In recent years, mechanization has been actively implemented to address labor challenges and improve agricultural productivity [

1]. This has also increased the utilization of tractors worldwide. In South Korea, the number of tractors increased from 250,000 in 2009 to 290,000 in 2018 [

2]. In France, the number of new agricultural tractors registered in 2023 was 36,396, an approximately 2% increase over those registered in 2022. The number of tractors registered in Turkey in 2023 was 77,901, a 16% increase compared to that in 2022 [

3]. The global agricultural machinery market size was approximately USD 132.5 billion in 2019 and was expected to reach USD 160.3 billion in 2024 through an average annual growth rate of over 3.9% [

4]. With increasing use of tractors, ensuring safety in the driving environment has emerged as an important issue [

5,

6]. Generally, farmland is relatively irregular and has steep slopes [

7], which makes tractor driving unstable and lateral overturning and backward rollover highly likely [

8]. More than 50% of deaths during farming operations that involve tractors are caused by lateral overturning and backward rollover accidents [

9]. In Korea, 12.3% of the agricultural machinery accidents that occurred in 2020 were caused by tractors. Among them, accidents causing farmer injuries from lateral overturning and backward rollover constituted the largest proportion of 34.1% [

4]. In Spain, 69% of approximately 200 accidents from 2004 to 2013 occurred during tractor operations, and 30% of them were classified as overturning or rollover [

10]. An analysis of 817 tractor accident cases that occurred in Italy from 2002 to 2012 showed that 25.1% of all accidents were caused by overturning and rollover [

11]. As lateral overturning accidents continue to occur under the dynamic conditions of tractors [

12], various studies have been conducted to analyze and improve tractor driving safety.

In related work, Gravalos et al. [

13] analyzed the lateral overturning safety of a 26.8 kW tractor located on a slope in relation to rear wheel width. They found that lateral overturning safety tends to increase as rear wheel width increases because of the relatively lower center of gravity of the tractor. They suggested the need for further research regarding the dynamic conditions of the tractor, such as driving speed and ground conditions. Pereira et al. [

14] derived the critical slope angle for operations by calculating the center of gravity coordinates and static equilibrium of a 112 kW tractor. They also constructed a lateral overturning safety zone for tractors operating on a slope by conducting topographic analyses through a digital elevation model. Mazzetto et al. [

15] developed a mathematical model of tractors to assess the safety of a reversible wheeled articulated tractor. Analyzing the dynamic characteristics of the tractor according to the ground slope angle using key geometric and mechanical parameters, they found that the safety of the tractor is lower when making turns on a slope than during straight driving. Li et al. [

16] used a scale-model tractor to determine the factors that affect lateral overturning safety and analyzed their importance, identifying moment of inertia, center of gravity position, wheelbase, and track width characteristics, as key factors. Among these, the position of the center of gravity was observed to have the largest impact on lateral overturning safety. Sheichenko et al. [

17] developed a mathematical model for a three-wheeled tractor, to analyze lateral overturning safety. They concluded that the static sidelong falling angle increases as the tractor wheel width and diameter increase, and a lower position of the center of gravity improves tractor safety on a slope. Hung et al. [

18] developed a mathematical model, analyzing lateral overturning and steering instability as a function of ground conditions during the operation of a tractor. They analyzed the dynamic characteristics of the tractor for asphalt, gravel, snowy, and icy road ground conditions, concluding that steering instability increases at a driving speed of 60 km/h or higher on snowy and icy roads because of the low frictional force. They also concluded that the likelihood of tractor lateral overturning is highest on dry asphalt. Nguyen and Luong [

19] developed a mathematical model to analyze the effects of the driving speed and steering angle of a tractor on lateral overturning. They found that the steering angle range for stable steering decreases as driving speed increases and that relatively stable driving is possible at low speeds. Lee et al. [

20] evaluated the lateral overturning safety of small agricultural off-road vehicles during slope work. The experimental results confirmed that the lower the vehicle’s center of gravity and the wider the vehicle width, the better is lateral stability. Franceschetti et al. [

21] modified the existing mathematical model to reflect the dynamic characteristics of a narrow-track tractor using rubber tracks. They calculated that tracked wheels increase the total mass of the tractor and affect the center of gravity, moving the center of gravity downward and rearward compared to that of a wheeled tractor. In addition, Franceschetti et al. [

22] developed a kinematic model of articulated narrow-track tractors on slopes and predicted the direction, lateral stability, and lateral overturning risk of the tractor at steady state. The experimental results confirmed that the lateral overturn stability decreased linearly as the roll angle of the tractor increased; however, the relationship with the yaw angle was nonlinear. Previous studies mostly derived the lateral overturning safety of tractors through mathematical modeling under static conditions or theoretical analysis that applied simplified assumptions [

23]. They could not analyze lateral overturning characteristics under the dynamic conditions of tractor operation, and the various assumptions limited the accuracy. Research has also been conducted on wheeled tractors, but few have investigated tracked forestry tractors that operate in challenging environments, such as rough terrains and slopes [

24].

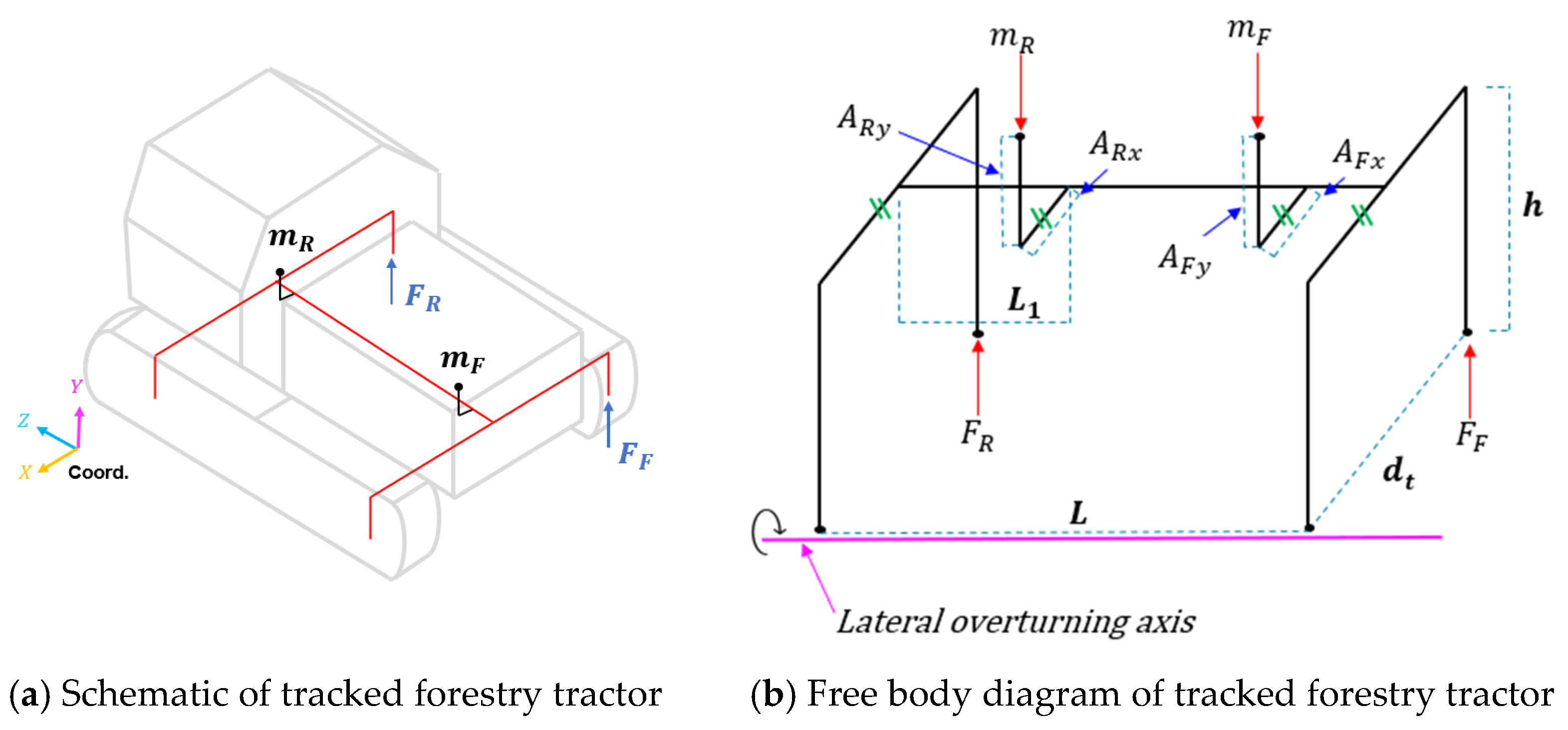

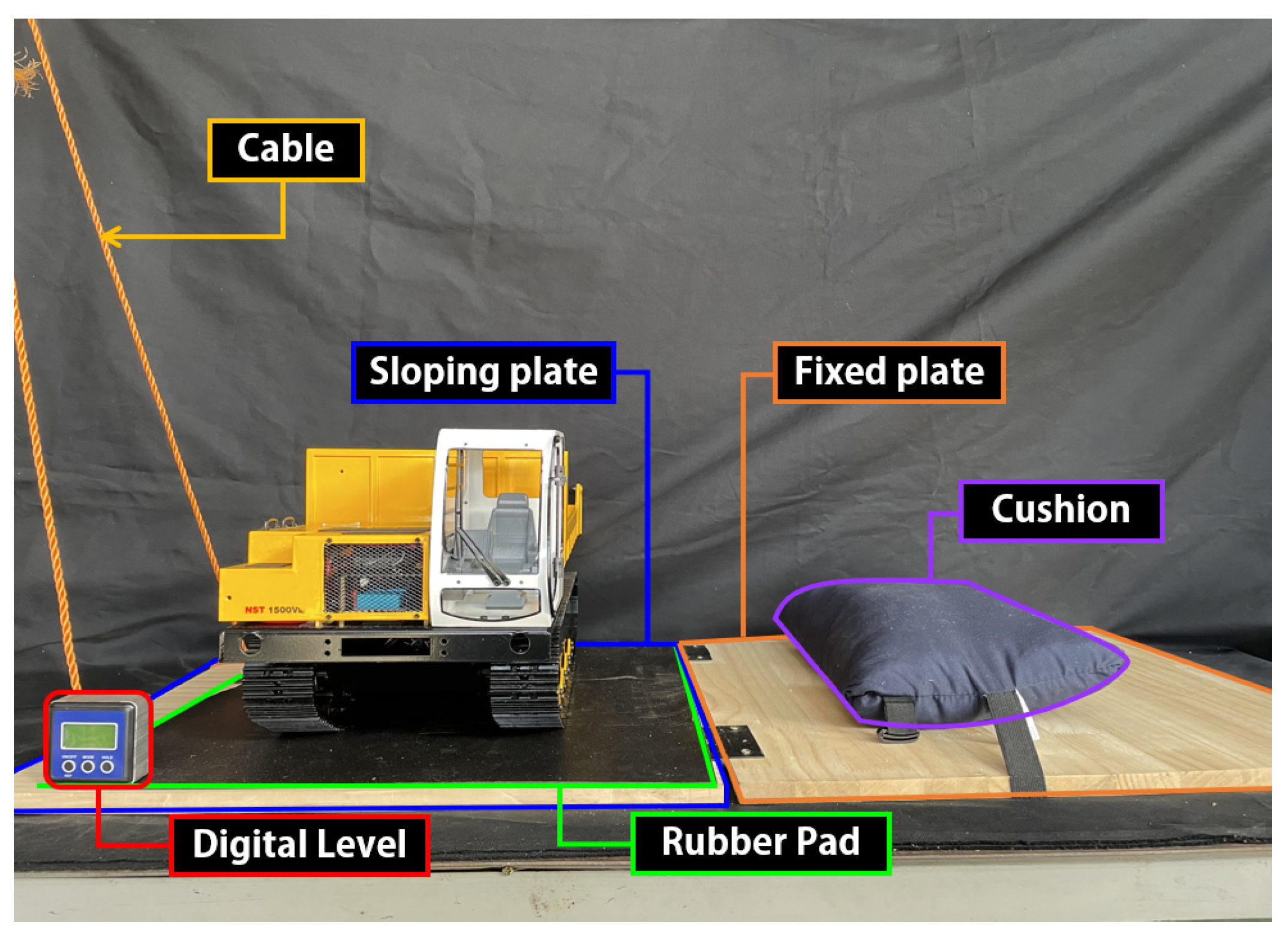

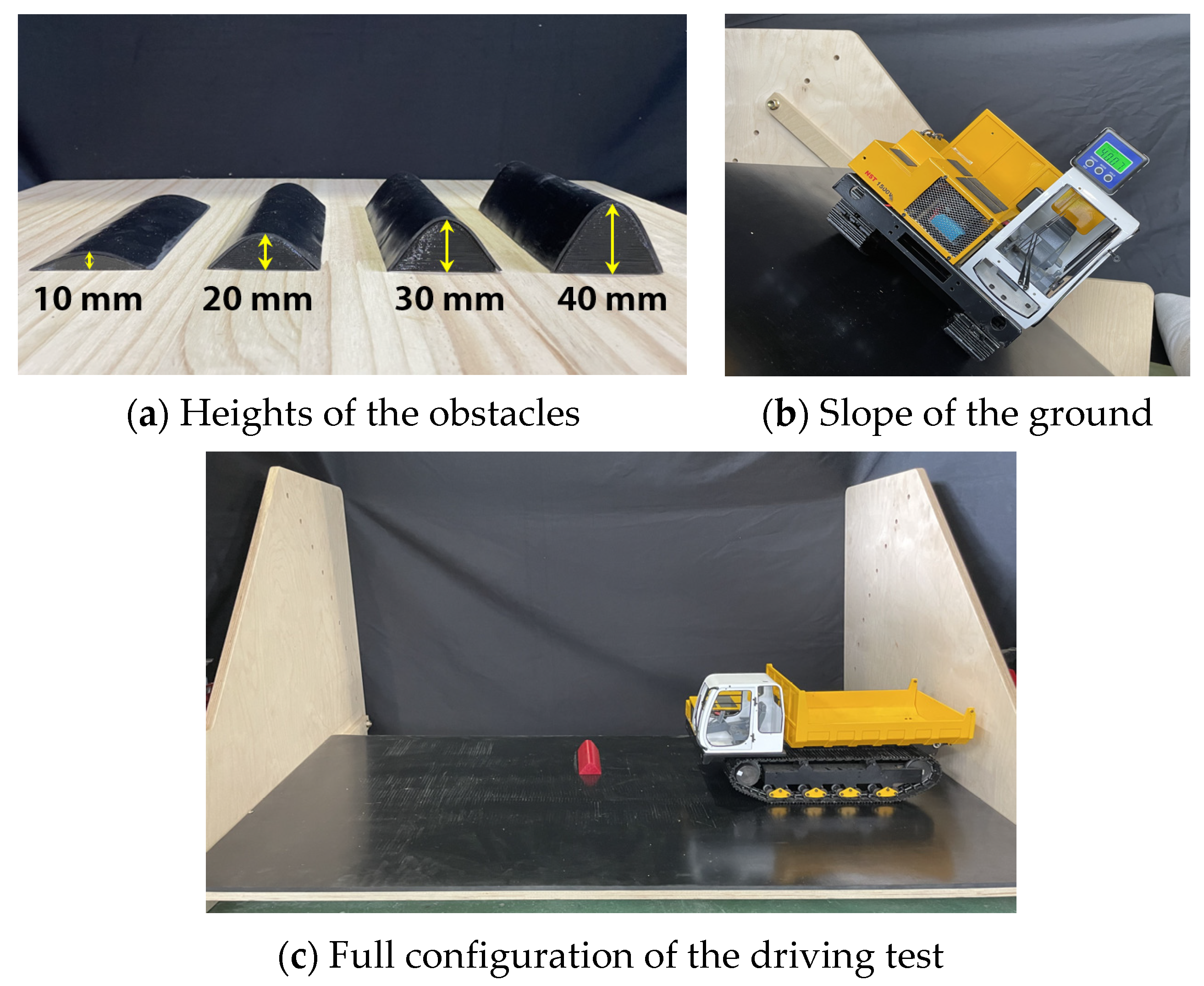

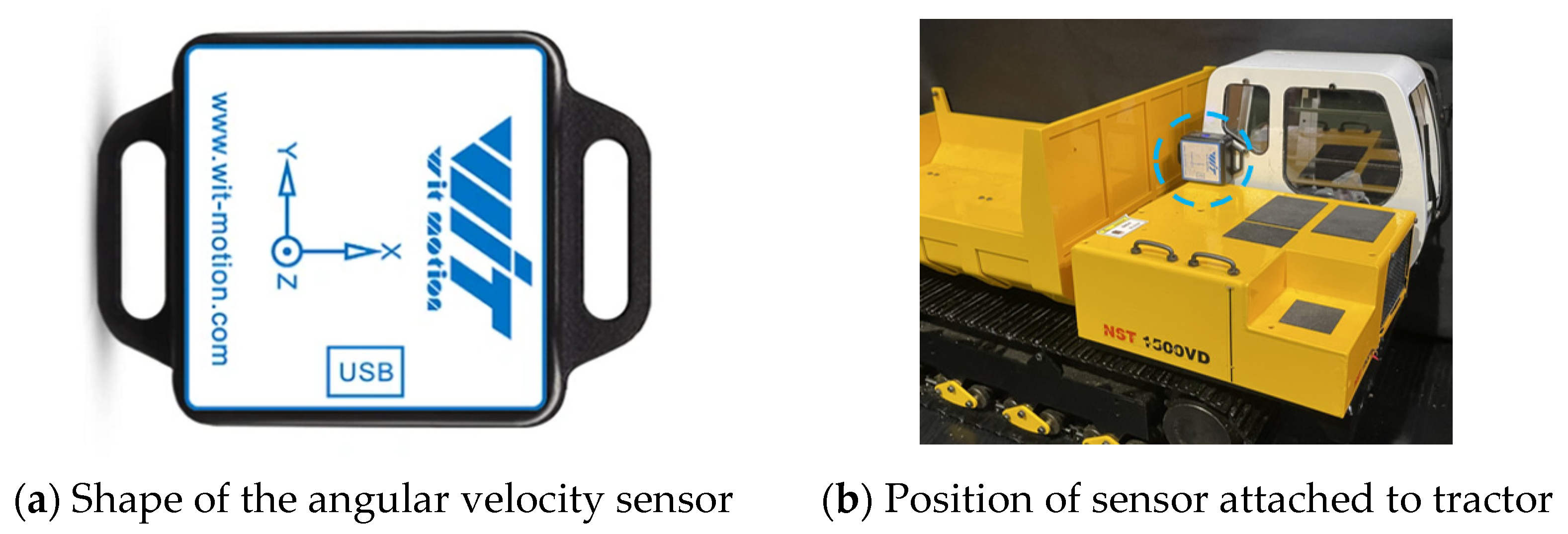

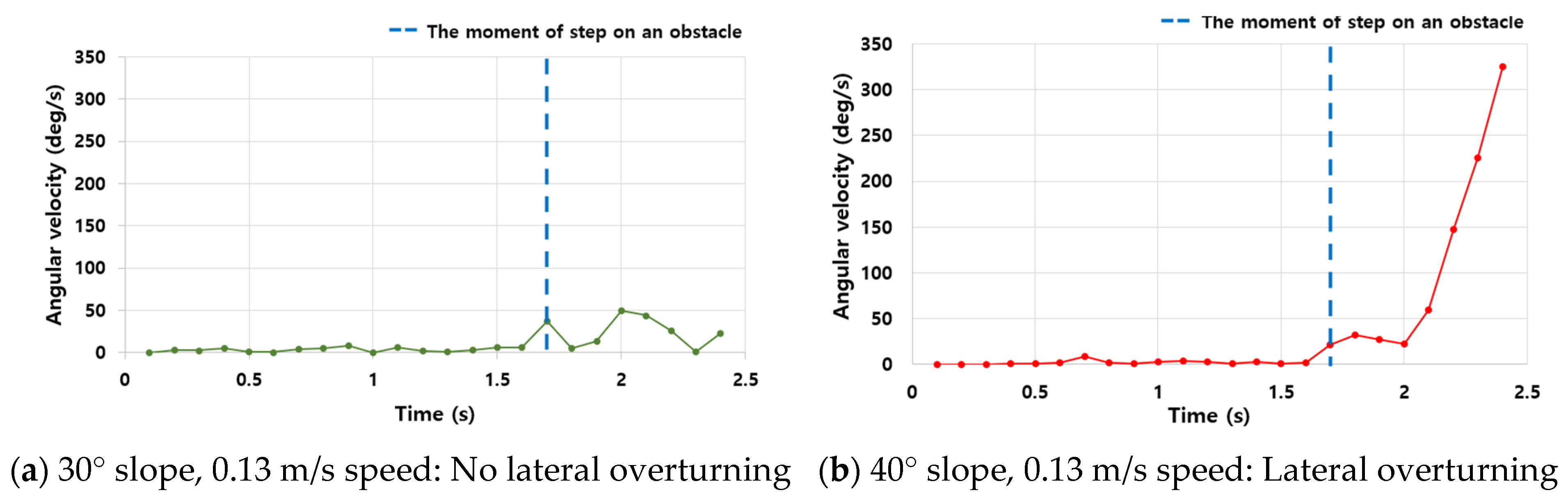

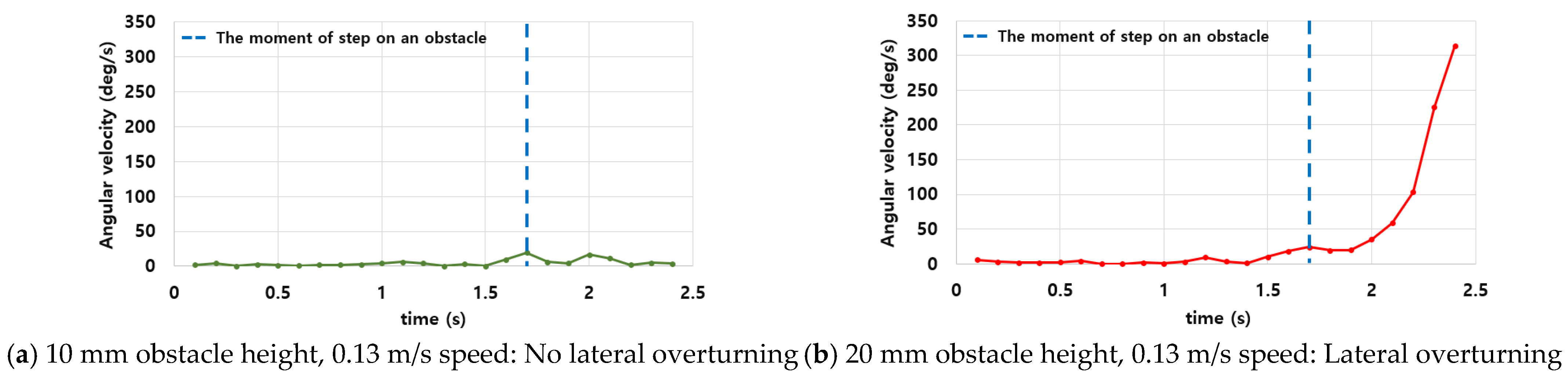

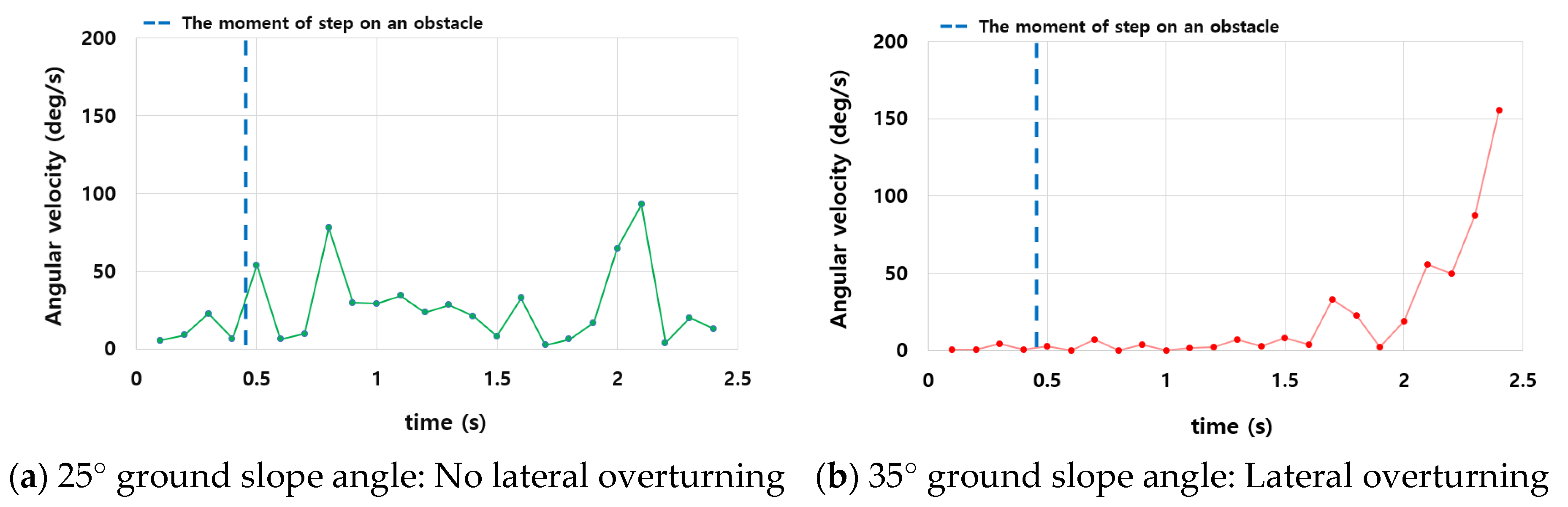

Therefore, in this study, a small-tracked forestry tractor was used to analyze the tendency between lateral overturning and roll angular velocity under various driving conditions, identifying the critical angular velocity that leads to lateral overturning.