1. Introduction

In recent years, global demand for engineered wood products has surged, driven by the construction and furniture industries. However, this trend raises serious environmental concerns, including deforestation, biodiversity loss, and increased greenhouse gas emissions resulting from wood processing and prolonged forest regeneration cycles [

1,

2,

3]. As a result, the search for sustainable, renewable, and low-impact alternatives to conventional wood materials has gained momentum.

Industrial hemp (

Cannabis sativa L.) has emerged as one of the most promising candidates for sustainable biomass production. It is one of humanity’s oldest cultivated plants, historically used for making textiles, ropes, and paper due to the exceptional strength of its bast fibers found in the stem bark [

4,

5,

6,

7]. In recent decades, hemp seeds have also gained importance as a source of nutritional oil, while the woody core of the stem—known as hemp shives or hurds—has often been regarded as agricultural waste [

8,

9,

10].

Anatomically, the hemp stalk comprises the epidermis, cortex, bast (phloem), cambium, xylem (woody core), and pith [

11,

12]. The bast fibers are long, cellulose-rich, and highly tensile, whereas the xylem, making up ~75% of the stalk’s volume, is composed of shorter lignocellulosic elements with lower strength but excellent thermal and dimensional properties [

13,

14,

15]. The chemical composition of bast fibers includes ~60% cellulose, 15%–20% hemicellulose, and low lignin content (~2%–4%), while the xylem contains ~40% cellulose, 25% hemicellulose, and higher lignin (~20%) [

16,

17].

Due to its favorable agronomic traits—fast growth (3–4 months to maturity), low input requirements, and high biomass yield—hemp is particularly suitable for circular bioeconomy models [

5,

18,

19]. One hectare of hemp can sequester between 8 and 15 tons of CO

2 per year, outperforming most tree plantations [

20,

21]. It also improves soil health and fits well in crop rotation schemes [

22,

23].

Hemp’s application in composite panel manufacturing is gaining ground. Previous research has demonstrated that hemp fibers and shives can be effectively utilized in particleboards, fiberboards, and bio-based polymer composites, yielding competitive mechanical and hygroscopic properties [

24,

25,

26,

27]. When used as core material, hemp shives provide lightweight bulk with good water resistance and dimensional stability [

28,

29,

30]. Meanwhile, incorporating bast fibers in face layers significantly enhances bending strength and surface quality [

31,

32,

33].

Recent studies have optimized three-layer panels with hemp shive cores and fiber-based surfaces, achieving flexural strength values up to 15–18 N·mm

−2, low water absorption (<70%), and swelling rates below 28%—comparable or superior to standard wood-based boards used in furniture production [

34,

35,

36,

37]. These results confirm the suitability of hemp as a structurally viable and sustainable alternative to wood.

Beyond performance, Life Cycle Assessment (LCA) studies support hemp’s environmental advantages. Hemp composites exhibit lower embodied energy, reduced VOC emissions, shorter supply chains, and greater end-of-life recyclability than traditional wood-based or petroleum-derived materials [

38,

39,

40,

41]. In many LCA models, hemp boards outperform plywood and MDF in climate change, eutrophication, and fossil depletion categories [

42,

43,

44].

In parallel with growing academic interest, regulatory frameworks are gradually shifting to re-enable industrial hemp cultivation across many countries. Since the early 2000s, the loosening of cultivation bans—due to the extremely low THC content in industrial hemp—has allowed new markets to emerge in Europe, North America, and Asia [

5,

19]. This legal shift has reignited interest in hemp as a multifaceted crop for various applications, including materials, food, and biochemicals. Government programs promoting green building, bio-based materials, and carbon sequestration have further stimulated R&D and investment in hemp-based boards [

20,

45].

Despite these advantages, several challenges prevent the large-scale adoption of hemp-based panels in the furniture sector. One issue is the lack of standardization in panel production, particularly in terms of thickness swelling, surface quality, and the use of formaldehyde-free bonding agents [

3,

30,

33]. Another is the compatibility with existing industrial technologies, where equipment and presses are optimized for wood-based raw materials. Moreover, sourcing sufficient quantities of uniformly processed hemp raw material—particularly clean shives and long bast fibers—remains logistically complex in many regions [

36,

38,

46,

47,

48,

49]. These constraints underline the need for applied studies that tailor hemp panel design specifically for industrial furniture production.

Several studies have focused on the valorization of industrial hemp in the context of furniture-grade panel production. Research has explored a wide range of configurations, including single-layer particleboards, three-layer sandwich structures, and hybrid fiberboards, where hemp shives are used as the core material and bast fibers reinforce the surface layers [

6,

14,

24,

26,

30]. Such approaches aim to combine low weight with sufficient bending strength and dimensional stability to meet the requirements of the furniture industry.

The use of natural or bio-based adhesives in hemp panels is also being investigated as part of the effort to develop fully renewable and non-toxic materials. Some studies have successfully used tannin-formaldehyde, citric acid, or lignin-based binders, demonstrating strength values comparable to those achieved with conventional urea-formaldehyde resins [

31,

32,

38]. This opens new possibilities for low-emission indoor furniture applications, where regulations regarding formaldehyde release are becoming increasingly strict.

More recently, structurally optimized three-layer panels have gained attention as a viable approach for maximizing performance. In such designs, the hemp shive core ensures weight reduction, while densified hemp fibers on the faces provide resistance to bending and impact [

21,

27,

33]. By adjusting the proportion and compaction of each layer, it is possible to tailor the panel to specific furniture functions—such as shelving, cabinet sides, or load-bearing surfaces.

In contrast to conventional medium-density fiberboards (MDF), which typically fall within the density range of 600–800 kg·m

−3, this study deliberately focuses on the lightweight interval of 400–600 kg·m

−3. Several authors have demonstrated that agro-residue and hemp-based composites can be effectively engineered in this lower density range for furniture and interior applications, achieving sufficient bending strength and dimensional stability while offering clear advantages in terms of weight reduction and material efficiency [

1,

2,

3]. The pursuit of lighter panels is motivated by industry demand for easier handling, reduced transportation costs, and improved sustainability profiles. While a certain trade-off in stiffness and swelling resistance compared to conventional MDF is expected, the targeted range allows the production of competitive boards that meet particleboard type P2 (EN 312) requirements and, under optimized conditions, approach MDF standards for dry-use applications.

Despite promising results, the industrial integration of hemp panels into the furniture sector remains limited, often due to scalability issues, variability in raw material properties, and the lack of direct equivalence to existing wood-based board classifications (e.g., P2 or MDF, as per EN 312 or EN 622-5) [

24,

30,

46]. The current research contributes to this evolving field by systematically evaluating the influence of layer structure and density on the mechanical, physical, and hygroscopic properties of composite hemp panels designed for furniture use, using standardized testing protocols.

In summary, previous studies confirm the technical potential of hemp-based composites but also reveal critical gaps: the absence of standardized production methods, limited optimization of multi-layer structures, and insufficient benchmarking against European product standards. These limitations constrain the industrial uptake of hemp boards despite their ecological advantages. Moreover, the transition from laboratory to industrial scale presents additional challenges, including raw material variability, non-uniformity in hemp shives and fibers, and the lack of harmonized classification for hemp panels within the EN framework. Scaling production also raises concerns regarding process control, compatibility with existing equipment designed for wood particles, and cost efficiency. These constraints highlight the need for applied studies that not only optimize density and layer composition but also address variability, scalability, and standardization to ensure market acceptance. The present work contributes to this effort by systematically evaluating the influence of density and face-layer ratio on the physical and mechanical performance of three-layer hemp panels, using standardized testing protocols and statistical optimization.

2. Materials and Methods

To investigate the effect of structural parameters on the performance of lightweight hemp-based panels, a regression analysis was conducted using a D-optimal experimental design of type B2. This design enabled systematic variation in two key factors—panel density and face layer proportion—with a minimal number of experiments while ensuring adequate coverage of the design space.

The study involved the production of nine series of three-layer panels, each with a nominal thickness of 16 mm. The core layer consisted of hemp shives, while the face layers were formed from chopped hemp fibers. The experiment focused on two independent variables: X1–target density of the panels, varied between 400 and 600 kg·m−3; and mass share of the face layers, varied between 30% and 50%. The target density of the panels was achieved by calculating the required mass of hemp shives and fibers according to the designed panel volume. During hot pressing, metal stops were used to fix the final thickness, ensuring that the boards could not be compressed beyond the intended dimension. This method allowed accurate control of density, with final measured values remaining very close to the targets.

Each factor was examined at three levels (coded as −1, 0, and +1), allowing the construction of second-order regression models. The experimental matrix is presented in

Table 1.

Sevarex Ltd., Sofia, Bulgaria, supplied the hemp raw materials used in this study. Two types of fractions were used: hemp shives (from the woody core) and processed hemp stalks, serving as fiber-rich material for the face layers.

The bulk density of the hemp shives was determined using a standardized 1000 cm3 container and was found to be 95 kg·m−3. Their moisture content before processing was measured at 11.3%. The hemp stalks were chopped to lengths of approximately 20 mm and mechanically defibrated using a hammer mill model FCh-500 (manufactured by OSO Agromashina, Yambol, Bulgaria, 1985). The material was processed without a sieve and passed through the mill three consecutive times. The resulting mixture consisted of a combination of coarse fibers and small particles, with an overall moisture content of 10.6%. Both the hemp shives and the defibrated stalk material were subjected to a fractional size analysis using a laboratory sieve analyzer, “CISA BA 200N”.

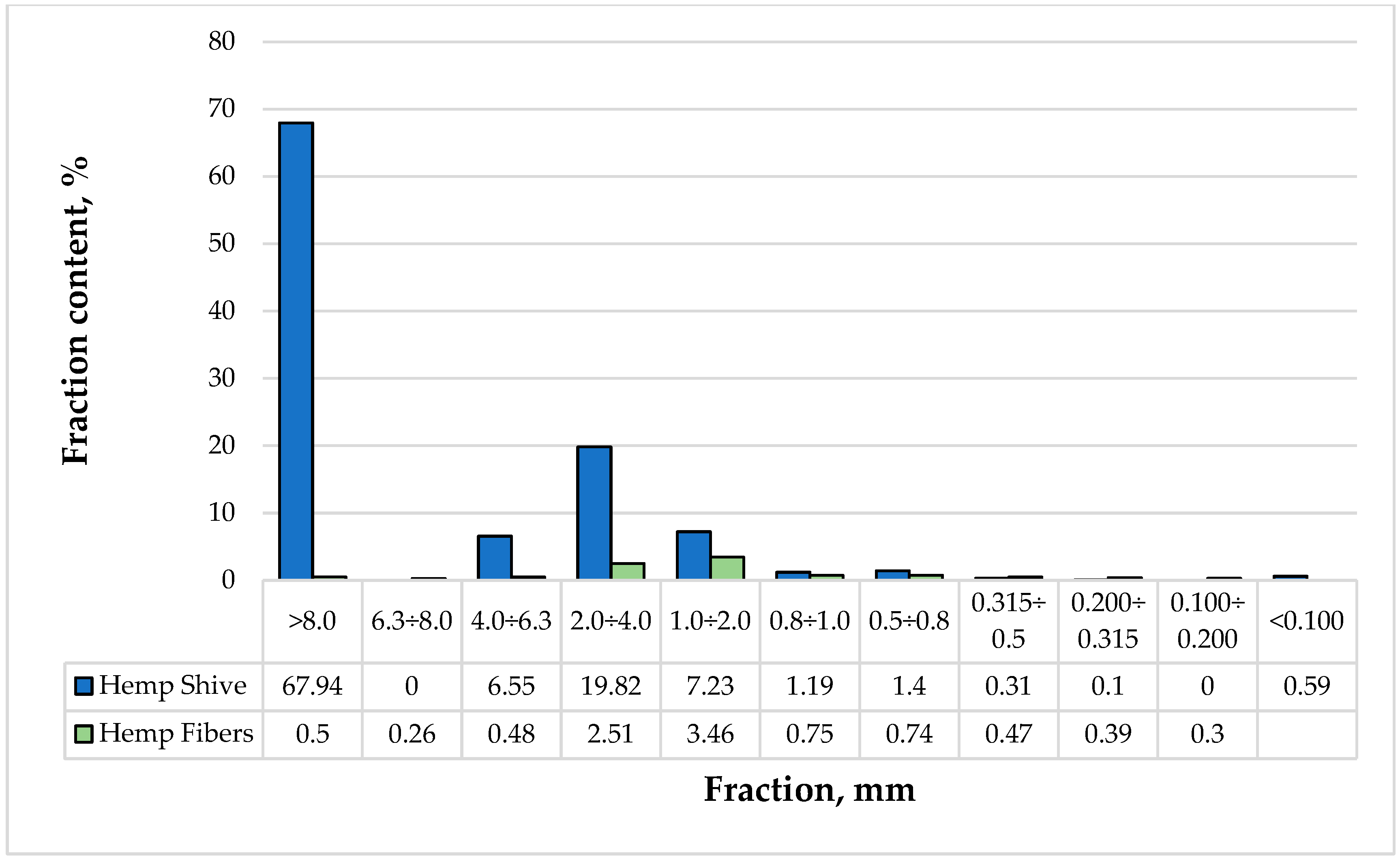

The particle size distribution (

Figure 1) revealed that the dominant fraction in the hemp shives exceeded 8 mm, classifying it as coarse material suitable for core layer application. In contrast, the processed stalk fibers exhibited a more uniform grain profile, with the majority of particles falling within the 1.0–4.0 mm range.

A notable portion of the fiber mixture was composed of particles smaller than 1.0 mm, which can serve to fill voids within the panel structure and enhance internal cohesion. The materials—hemp shives for the core layer and hemp fibers for the face layers—were stored separately and conditioned to uniform moisture content before blending.

Panels were bonded with urea-formaldehyde (UF) at 50% solid content. The UF resin had a molar ratio 1.06 and viscosity 23.76 ± 0.52 mPa·s. Ammonium sulfate (20%) was used as a hardener at 1% of dry resin solids, introduced as a 30% aqueous solution. A paraffin emulsion (50%) was added at 1% of dry fibers as a hydrophobic agent. The overall adhesive content was 10% (based on dry shives or fibers). It should be noted that the use of UF resin, although standard in conventional particleboard production, represents a limitation with respect to sustainability. Alternative adhesive systems, including tannin-, citric acid-, or lignin-based resins, have shown promising results in natural-fiber composites and could further enhance the eco-profile of hemp-based panels. Future studies will focus on integrating such binders into the layered structure to reconcile mechanical performance with environmental goals.

Hemp shives were blended with the adhesive in a low-speed paddle mixer, while hemp fibers were blended in a high-speed needle mixer, ensuring thorough distribution of the resin. The adhesive was sprayed using a pneumatic gun with a 1.5 mm nozzle, with a spraying duration of approximately 60 s per batch, followed by several minutes of post-mixing. After blending, the fiber mixture was evenly split into two parts (for the top and bottom face layers), and the shive mixture was prepared for the intermediate layer. A three-layer mat was assembled using a wooden forming frame (400 × 400 mm) placed on a paraffin-coated steel caul plate to prevent sticking. The layering sequence began with the bottom hemp fiber layer (lightly hand-pressed), followed by the core hemp shives, and concluded with the top fiber layer. The entire mat was pre-pressed cold using a wooden plate to stabilize the structure and facilitate removal of the frame. The thickness after cold pressing was approximately 80 mm. Subsequently, the mat was covered with a second paraffin-treated caul plate (

Figure 2) and transferred to a laboratory hot press—model “Manni” PMC ST 100, Italy. Temperature of hot-pressing was 180 °C.

The pressing cycle followed a standard three-stage regime commonly used for lignocellulosic composites. In Stage I, a high pressure of 2.2 MPa was applied to densify the mat. In Stage II, the pressure was reduced to 1.5 MPa to relieve part of the internal steam pressure while facilitating heat transfer towards the core. In Stage III, pressure was further decreased to 0.6 MPa, allowing complete evacuation of vapor–gas mixtures at a safe rate and preventing delamination or panel cracking. This gradual pressure reduction ensured uniform curing and strong adhesion between core and face layers.

The total pressing time was determined using a pressing factor of 15 s·mm−1, resulting in full curing and densification of the composite to the desired final thickness of 16 mm.

The physical and mechanical characterization of the produced panels was performed in accordance with the applicable European testing standards. For each experimental configuration, ten test specimens (n = 10) were prepared and tested for every property. The apparent density of the samples was determined using EN 323. Dimensional stability, including thickness swelling and water absorption, was evaluated according to EN 317, while bending strength (MOR) and modulus of elasticity (MOE) were measured under static loading according to EN 310. To minimize systematic bias, panels were produced and tested in randomized order, and the experimental series was organized in blocks to avoid potential batch effects. All specimens were prepared to the dimensions and quantities defined by each standard, and tests were conducted after panel conditioning under a standard laboratory climate (20 ± 2 °C, 65 ± 5% RH).

To quantify the influence of the selected structural parameters—panel density (X

1) and mass share of face layers (X

2)—on the physical and mechanical properties of the hemp-based panels, a multiple linear regression model was developed. The general form of the regression Equation used was:

where

is the predicted value of the measured property (e.g., bending strength, swelling);

Bij are the regression coefficients;

X1 and X2 are the values of the experimental factors.

Stepwise regression analysis with 1000 iterations was performed to identify significant terms and optimize the panel structure. The statistical processing was carried out using the software package QstatLab, version 6.0, which enabled the evaluation of model adequacy, interaction effects, and prediction accuracy for each property under investigation. This analytical approach was employed to construct response surfaces and determine the optimal panel configurations for furniture applications, striking a balance between mechanical performance and dimensional stability.

3. Results and Discussion

3.1. Panel Appearance and Experimental Consistency

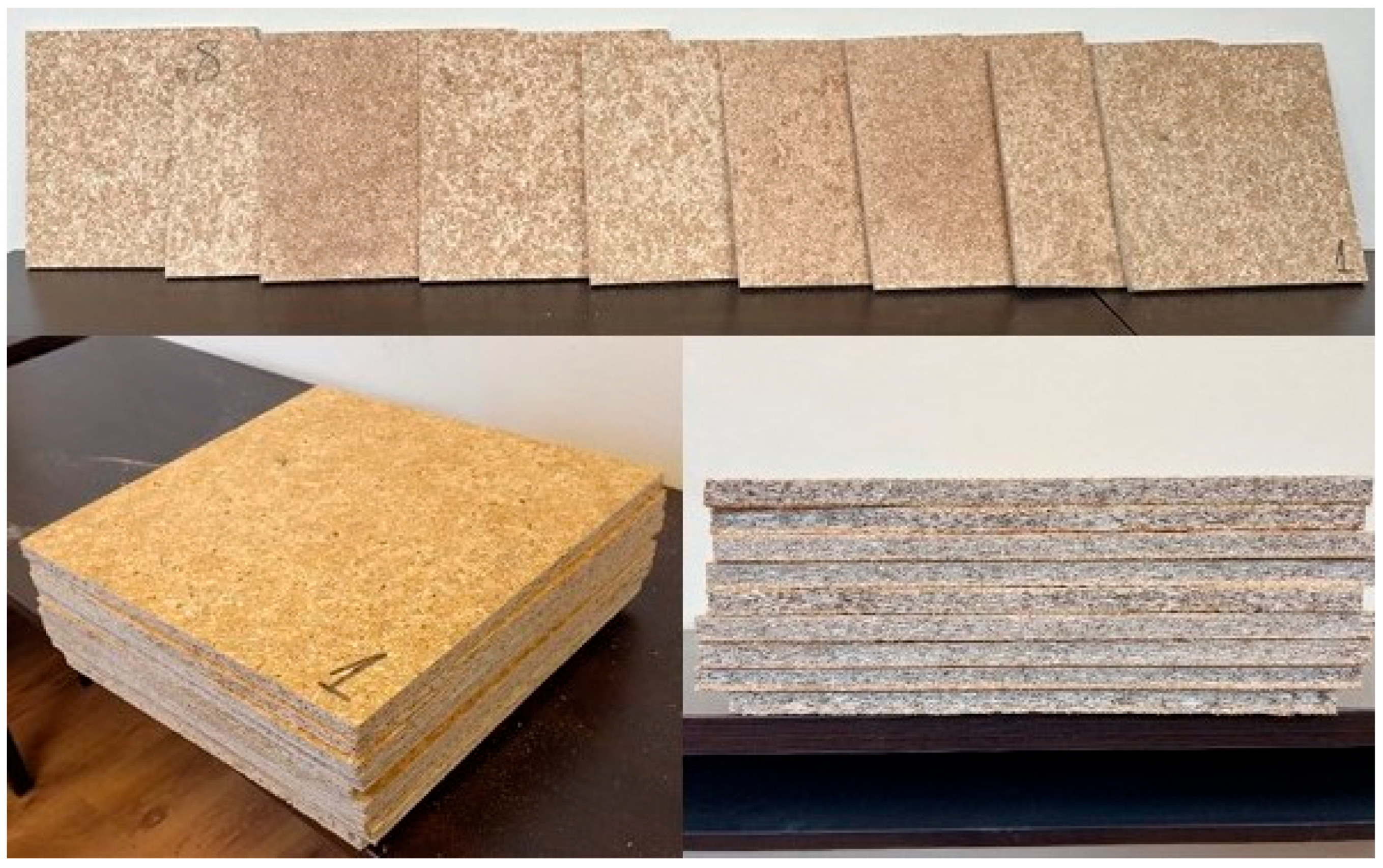

The laboratory-produced three-layer panels incorporating hemp shives in the core and defibrated hemp stalks in the face layers are shown in

Figure 3. The panels were manufactured under controlled conditions according to the methodology described in

Section 2. Their appearance demonstrated good compaction, uniformity of surface texture, and clear structural integrity across all variants.

These results confirm the technical feasibility of producing lightweight lignocellulosic panels using hemp-derived biomass, with sufficient layer cohesion and surface uniformity. The well-defined internal structure provided a reliable basis for mechanical and physical testing, with each sample group corresponding to the experimental plan described in

Table 1.

The summarized results of the physical and mechanical tests for the nine panel variants are presented in

Table 2. The target and actual densities are closely matched, demonstrating the consistency and precision of the laboratory manufacturing process. The properties evaluated include water absorption (WA), thickness swelling (TS), modulus of elasticity (MOE), and bending strength (MOR).

3.2. Regression Models and Statistical Adequacy

The regression models are presented in

Table 3.

The models for water absorption, MOE, and MOR exhibit high R2 (>0.95) and adjusted R2 (>0.95), confirming their robustness. Thickness swelling, however, is less strongly fitted (R2 = 0.67; Adj. R2 = 0.56), which is consistent with the higher variability of swelling measurements.

3.3. Water Absorption

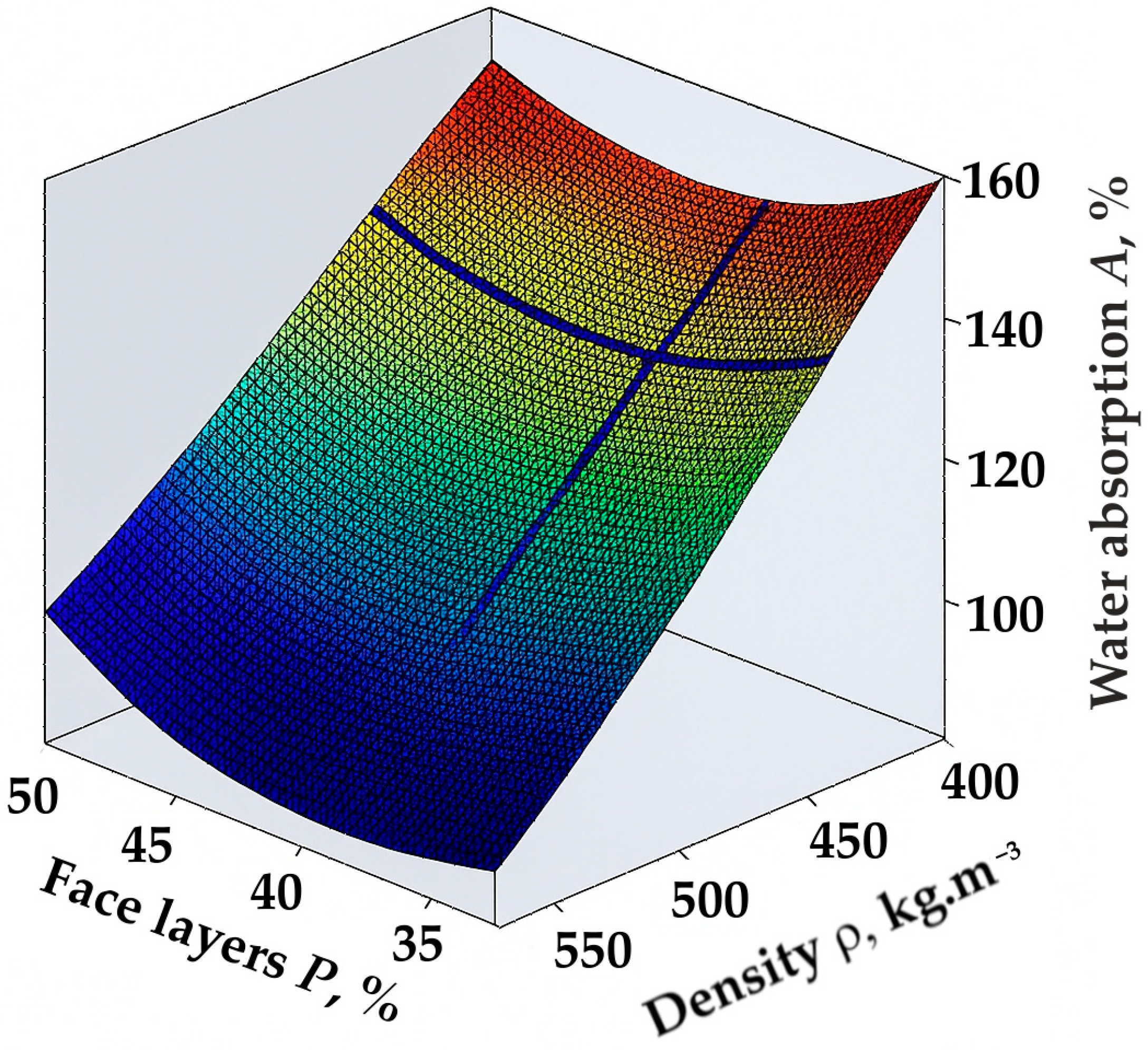

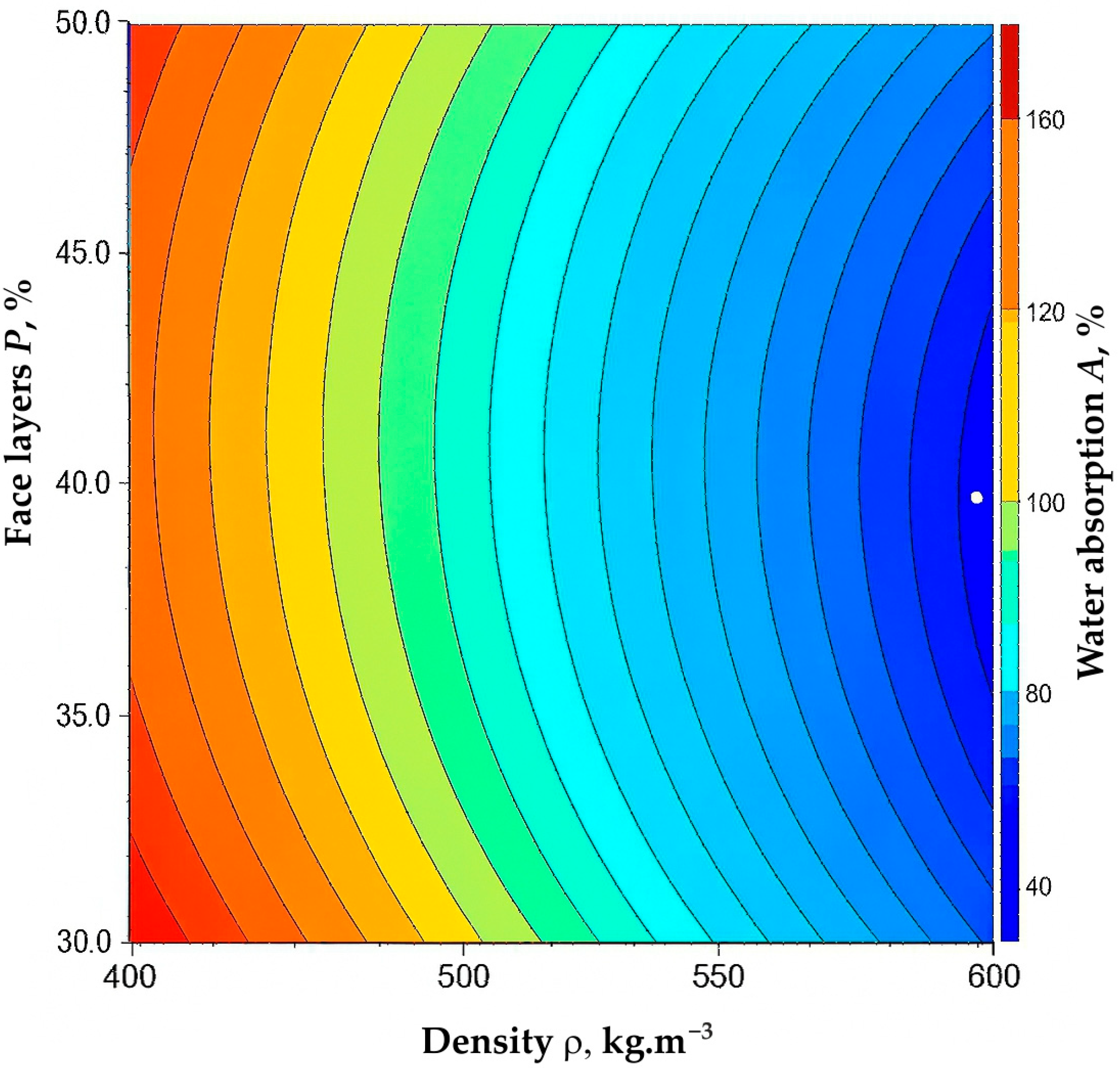

The dependence of water absorption on the panel density and the mass share of face layers is visualized in the three-dimensional response surface (

Figure 4). These regression models clearly illustrate the dominant effect of panel density on water absorption, accompanied by a secondary but nonlinear influence of the face-layer proportion.

As observed in the regression analysis (

Table 3), increasing the panel density from 400 to 600 kg/m

3 results in a substantial decrease in water absorption, from approximately 160% to 80%. This inverse relationship is nearly linear and can be attributed to the reduction in internal porosity and improvement in compaction at higher densities, resulting in fewer capillary pathways for water uptake. A similar trend has been documented in previous studies on hemp-based composites. For instance, it has been reported that [

50,

51] increased density improves the dimensional stability of boards made with hemp shives, while it was found that water absorption dropped by over 35% in panels compacted under higher pressing pressures [

52]. In contrast, the effect of face-layer share (

P) follows a quadratic (nonlinear) pattern. Up to around 37%, increasing the amount of face-layer material (made of hemp fibers) significantly improves water resistance. This is likely due to better consolidation of the top and bottom surfaces, which act as barriers to moisture ingress. However, as the face-layer share increases beyond 42%, a reverse effect is observed: water absorption rises again (

Figure 5).

This phenomenon can be explained by the imbalanced compaction profile that occurs when too much of the structure is allocated to the surface layers. Since the face layers consist of defibrated stalks with high specific surface area and lower stiffness compared to the coarser core material (hemp shives), they dominate the compression process during hot pressing. As a result, the interior layer becomes insufficiently compacted, creating zones of porosity along the edges and within the core that promote water uptake—particularly at the panel edges. Comparable findings were reported by Lykidis and Grigoriou [

53], who noted that an uneven structure of particleboards using non-wood materials can lead to enhanced moisture sensitivity in marginal areas. The optimal configuration, derived from the regression surface, appears at a density of 600 kg·m

−3 and a 37% face-layer share, balancing mechanical integrity and reduced porosity to yield the lowest observed water absorption (~83%) in the study.

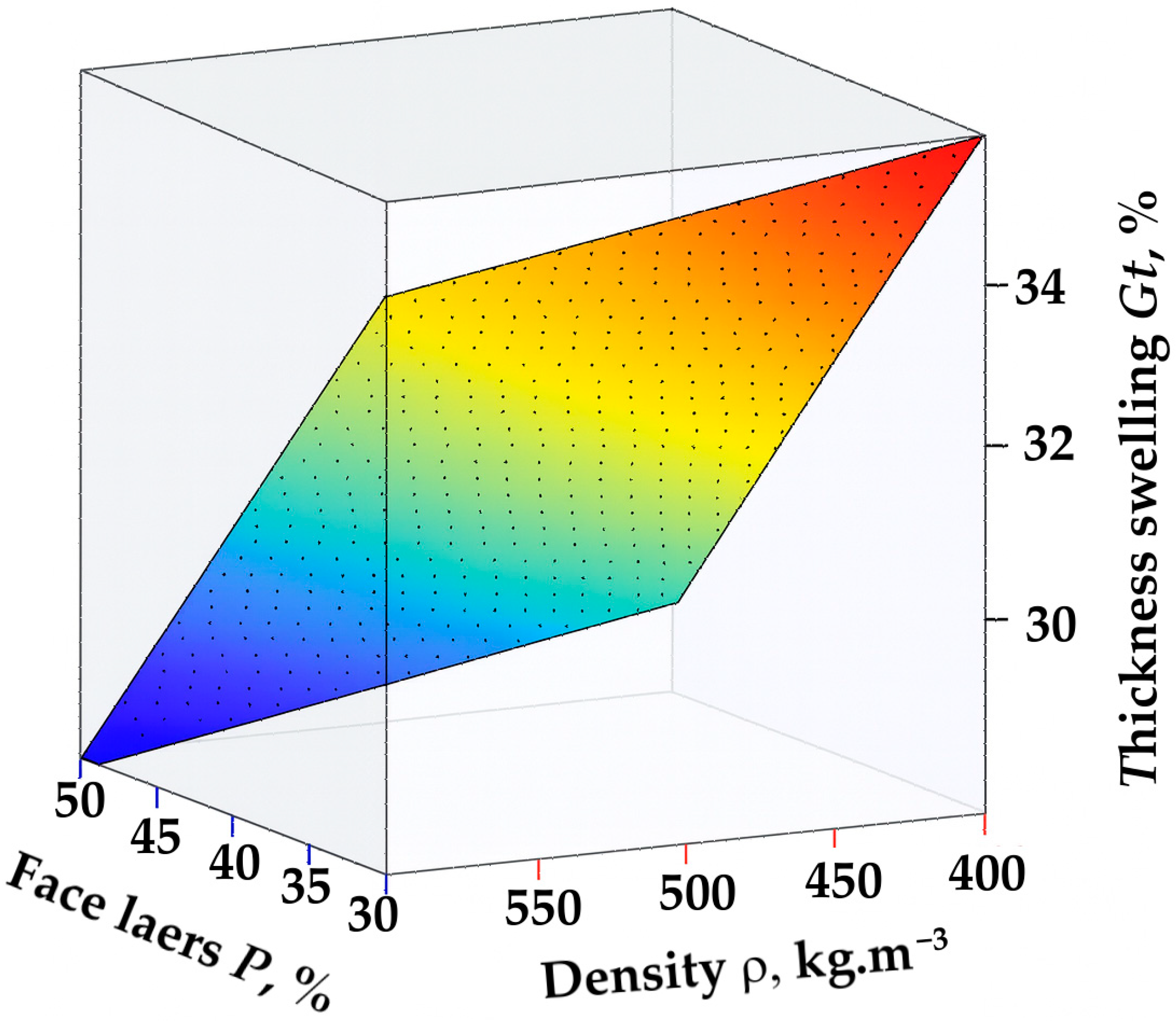

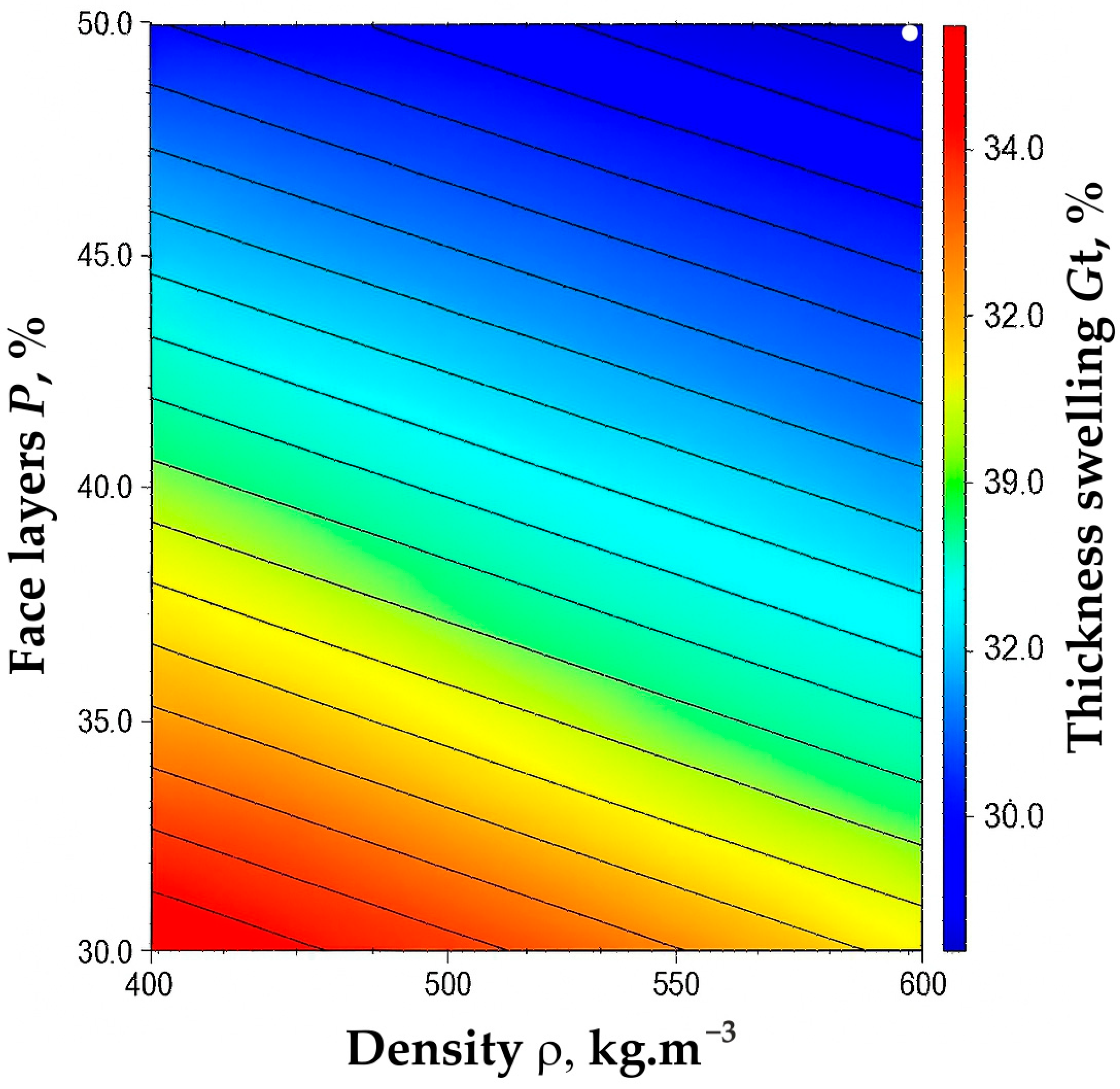

3.4. Thickness Swelling

The influence of board density and face layer content on the thickness swelling after 24 h water immersion is illustrated in

Figure 6. A clearly linear negative correlation can be observed for both studied factors. The response surface, derived from the regression model, indicates that increasing the density of the panels from 400 to 600 kg·m

−3 leads to a significant decrease in thickness swelling from approximately 34.5% to 29.0%.

This result contradicts the conventional trend described in earlier studies on medium-density lignocellulosic panels, where higher density (600–850 kg·m

−3) generally correlates with higher swelling due to increased compactness and more material available to absorb water per unit volume [

13,

18,

30]. However, in the current study, it appears that the overall water absorption significantly decreases with increasing density (

Figure 5), which directly offsets the tendency for more material to swell. Hence, the net effect remains a reduction in swelling, as less moisture enters the board initially.

The presence of more hemp fibers in the face layers, which are well impregnated with adhesive resin, contributes to improved dimensional stability of the panels. Similar conclusions were reported by Lu et al. [

54], who demonstrated that moisture sorption and swelling behavior in flax fiber composites is highly influenced by the fiber–matrix interaction and the degree of impregnation with resin, particularly in the outer regions. This finding is supported by Pandey et al. [

55] and Cheour et al. [

56], who observed that enhanced resin distribution in face layers leads to reduced water absorption and thickness swelling in natural fiber composites reinforced with flax or hemp.

However, the positive effect of increasing face layer content plateaus beyond approximately 37%–40%. This can be attributed to insufficient compaction in the core layer, resulting from the redistribution of pressing pressure, which creates internal zones with higher porosity and greater moisture accessibility. A similar behavior has been observed in hemp particleboards with a layered structure. Benthien and Ohlmeyer [

57] demonstrated that the bonding quality of the core layer significantly influences the dimensional stability of low-density particleboards, with weak core layer support limiting performance improvements despite modifications such as vertical orientation of particles in the core.

The minimum swelling in thickness, with a value of 29.12%, was achieved at the maximum board density of 600 kg·m

−3 and face layer content of 50%. This combination of factors represents the optimum formulation for minimizing dimensional instability within the experimental matrix (

Figure 7). Nevertheless, this value still does not comply with the requirement of EN 622-5 [

58] for MDF with general purpose use in dry conditions, which limits thickness swelling to 12% after 24 h of water immersion. When evaluated under EN 312 for particleboards (type P2, intended for dry-use furniture), however, no thickness swelling limit is specified. Given that the panels satisfy the corresponding mechanical requirements for P2, they can be considered suitable for such applications. It should be emphasized, however, that the current boards are experimental prototypes and not yet standardized products. Further improvement would therefore require additional strategies, such as the incorporation of stronger hydrophobic agents (e.g., nano-silica) [

28,

39], optimization of pressing cycles and resin distribution, or hybridization with thermosetting or thermoplastic additives [

17,

41].

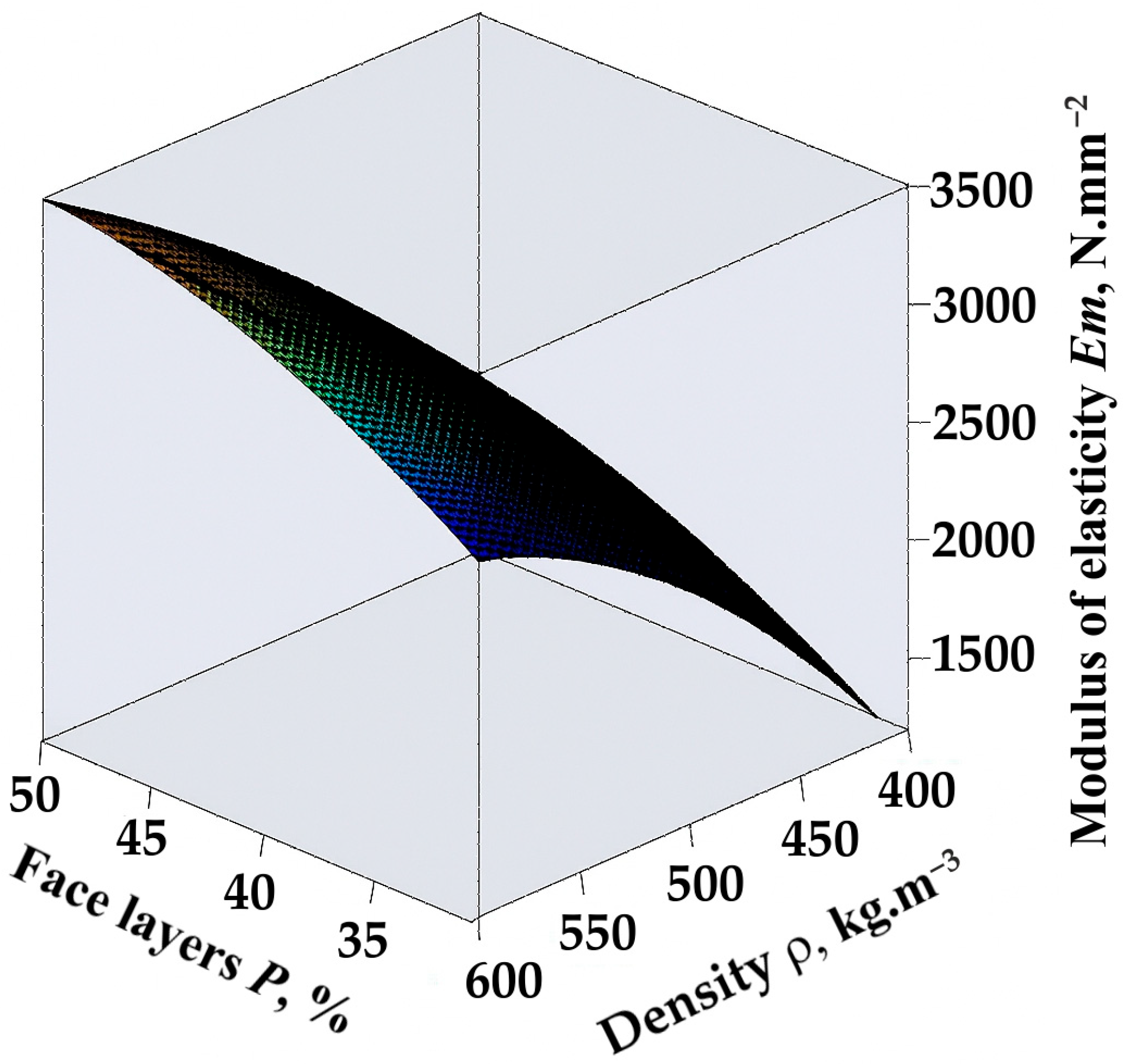

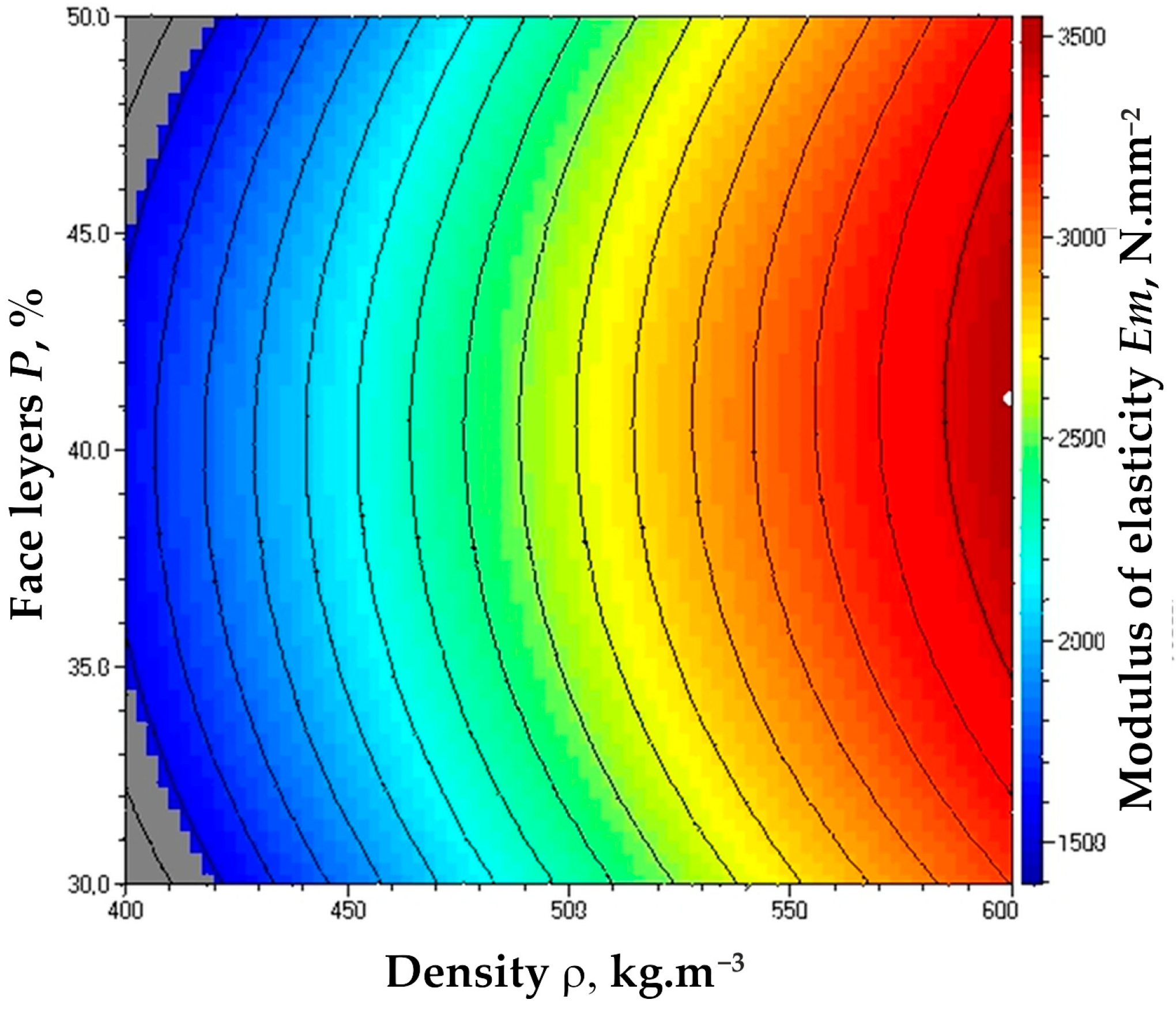

3.5. Modulus of Elasticity (MOE)

The modulus of elasticity (MOE) is a key parameter for the structural performance of composite panels, especially in applications such as furniture manufacturing, where both rigidity and lightweight design are critical. The influence of board density and face layer content on MOE is presented in

Figure 8.

The MOE values of the experimental hemp-based boards increased from 1434 N·mm

−2 to 3750 N·mm

−2 as board density rose from 400 to 600 kg·m

−3 and face layer content increased from 30% to 50%. The lowest MOE was observed at the combination of 400 kg·m

−3 and 30% face layers, while the highest MOE was achieved at 600 kg·m

−3 and 40% face layers. The response surface plot (

Figure 9) confirms that the relationship between the studied factors and MOE is nonlinear and quadratic in nature.

Increasing the density had a significant positive effect on stiffness, especially up to 500 kg·m

−3, after which further increases produced diminishing returns. This plateauing trend is consistent with other findings in lignocellulosic boards, as reported in [

15], where similar mechanical saturation points were observed. Denser core structures enhance inter-particle contact and stress transfer, but at some point, additional compaction does not yield proportional gains. The share of face layers also positively influenced MOE, particularly up to around 42%, after which a slight decline was recorded. This effect may be due to excessive face layer content limiting the thickness and compression of the core layer, resulting in a less compact internal structure. However, the reduction in MOE was moderate because MOE is largely dominated by the outer layers, which primarily resist bending forces. Similar effects were observed in hybrid particleboards containing hemp, flax, or jute fibers [

21,

31].

At the same time, the interaction between density and face layer content revealed an important inverse relationship: at higher densities, MOE decreased when the face layer proportion exceeded ~45%. This suggests that excessive face content redistributes the pressing pressure, reducing the densification of the core and weakening stress transfer between layers. In such cases, the benefits of densification are offset by weaker core–face bonding, explaining why stiffness did not continue to increase with higher density.

The optimal formulation for maximum stiffness was identified at a density of 600 kg/m

3 and a face layer content of 41.2%, yielding a MOE value of 3750 N/mm

2 (

Figure 10). These results are highly promising in terms of performance and sustainability.

All boards with density bigger than 420 kg·m

−3 and face layers less than 45% meet the P2 particleboard standard (EN 312) [

59] for furniture use, which requires a minimum MOE of 1600 N·mm

−2. Boards with density above 500 kg·m

−3 also meet the stricter standard for medium-density fibreboards (MDF) for general dry use per EN 622-5 [

58], which requires at least 2200 N·mm

−2.

3.6. Bending Strength (MOR)

Thus, hemp-based composites optimized for density and layer structure can outperform wood-based boards of a similar class, offering a sustainable alternative for furniture-grade applications. The bending strength (modulus of rupture, MOR) is another critical parameter for assessing the structural reliability of bio-based panels in furniture production. The results from the experimental series demonstrate that both density and face layers share significantly influence the bending strength of the hemp shives–fiber boards. The surface plot of this relationship is shown in

Figure 10.

The effect of density is especially pronounced up to around 500 kg·m

−3, after which additional compaction yields diminishing returns. This trend has been confirmed in hemp-reinforced particleboards, where mechanical performance such as staple withdrawal resistance and internal bonding improves with density but begins to plateau beyond 700 kg·m

−3. Hristodorova et al. [

10] demonstrated that the withdrawal resistance of hemp shive panels nearly doubled between 600 and 900 kg·m

−3, although the marginal benefit decreased at higher compaction levels, suggesting that the efficiency of densification has practical limits for optimization.

The face layer content also exhibited a quadratic influence on bending strength, albeit to a lesser degree than density. An increase of up to 40% in face layer content improved strength, likely due to the greater concentration of resin and fiber reinforcement at the surfaces—key zones for stress under bending. Beyond this level, however, excess face material may compromise the compactness of the core, thereby decreasing the efficiency of stress transfer and weakening structural coherence.

The optimal combination for bending strength was observed at a density of 600 kg·m

−3 and a face layer share of 37%, yielding a maximum bending strength of 21.57 N·mm

−2 (

Figure 11).

It should be noted, however, that the MOR value at 600 kg·m−3 and 50% face layer content was unexpectedly lower (~12 MPa) compared to the surrounding data points. Post-experimental inspection suggests that insufficient resin distribution and uneven core consolidation may have contributed to this anomaly. At the same time, the result is consistent with the hypothesis that excessive face layer proportion can reduce the effective compaction of the core, thereby limiting stress transfer and weakening structural coherence. Although this data point was included in the regression model, its influence on the response surface was checked and found not to compromise overall model adequacy.

A minimum density of 450 kg·m

−3 and face layer share of 35%–40% satisfy the EN 312 requirement for P2 particleboards (MOR ≥ 11 N·mm

−2), boards produced at 600 kg·m

−3 and 37% face layers content meet the higher requirement for medium-density fiberboards (MOR ≥ 20 N·mm

−2), intended for structural applications in dry conditions as per EN 622-5:2019 [

58].

These findings validate the mechanical viability of optimized hemp shive–fiber boards for furniture and interior applications, providing a sustainable and high-performance alternative to wood-based composites.

3.7. General Performance and Sustainability Considerations

The results from the conducted experimental program clearly demonstrate that the use of hemp shives in the core and refined hemp fibers in the face layers, when optimized, can produce lightweight three-layer panels with mechanical and physical properties comparable to or better than those of traditional wood-based panels. The influence of two main factors—density and face layer share—was systematically evaluated using a D-optimal regression design, yielding statistically valid predictive models for each key property.

From a mechanical performance perspective, both modulus of elasticity (MOE) and bending strength (MOR) improved significantly with increased board density, particularly in the range of 400 to 500 kg·m

−3. The effect of increasing face layer content was also notable, with optimum performance typically observed around 37%–41%, beyond which diminishing returns were recorded. Similar patterns have been observed in layered kenaf core particleboards, where higher density and optimized layering substantially enhanced MOE and MOR values [

60]. Melo et al. [

61] reported that adjusting the face-to-core ratio in bamboo-based panels led to significant gains in flexural properties, with optimal results around 30%–40% face layer content.

In terms of dimensional stability, particularly water absorption and thickness swelling, improvements were observed at higher densities and moderate face layer shares. The regression analysis revealed a complex interaction between the two factors, highlighting that overloading face layers beyond 42% may lead to inadequate compaction of the core, resulting in increased porosity and moisture uptake. Similar effects were highlighted in studies by Xu et al. [

60], who demonstrated that excessive bast fiber proportions in the surface layers can impair dimensional stability due to uneven densification and poor internal bonding. Nevertheless, the large variation in water absorption (83%–160%) observed in this study reflects the porosity differences between low- and high-density boards, with incomplete compaction in the core layer of lighter panels leading to pronounced capillary uptake. Thickness swelling values also remained high (≥29%), exceeding the 12% limit specified for MDF in EN 622-5. While this restricts direct application as MDF substitutes, it is important to note that EN 312 for P2 particleboards imposes no thickness swelling requirement, and the optimized boards fully meet the corresponding mechanical criteria. Future work should therefore focus on strategies to improve dimensional stability, such as the use of hydrophobic additives (e.g., nano-silica, waxes), modified resin systems, or protective surface treatments like lamination and coatings.

The overall performance of the boards also suggests a promising sustainability profile. Hemp is an annual crop with rapid growth, high CO

2 absorption capacity, and minimal agrochemical requirements, making it a favorable feedstock for low-carbon panel products [

62,

63]. Moreover, the use of agricultural residues (e.g., shives and stalks) in high-performance applications addresses the waste valorization goals emphasized in recent LCA and circular economy studies [

64,

65].

A limitation of the present study is the absence of direct microscopic evidence (e.g., SEM of fracture surfaces or bond-line analysis) to confirm adhesion quality, fiber distribution, and the presence of defects such as voids or delamination. While the mechanical data and regression models are consistent with mechanisms reported in the literature, further studies using microscopy are needed to verify these assumptions. Such analyses will be a priority in future work to strengthen the mechanistic understanding of hemp-based layered panels.

Despite not fully meeting the EN standards for medium-density fiberboards (e.g., thickness swelling under 12%), the optimized boards demonstrated substantial mechanical performance, qualifying as P2 particleboards under EN 312:2010 [

59], and in some cases exceeding MDF benchmarks for dry-use environments. This outcome supports the concept of partially substituting wood particles with hemp residues as a viable approach for eco-friendly panel production without compromising performance standards.

In conclusion, the research demonstrates that properly engineered hemp-based panels can match or exceed the performance of standard wood-based alternatives in key functional criteria. These findings support their integration into the furniture sector, with further potential for adaptation to other interior and semi-structural applications. A limitation of the present work is the reliance on urea–formaldehyde resin, which, although effective for laboratory optimization, is inconsistent with long-term sustainability goals and tightening formaldehyde regulations. Future research will therefore prioritize the development and testing of bio-based binder systems (e.g., tannin-, lignin-, or citric acid-based adhesives) in combination with hydrophobic additives and surface treatments. Such approaches are expected to further improve dimensional stability, reduce formaldehyde emissions, and align hemp-based composites with the requirements of circular economy and carbon-reduction policies.

4. Conclusions

The study confirmed that panel density is the dominant factor influencing both mechanical and physical properties of hemp-based composites. Increasing density improved stiffness and bending strength while reducing water absorption and thickness swelling, although the latter still exceeded the EN 622-5 requirement for MDF. The face layer share exerted a secondary but nonlinear effect: moderate levels (~37%–41%) enhanced performance through improved surface compaction, whereas excessive proportions (>45%) redistributed pressing pressure, leading to weaker core densification and reduced stiffness.

An important finding of this study is that the positive effect of increasing density on stiffness can be offset when the face layer content becomes excessive (>45%). Under these conditions, pressing pressure is redistributed towards the surface layers, reducing core densification and weakening stress transfer between layers. This highlights the need for a balanced optimization of both density and layer composition, as simply maximizing either parameter does not guarantee superior performance. The optimal design therefore requires a controlled interaction between core compaction and face reinforcement to achieve the best stiffness and bending strength values.

The novelty of this work lies in adopting a layered structure that combines lightweight hemp shives in the core with fiber-rich face layers, optimized through response surface methodology to balance strength, dimensional stability, and sustainability. While thickness swelling and reliance on formaldehyde-based resin remain key limitations, the results demonstrate that properly engineered hemp panels can serve as viable substitutes for wood-based boards in dry-use furniture applications. At the same time, full industrial deployment will depend not only on technical improvements but also on the economic feasibility of greener adhesives, compatibility with existing production equipment, and assessment of environmental trade-offs. Future research should therefore focus on alternative binder formulations, hydrophobic modifications, and pilot-scale validation to enhance dimensional stability, reduce emissions, and ensure both ecological and commercial viability of this material system.