Analysis and Use of Wood Waste in Lithuania for the Development of Engineered Wood Composite

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of EWC

2.3. Test Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| EWC | Engineered wood composite |

| PLY | Construction demolition and furniture waste |

| DW | Door production waste |

| W | Packaging waste |

| H2O2 | Hydrogen peroxide |

| Na2CO3 | Sodium carbonate |

| Ca (OCl)2 | Calcium hypochlorite |

References

- Guo, J.; Zhang, Y.; Fang, J.; Ma, Z.; Li, C.; Yan, M.; Qiao, N.; Liu, Y.; Bian, M. Reduction and Reuse of Forestry and Agricultural Bio-Waste Through Innovative Green Utilization Approaches: A Review. Forests 2024, 15, 1372. [Google Scholar] [CrossRef]

- CONAMA. Ministry of Environment. National Council of the Environment, Resolution. 2016, No. 474. p. 74. Available online: https://www.in.gov.br/materia/-/asset_publisher/Kujrw0TZC2Mb/content/id/22787983/do1-2016-05-02-resolucao-n-474-de-6-de-abril-de-2016--22787761 (accessed on 22 February 2025).

- Association of Private Forest Owners. Classification of the Wood Stem According to the Parts of the Tree. 2024. Available online: https://www.pmsa.lt/ (accessed on 22 February 2025).

- Official Statistics Portal. Waste Generation in Lithuania, 2019–2021. Environment, Agriculture and Energy in Lithuania (Edition 2023). 2023. Available online: https://osp.stat.gov.lt/lietuvos-aplinka-zemes-ukis-ir-energetika-2023/aplinka/atliekos (accessed on 16 February 2025).

- Bergeron, F.C. Assessment of the Coherence of the Swiss Waste Wood Management. Resour. Conserv. Recycl. 2014, 91, 62–70. [Google Scholar] [CrossRef]

- Edo, M.; Björn, E.; Persson, P.E.; Jansson, S. Assessment of Chemical and Material Contamination in Waste Wood Fuels—A Case Study Ranging over Nine Years. Waste Manag. 2016, 49, 311–319. [Google Scholar] [CrossRef]

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading Recycling of Wood Waste: A Review. Polymers 2021, 13, 1752. [Google Scholar] [CrossRef] [PubMed]

- Jan, V.M. Überblick Über Den Europäischen Markt, SUEZ Trading. BAV-Altholztag, München, Deutschland; European Market Overview, SUEZ Trading; German Waste Wood Association—Waste Wood Day: Munich, Germany, 2019. [Google Scholar]

- Rautkoski, H.; Vähä-Nissi, M.; Kataja, K.; Gestranius, M.; Liukkonen, S.; Määttänen, M.; Liukkonen, J.; Kouko, J.; Asikainen, S. Recycling of Contaminated Construction and Demolition Wood Waste. Waste Biomass Valorization 2016, 7, 615–624. [Google Scholar] [CrossRef]

- Mulder, E.; de Jong, T.P.R.; Feenstra, L. Closed Cycle Construction: An Integrated Process for the Separation and Reuse of C&D Waste. Waste Manag. 2007, 27, 1408–1415. [Google Scholar] [CrossRef]

- Woolf, D.; Lehmann, J.; Fisher, E.M.; Angenent, L.T. Biofuels from Pyrolysis in Perspective: Trade-Offs between Energy Yields and Soil-Carbon Additions. Environ. Sci. Technol. 2014, 48, 6492–6499. [Google Scholar] [CrossRef]

- European Commission. Construction and Demolition Waste. EU Rules Aim to Ensure That This Waste Is Managed in an Environmentally Sound Way, and to Contribute to the Circular Economy. December 2008. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/construction-and-demolition-waste_en?prefLang=lt (accessed on 22 February 2025).

- Purkus, A.; Lüdtke, J.; Becher, G.; Dieter, M.; Jochem, D.; Lehnen, R.; Liesebach, M.; Polley, H.; Rüter, S.; Schweinle, J.; et al. Evaluation of the Charter for Wood 2.0: Methodological Principles and Evaluation Concept; Thünen Report 68; Johann Heinrich von Thünen-Institut: Braunschweig, Germany, 2019. [Google Scholar]

- Ikenze, N.; Rizos, V.; Nipius, L. Improving Waste Wood Circularity in the EU: Classification Frameworks and Policy Options; Technical Report; CEPS: Brussels, Belgium, 2024. [Google Scholar]

- Waste Incineration in the Nordic Countries. 2024. Available online: https://pub.norden.org/temanord2024-524/temanord2024-524.pdf (accessed on 16 February 2025).

- German Waste Wood Association. Waste Wood Markets in Europa, Category Europe. Bundesverband der Altholzaufbereiter und -Verwerter (BAV e.V.). 2021. Available online: https://altholzverband.de/2021/09/27/waste-wood-markets-in-europe/ (accessed on 22 February 2025).

- Faraca, G.; Boldrin, A.; Astrup, T. Resource Quality of Wood Waste: The Importance of Physical and Chemical Impurities in Wood Waste for Recycling. Waste Manag. 2019, 87, 135–147. [Google Scholar] [CrossRef]

- Nagalli, A.; Lopes, F.P.; Pereira, P.M.; Hamaya, R.M.; Luis, R.; Izzo, S. Analysis of Wood Waste Contamination Used in Construction Sites. EJGE 2013, 18, 3999. [Google Scholar]

- Lesar, B.; Humar, M.; Hora, G. Quality Assessment of Recycled Wood with and without Non-Wooden Materials from Selected Recycling Companies in Europe. Waste Manag. 2018, 79, 362–373. [Google Scholar] [CrossRef]

- Robey, N.M.; Solo-Gabriele, H.M.; Jones, A.S.; Marini, J.; Townsend, T.G. Metals Content of Recycled Construction and Demolition Wood before and after Implementation of Best Management Practices. Environ. Pollut. 2018, 242, 1198–1205. [Google Scholar] [CrossRef]

- Azambuja Rda, R.; de Castro, V.G.; Trianoski, R.; Iwakiri, S. Recycling Wood Waste from Construction and Demolition to Produce Particleboards. Maderas. Cienc. Tecnol. 2018, 20, 681–690. [Google Scholar] [CrossRef]

- Hameed, M.; Rönnols, E.; Bramryd, T. Particleboard Based on Wood Waste Material and Bonded by Hibrid Resin of TF and PMDI. Part 1. The Mechanical and Physical Properties of the Particle Boards. Holztechnologie 2018, 59, 24–32. [Google Scholar]

- Laskowska, A.; Mamiński, M. Properties of Particleboard Produced from Post-Industrial UF- and PF-Bonded Plywood. Eur. J. Wood Wood Prod. 2018, 76, 427–435. [Google Scholar] [CrossRef]

- Mirski, R.; Dziurka, D. The Utilization of Chips from Comminuted Wood Waste as a Substitute for Flakes in the Oriented Strand Board Core. For. Prod. J. 2011, 61, 473–477. [Google Scholar] [CrossRef]

- Roffael, E.; Behn, C.; Schneider, T.; Krug, D. Bonding of Recycled Fibres with Urea-Formaldehyde Resins. Int. Wood Prod. J. 2016, 7, 36–45. [Google Scholar]

- Schild, A.; Cool, J.; Barbu, M.C.; Smith, G.D. Feasibility of Substituting Core Layer Strands in Randomly OSB with Contaminated Waste Wood Particles. Wood Mater. Sci. Eng. 2019, 16, 170–177. [Google Scholar]

- Yang, T.H.; Lin, C.J.; Wang, S.Y.; Tsai, M.J. Characteristics of Particleboard Made from Recycled Wood-Waste Chips Impregnated with Phenol Formaldehyde Resin. Build. Environ. 2007, 42, 189–195. [Google Scholar] [CrossRef]

- Nguyen, D.L.; Luedtke, J.; Nopens, M.; Krause, A. Production of Wood-Based Panel from Recycled Wood Resource: A Literature Review. Eur. J. Wood Wood Prod. 2023, 81, 557–570. [Google Scholar] [CrossRef]

- Alsaffar, A.K.K.; Alquzweeni, S.S.; Al-Ameer, L.R.; Ali, A.H.; Mohamed, A.; Aldaihani, H.M.; Reham, A.; Al-Ansari, N.; Al-Hashimi, O.; Shubbar, A.; et al. Development of Eco-Friendly Wall Insulation Layer Utilising the Wastes of the Packing Industry. Heliyon 2023, 9, e21799. [Google Scholar] [CrossRef]

- Tanthanawiwat, K.; Gheewala, S.H.; Nilsalab, P.; Schoch, M.; Silalertruksa, T. Environmental Sustainability and Cost Performances of Construction and Demolition Waste Management Scenarios: A Case Study of Timber and Concrete Houses in Thailand. J. Clean. Prod. 2024, 436, 140652. [Google Scholar] [CrossRef]

- Gibier, M.; Sadeghisadeghabad, M.; Girods, P.; Zoulalian, A.; Rogaume, Y. Furniture Wood Waste Depollution through Hydrolysis under Pressurized Water Steam: Experimental Work and Kinetic Modelization. J. Hazard. Mater. 2022, 436, 129126. [Google Scholar] [CrossRef]

- Asa, P.; El Feghali, C.; Steixner, C.; Tahouni, Y.; Wagner, H.J.; Knippers, J.; Menges, A. Embraced Wood: Circular Construction Method for Composite Long-Span Beams from Unprocessed Reclaimed Timber, Fibers and Clay. Constr. Build. Mater. 2024, 416, 135096. [Google Scholar] [CrossRef]

- Pazzaglia, A.; Castellani, B. A Decision Tool for the Valorization of Wood Waste. Environ. Clim. Technol. 2023, 27, 824–835. [Google Scholar] [CrossRef]

- Astari, L.; Prasetiyo, K.W.; Suryanegara, L. Properties of Particleboard Made from Wood Waste with Various Size. In Proceedings of the Humanosphere Science School 2017 & the 7th International Symposium for a Sustainable Humanosphere, Bogor, Indonesia, 1–2 November 2017; Volume 166. [Google Scholar] [CrossRef]

- Bekhta, P.; Kozak, R.; Gryc, V.; Sebera, V.; Tippner, J. Effects of Wood Particles from Deadwood on the Properties and Formaldehyde Emission of Particleboards. Polymers 2022, 14, 3535. [Google Scholar] [CrossRef]

- Stoeckel, F.; Konnerth, J.; Gindl-Altmutter, W. Mechanical Properties of Adhesives for Bonding Wood-A Review. Int. J. Adhes. Adhes. 2013, 45, 32–41. [Google Scholar] [CrossRef]

- Chen, H.; Wu, Q.; Ren, X.; Zhu, X.; Fan, D. A Fully Bio-Based Adhesive with High Bonding Strength, Low Environmental Impact, and Competitive Economic Performance. Chemical Eng. J. 2024, 494, 153198. [Google Scholar] [CrossRef]

- Solt, P.; Konnerth, J.; Gindl-Altmutter, W.; Kantner, W.; Moser, J.; Mitter, R.; van Herwijnen, H.W.G. Technological Performance of Formaldehyde-Free Adhesive Alternatives for Particleboard Industry. Int. J. Adhes. Adhes. 2019, 94, 99–131. [Google Scholar] [CrossRef]

- Thoemen, H. Wood-Based Panels—An Introduction for Specialists; Brunel University Press: Brunel, UK, 2010. [Google Scholar]

- Olszewski, A.; Kosmela, P.; Piszczyk, Ł. A Novel Approach in Wood Waste Utilization for Manufacturing of Catalyst-Free Polyurethane-Wood Composites (PU-WC). Sustain. Mater. Technol. 2023, 36, e00619. [Google Scholar] [CrossRef]

- ISO Standard No. 29469; Thermal Insulating Products for Building Applications—Determination of Compression Behaviour. European Committee for Standartization: Brussels, Belgium, 2022.

- EN 310:1993; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength (EN Standard No. EN 310). European Standard: Brussels, Belgium, 1993.

- TIMCO Software Inc. Data Science Textbook. 2020. Available online: https://docs.tibco.com/data-science/GUID-FE8CE528-28B3-4898-993D-097A87EF8407-homepage.html (accessed on 22 February 2025).

- Ferreira, T.; Rasband, W. ImageJ User Guide. 2012. Available online: https://imagej.net/ij/docs/guide/user-guide.pdf (accessed on 22 February 2025).

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Roy, R.; Rahman, M.S.; Raynie, D.E. Recent Advances of Greener Pretreatment Technologies of Lignocellulose. Curr. Res. Green Sustain. Chem. 2020, 3, 100035. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S. Comparative LCA of Wood Waste Management Strategies Generated from Building Construction Activities. J. Clean. Prod. 2018, 177, 387–397. [Google Scholar] [CrossRef]

- Pędzik, M.; Kwidziński, Z.; Janiszewska-Latterini, D.; Rogoziński, T. Particleboard from the Residues of Wooden Door Production as a Closed Material Cycle. Ind. Crop. Prod. 2024, 222, 119653. [Google Scholar] [CrossRef]

- Bazzetto, J.T.D.L.; Bortoletto Junior, G.; Brito, F.M.S. Effect of Particle Size on Bamboo Particle Board Properties. Floresta Ambiente 2019, 26, e20170125. [Google Scholar] [CrossRef]

- Liu, D.; Qasem, B.; Hou, J.; Wang, Z.; Cen, J.; Arkin, S.; Zhang, X.; Zhang, Y.; Yu, Y. Recycling Construction Wastes to Fabricate Particle Boards with Admirable Flame Retardancy, Smoke Suppression and Mechanical Performance. Constr. Build. Mater. 2023, 404, 133265. [Google Scholar] [CrossRef]

- Lu, H.; Ip, E.; Scott, J.; Foster, P.; Vickers, M.; Baxter, L.L. Effects of Particle Shape and Size on Devolatilization of Biomass Particle. Fuel 2010, 89, 1156–1168. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pedzik, M.; Rogozinski, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from Agricultural Biomass and Recycled Wood Waste: A Review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Esteves, B.; Aires, P.; Sen, U.; Gomes, M.D.G.; Guiné, R.P.F.; Domingos, I.; Ferreira, J.; Viana, H.; Cruz-Lopes, L.P. Particleboard Production from Paulownia Tomentosa (Thunb.) Steud. Grown in Portugal. Polymers 2023, 15, 1158. [Google Scholar] [CrossRef]

- Krumins, J.A.; Vamza, I.; Dzalbs, A.; Blumberga, D. Particle Boards from Forest Residues and Bio-Based Adhesive. Buildings 2024, 14, 462. [Google Scholar] [CrossRef]

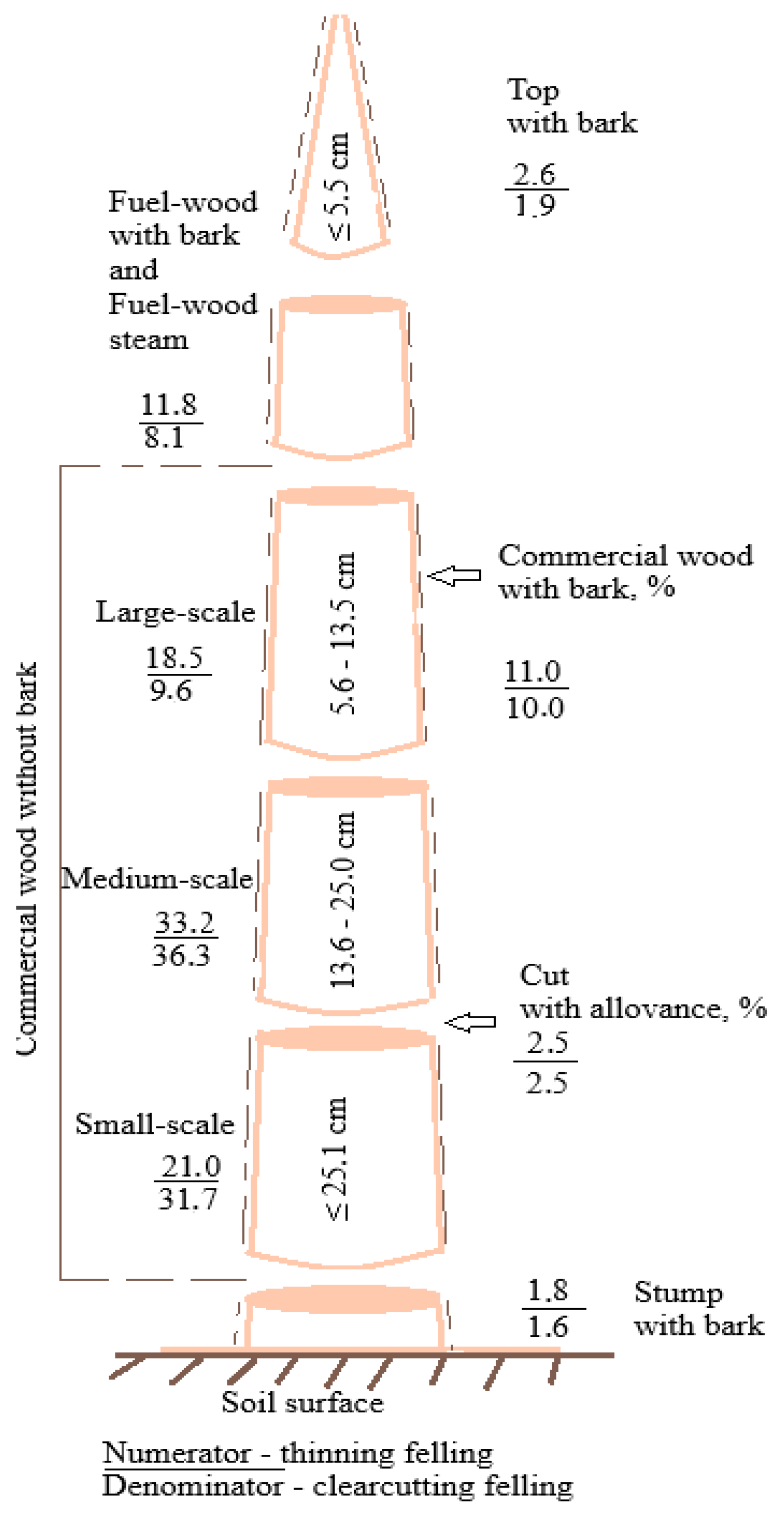

| Felling | Trees | Commercial Wood | Fuel-Wood | Residues | Stems | Dead Trees | Branches | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Large-Scale | Medium-Scale | Small-Scale | Total | |||||||

| % of the Volume of Green Tree Stems | m/ha | |||||||||

| Clearcutting | Green | 31.7 | 36.3 | 9.6 | 77.6 | 8.1 | 14.3 | 230.2 | 36.5 | |

| Dry | on an area of 20 987 ha | 8.7 | ||||||||

| Thinning | Green | 21.0 | 33.2 | 18.5 | 72.7 | 11.8 | 15.5 | |||

| Dry | on an area of 120 315 ha. | 6.0 | ||||||||

| No. | Sample Code | Wood Waste Source | Wood Particle Size, mm | Chemical Treatment Solution, 10% |

|---|---|---|---|---|

| 1 | PLY 0/5_H2O2 | PLY | ≤5 | hydrogen peroxide |

| 2 | PLY 0/5_Na2CO3 | sodium carbonate | ||

| 3 | PLY 0/5_Ca(OCl)2 | calcium hypochlorite | ||

| 4 | PLY 0/10_H2O2 | ≤10 | hydrogen peroxide | |

| 5 | PLY 0/10_Na2CO3 | sodium carbonate | ||

| 6 | PLY 0/10_Ca(OCl)2 | calcium hypochlorite | ||

| 7 | PLY 0/20_H2O2 | ≤20 | hydrogen peroxide | |

| 8 | PLY 0/20_Na2CO3 | sodium carbonate | ||

| 9 | PLY 0/20_Ca(OCl)2 | calcium hypochlorite | ||

| 10 | DW 0/5_H2O2 | DW | ≤5 | hydrogen peroxide |

| 11 | DW 0/5_Na2CO3 | sodium carbonate | ||

| 12 | DW 0/5_Ca(OCl)2 | calcium hypochlorite | ||

| 13 | DW 0/10_H2O2 | ≤10 | hydrogen peroxide | |

| 14 | DW 0/10_Na2CO3 | sodium carbonate | ||

| 15 | DW 0/10_Ca(OCl)2 | calcium hypochlorite | ||

| 16 | DW 0/20_H2O2 | ≤20 | hydrogen peroxide | |

| 17 | DW 0/20_Na2CO3 | sodium carbonate | ||

| 18 | DW 0/20_Ca(OCl)2 | calcium hypochlorite | ||

| 19 | W 0/5_H2O2 | W | ≤5 | hydrogen peroxide |

| 20 | W 0/5_Na2CO3 | sodium carbonate | ||

| 21 | W 0/5_Ca(OCl)2 | calcium hypochlorite | ||

| 22 | W 0/10_H2O2 | ≤10 | hydrogen peroxide | |

| 23 | W 0/10_Na2CO3 | sodium carbonate | ||

| 24 | W 0/10_Ca(OCl)2 | calcium hypochlorite | ||

| 25 | W 0/20_H2O2 | ≤20 | hydrogen peroxide | |

| 26 | W 0/20_Na2CO3 | sodium carbonate | ||

| 27 | W 0/20_Ca(OCl)2 | calcium hypochlorite | ||

| 28 | PLY | PLY | ≤20 | without chemical treatment |

| 29 | DW | DW | ||

| 30 | W | W |

| Biopolyurethane, % | Wood Waste, % | ||

|---|---|---|---|

| Isocyanate | Polyol | Rapeseed Oil | |

| 18 | 22 | 10 | 50 |

| Type and Fraction of Wood Waste | Aspect Ratio | Roundness | Circularity |

|---|---|---|---|

| W, 0–<5 | 4.110 ± 3.270 | 0.373 ± 0.209 | 0.515 ± 0.224 |

| W, ≥5–<10 | 4.869 ± 6.388 | 0.446 ± 0.255 | 0.558 ± 0.259 |

| W, ≥10–<20 | 3.228 ± 2.352 | 0.460 ± 0.242 | 0.616 ± 0.235 |

| PLY, 0–<5 | 3.850 ± 1.818 | 0.317 ± 0.143 | 0.435 ± 0.172 |

| PLY, ≥5–<10, | 6.153 ± 4.028 | 0.245 ± 0.186 | 0.432 ± 0.188 |

| PLY, ≥10–<20 | 6.952 ± 5.874 | 0.210 ± 0.112 | 0.389 ± 0.151 |

| DW, 0–<5 | 2.499 ± 1.734 | 0.525 ± 0.236 | 0.709 ± 0.237 |

| DW, ≥5–<10 | 3.838 ± 2.550 | 0.364 ± 0.189 | 0.365 ± 0.220 |

| DW, ≥10–<20 | 3.348 ± 2.350 | 0.391 ± 0.165 | 0.378 ± 0.198 |

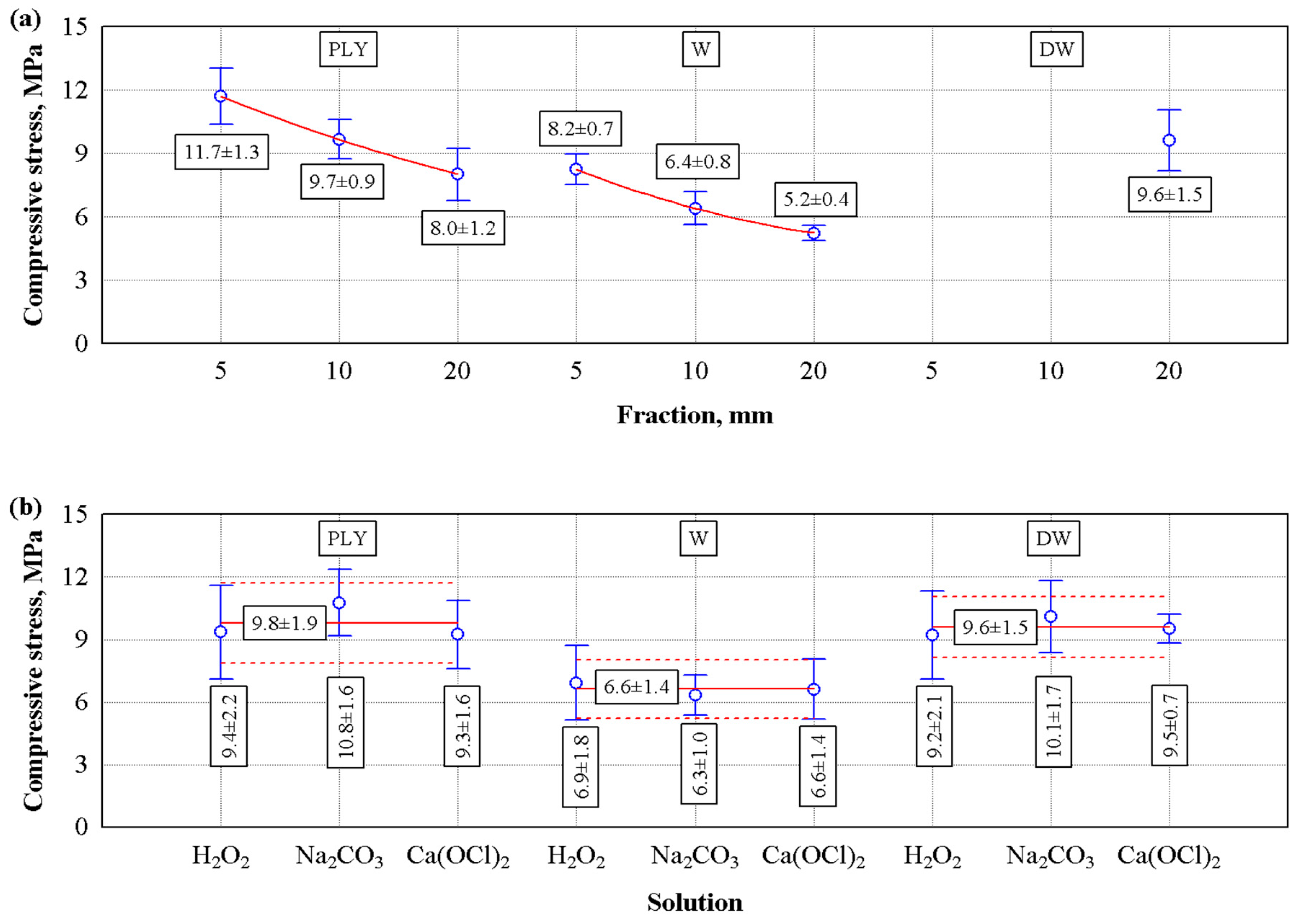

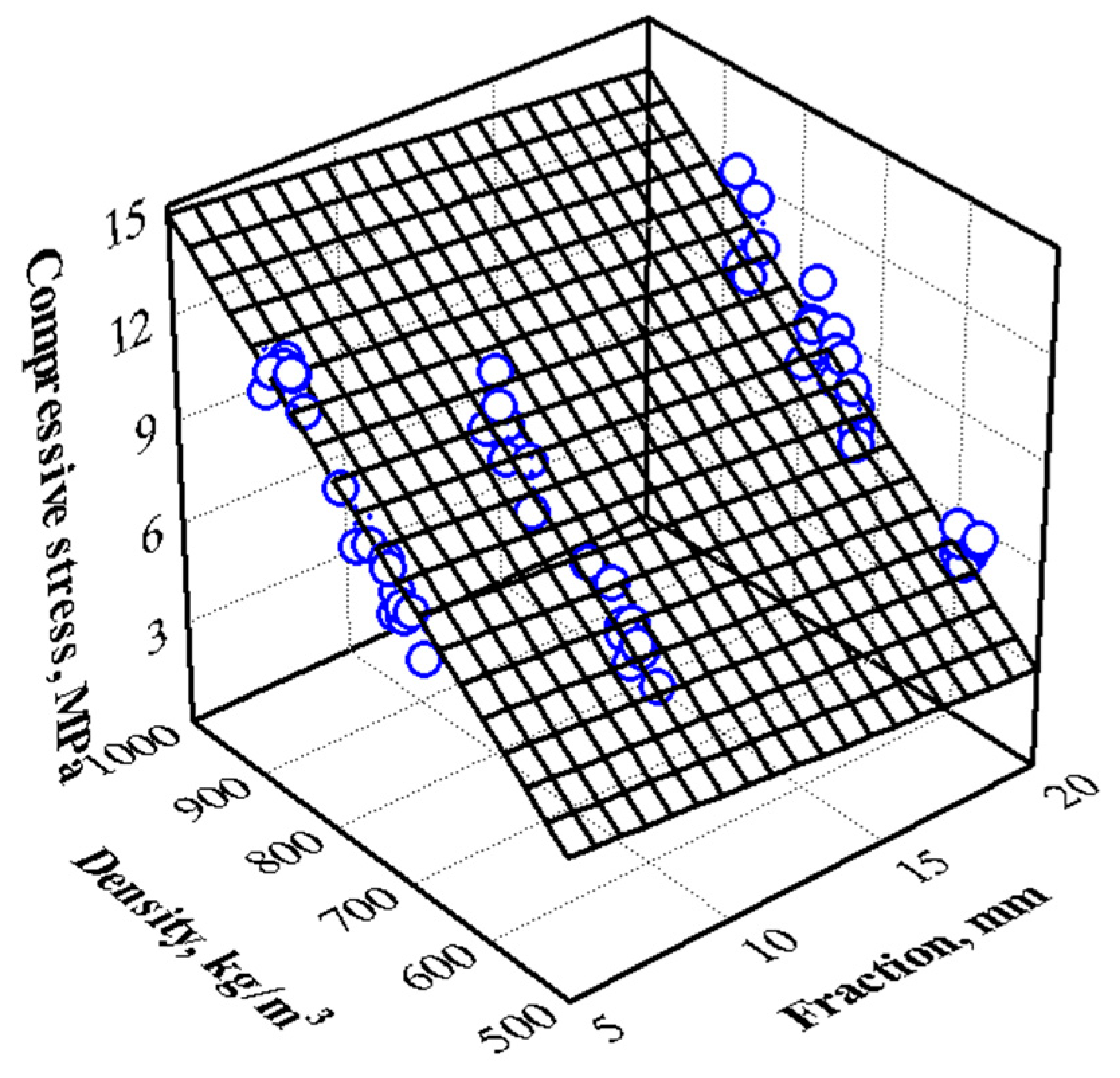

| Type of Composite | Number of Specimens | Correlation Coefficient R | Coefficient of Determination R2 | Standard Deviation Sr, kg⁄m3 |

|---|---|---|---|---|

| PLY waste (Equation (4)) | 54 | 0.647 | 0.420 | 40.4 |

| W waste (Equation (5)) | 54 | 0.904 | 0.818 | 30.0 |

| Type of Composite | Density, kg/m3 | F Criterion | p Value | Correlation Coefficient R | Coefficient of Determination R2 |

|---|---|---|---|---|---|

| PLY waste | 752 ± 52 | 0.15 | 0.86 | 0.071 | 0.00596 |

| W waste | 639 ± 69 | 0.36 | 0.70 | 0.117 | 0.0137 |

| DW | 815 ± 37 | 0.59 | 0.56 | 0.271 | 0.0734 |

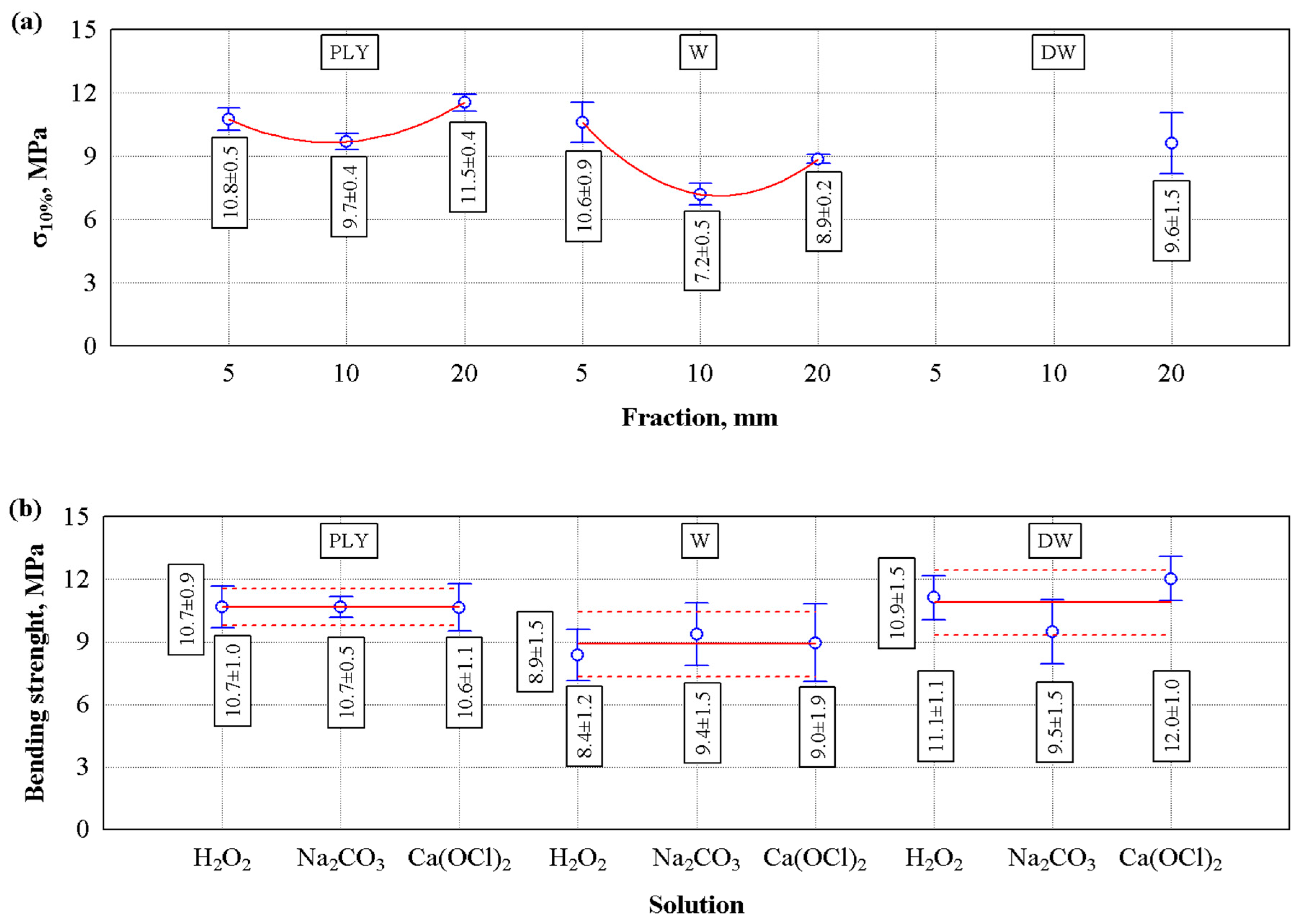

| Type of Composite | Number of Specimens | Correlation Coefficient R | Coefficient of Determination R2 | Standard Deviation Sr, MPa |

|---|---|---|---|---|

| PLY waste (Equation (7)) | 27 | 0.804 | 0.647 | 1.18 |

| W waste (Equation (8)) | 27 | 0.897 | 0.805 | 1.94 |

| Type of Composite | F Criterion | p Value | Correlation Coefficient R | Coefficient of Determination R2 |

|---|---|---|---|---|

| PLY waste | 1.90 | 0.17 | 0.370 | 0.137 |

| W waste | 0.37 | 0.69 | 0.174 | 0.0302 |

| DW | 0.24 | 0.79 | 0.272 | 0.0742 |

| Type of Composite | Number of Specimens | Correlation Coefficient R | Coefficient of Determination R2 | Standard Deviation Sr, MPa |

|---|---|---|---|---|

| PLY waste (Equation (7)) | 27 | 0.878 | 0.771 | 0.440 |

| W waste (Equation (8)) | 27 | 0.918 | 0.844 | 0.635 |

| Type of Composite | Bending Strength, MPa | F criterion | p Value | Correlation Coefficient R | Coefficient of Determination R2 |

|---|---|---|---|---|---|

| PLY waste | 10.7 ± 0.9 | 0.0023 | 0.99 | 0.0139 | 0.000193 |

| W waste | 8.9 ± 1.5 | 0.98 | 0.39 | 0.275 | 0.0758 |

| DW | 10.9 ± 1.5 | 0.24 | 0.80 | 0.271 | 0.0735 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rimkienė, A.; Vėjelis, S.; Vaitkus, S. Analysis and Use of Wood Waste in Lithuania for the Development of Engineered Wood Composite. Forests 2025, 16, 577. https://doi.org/10.3390/f16040577

Rimkienė A, Vėjelis S, Vaitkus S. Analysis and Use of Wood Waste in Lithuania for the Development of Engineered Wood Composite. Forests. 2025; 16(4):577. https://doi.org/10.3390/f16040577

Chicago/Turabian StyleRimkienė, Aurelija, Sigitas Vėjelis, and Saulius Vaitkus. 2025. "Analysis and Use of Wood Waste in Lithuania for the Development of Engineered Wood Composite" Forests 16, no. 4: 577. https://doi.org/10.3390/f16040577

APA StyleRimkienė, A., Vėjelis, S., & Vaitkus, S. (2025). Analysis and Use of Wood Waste in Lithuania for the Development of Engineered Wood Composite. Forests, 16(4), 577. https://doi.org/10.3390/f16040577