinelli, Cinzia, Emilia-Adela Manea Salca, and Florin Dinulica. 2025. "Evaluation of Discolourations of Wooden Shingles as a Function of Outdoor Exposure" Forests 16, no. 11: 1638. https://doi.org/10.3390/f16111638

APA StyleMartinelli, C., Salca, E.-A. M., & Dinulica, F. (2025). Evaluation of Discolourations of Wooden Shingles as a Function of Outdoor Exposure. Forests, 16(11), 1638. https://doi.org/10.3390/f16111638